Large-size freely combined model test device for high ground stress underground engineering

A model test device, high ground stress technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of cumbersome operation, limitation of stiffness and strength model space size, inability to conveniently and intuitively observe the cracking phenomenon and development of surrounding rock Process and other issues, to achieve the effect of improving test accuracy, good impact toughness, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

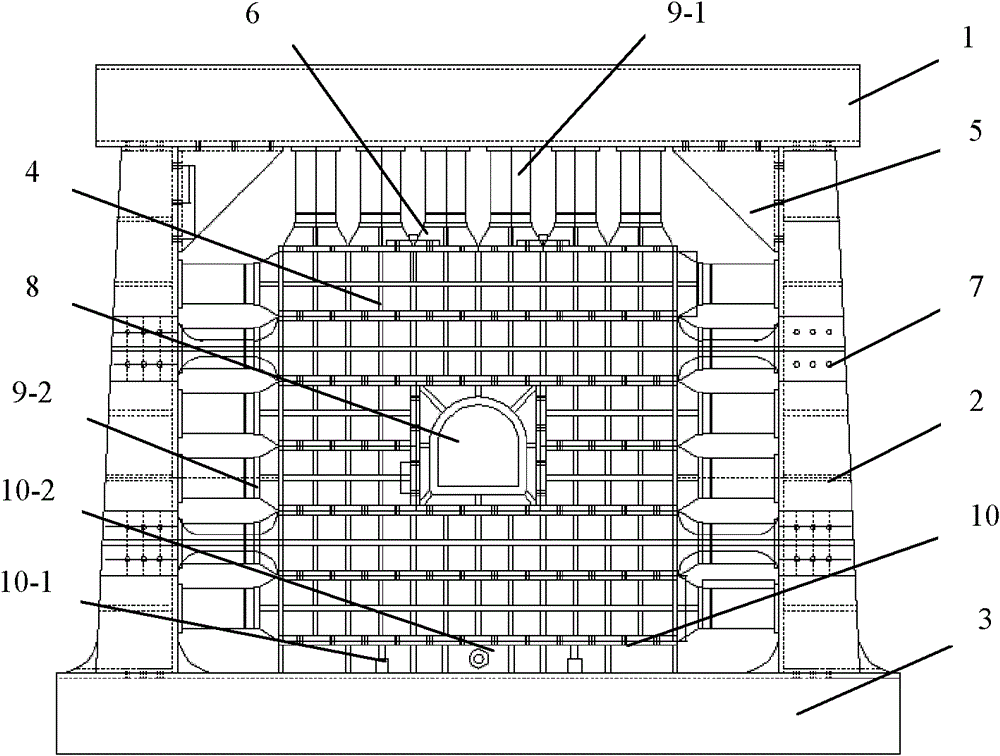

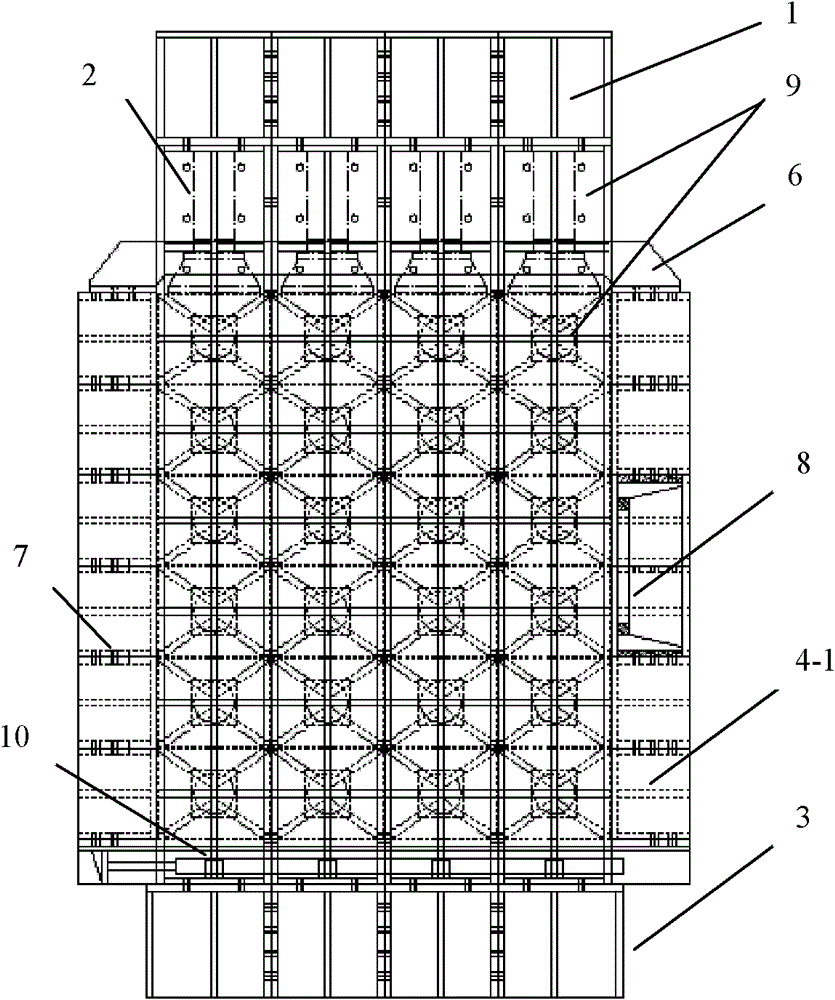

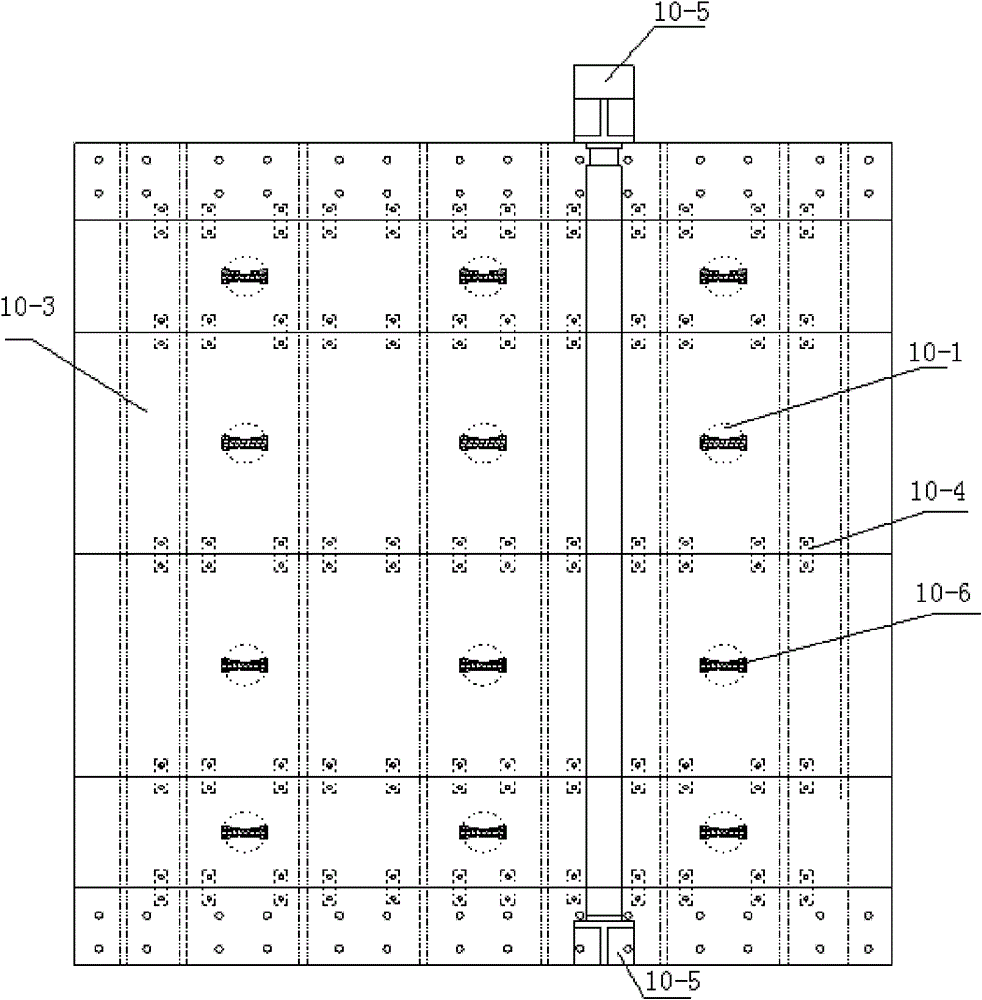

[0048] Such as figure 1 , 2 As shown in the figure, the large-scale freely assembled high-in-situ stress underground engineering model test device includes an assembled reaction force bench device, each of which is connected by a top beam 1, a side beam 2 and a bottom beam 3; The side of the force beam is connected to the side beam 2, and the bottom is connected to the model lift and translation trailer system 10; a hydraulic loading system 9 is provided on the top beam 1 and side beam 2; the hydraulic loading system 9 is connected to the thruster; the whole test device is integrated The top is narrow and the bottom is wide, and the side is inclined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com