Patents

Literature

32results about How to "High normal stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

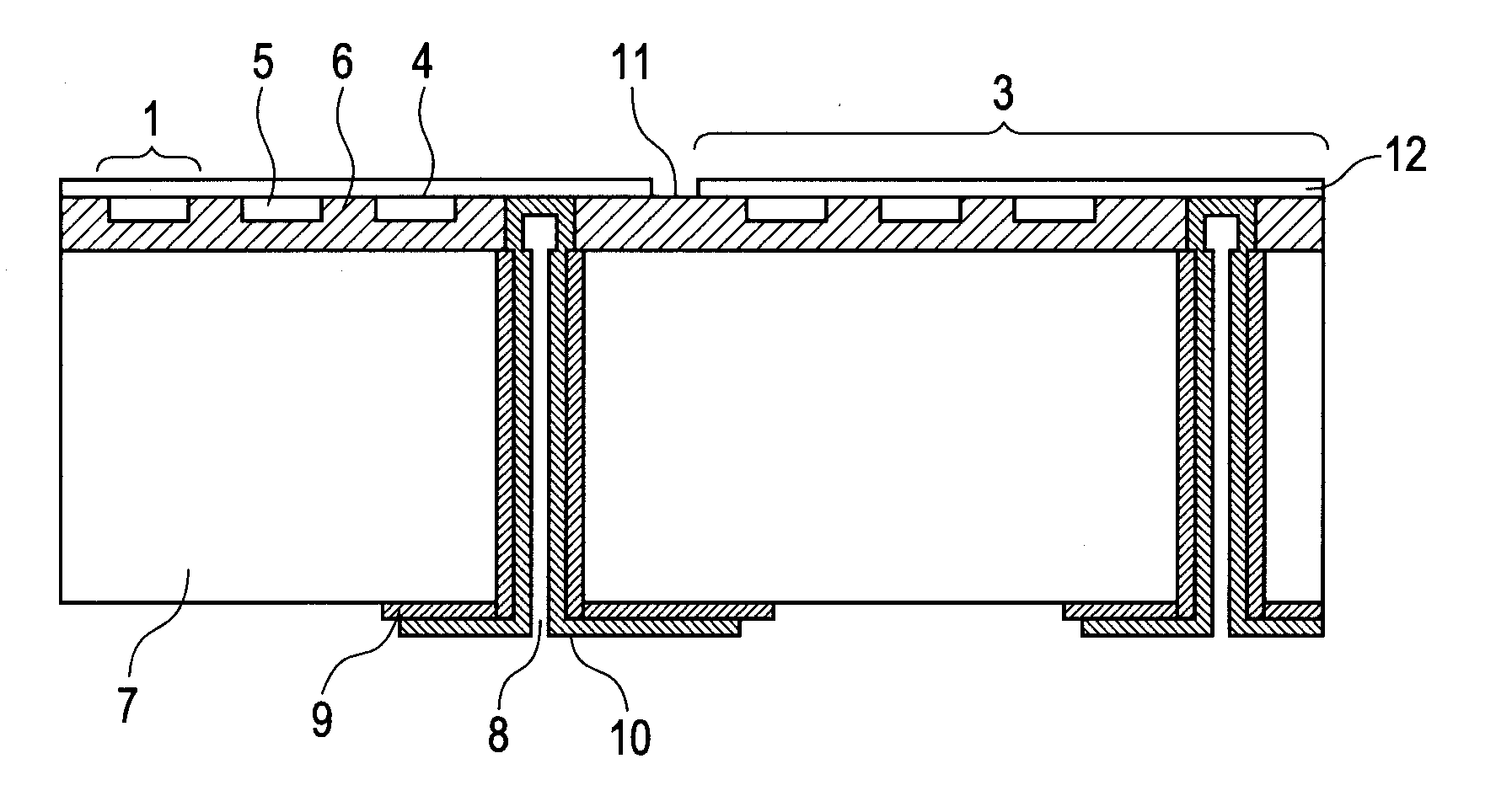

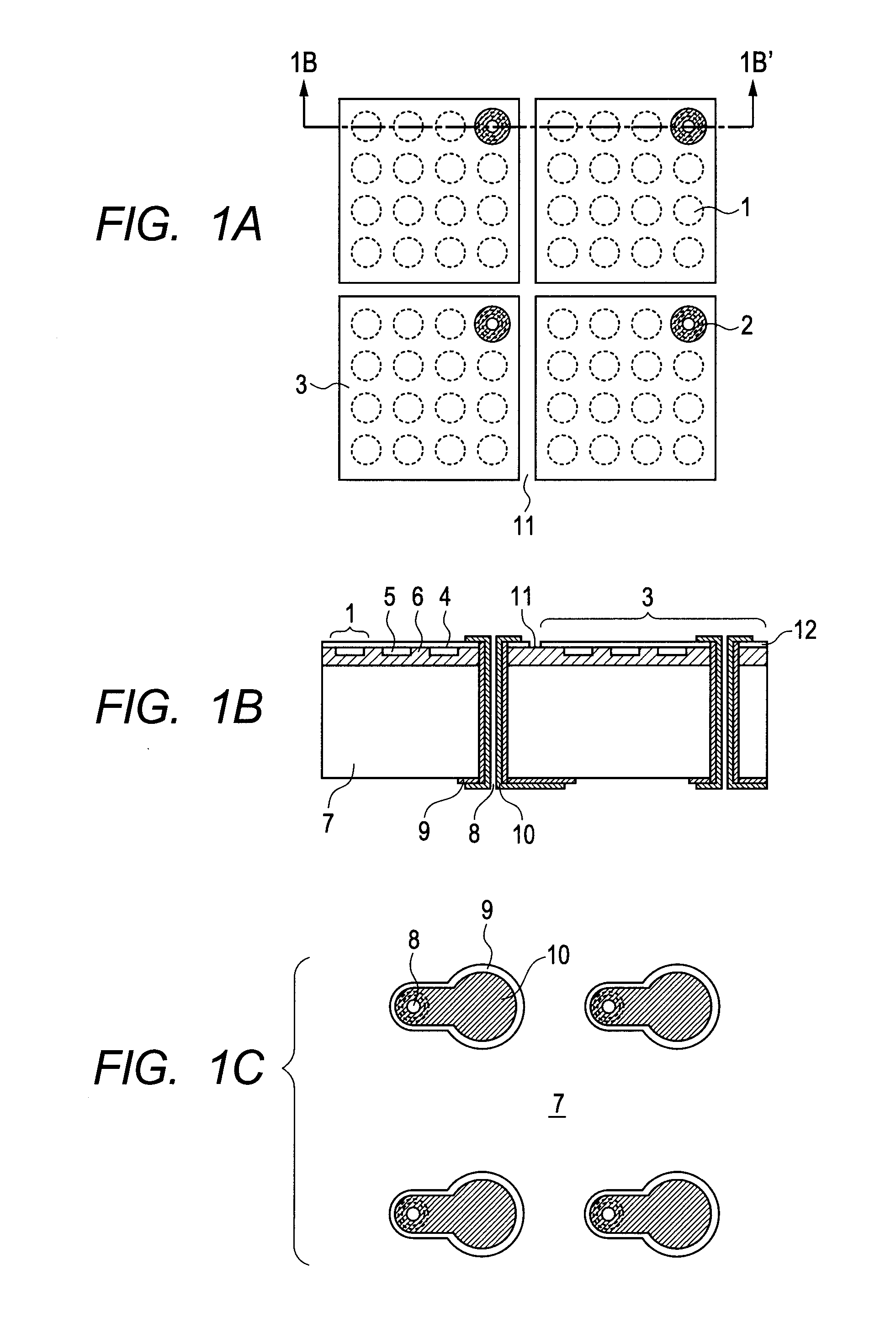

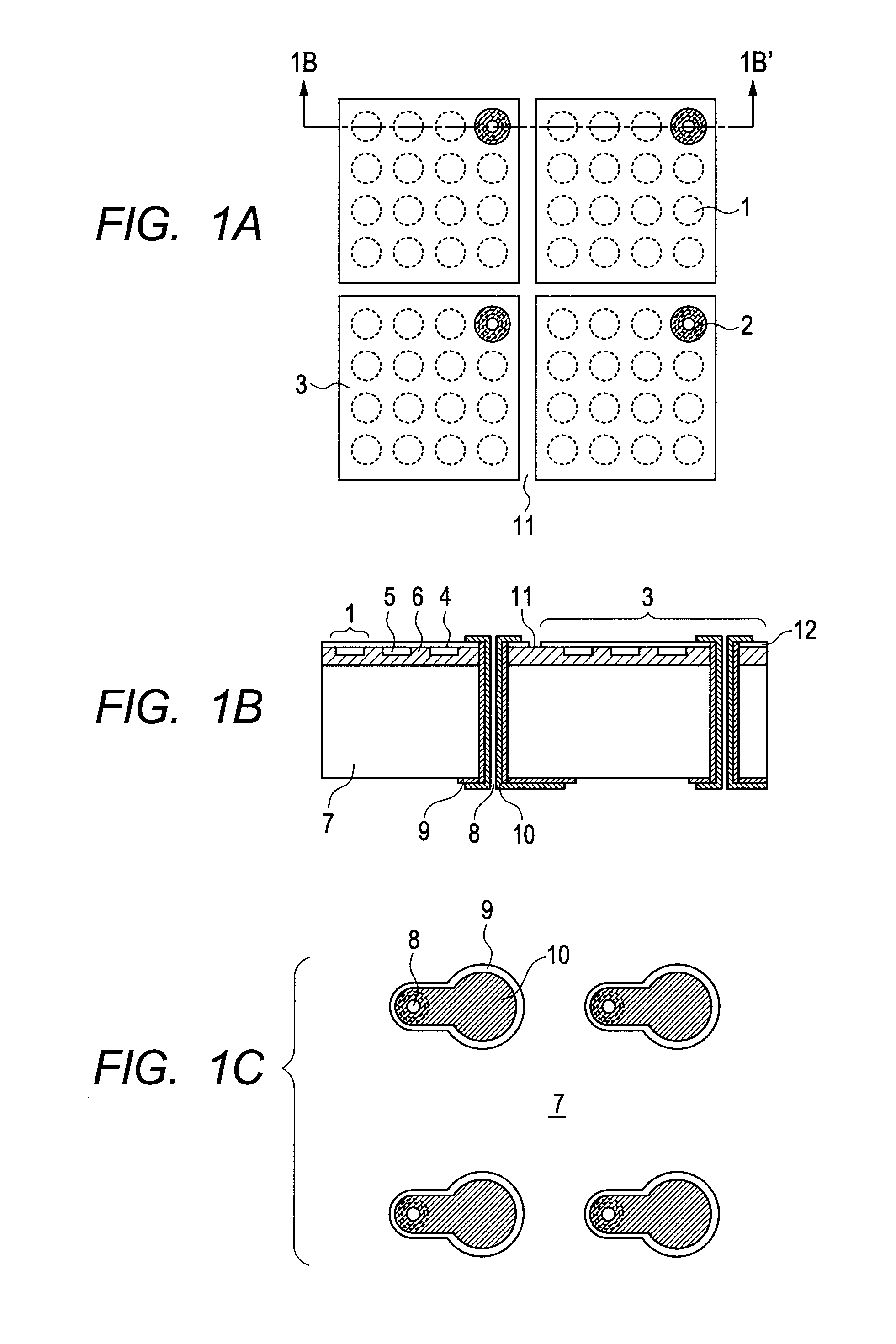

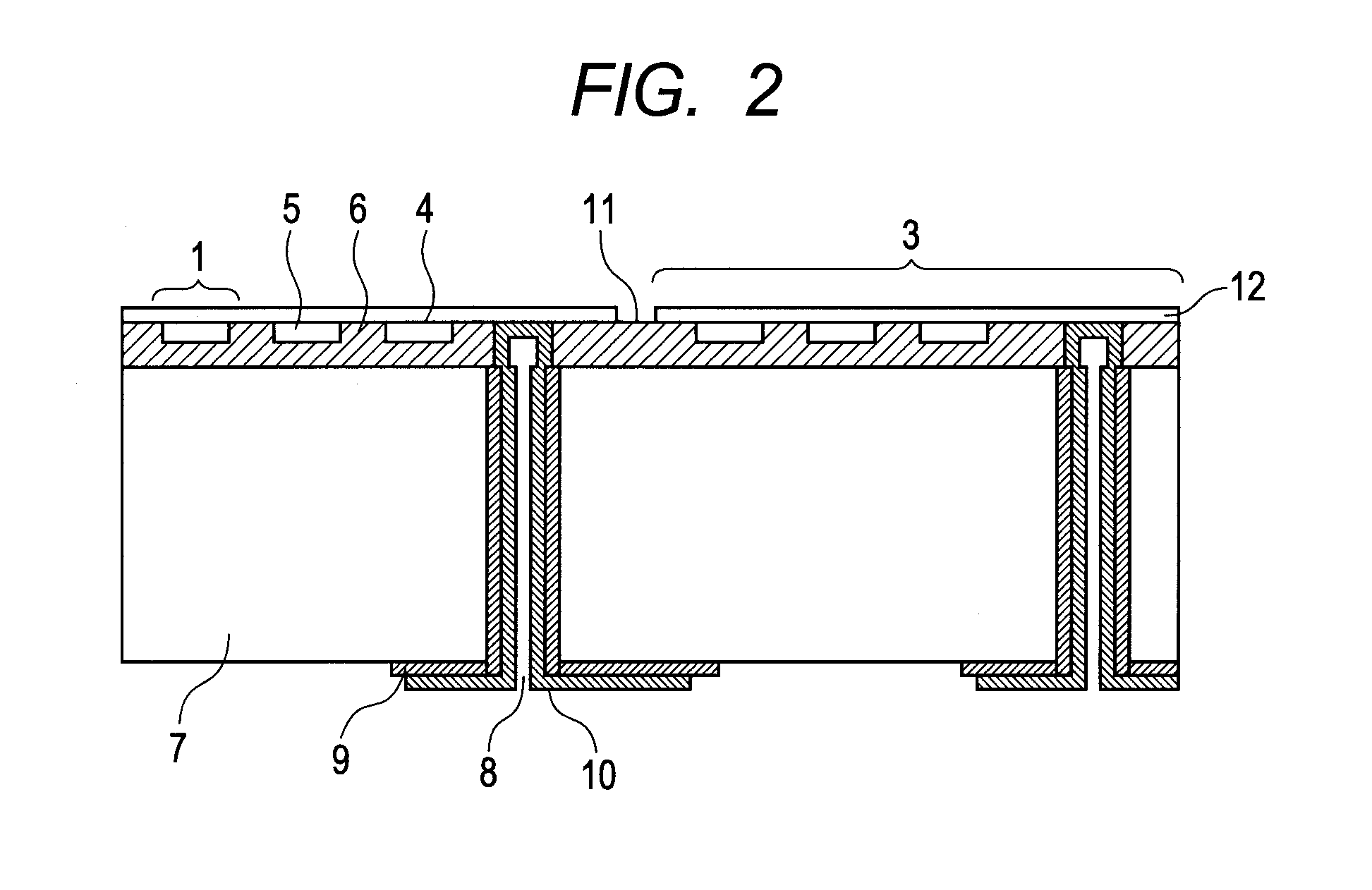

Electromechanical transducer and method of manufacturing the same

InactiveUS20120091543A1High normal stiffnessImprove consistencySemiconductor/solid-state device manufacturingMechanical vibrations separationElectrical conductorSemiconductor

An electromechanical transducer includes multiple elements each including at least one cellular structure, the cellular structure including: a semiconductor substrate, a semiconductor diaphragm, and a supporting portion for supporting the diaphragm so that a gap is formed between one surface of the substrate and the diaphragm. The elements are separated from one another at separating locations of a semiconductor film including the diaphragm. Each of the elements includes in a through hole passing through a first insulating layer including the supporting portion and the semiconductor substrate: a conductor which is connected to the semiconductor film including the diaphragm; and a second insulating layer for insulating the conductor from the semiconductor substrate.

Owner:CANON KK

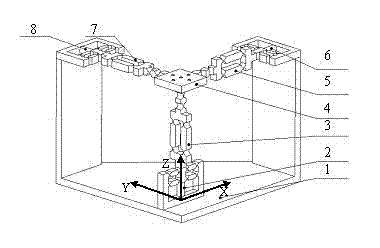

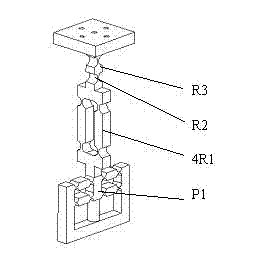

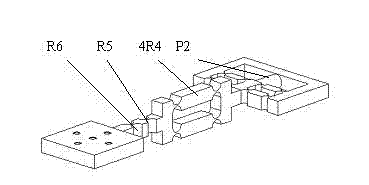

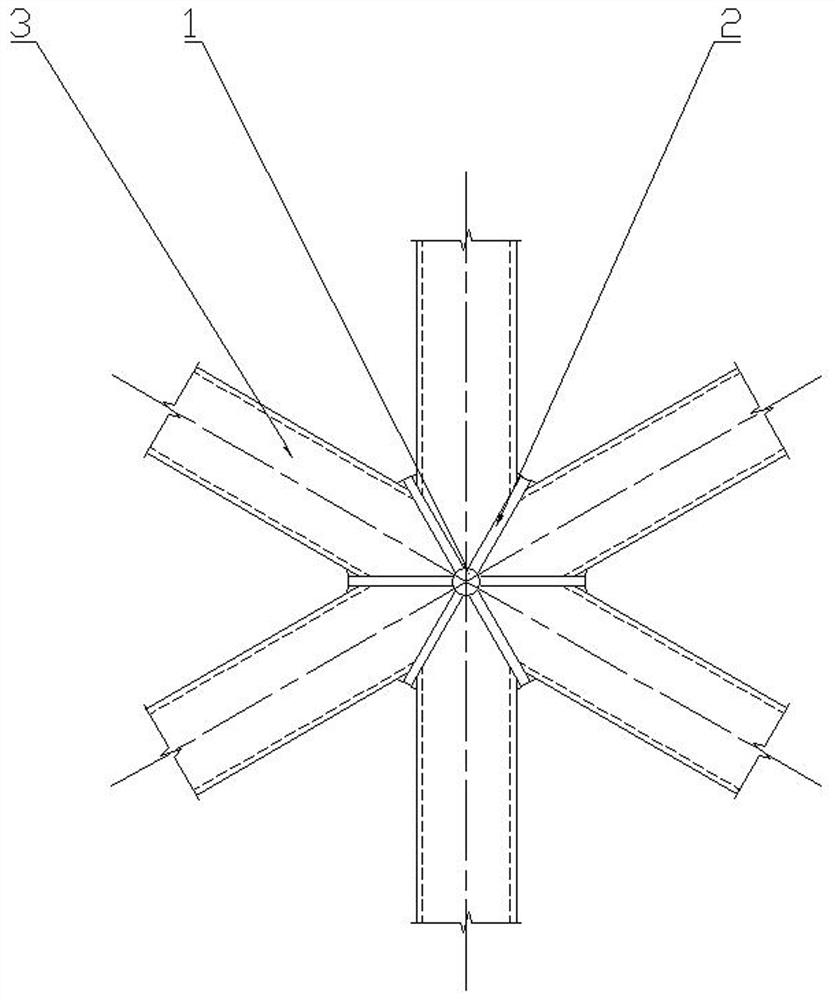

Three-degree-of-freedom microoperation orthogonal parallel operating platform used for ultraprecise location

The invention discloses a three-degree-of-freedom microoperation orthogonal parallel operating platform used for ultraprecise location, which realizes space three-dimensional translation ultraprecise location. The three-degree-of-freedom microoperation orthogonal parallel operating platform is provided with a static platform and a movable platform, wherein a piezoelectric ceramic driver is fixedly vertically arranged on each panel of the static platform, a drive of each piezoelectric ceramic driver is connected with the top end of a branched chain, the tail end of each branched chain is vertically connected with the movable platform, three branched chains are formed by sequentially serially connecting a flexible movable pair, a parallelogram structure, a first rotating pair and a second rotating pair according to position relationships of vertical, vertical and parallel among axial lines, the top end of each branched chain is a movable pair, the tail end of each branched chain is a second rotating pair, the three movable pairs are mutually orthogonal, and the three second rotating pairs are mutually orthogonal. According to the invention, the advantages of a parallel mechanism and a flexible movement pair are combined, a movement is generated by depending self elastic deformation, and output reaches high precision of micro level even nano level.

Owner:JIANGSU UNIV

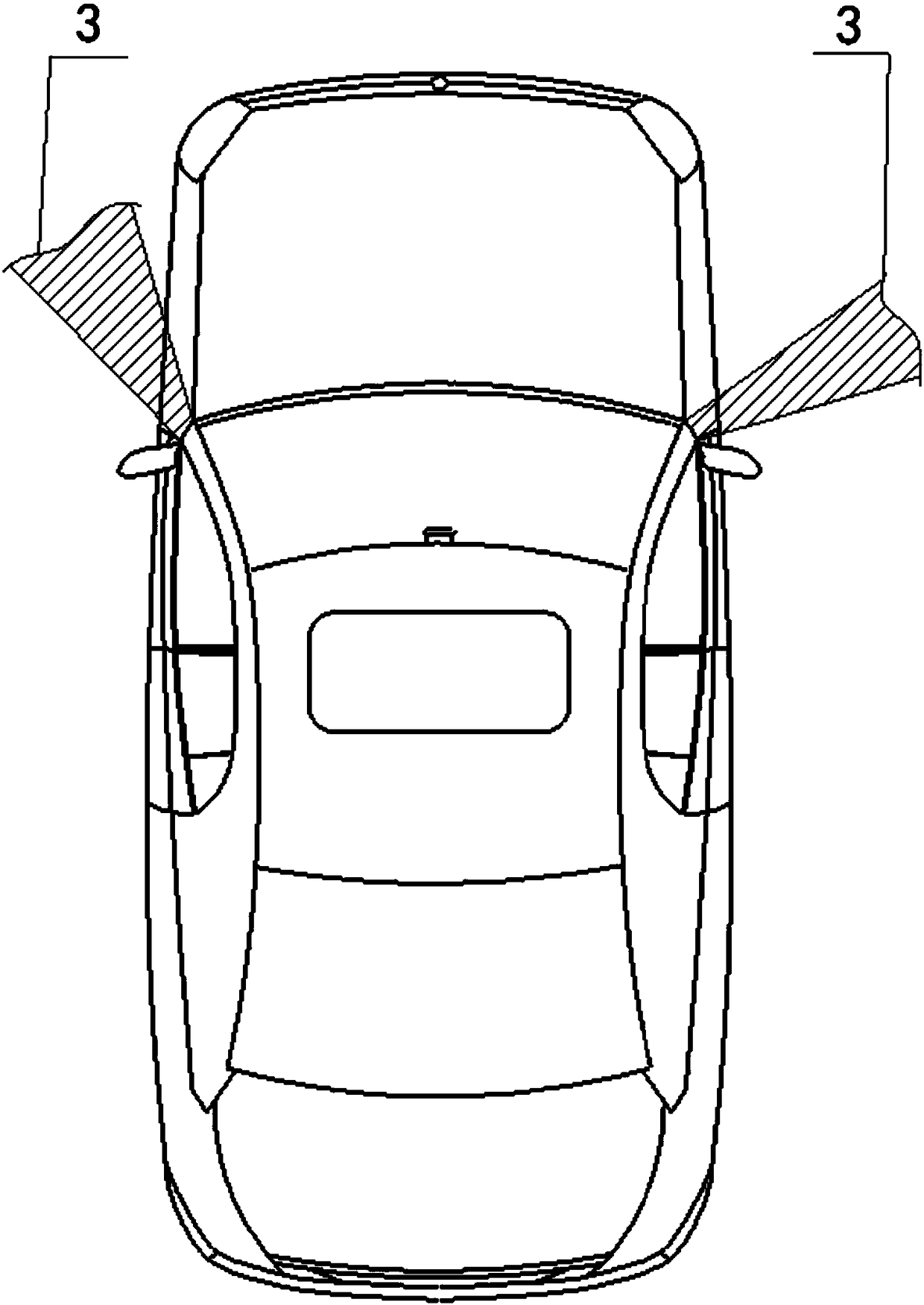

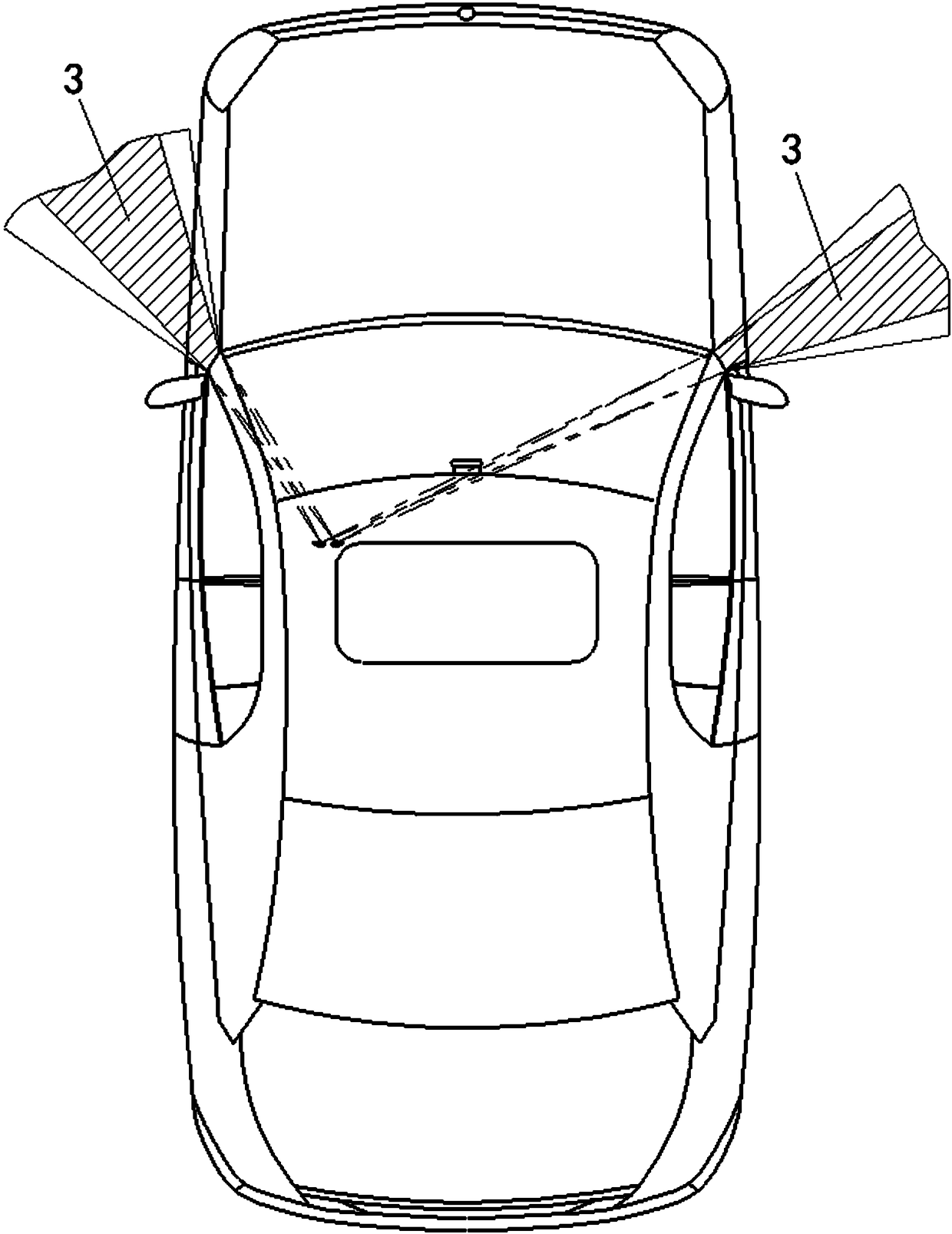

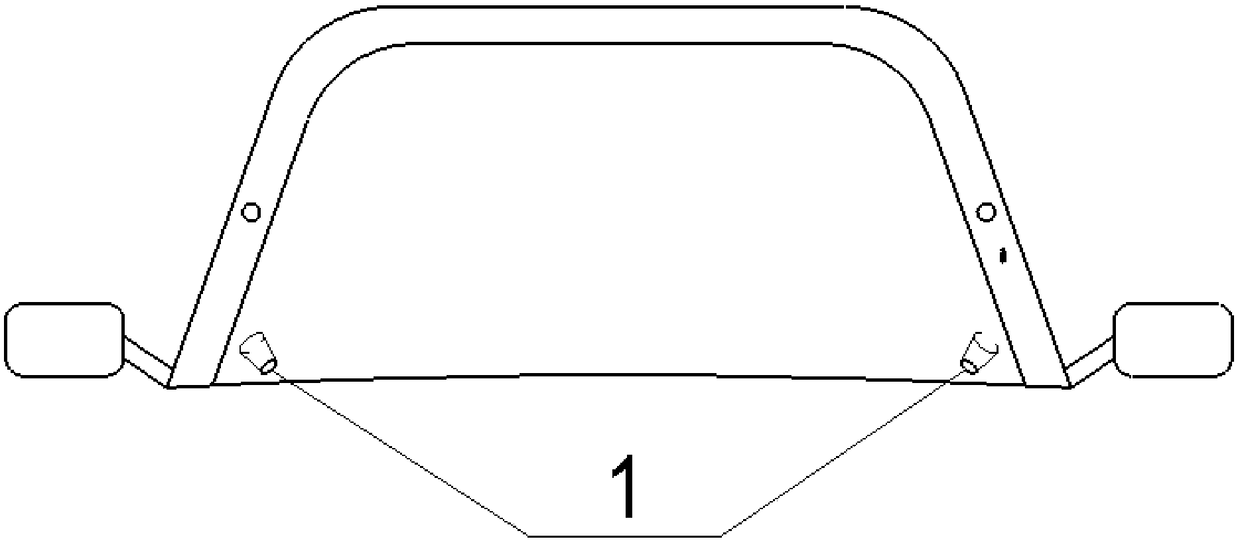

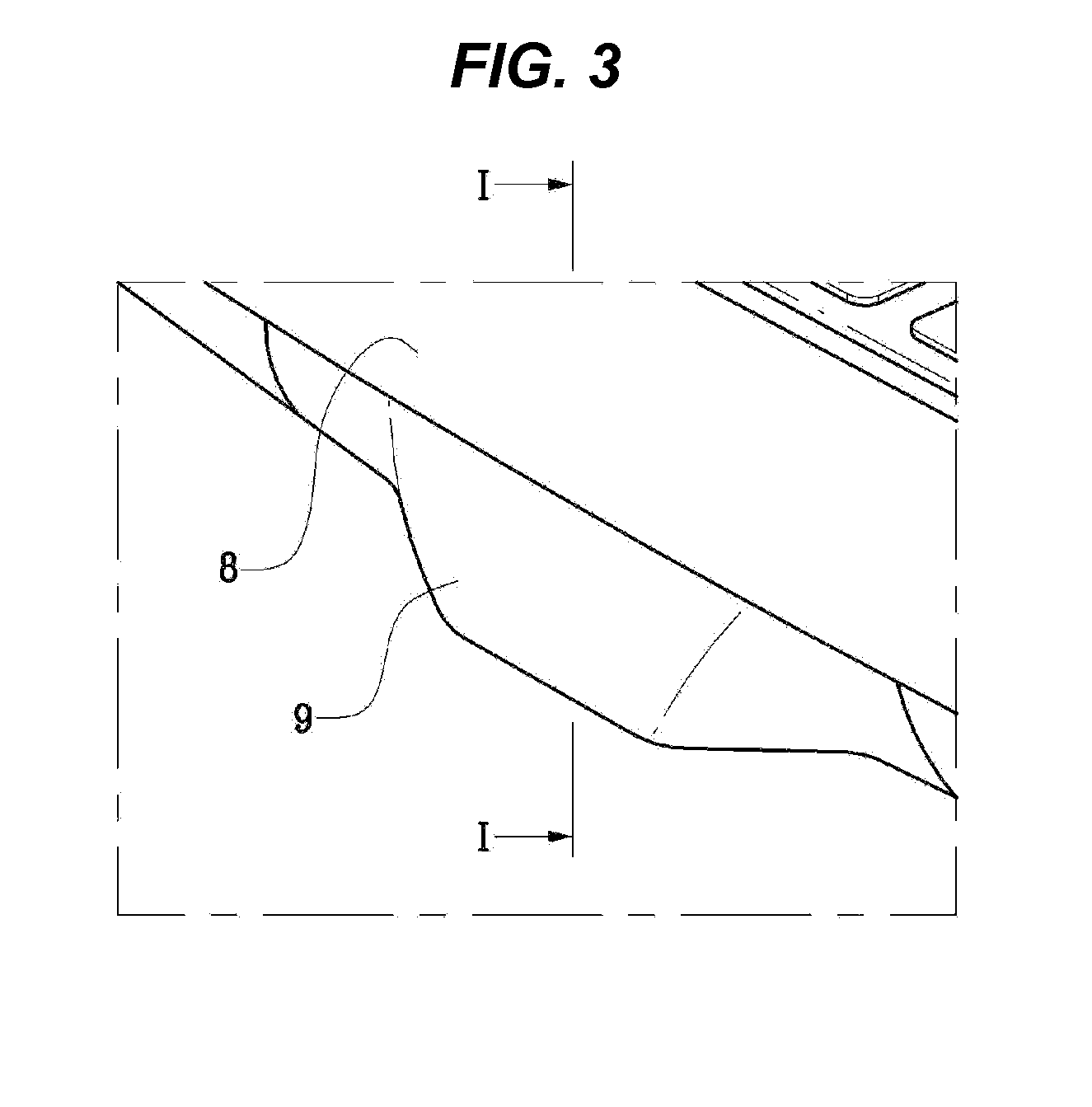

Automobile pillar A display system

PendingCN108340836AImprove driving comfortEliminate blind spotsOptical viewingEngineeringControl unit

The invention provides an automobile pillar A display system which comprises a blind area camera, a display screen, an image processing and display output unit, and a control unit, wherein the blind area camera is arranged in a position close to a front windshield inside an automobile and is connected with the image processing and display output unit; the image processing and display output unit is arranged close to the console inside the automobile and is connected with the display screen; the control unit is arranged close to the console inside the automobile and is connected with the blindarea camera; the display screen is arranged on the inner surface inside an automobile pillar A; the area of the display screen is not greater than that of the inner surface of the pillar A; the imageprocessing and display output unit is used for outputting images acquired by using the blind area camera to the display screen. The automobile pillar A display system can be adaptive to different running states of the automobile, different adaptive images can be displayed on the pillar A, and thus relatively high driving security can be achieved; the units are compactly arranged inside the automobile, the response speed and the precision of the system can be improved, and the driving comfort can be improved.

