Polymeric thin film polarization method, polarizing film and electronic device

A polymer thin film and thin film technology, which is applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problems of low qualification rate of thin film polarization production, Achieve mass production, avoid breakdown, and achieve good performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

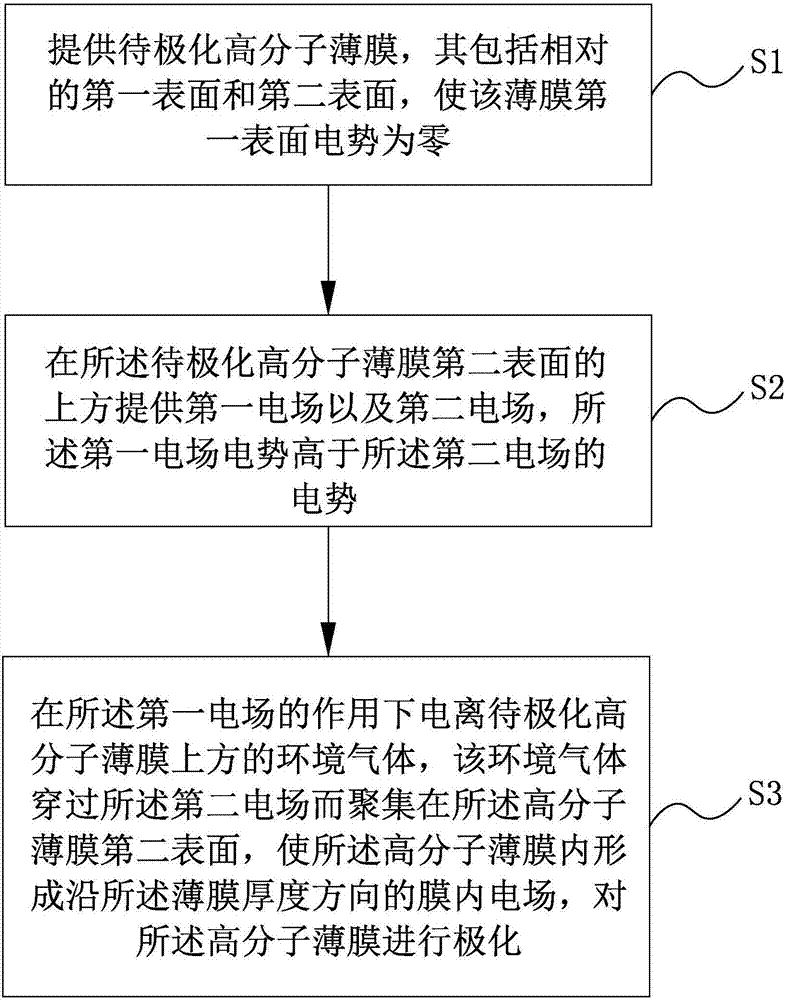

[0032] Such as figure 1 Shown, a polymer film polarization method, comprising:

[0033] Step S1: providing a polymer film to be polarized, which includes an opposite first surface and a second surface, so that the potential of the first surface of the film is zero;

[0034] Step S2: providing a first electric field and a second electric field above the second surface of the polymer film to be polarized, the potential of the first electric field is higher than the potential of the second electric field;

[0035] Step S3: ionize the ambient gas above the polymer film to be polarized under the action of the first electric field, and the ambient gas passes through the second electric field and gathers on the second surface of the polymer film, so that the high An electric field inside the film along the thickness direction of the film is formed in the molecular film to polarize the polymer film.

[0036] Compared with directly arranging electrodes on the upper and lower surfaces...

