Patents

Literature

62results about How to "No friction and wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

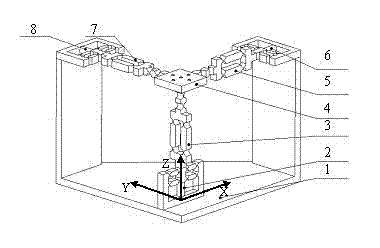

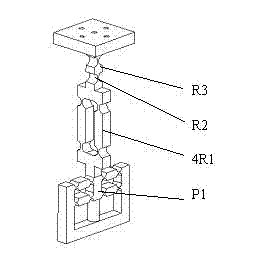

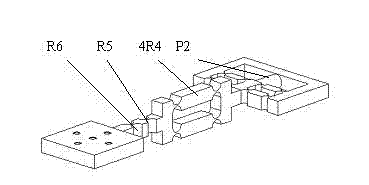

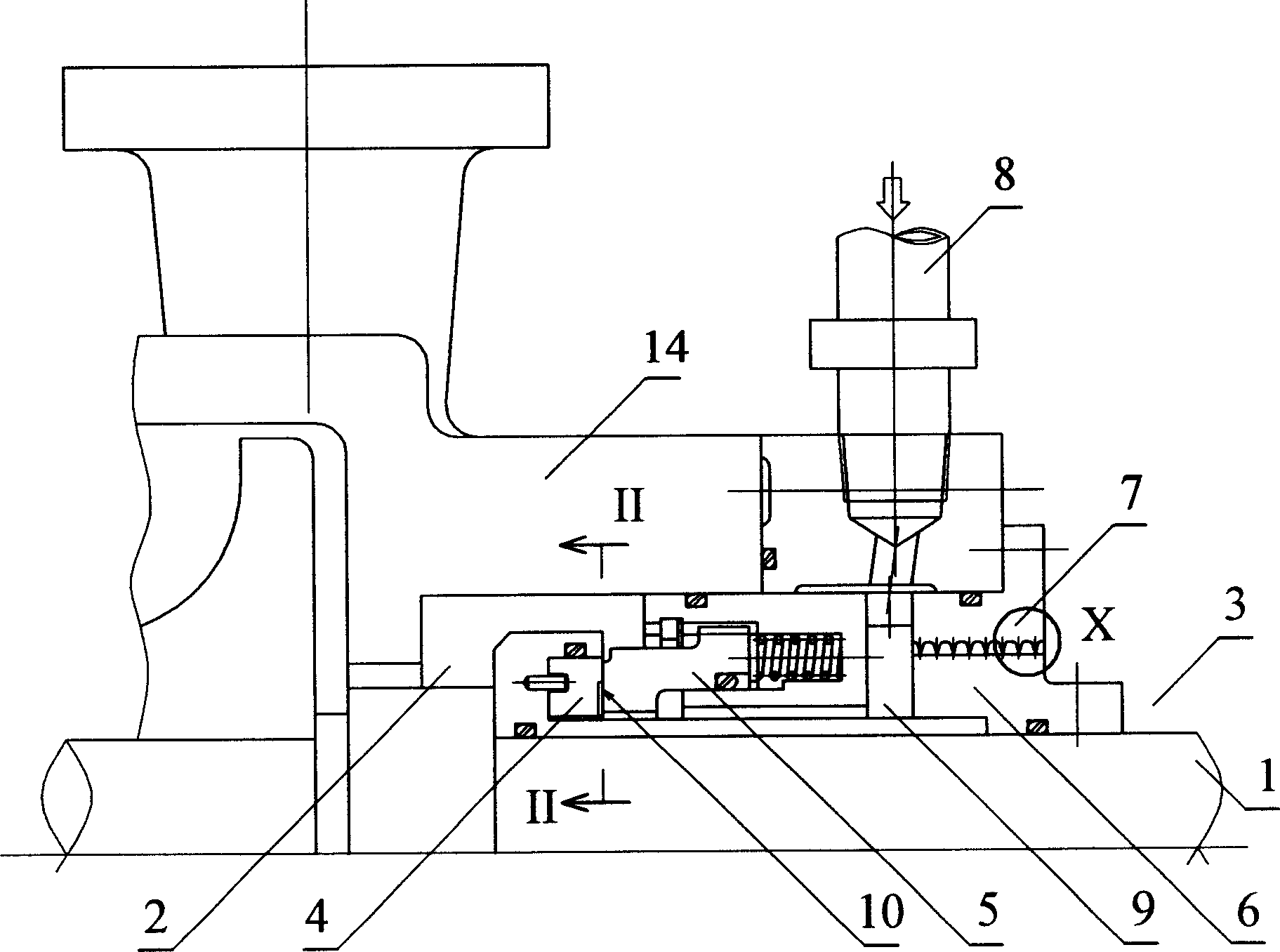

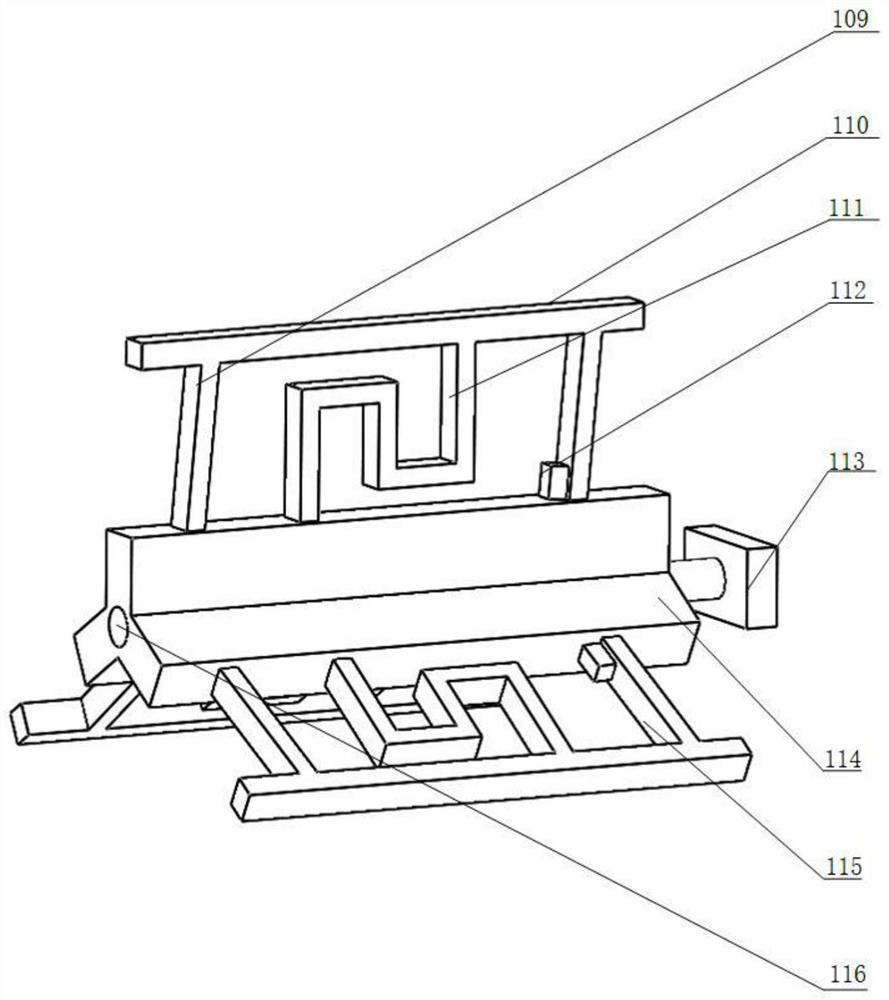

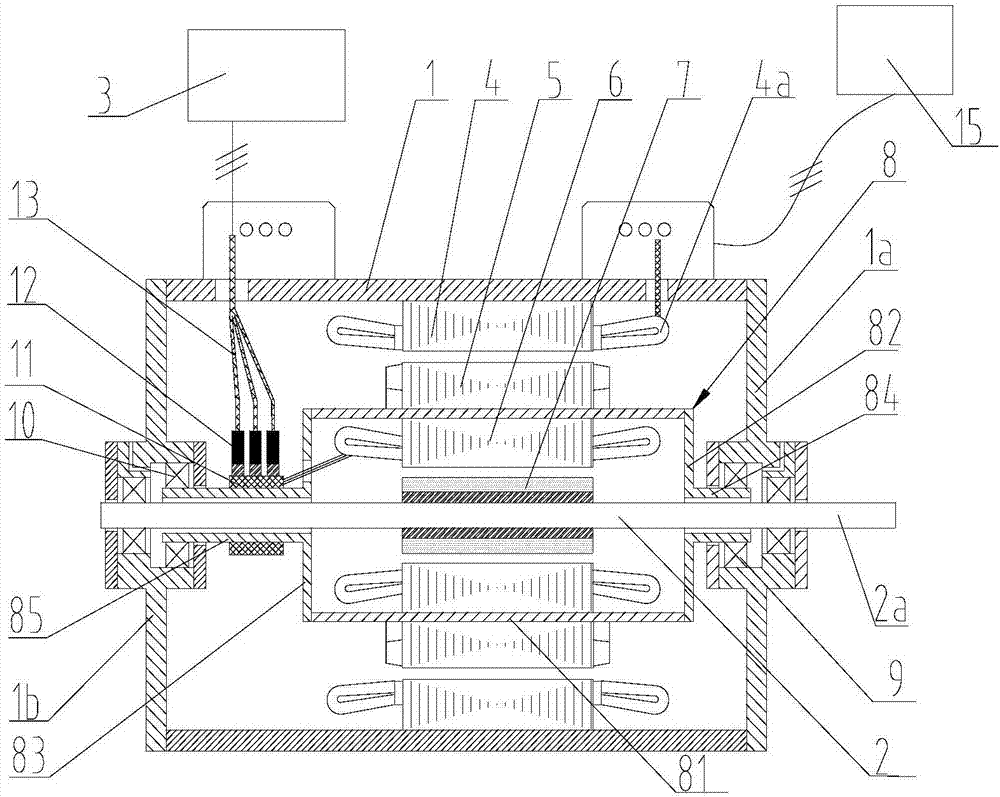

Three-degree-of-freedom microoperation orthogonal parallel operating platform used for ultraprecise location

The invention discloses a three-degree-of-freedom microoperation orthogonal parallel operating platform used for ultraprecise location, which realizes space three-dimensional translation ultraprecise location. The three-degree-of-freedom microoperation orthogonal parallel operating platform is provided with a static platform and a movable platform, wherein a piezoelectric ceramic driver is fixedly vertically arranged on each panel of the static platform, a drive of each piezoelectric ceramic driver is connected with the top end of a branched chain, the tail end of each branched chain is vertically connected with the movable platform, three branched chains are formed by sequentially serially connecting a flexible movable pair, a parallelogram structure, a first rotating pair and a second rotating pair according to position relationships of vertical, vertical and parallel among axial lines, the top end of each branched chain is a movable pair, the tail end of each branched chain is a second rotating pair, the three movable pairs are mutually orthogonal, and the three second rotating pairs are mutually orthogonal. According to the invention, the advantages of a parallel mechanism and a flexible movement pair are combined, a movement is generated by depending self elastic deformation, and output reaches high precision of micro level even nano level.

Owner:JIANGSU UNIV

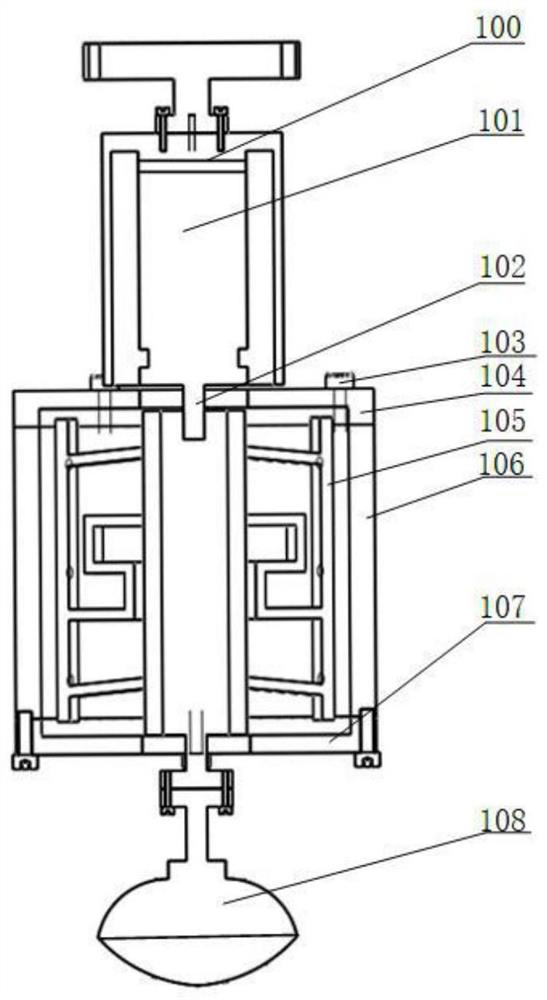

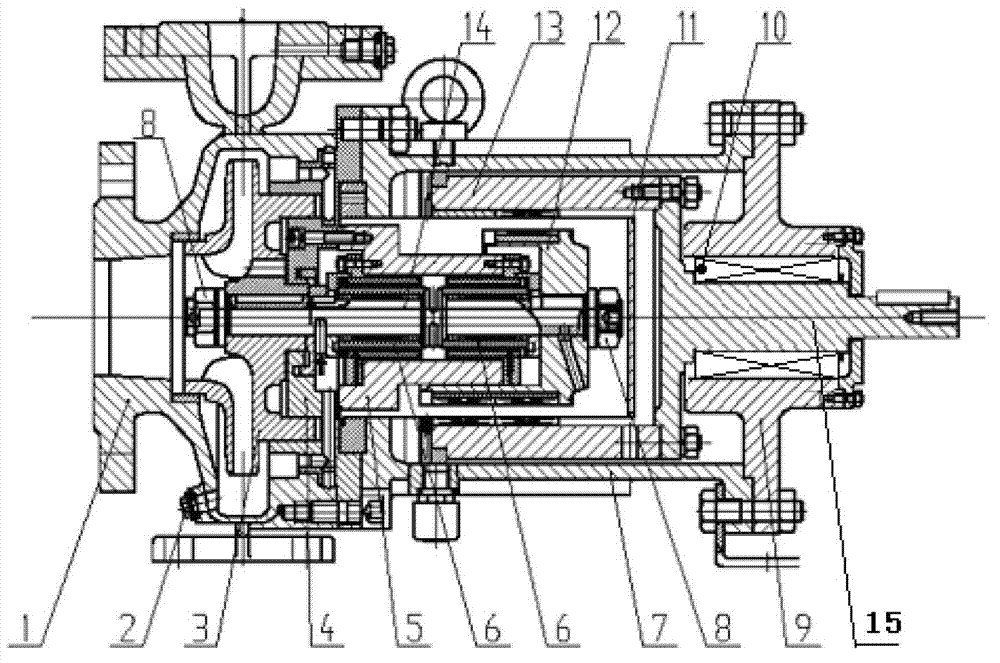

Screw groove non-contact leak-less mechanical seal system for centrifugal pump

InactiveCN1492152AGuaranteed uptimeSolution to short lifePump componentsPumpsGas lubricationFriction loss

The present invention relates to mechanical non-contact spiral groove sealing system for centrifugal pump. The sealing system is installed on the rotation shaft of centrifugal pump to form mechanical non-contact sealing system, and the sealing cavity provides the sealing system with buffering fluid with pressure lower than that in pump work cavity. Besides, externally non-contact cylindrical sealing is provided as auxiliary sealing. The non-contact sealing has no friction loss and no leakage, and makes centrifugal pump operate safely and reliably.