Owner:HASCO VISION TECHNOLOGY CO LTD

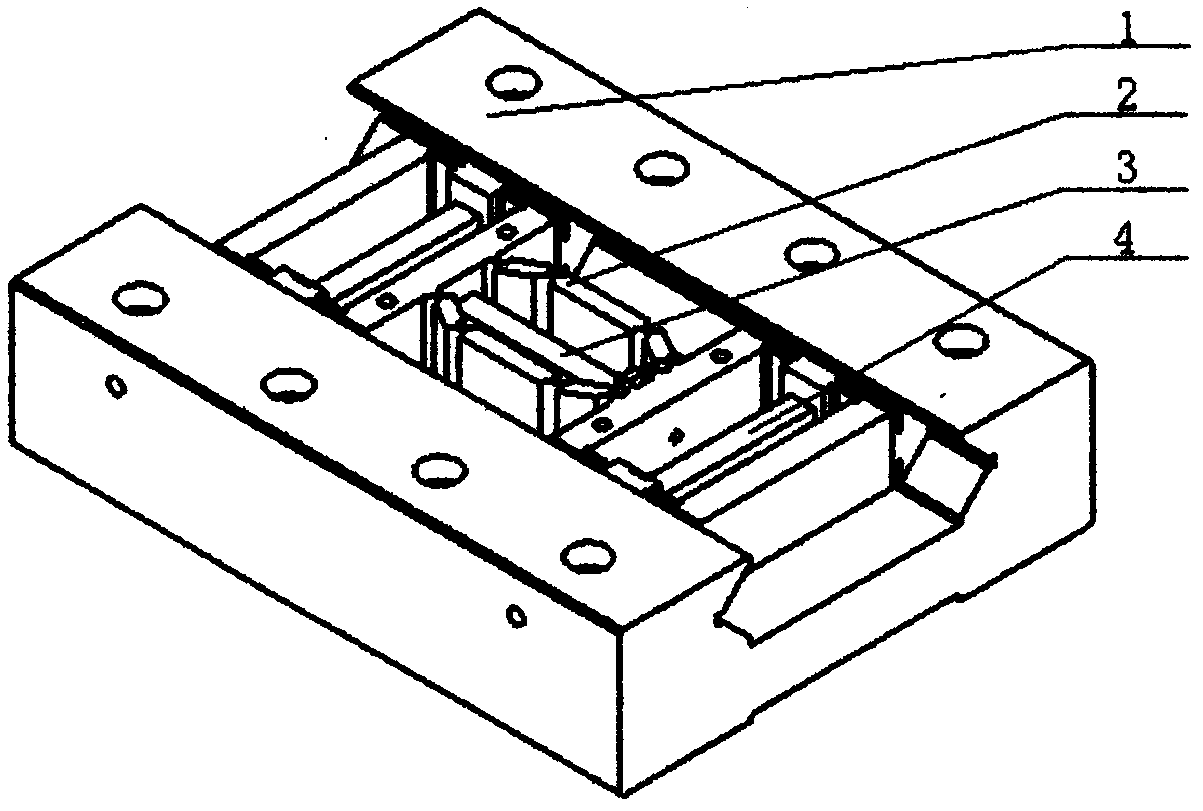

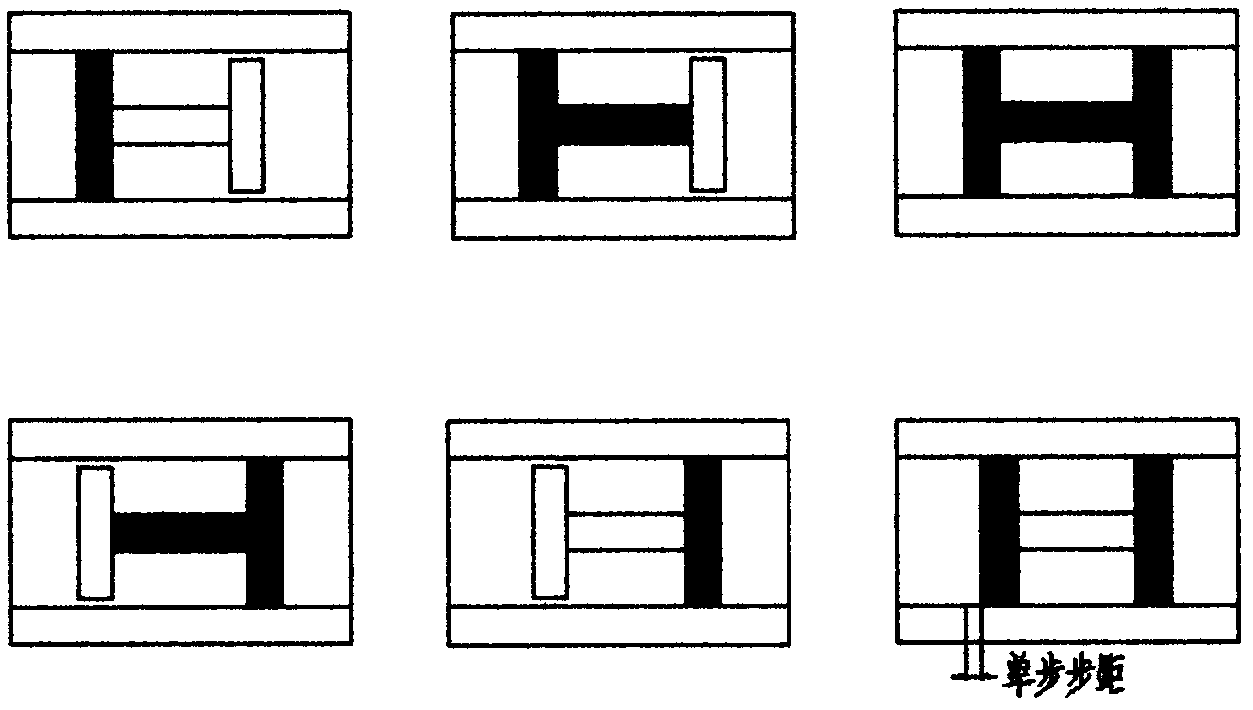

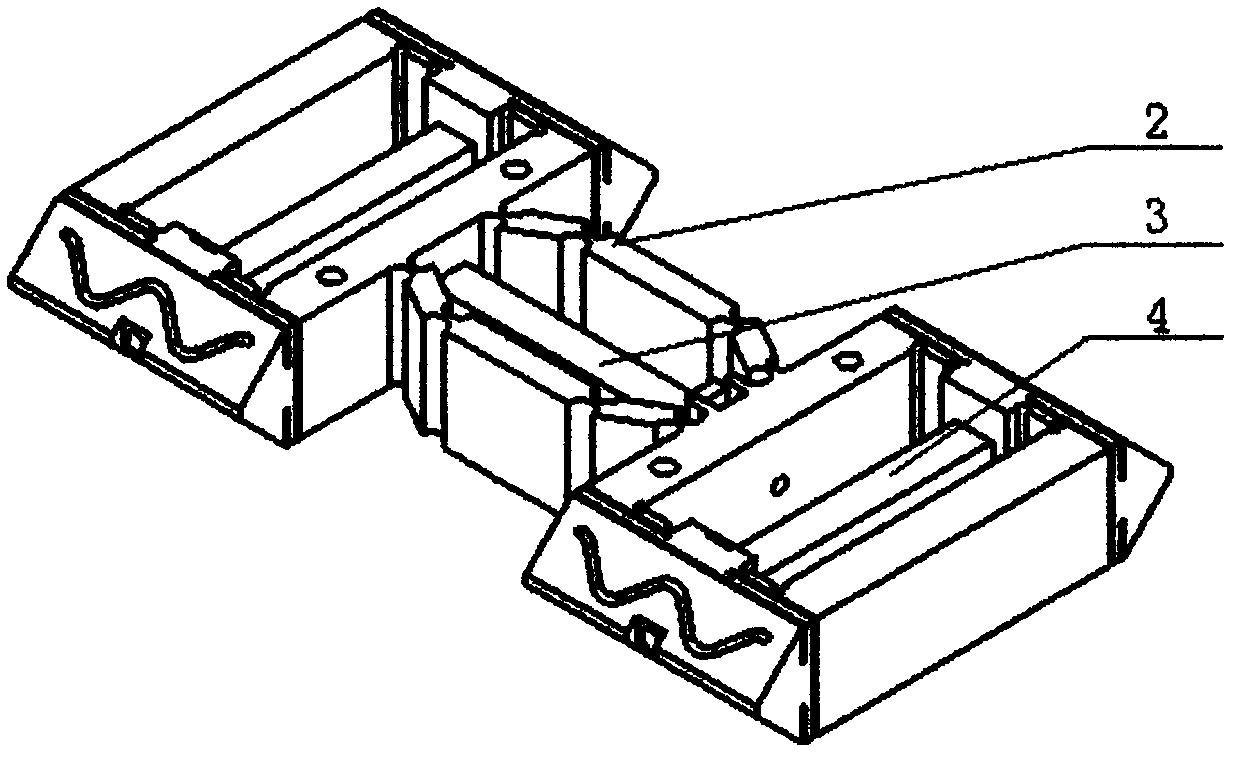

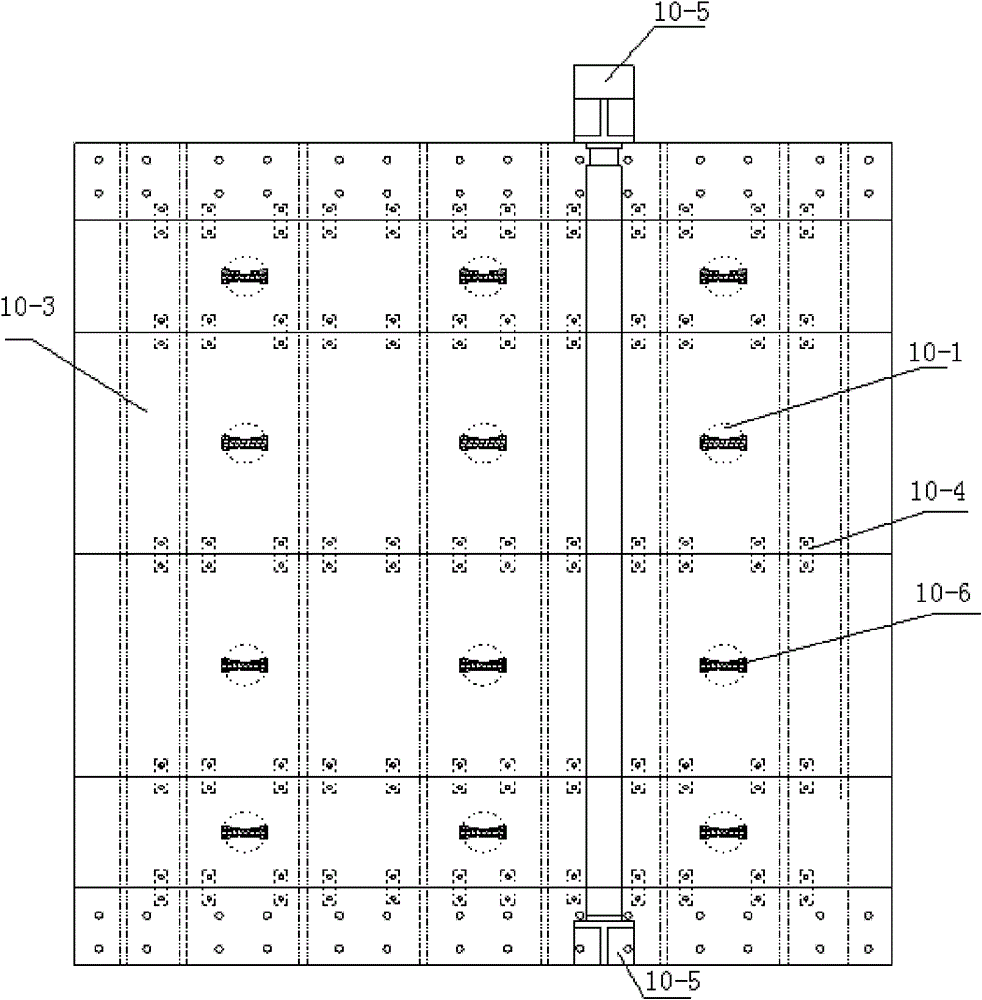

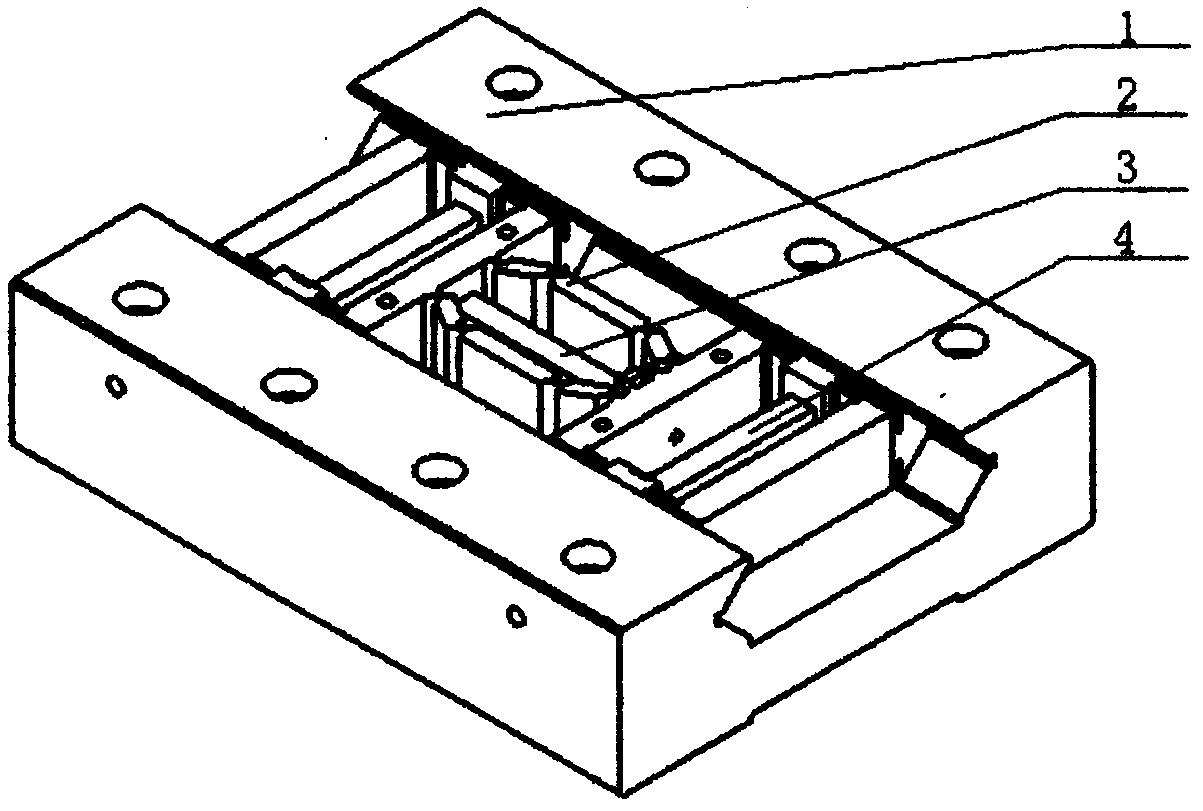

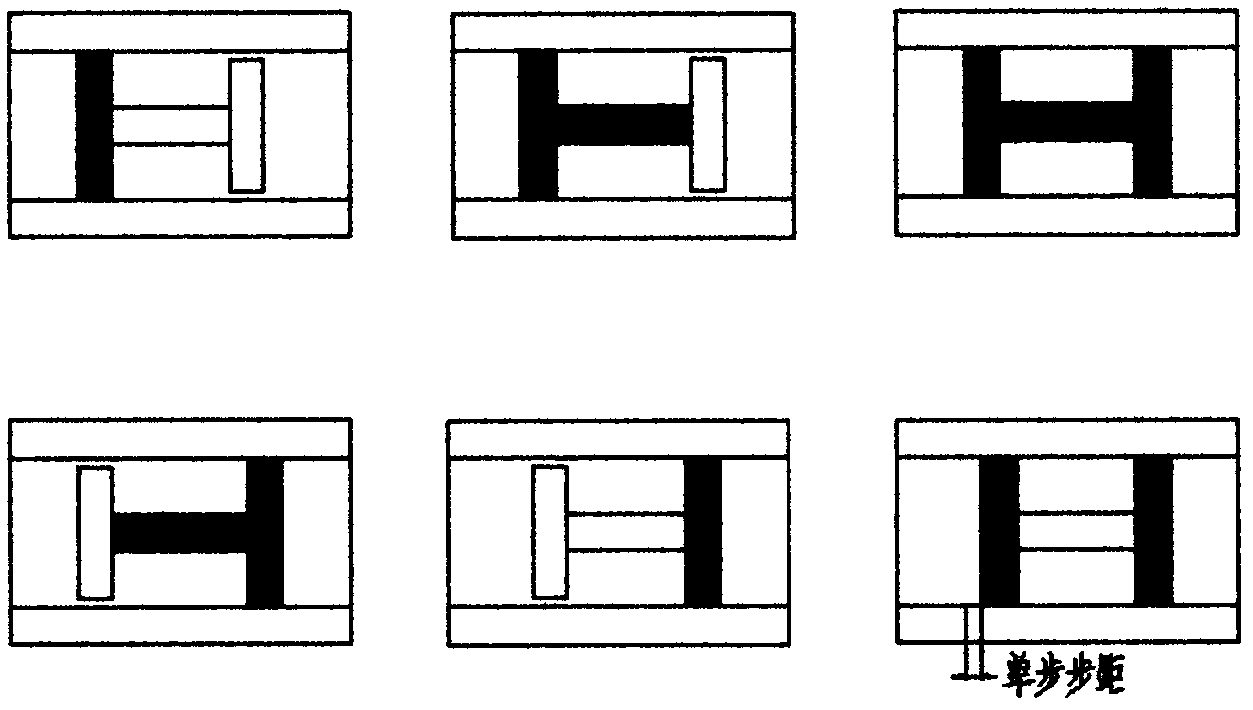

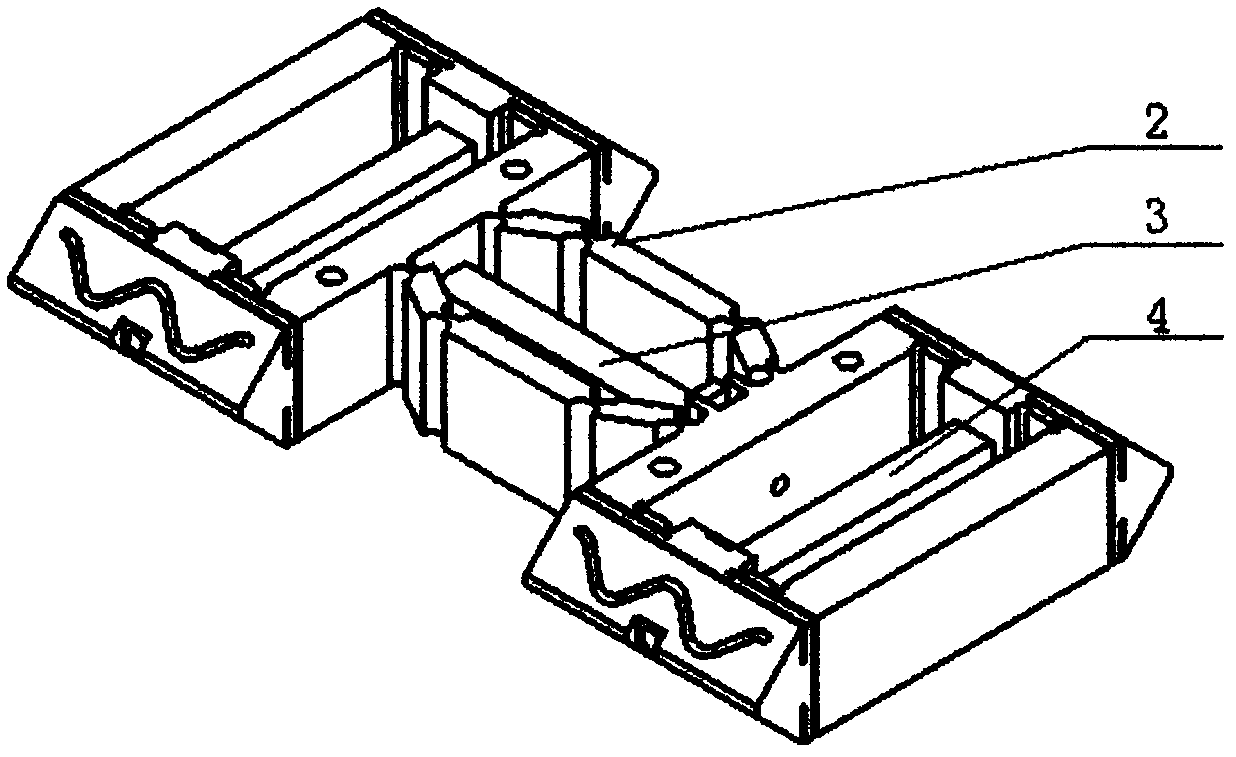

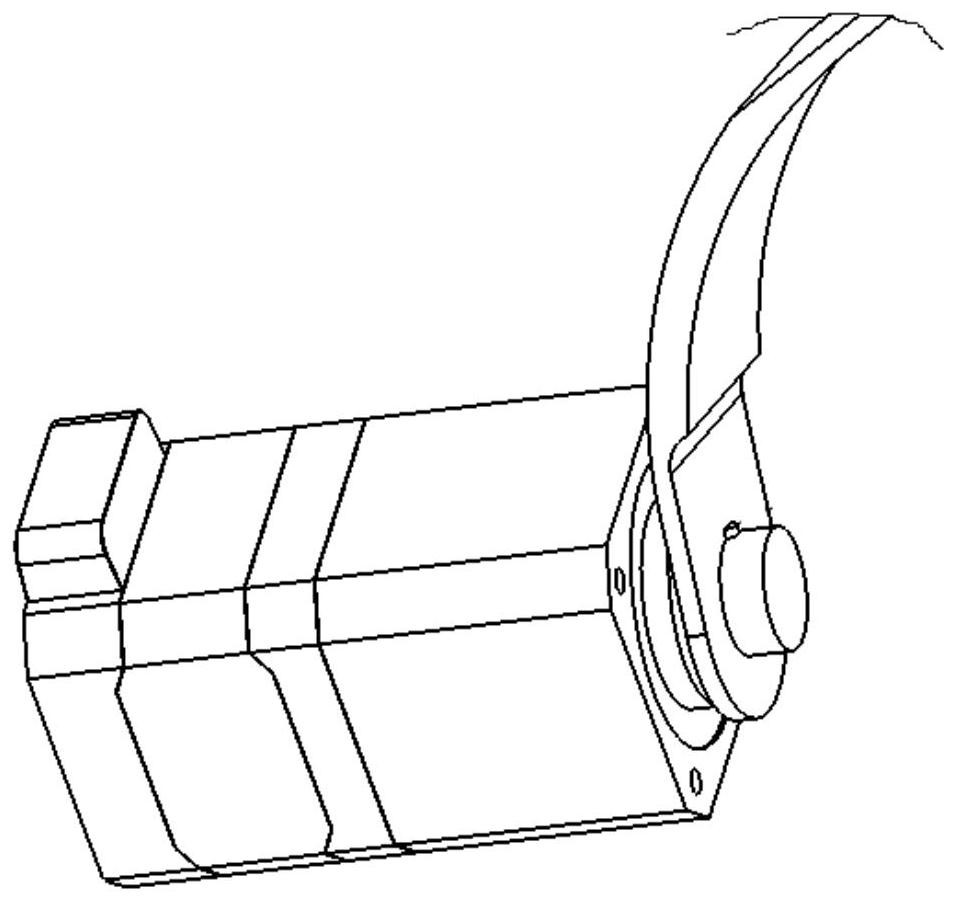

Piezoelectric linear driver

InactiveCN102361411AReduce assembly errorsReduce usagePiezoelectric/electrostriction/magnetostriction machinesFlexible MechanismsEngineering