Embodiment 2

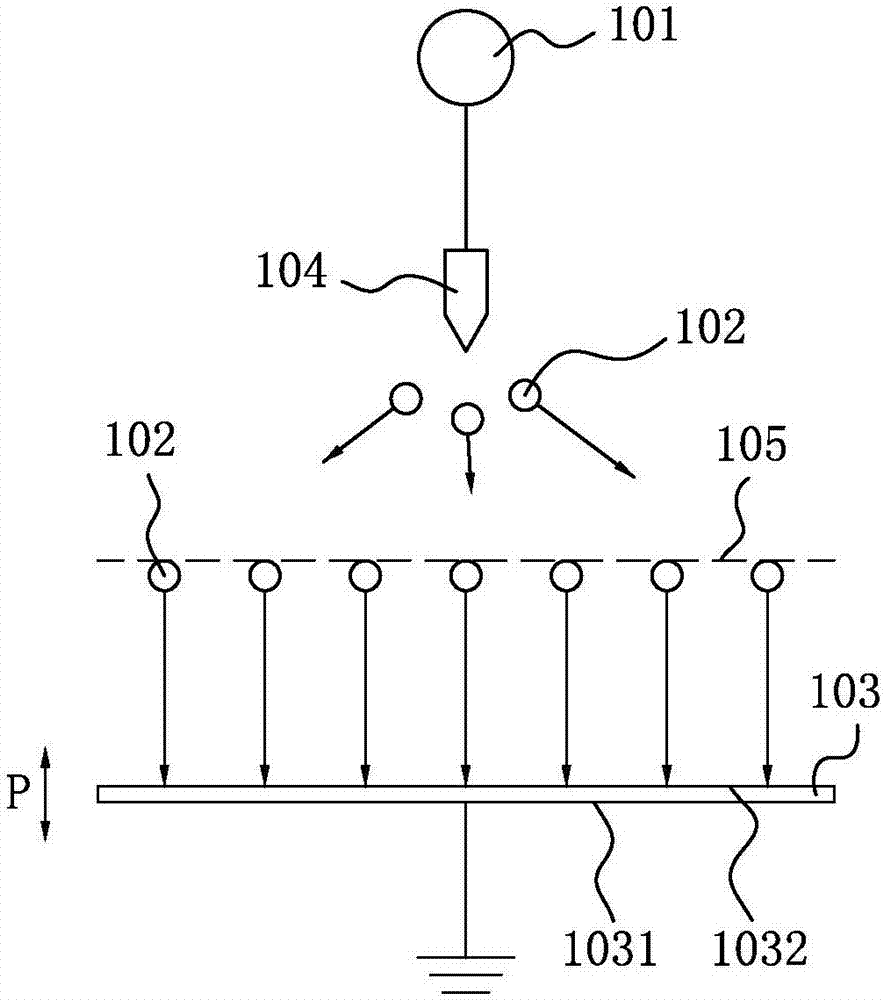

[0053] Such as Image 6 As shown, the present invention also provides a polymer film polarizing device 20 for polarizing a polymer film 203, the polymer film polarizing device 20 includes an electric field assembly 23 and an article carrying platform 24; the article carrying platform 24 is used to carry the polymer film 203 to be polarized, and the polymer film 203 to be polarized includes a first surface 2031 close to the article carrying platform 24 and a second surface 2032 away from the article carrying platform 24 , the article carrying platform 24 is grounded and the potential of the first surface 2031 of the to-be-polarized polymer film 203 is zero. The electric field component includes a high voltage electrode terminal 234 and a low voltage electrode terminal 235 . The high-voltage electrode end 234 is located above the object carrying platform 24 , and the low-voltage electrode end 235 is located between the high-voltage electrode end 234 and the object carrying plat...

Embodiment 3

[0070] Such as Figure 9 , 10 As shown, the present invention also provides a polymer thin film polarization system 50a, 50b, which includes a plurality of polymer thin film polarizers 20a, 20b, 20c, 20d, 20e, the polymer thin film polarizers 20a, 20b, 20c, 20d, and 20e are the polymer film polarizers 20 provided in the second embodiment. The polymer thin film polarization system 50a, 50b provided by the present invention can effectively improve the production pass rate of the polarized film, and realize large-scale production; and the prepared polarized film has a strong piezoelectric effect and a long service life. life.

[0071] In this embodiment, two systems are provided, one such as Figure 9 As shown, in order to distinguish, the polymer thin film polarization system 50a is called a cluster system, which includes a plurality of independent polymer thin film polarizers 20a, 20b, 20c, 20d, 20e, so each polymer thin film pole Polarizing devices 20a, 20b, 20c, 20d, 20e ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com