Owner:徐万福

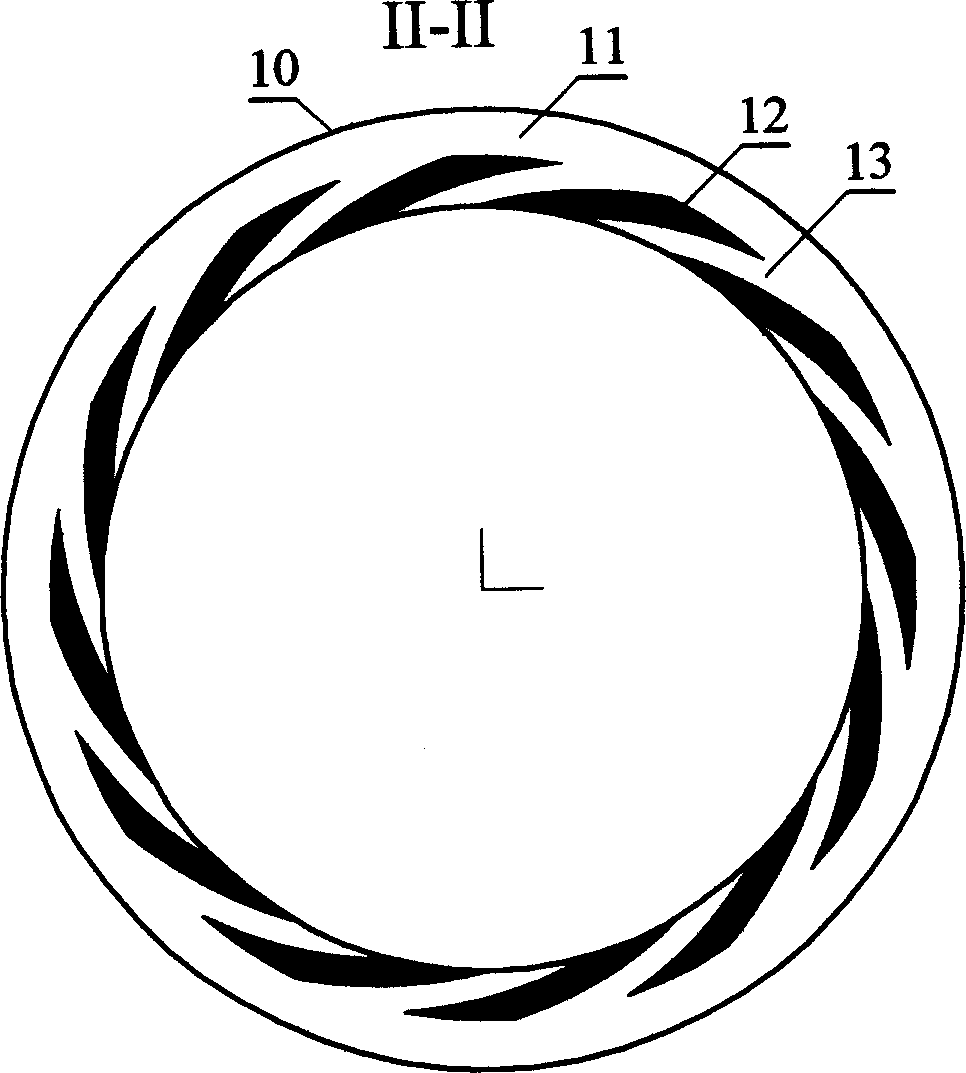

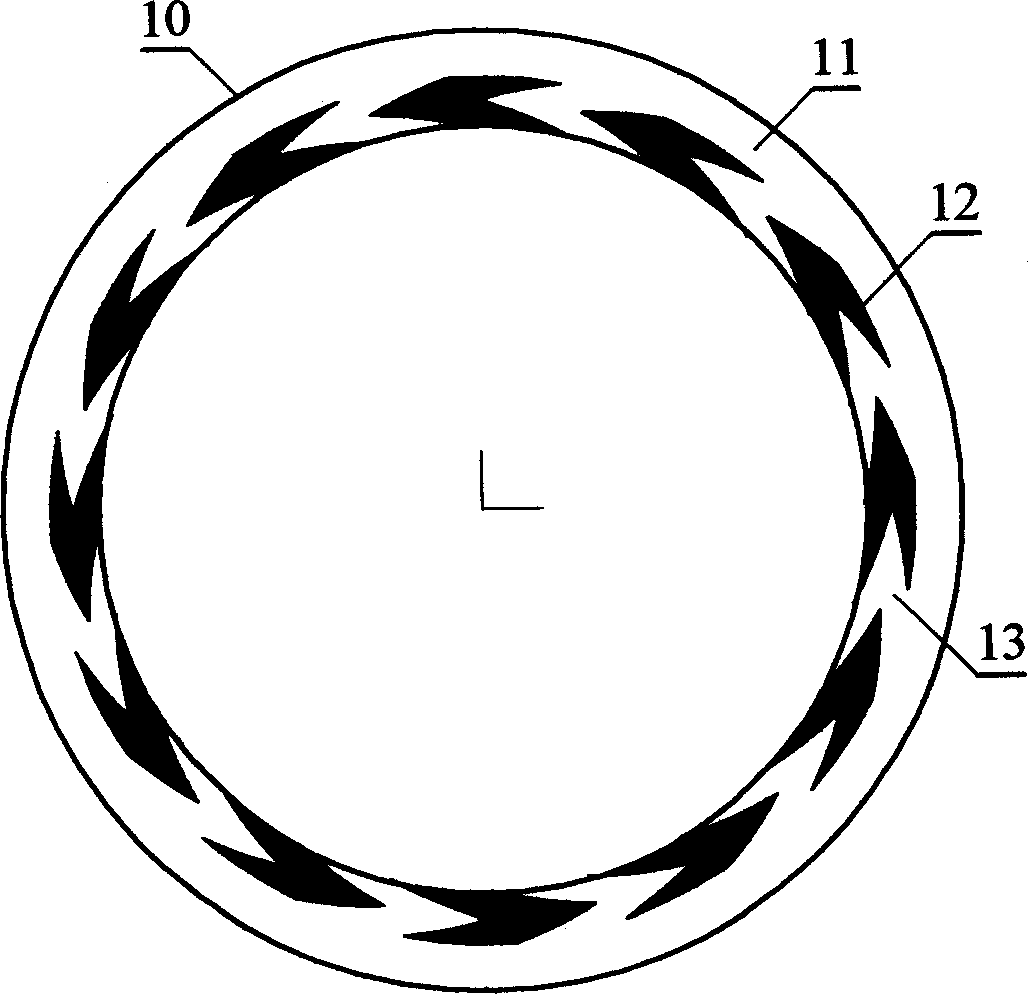

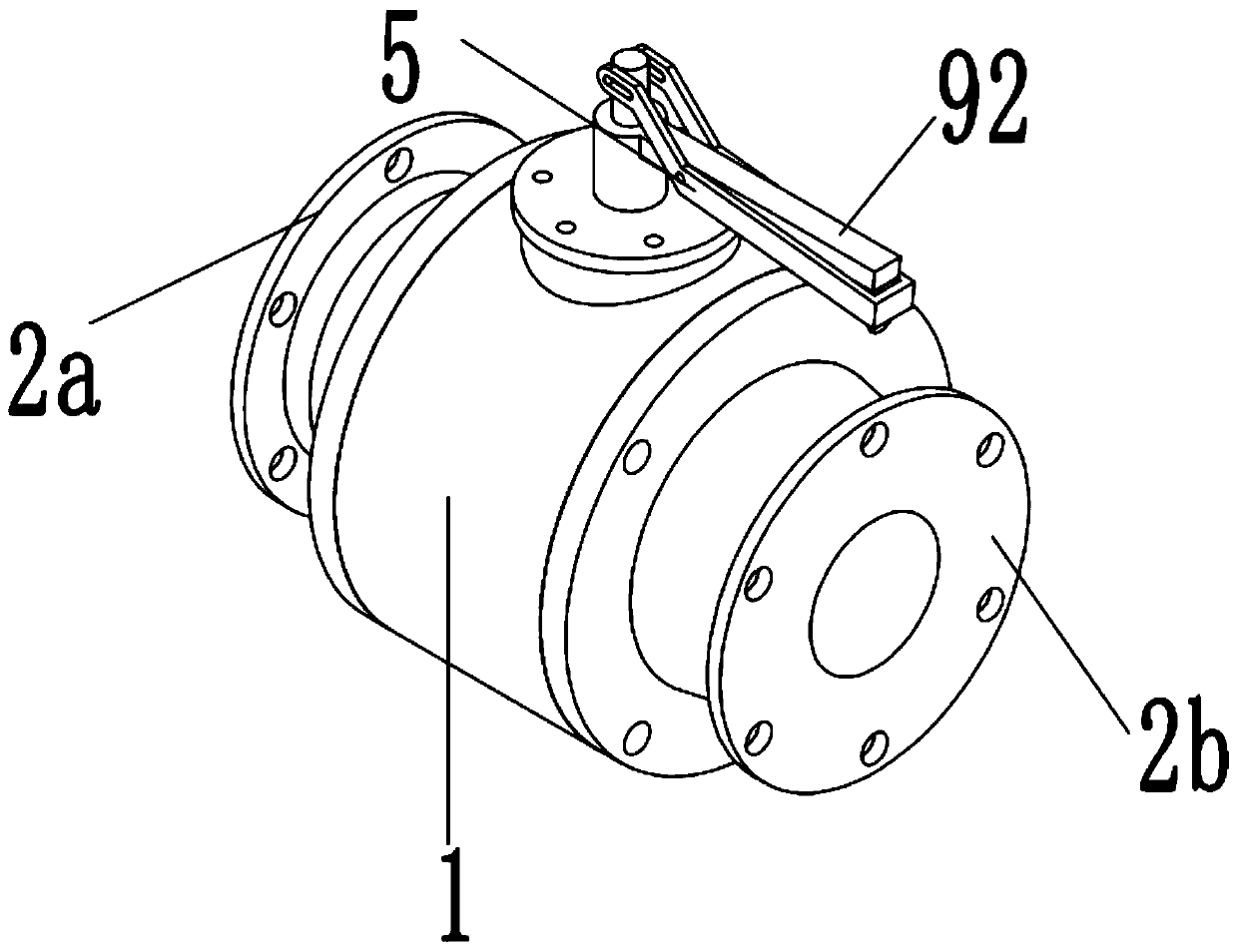

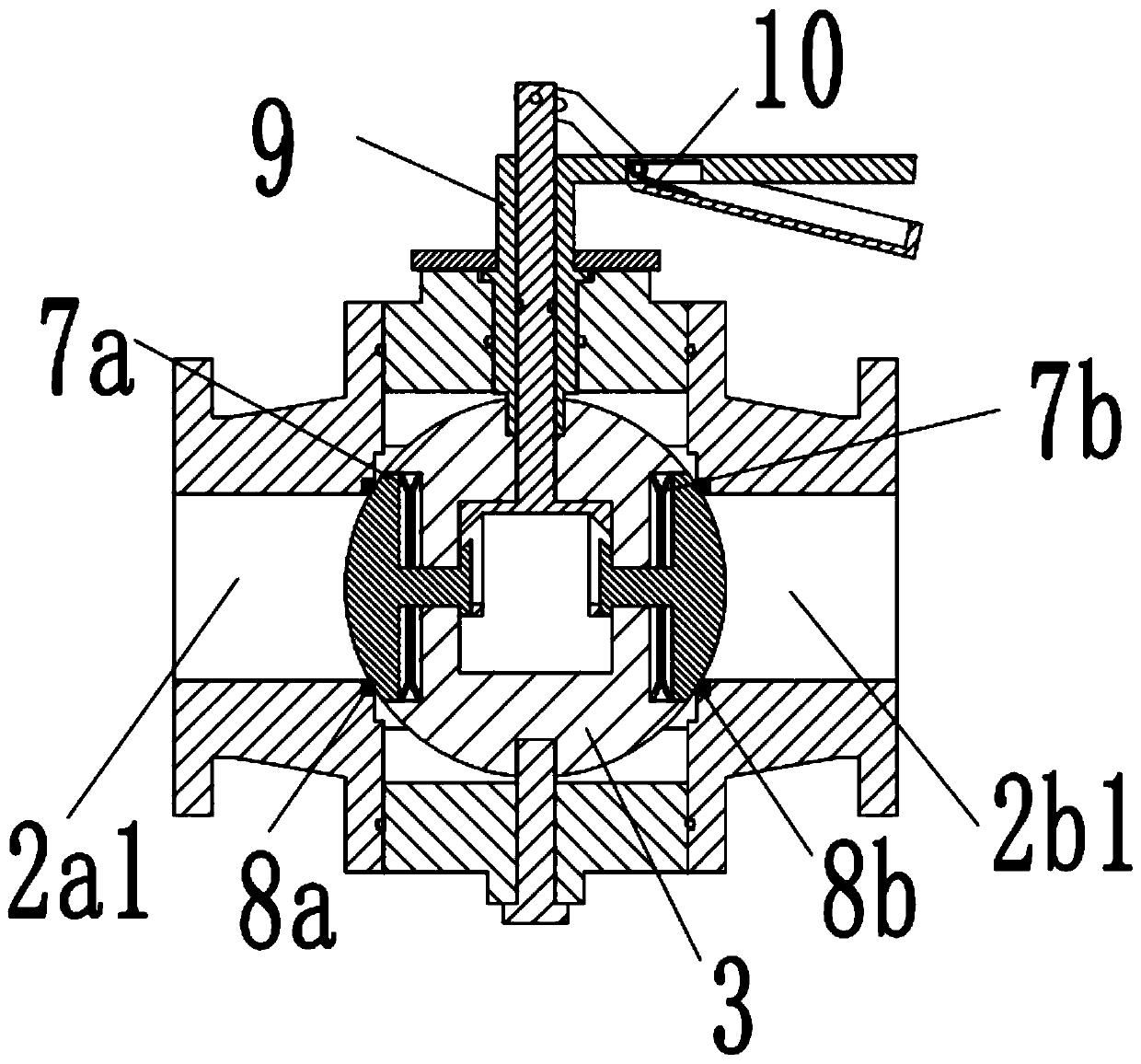

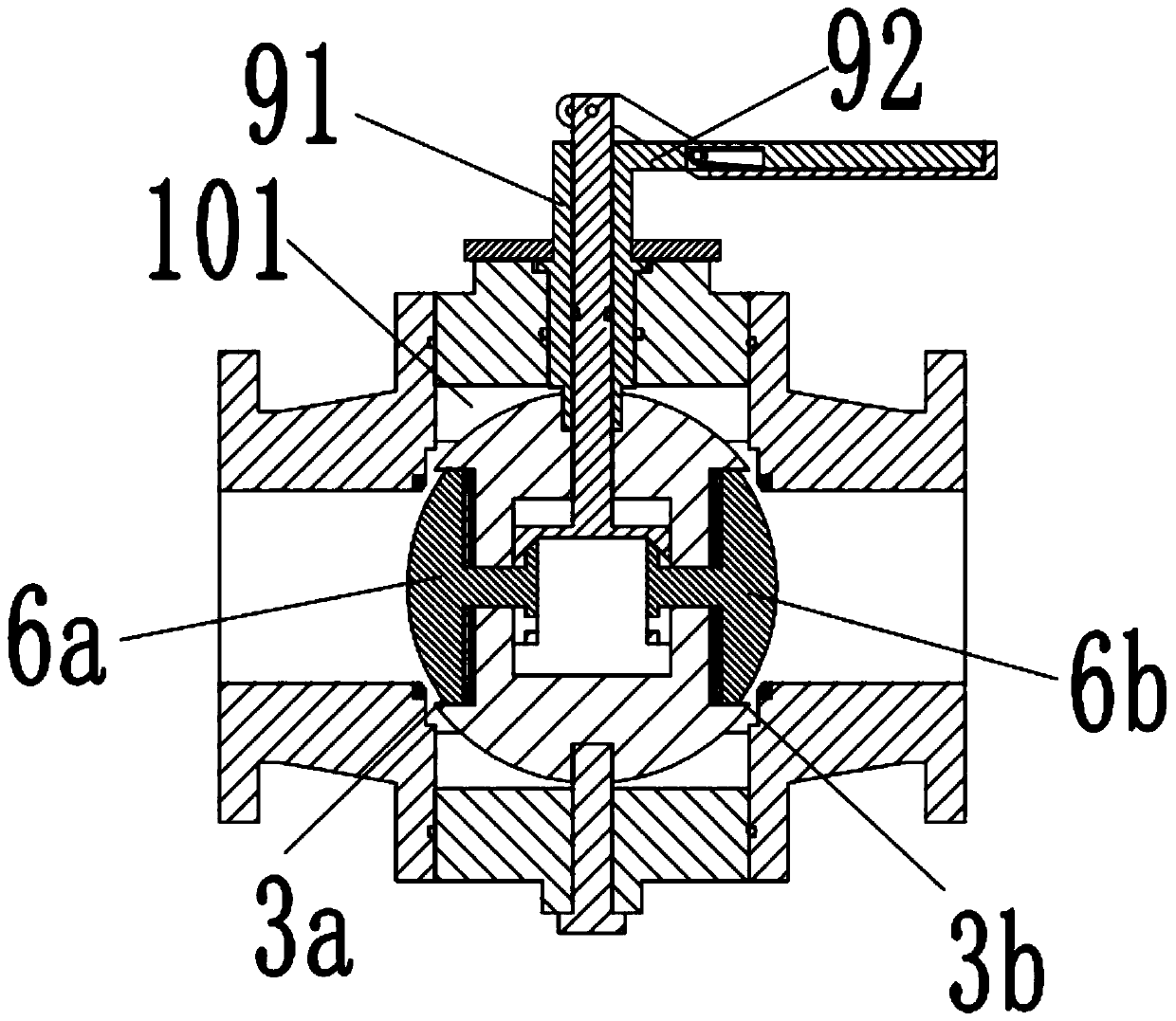

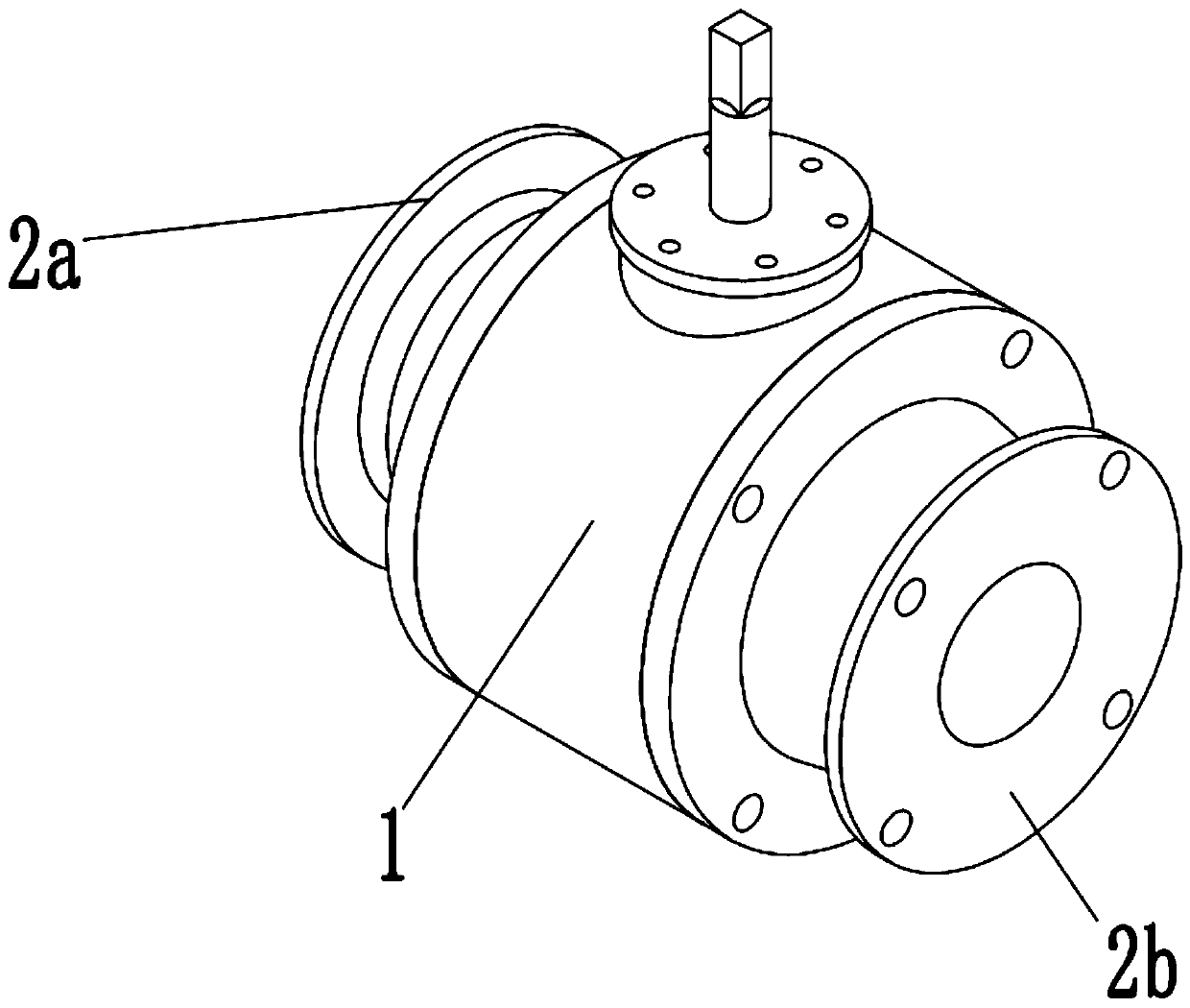

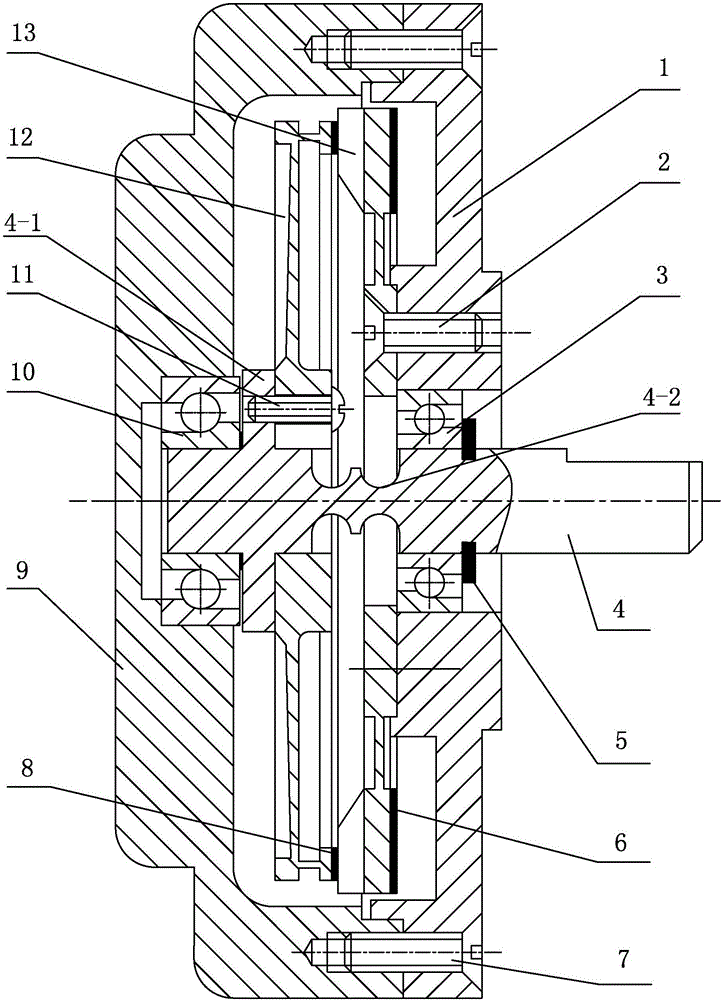

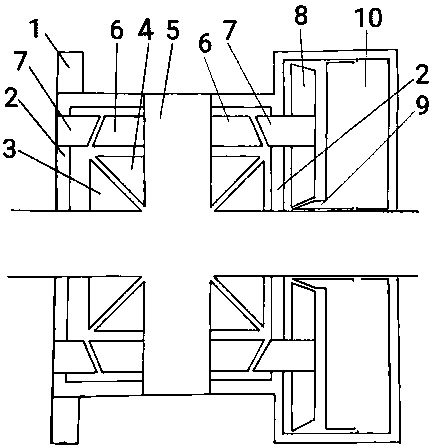

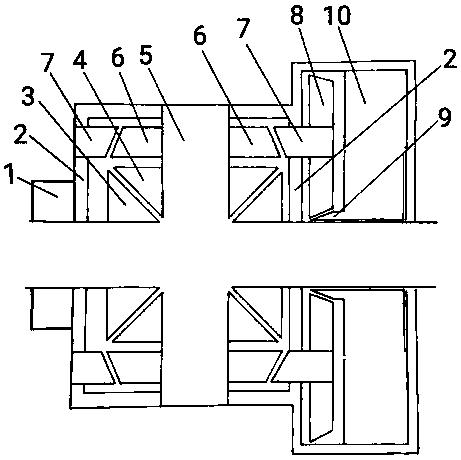

Improved ball valve

The invention relates to an improved ball valve. The improved ball valve comprises a valve body, a left valve cover and a right valve cover, a valve ball, a left valve clack and a right valve clack, arotary shaft, and a control rod, wherein a cavity body is formed in the valve body; the left valve cover and the right valve cover are fixedly installed at the two ends of the valve body separately;the valve ball is rotationally arranged in the cavity body, and a left valve cavity and a right valve cavity are formed in the valve ball; the left valve clack and the right valve clack are arranged in the left valve cavity and the right valve cavity separately; the rotary shaft comprises a rotary rod and a handle; and the control rod comprises a pull rod and a control block. According to the improved ball valve, in an opening process, the left valve clack and the right valve clack are free from friction and wear, so that the service life can be prolonged, and the reliability can be improved.

Owner:JIANGSU JIANGTE TECH

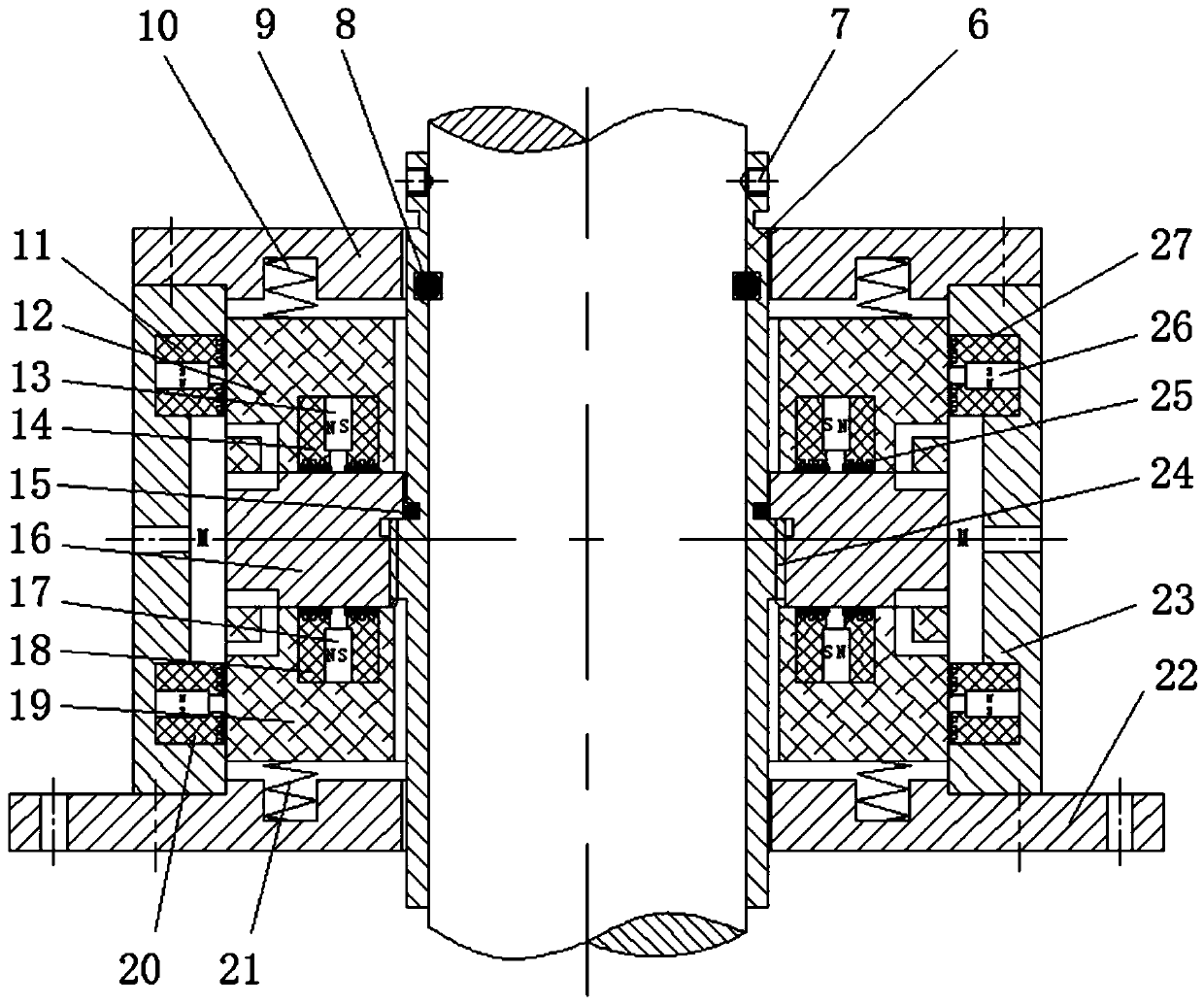

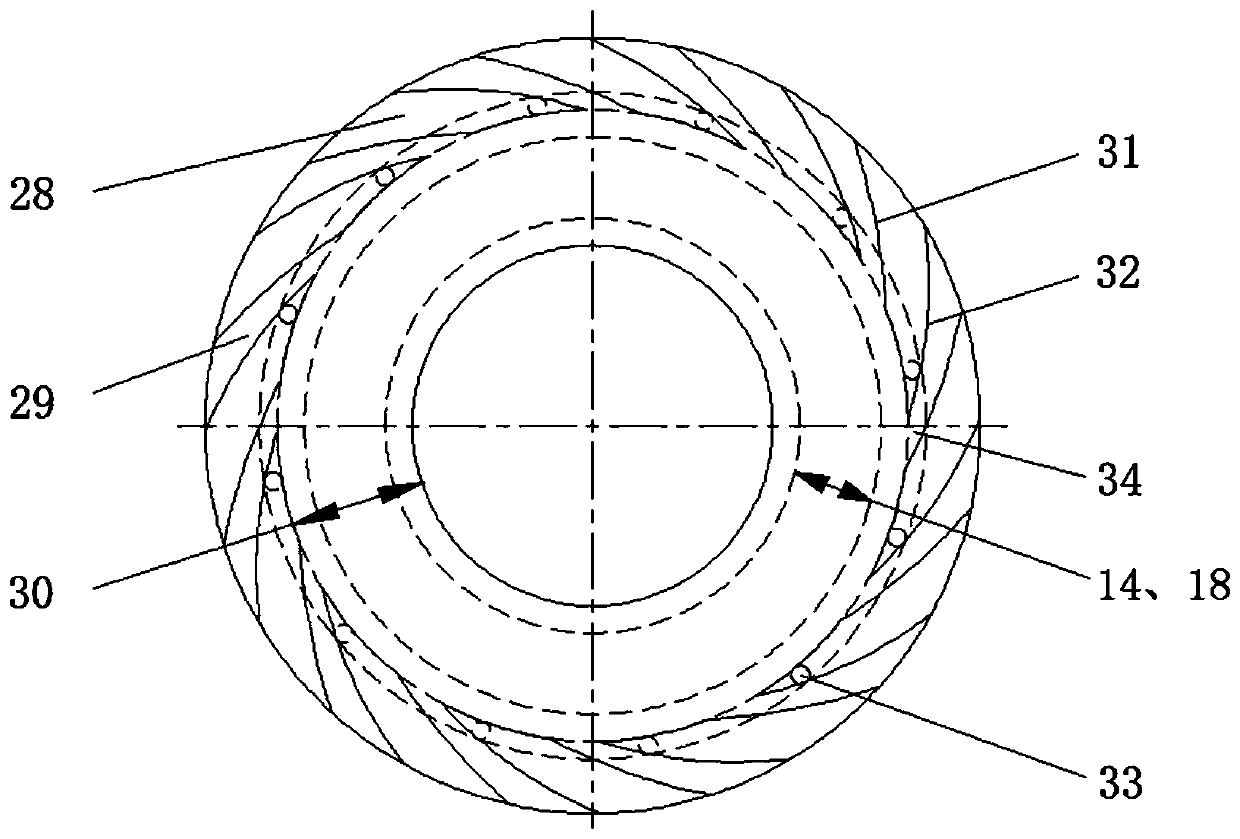

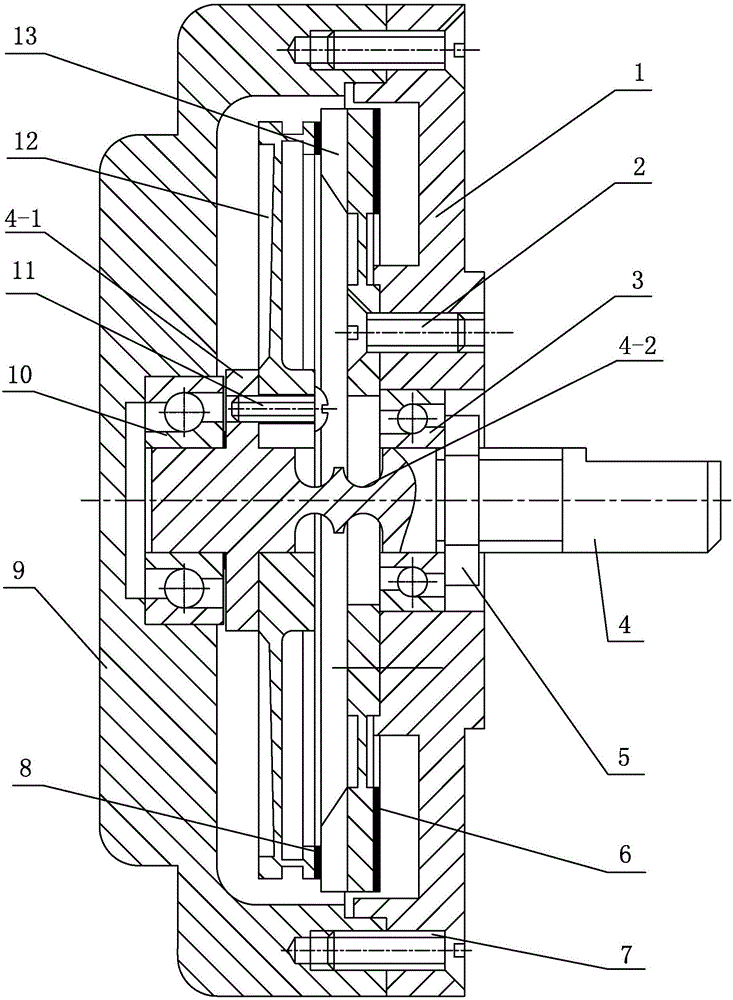

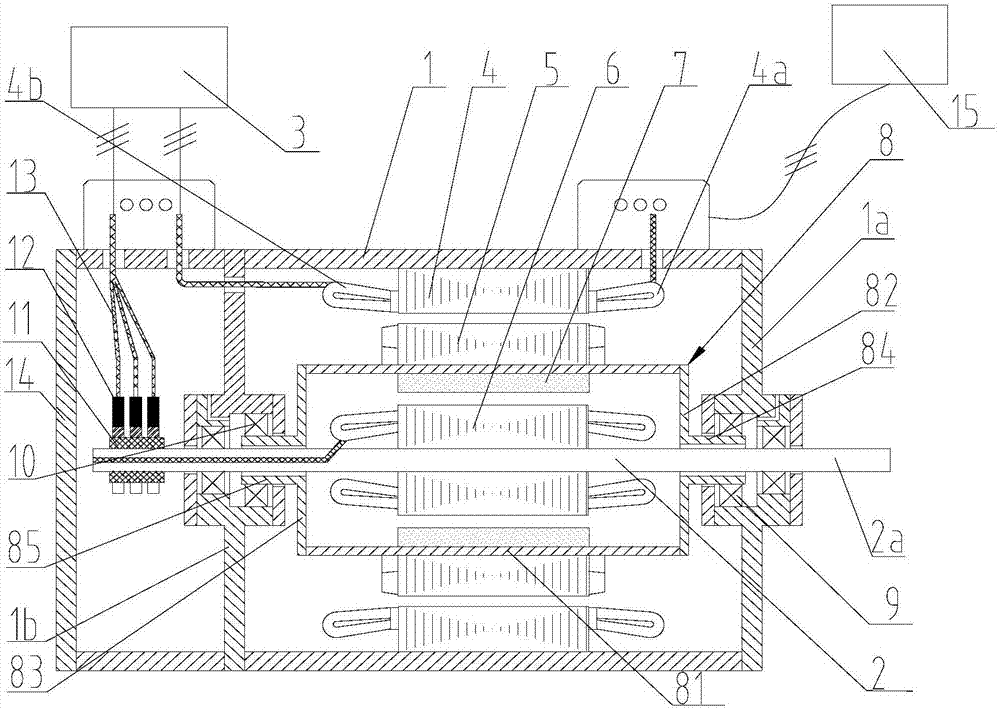

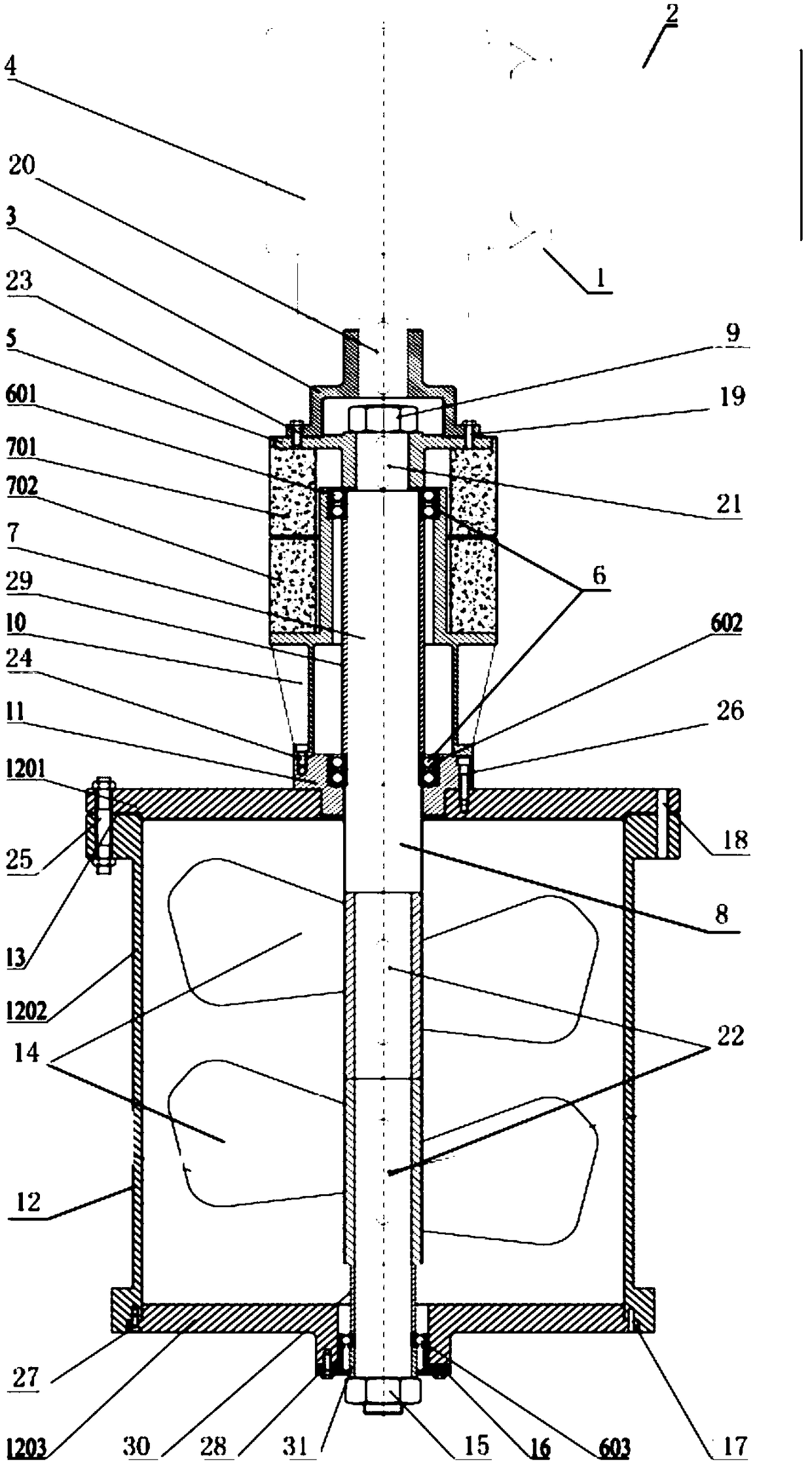

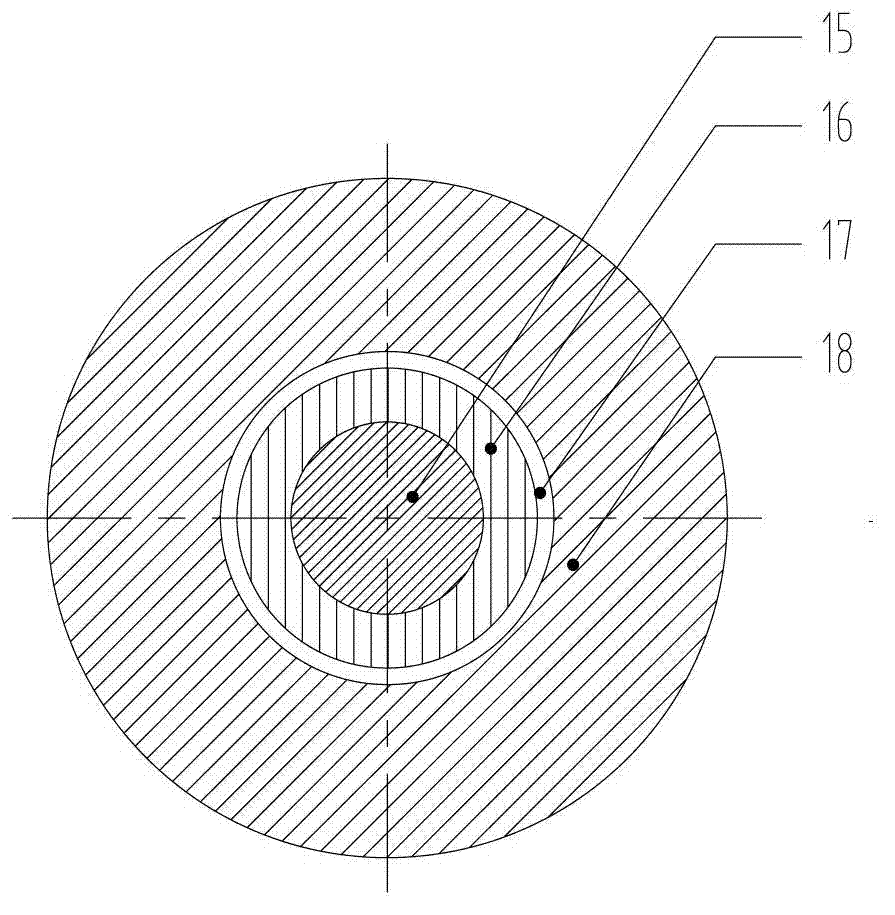

Combined non-contact double-end-face seal based on magnetic liquid sealing and fluid dynamic-pressure mechanical sealing

PendingCN110185653AAchieving Zero LeakagePrevent leakagePump componentsPumpsMagnetic tension forceMolten salt

The invention provides a combined type non-contact double-end-face seal based on magnetic liquid sealing and fluid dynamic-pressure mechanical sealing, so that the zero leakage and the long-period safe and stable operation of the molten salt pump shaft seal can be guaranteed. The combined type non-contact double-end-face seal is arranged between a shell and a rotary shaft of the rotary equipment,the combined non-contact double-end-face seal is composed of "a pumping-in type" fluid dynamic-pressure mechanical seal and a magnetic liquid seal, the upper end surface and the lower end surface of movable rings are movable ring sealing end surfaces, each movable ring sealing end surface is provided with a groove table area and a sealing dam, and the groove table area is provided with uniformly distributed spiral grooves; a current collecting ring groove is located on the outer diameter side of a sealing end surface, the drainage hole channel is used for communicating the current collecting ring groove with a blocking fluid cavity, and a magnetic generating mechanism is located at the inner diameter side part of the sealing end surface; when the movable rings rotate relative to static rings, the spiral grooves are pumped into blocking fluid, the opening force of the end face is generated, the sealing end face is separated, at the moment, the opening distance delta of the end face formed by the fluid dynamic pressure and the distance d between the pole shoe and the end face of the static rings form an operation state magnetic liquid sealing clearance d+delta.