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

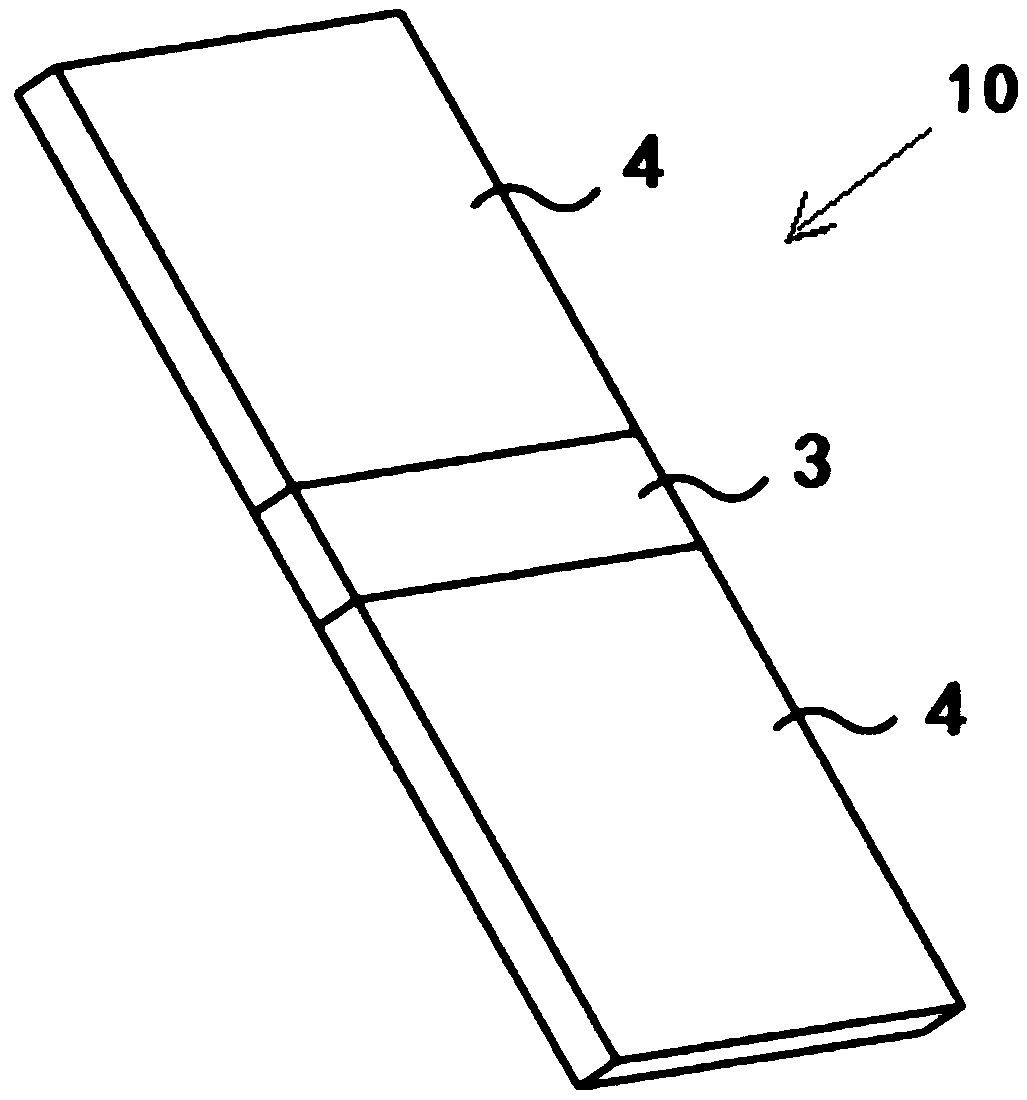

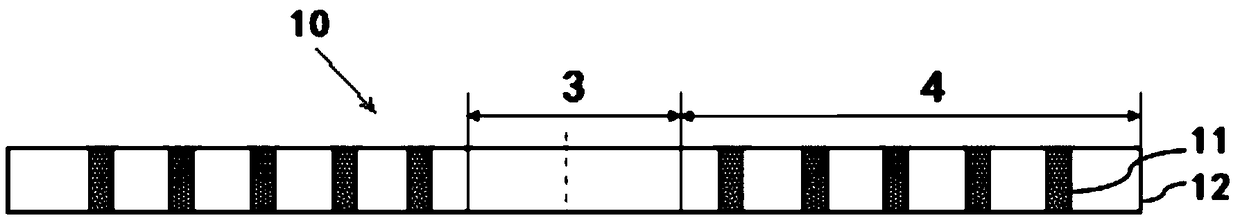

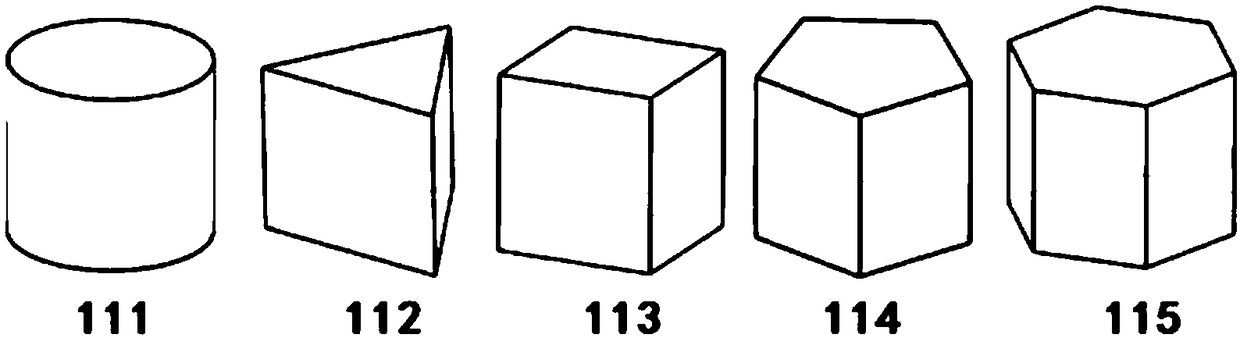

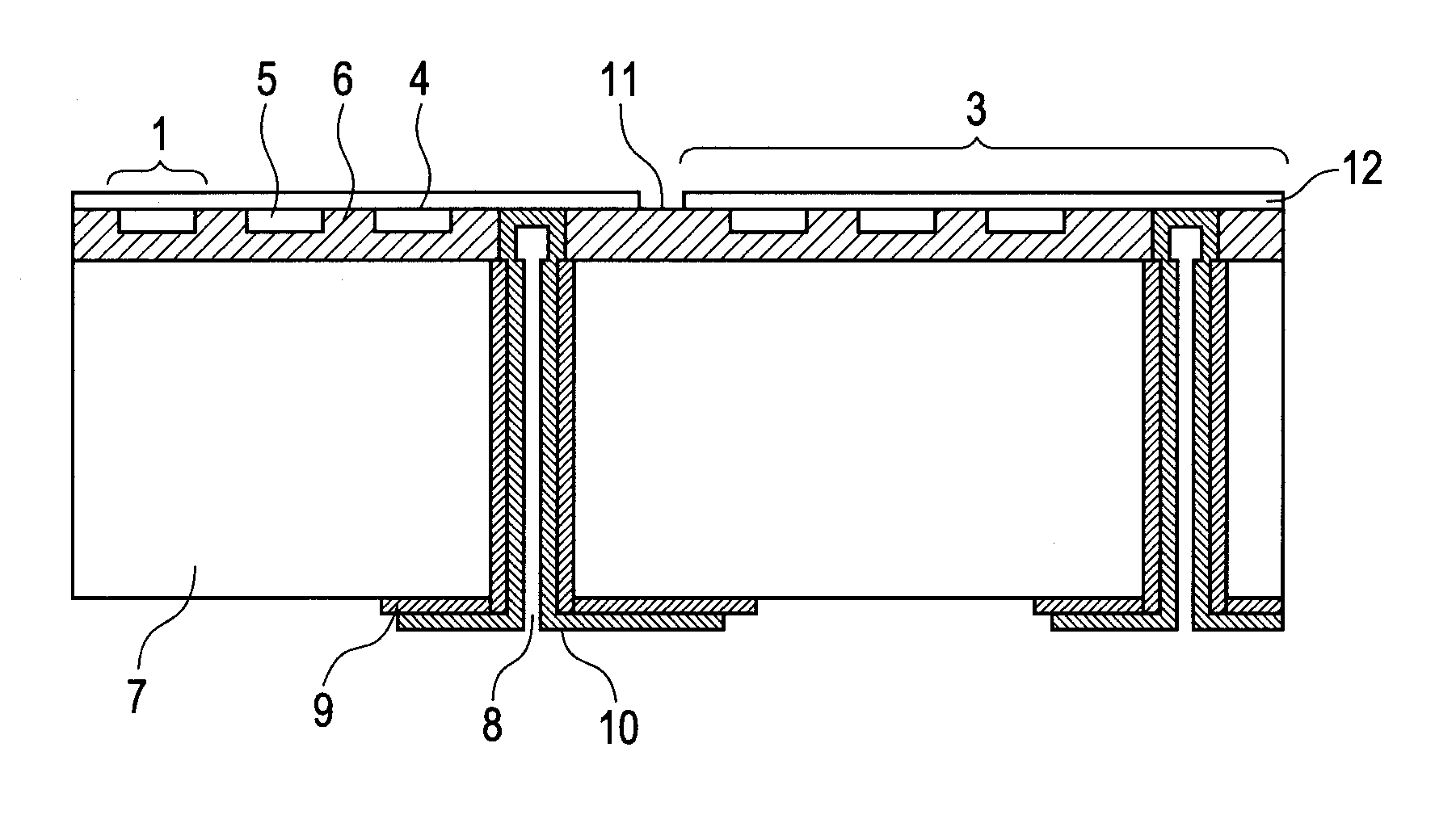

Optical adhesive and manufacturing method and flexible display screen thereof

The embodiment of the invention discloses an optical adhesive and a manufacturing method and flexible display screen thereof. The optical adhesive includes a first section and second sections disposedon both sides of the first section, the first section includes an OCA adhesive layer, and the second section includes OCA adhesive layers and support columns disposed in the OCA adhesive layers. Themanufacturing method of the optical adhesive includes the steps of defining the first section and the second sections which are located on the two sides of the first section on the surface of a provided substrate; preparing the support columns on the portions, in the second sections, of the substrate; coating the portions, in the first section and the second section, of the substrate with an OCA adhesive. The flexible display screen includes the optical adhesive. By embedding a support column in a non-bending area of the flexible display screen, the normal stiffness of the flexible display screen is improved, correspondingly the hardness of the flexible display screen is improved, and thus the flexible display screen can pass through pencil hardness and nanoindentation tests; the conventional OCA adhesive is adopted in a bending area without reinforcing the bending area, and therefore not only can the high hardness of the non-bending area be ensured, but also a good bending property ofthe flexible display screen in the bending area can be ensured.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

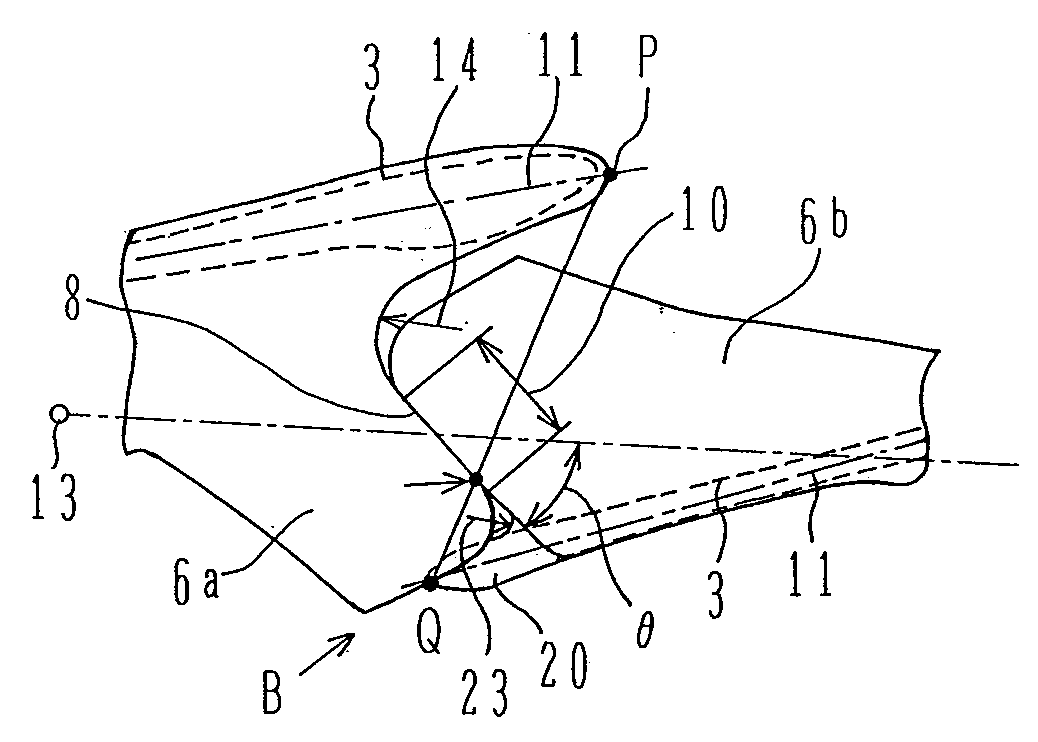

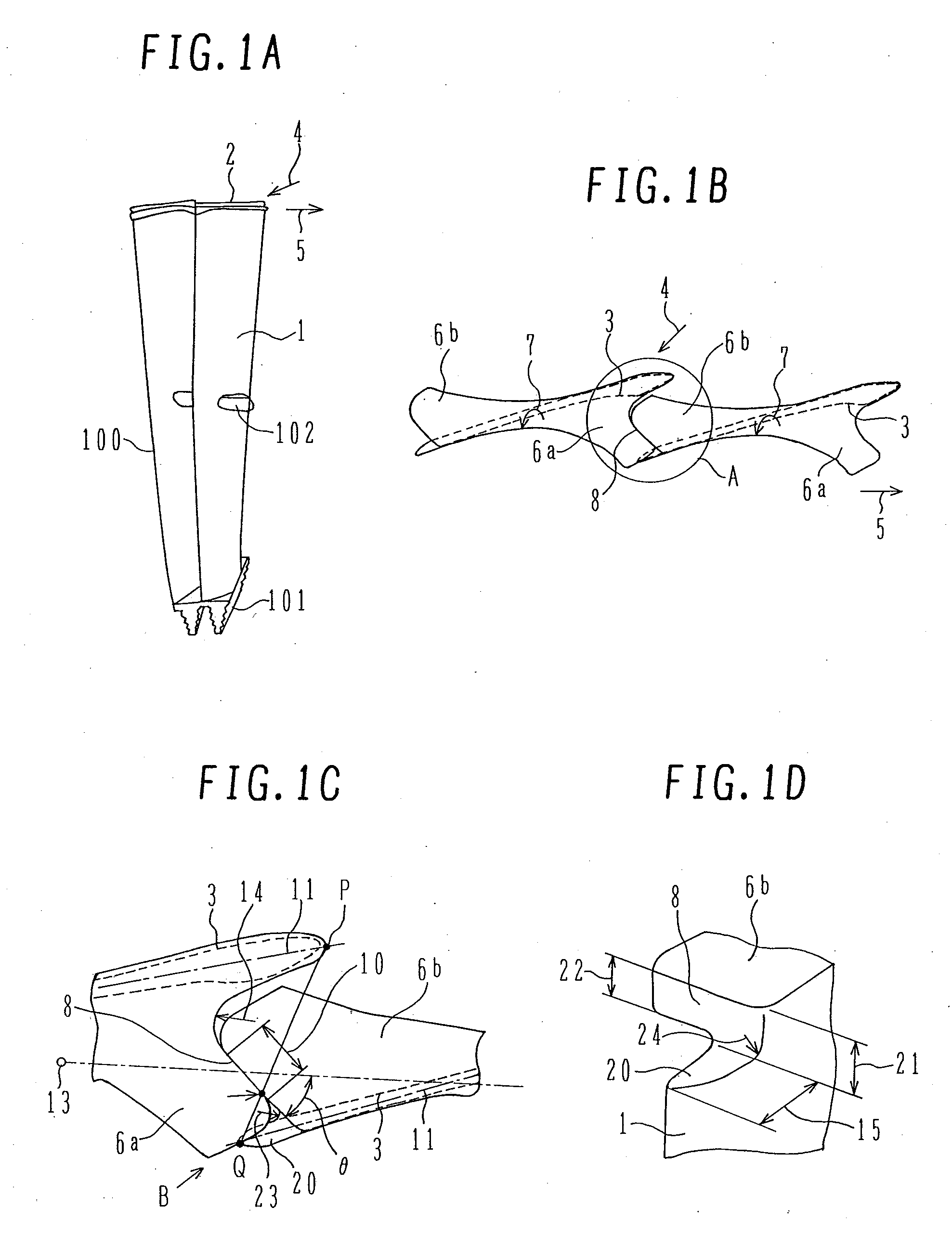

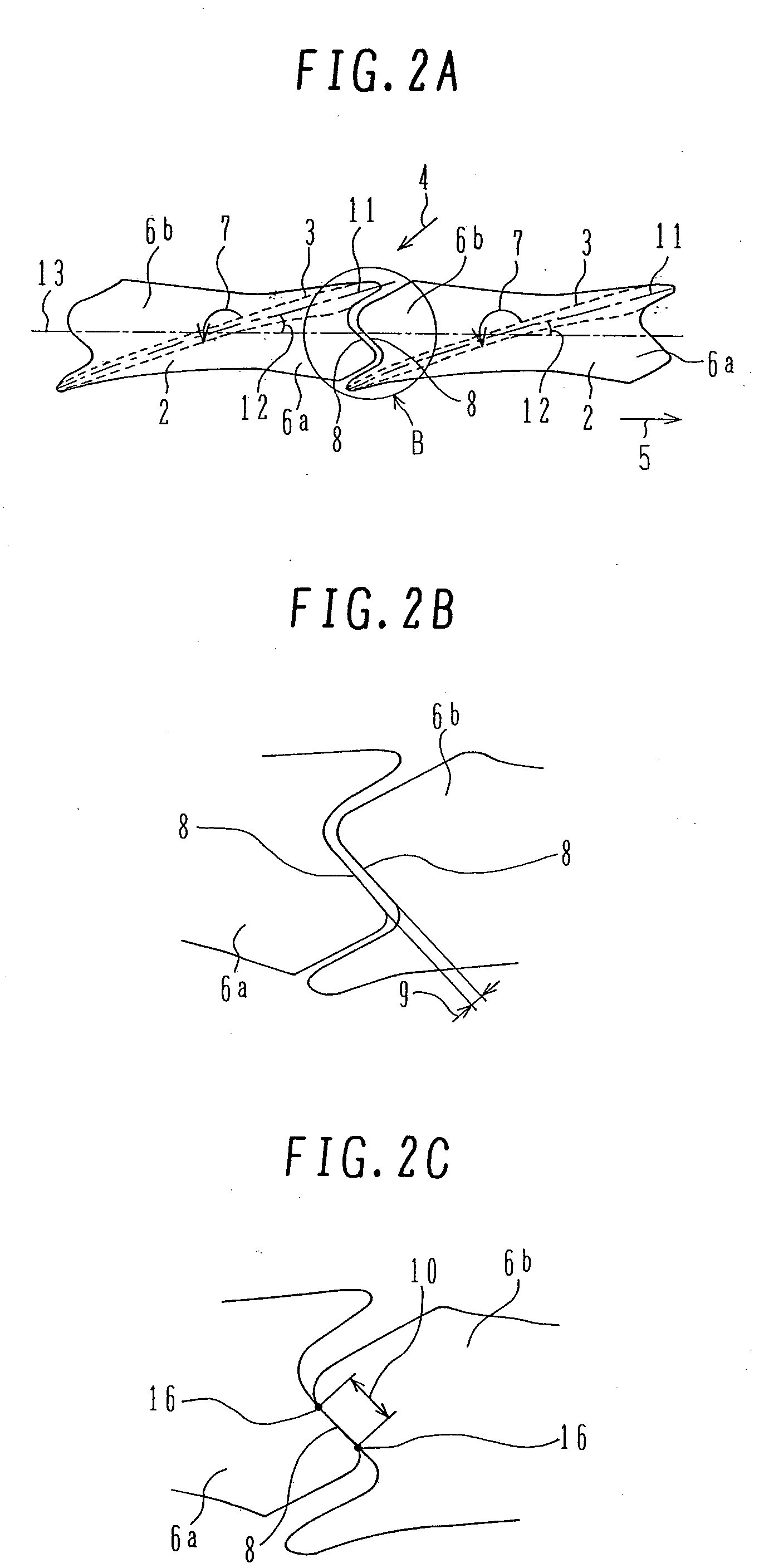

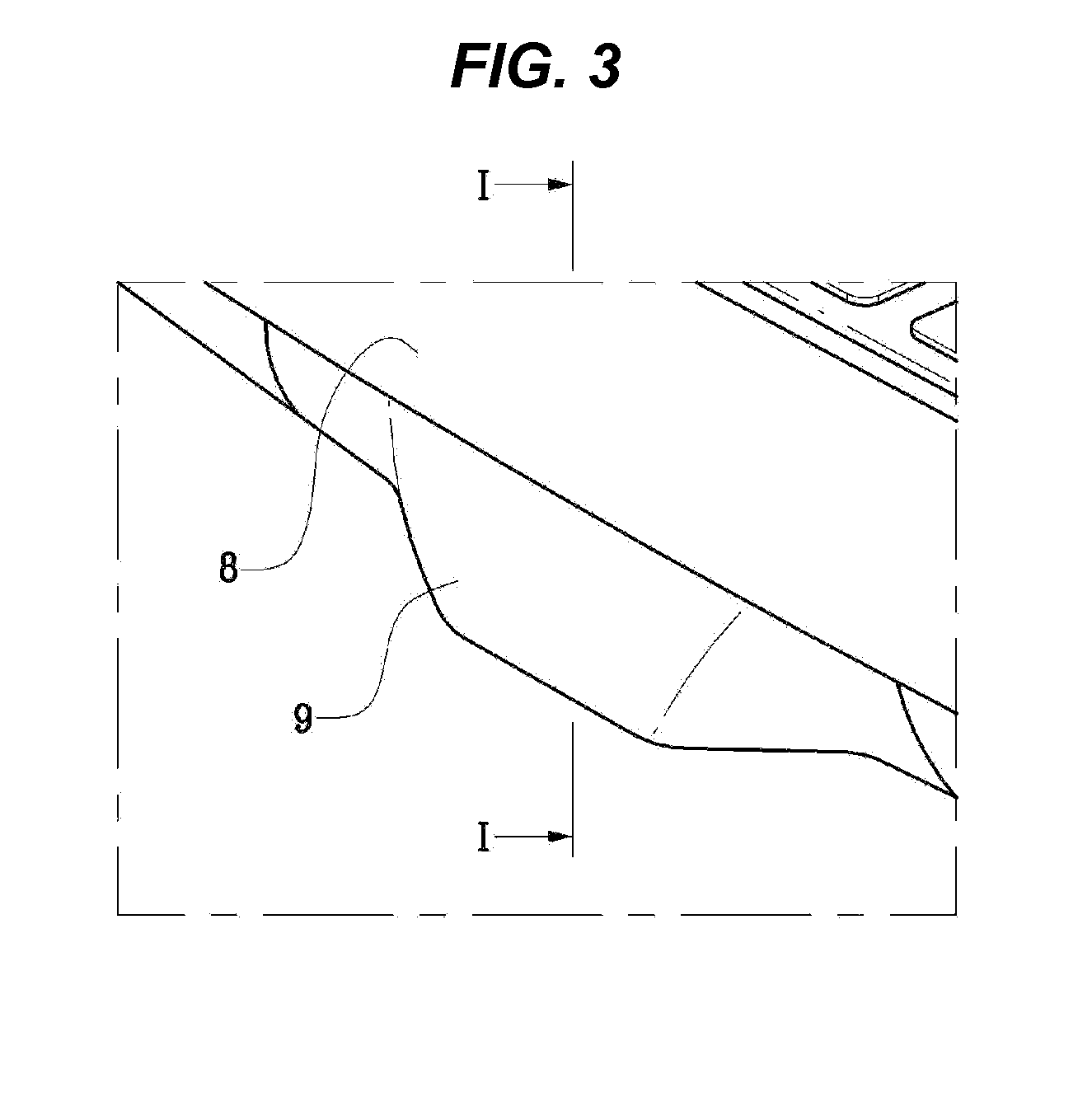

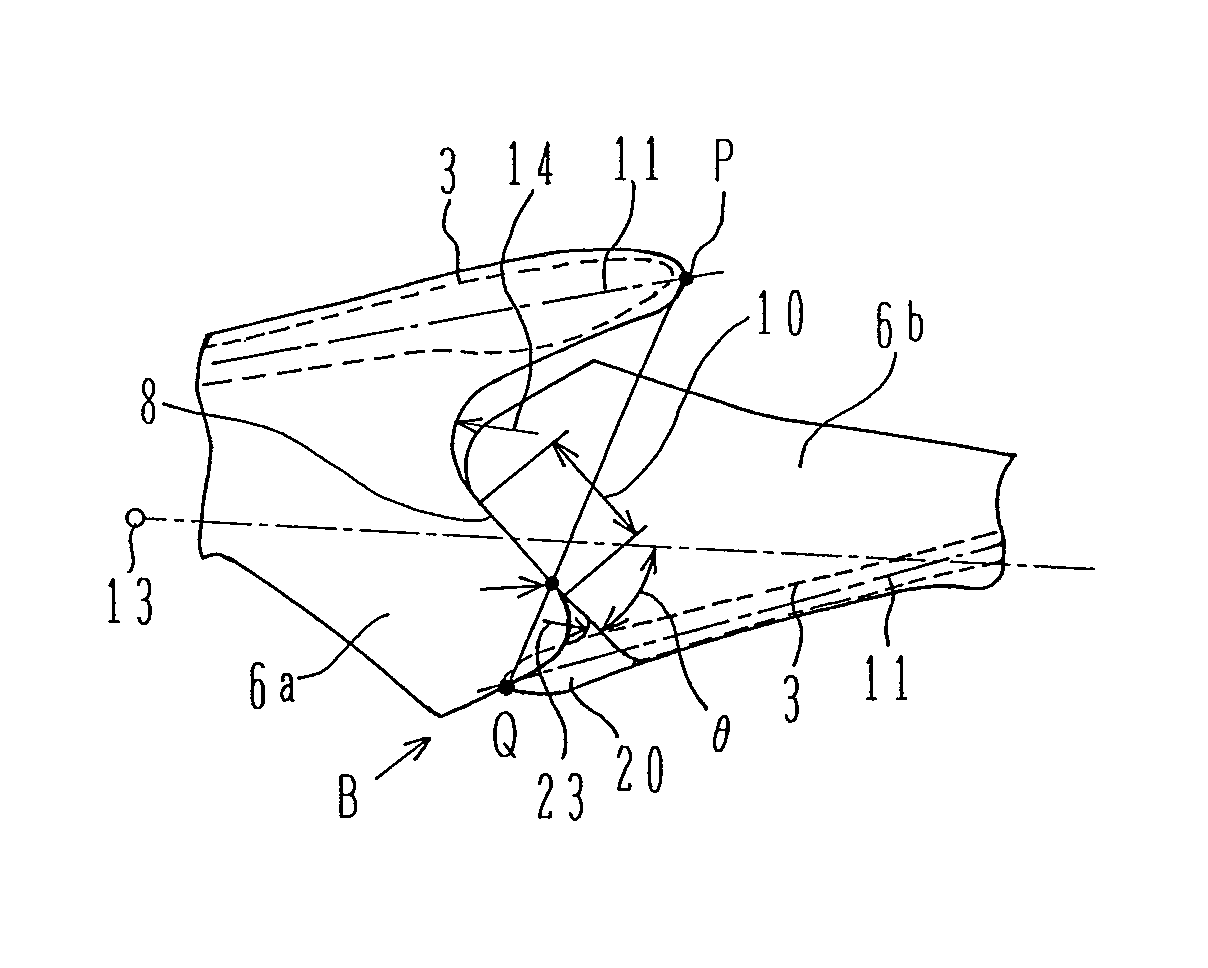

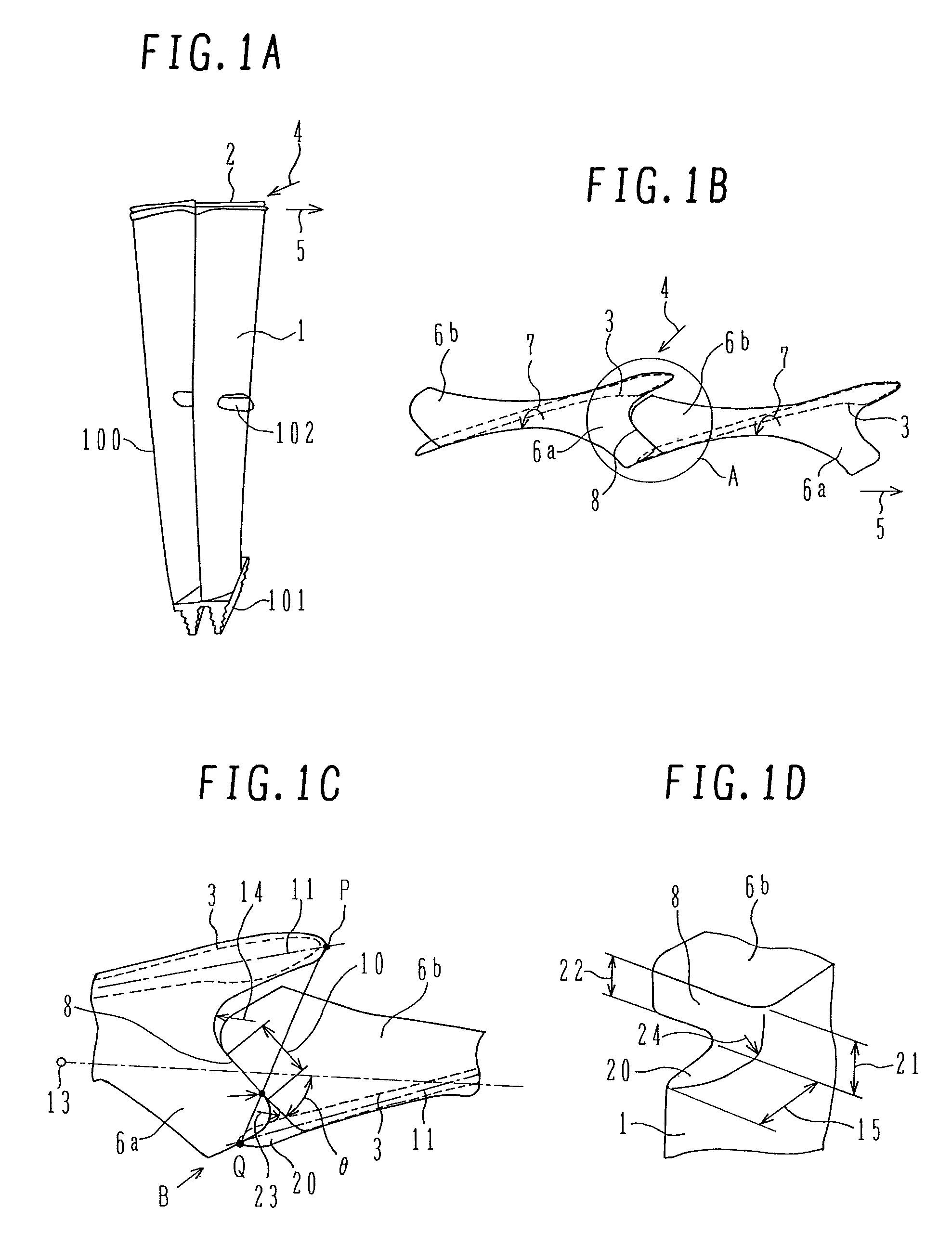

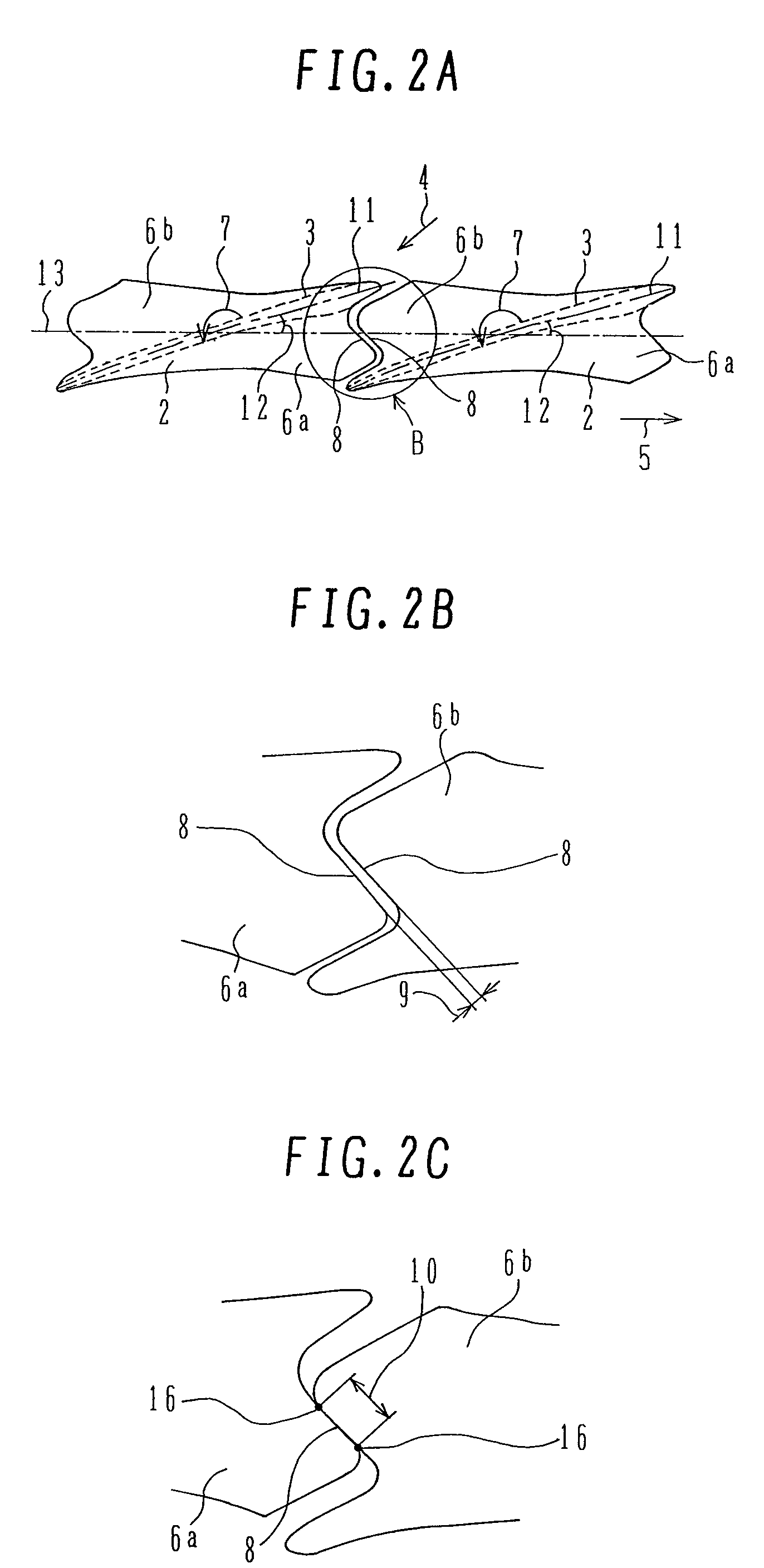

Steam turbine rotor blade

InactiveUS20080175712A1High normal stiffnessIncrease the lengthPropellersPump componentsLeading edgeEngineering

