Multi-channel combined type linear vibration conveying system

A linear vibration and transmission system technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of transmission and clamping accumulation, part feature detection, and high production costs, achieving no lubrication, high machining accuracy, and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is a multi-channel composite linear vibration transmission system. The following takes the four-channel transmission system as an example to describe the specific implementation in detail, and the invention is not limited to the four-channel transmission system.

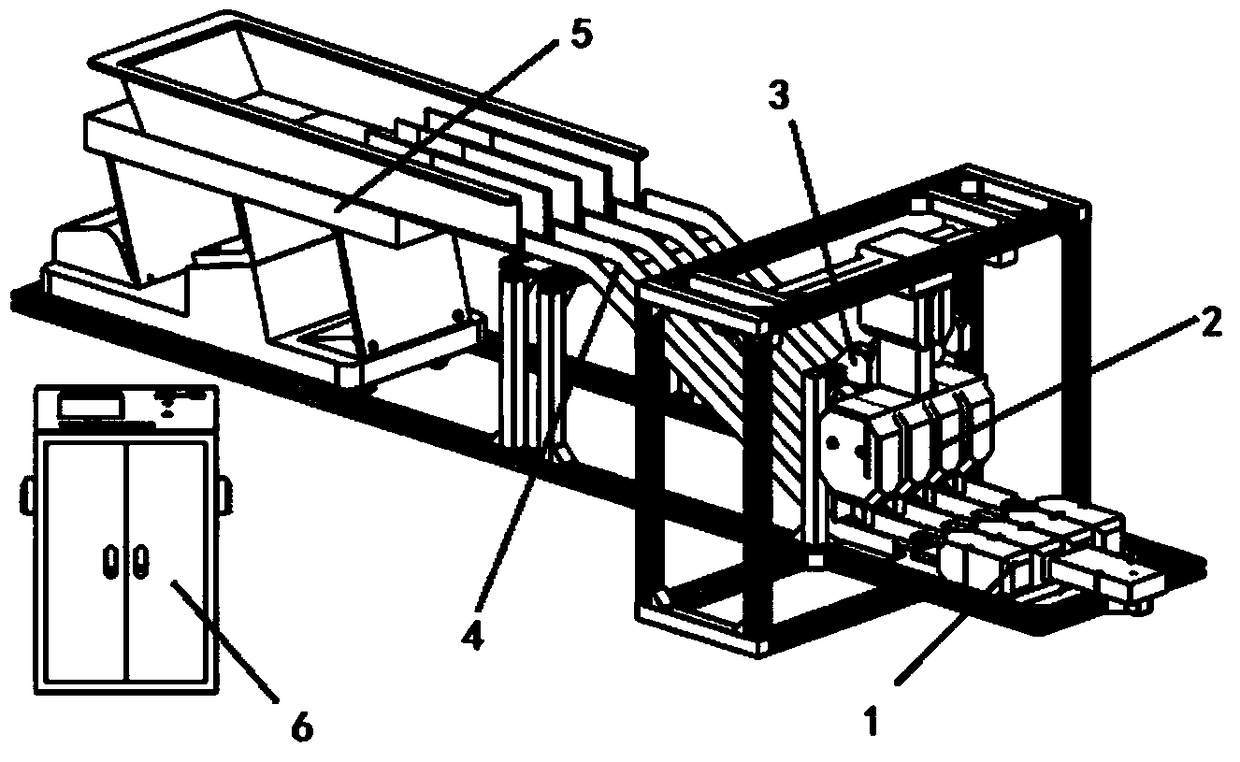

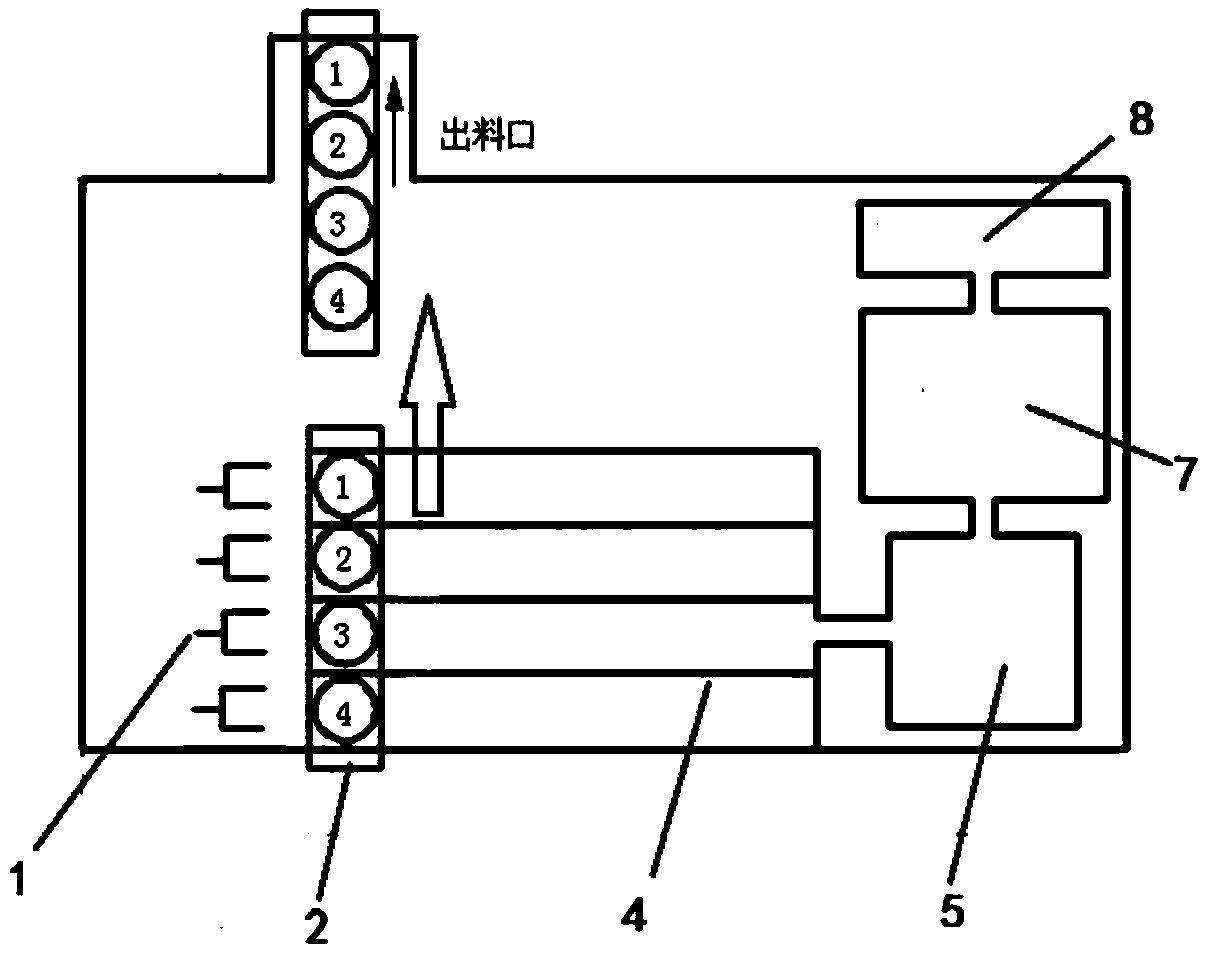

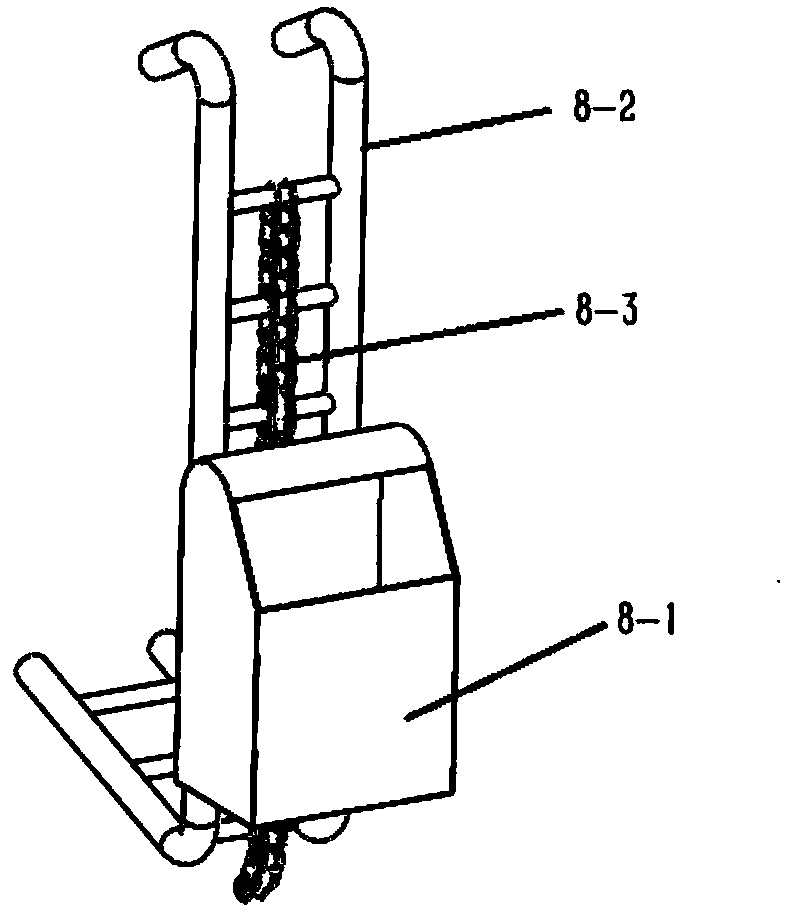

[0040] Such as figure 1 , figure 2 As shown, the linear vibration transmission system of the present invention includes: a turning manipulator 1, a translation manipulator 2, a photoelectric switch assembly 3, a four-channel material tray 4, a vibrating feeder 5, a control box 6, a material bin 7 and a lifting mechanism 8. Vibrating feeder 5 is installed on such as by screw figure 1In the horizontal aluminum profile frame shown, the aluminum profile adopts a standard part of 30mm*30mm, and the size of the horizontal aluminum profile frame is 1600mm*300mm. The feeding end of vibrating feeder 5 is welded with three stainless steel vertical plates, in order to separate the feedway. Vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com