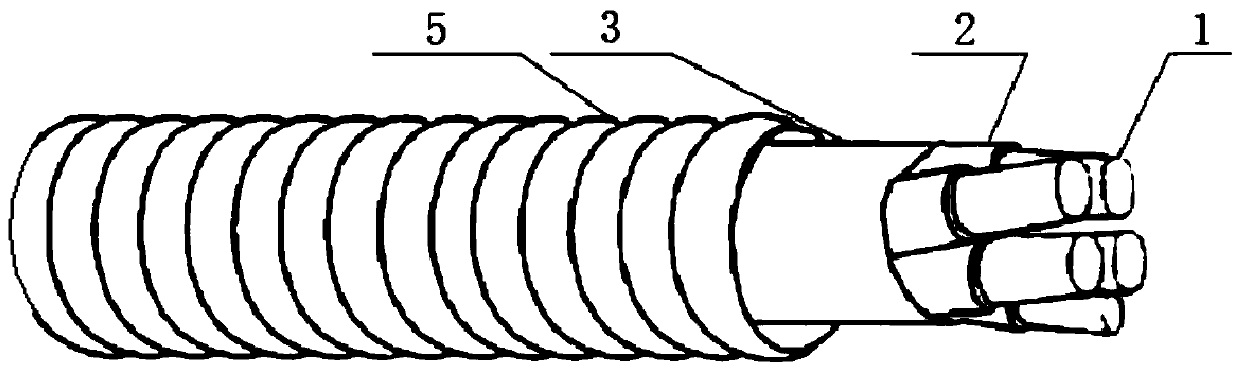

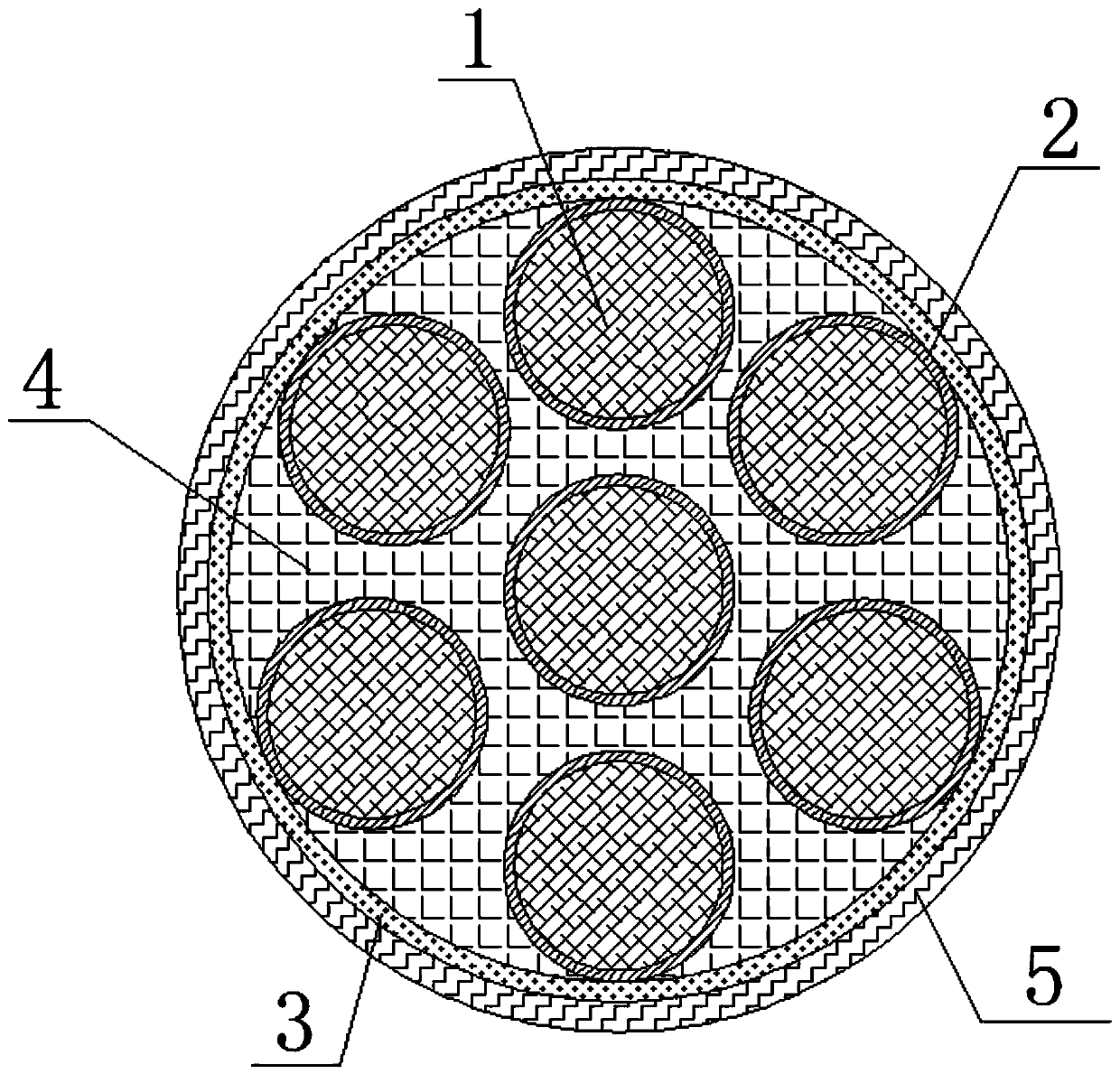

Interlocking armored cable for indoor decoration and wiring method thereof

An interlocking armoring and interior decoration technology, which is applied in the direction of insulating cables, cable laying equipment, cable/conductor manufacturing, etc., can solve the problems of shortening cable service life, cable damage, impact resistance, corrosion resistance and poor tensile strength, etc. problems, to improve the impact resistance, ensure long-term use, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

