Overrunning clutch for confluence mechanism of double-turbine hydraulic torque converter

A hydraulic torque converter and overrunning clutch technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve the problems of high manufacturing precision, wear failure, unreasonable, etc., to eliminate the influence of machining accuracy and reduce diameter. Centrifugal force, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

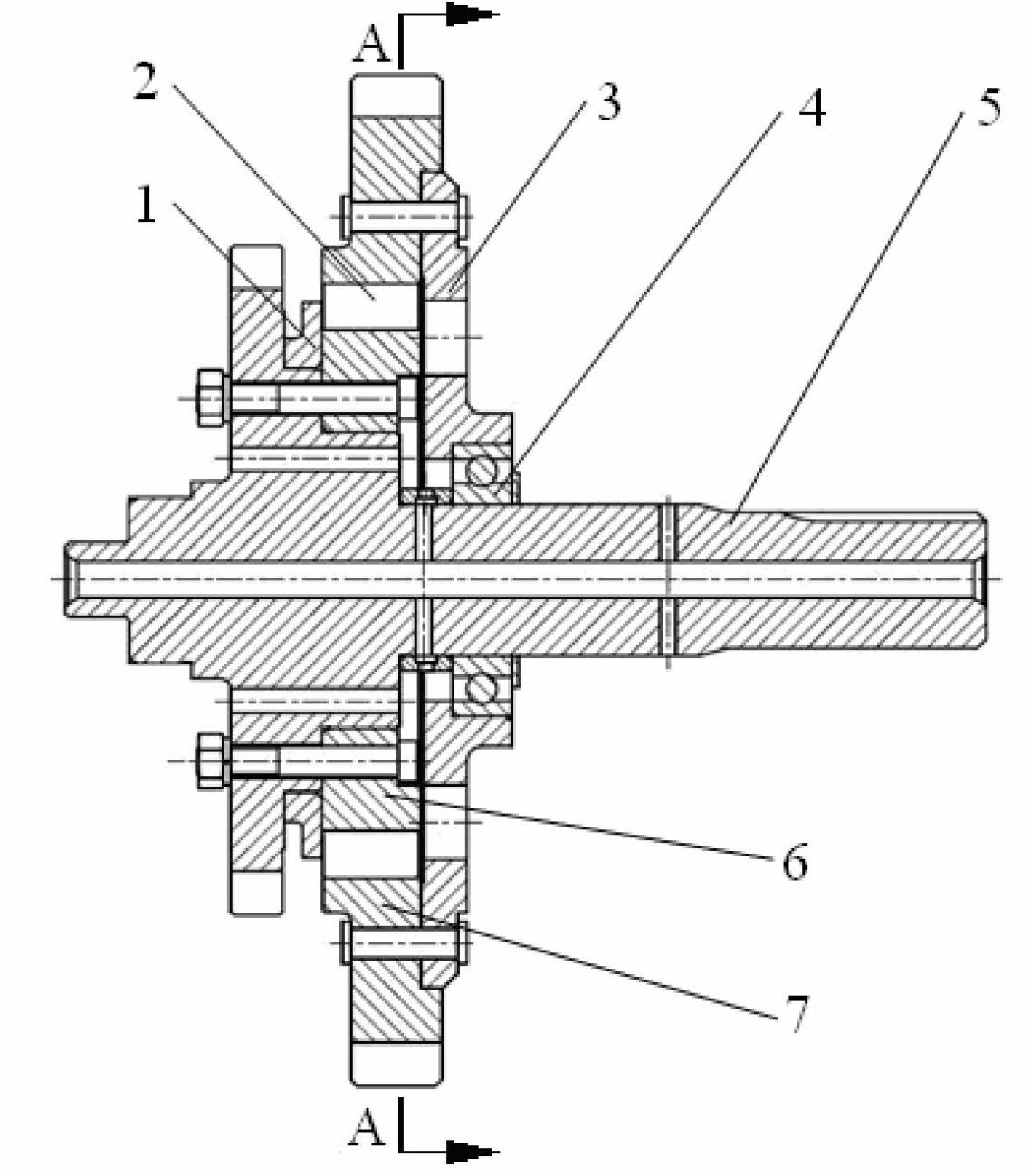

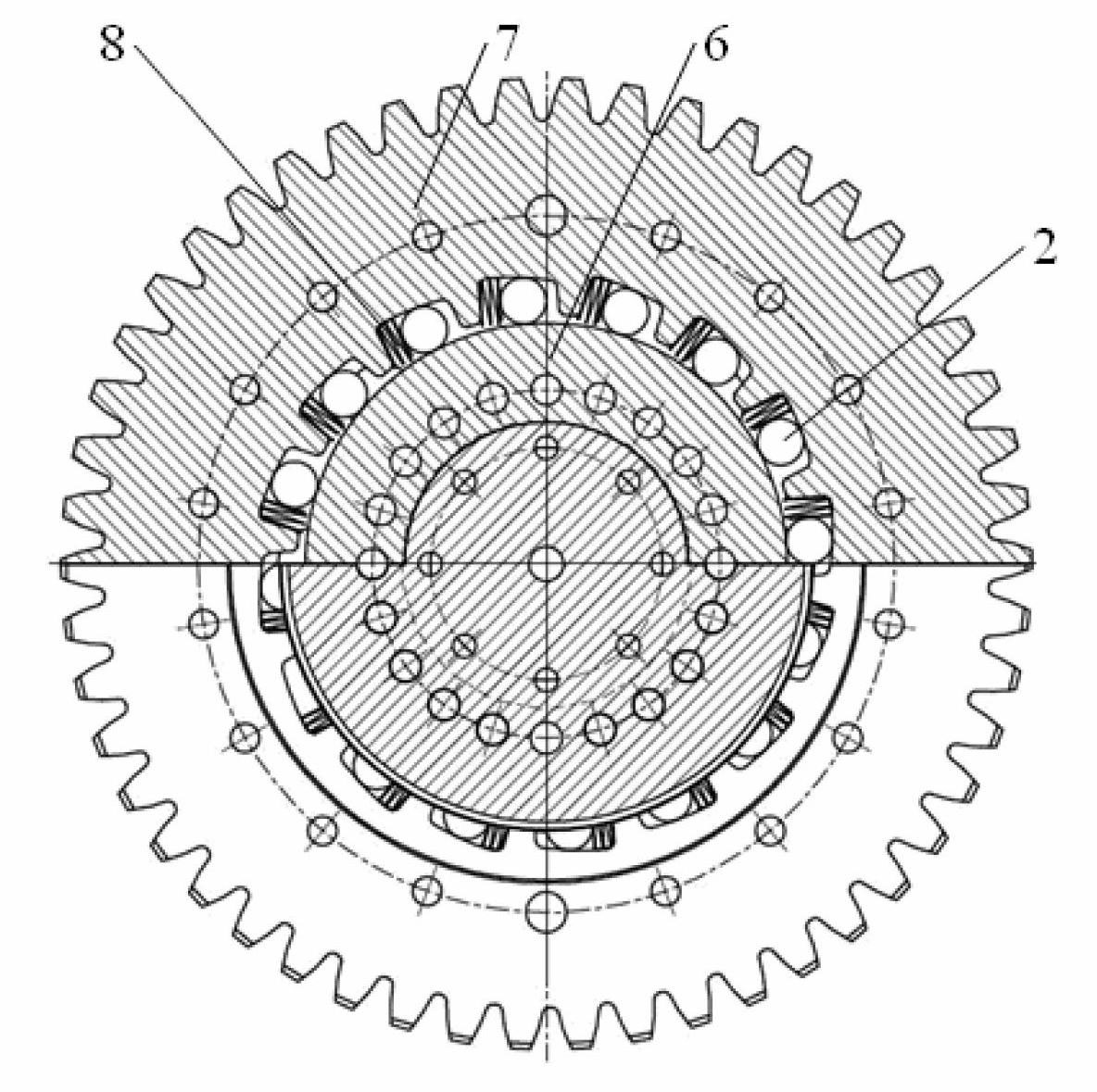

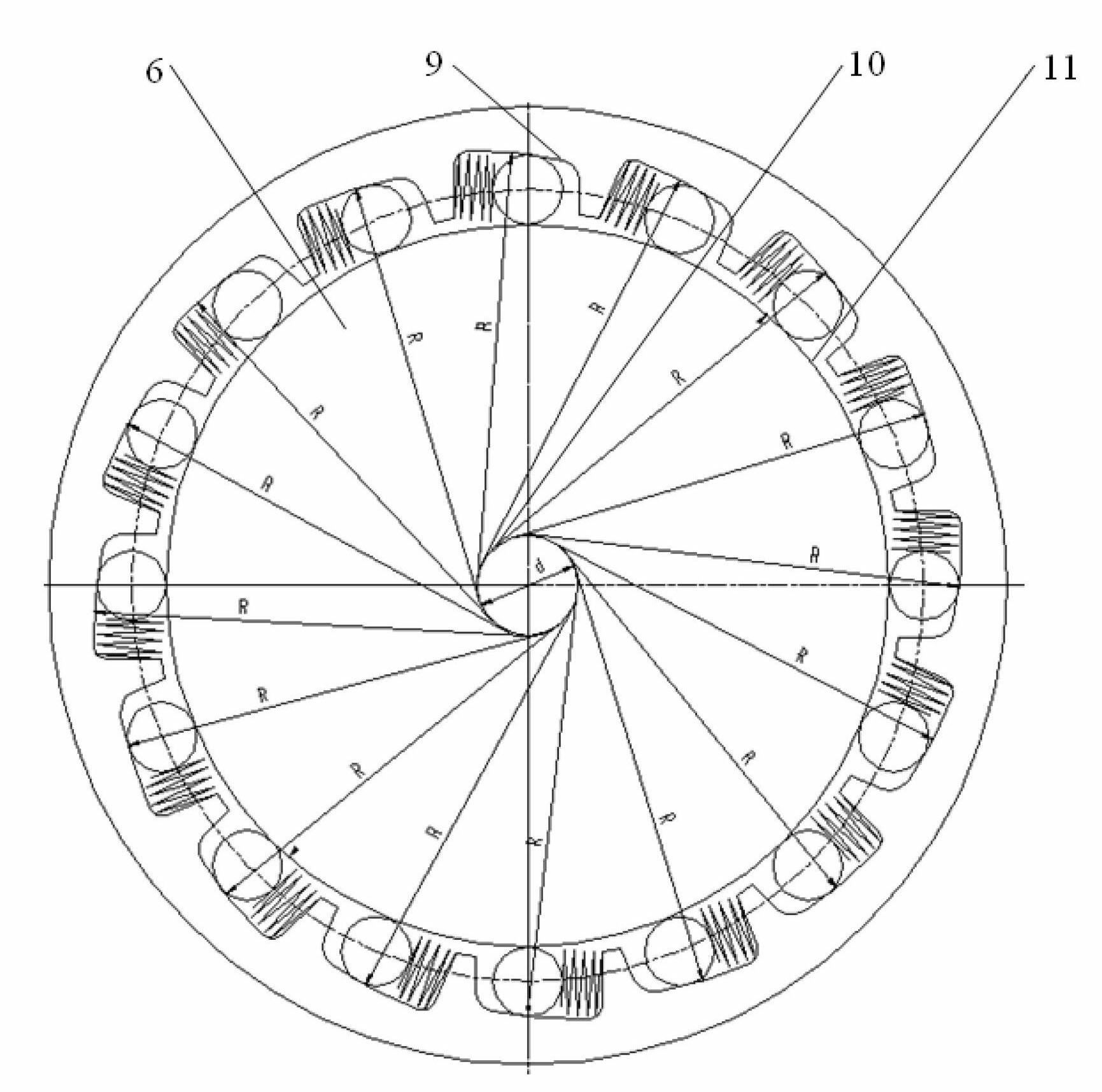

[0040] In the overrunning clutch of the converging mechanism of the twin-turbo torque converter, the cam surface 9 is set in the inner hole of the outer ring gear 7, the outer surface of the inner star wheel 6 is a cylindrical surface 11, and the roller 2 is installed on the cam surface 9 of the outer ring gear 7 In