Array mixing magnetic bearing magnetic drive pump

A hybrid magnetic bearing and magnetic pump technology, applied in the direction of pumps, pump devices, non-variable-capacity pumps, etc., can solve the problems affecting the normal operation of the magnetic pump, the bearing capacity is not high, the service life is short, etc., to achieve reliable performance, The effect of less maintenance work and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

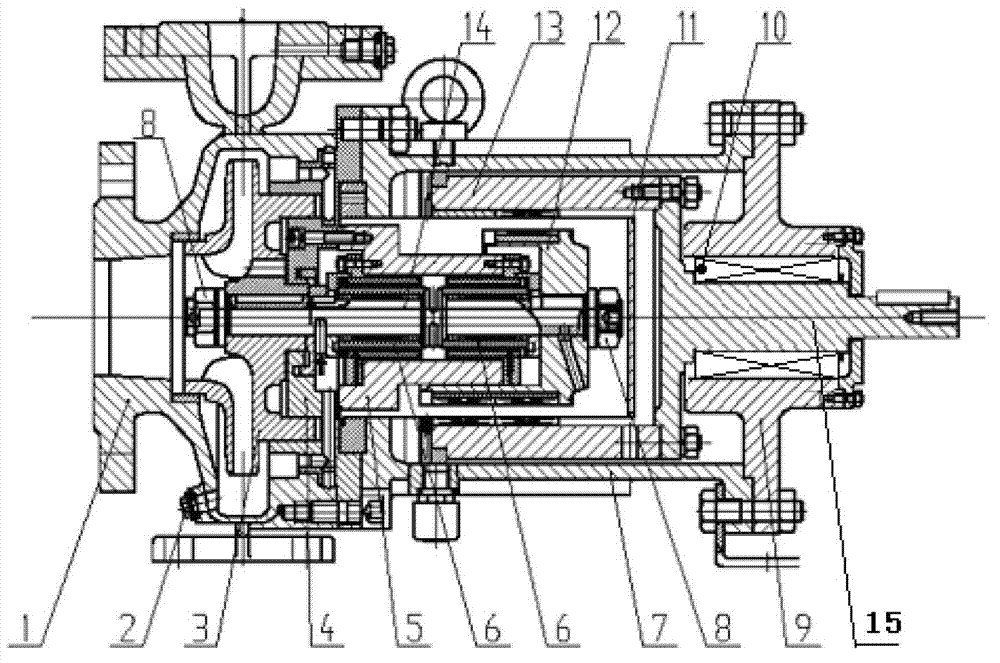

[0012] figure 1 It is a structural schematic diagram of the array hybrid magnetic bearing magnetic pump of the present invention; the array hybrid magnetic bearing magnetic pump device of the present invention includes a pump body 1, a screw plug 2, an impeller 3, a pump cover 4, a sliding bearing support 5, a sliding bearing 6, a connecting Frame 7, lock nut 8, bearing support 9, Halbach array hybrid magnetic bearing 10, spacer sleeve 11, inner rotor 12, outer rotor 13, pump shaft 14, rotating main shaft 15. These components constitute the base part, the power part, the pump body part and the transmission part of the array hybrid magnetic bearing magnetic drive pump of the present invention.