Owner:NANJING FORESTRY UNIV

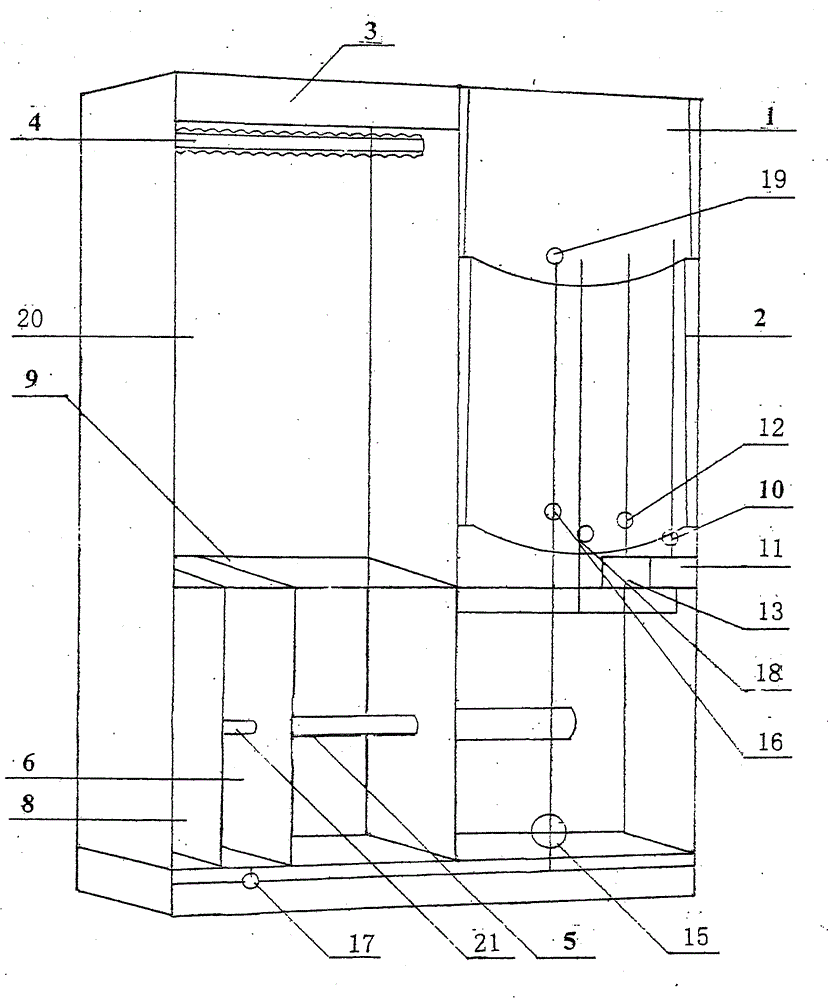

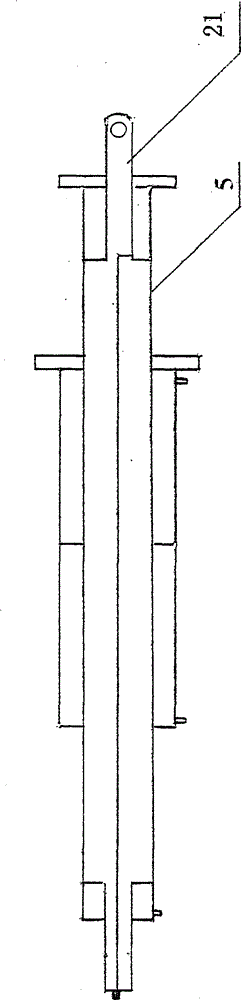

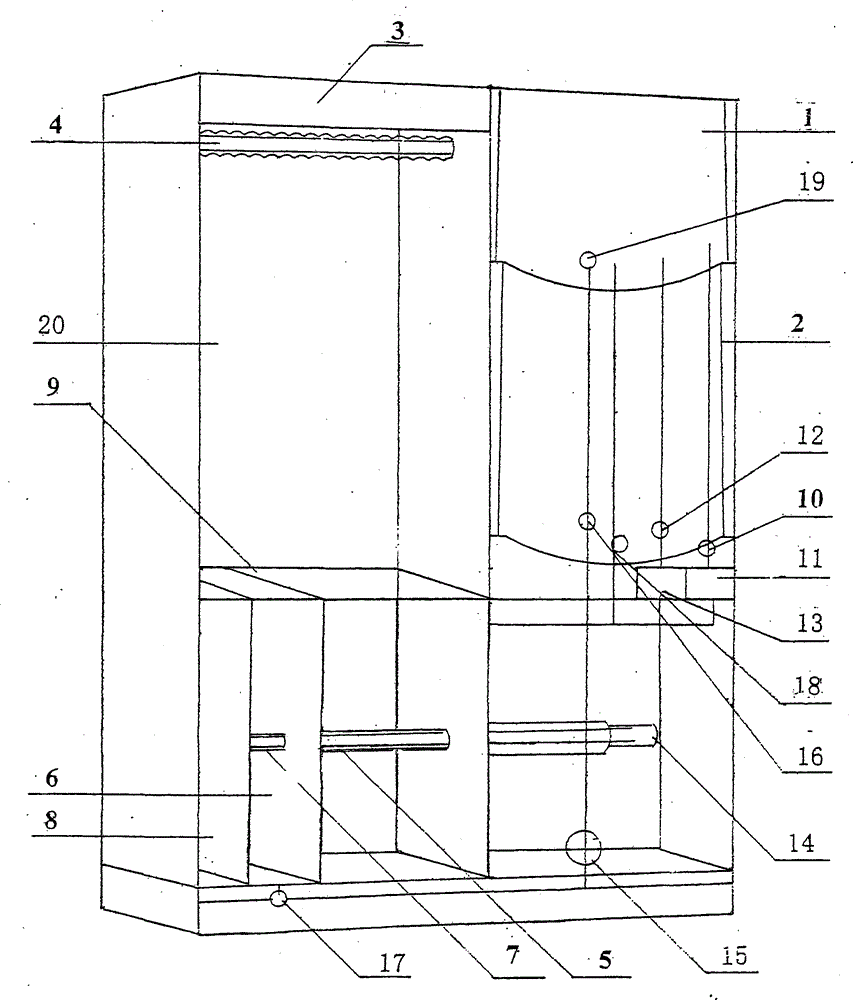

Multifunctional automatic intelligent laundry wardrobe

ActiveCN104153156ANo fall damageNo friction and wearWardrobesOther washing machinesWater turbineWastewater

Disclosed is a multifunctional automatic intelligent laundry wardrobe. The multifunctional automatic intelligent laundry wardrobe relates to hydraulic single-top laundry, hydraulic impact single-top laundry and hydraulic impact double-top laundry of a hollow shaft. The multifunctional automatic intelligent laundry wardrobe comprises a wardrobe, a washing drum, a double-acting hydraulic device, an impactor, a water turbine, a washing powder or detergent feed mechanism and a water recycling mechanism, the problems that clothes are damaged by beating and worn by friction, threads and plush are attached to the clothes, washing powder or detergent are not fed accurately, water and electricity are wasted, water are not recycled, stains on collars and cuffs are not completely removed and the clothes are draped and are not automatically disposed into the wardrobe are solved. Since the wardrobe and a laundry tank are integrated, capacity of the laundry tank is adjusted to save water by hydraulic pressure of the hollow shaft and a water baffle, laundry time is shortened to save electricity, the impactor and a dewatering plate quickly squeeze the still water-absorbing clothes or the collars or the cuffs, and water jet penetrates the clothes to remove the stains. The water turbine drives to proportion the washing powder or detergent in a rigid manner. Wastewater is cleaned and recycled for later washing, washing and rinsing wastewater is recycled for flushing a toilet, and the clothes can be automatically disposed into the wardrobe without drape after washed and dried.

Owner:游振兴

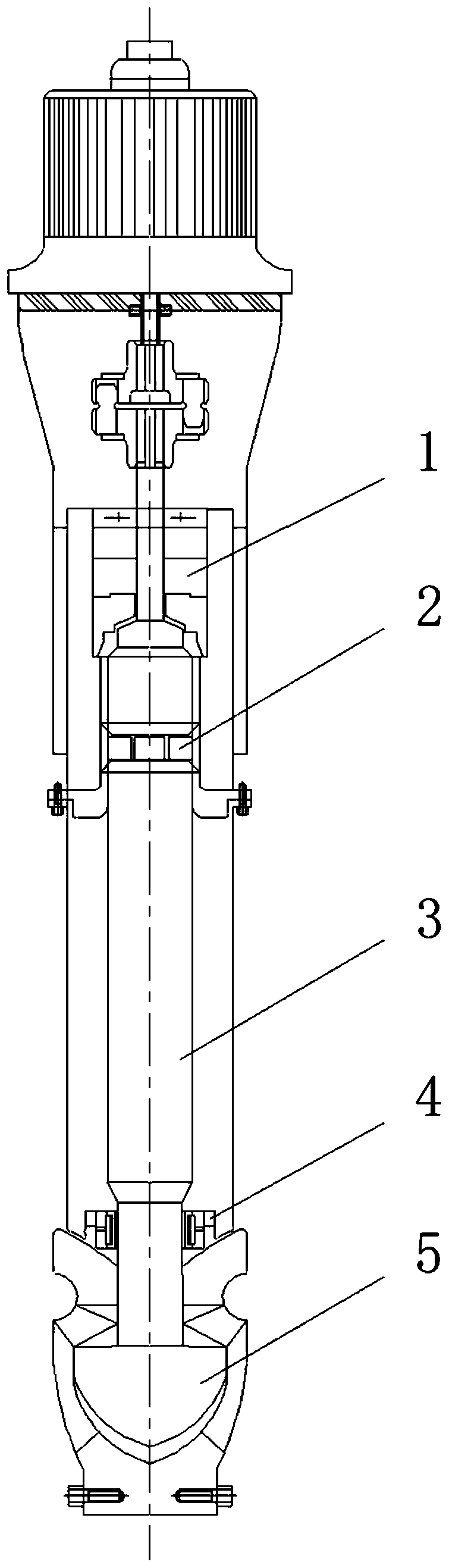

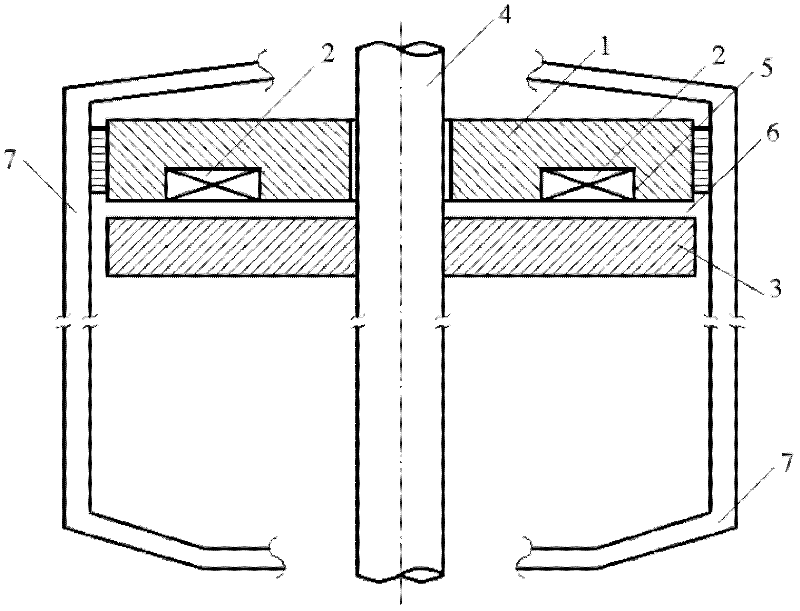

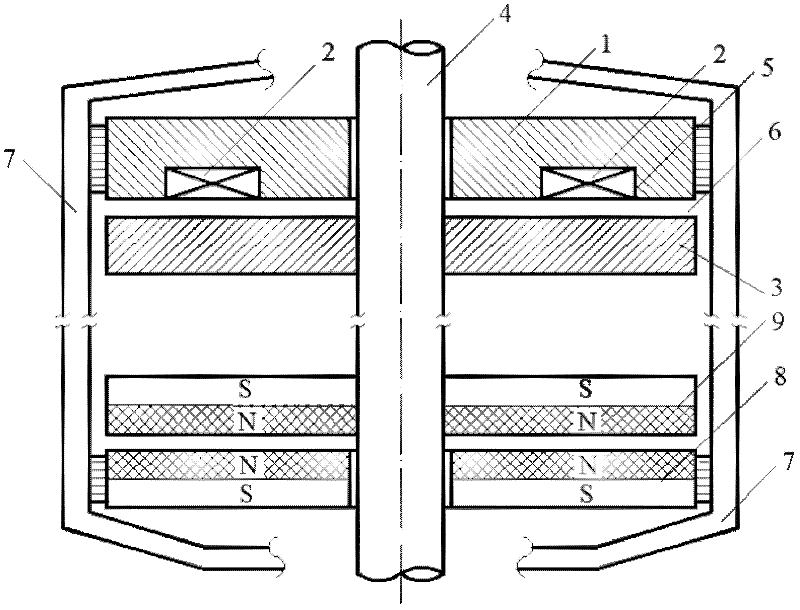

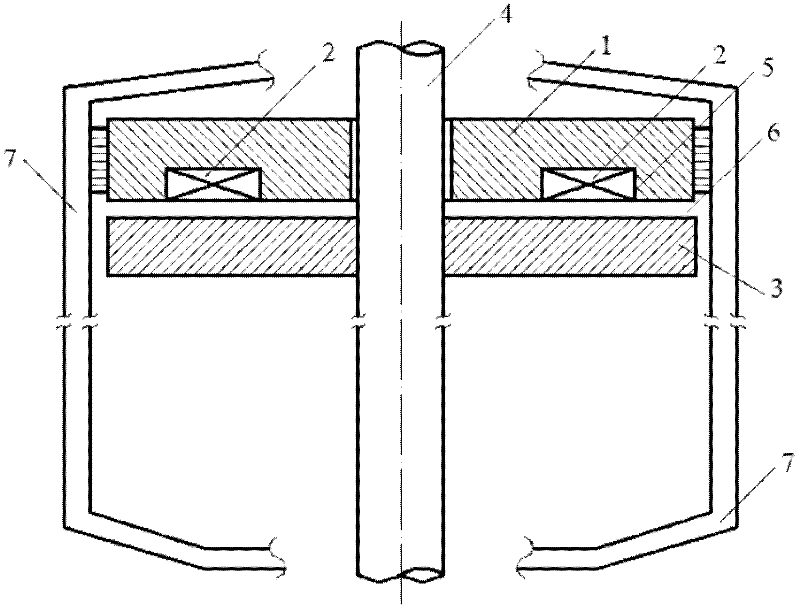

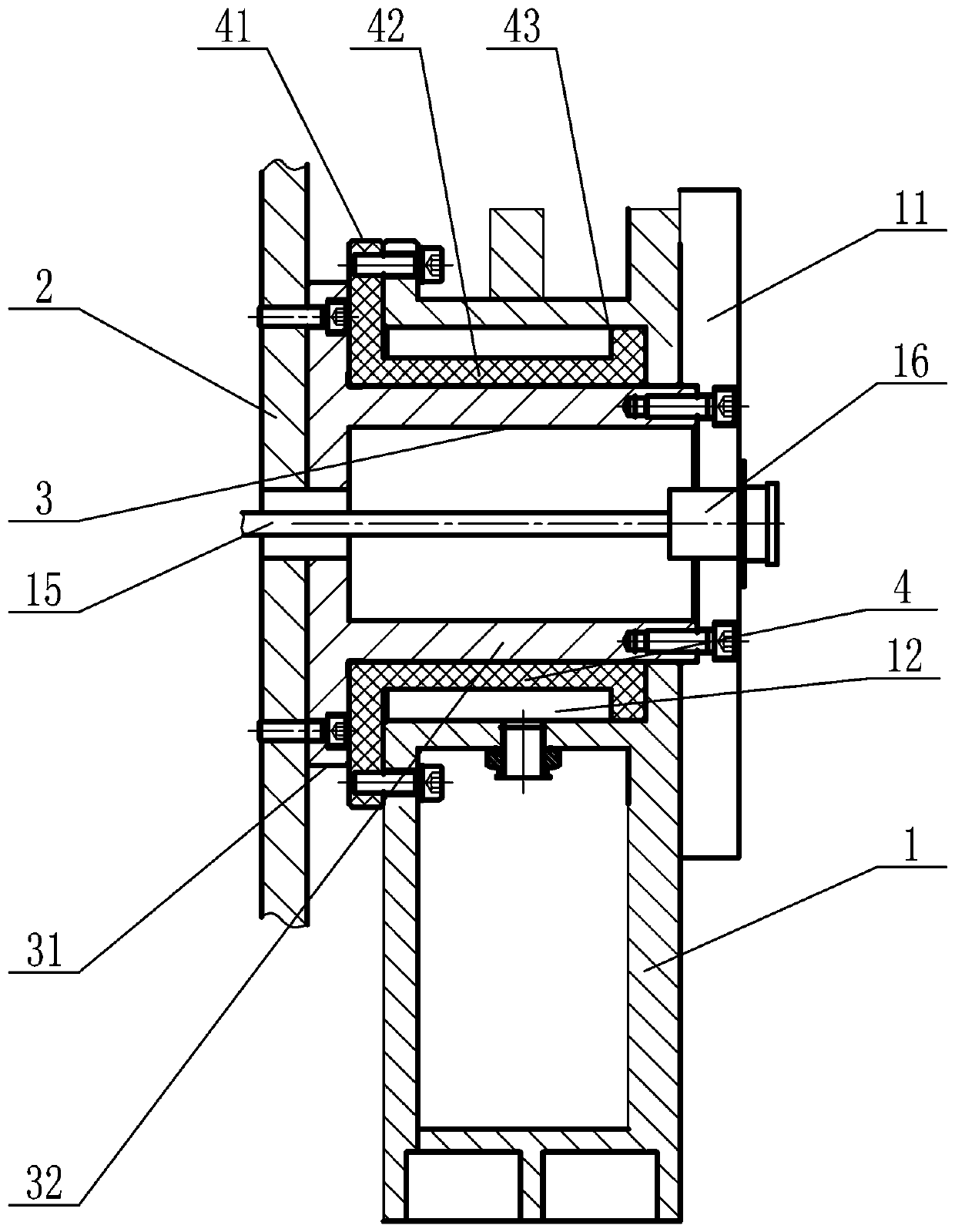

Electromagnetic load reduction bearing for hydraulic generator

The invention discloses an electromagnetic load reduction bearing for a hydraulic generator, which is arranged on a motor stator. The load reduction bearing is of the following structure that an iron core 1 made of a ferromagnetic material is fixed on the motor stator 7; a coil 2 is embedded into a groove 5 of the iron core made of the ferromagnetic material to form an electromagnet; a thrust disc 3 made of the ferromagnetic material is fixed on a motor rotor 4 and is arranged in a mode of facing the side of the groove of the electromagnet; a gap 6 is reserved between the electromagnet and the thrust disc; and a lead wire in the coil 2 is connected with the control system. Compared with a conventional sliding bearing, the electromagnetic bearing has the characteristics of environment protection and low consumption and has wide application range. The environment pollution can be reduced. The energy consumption can be reduced. The electromagnetic load reduction bearing has outstanding advantages.

Owner:SOUTHWEST JIAOTONG UNIV

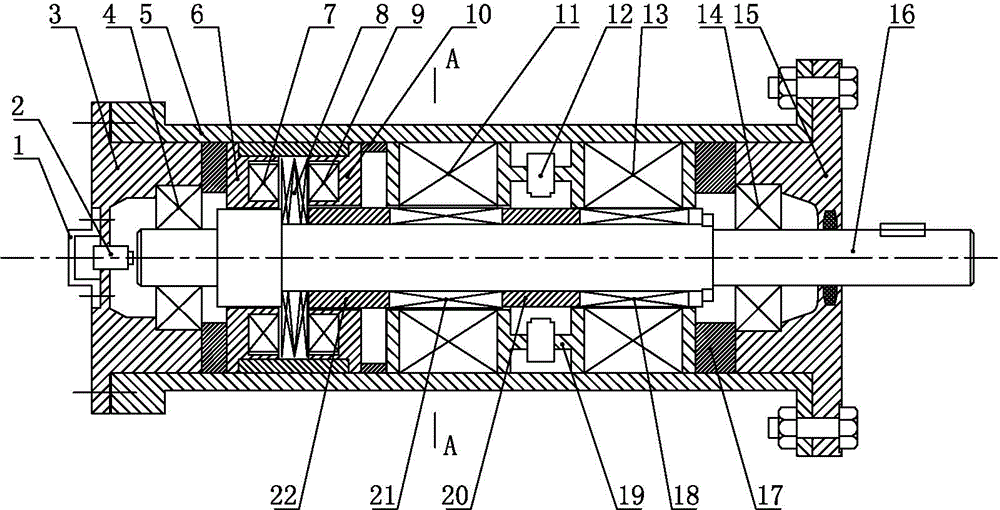

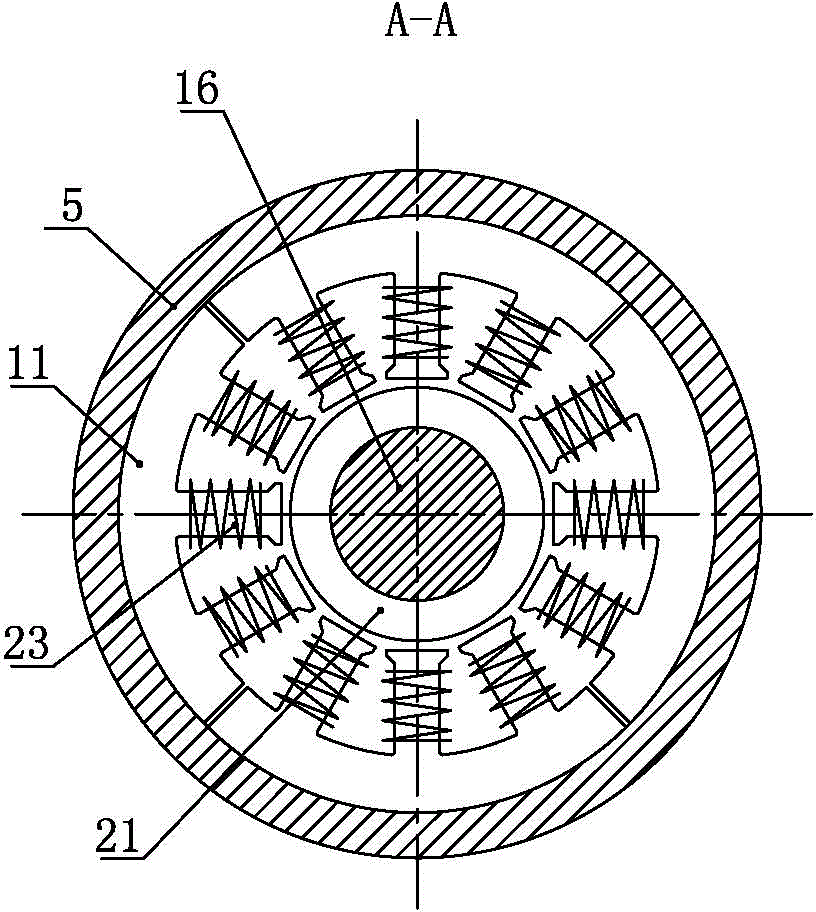

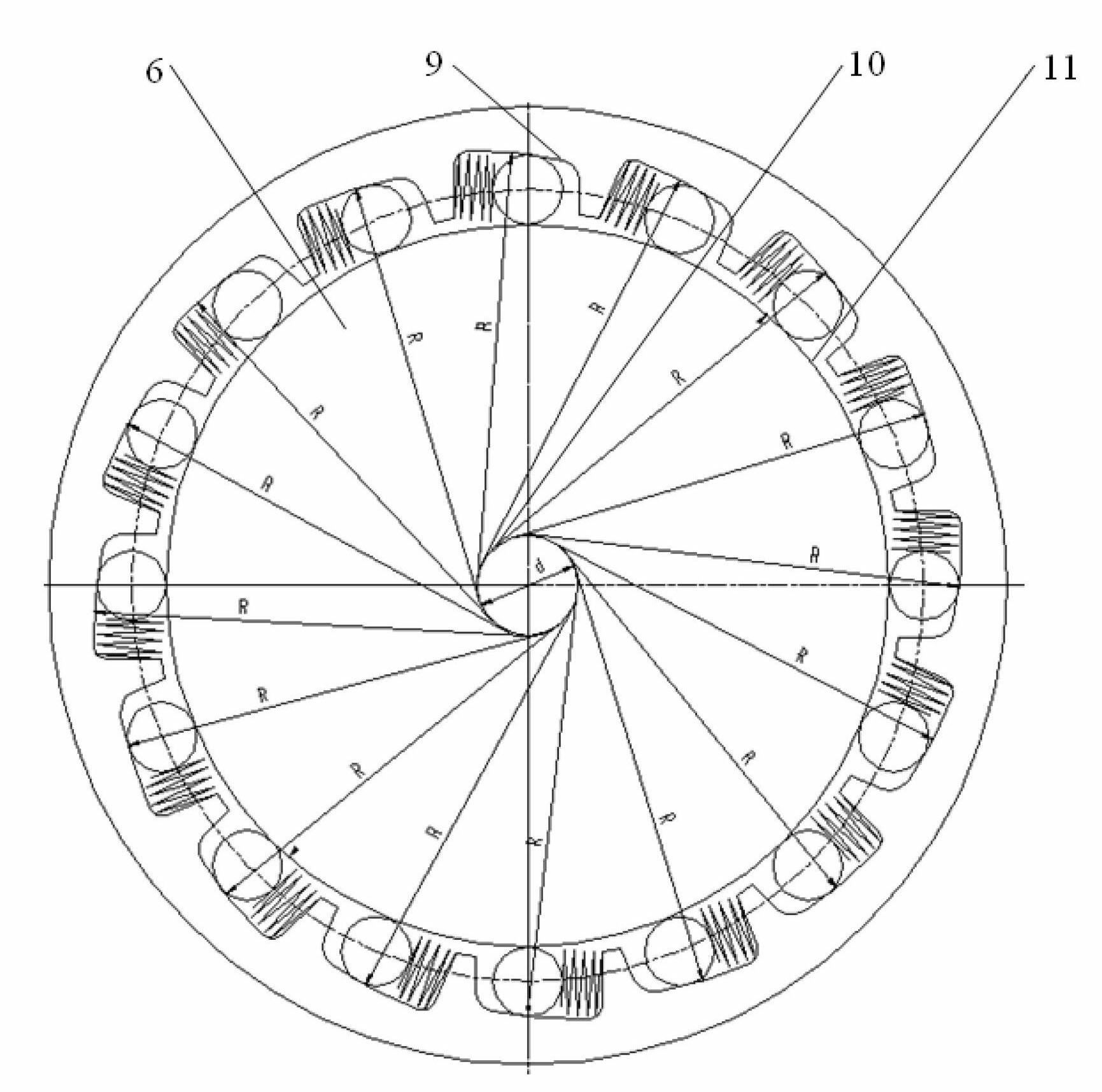

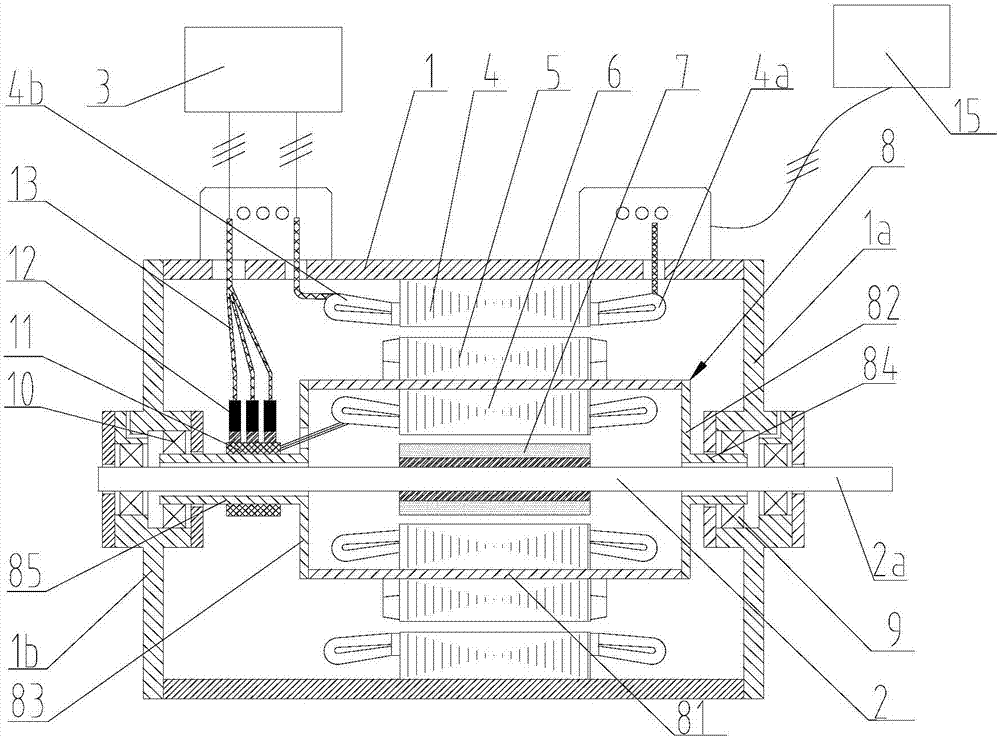

Arc stator winding magnetic suspension bearing drive motor

ActiveCN104092411ASimple structureNo friction and wearMagnetic holding devicesAxial displacementDrive motor

The invention relates to an arc stator winding magnetic suspension bearing drive motor in the technical field of electrodes. A rotor assembly is arranged in inner cavities of stators of the arc stator winding magnetic suspension bearing drive motor, the two ends of the rotor assembly are borne on bearings in end covers, the rotor assembly comprises a rotor shaft, a disk rotor and two rotor rings are arranged on the rotor shaft, and a displacement sensor reference ring is arranged between the two rotor rings; the stators comprise the first axial stator, the second axial stator, the first radial stator and the second radial stator, and the first axial stator and the second axial stator are arranged on the two sides of the disk rotor in a matched mode; the first radial stator and the second radial stator are arranged on the peripheries of the two rotor rings respectively in a sleeved mode, a sensor support is arranged between the first radial stator and the second radial stator, and a plurality of radial displacement sensors are arranged on the sensor support in the direction of the circle; the radial displacement sensors are correspondingly distributed on the periphery of the displacement sensor reference ring; axial displacement sensors are correspondingly arranged in the position, corresponding to the end of the rotor shaft, on the end cover on one side. The arc stator winding magnetic suspension bearing drive motor can achieve magnetic suspension in the radial direction and the axial direction, driving efficiency is improved, and energy consumption is reduced.