A subject of the present invention is to prevent the reduction of rigidity caused by the increased length of a steam turbine rotor blade and the degradation of vibration characteristics. A steam turbine rotor blade according to the present invention comprises a profile and a cover integrally formed on and at an end of the profile, the leading edge of the cover formed on the profile and the trailing edge of a cover formed on an adjacent preceding profile being in contact and connected with each other by the torsional return force produced during rotation, and wherein the cover formed on the profile is provided with a radially-formed stepped portion at the trailing edge, the stepped portion having a height large than the thickness of the cover.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

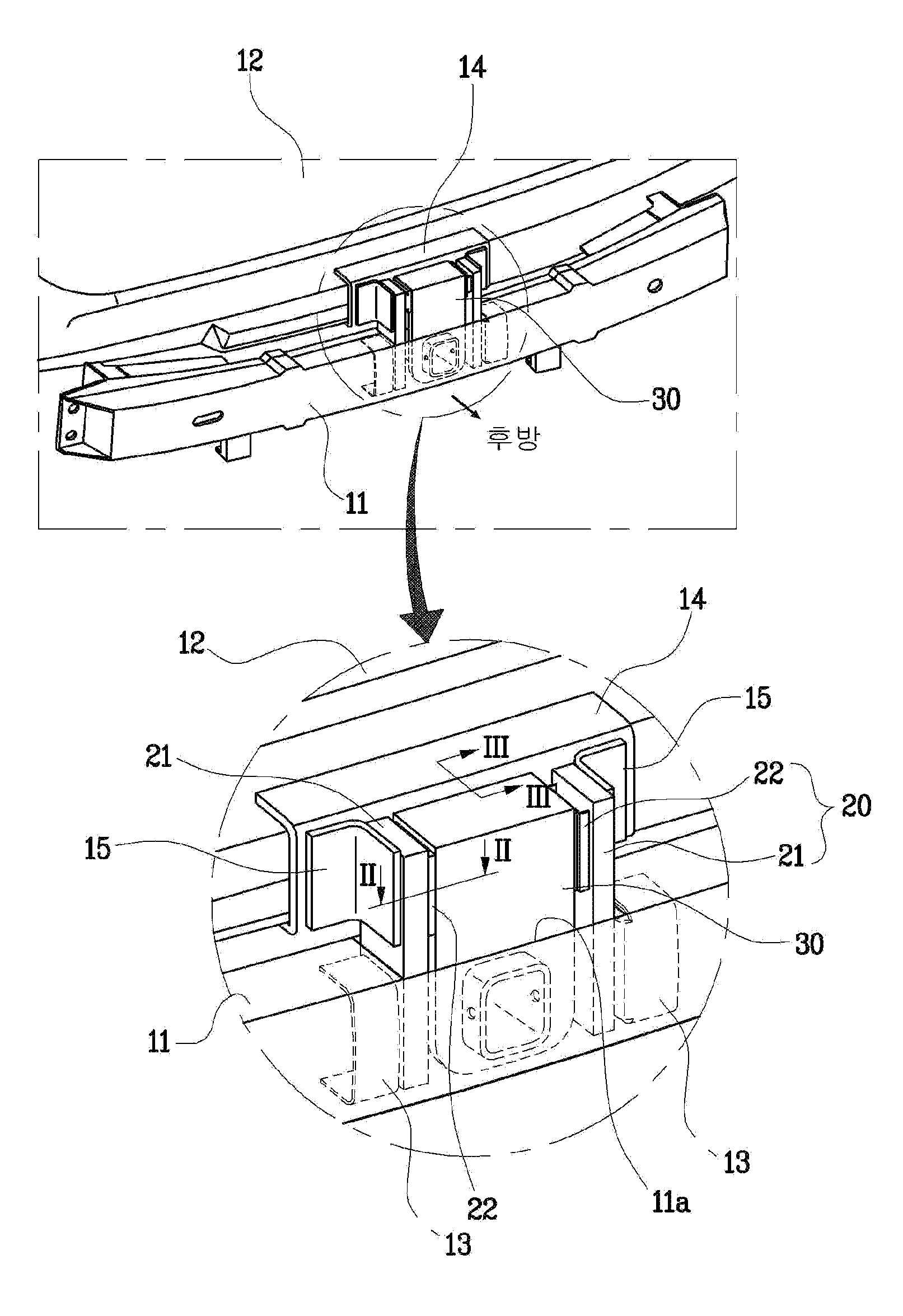

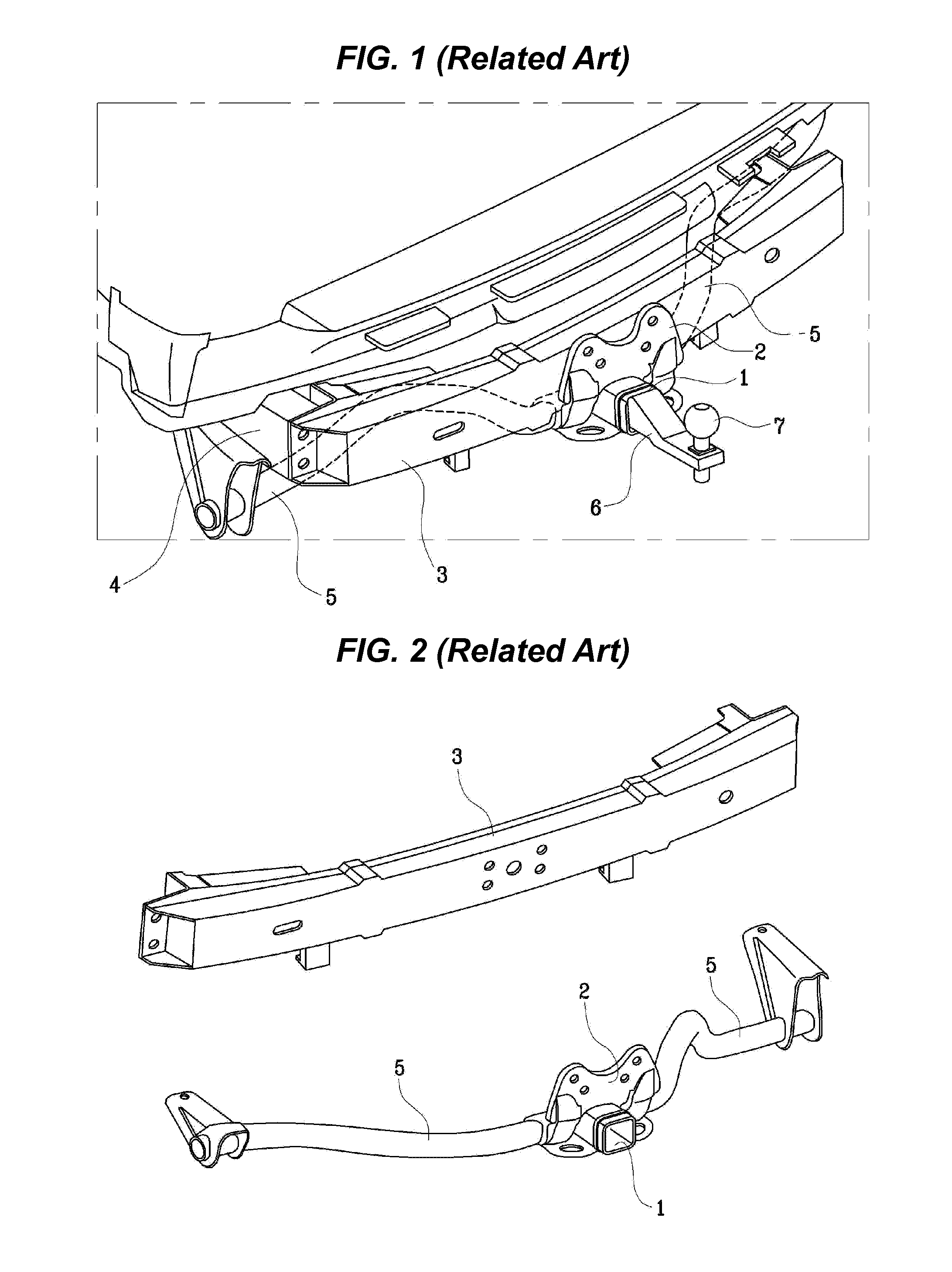

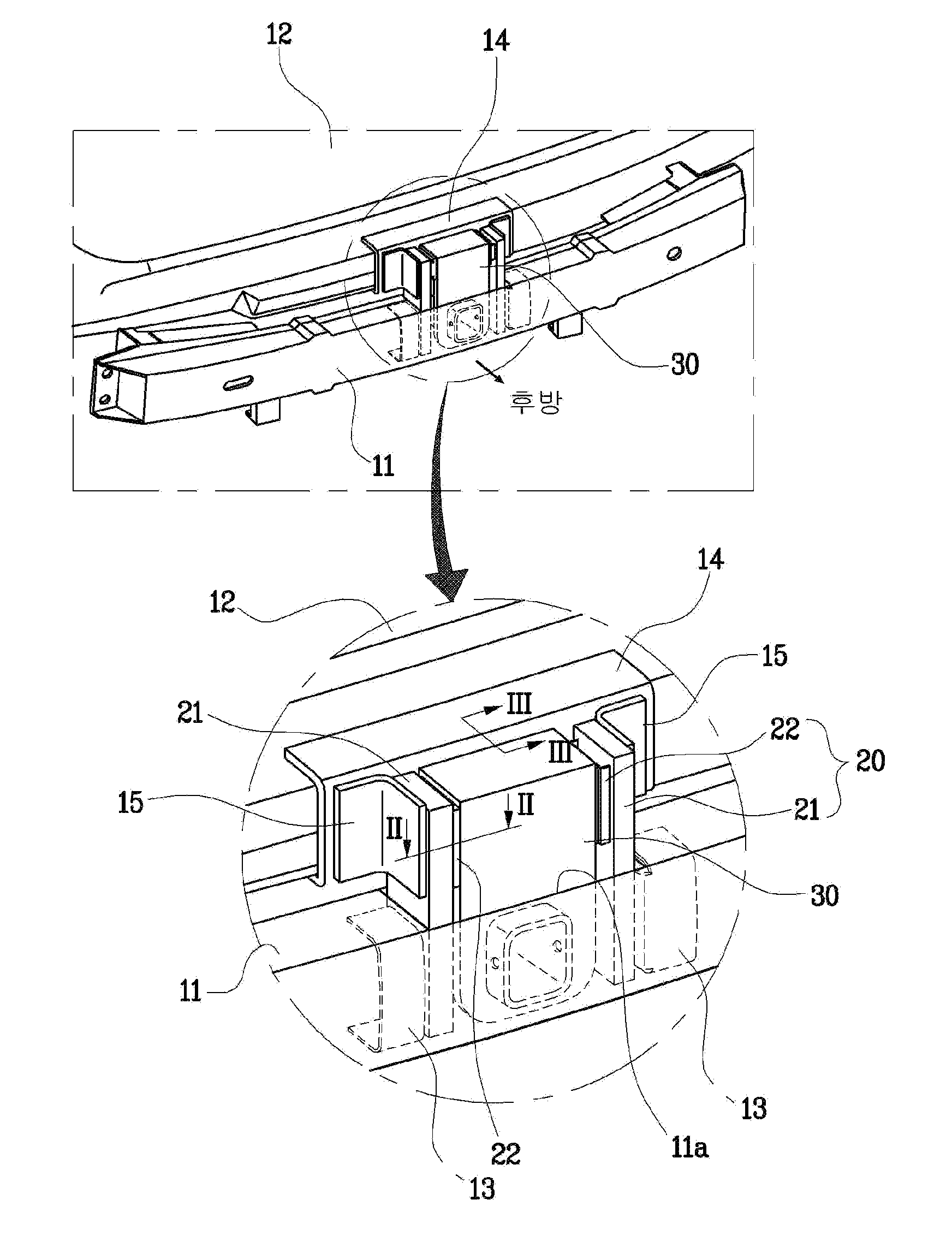

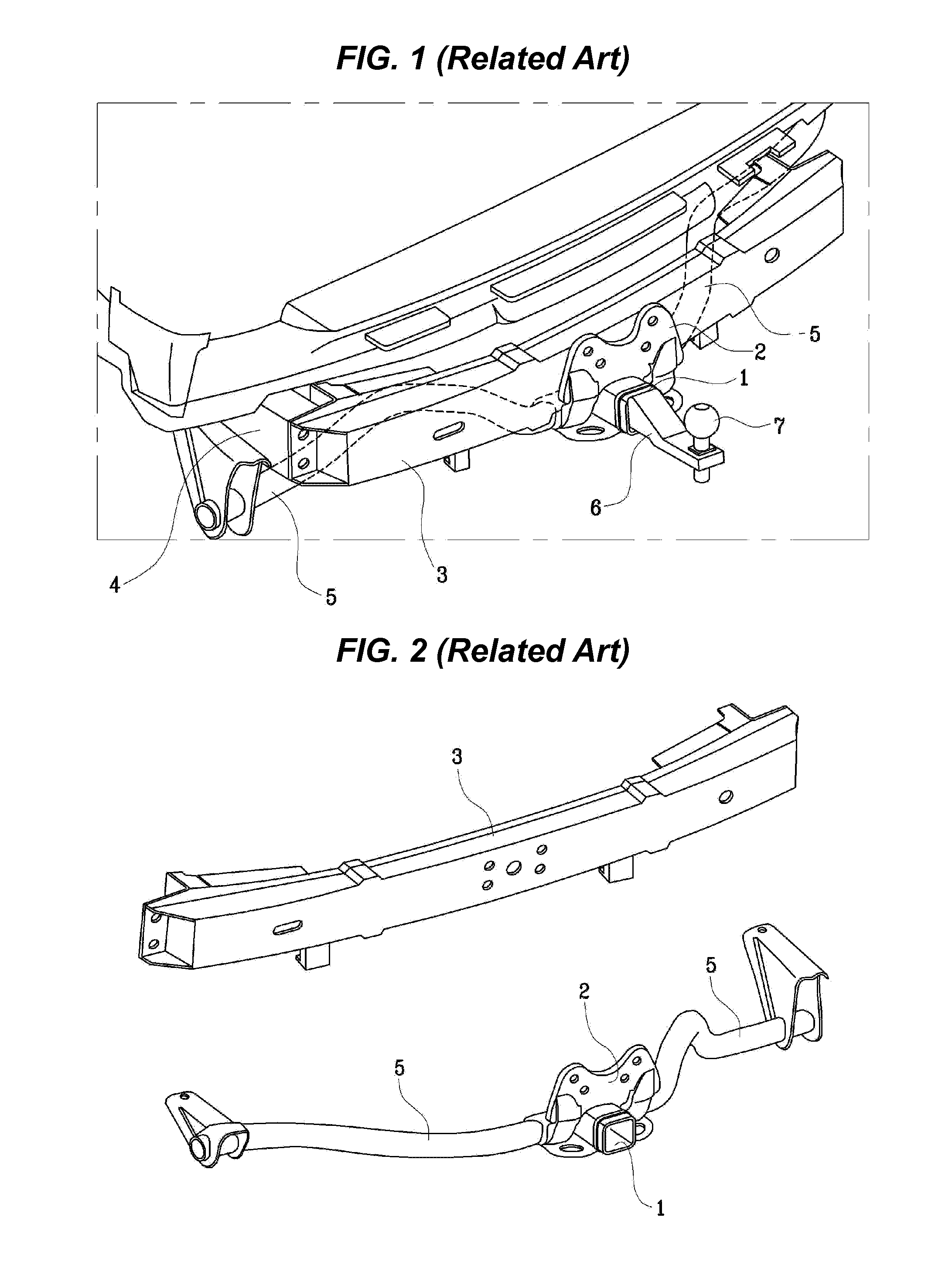

Hitch receiver apparatus for vehicle

ActiveUS8720932B2Increase freedomLow costTowing devicesBumpersEngineeringElectrical and Electronics engineering

A hitch receiver apparatus for a vehicle is provided in which a hitch receiver is disposed without being directly connected with a rear back beam, such that the hitch receiver is kept in the rear back beam when not being used, and the hitch receiver protrudes down under the rear back beam when using the function of a trailer.

Owner:HYUNDAI MOTOR CO LTD

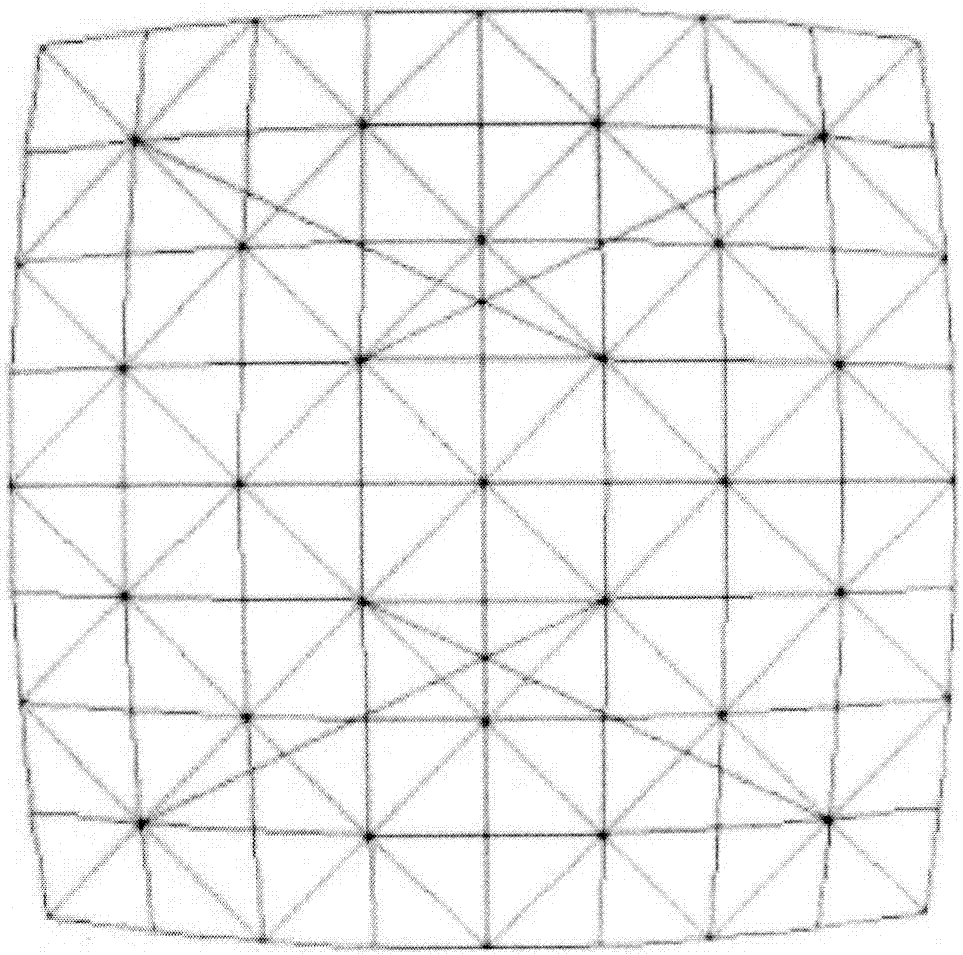

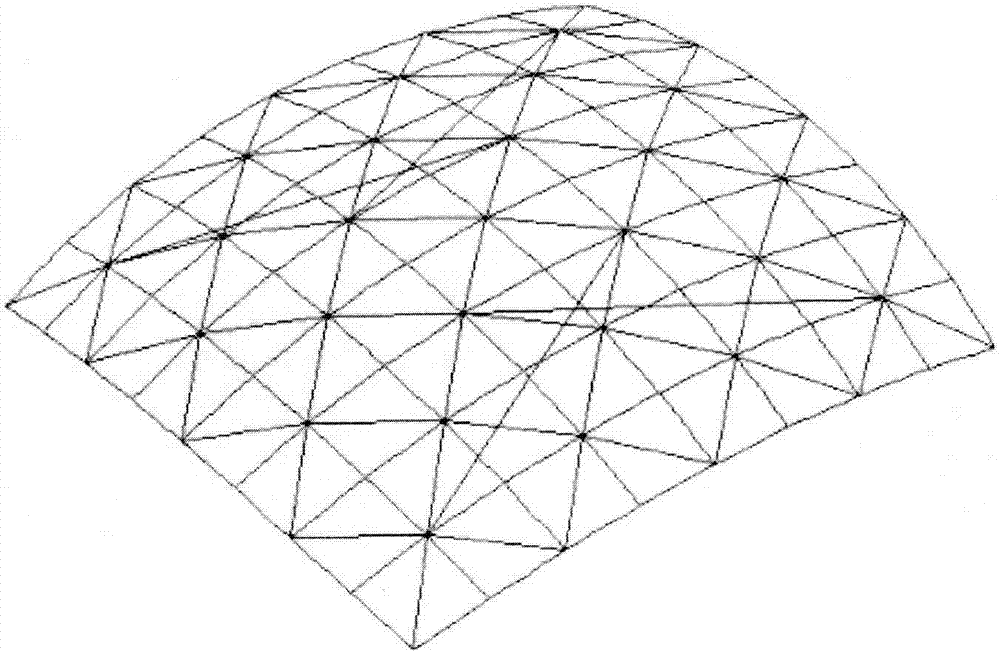

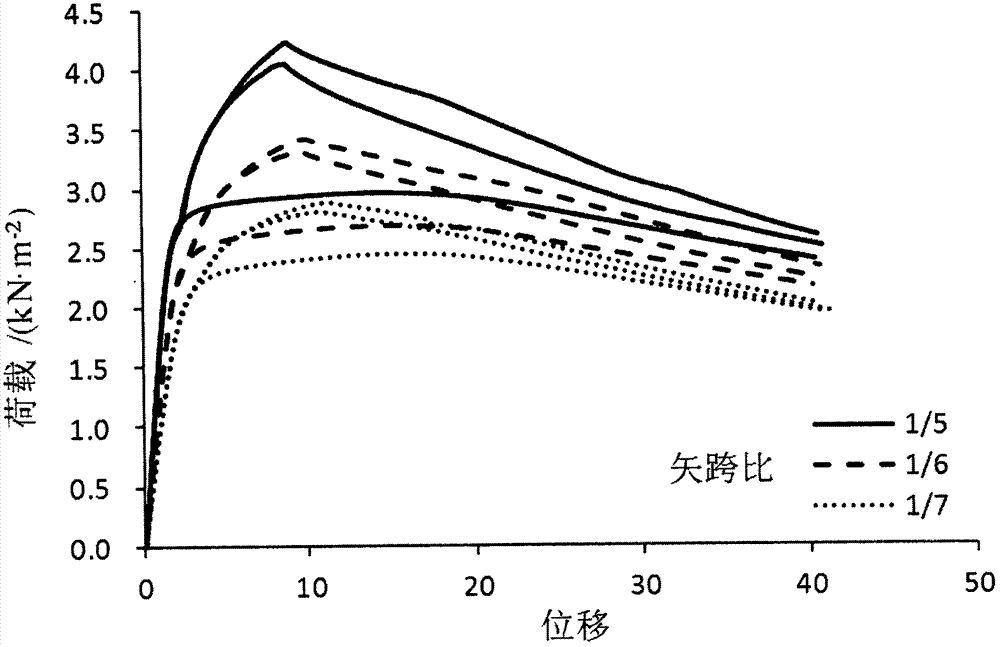

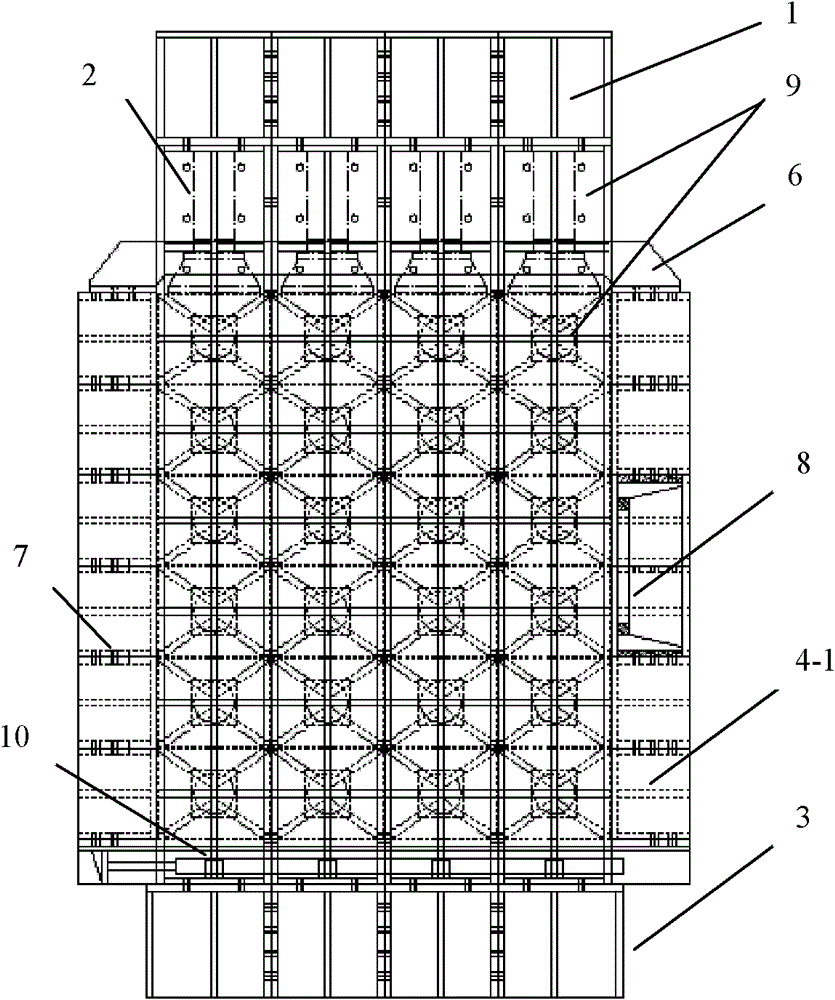

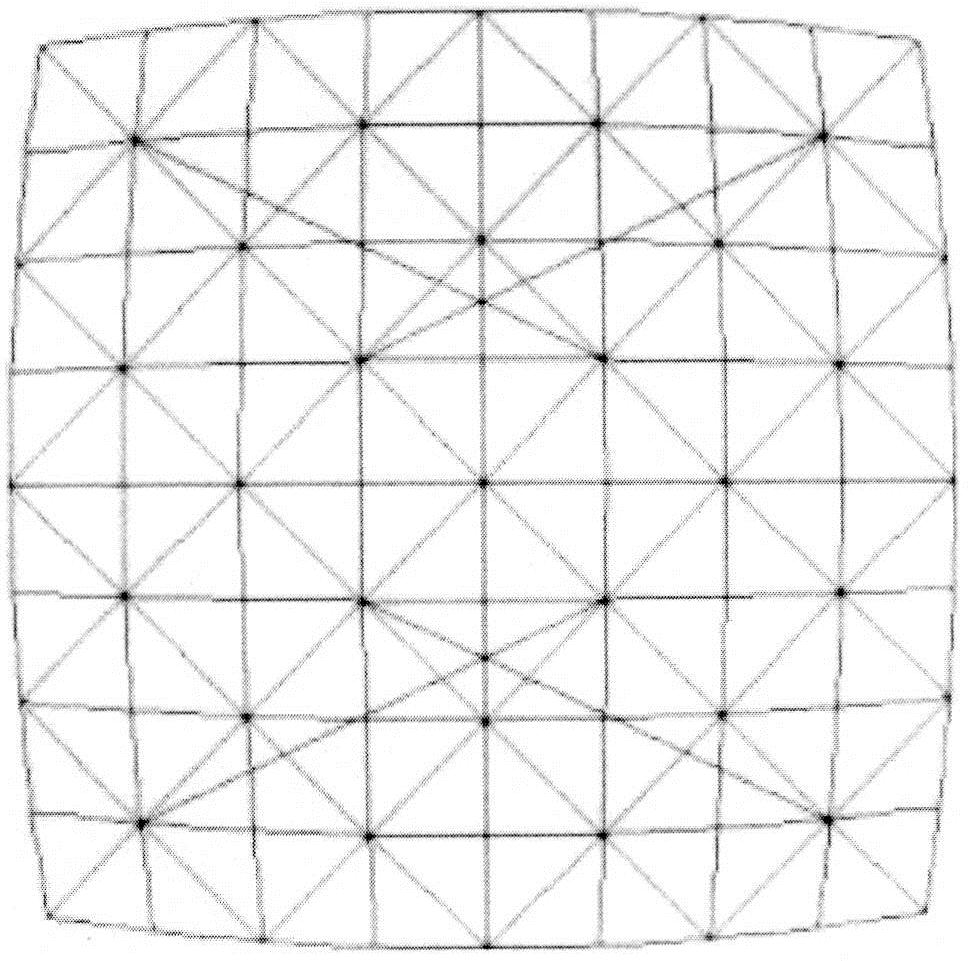

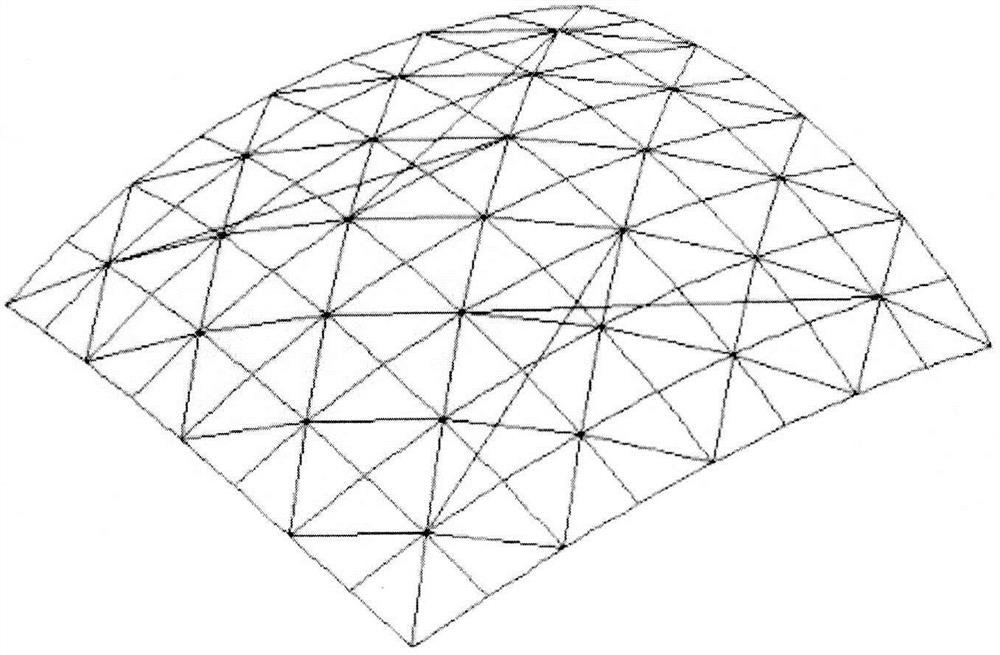

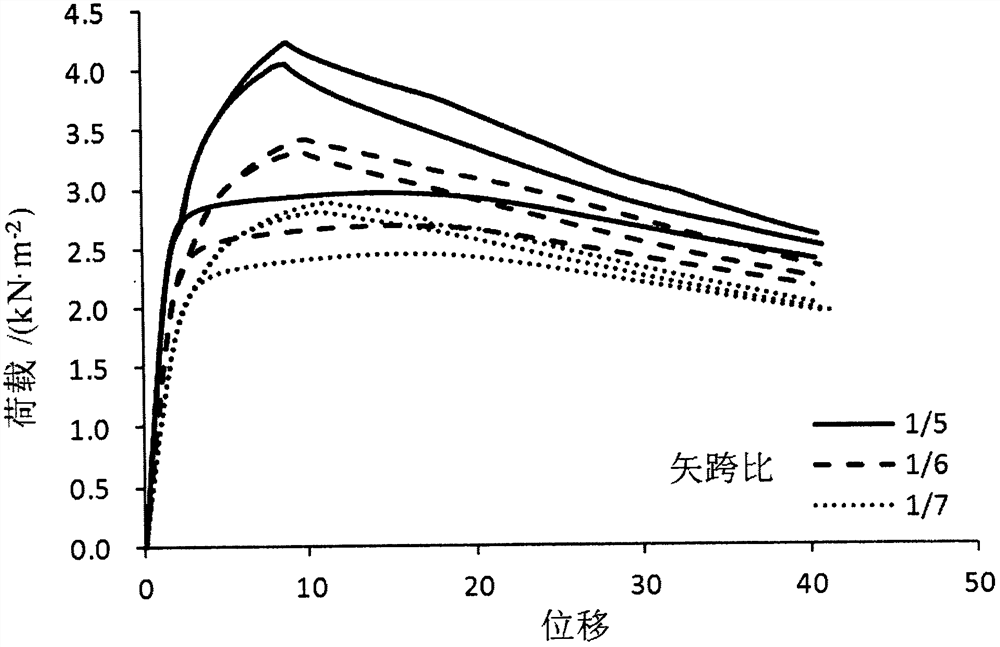

Diagonal pull rod type single-layer spherical greenhouse latticed shell system and design method thereof

