Arc stator winding magnetic suspension bearing drive motor

An arc stator and drive motor technology, applied in electrical components, holding devices with magnetic attraction or thrust, etc., can solve the problems of low motor structure bearing capacity and complex comprehensive decoupling control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

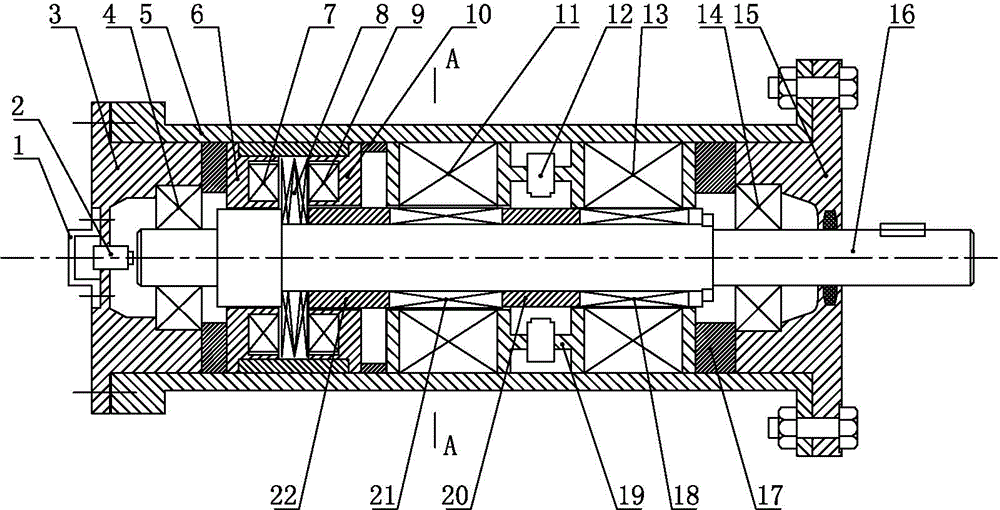

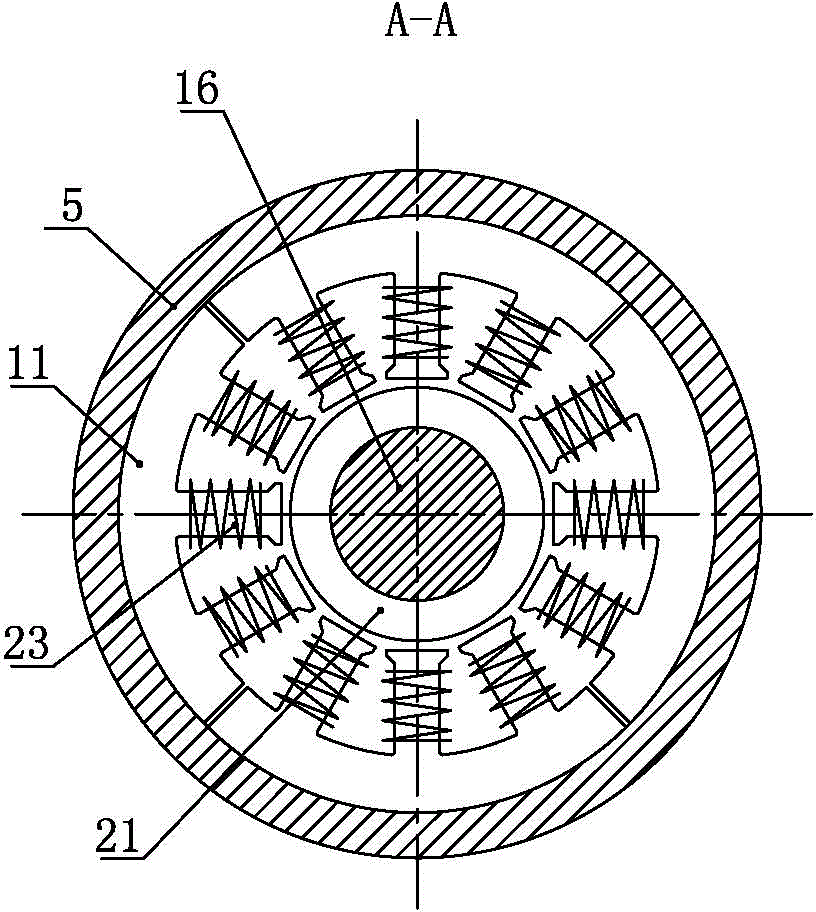

[0012] like figure 1 and 2 As shown, it is a circular arc stator winding magnetic levitation support drive motor, including a housing 5, a stator is arranged in the housing 5, a rotor assembly is arranged in the inner cavity of the stator, and end covers are respectively provided at both ends of the housing 5, and the end covers There are bearings 4, 14 inside, and the two ends of the rotor assembly are supported in the bearings 4, 14. The rotor assembly includes a rotor shaft 16, and a set of disc rotors 8 and two sets of rotor rings 18, 21 are arranged on the rotor shaft 16. A displacement sensor reference ring 20 is provided between the two groups of rotor rings 18, 21; the stator includes an axial stator one 7, an axial stator two 9, a radial stator one 11 and a radial stator two 13, and the axial stator one 7 and axial stator two 9 are co-located on both sides of the disc rotor 8; radial stator one 11 and radial stator two 13 are respectively set on the outer peripheries...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com