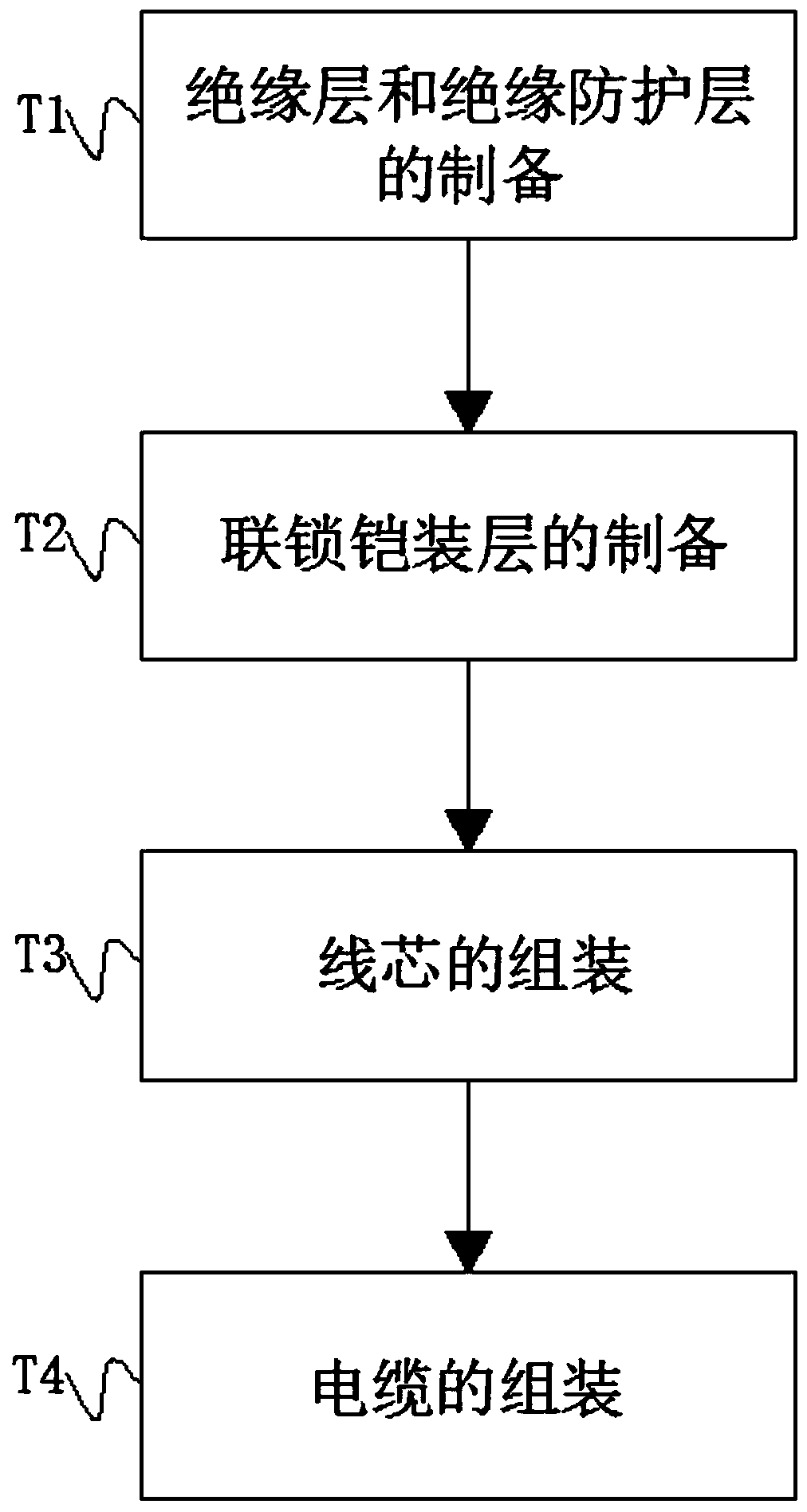

[0045] T1. Preparation of insulating layer and insulating protective layer: respectively select 55 parts of polyvinyl chloride and 7 parts of plasticizer in corresponding weight ratios and add them to the mixing mixer in turn, with the speed of 650r / min and the temperature of 75°C Mix and stir for 1.5 hours, then add 15 parts of heat-conducting silica gel and 7 parts of cross-linking agent into the mixing tank in turn, and continue stirring for 1.5 hours at a speed of 750r / min and a storage temperature of 75°C. Obtain low-smoke and halogen-free materials, and then pass the obtained low-smoke and halogen-free materials through injection molding, cooling and forming processes to obtain the insulating layer 2 and insulating protective layer 4 of the required size, and the plasticizer is dibutyl phthalate ester, dioctyl phthalate, adipate, azelaic acid ester, sebacic acid ester and stearic acid ester, the thermal conductive silica gel is a molecular chain base glue containing a C-S...

Embodiment 2

[0050] T1. Preparation of insulating layer and insulating protective layer: select 50 parts of polyvinyl chloride and 5 parts of plasticizer in corresponding weight ratios and add them to the mixing mixer in turn, with the speed of 600r / min and the temperature of 65°C Mix and stir for 1 hour, then add 10 parts of heat-conducting silica gel and 5 parts of cross-linking agent into the mixing tank in sequence, and continue stirring for 1 hour at a speed of 700r / min at a storage temperature of 65°C