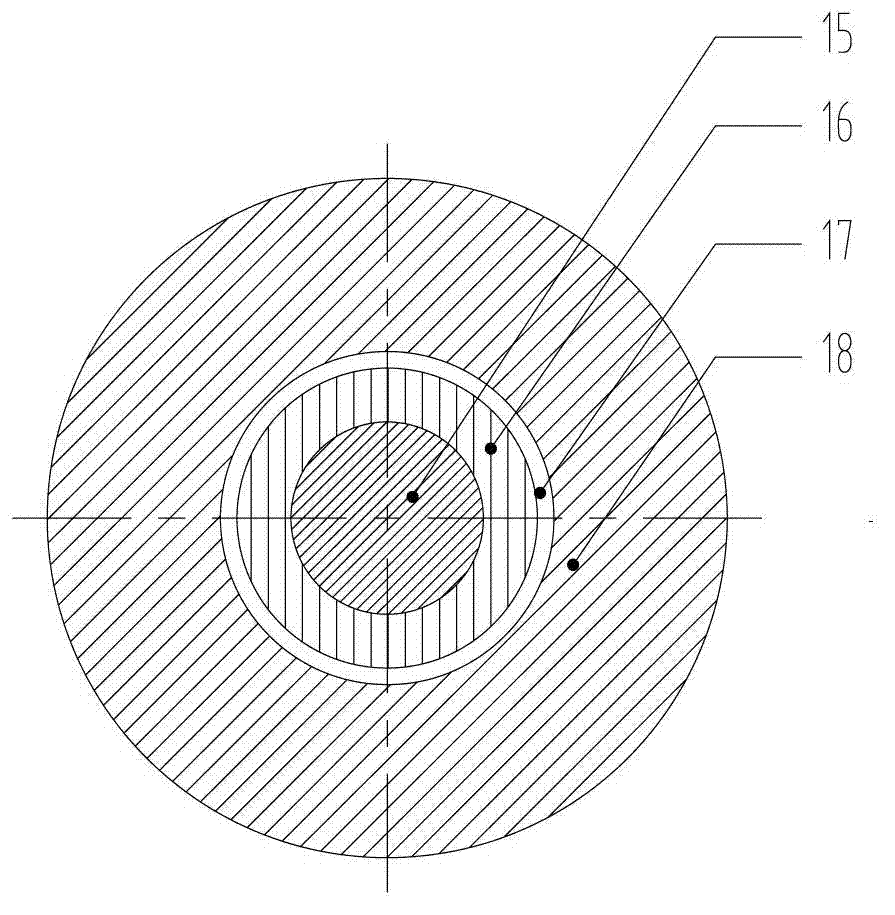

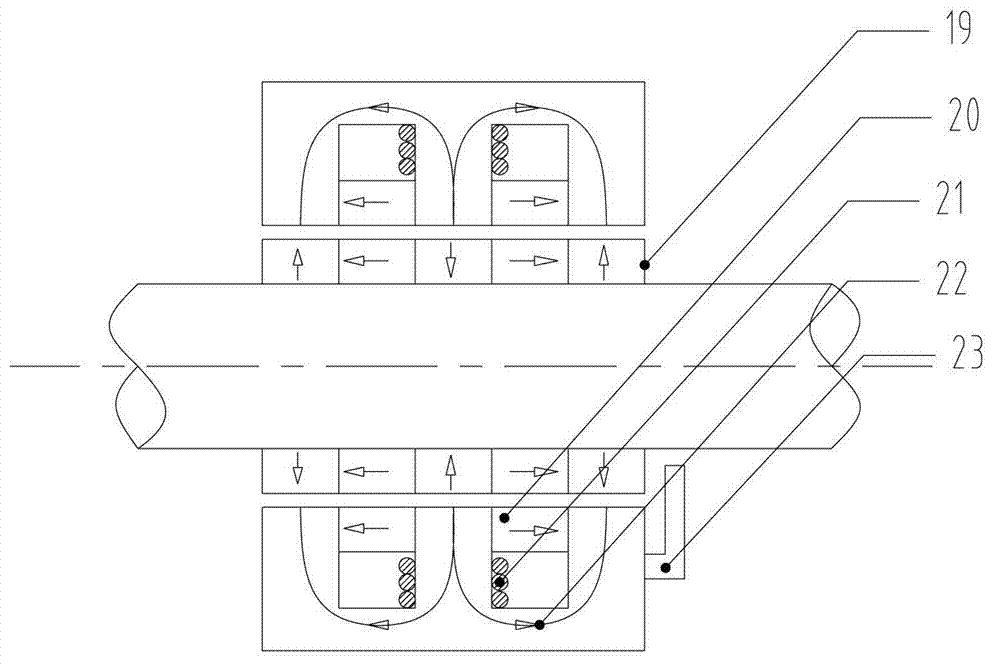

[0013] figure 2 and image 3 It is a structural schematic diagram of the Halbach array hybrid magnetic bearing in the array hybrid magnetic bearing magnetic drive pump of the present invention; it includes a rotating main shaft 15, an inner magnetic ring 16, and an outer magnetic rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com