Method for measuring normal rigidity of large contact interface by completely considering plastic influence

A contact interface, normal stiffness technology, applied in the field of laser scanning and measurement, to achieve the effect of breaking through the limitations of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

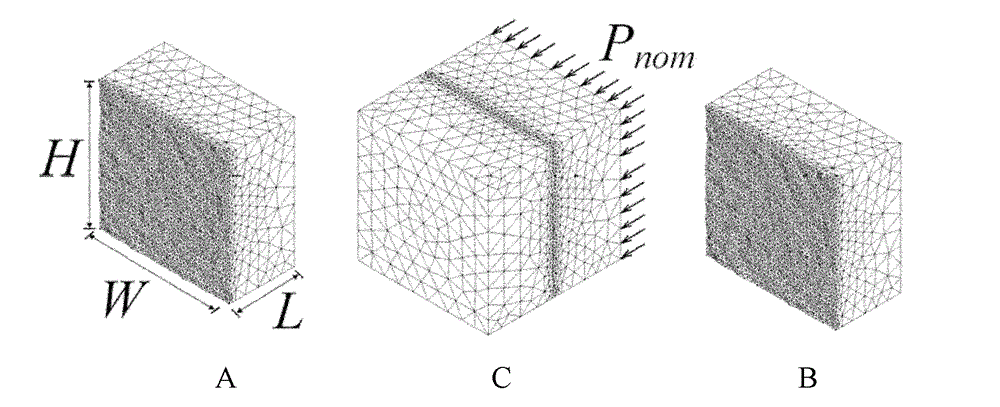

[0048] In order to verify the method of the present invention: the method of measuring the normal stiffness of the large contact interface that fully takes into account the influence of plasticity, the existing direct loading measurement method and ultrasonic measurement method are used as comparison objects. Wherein, the numerical value of ultrasonic measurement method is obtained by the experiment that people such as Gonzalez-Valadez M, (see literature Gonzalez-Valadez M, Baltazar A, Dwyer-Joyce R S.Study of interfacialstiffness ratio of a rough surface in contact suing a spring model[ J].Wear, 2010,268:373-379); The numerical value of directly loading measurement method and the inventive method obtains by finite element simulation, and its model is as figure 1 shown. In order to make an effective comparison with the ultrasonic measurement method, the size and material of the two rough bodies are consistent, and one of the contact surfaces is a smooth plane. The relevant par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com