InactiveCN107201778AHigh normal stiffnessIncrease stiffnessGeometric CADClimate change adaptationPre stressGreenhouse

The invention belongs to the technical field of large-span greenhouse space structural design in civil engineering and discloses a diagonal pull rod type single-layer spherical greenhouse latticed shell system and a design method thereof. The latticed shell system comprises a bidirectional lattice type single-layer spherical latticed shell, and diagonal pull rods are arranged at lattice diagonal positions in the bidirectional lattice type single-layer spherical latticed shell and / or outside the lattice shell surface. The design method includes: constructing a latticed shell structural model, and designing a diagonal pull rod scheme; adopting finite element software ANSYS for developing of a whole elastoplasticity analysis process to analyze influences of a pull rod arrangement form and prestress to an ultimate load of the spherical greenhouse latticed shell, and verifying and determining a structural design scheme of the diagonal pull rod type single-layer spherical greenhouse latticed shell system. By arrangement of the pull rods in the bidirectional lattice surface, internal rigidity of the structural surface is improved; by arrangement of the pull rods outside the lattice shell surface, external rigidity of the structural surface is improved, and the prestress in a certain range is applied to improve structural bearing capacity, and the structure has advantages of high light transmittance, low material consumption, high rigidity and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Hitch receiver apparatus for vehicle

ActiveUS20130134690A1Reduce weight and costIncrease degree of freedomTowing devicesBumpersElectrical and Electronics engineeringEngineering

A hitch receiver apparatus for a vehicle is provided in which a hitch receiver is disposed without being directly connected with a rear back beam, such that the hitch receiver is kept in the rear back beam when not being used, and the hitch receiver protrudes down under the rear back beam when using the function of a trailer.

Owner:HYUNDAI MOTOR CO LTD

Long steam turbine rotor blade having particular cover

InactiveUS8333562B2High normal stiffnessIncrease the lengthPropellersPump componentsLeading edgeEngineering

A steam turbine rotor blade has a profile and a cover integrally formed on and at an end of the profile, the leading edge of the cover formed on the profile and the trailing edge of a cover formed on an adjacent preceding profile being in contact and connected with each other by the torsional return force produced during rotation. The cover formed on the profile is provided with a radially-formed stepped portion at the trailing edge, the stepped portion having a height large than the thickness of the cover.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

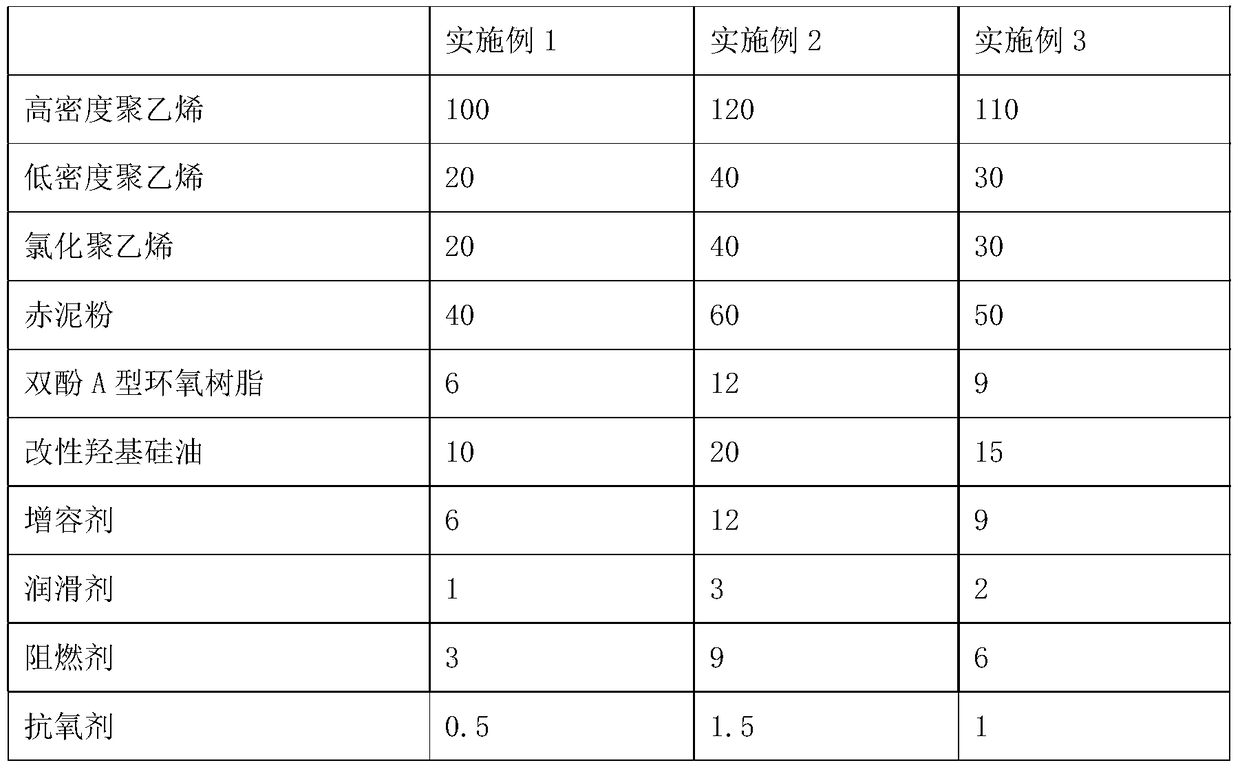

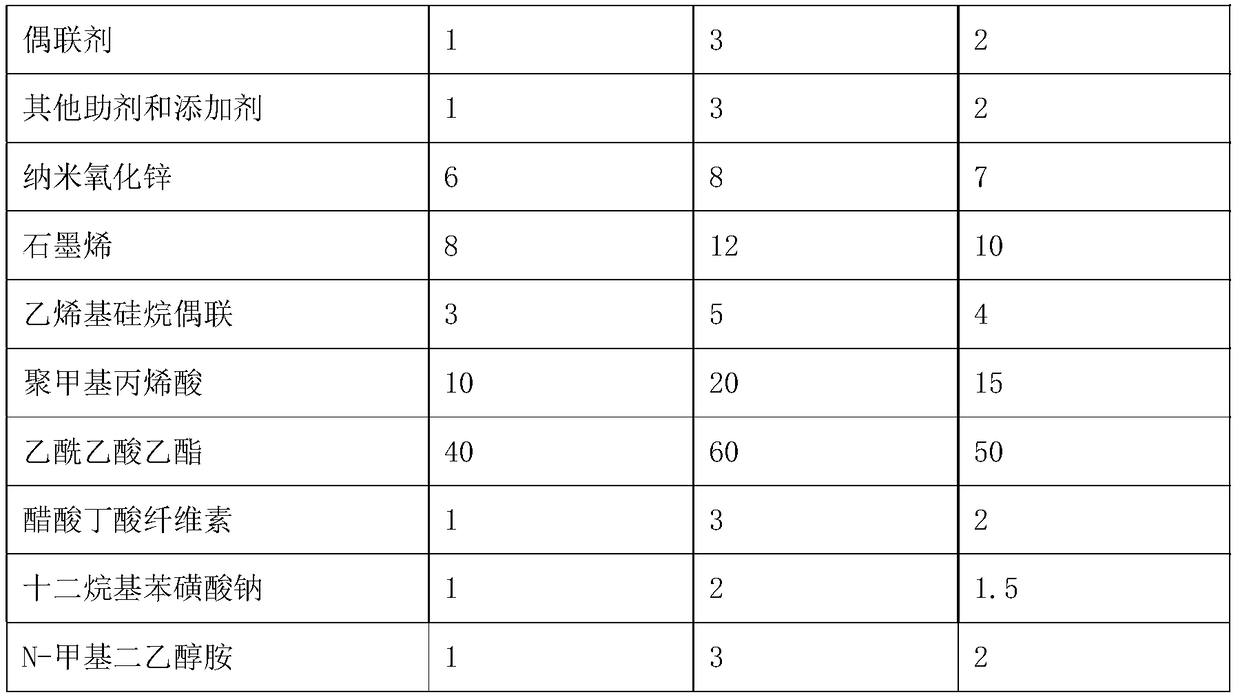

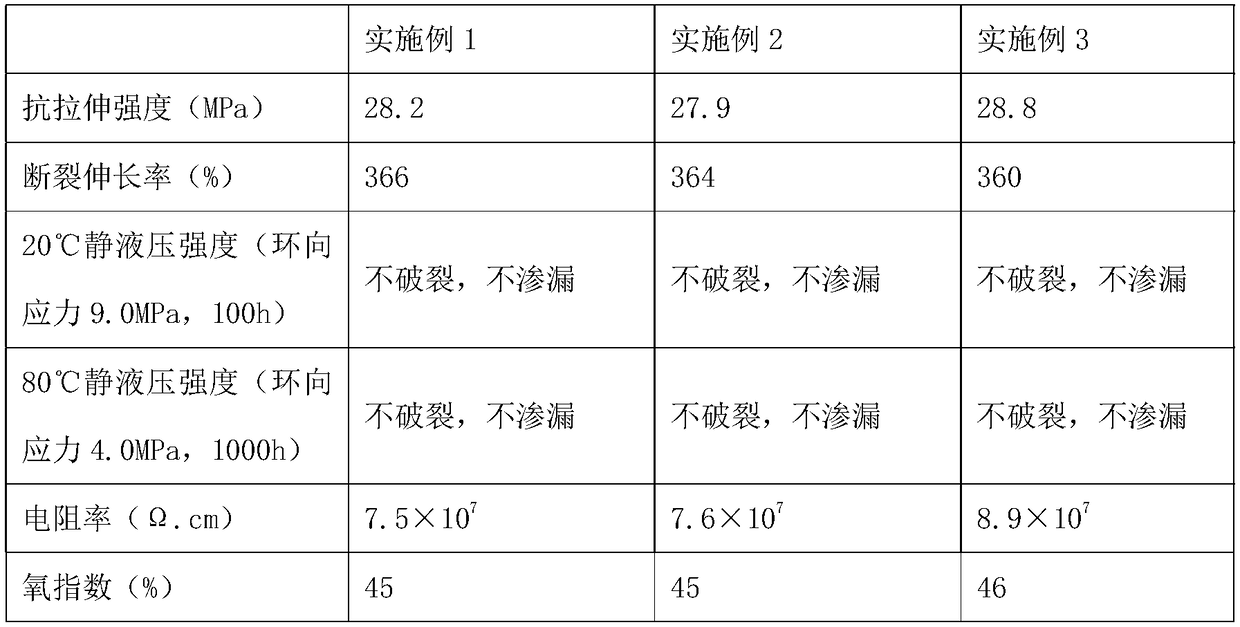

Preparation method of high toughness PE hollow wall twined pipe based on red mud modification

InactiveCN109021358AGood compatibilityIncrease the amount of carbonTubular articlesRed mudVolumetric Mass Density

The invention relates to a preparation process of a high toughness PE hollow wall twined pipe based on red mud modification. The process utilizes nano-zinc oxide and graphene for modification to improve the mechanical properties, toughness and rigidity of the pipe; nano-zinc oxide and graphene cooperate to form a continuous conductive path between systems, thus greatly improving the pipe conductivity; red mud is utilized for blending modification of a PE composite material, while the rigidity is improved, the PE pipe also has strong toughness, waste is turned into wealth, and the cost is greatly saved. Hydroxyl silicone oil can migrate on the PE surface and form a flame retardant layer to achieve flame retardant effect. Moreover, addition reaction can be carried out on the hydroxyl in themodified hydroxyl silicone oil and the epoxy group in a bisphenol A epoxy resin structure to enhance the crosslinking density and mechanical strength of the pipe. At the same time, hydroxyl silicone oil has low surface energy and endows the PE pipe with excellent waterproof performance. The preparation method is simple and scientific, the cost is low, the preparation process is environment-friendly, and has no pollution to the environment.

Owner:徐州辛辛那提新型材料有限公司

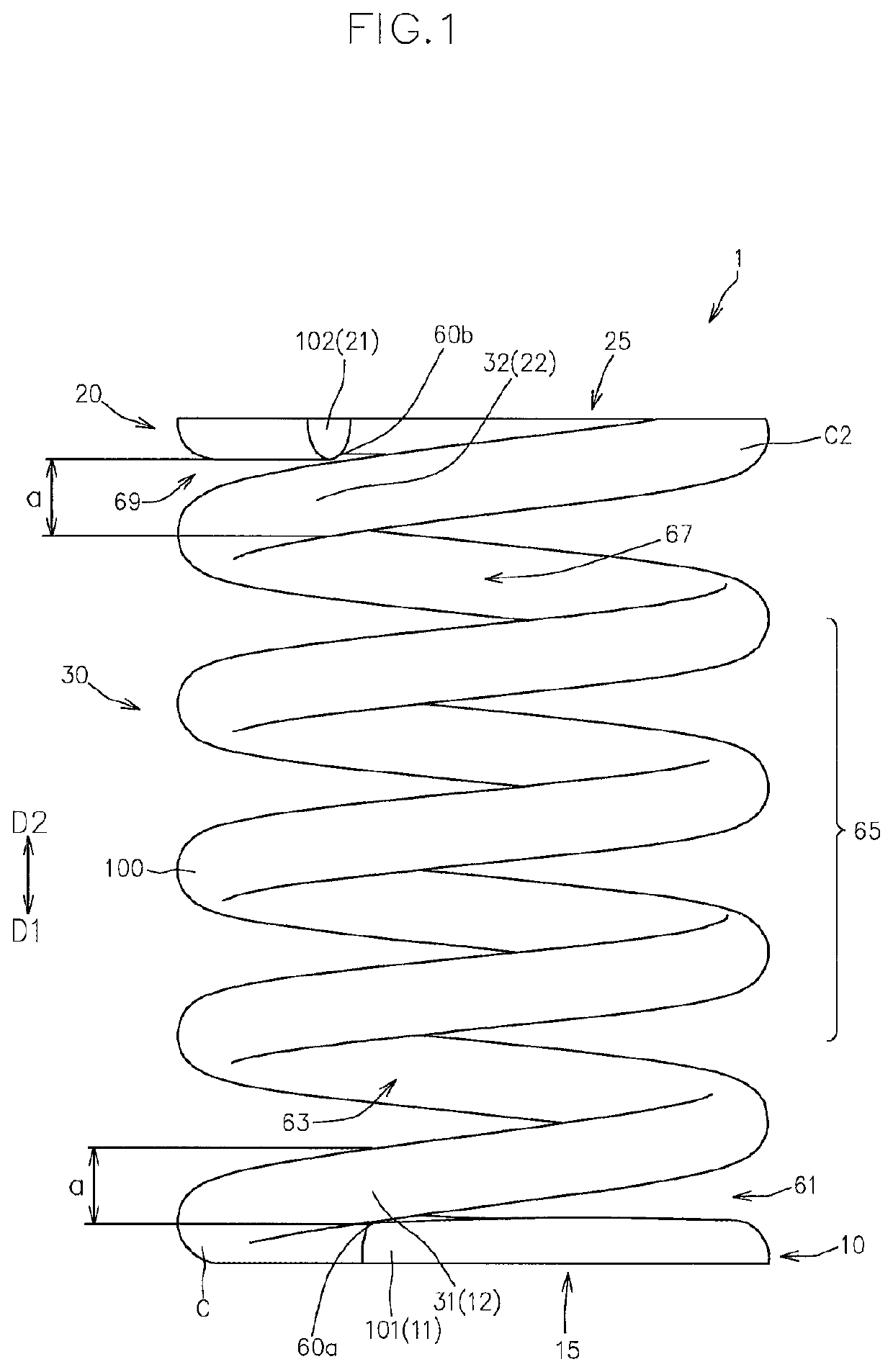

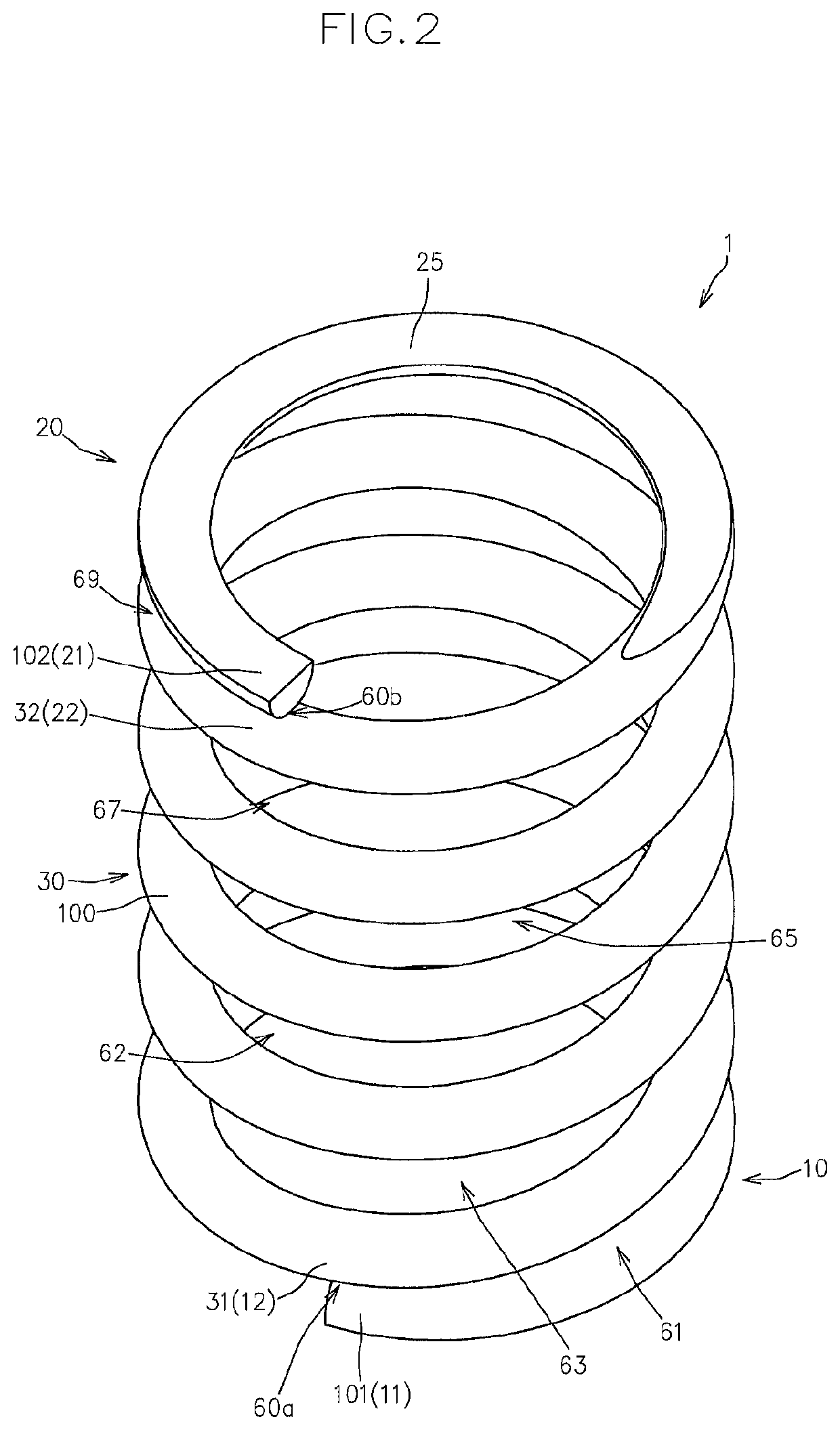

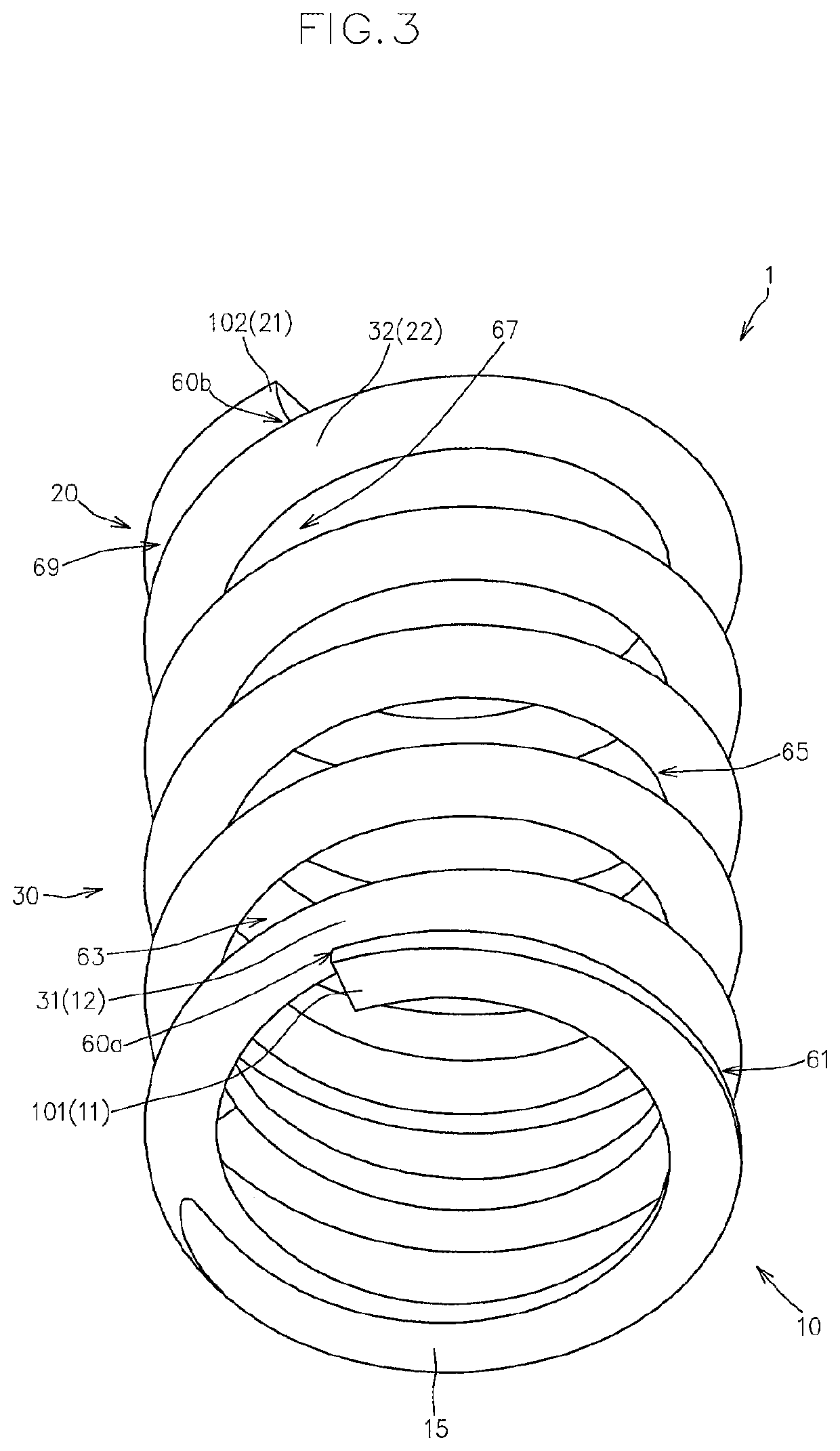

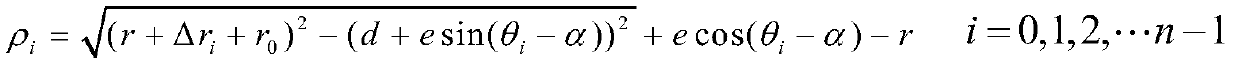

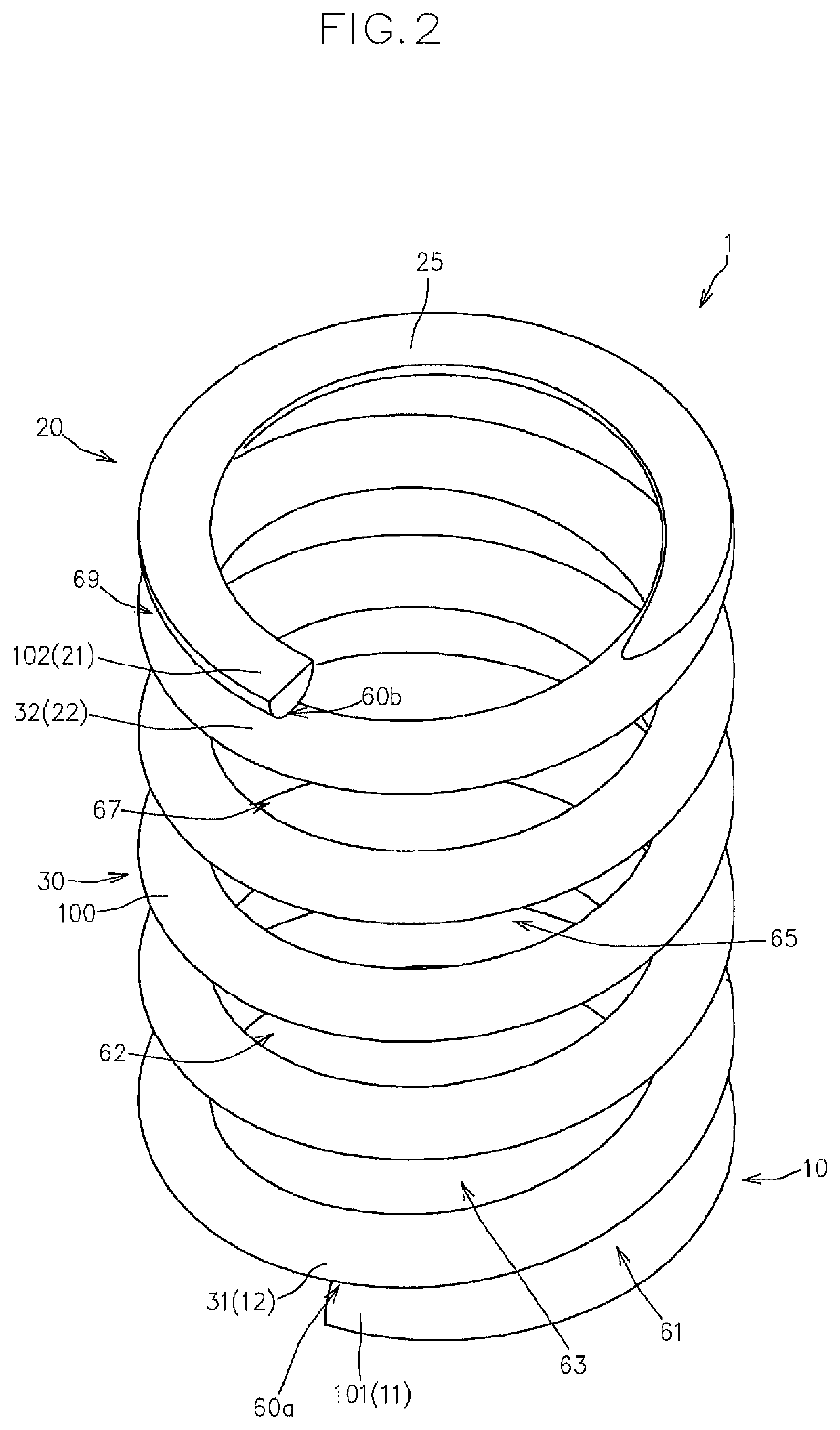

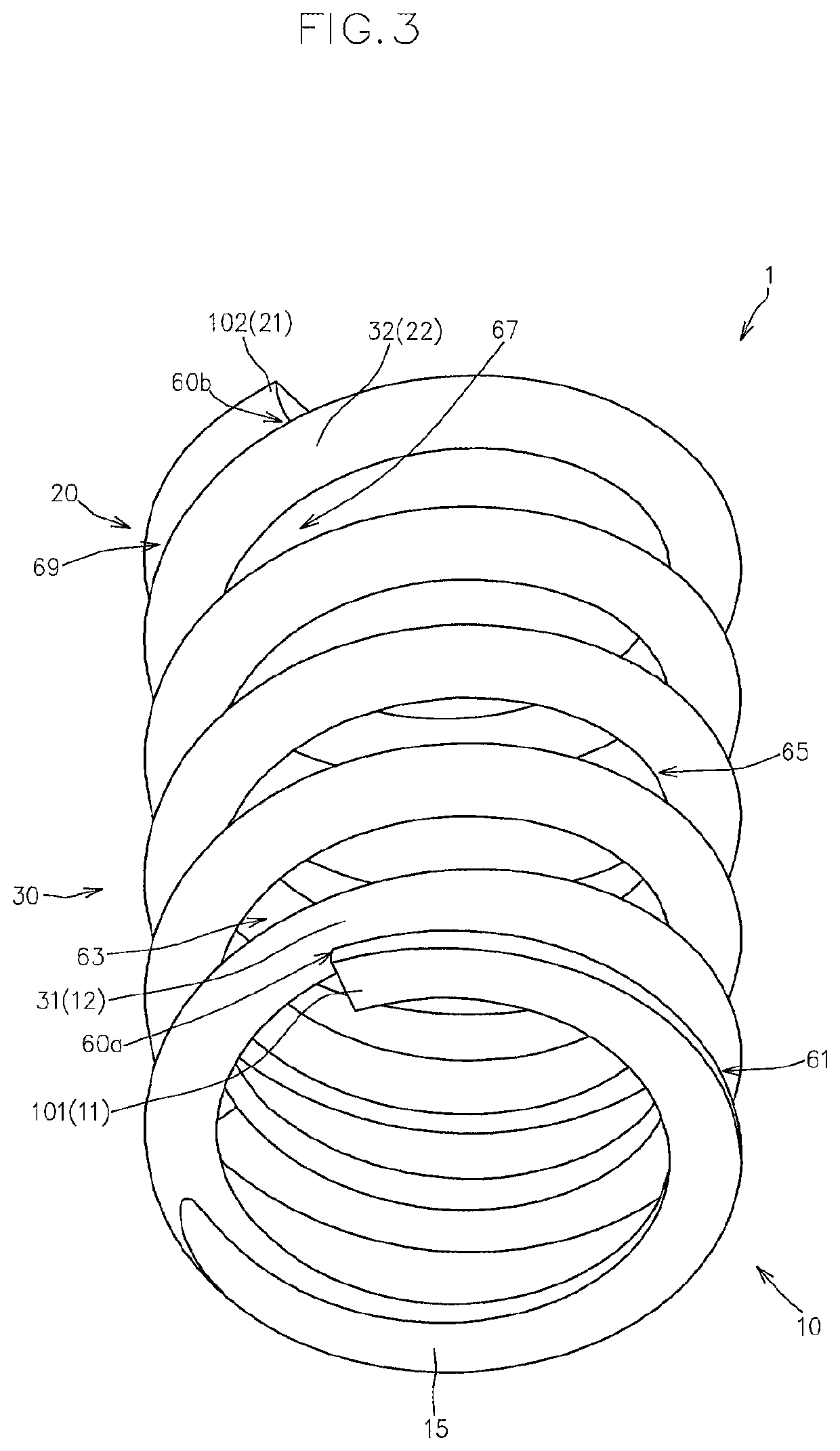

Coil spring

ActiveUS20210190163A1Inhibit deteriorationHigh normal stiffnessValve arrangementsMachines/enginesAxial displacementCoil spring

A coil spring of this invention includes a first end coil part with a first bearing surface facing to the first side in the axial direction, a second end coil part with a second bearing surface facing to the second side in the axial direction and a central coil part connecting the first and second end coil parts. A displacement length in the axial direction from the outer end portion until the inner end portion of the first end coil part is a thickness of a spring wire forming the coil spring so that a space between the outer end portion of the first end coil part and an inner end portion of the central coil part is zero, and a displacement length in the axial direction between the outer end portion of the first end coil part and a point away along the circumferential direction from the outer end portion toward the inner end portion of the first end coil part by a half of turn around the axial line is less than a half of the thickness of the spring wire.