to obtain a low Smoke-free halogen-free materials, and then the obtained low-smoke halogen-free materials can be obtained through injection molding, cooling and forming processes to obtain the insulating layer 2 and insulating protective layer 4 of the required size. The plasticizers are dibutyl phthalate and The composition of stearic acid ester, the thermal conductive silicone adopts the molecular chain base rubber containing C-Si structure, adding thermal conductive powder to the base...

Embodiment 3

[0055] T1. Preparation of insulating layer and insulating protective layer: select 60 parts of polyvinyl chloride and 10 parts of plasticizer in corresponding weight ratios and add them to the mixing mixer in turn, with the rotation speed at 700r / min and the temperature at 80°C Mix and stir for 2 hours, then add 20 parts of heat-conducting silica gel and 10 parts of cross-linking agent into the mixing tank in sequence, and continue stirring for 2 hours at a speed of 800r / min at a storage temperature of 80°C to obtain a low Smoke-free and halogen-free materials, and then the obtained low-smoke and halogen-free materials are injected, cooled and formed to obtain the insulating layer 2 and insulating protective layer 4 of the required size. The plasticizer is stearate, and the heat-conducting silicone is made of The most important is the molecular chain base glue containing C-Si structure. Add thermal conductive powder to the base glue, and then cross-link the molecular chain thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com