Owner:江苏亚盛金属制品有限公司

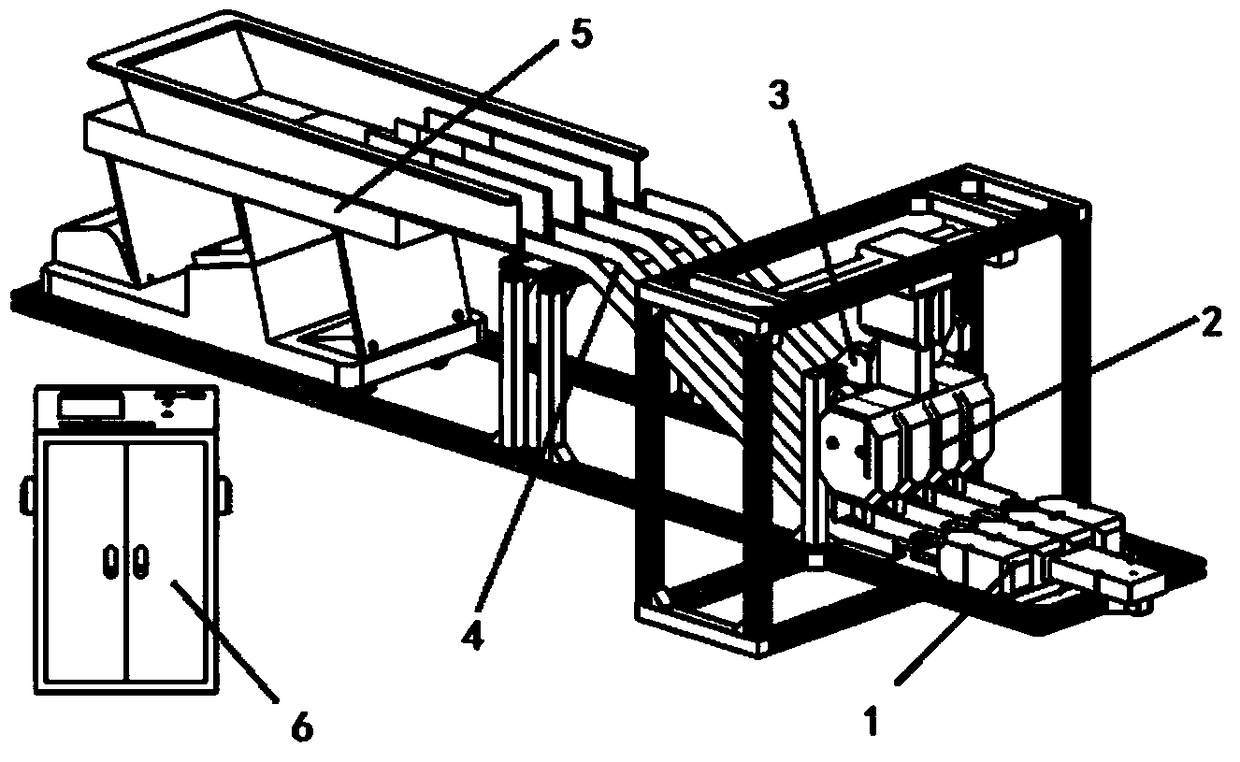

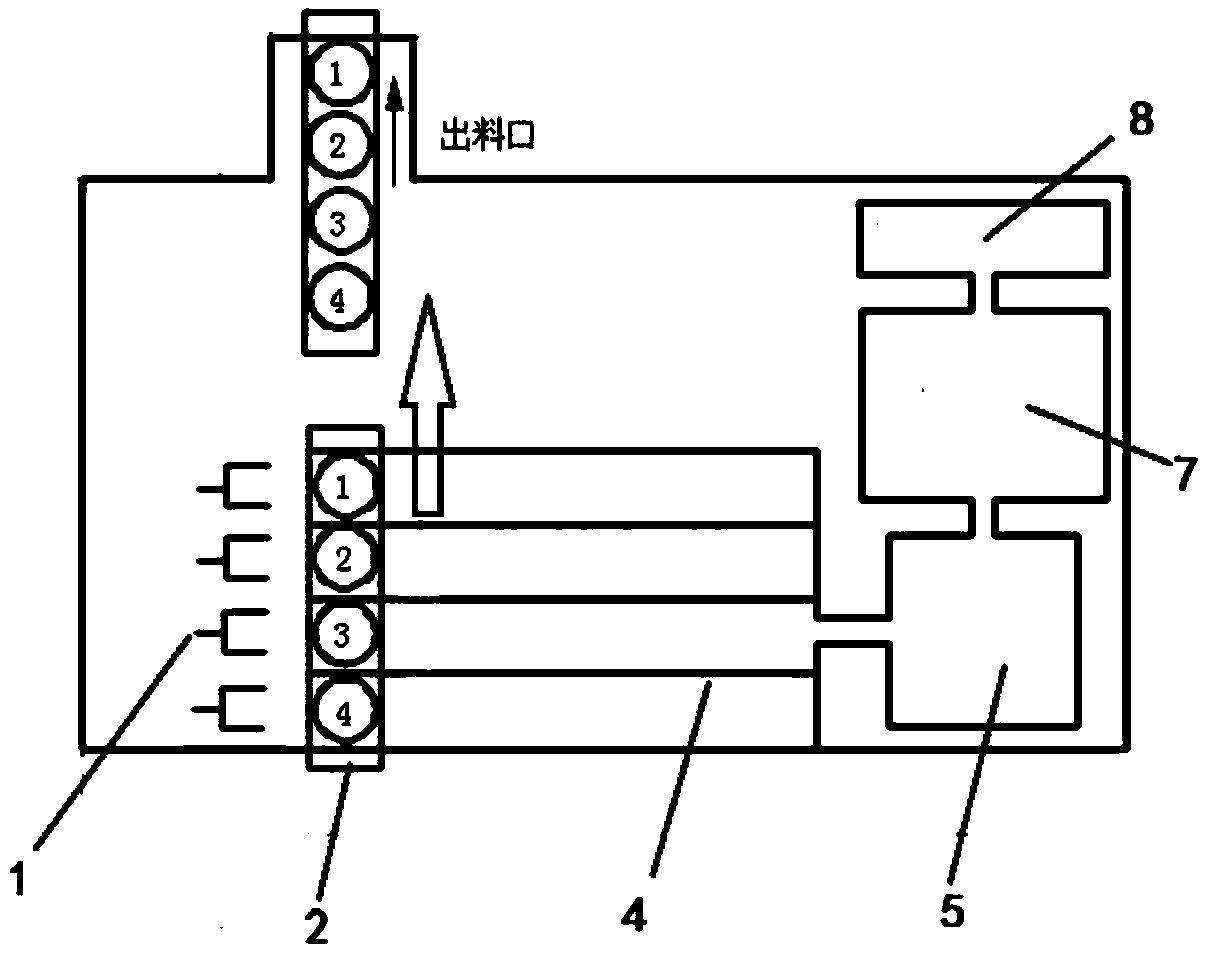

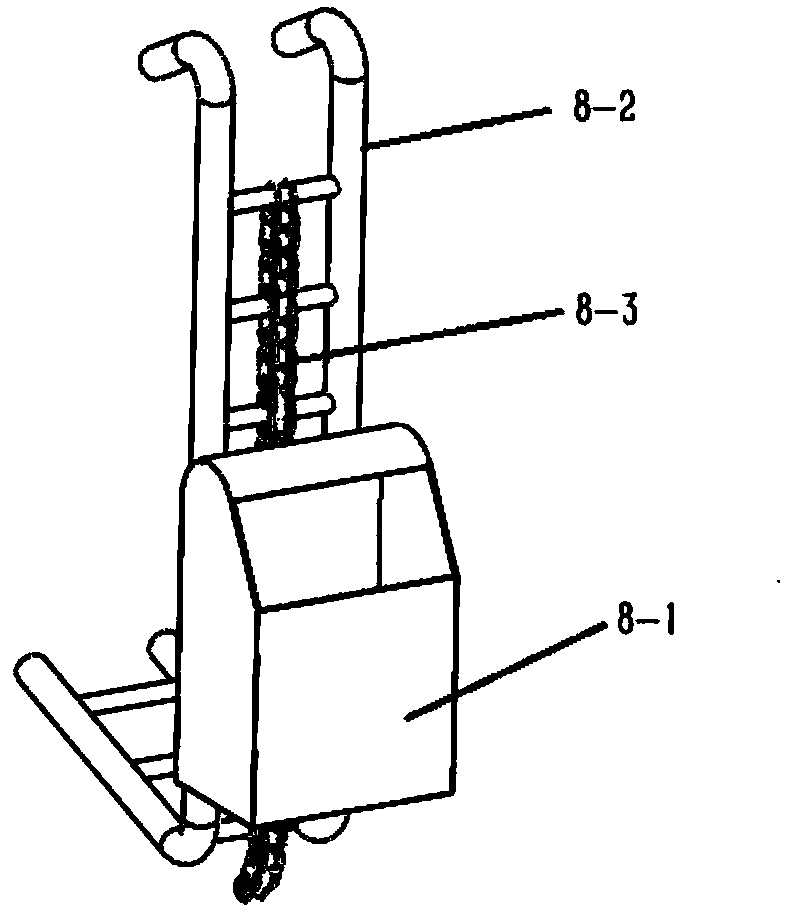

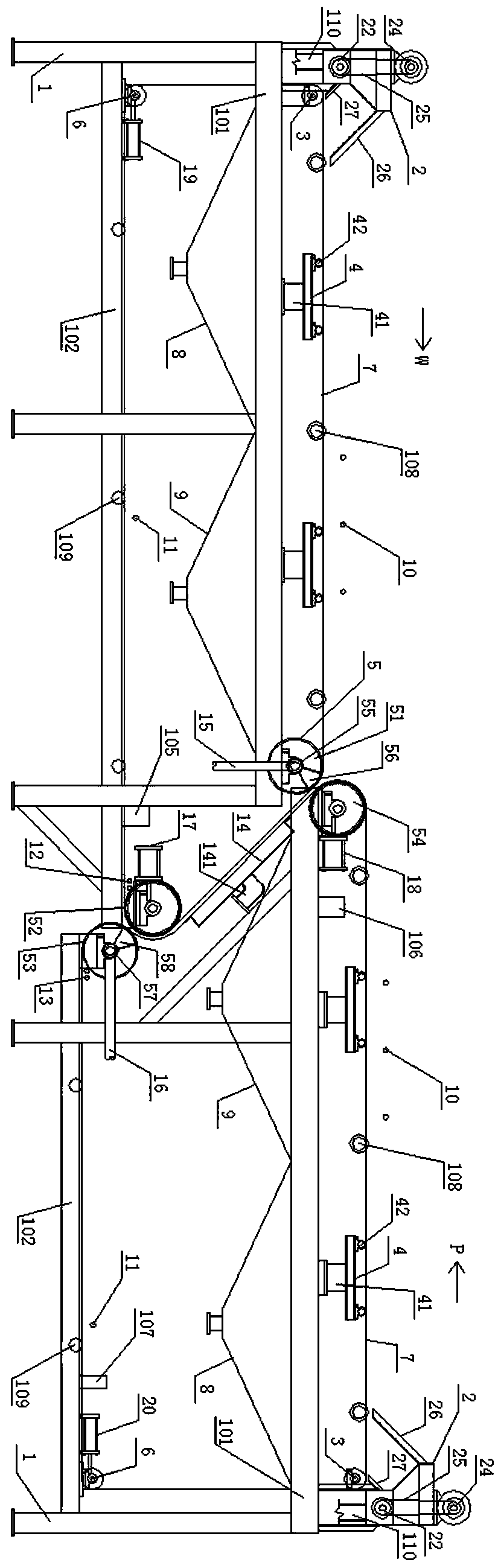

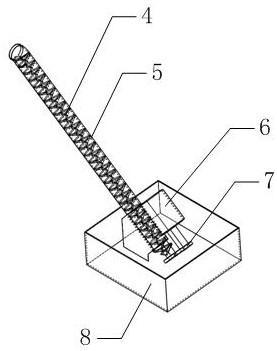

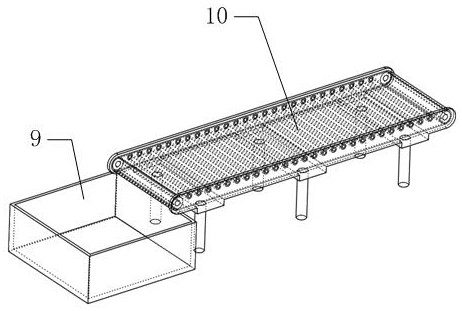

Multi-channel combined type linear vibration conveying system

ActiveCN109230389AEasy to adjustEasy to placeJigging conveyorsConveyor partsProduction lineTransport system

The invention discloses a multi-channel combined type linear vibration conveying system and relates to a round pie-shaped component based posture adjustment and feeding device. In the system disclosedin the invention, an automatic posture adjustment and feeding device for round pie-shaped components based on a conventional mechanical hand and a conventional round pie-shaped component processing production line. The round pie-shaped components may include screw nuts, linings for decelerators, spring seats and the like; all of the components of this kind need to be conveyed inward in a correctposture before feeding operation. The system comprises an elevating system, a material bin, a vibration feeder, a photoelectric switch module and an overturning and translating mechanical hand; via research and development of a mechanical hand and auxiliary equipment coordinated motion control system, synchronous movement of the mechanical hand and auxiliary equipment can be realized, and the components can be conveniently adjusted and placed via the mechanical hand. Compared with a system of the prior art, the system disclosed in the invention is advantageous in that production cost can be lowered, rapid parallel arrangement of the round pie-shaped components can be realized, a problem of difficult component ordering during processing procedures can be solved, and a work mode of manual arranging operation can be replaced.

Owner:SOUTHEAST UNIV

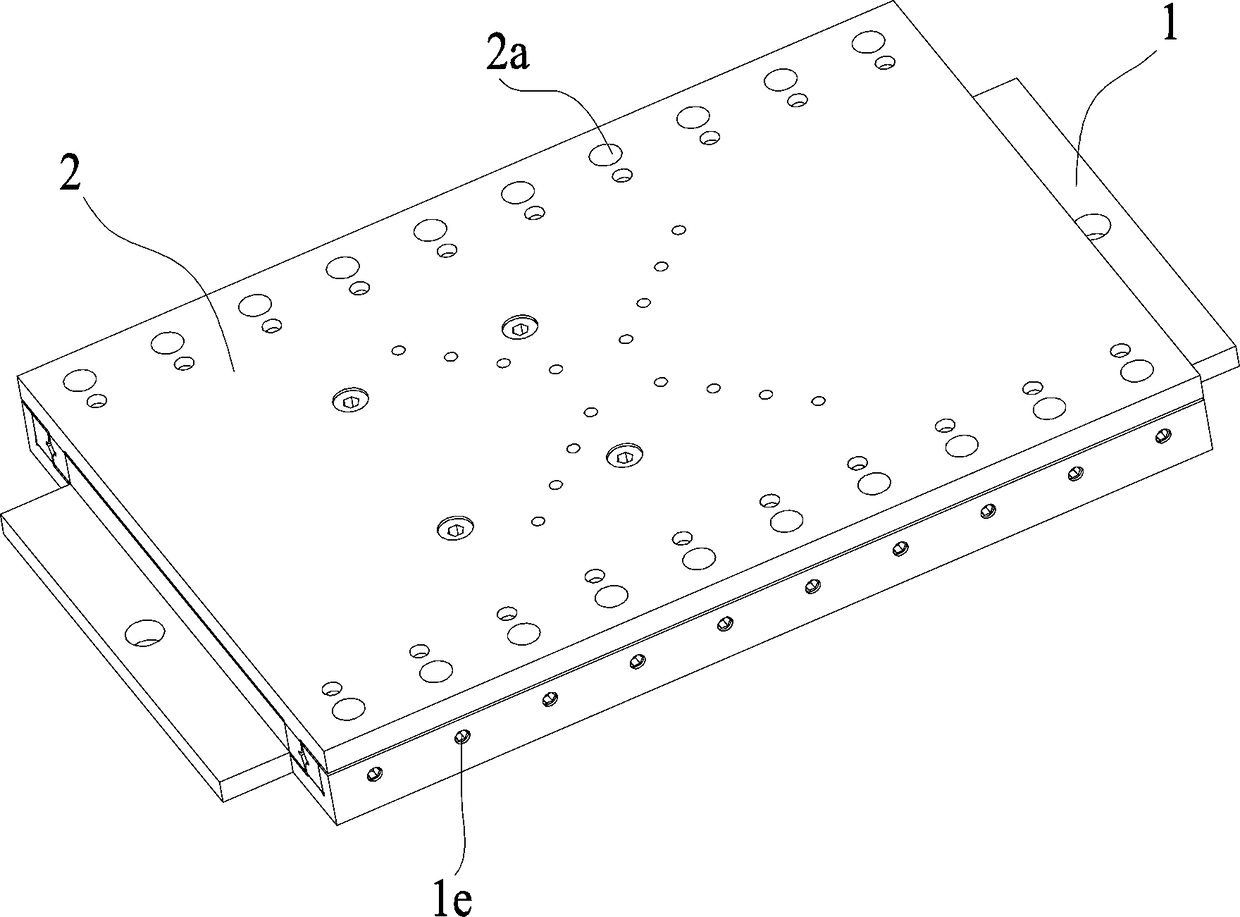

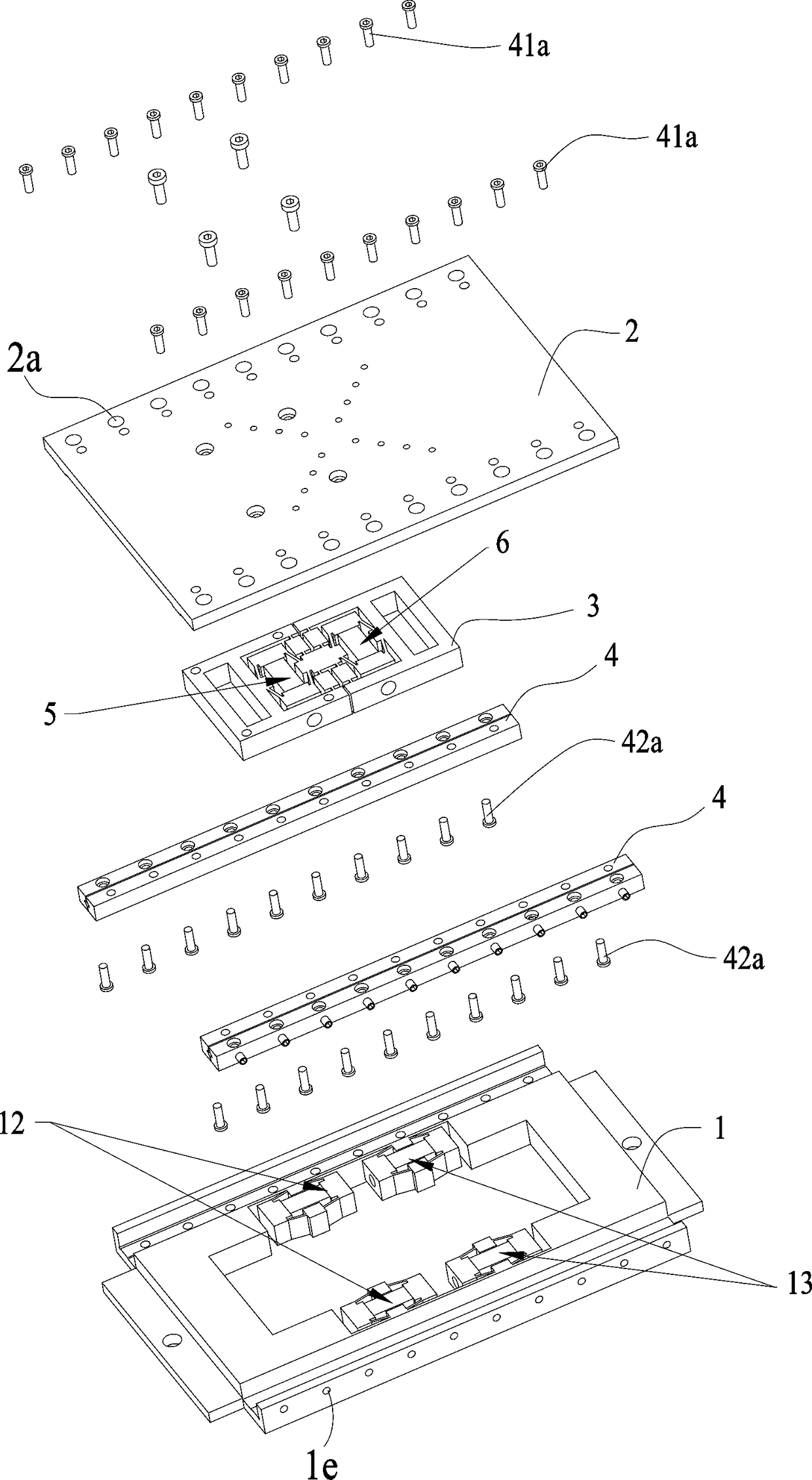

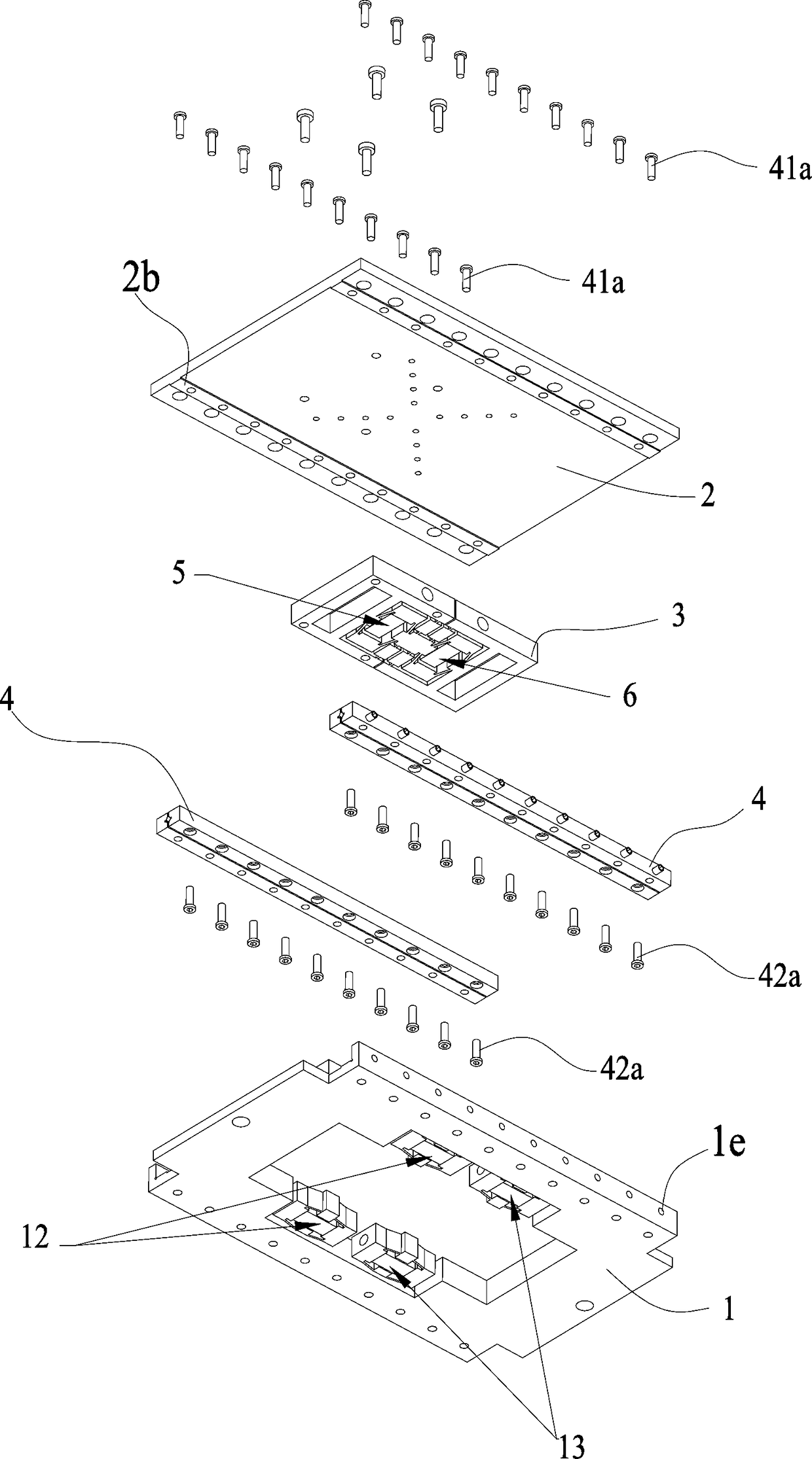

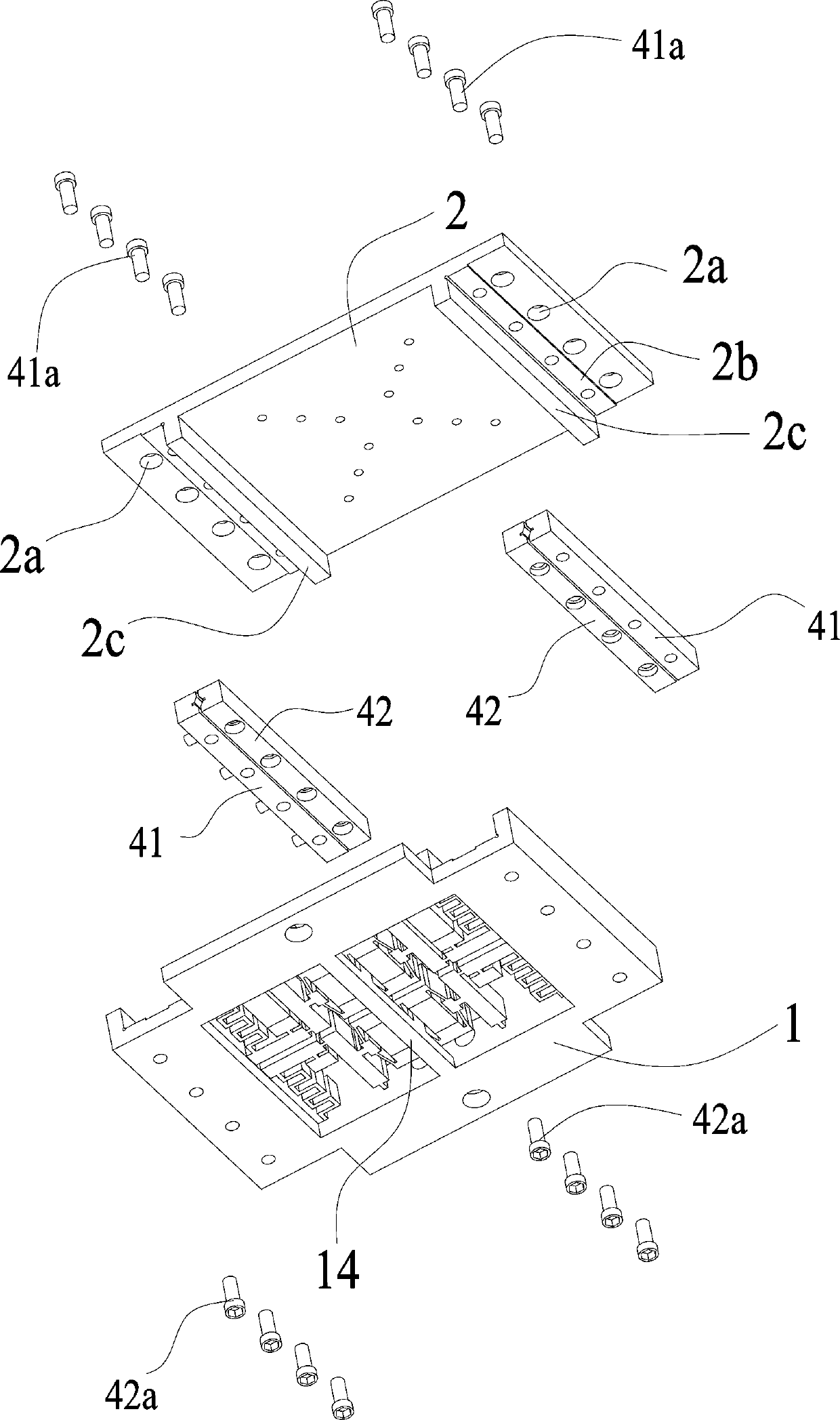

A fully-displacement amplified piezoelectric inchworm straight-line platform

ActiveCN109217724ACompact structureLarge moving tablePiezoelectric/electrostriction/magnetostriction machinesMoving speedEngineering

The invention discloses a full-displacement amplified piezoelectric inchworm linear platform, wherein, the fixed platform is provided with a slideway; a mover is arranged in the slideway; the mover comprises a first frame body and a second frame body arranged along the slideway length direction gap; the first frame body is fixedly arranged on the movable table surface; the first frame body and thesecond frame body are respectively connected with a first driving unit and a second driving unit; A bridge portion is implicated between the first driving unit and the second driving unit; The fixedplatform is provided with a first clamping group clamped on the first frame body and a second clamping group clamped on the second frame body, wherein the first clamping group and the second clampinggroup are respectively telescopically arranged along the slideway width direction; By sequencing the first clamping group, the first driving unit, the second clamping group and the second driving unit, the mover and the movable table are inchworm-like traveled and positioned along the slideway. The invention has the advantages of compact structure, large movable table surface, low requirement formachining and assembling precision of the clamping unit and the driving mechanism, sufficient clamping and releasing, power-off clamping, fast moving speed and small moving error.