Owner:SANCALL +1

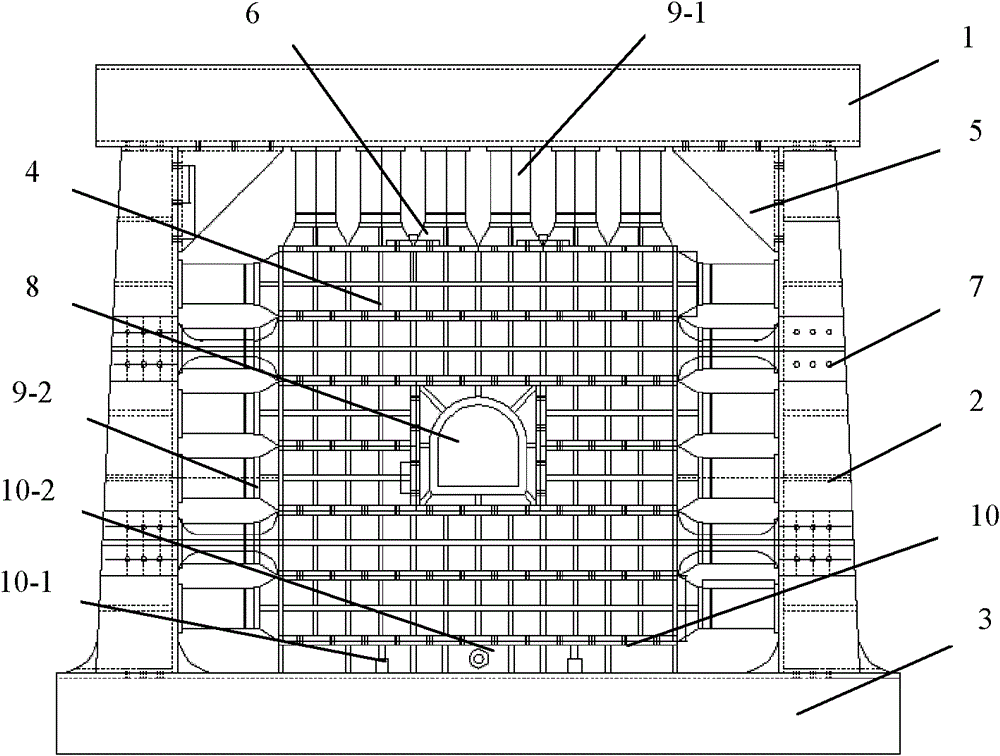

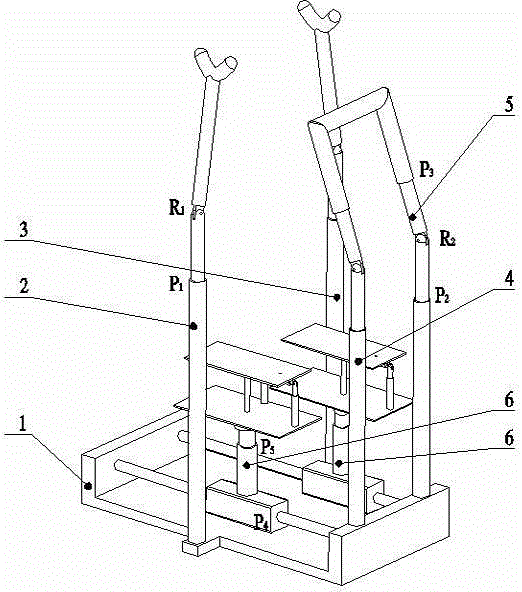

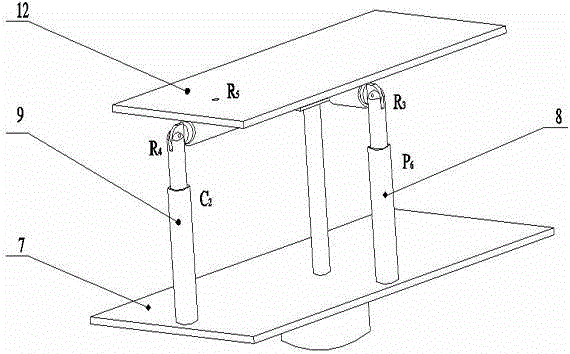

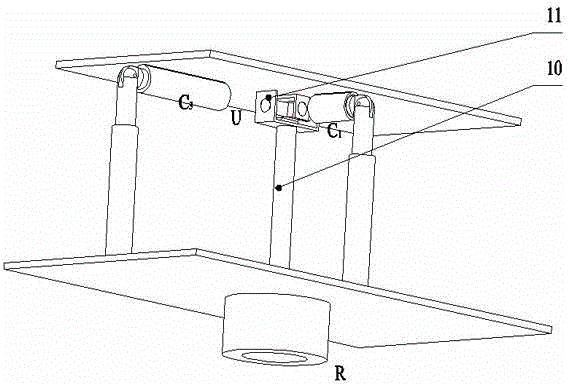

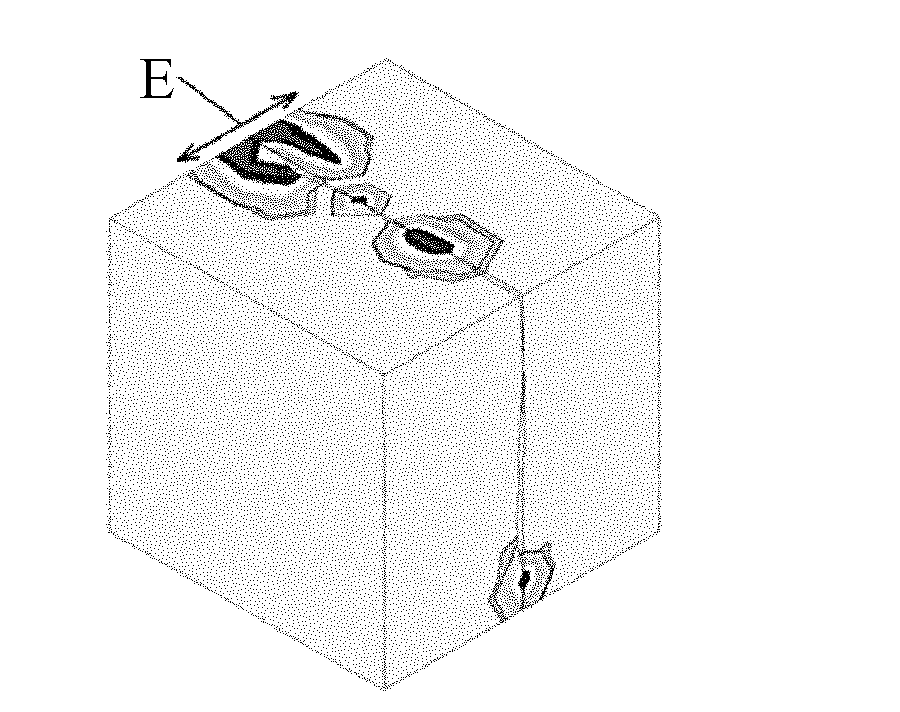

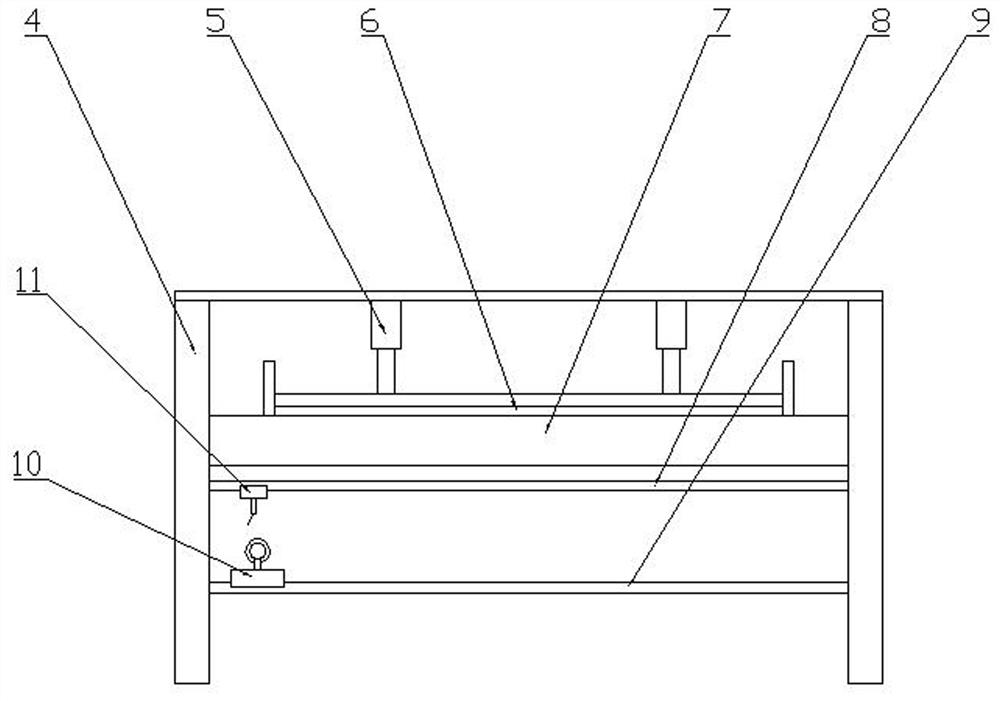

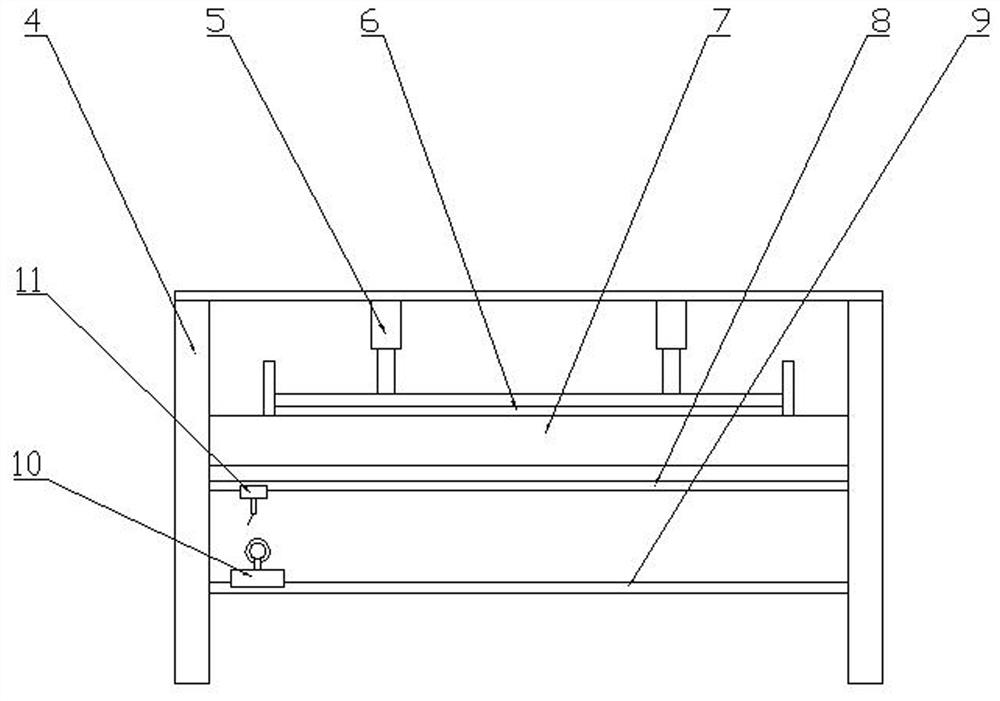

Large-size freely combined model test device for high ground stress underground engineering

InactiveCN102175517BHigh strengthImprove impact toughnessStrength propertiesStress conditionsMechanical models

The invention relates to a large-size freely combined model test device for a high ground stress underground engineering, and the device provided by the invention comprises a plurality of split mounting type counter-force jack horse devices, wherein the whole test device has a narrower upper part and a wider lower part; the side face of the whole test device is a slope; each split mounting type counter-force jack horse device comprises a top beam, a side beam and a bottom beam; flanges and high-strength bolts are used for connecting the top beam to the side beam and connecting the side beam to the bottom beam; the counter-force jack horse devices can be connected mutually or be connected to front and back counter-force beams; the upper parts of the front and back counter-force beams are connected to left and right pulling rods while the lower parts of the front and back counter-force beams are connected to a model lifting translation trailer system on the bottom beam; the top beam andthe side beam are both provided with hydraulic loading systems; and the baseboard of the device is provided with an automatic hydraulic model lifting translation trailer system, thereby being convenient and stable to move a test model in and out. The test device is flexibly assembled, is simply operated, can be used for conveniently loading and observing, is provided with the model lifting translation trailer system, and can be applied to the plane and three-dimensional geo-mechanical model test for the geotechnical engineering under the high ground stress condition.

Owner:SHANDONG UNIV

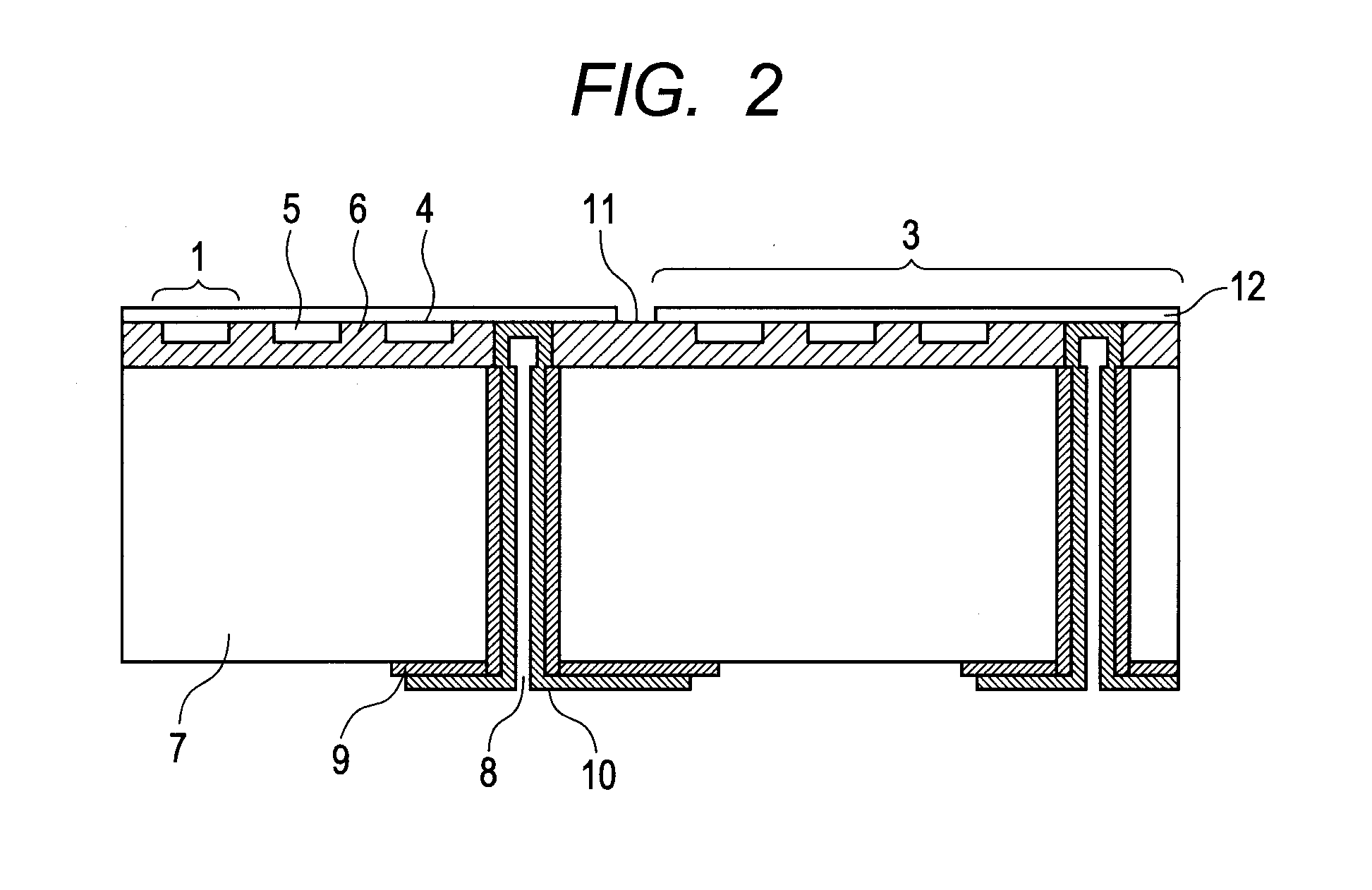

Electromechanical transducer and method of manufacturing the same

InactiveUS8653613B2High normal stiffnessImprove consistencyFluid pressure measurement by electric/magnetic elementsSemiconductor/solid-state device manufacturingElectrical conductorEngineering

An electromechanical transducer includes multiple elements each including at least one cellular structure, the cellular structure including: a semiconductor substrate, a semiconductor diaphragm, and a supporting portion for supporting the diaphragm so that a gap is formed between one surface of the substrate and the diaphragm. The elements are separated from one another at separating locations of a semiconductor film including the diaphragm. Each of the elements includes in a through hole passing through a first insulating layer including the supporting portion and the semiconductor substrate: a conductor which is connected to the semiconductor film including the diaphragm; and a second insulating layer for insulating the conductor from the semiconductor substrate.

Owner:CANON KK

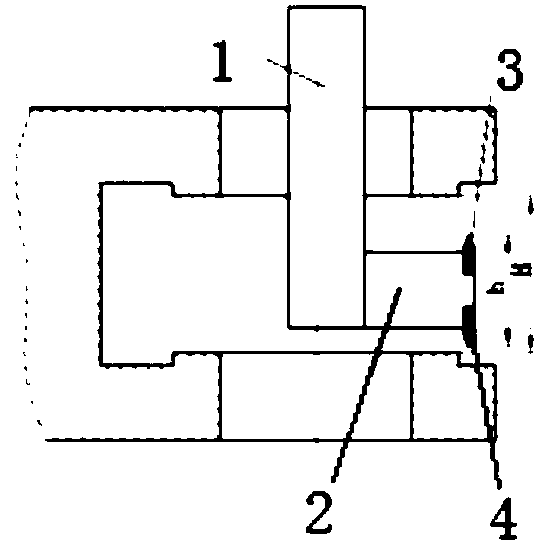

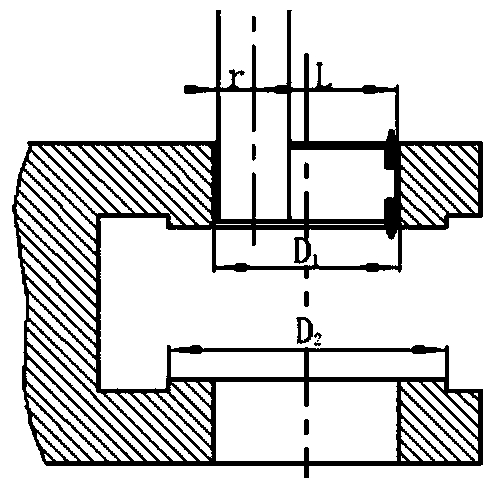

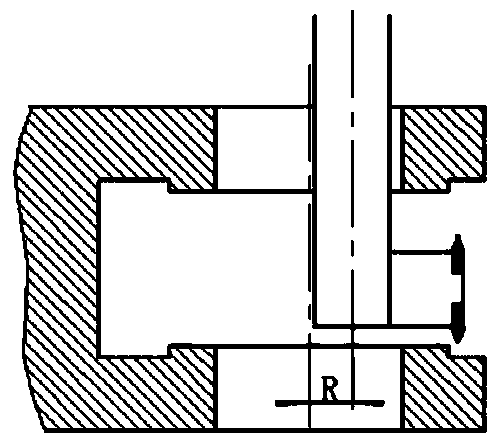

Method for machining end surfaces of inner cavity holes by using two-end cutter

PendingCN110722200AReduce tool change timeImprove processing efficiencyMilling equipment detailsEngineeringMachine tool

The invention discloses a method for machining end surfaces of inner cavity holes by using a two-end cutter, and solves the problems of low precision, low machining efficiency and short life of the cutter in traditional end surface machining; and the cutter has no need to be changed during machining of upper and lower end surfaces of the inner cavity holes, so that the machining efficiency is high. The method is characterized in that the lower end surfaces / the upper end surfaces of the inner cavity holes are firstly machined; the two-end cutter is clamped on a main shaft; the main shaft is oriented to stop the two-end cutter above the centers of the holes, and then, is deviated from the centers of the holes by a set distance to feed the two-end cutter from upper end holes to a molding cavity; after the two-end cutter enters inner cavities, the main shaft is leveled with the centers of the holes, and then, the center of a cutter rod moves to deviate from the centers of the holes by a set distance R; the main shaft is started, and a machine tool drives the main shaft to perform a circular interpolation motion with the centers of the holes as circle centers and with R as radius; aftermachining of the lower end surfaces / the upper end surfaces, the two-end cutter machines the lower end surfaces / the upper end surfaces according to a given feeding quantity; and after machining, the two-end cutter is deviated from the machined end surfaces by a set distance, the center of the two-end cutter is aligned to the centers of the holes, and the cutter is withdrawn.

Owner:SHANDONG UNIV

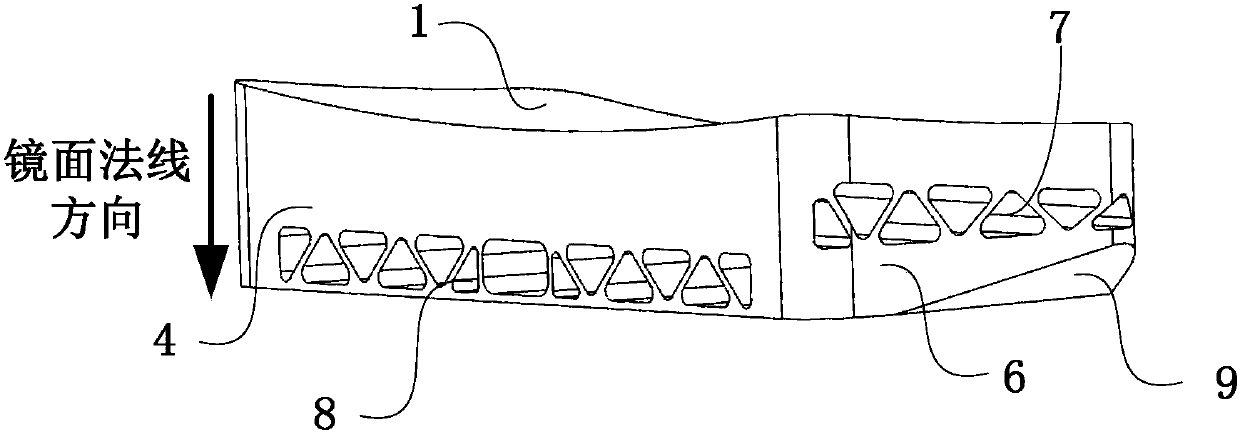

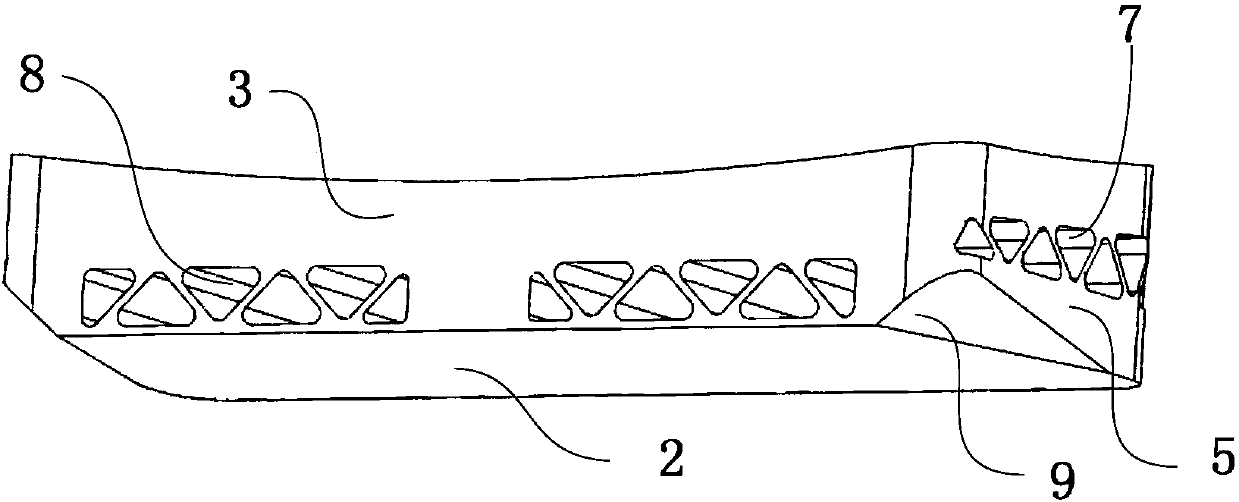

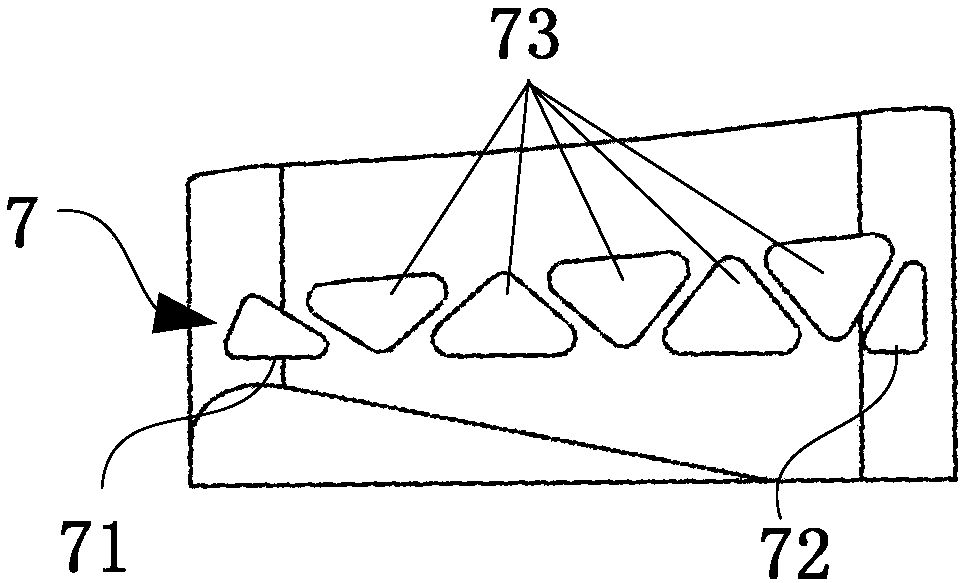

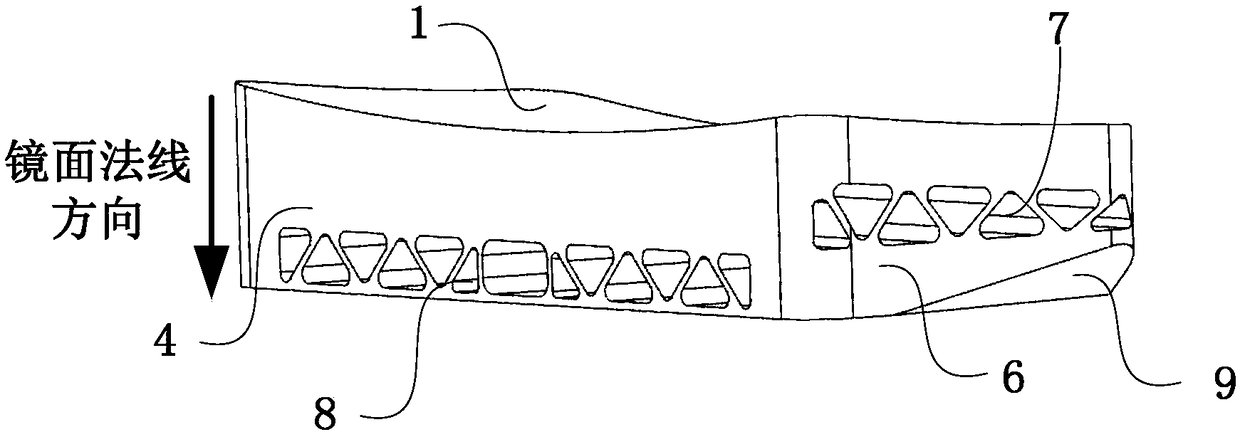

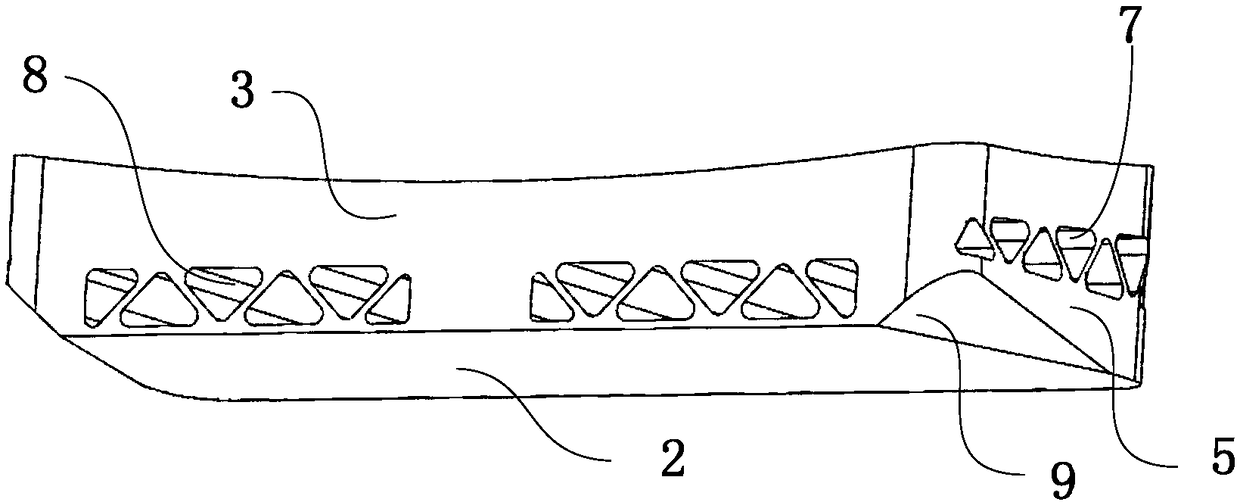

Off-axis reflector and processing method therefor

ActiveCN107797169AImprove surface accuracyHigh surface finishMirrorsSurface finishOptical processing

