High-temperature-resistant dry friction permanent magnet maglev stirrer

A technology of agitator and dry friction, which is applied in the directions of agitator accessories, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of high cost and short service life, and achieve extended service life, long service life, and improved bearing. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

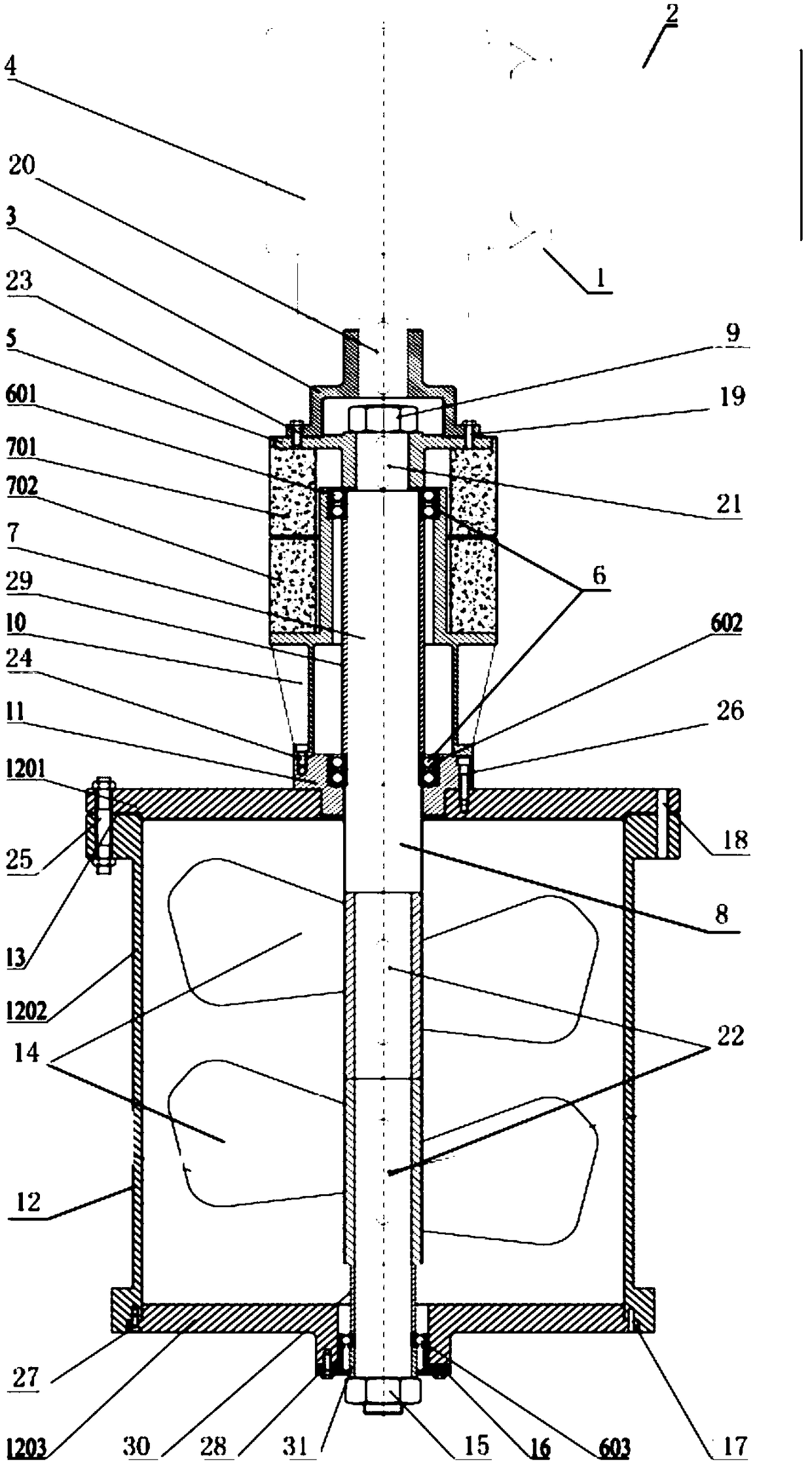

[0018] Attached below figure 1 Embodiments of the present invention are described.

[0019] High temperature resistant dry friction permanent magnetic levitation stirrer, such as figure 1 As shown, a drive device 1 , a drive shaft 8 and an agitator drum assembly 12 are included. The agitator cylinder assembly 12 includes an agitator cylinder 1202 , an agitator cylinder upper cover 1201 fixed on the upper port of the agitator cylinder 1202 , and an agitator bottom flange 1203 fixed on the lower port of the agitator cylinder 1202 . The upper cover plate 1201 of the agitator cylinder and the agitator cylinder 1202 are positioned by the pin II18 and fixedly connected by the screw III25, and the position between the bottom flange 1203 of the agitator and the agitator cylinder 1202 is positioned by the pin I17 Finally, it is fixedly connected by screw V27, the connection between the upper cover plate 1201 of the agitator cylinder and the agitator cylinder 1202 and the connection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com