Owner:NINGBO UNIV

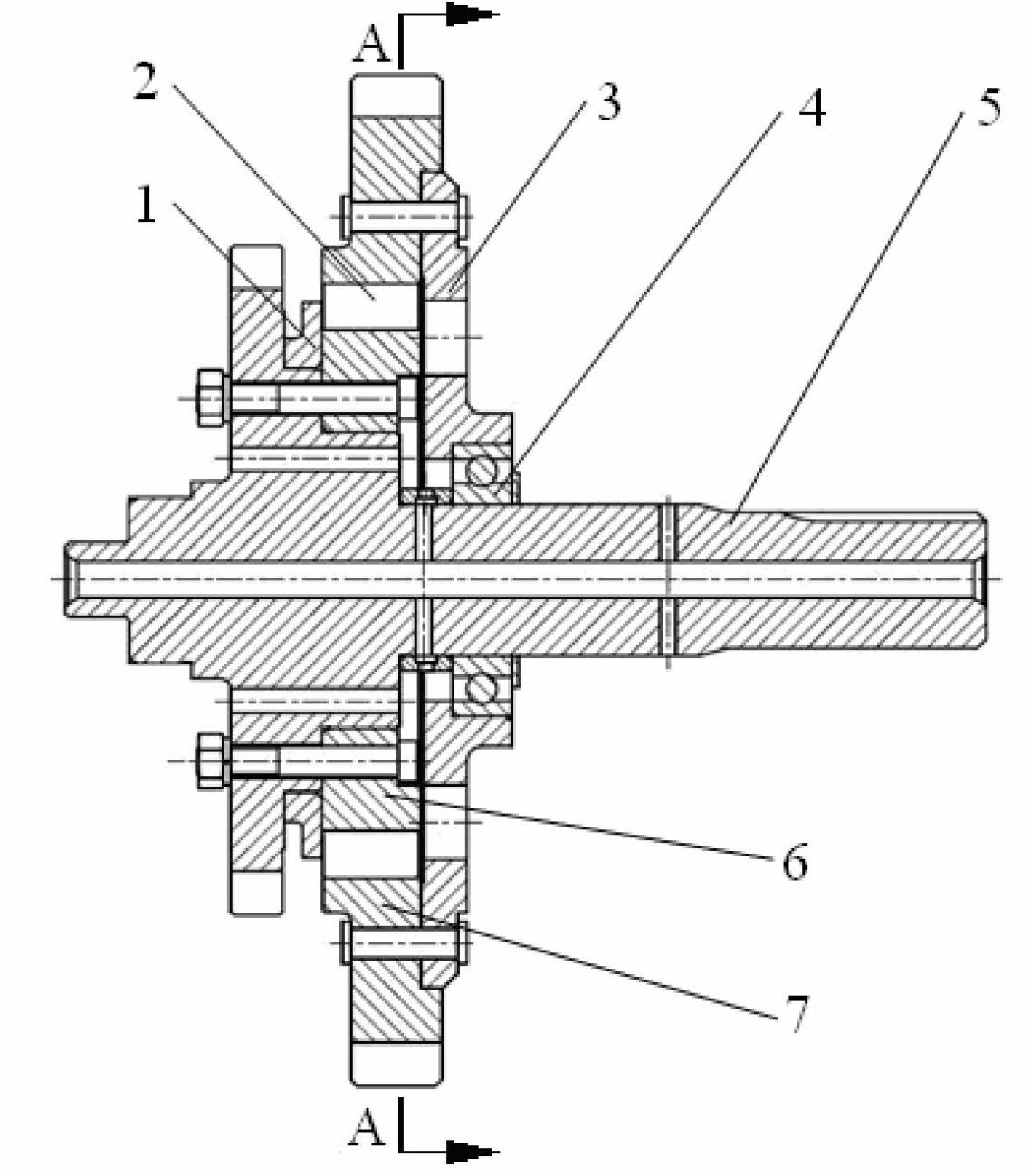

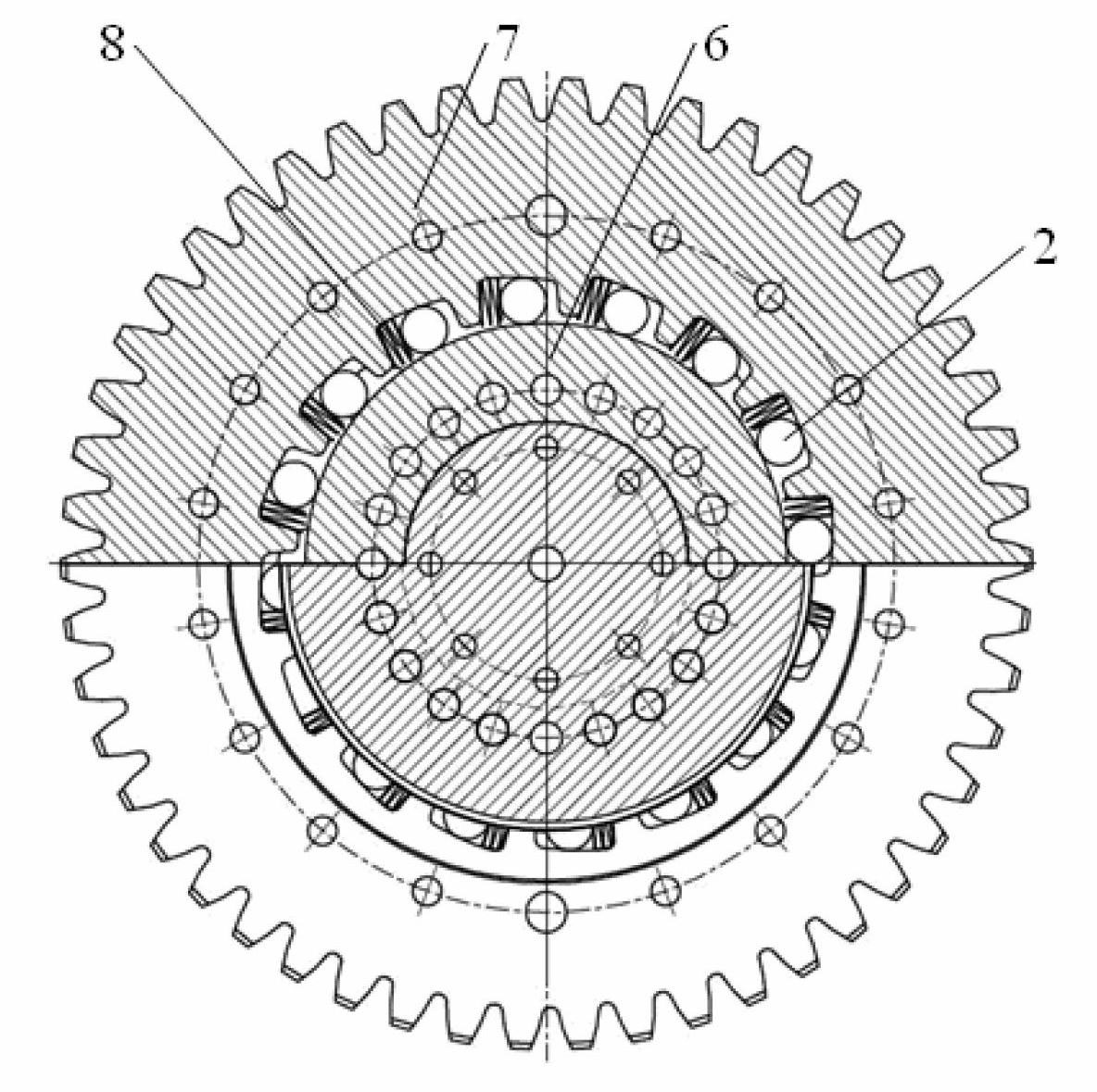

Overrunning clutch for confluence mechanism of double-turbine hydraulic torque converter

InactiveCN102661337AImprove stress conditionImprove the stress condition of the structureFreewheel clutchesLocking mechanismEngineering

The invention relates to an overrunning clutch for a confluence mechanism of a double-turbine hydraulic torque converter. A cam surface of a self-locking mechanism is arranged in an inner bore of an outer ring gear, and an inner planetary gear is of a cylindrical surface. The outer ring gear is positioned on a middle shaft gear and positioned by utilizing self locking of a deep groove ball journal and a pin roller, thus changing the existing three-point over-positioning structure. The outer ring gear of the overrunning clutch has low rotation speed, and the pin roller is arranged on the cam surface of the outer ring gear, thus greatly reducing the self radial centrifugal force; and furthermore, no normal action force exists in the contact process of the pin roller and the inner planetary gear, thus avoiding frictional wear and prolonging the service life. The inner planetary gear and the middle shaft gear adopt an equal length locating surface structure, and the stress surface can not generate plastic deformation due to increasing of a load, thus improving the bearing capacity of parts. The left side of the pin roller is limited by a baffle plate and the right side of the pin roller is limited by a supporting disc in the axial direction. The structure form that the cam surface of the existing overrunning clutch is arranged on the inner planetary gear is changed, the machining is simple and convenient and the manufacturing cost is low.