The invention provides an off-axis reflector, and the reflector comprises a reflective surface, a back surface, a front surface, a back surface, a first side surface, and a second side surface. The reflective surface is opposite to the back surface, and the front surface is opposite to the back surface. The first side surface is opposite to the second side surface, and a first light weight hole layer is disposed between the first side surface and the second side surface. A second light weight hole layer is disposed between the front surface and the back surface. The reflector can obtain higherrigidity, and can effectively solve problems that a conventional reflector is long in processing period and is high in manufacturing cost and a long-strip off-axis reflector is low in rigidity. The invention also provides a processing method for the reflector, and the employs the modification technology for modifying the reflector. Optical processing is carried out on the surface of a modified layer, thereby improving the surface figure accuracy and surface cleanness of the reflector. The method can meet the requirements of visible light.

Owner:CHANNGCHUN CHANGGUANG ADVANCED OPTICS TECH CO LTD

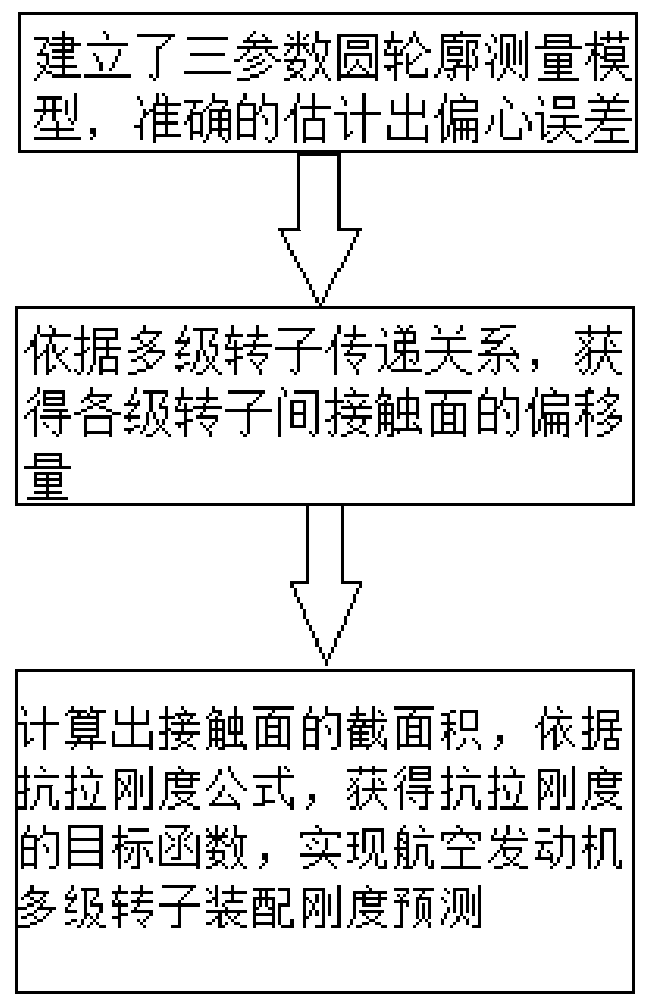

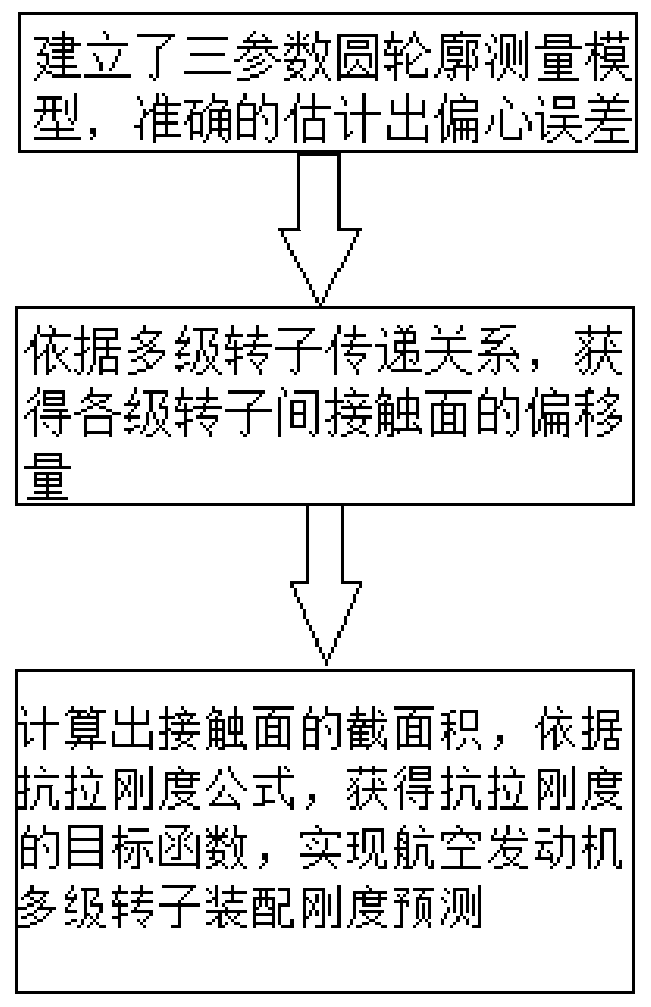

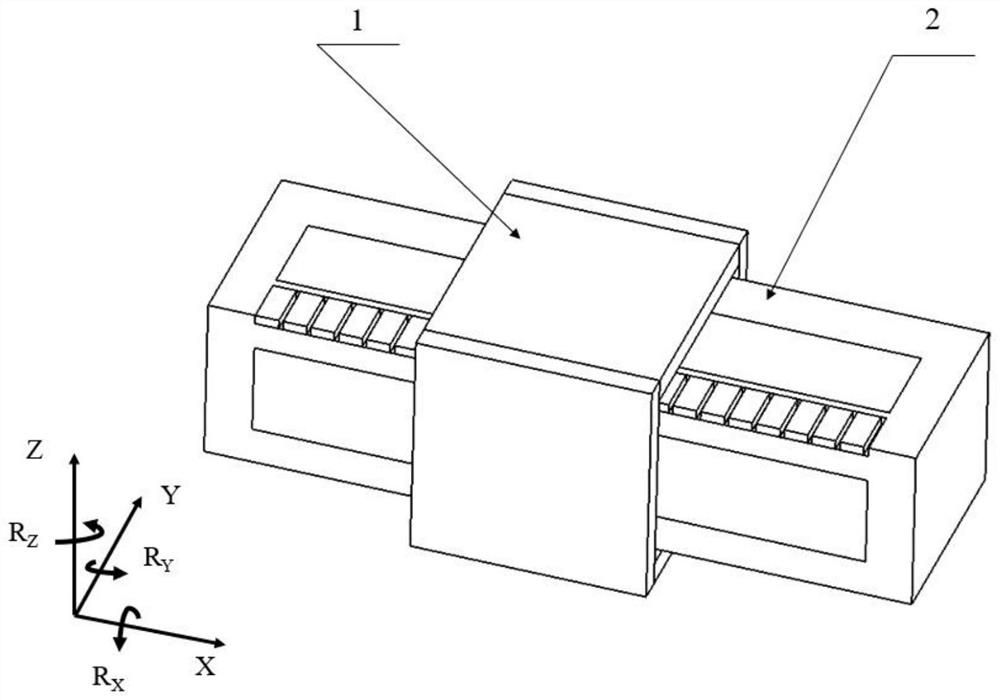

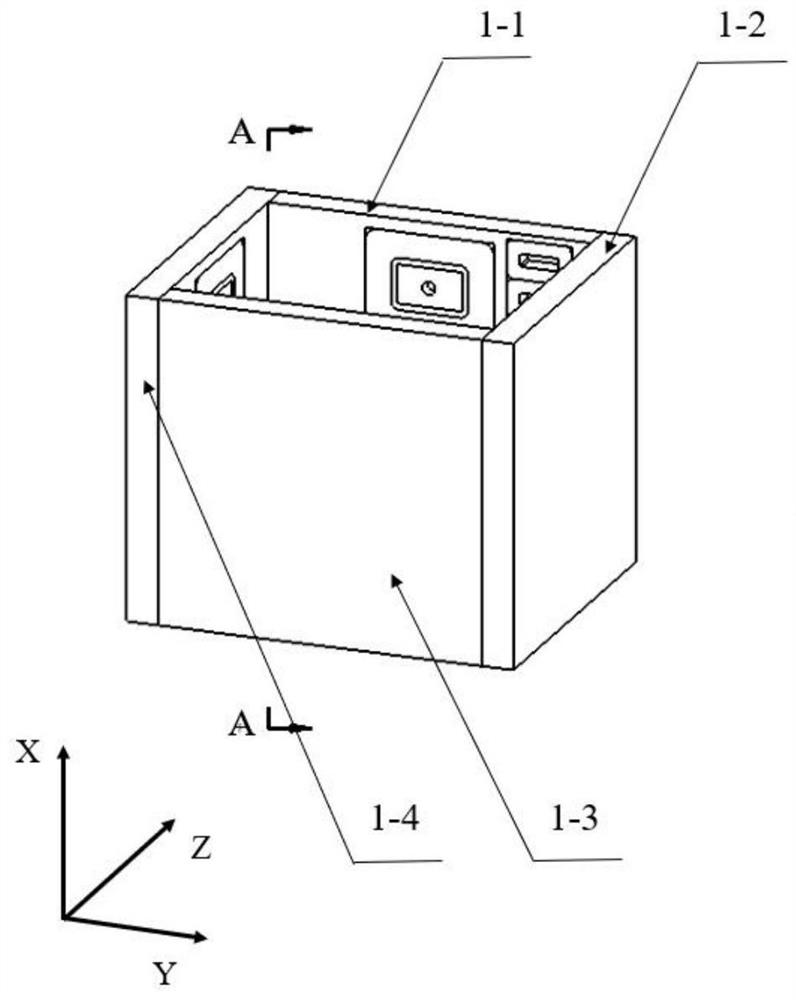

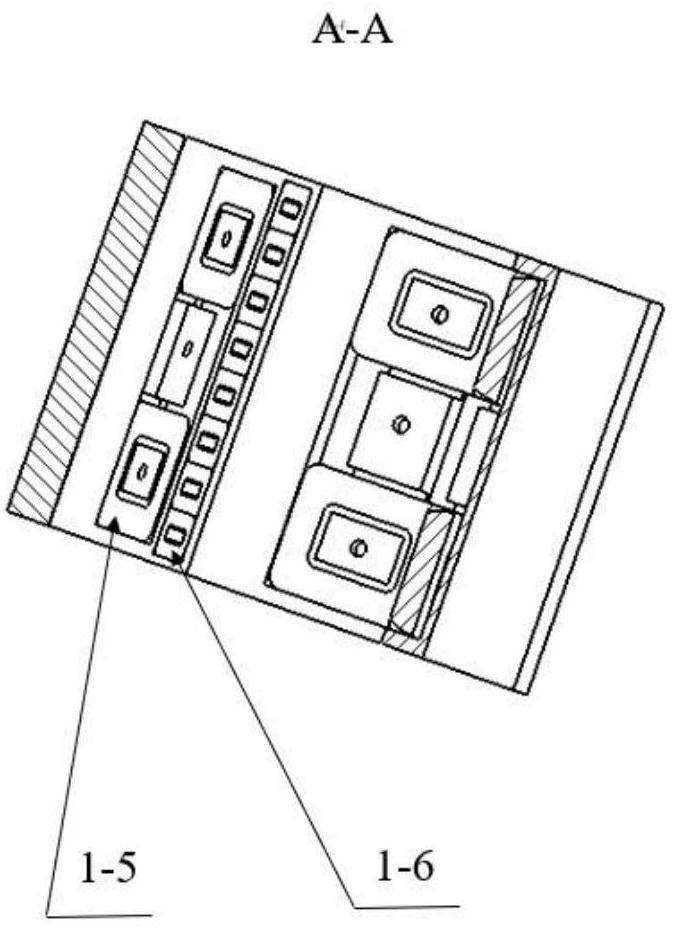

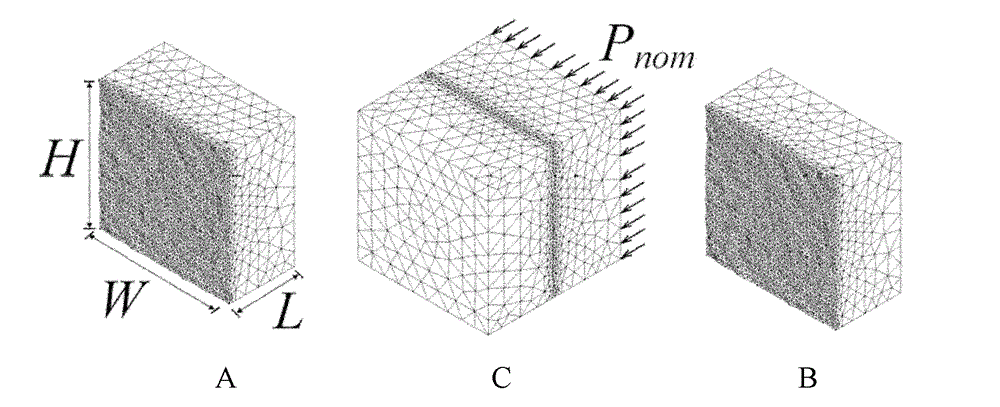

Large-scale high-speed rotary equipment multistage part rigidity prediction method based on contact area maximization testing and adjustment

ActiveCN109960870AImprove performanceHigh normal stiffnessGeometric CADDesign optimisation/simulationAviationObject function

The invention provides a large-scale high-speed rotary equipment multi-stage part rigidity prediction method based on contact area maximization testing and adjustment. According to the method, the three parameter components of the rotor eccentricity error, the sensor measuring head offset and the sensor measuring ball radius in the circular profile measurement are considered, a three-parameter circular profile measurement model is established, and the eccentricity error can be accurately estimated; according to the multistage rotor transfer relation, the offset of the contact surface between the rotors at all stages is obtained, the sectional area of the contact surface is calculated, an objective function of tensile rigidity is obtained according to a tensile rigidity formula, and multistage rotor assembly rigidity prediction of the aero-engine is achieved.

Owner:HARBIN INST OF TECH

Coil spring

ActiveUS11499600B2Inhibit deteriorationHigh normal stiffnessValve arrangementsMachines/enginesAxial displacementCoil spring

Owner:SANCALL CORP +1

Off-axis mirror and its processing method

ActiveCN107797169BImprove surface accuracyHigh surface finishMirrorsSurface finishOptical processing

Owner:CHANNGCHUN CHANGGUANG ADVANCED OPTICS TECH CO LTD

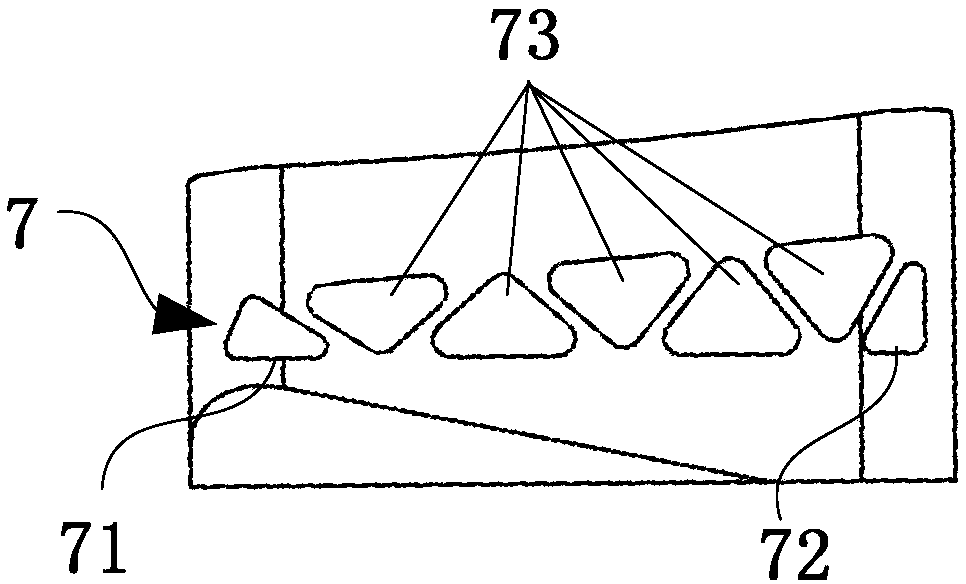

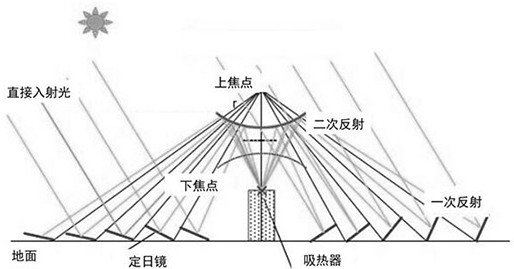

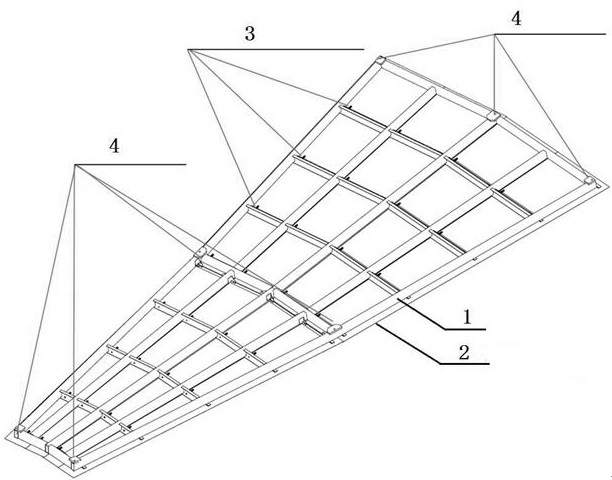

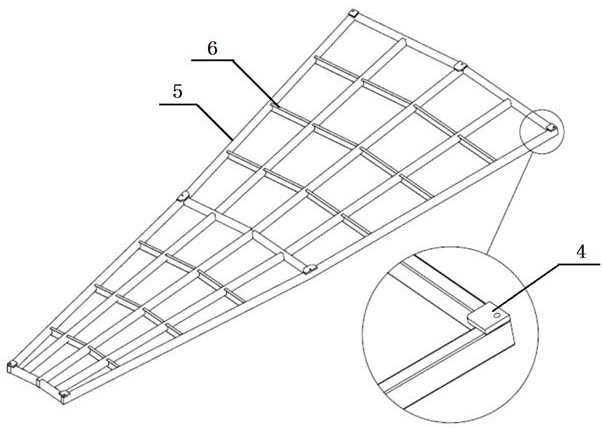

Secondary reflector substructure device for tower type photo-thermal power generation

PendingCN112393440AImprove rigiditySmall distortion of spot contourSolar heating energySolar heat collector for particular environmentEngineeringTower

The invention relates to a secondary reflector substructure device for tower-type photo-thermal power generation. The device comprises a substructure steel structure assembly (1), a secondary reflector assembly (2) and a spring tensioning and limiting connecting assembly (3), and the secondary reflector assembly (2) is provided with the substructure steel structure assembly (1). The secondary structure steel structure assembly (1) and the secondary reflector assembly (2) are connected through the spring tensioning and limiting connecting assembly (3). A secondary reflector can realize free mirror surface extension under a high-temperature working condition and high rigidity under a strong wind working condition. In addition, the processing, manufacturing, assembling and construction efficiencies are improved, the process difficulty is reduced, and the effects of improving the surface precision of a secondary reflector substructure and reducing the cost are achieved.

Owner:JIANGSU XINCHEN SOLAR THERMAL TECH CO LTD

Piezoelectric linear driver

InactiveCN102361411BReduce assembly errorsReduce usagePiezoelectric/electrostriction/magnetostriction machinesMechanical engineeringEngineering

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

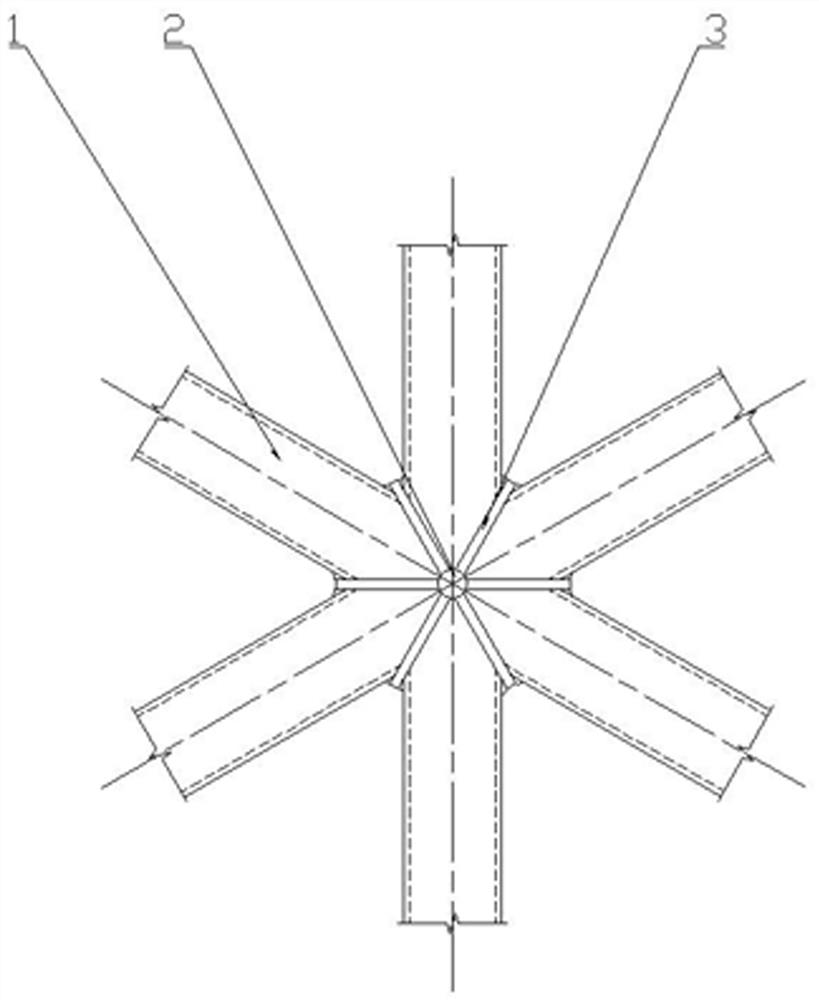

Structural system and design method of oblique tie-rod single-layer spherical greenhouse reticulated shell

InactiveCN107201778BHigh normal stiffnessIncrease stiffnessGeometric CADClimate change adaptationGreenhouseClassical mechanics

The invention belongs to the technical field of large-span greenhouse space structural design in civil engineering and discloses a diagonal pull rod type single-layer spherical greenhouse latticed shell system and a design method thereof. The latticed shell system comprises a bidirectional lattice type single-layer spherical latticed shell, and diagonal pull rods are arranged at lattice diagonal positions in the bidirectional lattice type single-layer spherical latticed shell and / or outside the lattice shell surface. The design method includes: constructing a latticed shell structural model, and designing a diagonal pull rod scheme; adopting finite element software ANSYS for developing of a whole elastoplasticity analysis process to analyze influences of a pull rod arrangement form and prestress to an ultimate load of the spherical greenhouse latticed shell, and verifying and determining a structural design scheme of the diagonal pull rod type single-layer spherical greenhouse latticed shell system. By arrangement of the pull rods in the bidirectional lattice surface, internal rigidity of the structural surface is improved; by arrangement of the pull rods outside the lattice shell surface, external rigidity of the structural surface is improved, and the prestress in a certain range is applied to improve structural bearing capacity, and the structure has advantages of high light transmittance, low material consumption, high rigidity and the like.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Five-freedom-degree series-parallel lower limb rehabilitation robot

ActiveCN103083157BGood more comprehensive rehabilitation trainingPlay a supporting roleChiropractic devicesMuscle exercising devicesPhysical medicine and rehabilitationMulti degree of freedom

The invention discloses a five-freedom-degree series-parallel lower limb rehabilitation robot, and belongs to the technical field of medical rehabilitation instruments. The five-freedom-degree series-parallel lower limb rehabilitation robot can achieve the attitude rotation around the X axis, the Y axis and the Z axis, conducts axial movement along the Y axis and the Z axis, and actually simulates multi-free-degree complex motions of human lower limb and foot walking. The five-freedom-degree series-parallel lower limb rehabilitation robot comprises a rack and two moving platforms, and a base and a support are connected in a series mode to form the rack. When a patient is in the early days of rehabilitation, the patient can keep balance with the help of a supporting frame and passively conduct rehabilitation trainings of lower limb joint motion. When the patient is in the later stage of rehabilitation, the patient can actively conduct the rehabilitation exercises of walking and the like with the help of handles frames, so that the rehabilitation trainings are more effectively and continuously provided for the patient. The five-freedom-degree series-parallel lower limb rehabilitation robot is comprehensive in functions, simple in structure, convenient to operate, and suitable for different training stages of different patients, so that the patient with lower limb walking function damaged can more effectively and continuously conduct the rehabilitation trainings.

Owner:南京鼎世医疗器械有限公司

A moving coil type self-driven maglev guide rail device and its control method

A moving coil type self-driven maglev guide rail device and a control method thereof belong to the technical field of high-end equipment. Four guide sleeve support frames are combined to form a square sleeve, and the centers of the inner sides of the four guide sleeve support frames are respectively packaged with E-shaped components, and the coil windings are packaged on the inner side of the upper guide sleeve support frame, and are located One side of the component; four I-type electromagnets are respectively packaged on the four sides of the guide shaft support frame, the four I-type electromagnets are arranged opposite to the four E-type components, and the permanent magnets are packaged on the guide shaft support On the upper side of the frame, the permanent magnet and the coil winding are arranged oppositely; the bipolar electromagnet is E-type, and the two Hall elements are installed at the center of the two-stage pole faces of the bipolar electromagnet, and the induction coil is wound on the two-stage of the bipolar electromagnet. On the surface, the primary coil is wound on the surface of the two-stage induction coil of the bipolar electromagnet, and the eddy current sensor is installed at the center of the middle tooth of the bipolar electromagnet. The invention is used in ultra-precision systems.

