Underground pressure wind spot sampling device and process

A technology of fixed-point sampling and air inlet, which is used in the extraction of undisturbed core devices, drilling equipment, earth-moving drilling, etc., can solve the problems of affecting the sampling effect, long sampling time, low success rate, etc. High-quality, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

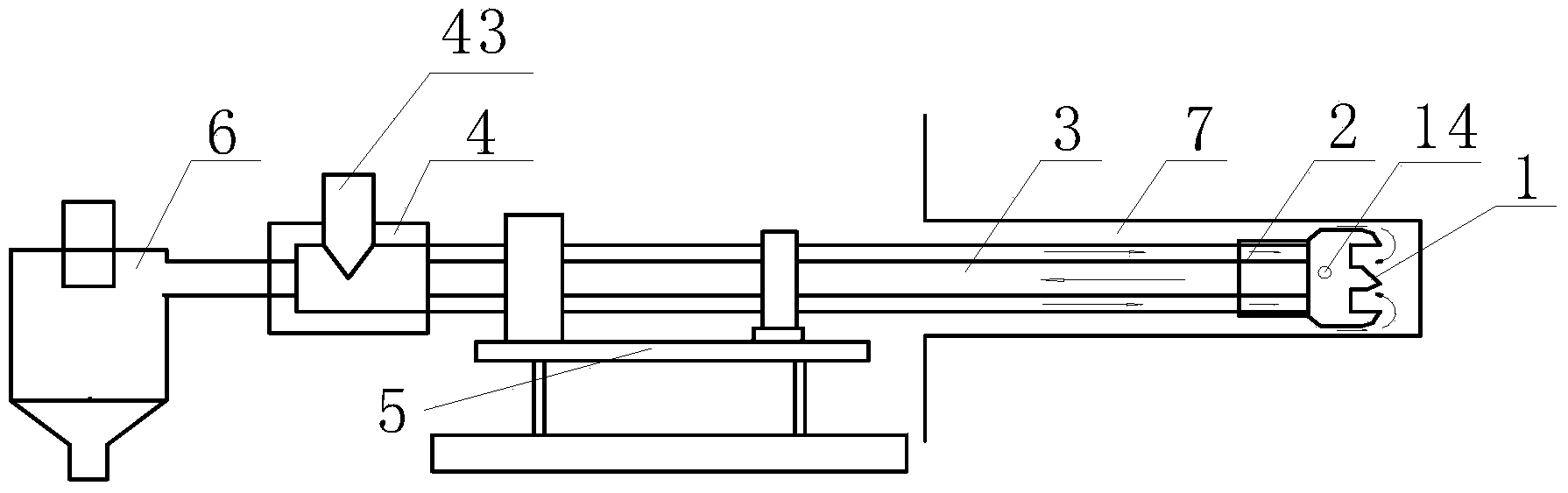

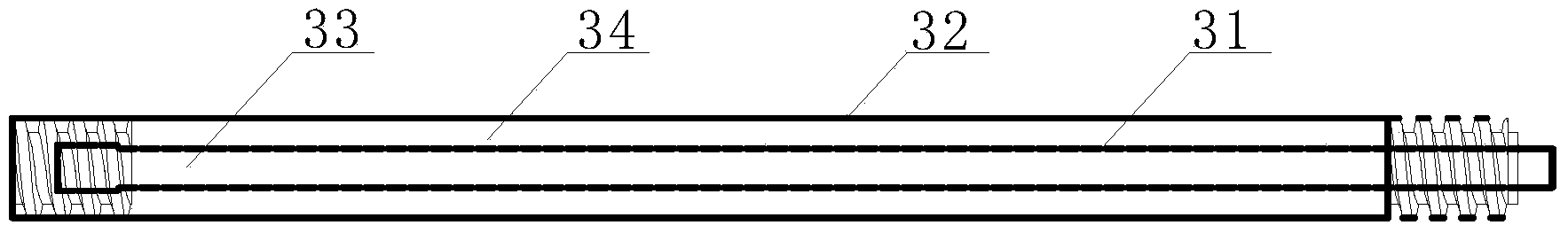

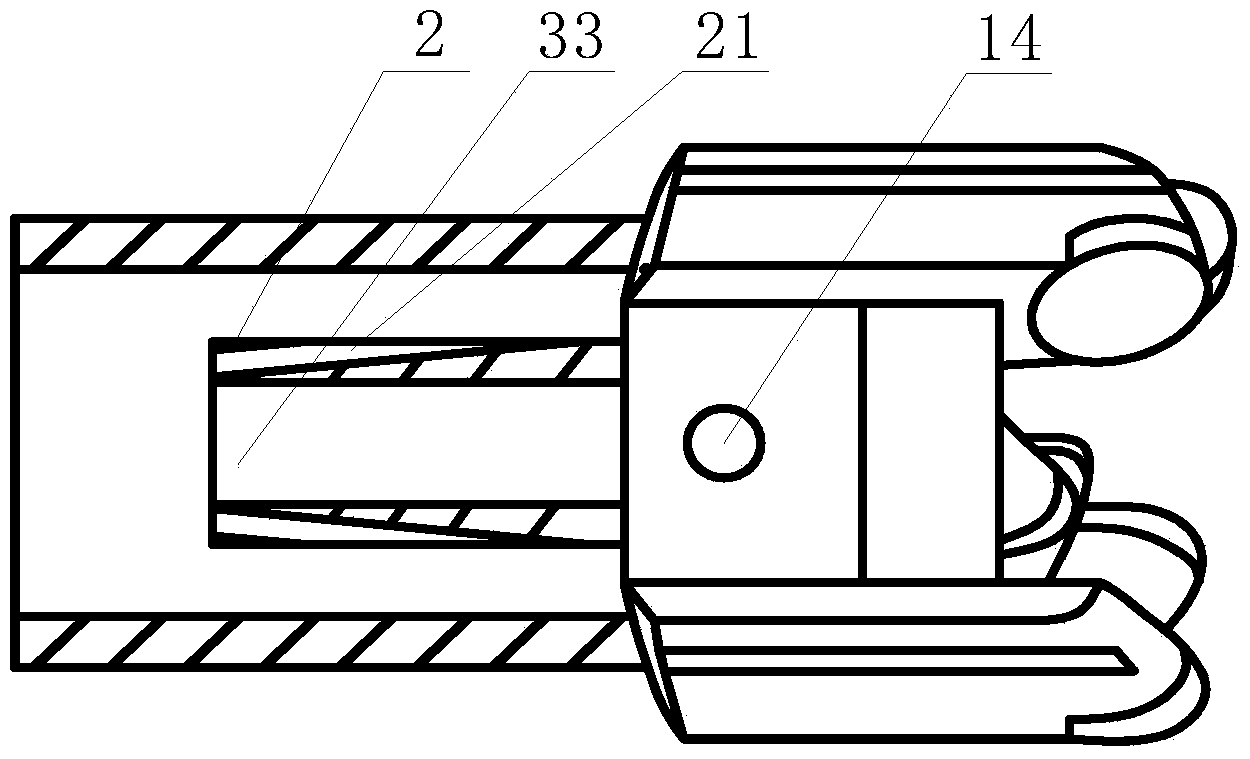

[0017] see figure 1 , figure 2 , image 3 , Figure 4 , a downhole compressed air fixed-point sampling device, which is connected to the water transformer 4 with the compressed air joint 43 by the sample collection device 6 tubes, the double-walled drill pipe 3 connected to the water transformer 4 is connected to the drilling rig 5, and is connected by the double-walled drill pipe 3 The drill bit 1 is characterized in that: the outer wall of the drill bit 1 has four air outlet inclined holes 14, and the top of the drill bit 1 has an air inlet 15.

no. 2 example

[0019] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a downhole compressed air fixed-point sampling device, which is connected to the water transformer 4 with the compressed air joint 43 by the sample collection device 6 tubes, the double-walled drill pipe 3 connected to the water transformer 4 is connected to the drilling rig 5, and is connected by the double-walled drill pipe 3 The drill bit 1 is characterized in that: the outer wall of the drill bit 1 has four air outlet inclined holes 14, and the top of the drill bit 1 has an air inlet 15.

[0020] Wherein: the drill bit 1 also includes an ejection tube body 2 with six ejection oblique holes 21 .

no. 3 example

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a downhole compressed air fixed-point sampling device, which is connected to the water transformer 4 with the compressed air joint 43 by the sample collection device 6 tubes, the double-walled drill pipe 3 connected to the water transformer 4 is connected to the drilling rig 5, and is connected by the double-walled drill pipe 3 The drill bit 1 is characterized in that: the outer wall of the drill bit 1 has four air outlet inclined holes 14, and the top of the drill bit 1 has an air inlet 15.

[0023] Wherein: the drill bit 1 also includes an ejection tube body 2 with six ejection oblique holes 21 .

[0024] Wherein: drill bit 1 top is provided with drill bit outer tooth 12 four with drill bit outer tooth inner alloy 121 and drill bit outer tooth alloy 122, and drill bit inner tooth 13 three with drill bit inner tooth alloy 131.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com