Owner:JILIN UNIV

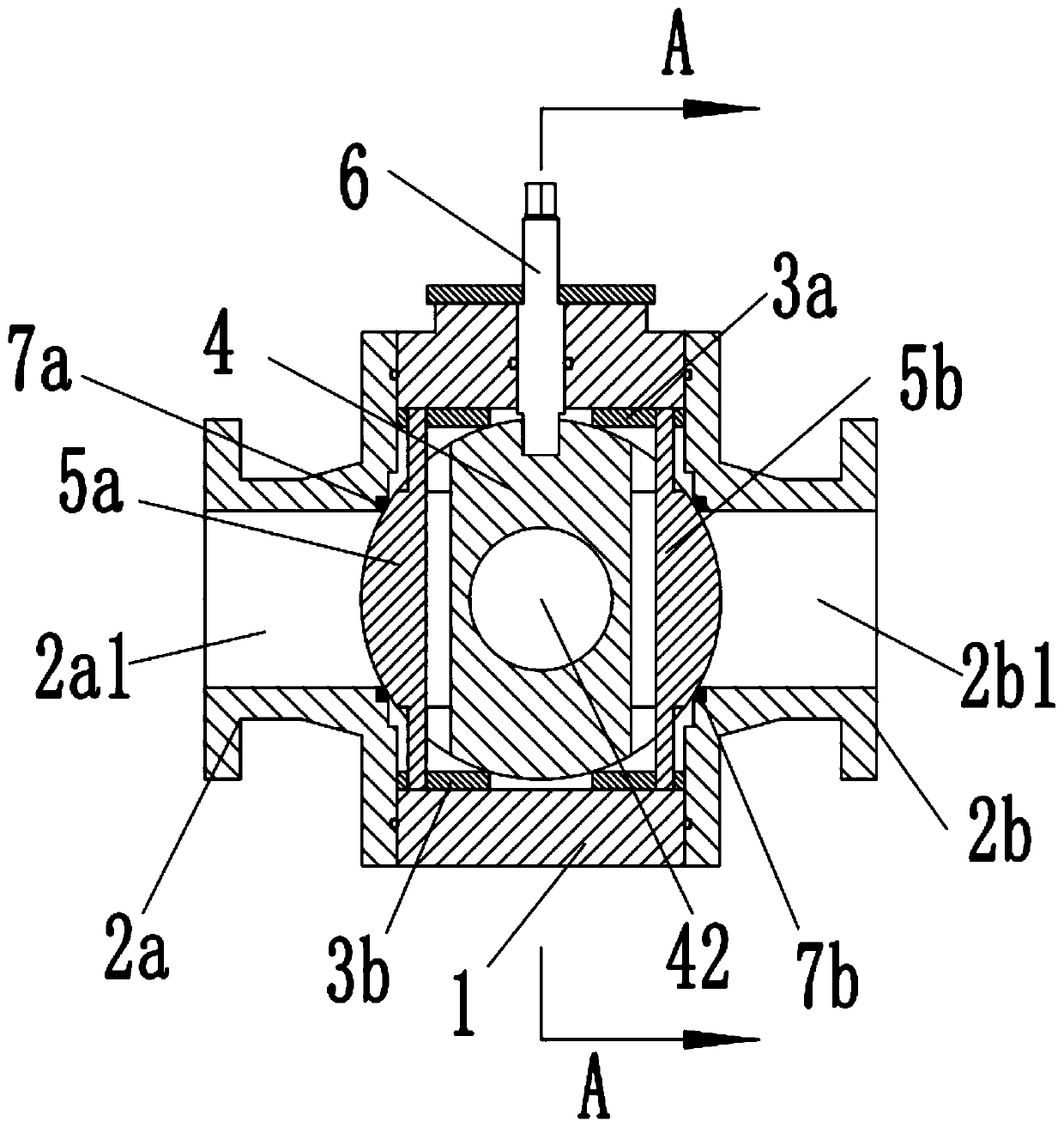

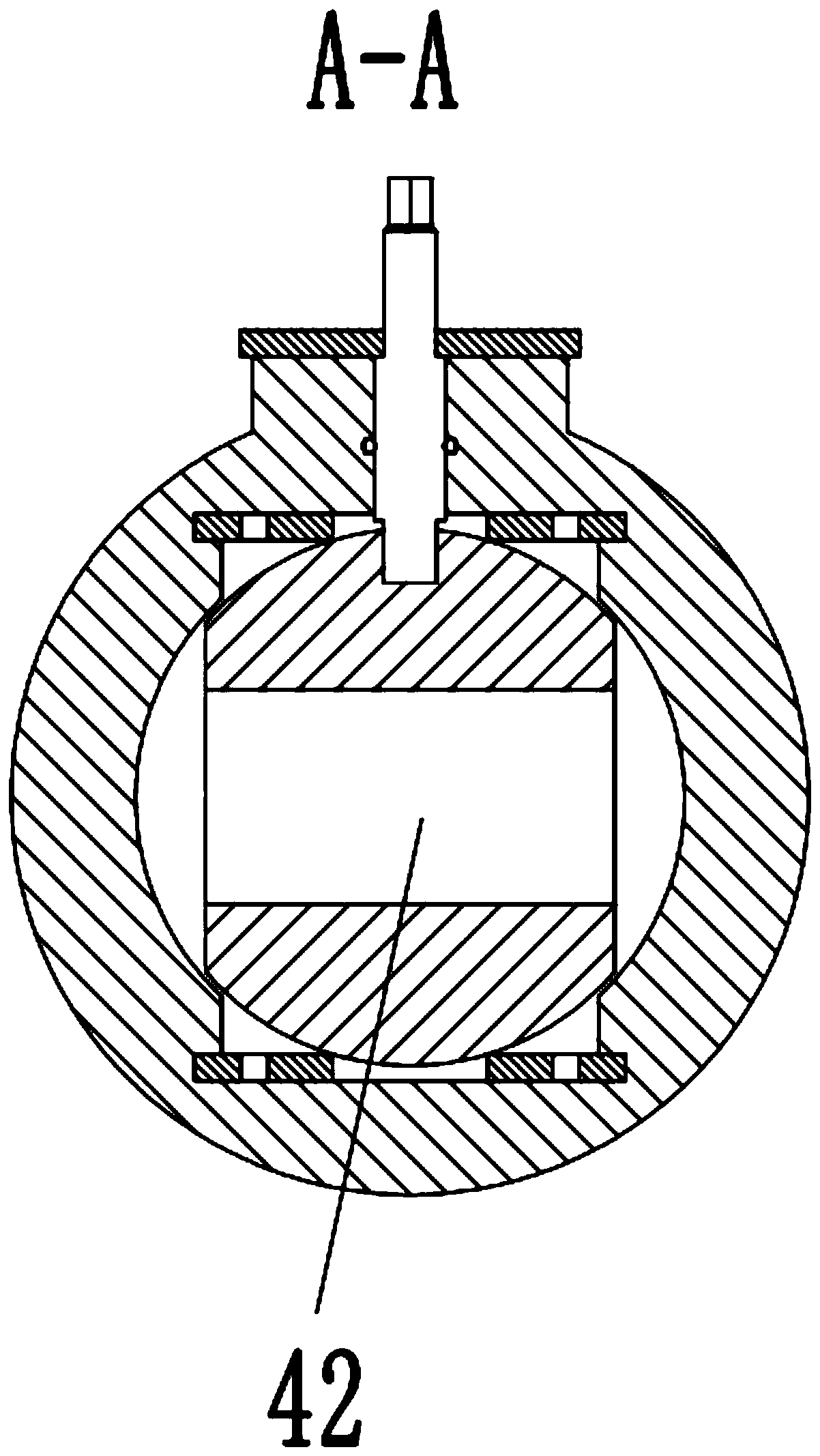

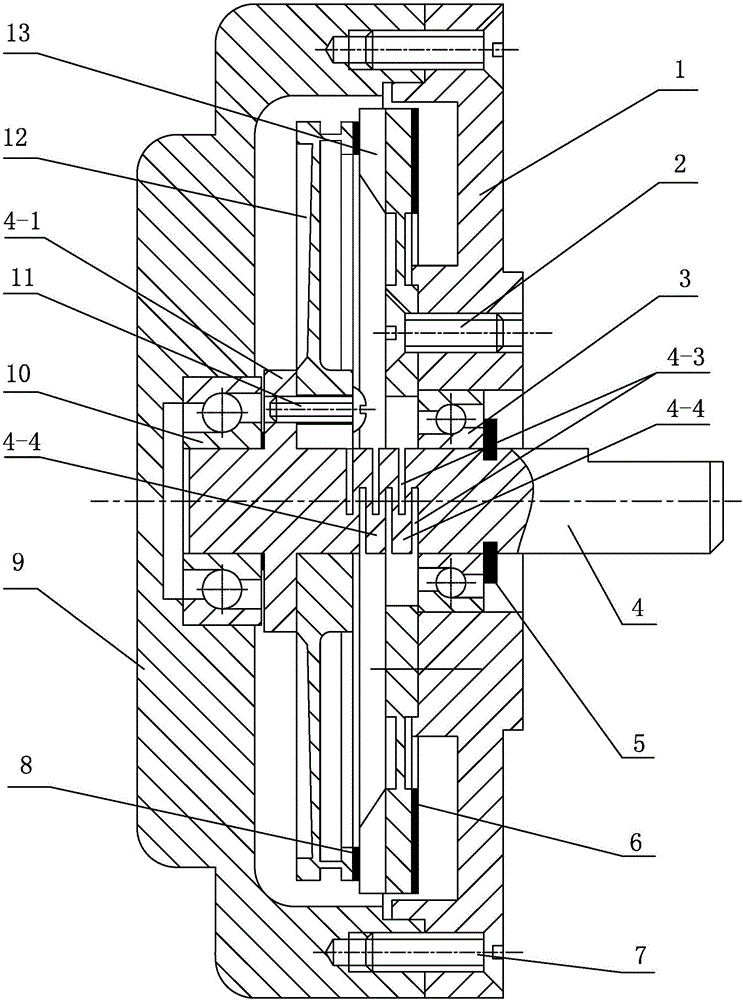

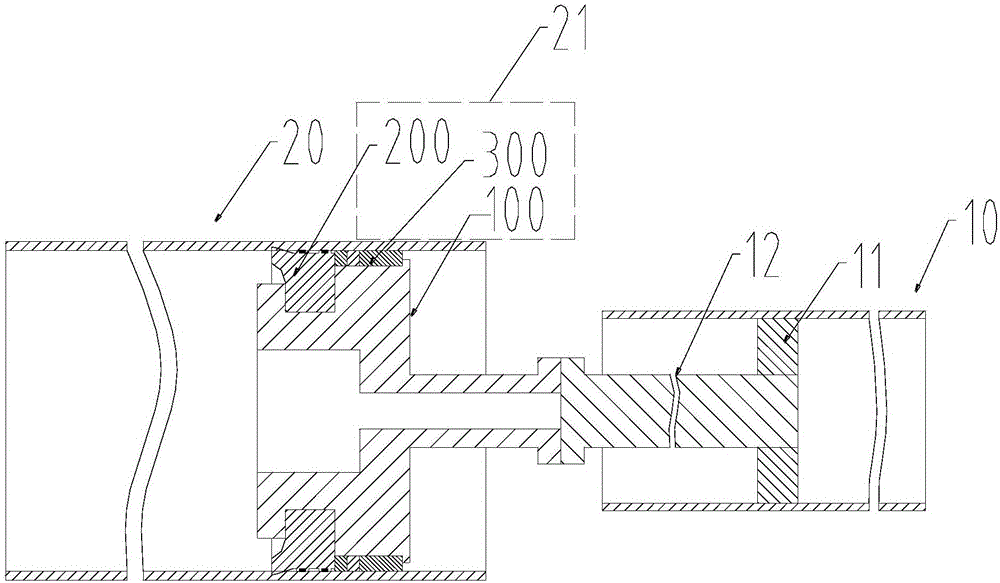

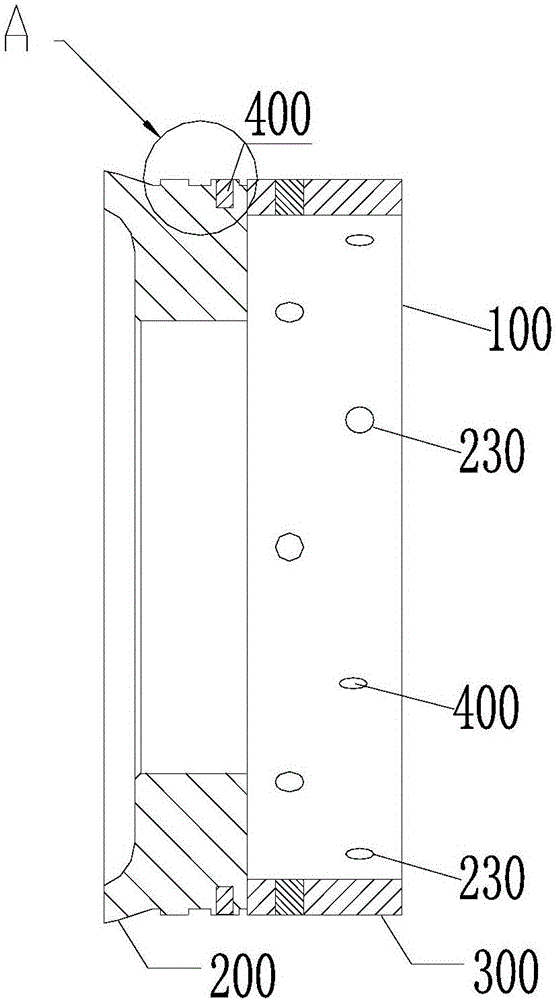

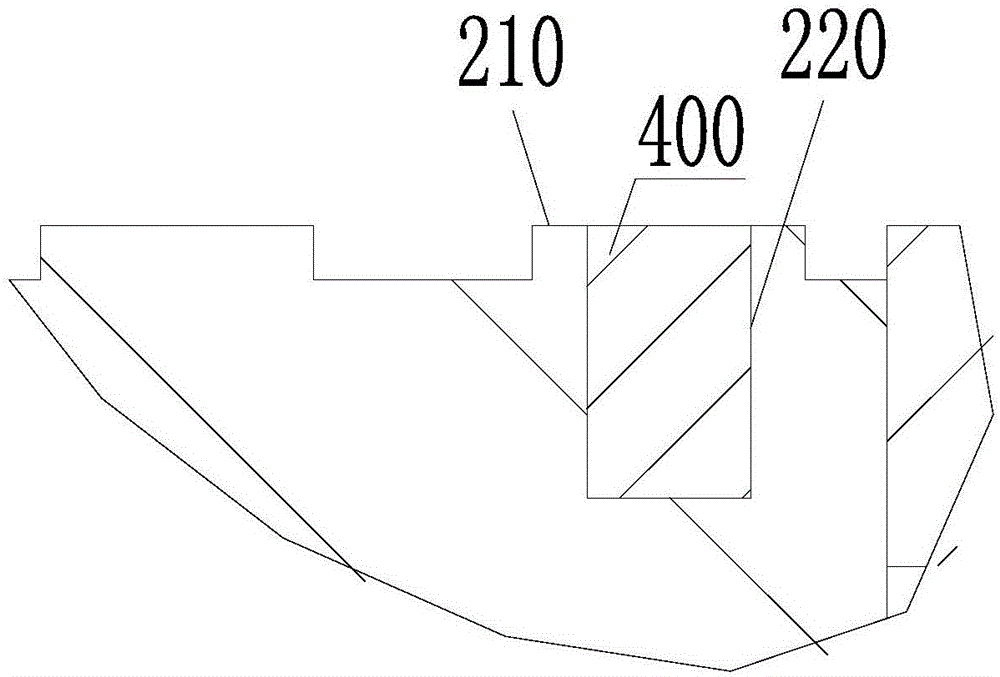

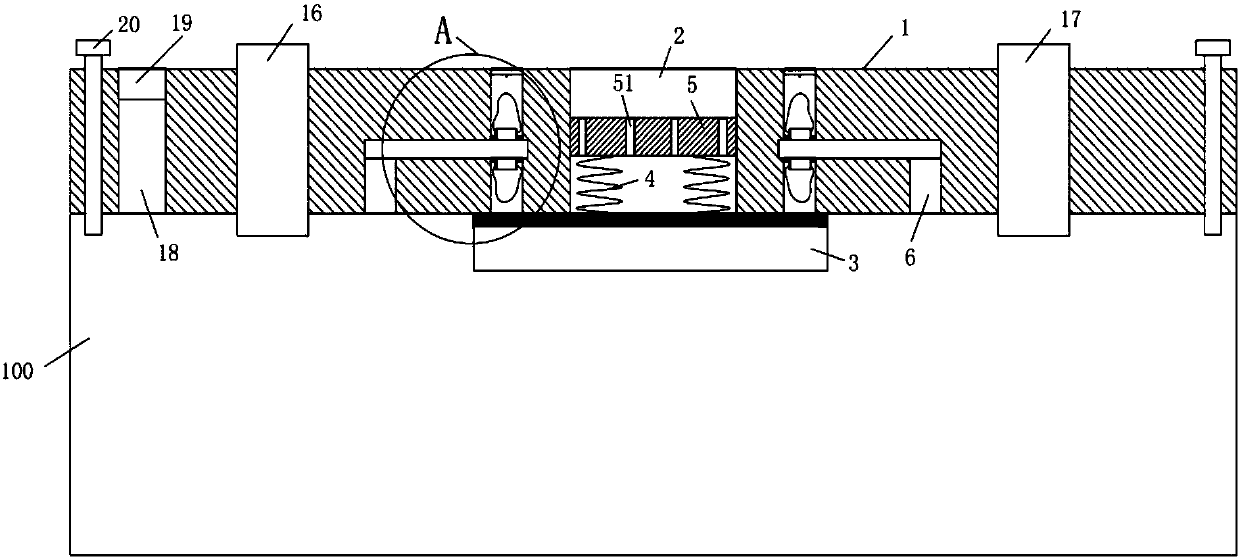

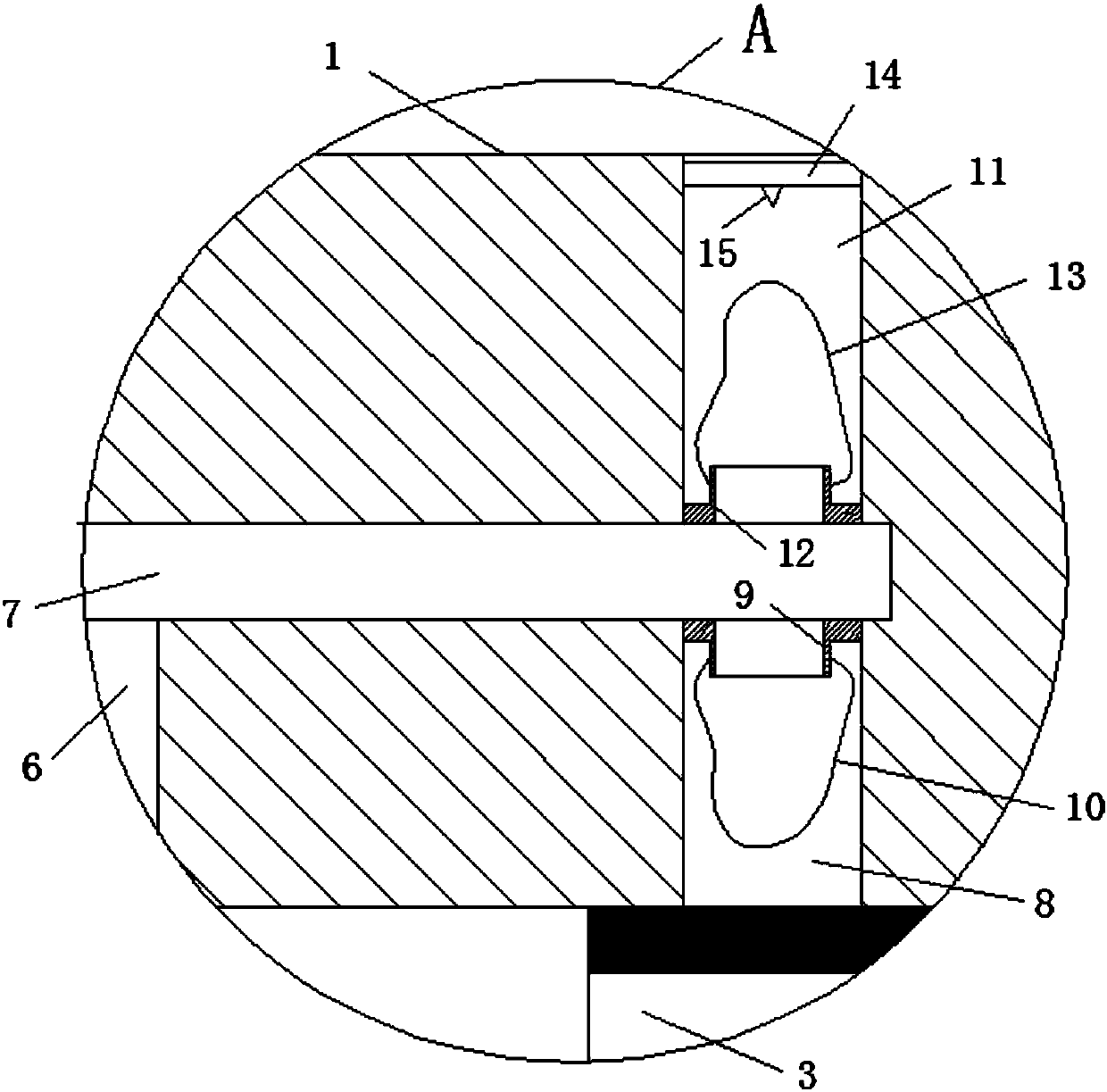

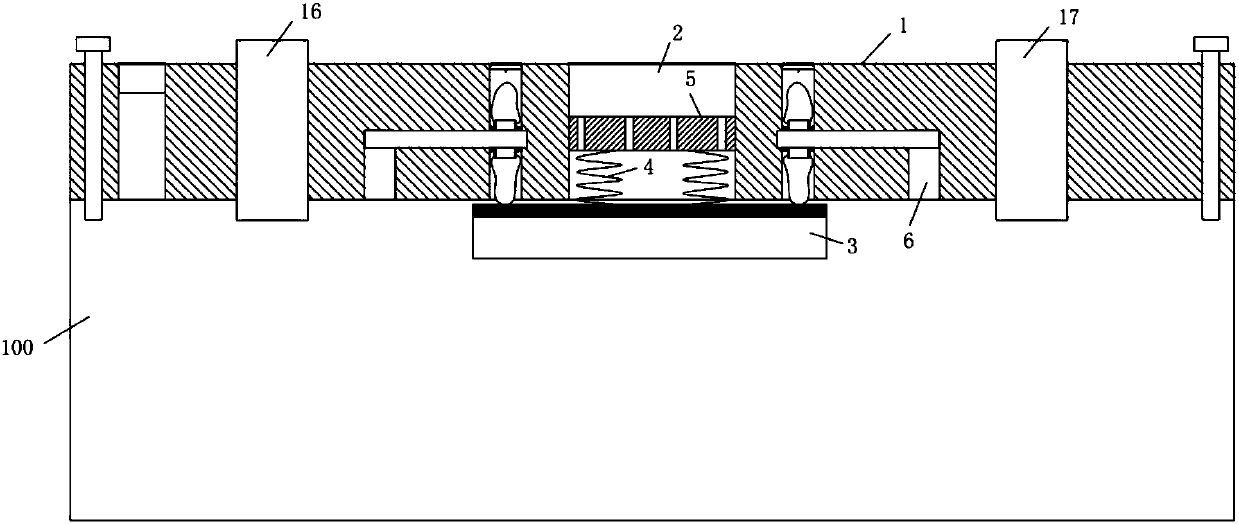

Ball valve

ActiveCN110185812ANo friction and wearExtended service lifePlug valvesValve housingsDrive shaftEngineering

The invention relates to a ball valve which comprises a valve body, a left valve bonnet, a right valve bonnet, an upper guide plate, a lower guide plate, a valve ball, a left valve clack, a right valve clack and a drive shaft, wherein a cavity, an upper rectangular groove and a lower rectangular groove are formed in the valve body; the left valve bonnet and the right valve bonnet are fixedly mounted at two ends of the valve body respectively; the upper guide plate and the lower guide plate are arranged in the upper rectangular groove and the lower rectangular groove respectively, and have thesame structure, which comprises a support hole, a first cambered groove and a second cambered groove; the valve ball is rotationally arranged in the cavity; a left valve cavity and a right valve cavity are formed in the valve ball; the left valve clack and the right valve clack are arranged in the left valve cavity and the right valve cavity respectively; and the drive shaft is used to drive the valve ball to rotate. In the process of opening the ball valve, the left valve clack and the right valve clack are free of friction and wear, so that the service life can be prolonged.

Owner:TEJI VALVE GRP

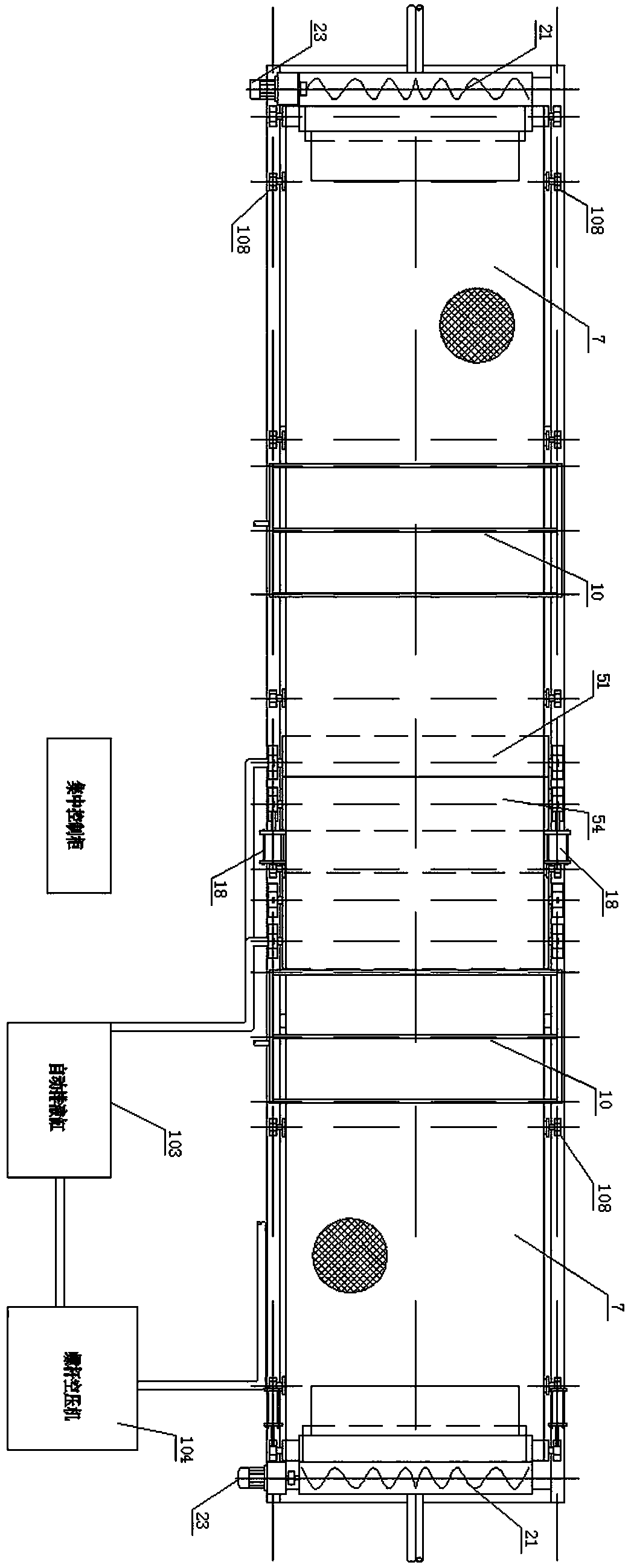

Novel belt type vibratory rolling filtering device

ActiveCN108211478AExtended service lifePrevent extrusionMoving filtering element filtersMechanical engineeringLiquid content

The invention provides a novel belt type vibratory rolling filtering device. The novel belt type vibratory rolling filtering device comprises belt type vibratory rolling filtering machines which are oppositely arranged, wherein each filtering machine comprises a rack; the rack comprises an upper supporting frame and a lower supporting frame; a layering distribution device is arranged at the upstream end of the upper supporting frame; in the material flowing direction, the rack is provided with a guiding roll, a vibrating part, a driving rolling part and a tensioning roll in sequence; a ring-shaped filtering belt is arranged around the guiding roll, the vibrating part, the driving rolling part and the tensioning roll; the left driving rolling part comprises a first extruding and dewateringroller positioned on the upper supporting frame and a second driving electric roller positioned on the lower supporting frame; the right driving rolling part comprises a second extruding and dewatering roller positioned on the lower supporting frame and a first driving electric roller positioned on the upper supporting frame; extruding gaps are respectively formed between the first extruding and dewatering roller and the first driving electric roller, between the two filtering belts surrounding the left driving rolling part and the right driving rolling part and between the second extruding and dewatering roller and the second driving electric roller. The novel belt type vibratory rolling filtering device provided by the invention has the advantages that the liquid content of filter cakesis low and the productivity is improved.

Owner:贾守民 +1

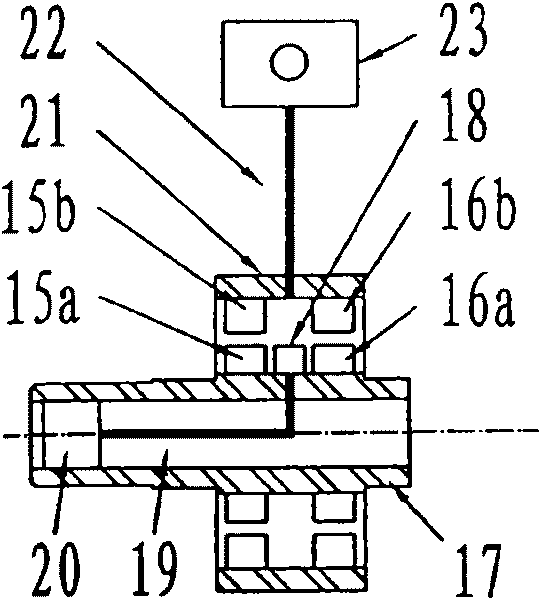

Traveling wave ultrasonic motor containing flexible shaft

ActiveCN106374775AEliminate playImprove running stabilityPiezoelectric/electrostriction/magnetostriction machinesElectricityPrism

The invention discloses a traveling wave ultrasonic motor containing a flexible shaft, relates to the traveling wave ultrasonic motor, and aims to solve the problems of poor uniformity of contact between a stator and a rotor and low operational stability of the motor of the existing traveling wave ultrasonic motor. The traveling wave ultrasonic motor comprises a base, a front angular contact ball bearing, a shell, the flexible shaft, a back angular contact ball bearing, a stator and a rotor, wherein the shell and the base are detachably connected; the flexible shaft is mounted on the front angular contact ball bearing and the back angular contact ball bearing; the rotor and the stator are arranged between the front angular contact ball bearing and the back angular contact ball bearing; the rotor and the shell are arranged adjacently, and are mounted on an annular convex prism of the flexible shaft; the stator is mounted on the base; a layer of annular friction material which is in contact with the stator is paved on the end plane of the rim of the rotor; an annular piezoelectric ceramic layer is paved on the end plane, close to the base, of the stator; and a flexible hinge structure or a flexible foldable beam structure is machined on the shaft section of the flexible shaft positioned between the rotor and the stator. The traveling wave ultrasonic motor is used for accurate driving.

Owner:NINGBO UNIV

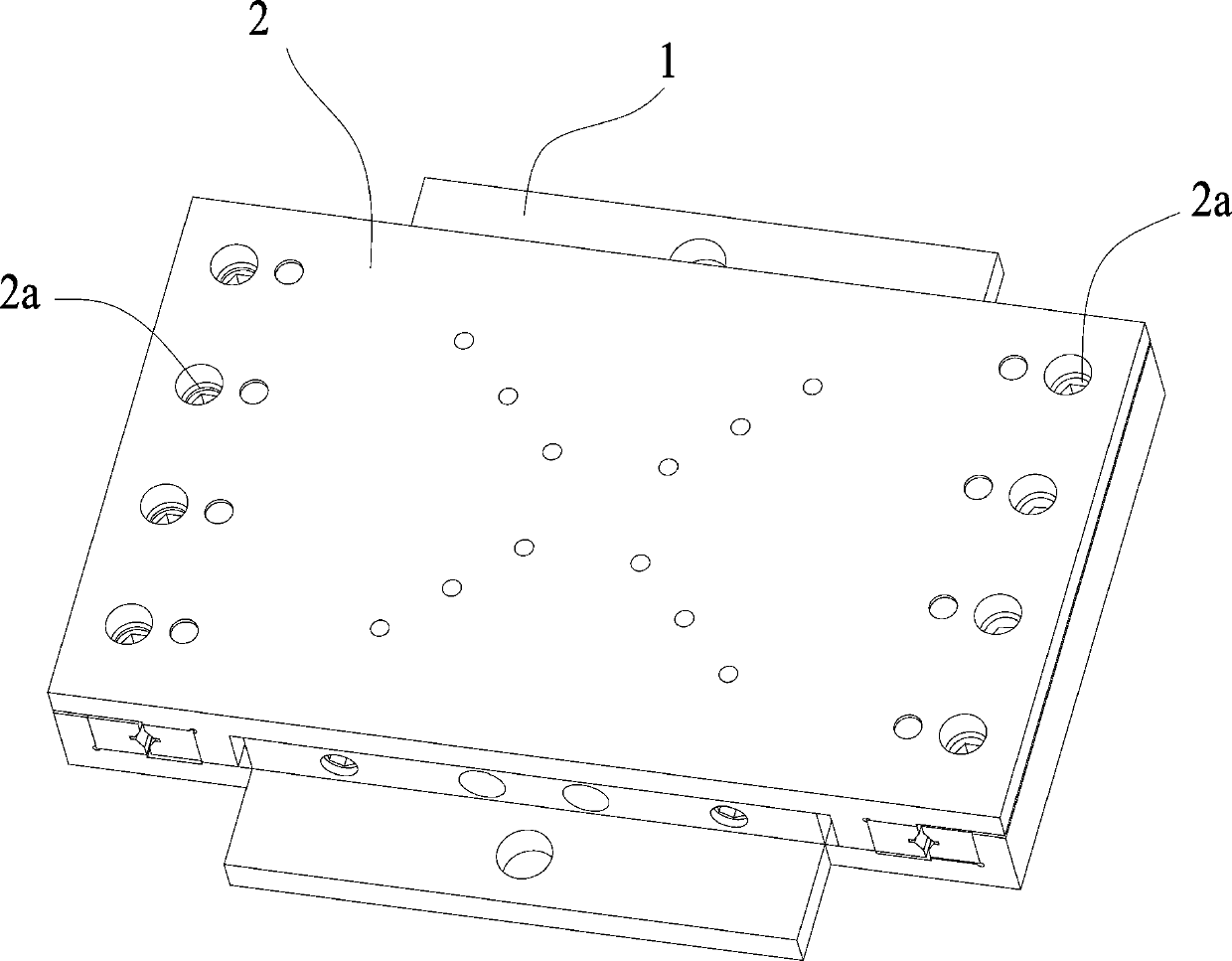

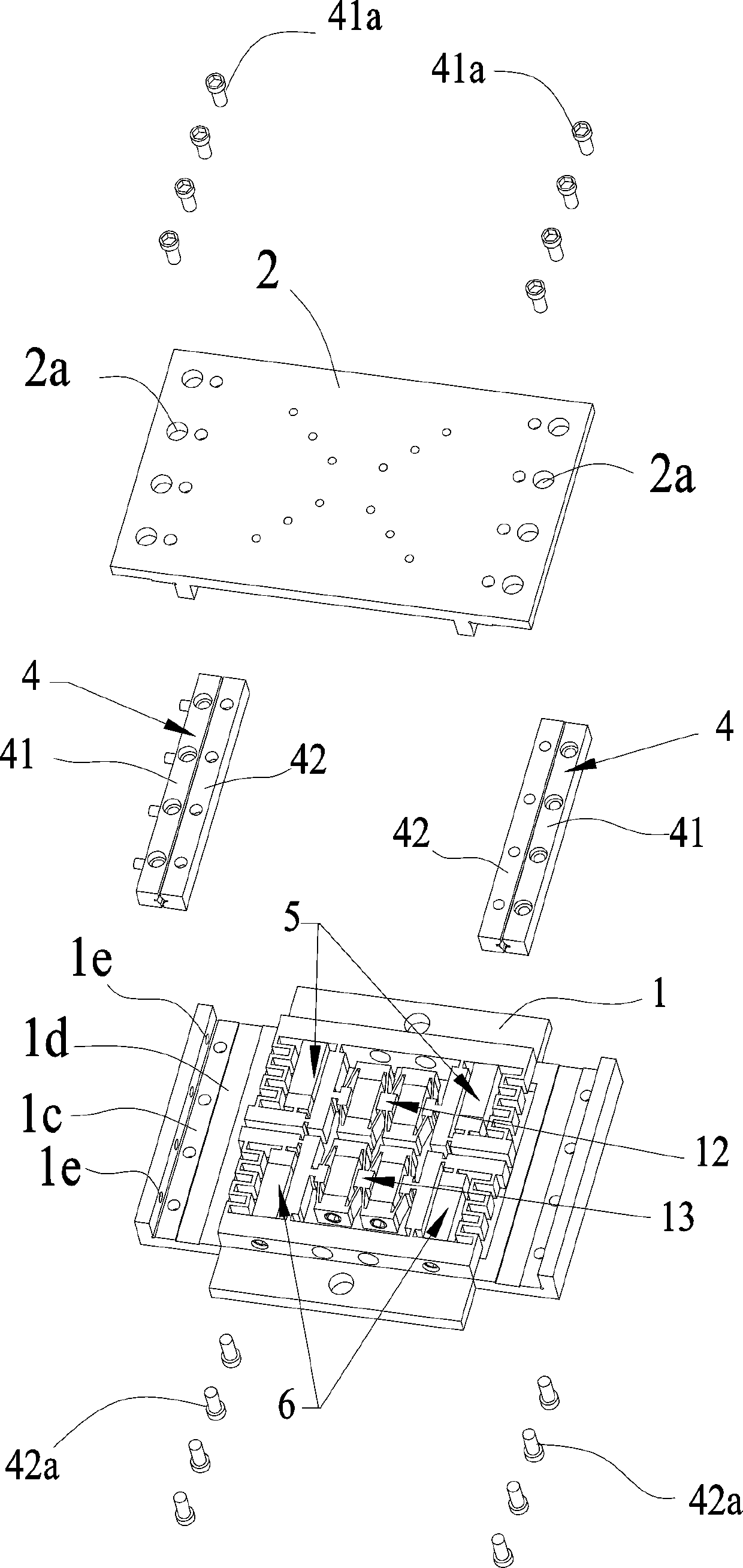

Structurally integrated in-situ actuation fully-displaced composite amplified piezoelectric inchworm linear platform

ActiveCN109104118ACompact platformLarge moving tablePiezoelectric/electrostriction/magnetostriction machinesMoving speedEngineering

A structurally integrated in-situ actuation fully-displaced composite amplified piezoelectric inchworm linear platform comprises a fixed platform and movable platform tops slidably connected through two cross roller guide rails, and stopper bars are arranged below the movable platform tops. A first clamping group and a second clamping group, and a first driving group and a second driving group arearranged between the two stopper bars, and driving units make telescopic movement along the length direction of the stopper bars; each driving unit comprises a clamping arm connected with the telescopic end of the driving unit, the clamping arms release and clamp the stopper bars, and a movable gap is arranged between the adjacent clamping arms. The first clamping group, the first driving group,the second clamping group and the second driving group are sequentially controlled to make the movable platform tops walk and position in an inchworm-like manner. The platform has the advantages of compact structure, large movable table tops, integrated clamping and driving mechanism, low requirement for the machining and assembling precision of the clamping and driving mechanism, sufficient clamping and releasing, power-off clamping, fast moving speed and small moving error.

Owner:NINGBO UNIV

Concrete piston, pumping system and concrete pump

InactiveCN106481542AReduce direct contactReduce frictionPositive displacement pump componentsPumpsFriction lossLubrication

The invention discloses a concrete piston, a pumping system and a concrete pump. The concrete piston comprises a piston body, a seal body and a guide ring, wherein the seal body and the guide ring are arranged at the front end and the back end of the piston body in the circumferential direction correspondingly. The concrete piston is characterized in that the seal body or / and the guide ring is / and further embedded with solid lubricant. Because the seal body or / and the guide ring is / and further embedded with the solid lubricant, the self-lubricating effect can be achieved, a solid lubrication film is formed between friction contact faces, and direct contact and friction between the friction faces are reduced; and in this way, the friction loss among the seal body and the guide ring of the concrete piston and a conveying cylinder can be lowered without the dependence on external supply, and the service lives of the concrete piston and the conveying cylinder are prolonged. When inputting of external lubricating grease is discontinuous or interrupted, a good lubricating effect is still kept, and the non-lubrication working condition and the dry friction working condition are avoided. Besides, automatic and continuous feeding of the external lubricating grease can be changed to manual and intermittent feeding, the use cost is lowered, and lubricating configuration is simplified.