Owner:HARBIN INST OF TECH

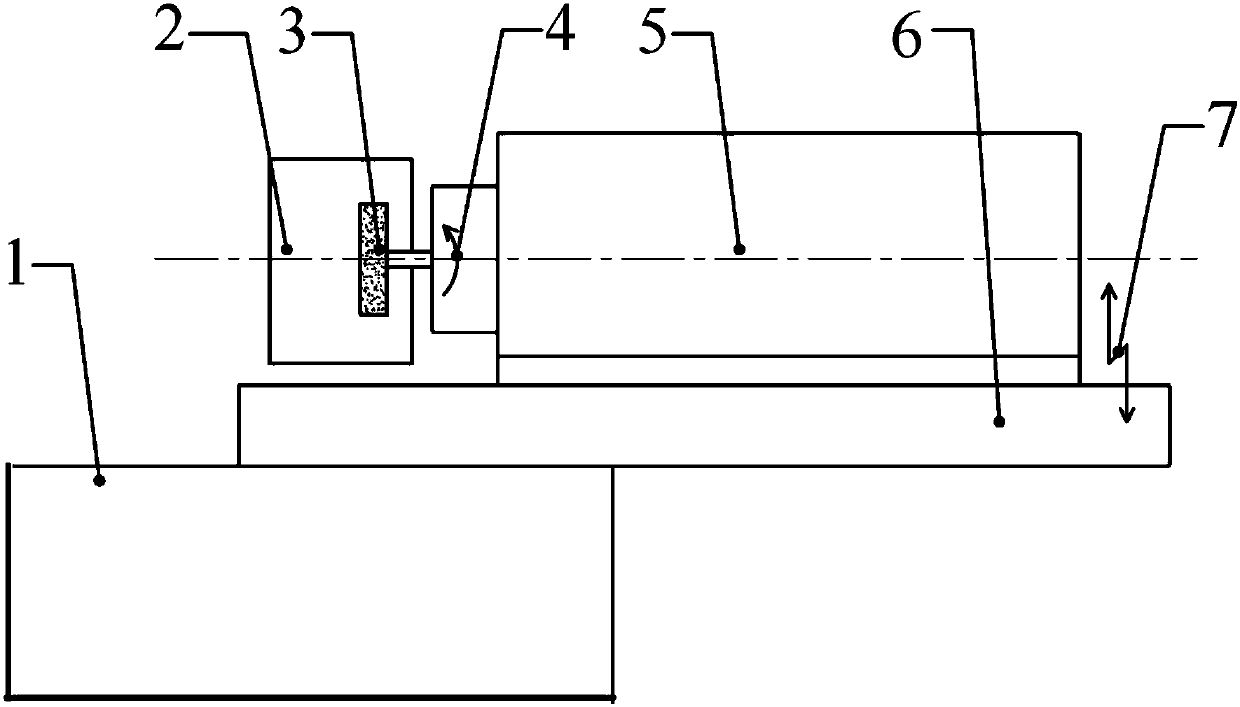

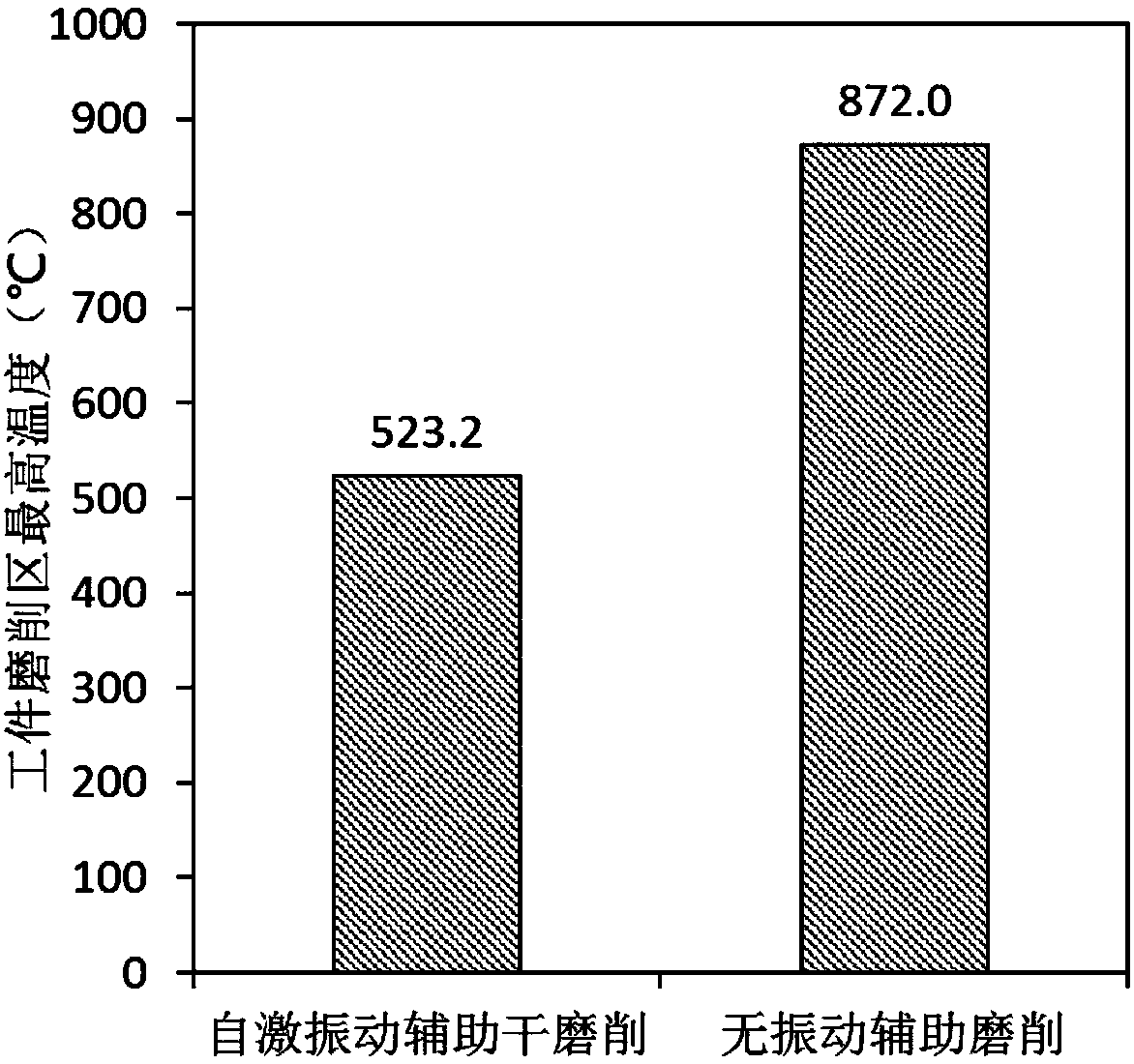

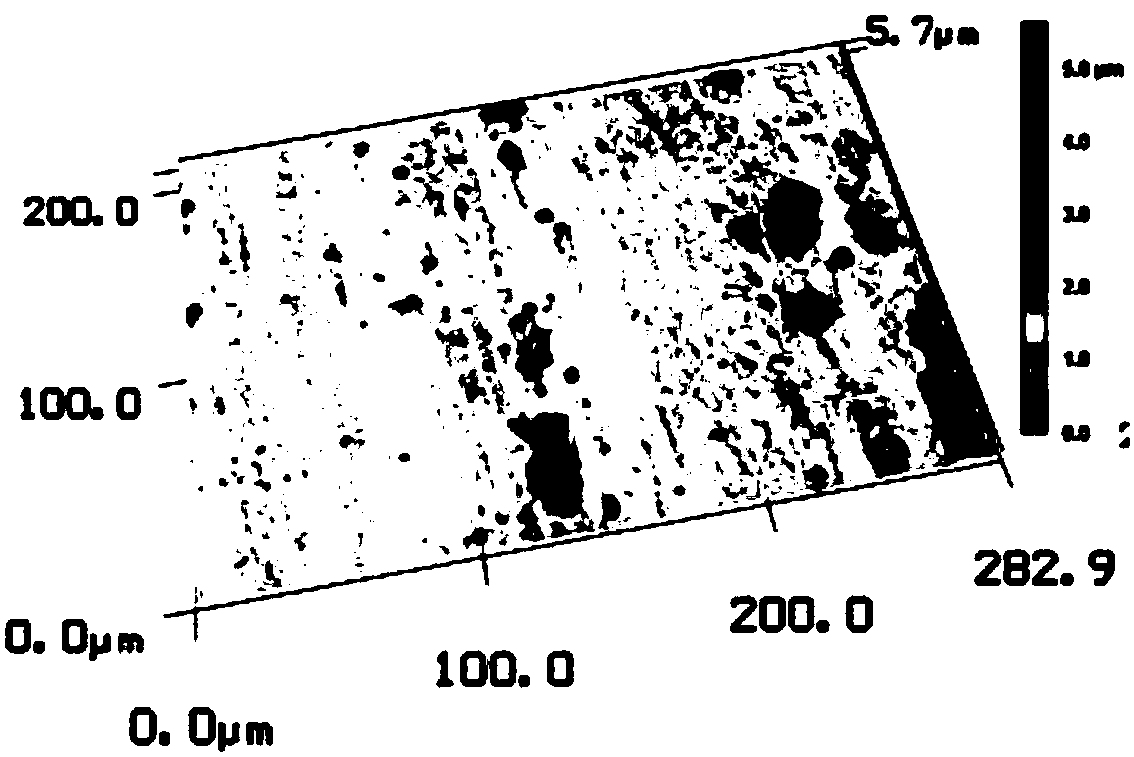

A tangential self-excited vibration assisted dry grinding system and method

ActiveCN106239273BEfficient releaseReduce grinding temperatureGrinding/polishing safety devicesSelf excitedEngineering

The invention discloses a tangential self-excited vibration auxiliary dry grinding system and method. A grinding head system is mounted on a self-excited vibration plate. The self-excited vibration plate is fixed to a machine tool body through a cantilever. During machining, a grinding wheel of the grinding head system rotates to serve as an excitation source of the whole system, energy is input to the self-excited vibration plate, and the self-excited vibration plate drives the grinding head system to subjected to self-excited vibration, so that abrasive grains of the grinding wheel are made to make reciprocating componential movement at a certain frequency in the tangential direction of the grinding wheel relative to a workpiece while grinding the workpiece. By controlling the rotating speed of the grinding wheel, the quantity of input self-excited vibration energy can be adjusted; by analyzing and designing the inherent frequency and modal of the self-excited vibration plate, the frequency of a self-excited vibration system can be controlled; and the abrasive grains of the grinding wheel make contact with or are separated from the workpiece periodically, so that grinding heat is effectively dissipated, and the purposes of decreasing the grinding temperature and avoiding grinding burns are achieved.

Owner:SHANDONG UNIV

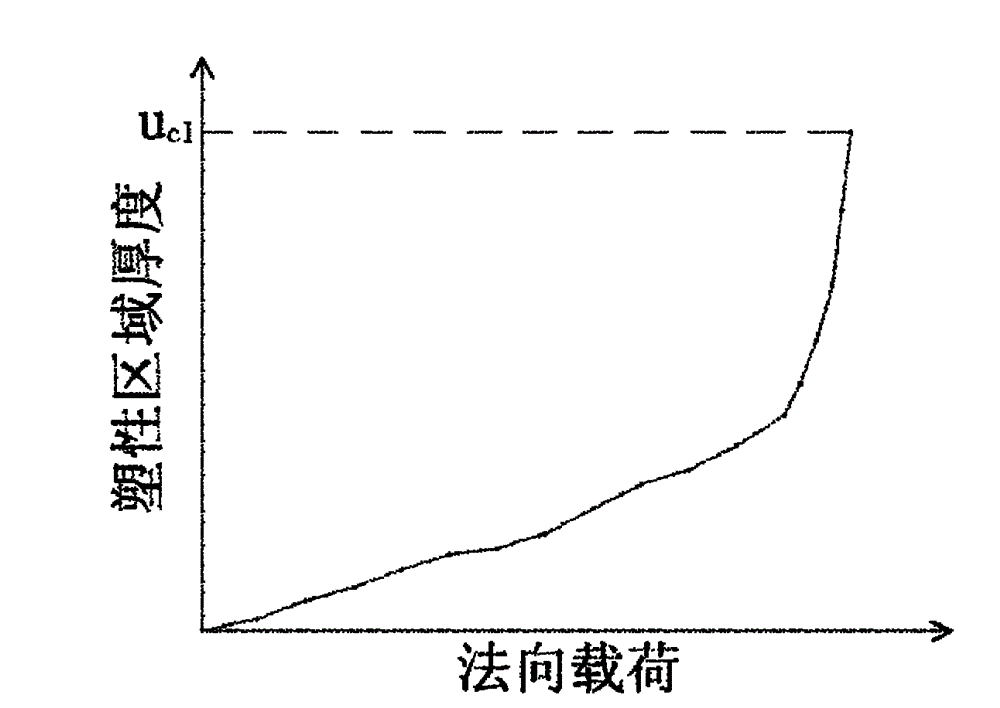

Method for measuring normal rigidity of large contact interface by completely considering plastic influence

InactiveCN102169065BThe measurement results are close to the actualMeasuring Normal StiffnessStrength propertiesEngineeringContact system

The present invention discloses a method for measuring normal rigidity of a large contact interface by completely considering plastic influence. The method comprises the steps of adopting a contact system of two rough bodies as a measuring object and the complete equivalence of the system as a principle, using laser to mark three straight lines which fulfill the measuring requirement on the two rough bodies, and obtaining the normal rigidity of the contact interface by observing normal displacements of the three straight lines during a loading procedure. The method considers the influence of the contact interface shape degree on the normal contact rigidity on the basis of a prior method, and uses a simple and easy laser mark method to measure the normal rigidity of the large contact interface without being influenced by contact areas. Moreover, the method, which breaks using limits of the prior method, can be used not only in laboratories, but also in practical engineering conveniently.

Owner:XI AN JIAOTONG UNIV

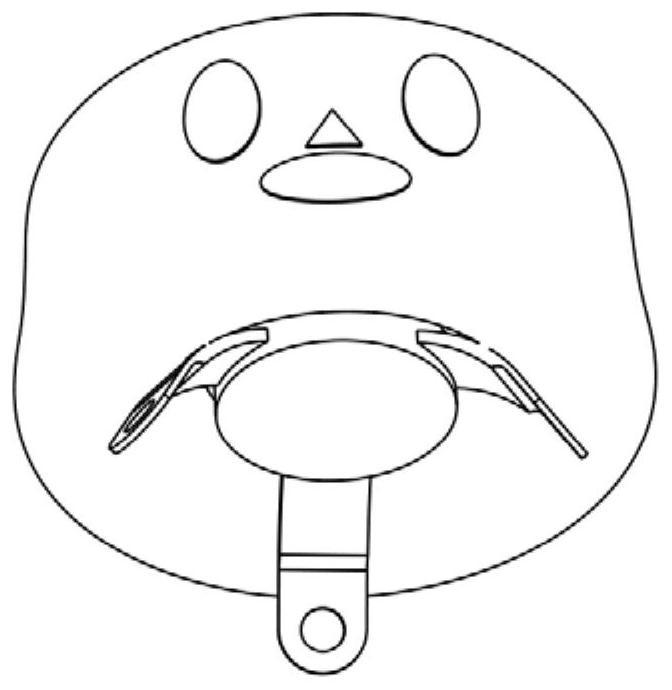

Three-degree-of-freedom robot neck device and working method

PendingCN112606035AIncrease flexibilityHigh normal stiffnessJointsPhysical medicine and rehabilitationControl system

The invention discloses a three-degree-of-freedom robot neck device and a working method, and belongs to the technical field of robot neck control. The invention provides a parallel robot neck device with high degree of freedom, high rigidity and high flexibility and a working method. The three-degree-of-freedom robot neck device is characterized in that a motor is fixed to a lower platform; a driving shaft of the motor is fixed to one end of a first connecting rod; the other end of the first connecting rod is rotationally connected with one end of a second connecting rod; the other end of the second connecting rod is rotationally connected with an upper platform; a control system is in two-way connection with a transmission set; and a robot head is arranged on the upper platform. The working method of the three-degree-of-freedom robot neck device comprises the following steps that current angle information of the transmission set is read in real time; a processor identifies the current state of the robot head; and the motor correspondingly rotates according to a target driving instruction, so that the robot head acts along with the action of the upper platform till the current angle information is consistent with target angle information. The method is mainly used for controlling the robot head.

Owner:创泽智能机器人集团股份有限公司

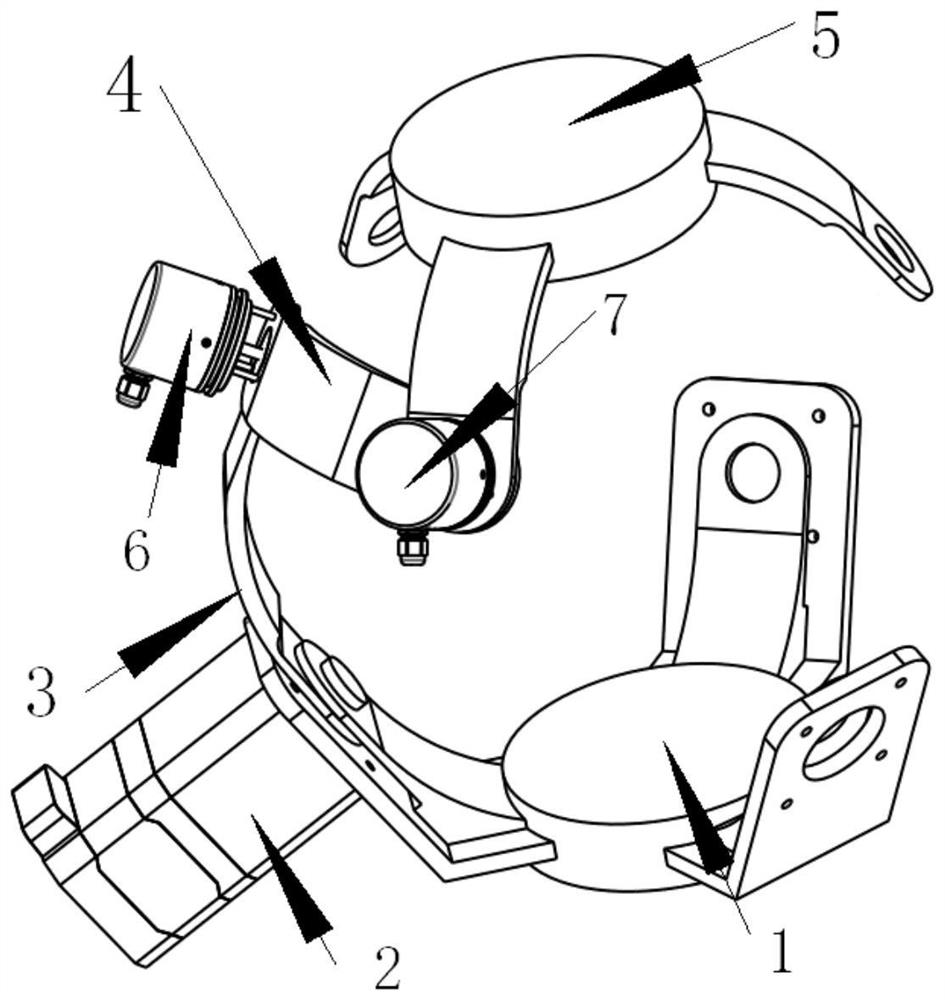

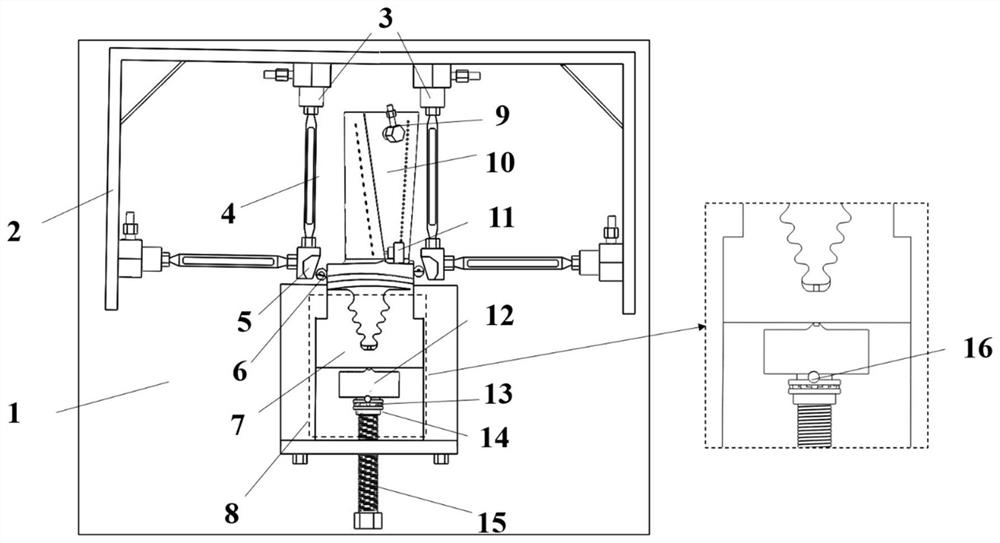

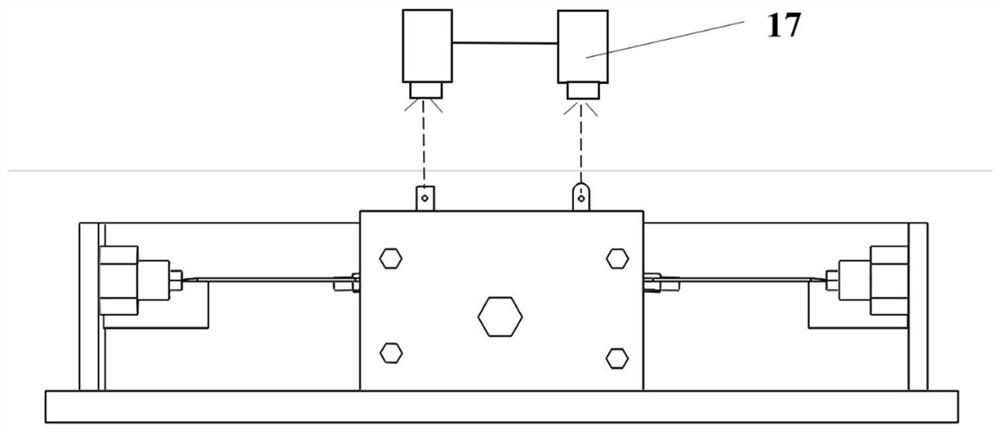

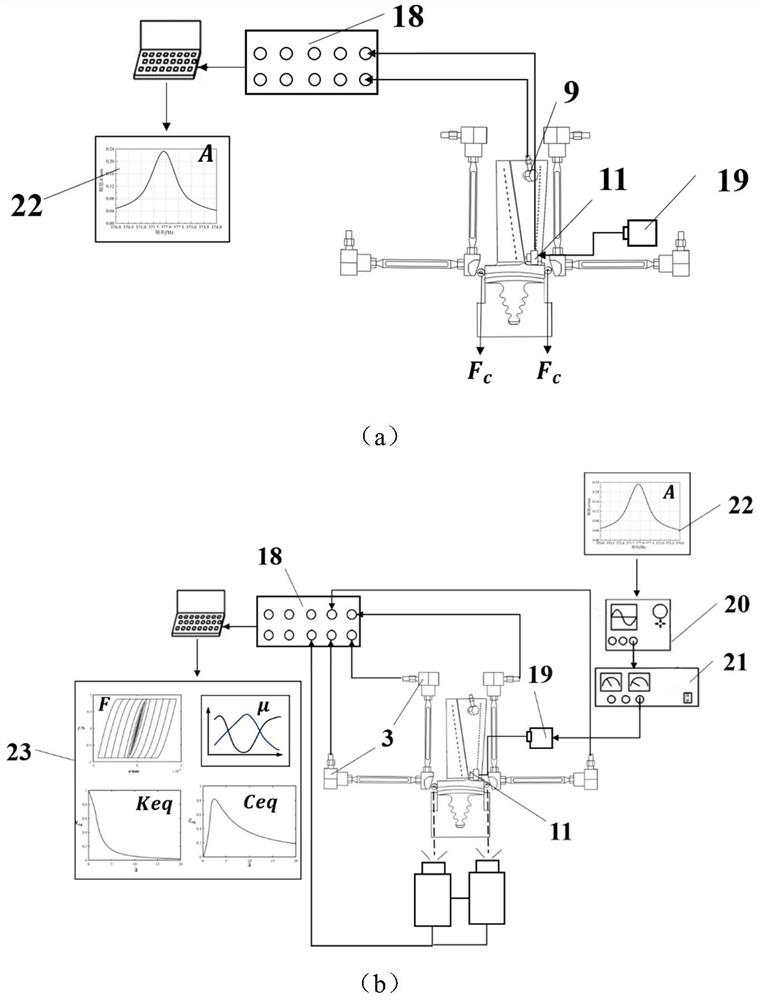

Experimental testing device and method for vibration contact characteristics of blade damper system of gas turbine

ActiveCN113740042AHigh precisionImprove reliabilityMachine part testingGas-turbine engine testingData acquisitionControl theory

The invention discloses an experimental testing device and method for the vibration contact characteristics of a blade damper system of a gas turbine. The device comprises an installation support; a fixed nipper in which a wheel flange is detachably mounted, wherein the fixed nipper is provided with a load applying device, piezoelectric force sensors are fixedly installed on the installation support, each piezoelectric force sensor is connected with a simulation piece clamp through a signal separator, and a blade root simulation piece is fixedly installed on the simulation piece clamp; a friction damper; a centrifugal force loading device; a laser vibration meter; an excitation probe which is used for applying step sinusoidal signals in different frequency ranges to the gas turbine blades; an electromagnetic vibration exciter; an eddy current displacement sensor which is used for measuring a vibration response signal; a multi-channel data acquisition system; a signal generator and a power amplifier. According to the invention, the accuracy and reliability of the gas turbine blade damper system vibration contact characteristic experiment test can be improved.

Owner:XI AN JIAOTONG UNIV

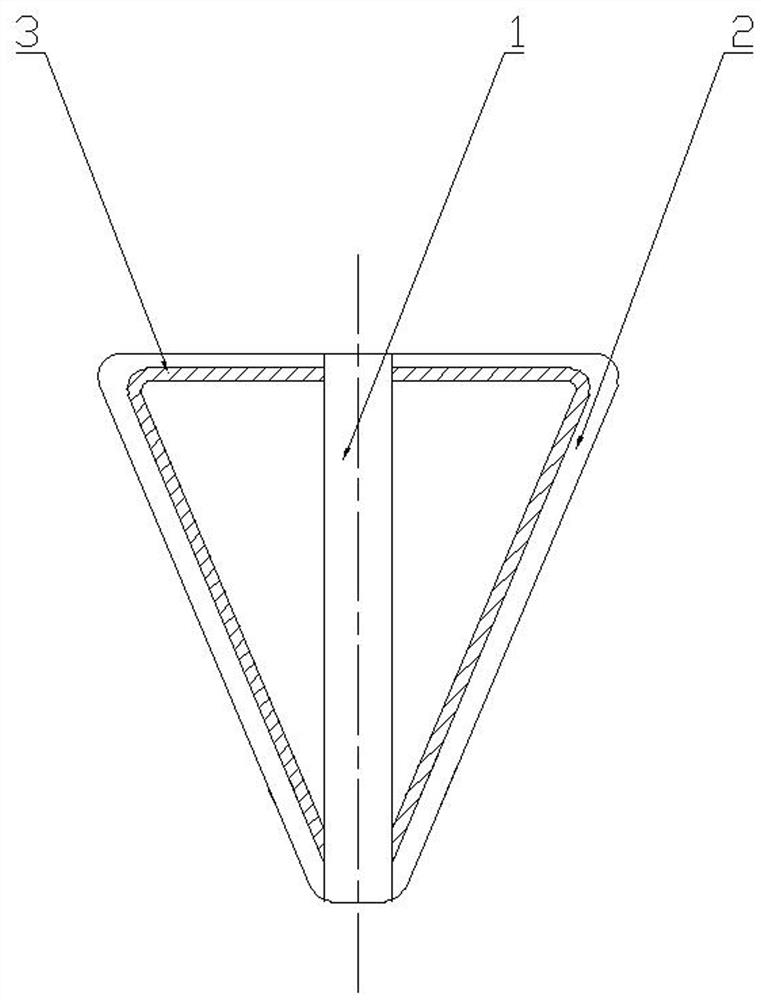

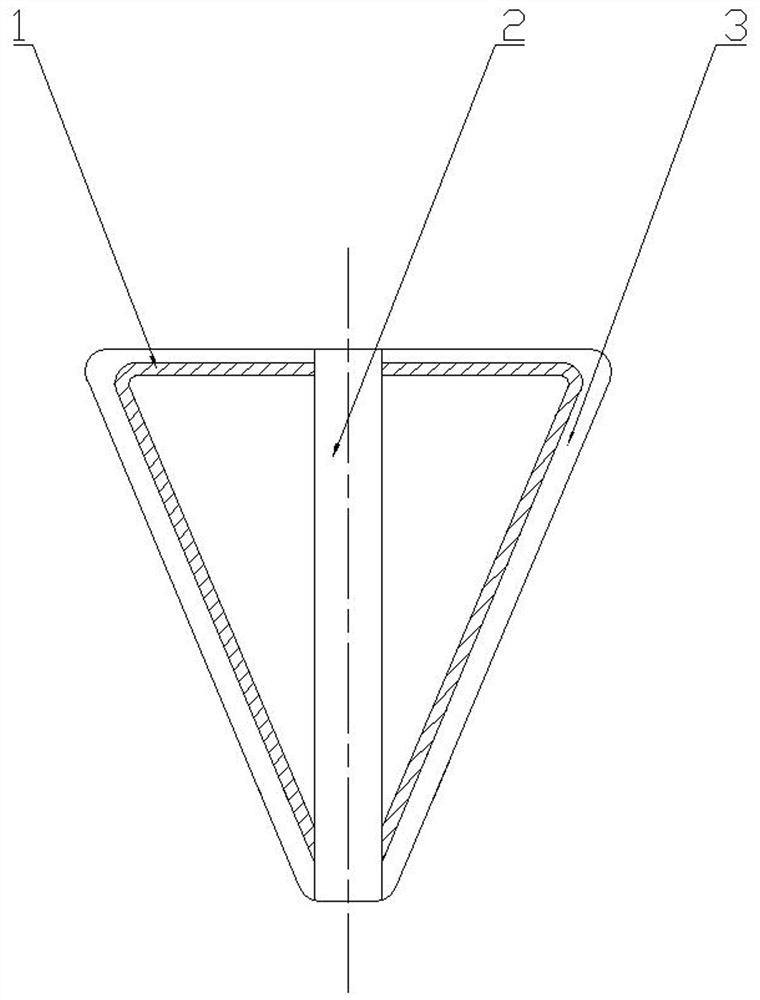

Manufacturing method of novel multi-manifold joint with isosceles triangle-shaped section

The invention relates to a manufacturing method of a novel multi-manifold joint with an isosceles triangle-shaped section, and belongs to the technical field of building steel structures. The method comprises the following steps of 1, bending a steel plate into a steel pipe with an isosceles triangle-shaped cross section; 2, taking a solid steel bar at one end, and polishing two end surfaces of the solid steel bar; 3, ensuring that a plurality of inserting plates are taken and annularly distributed at equal intervals with the solid steel bar as the center to be subjected to equal-strength groove welding with the solid steel bar. 4, between every two adjacent inserting plates, welding the steel pipe to the inserting plates in an opposite-side full-length mode, and finally polishing weld joints to be flat. The method has the advantages of simple structure, good stability and long service life. The problem that a space assembly type steel structure connecting joint is low in rigidity is solved.

Owner:浙江东南网架股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com