Combined non-contact double-end-face seal based on magnetic liquid sealing and fluid dynamic-pressure mechanical sealing

A magnetic fluid and fluid dynamic pressure technology, which is applied to the components of pumping devices for elastic fluids, liquid fuel engines, mechanical equipment, etc. cause accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

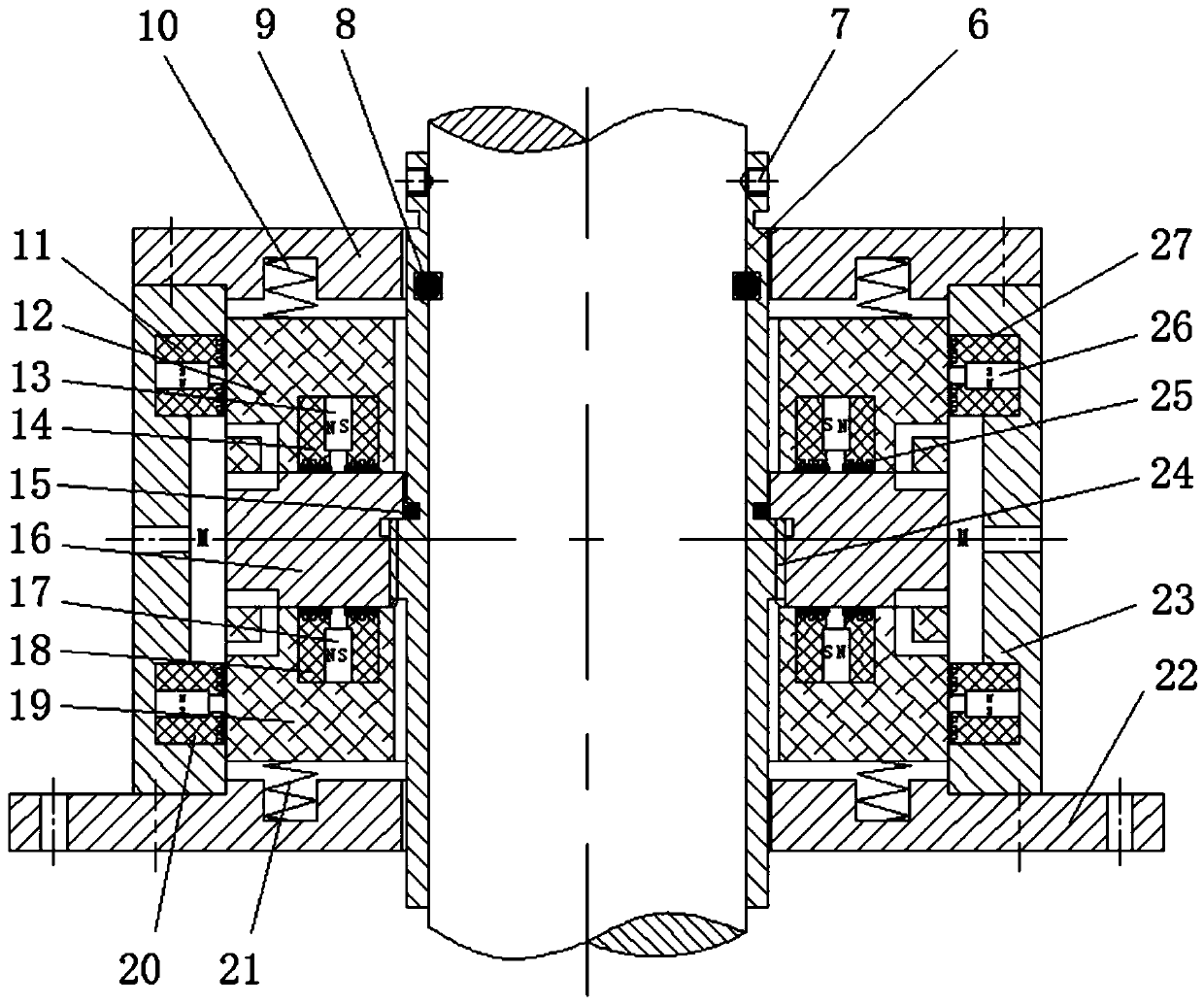

[0056] In order to describe the above-mentioned features and advantages of this patent more clearly, the specific implementation manners of this patent will be further described below in conjunction with the accompanying drawings.