Owner:SANY AUTOMOBILE MFG CO LTD

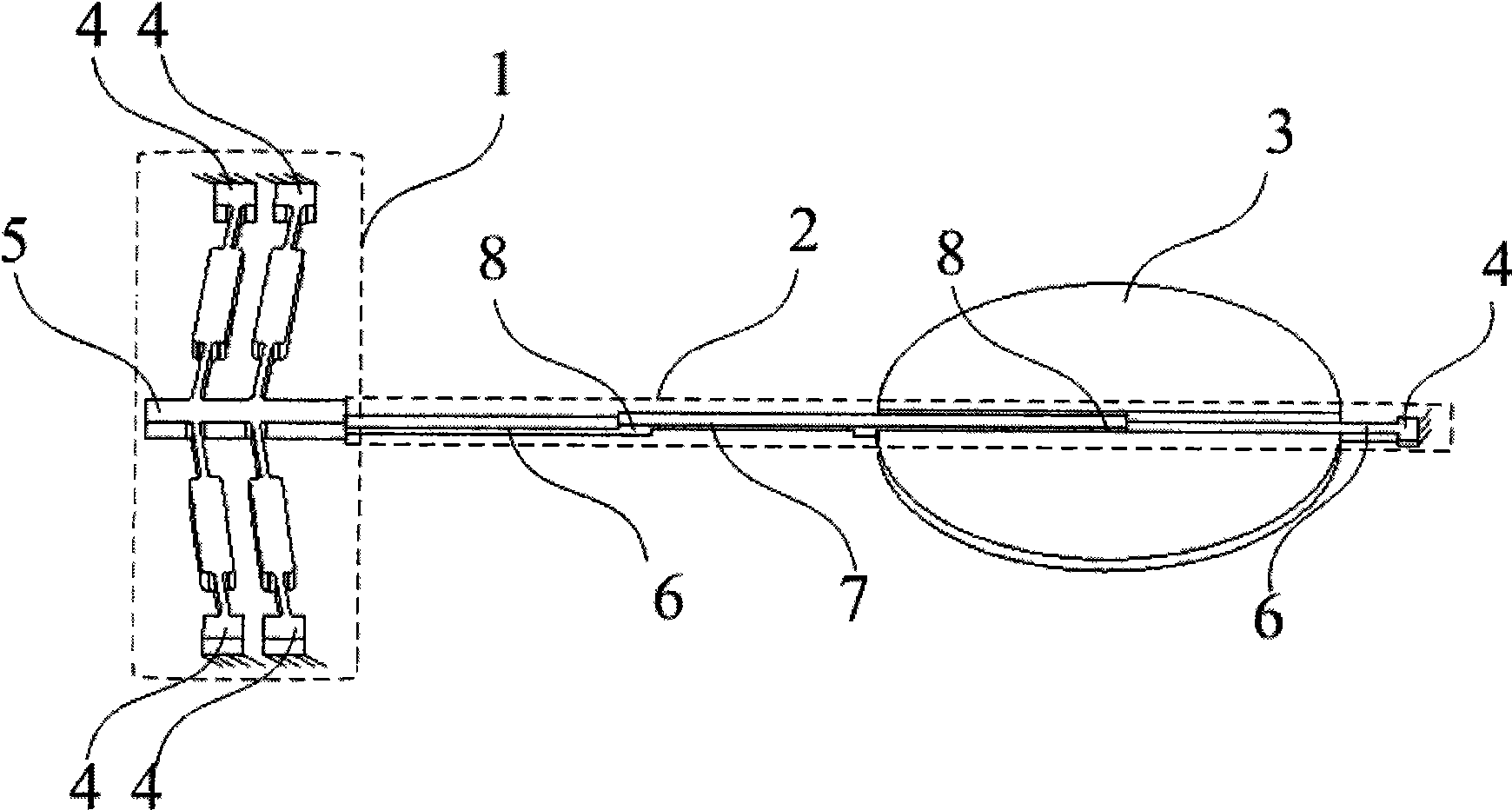

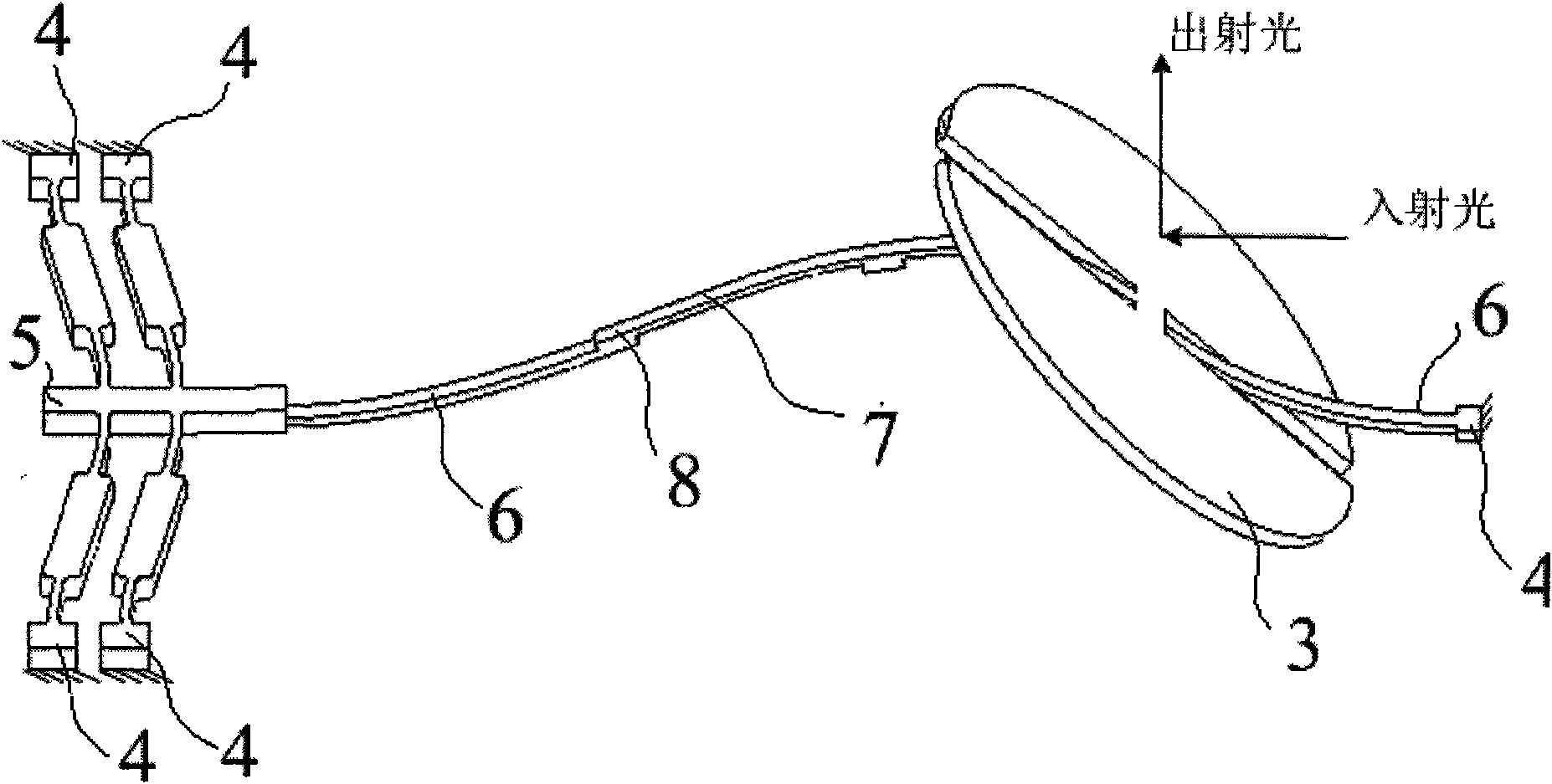

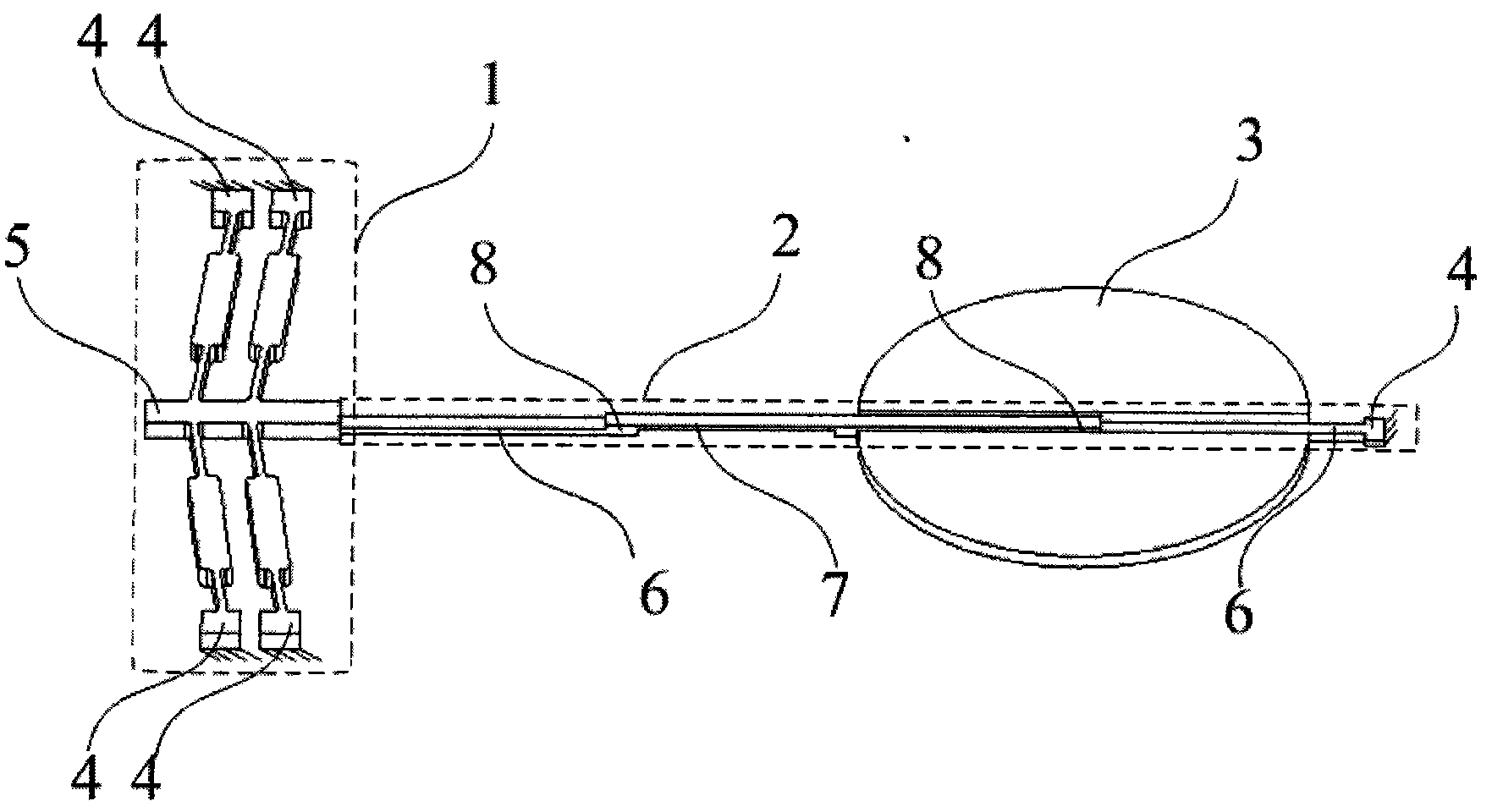

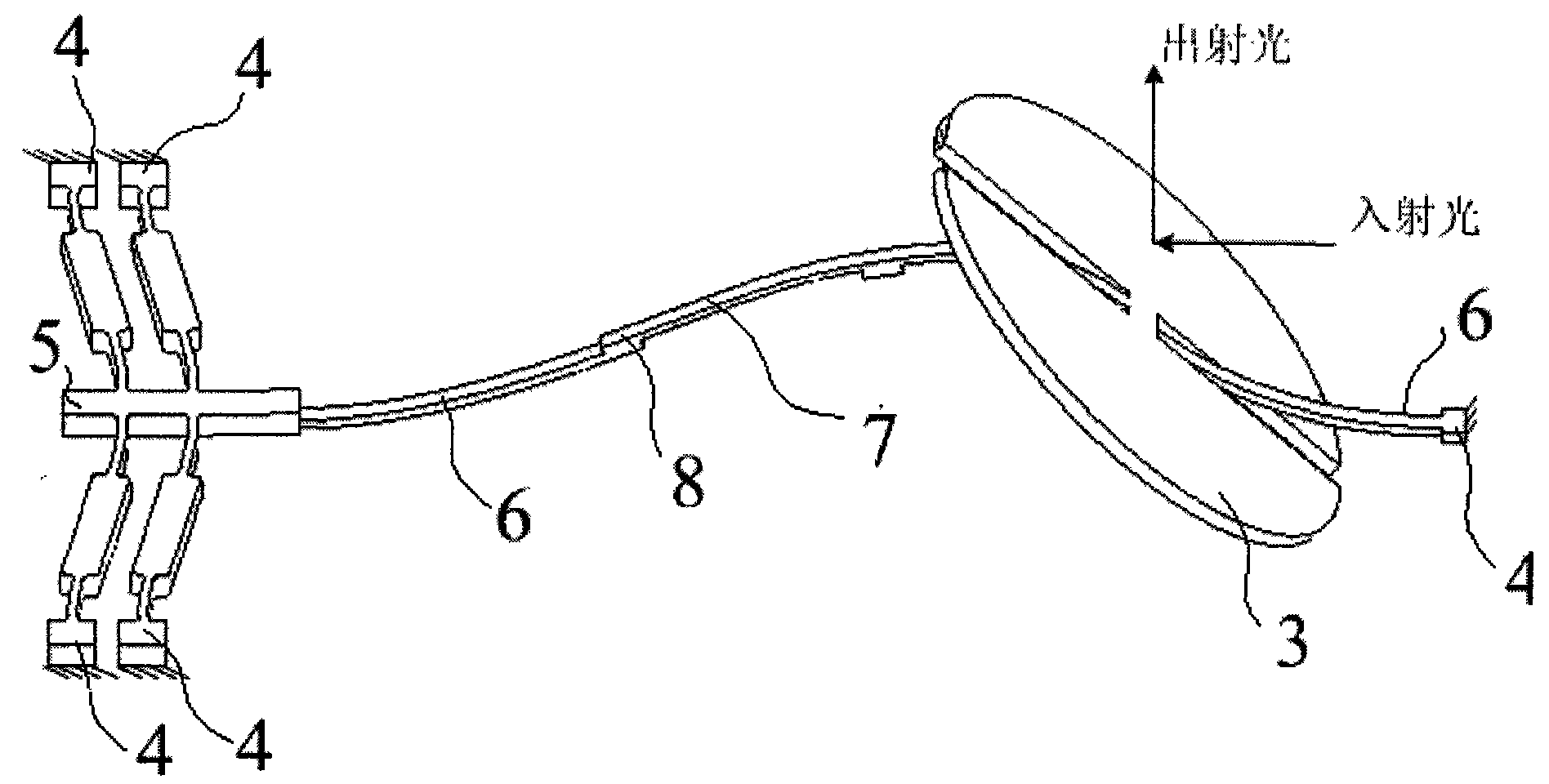

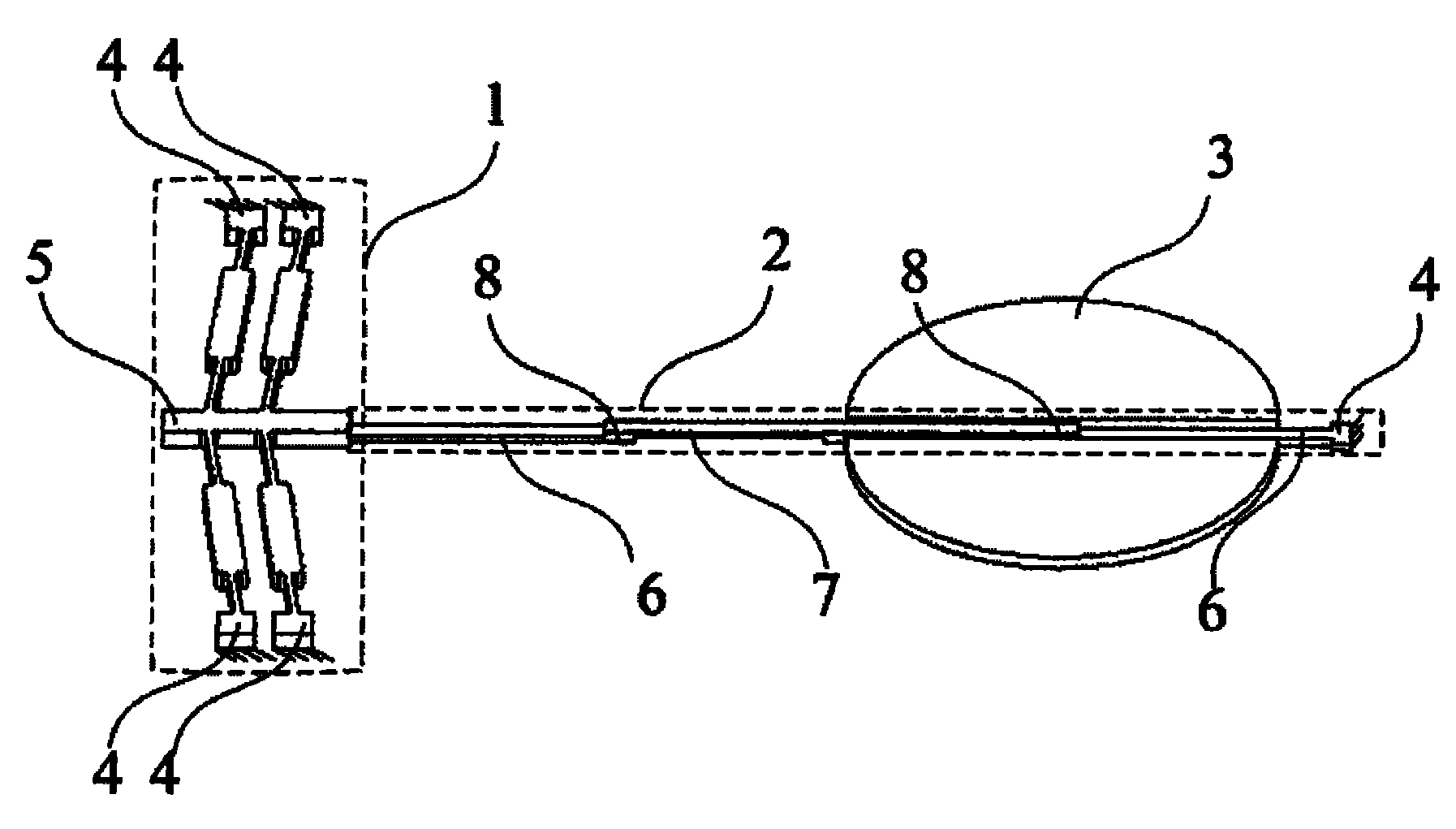

Fully flexible MEMS optical switch

InactiveCN101561556ALow processing technology requirementsSimple structureOptical elementsStable stateOptical communication

The invention relates to an optical switch, in particular to a fully flexible MEMS optical switch, belonging to the technical field of optical fiber communication. The invention is characterized by comprising a flexible bi-stable mechanism (1) and a micro reflector (3), a shuttle (5) of the flexible bi-stable mechanism (1) is connected with a flexible bridge (2), the micro reflector (3) is fixed with the flexible bridge (2) by a connecting block (8), the first stable state position and the second stable state position of the flexible bi-stable mechanism (1) respectively lead the micro reflector (3) to be in a light passing state and a light reflecting state. The invention provides an MEMS switch with simple structure, low manufacture cost, good stability, high repeatability precision, no frictional wearing and strong interference rejection capability.

Owner:XIDIAN UNIV

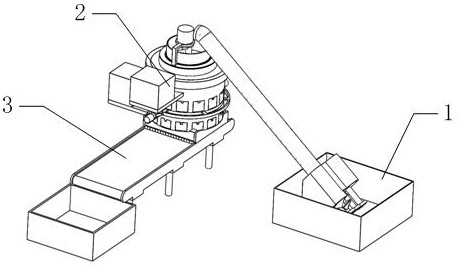

Green and environment-friendly stone powder treatment device for machine-made sand production

The invention belongs to the technical field of stone powder treatment, and particularly relates to a green and environment-friendly stone powder treatment device for machine-made sand production. The green and environment-friendly stone powder treatment device for machine-made sand production comprises a feeding module, a treatment module and a transportation module. According to the green and environment-friendly stone powder treatment device for machine-made sand production provided by the invention, machine-made sand can directly fall to the upper side of a transportation mechanism in the stone powder removal process, and friction abrasion between the machine-made sand and the inner wall of a treatment shell is avoided. A filter ring designed in the invention can prevent stone powder from entering the upper end of a first channel to damage a first air pump. According to the green and environment-friendly stone powder treatment device for machine-made sand production provided by the invention, through the design of the width of a discharging hole, the machine-made sand falling from the discharging hopper falls in the radial direction of the treatment shell in a thin form, so that after the stone powder in the falling machine-made sand is blown by air in a first air pipe, most of the stone powder can enter a second channel from third air holes formed in a third channel in the treatment shell, the most of the stone powder in the machine-made sand can be ensured to be removed, and the quality of the machine-made sand is improved.

Owner:三亚城投众辉新型建材有限公司

Anti-explosion device of lithium battery and lithium battery with anti-explosion device

InactiveCN107742687ARealize the effect of pressure reliefQuick releaseCell component detailsEngineeringLithium-ion battery

The invention discloses an anti-explosion device of a lithium battery. The anti-explosion device comprises a substrate and an anti-explosion mechanism arranged on the substrate, wherein the anti-explosion mechanism comprises a pressure release hole, a baffle plate, air inlet holes, connection holes, extrusion holes and an extrusion balloons; the substrate is provided with the air inlet holes on both sides of the baffle plate; one side which is close to the baffle plate of each connection hole is provided with an extrusion hole; the extrusion balloons are arranged on lower mounting sleeves. Theinvention further discloses a lithium battery. The lithium battery comprises a lithium battery body and an anti-explosion device of the lithium battery body, wherein the lithium battery body is fixedto the substrate through a screw. According to the anti-explosion device disclosed by the invention, the balloons are provided, and opening and closing of the pressure release hole are realized in cooperation with the baffle plate, so that anti-explosion pressure release can be performed; the balloons can be used repeatedly, have flexible structures, and are free from friction and abrasion, so that airtightness is not influenced; the anti-explosion device is very worthy of popularization; the anti-explosion performance of the lithium battery provided with the anti-explosion device can be improved better and more stably; the anti-explosion device is very effective.

Owner:蚌埠樱桐工业设计有限公司

Robot grinding actuator based on constant-force mechanism

PendingCN113172511ALarge output constant forceWide area of constant forceGrinding carriagesGrinding drivesEngineeringActuator

The invention relates to a robot grinding actuator based on a constant-force mechanism. The robot grinding actuator comprises a robot connecting flange, a driving mechanism, the constant-force mechanism and a grinding tool, wherein the upper end of the robot connecting flange is fixed to the tail end of an industrial robot, and the driving mechanism is coaxially mounted at the lower end of the robot connecting flange and is used for providing power for the constant-force mechanism coaxially mounted at the lower end of the driving mechanism; the grinding tool is mounted at the lower end of the constant-force mechanism; and an integrally-formed flexible constant-force mechanism body is mounted in the constant-force mechanism, and the flexible constant-force mechanism body can keep output force constant under the action of the driving mechanism for constant-force grinding on a workpiece. The robot grinding actuator has the advantages of being large in output constant force value and wide in constant force area and can adapt to complex conditions in the grinding process; and compared with an air cylinder, the flexible constant-force mechanism body is simple in structure, high in force control precision and suitable for various precision machining fields.

Owner:JISHOU UNIVERSITY

Permanent magnetic coupling adjustable-speed motor

PendingCN107317457ARun at high speedGuaranteed uptimeMagnetic circuit rotating partsPermanent-magnet clutches/brakesPermanent magnet rotorElectric machine

The invention relates to a permanent magnetic coupling adjustable-speed motor comprising a shell (1), an output shaft (2), a control structure (3), a power-driven structure and a speed adjustment structure, wherein the power-driven structure comprises an electric rotor (5) and a stator (4) arranged on the inner wall of the shell, the speed adjustment structure comprises a winding rotor (6) and a permanent magnetic rotor (7), magnetic fields of the stator and the electric rotor interact with each other to transmit the torque, and magnetic fields of the winding rotor and the permanent magnetic rotor interact with each other to transmit the torque; one of the winding rotor and the permanent magnetic rotor is fixedly connected with the electric rotor, while the other one is fixedly connected with the output shaft; the control structure is electrically connected with the winding rotor, and adjusts current or voltage of the winding rotor. The permanent magnetic coupling adjustable-speed motor can operate efficiently, is smooth in speed adjustment, large in speed adjustment range, hard in rigidity and short in axial size, and has the capacity of riding through low voltage.

Owner:JIANGSU MAGNET VALLEY TECH

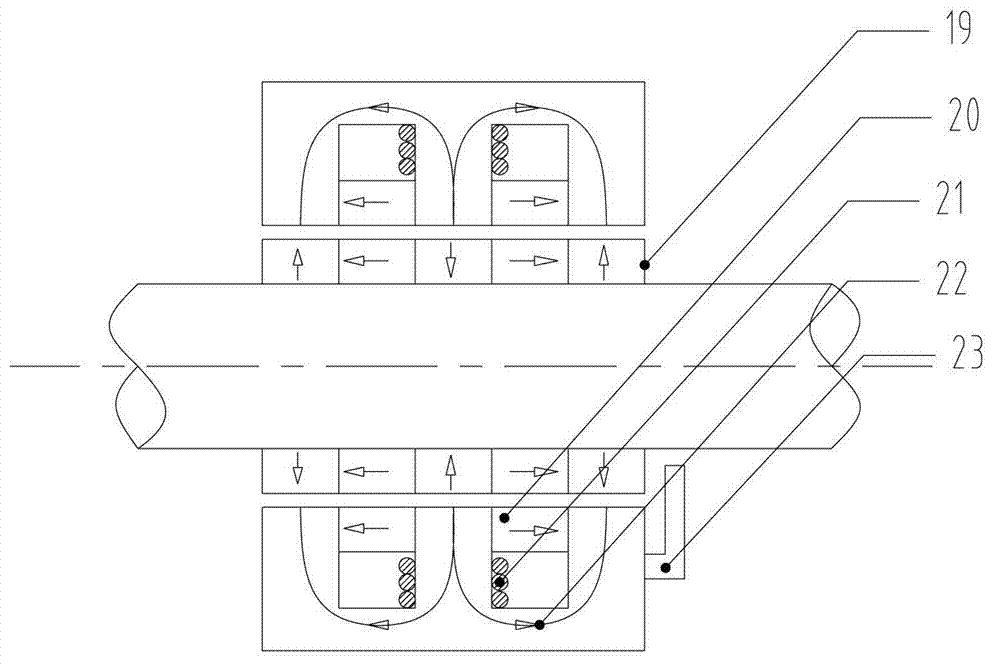

Hydraulic washing machine with triad-shaft planetary gear transmission

InactiveCN103266446ANo friction and wearNo fall damageOther washing machinesTextiles and paperElectricityHydraulic pump

The invention discloses a hydraulic washing machine with a triad-shaft planetary gear transmission and relates to a washing machine, a planetary gear reducer and a hydraulic machine. By the aid of the hydraulic washing machine, the technical problem of abrasion of materials washed by existing washing machines is solved, and technology biases of forward rotating, reversing rotating, transverse rotating, vertical rotating and various rotating of existing improved pulsator, double-power and drum washing machines are overcome. According to the technical scheme, the hydraulic washing machine simulates manual rubbing washing of clothes by two hands, different required rotating speeds of triad axes are output by the triad-shaft planetary gear transmission and transmitted to a pulsator, a hydraulic pump and an inner drum in a controlled mode through a clutch for different purposes, the double-action hydraulic machine is automatically protected and controlled by pressure electronic components to stretch and retract, a tray, the pulsator, a baffle ring and a drum cover are driven, the water-absorbent washed materials are squeezed and rubbed, produced water jets penetrate volumes of the washed materials in the drum, the adhesive power of dirt is damaged, and the dirt is removed, dissolved in the water and discharged from dehydration holes. The hydraulic washing machine has the advantages that the clothes can be cleaned without abrasion, and the time, the water and the electricity are saved.

Owner:游振兴

Fully flexible MEMS optical switch

InactiveCN101561556BLow processing technology requirementsSimple structureOptical elementsStable stateEngineering

The invention relates to an optical switch, in particular to a fully flexible MEMS optical switch, belonging to the technical field of optical fiber communication. The invention is characterized by comprising a flexible bi-stable mechanism (1) and a micro reflector (3), a shuttle (5) of the flexible bi-stable mechanism (1) is connected with a flexible bridge (2), the micro reflector (3) is fixed with the flexible bridge (2) by a connecting block (8), the first stable state position and the second stable state position of the flexible bi-stable mechanism (1) respectively lead the micro reflector (3) to be in a light passing state and a light reflecting state. The invention provides an MEMS switch with simple structure, low manufacture cost, good stability, high repeatability precision, no frictional wearing and strong interference rejection capability.

Owner:XIDIAN UNIV

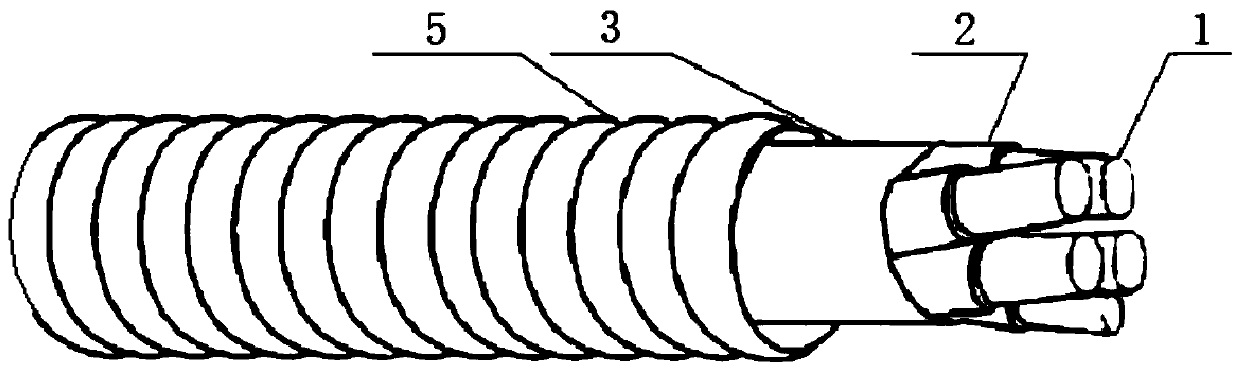

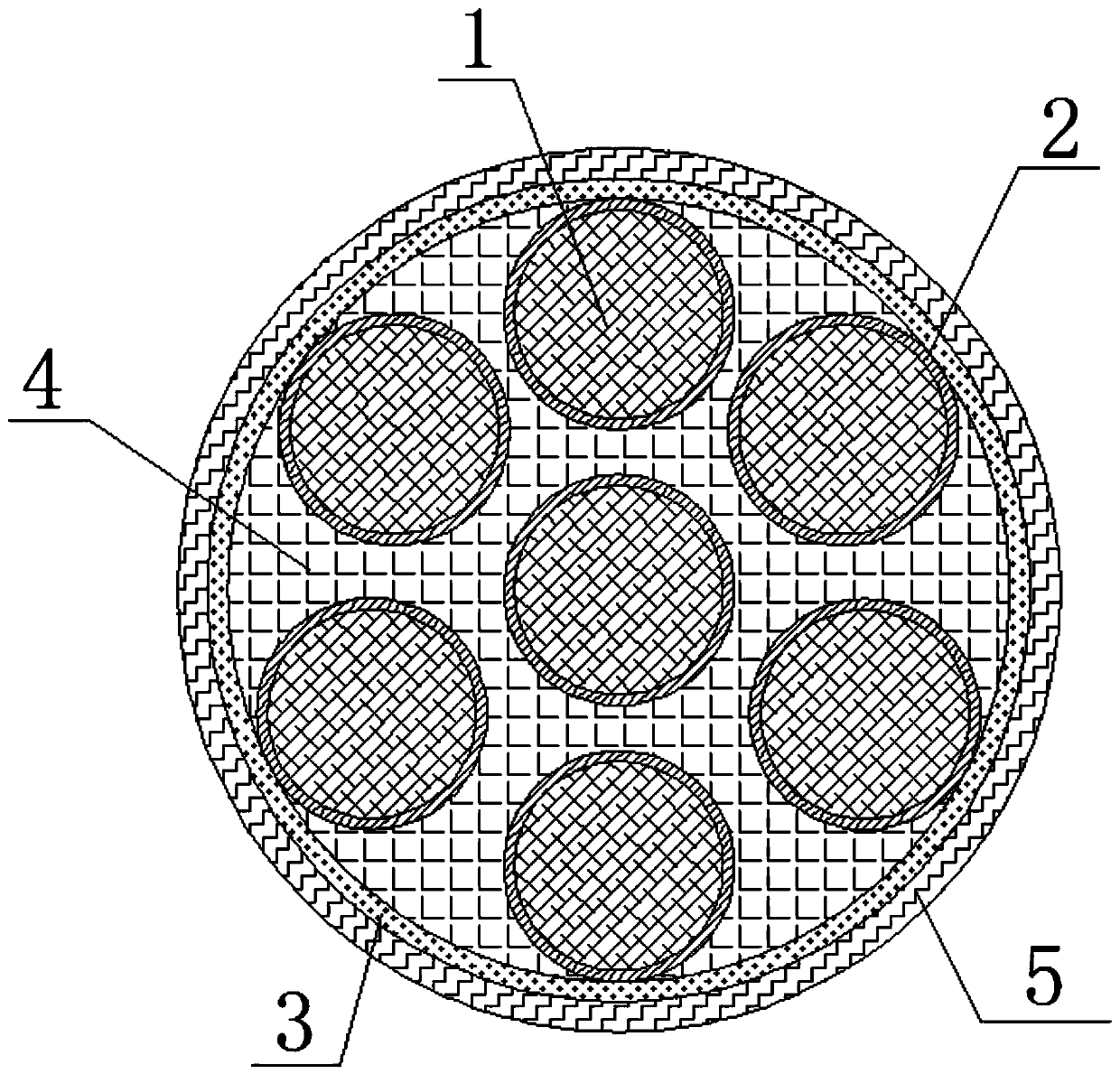

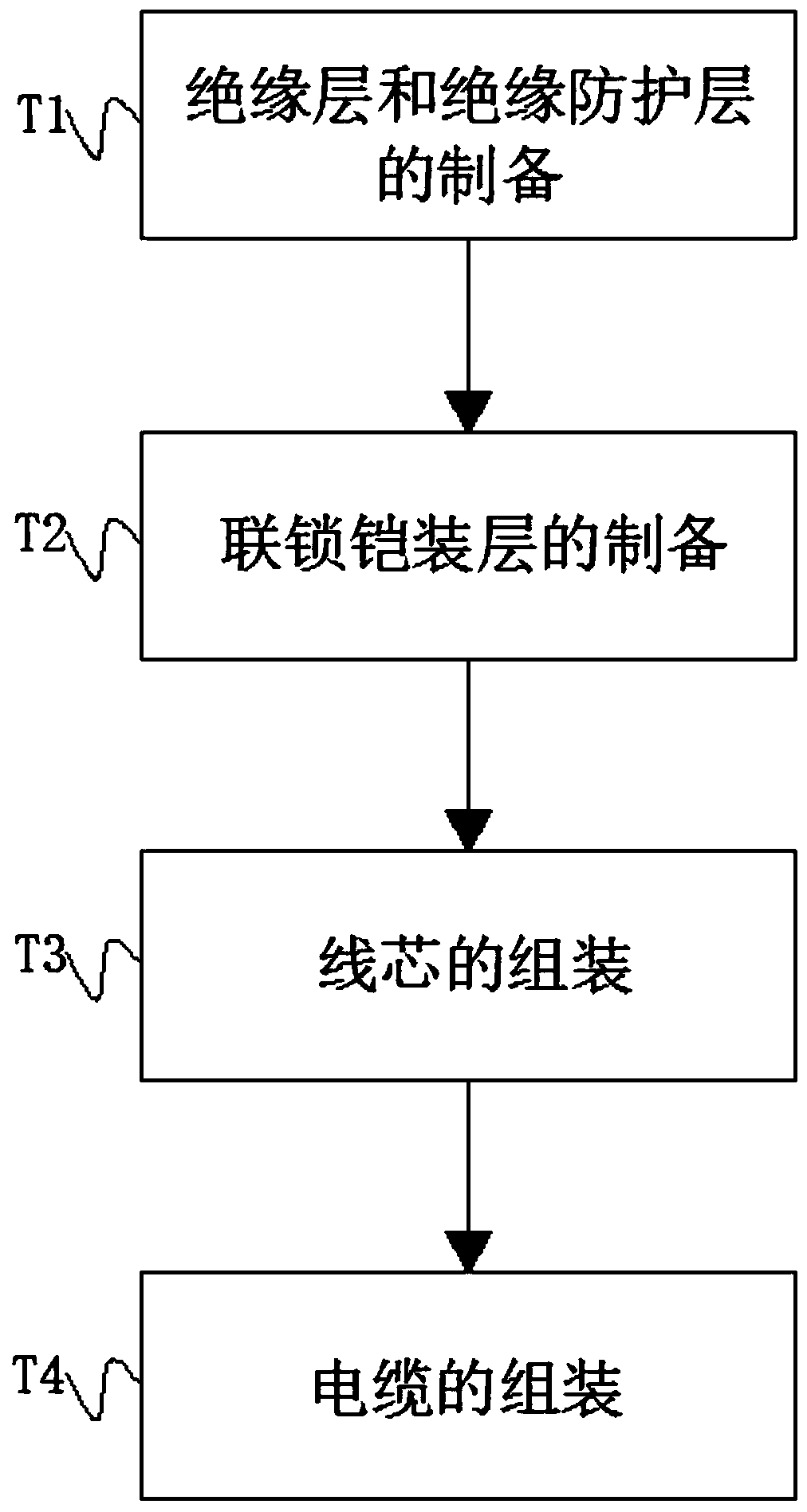

Interlocking armored cable for indoor decoration and wiring method thereof

PendingCN110148486AExtended service lifeGuaranteed long-term useInsulated cablesInsulated conductorsElectrical conductorEngineering

The present invention discloses an interlocking armored cable for indoor decoration and a wiring method thereof. The cable comprises a copper wire, the outer surface of the copper wire is coated withan insulation layer, the outer surface of the insulation layer is coated with a mylar tape layer, a gap between the mylar tape layer and the insulation layer is filled with an insulation protection layer, and the outer surface of the mylar tape layer is coated with an interlocking armored layer. The present invention relates to the technical field of indoor decoration. The interlocking armored cable for indoor decoration and the wiring method thereof improve the impact resistance, corrosion resistance and tensile strength of the interlocking armored cable, achieve the good insulation and heatconduction processing between the conductors, achieve the purposes of performing anti-interference shielding processing on the conductors in the cable by adopting the aluminum foil wheat drawstring, can achieve the fast construction of an electrical loop for indoor decoration, can combine original multiple steps into one step, can improve the efficiency by at least 80%, and can improve the overallsafety of the circuit.

