Fabrication method of multi-pipe junction with isosceles triangular section

A technology of isosceles triangle and manufacturing method, which is applied in the direction of architecture and building construction, can solve the problems of poor structural stability, low stiffness of connecting nodes, short service life, etc., and achieve long service life, simple structure and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

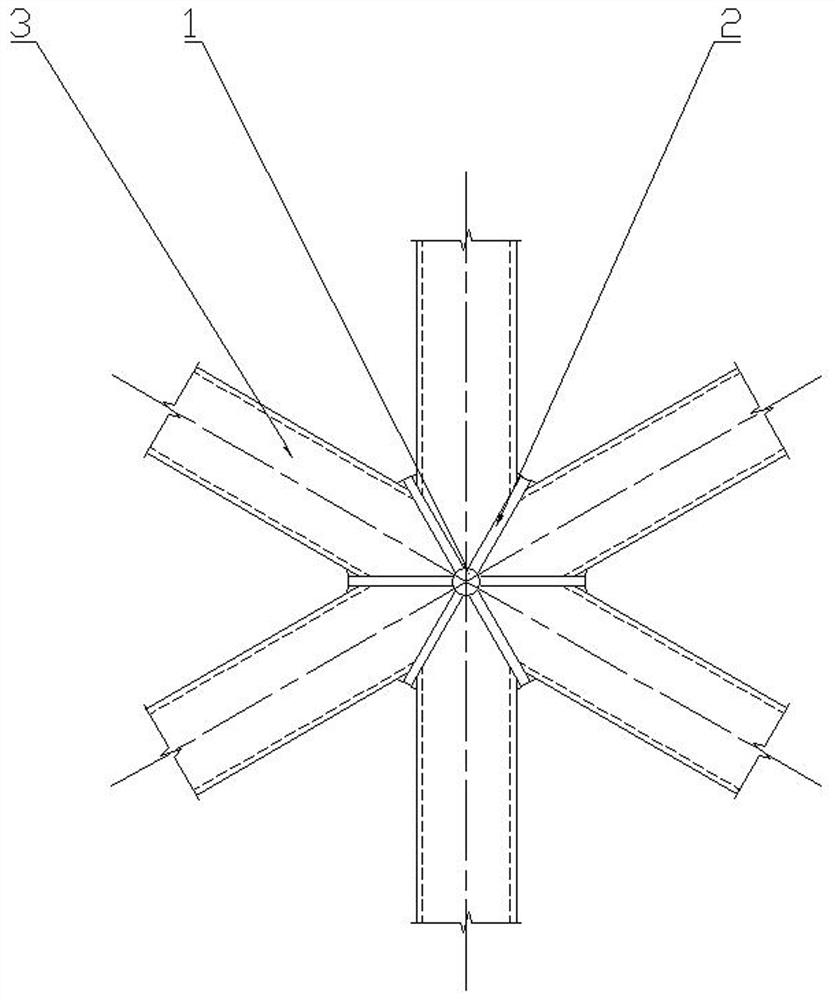

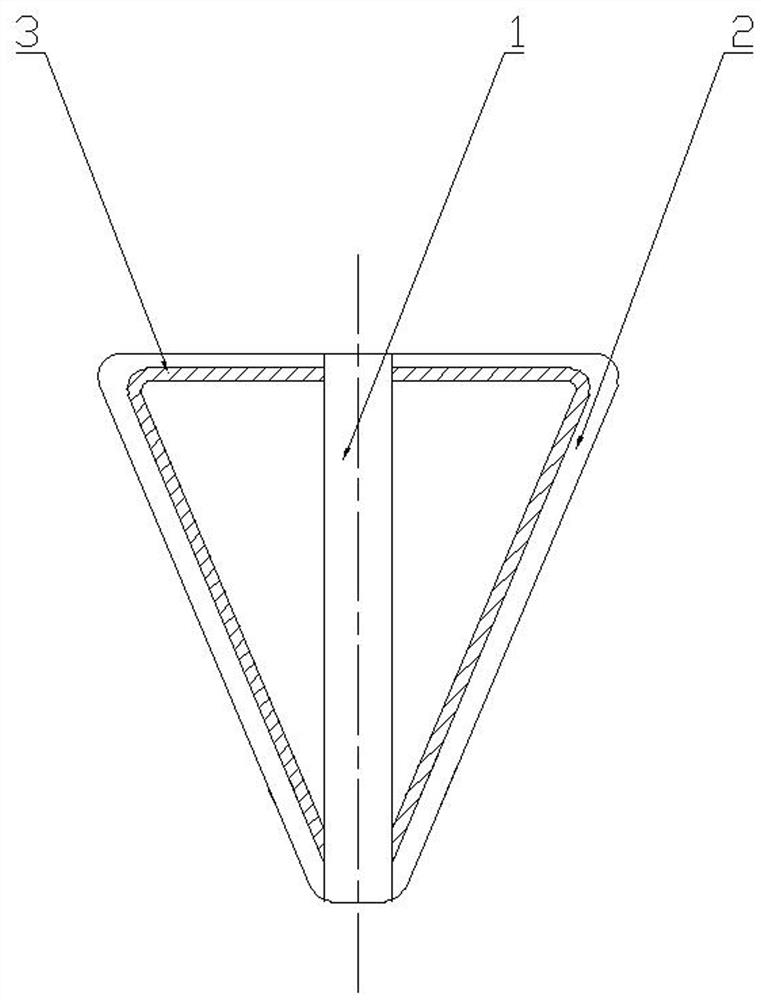

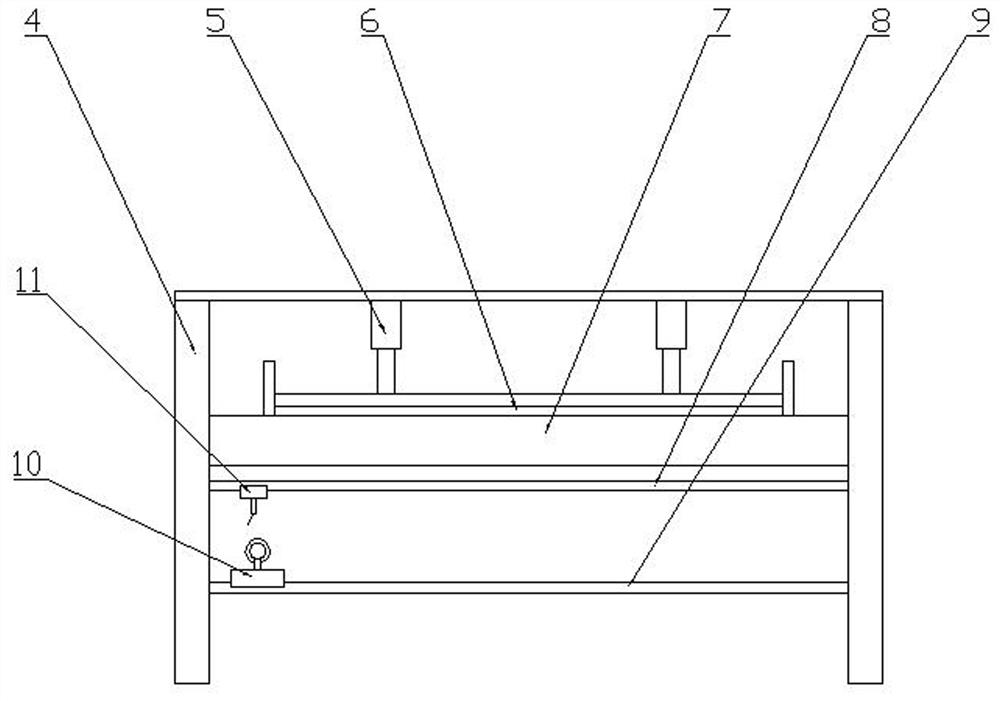

[0027] Example: such as Figure 1-4 As shown, the fabrication method of the isosceles triangular cross-section multi-pipe junction includes the following steps:

[0028] Step 1: Bending the steel plate 6 into a steel pipe 3, the cross-sectional shape of the steel pipe 3 is an isosceles triangle. The steel pipe 3 and the steel plate 6 have a thickness of 8 mm.

[0029] The steel plate 6 is placed on the bending and forming platform 7 of the frame 4, the steel plate 6 is bent into a steel pipe 3 with an isosceles triangle in cross section by using the forming stamping assembly 5, and the compression plate 14 on the limit compression cylinder 13 is used The steel plate 6 is fixed on the bending forming platform 7, and the bending stamping cylinder 12 at the two ends of the clamping oil cylinder 13 is stretched downward and the bending stamping block 15 performs the bending process on both sides of the steel plate 6. Then, at the welding rail 8 below the bending forming platform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com