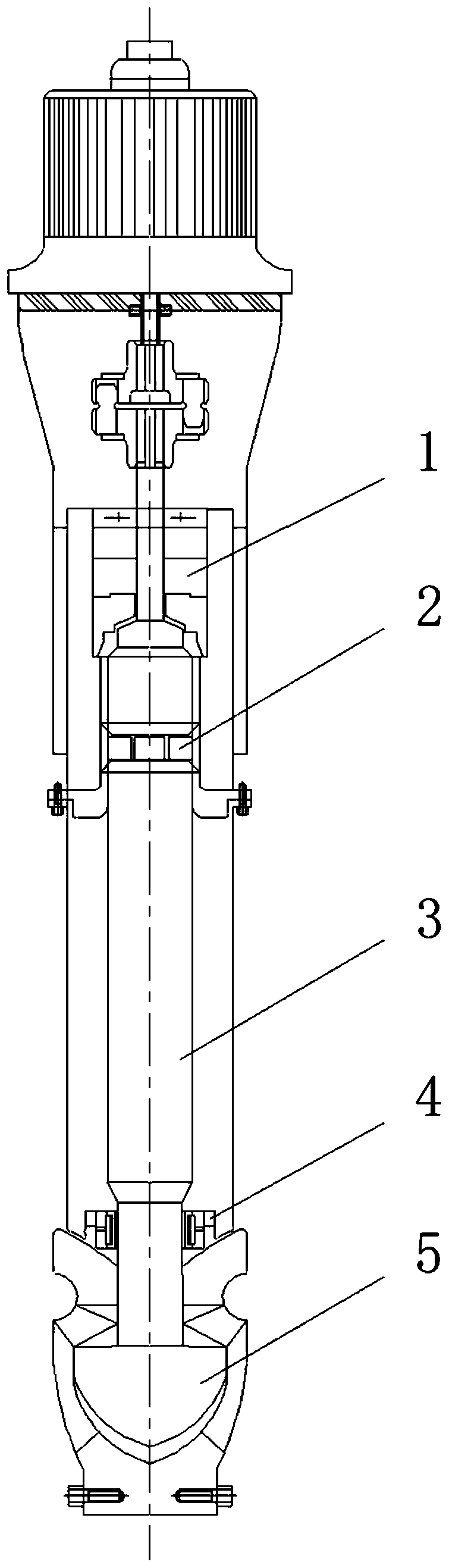

[0057] Figure 2 to Figure 7 A combined non-contact double-end seal based on a magnetic liquid seal and a hydrodynamic mechanical seal is described. It is used to seal the gap between the main pump shaft and the shell of the molten salt reactor, which can ensure the molten salt pump Zero leakage and long-term safe and stable operation of the shaft seal.

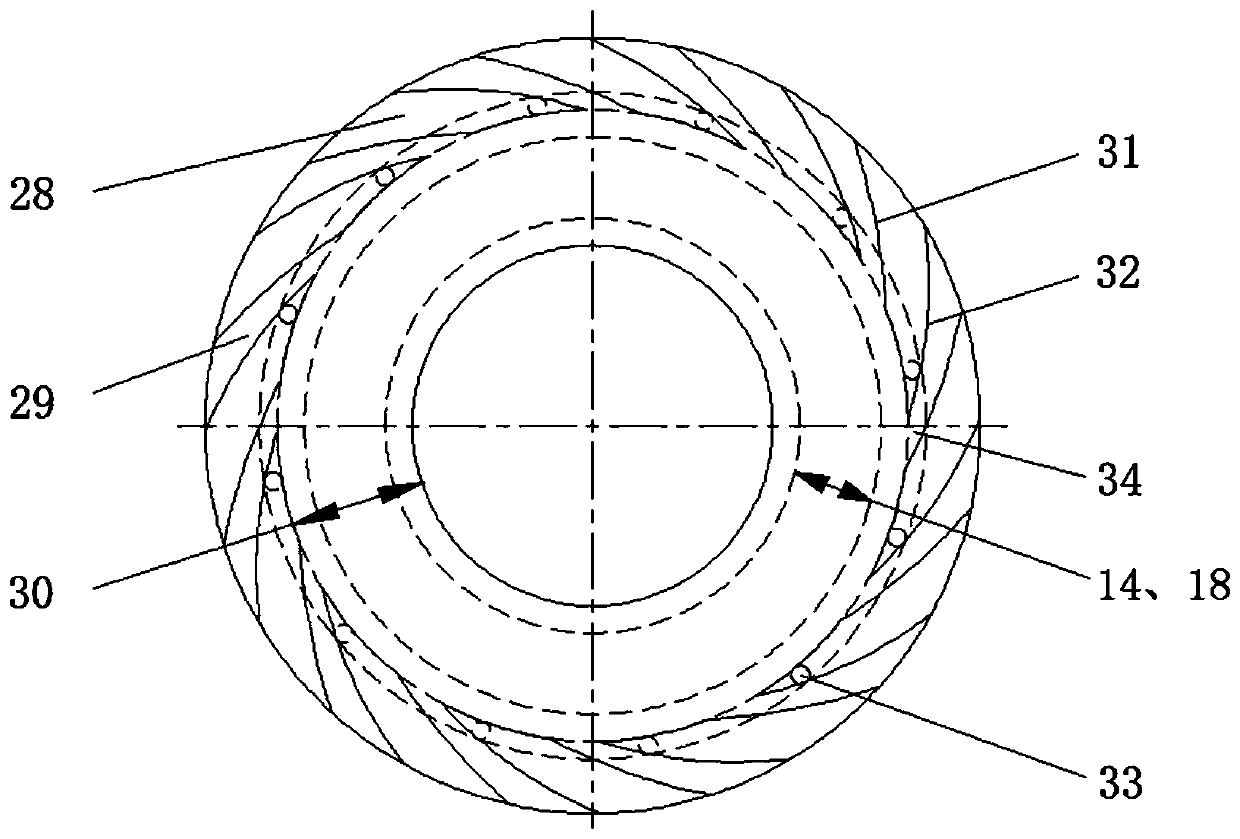

[0058] The structure of the upper and lower ends of the moving ring 16 is arranged symmetrically with the middle section M-M of the moving ring. Each end surface includes three parts: a spiral groove 28, a sealing weir 29 and a sealing dam 30. The spiral grooves 28 are evenly distributed on the outer diameter side of the end surface of the moving ring. The inner diameter side of the end face is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com