Owner:北京新光伟玮能源科技有限公司

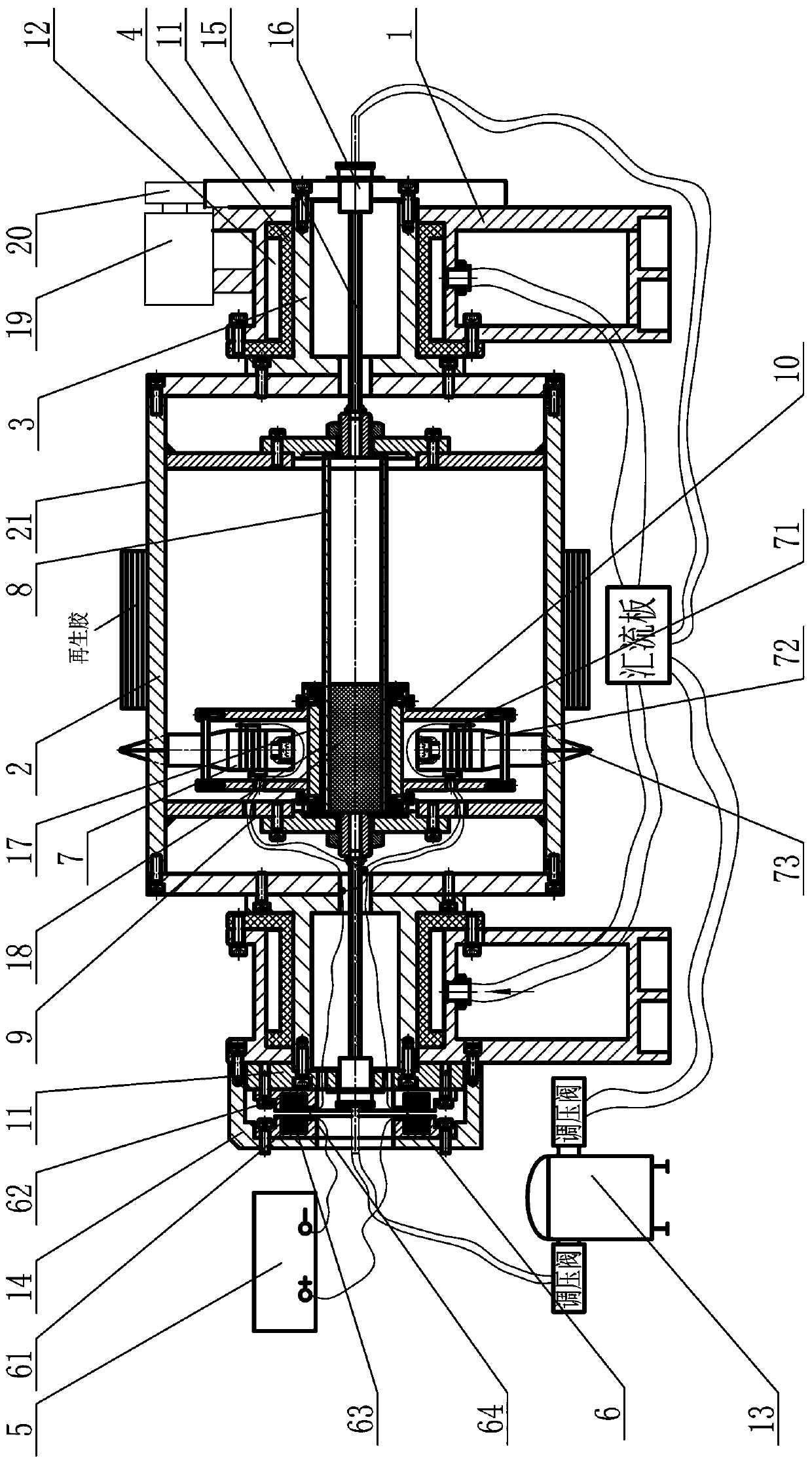

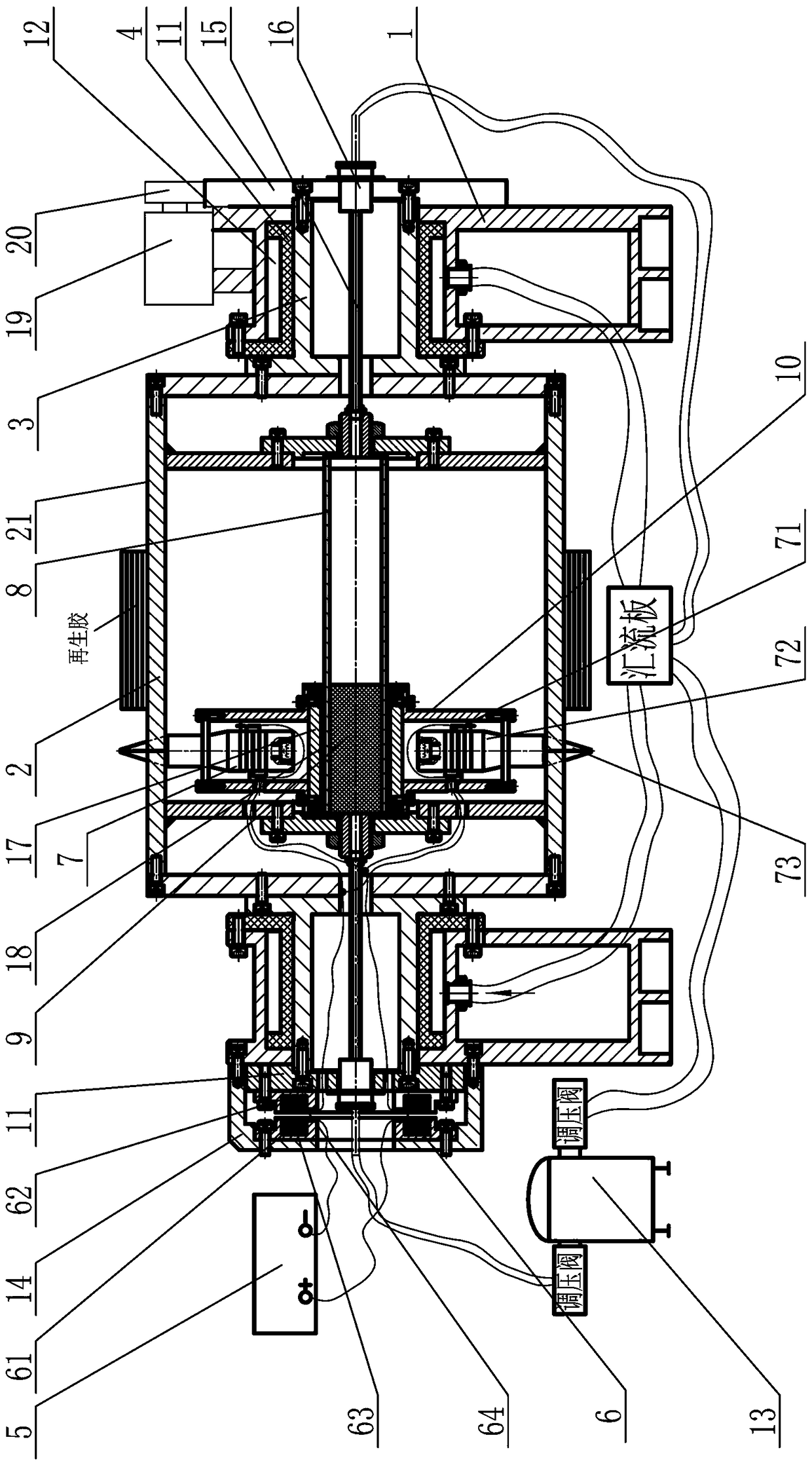

Ultrasonic cutting device for reclaimed rubber

InactiveCN108582260BReduce energy consumptionGuaranteed service lifeMetal working apparatusRubber materialUltrasonic vibration

The invention relates to an ultrasonic reclaimed rubber cutting device. The ultrasonic reclaimed rubber cutting device comprises a base, a coiling block, a rotation shaft, a supporting block, an ultrasonic generator, a wiring block, an ultrasonic tool, an air cylinder, a piston and a tool base. A supporting component of the coiling block is manufactured through porous materials. After the porous materials are inflated with high-pressure gas, a static pressure gas film can be generated on the outer wall of a main shaft, the gas film can suspend the coiling block, air suspension is achieved, andaccordingly influences on a bearing due to the rubber belt temperature are avoided. In addition, an ultrasonic cutting device body is adopted, a cutting edge is not needed during ultrasonic cutting,the molecular energy of rubber is activated through vibration energy, accordingly, a molecular chain of the rubber is opened, and cutting is achieved. The rubber is softened and melted through energygenerated through ultrasonic vibration, edge breakage, damage and other defects cannot be generated on the cut edge of the rubber material, and cutting banding is tidy.

Owner:XINXIANG UNIV

Quick-dry tight metal paint surface repairing agent

The invention discloses a quick-dry tight metal paint surface repairing agent. The quick-dry tight metal paint surface repairing agent is prepared from 20-30 parts of alkyl(meth)acrylate copolymer, 15-20 parts of polyimide, 15-20 parts of oil-soluble phenolic resin, 15-20 parts of tert-butylation phenyl phosphate, 15-20 parts of tributyl phosphate, 5-10 parts of polyacrylamide, 5-10 parts of polyaluminium chloride, 10-20 parts of surfactant and 0.02-0.4 part of stearic acid. The defects in the prior art are overcome, the metal surface repairing effect is good, no object surface is damaged, the quick-dry tight metal paint surface repairing agent is good in durability, high in lasting effect, free of toxins, harm and pollution and convenient to use, and repairing is fast.

Owner:ANHUI HONGQIAO METAL MFG

High-temperature-resistant dry friction permanent magnet maglev stirrer

InactiveCN109261010ANo friction and wearEasy to solveTransportation and packagingRotary stirring mixersAlloyEngineering

A high-temperature-resistant dry friction permanent magnet maglev stirrer comprises a driving device, a transmission shaft and a stirrer barrel component. The stirrer barrel component includes a stirrer barrel, a stirrer barrel upper cover plate fixed to an upper opening of the stirrer barrel, and a stirrer bottom flange fixed to a lower opening of the stirrer barrel; a bearing block is fixed to the upper end face of the stirrer barrel upper cover plate; a support is fixed onto the bearing block; the upper portion, middle and lower portion of the transmission shaft are sequentially and rotationally supported in the support, the bearing block and the stirrer bottom flange via rolling bearings respectively; the upper end of the transmission shaft is provided with a transmission flange fixedly connected to the output end of the driving device; the transmission flange is rotationally connected with the support via a maglev bearing component in a supported manner. The high-temperature-resistant dry friction permanent magnet maglev stirrer has the advantages that great axial force is borne by means of a maglev bearing non-contact mode, a high-temperature-resistant dry friction alloy rolling bearing is used to assist in supporting the transmission shaft, the problem that an existing stirrer has short life and high cost in a heavy-load high-temperature dry friction environment is solved, fewer maintenance times are required, and personnel safety is guaranteed.

Owner:宝鸡市泰得电子信息有限公司

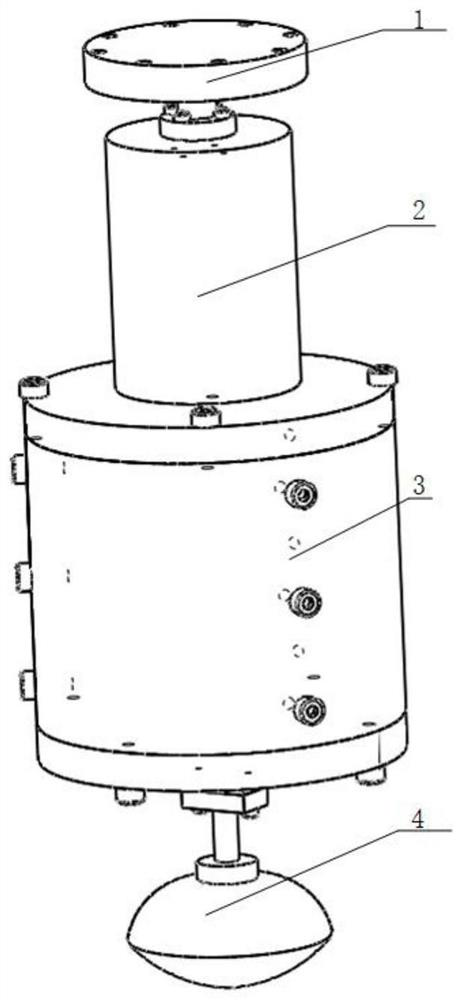

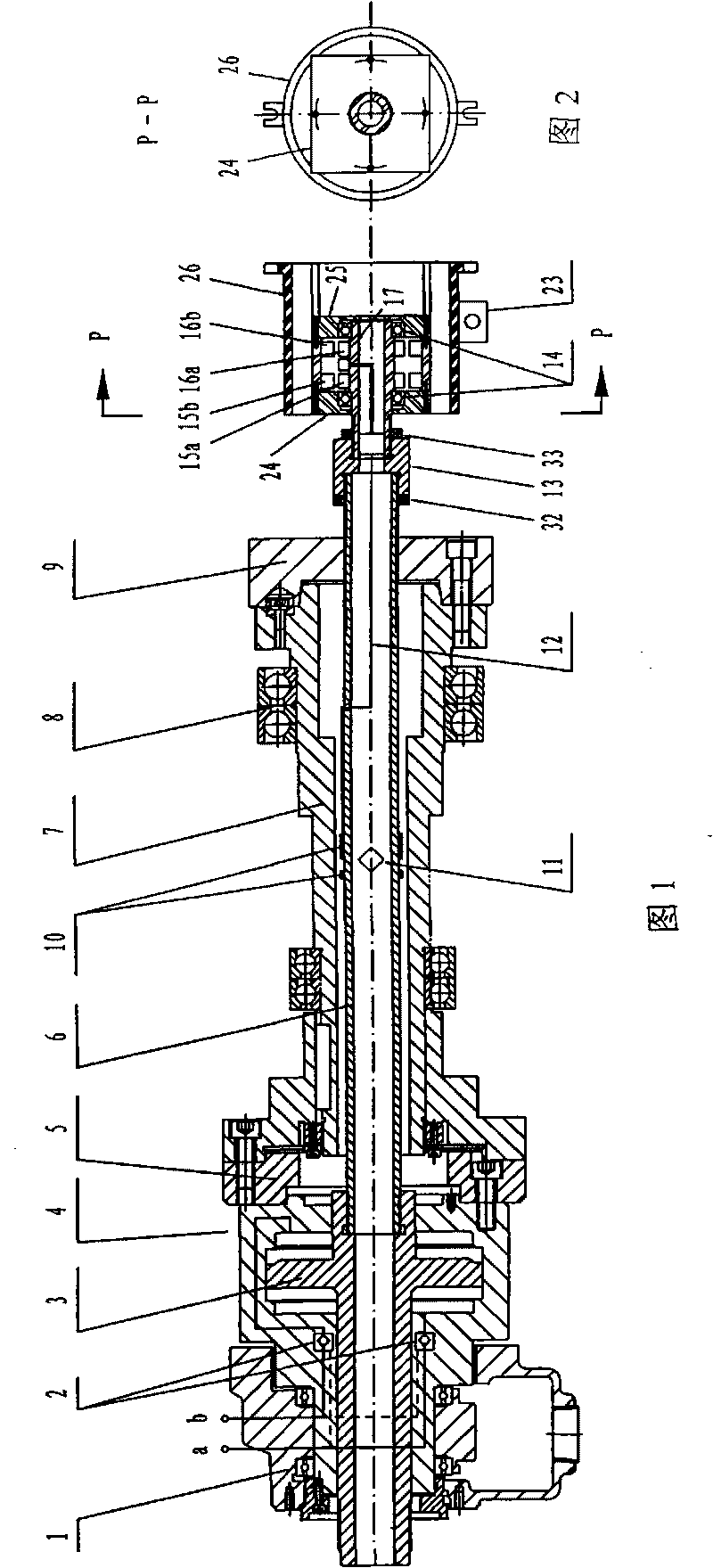

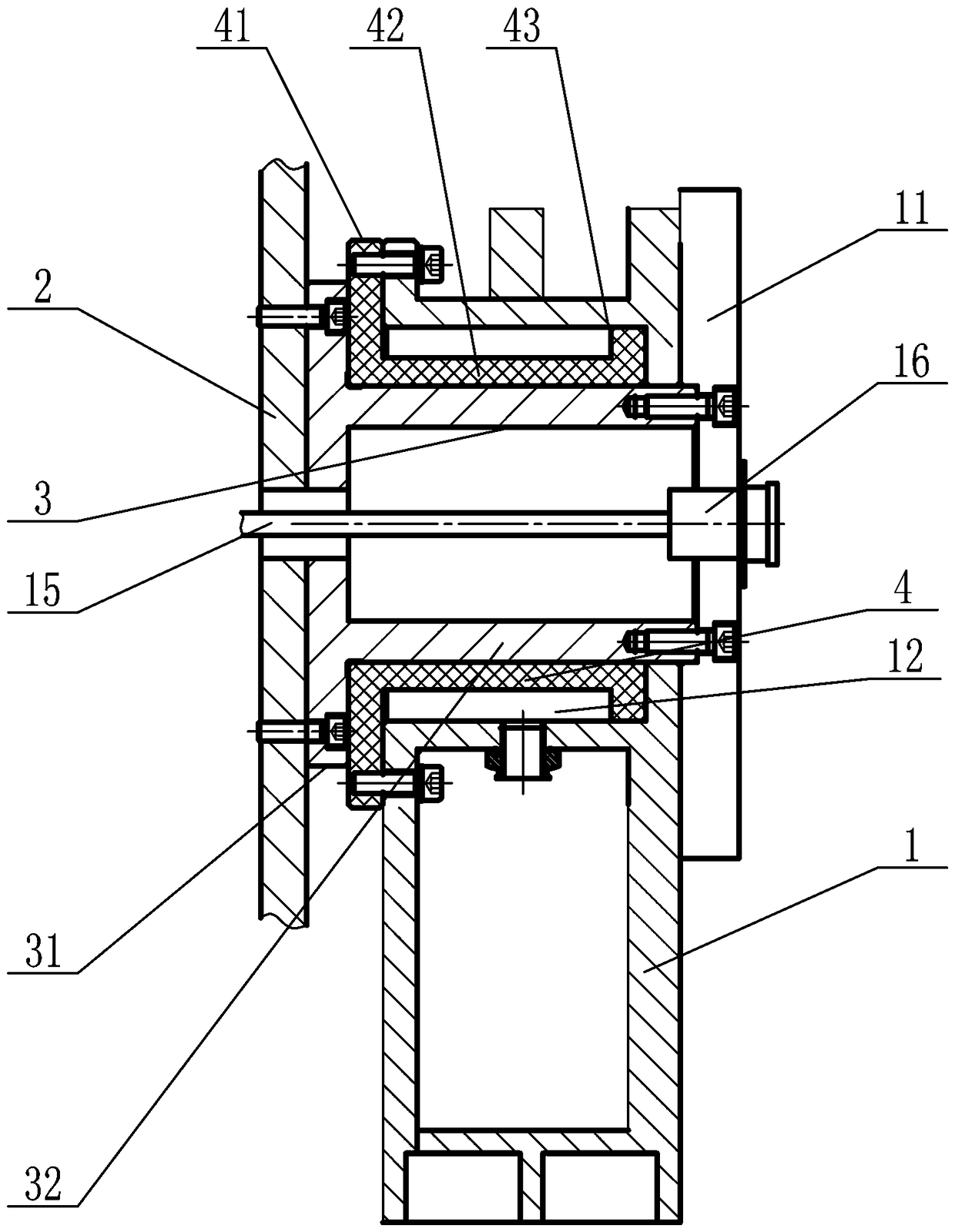

Device for measuring push-pull force output by rotating hydraulic cylinder

InactiveCN101718607AThe gap is stable and reliableNo friction and wearRapid change measurementPush pullDynamometer

The invention discloses a device for measuring a push-pull force output by a rotating hydraulic cylinder, which comprises a rotation strain signal coupler, wherein the rotation strain signal coupler consisting of a rotor, a stator, a power and signal preprocessing circuit, two groups of rotating transformation couplers, a rotor wiring end and a junction box provided with an alternating-direct current conversion and signal post-processing circuit; the two ends of the rotor are provided with a rolling bearing respectively; the two ends of the stator are provided with a square end cover respectively; the two square end covers are in fit with square guide rails in through holes of a guide rail sleeve; the junction box is arranged on the outer surface of the guide rail sleeve; the two ends of a dynamometer link are provided with screw thread with an identical thread pitch respectively; the outer surface of the middle part of the dynamometer link is pasted with strain foils which are connected into a wheatstone strain bridge; and two power terminals and two signal terminals of the wheatstone strain bridge are connected with the rotor of the rotation strain signal coupler. The device measures the push-pull force output by the hydraulic cylinder in rotation, and has the characteristics of stable and reliable gap between the rotor and the stator of the rotation strain signal coupler, no frictional wear, capacity of executing measurement at any position of a travel route of a piston rod, and convenient assembly and disassembly.

Owner:ZHEJIANG UNIV

Active auxiliary steering differential gear

PendingCN108458083AImproved directional stabilityIncreased sensitivityDifferential gearingsTransfer caseControl theory

The invention discloses an active auxiliary steering differential gear. The active auxiliary steering differential gear comprises a driven gear, a differential shell, a half-axle gear, a planetary gear, a planetary gear shaft, a worm gear, a worm, a transmission gear, a motor gear and a motor, wherein the worm gear is fixed connected to the outer end of the planetary gear shaft, and the worm is engaged with the worm gear; one end of the worm is fixedly connected to one side of the differential shell through a bearing, and the other end of the worm penetrates through the other side of the differential shell to be fixedly connected with the transmission gear; the transmission gear is engaged with the motor gear; and a motor rotor is connected to a motor stator through a bearing, and the motor stator is fixed to the inner side of the differential shell. According to the active auxiliary steering differential gear, the differential torque can be accurately improved, the differential speedcan be accurately controlled, and thus, the direction of a vehicle is stabilized. The active auxiliary steering differential gear can steer synchronously along with a direction system, and the steering degree of the differential gear can also be greater than the steering degree of the direction system, so that the direction turning radian is improved. The active auxiliary steering differential gear is suitable for differential devices and central differential locks of all vehicles and can replace transfer cases in other forms.

Owner:营山县臻安机电科技研究所

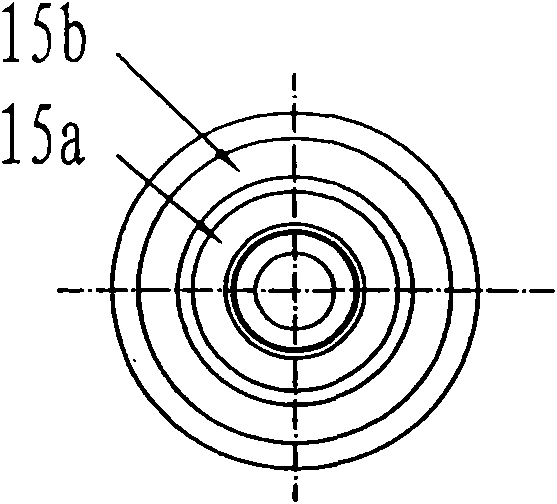

Array mixing magnetic bearing magnetic drive pump

InactiveCN103711702AReasonable designIncrease speedPump installationsNon-positive displacement fluid enginesMagnetic tension forceMagnetic bearing

The invention discloses an array mixing magnetic bearing magnetic drive pump comprising a base portion, a power portion, a pump body portion and a transmission portion, and is characterized in that a live spindle (15) of the transmission portion is fixed on the base portion via a Halbach array mixing magnetic bearing (10). Compared with the prior art, the array mixing magnetic bearing magnetic drive pump has the advantages that the array mixing magnetic bearing magnetic drive pump is reasonable in design, energy saving, and can realize high rotating speed, is no frictional wear, is stable in performance, long in service life, is free of pollution and is small in maintaining work by utilizing advantages of the array permanent magnet loop array and the Halbach array combining the permanent magnet and the electric magnet.

Owner:大连四方电泵有限公司

Ultrasonic reclaimed rubber cutting device

InactiveCN108582260AReduce energy consumptionGuaranteed service lifeMetal working apparatusRubber materialUltrasonic vibration

The invention relates to an ultrasonic reclaimed rubber cutting device. The ultrasonic reclaimed rubber cutting device comprises a base, a coiling block, a rotation shaft, a supporting block, an ultrasonic generator, a wiring block, an ultrasonic tool, an air cylinder, a piston and a tool base. A supporting component of the coiling block is manufactured through porous materials. After the porous materials are inflated with high-pressure gas, a static pressure gas film can be generated on the outer wall of a main shaft, the gas film can suspend the coiling block, air suspension is achieved, andaccordingly influences on a bearing due to the rubber belt temperature are avoided. In addition, an ultrasonic cutting device body is adopted, a cutting edge is not needed during ultrasonic cutting,the molecular energy of rubber is activated through vibration energy, accordingly, a molecular chain of the rubber is opened, and cutting is achieved. The rubber is softened and melted through energygenerated through ultrasonic vibration, edge breakage, damage and other defects cannot be generated on the cut edge of the rubber material, and cutting banding is tidy.

Owner:XINXIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com