the cavity formed by the outer cylindrical surface 11 of the inner star wheel 6, a spring 8 is installed at one end of the roller 2 to push the roller 2 to remain on the wedging side of the cavity, and the outer ring gear 7, the inner star wheel 6 and the roller 2 form a self-locking mechanism, the inner star wheel 6 can only rotate in one direction relative to the outer ring gear 7, and lock in the opposite direction.

[0041] The diameter of the outer cylindrical surface 11 of the inner star wheel 6 is 165 mm, the diameter of the roller 2 is φ = 15 mm, the radius R of the cam surface 9 of the outer ring gear 7 is an arc surface of R = 97 mm, and the center of the ...

Embodiment

[0046] In the overrunning clutch of the converging mechanism of the twin-turbo torque converter, the cam surface 9 is set in the inner hole of the outer ring gear 7, the outer surface of the inner star wheel 6 is a cylindrical surface 11, and the roller 2 is installed on the cam surface 9 of the outer ring gear 7 In the cavity formed by the outer cylindrical surface 11 of the inner star wheel 6, a spring 8 is installed at one end of the roller 2 to push the roller 2 to remain on the wedging side of the cavity, and the outer ring gear 7, the inner star wheel 6 and the roller 2 form a self-locking mechanism, the inner star wheel 6 can only rotate in one direction relative to the outer ring gear 7, and lock in the opposite direction.

[0047] The diameter of the outer cylindrical surface 11 of the inner star wheel 6 is 168mm, the diameter of the roller 2 is φ=18mm, the radius R of the cam surface 9 of the outer ring gear 7 is an arc surface of R=102mm, and the center of the arc is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com