Patents

Literature

872 results about "Work productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

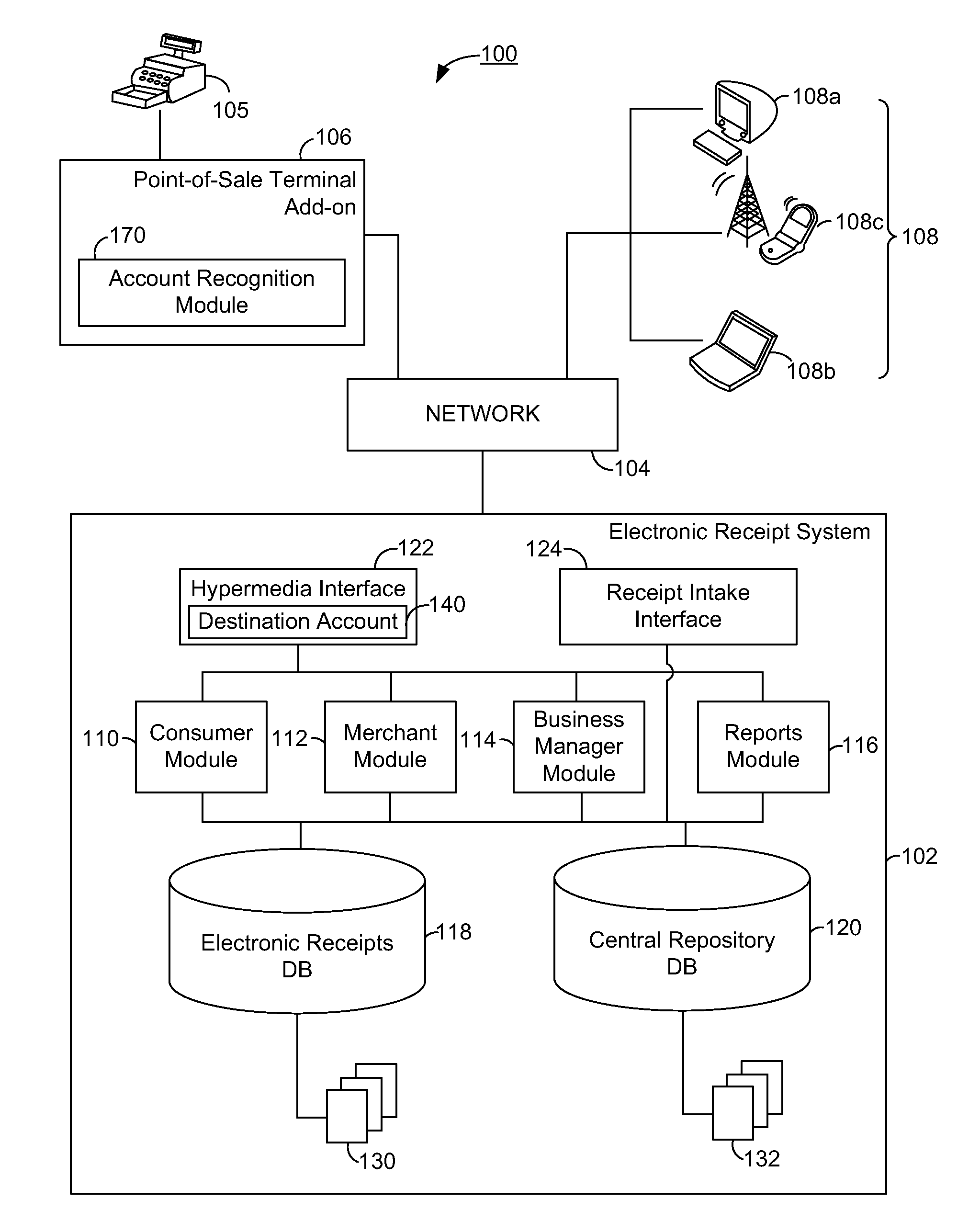

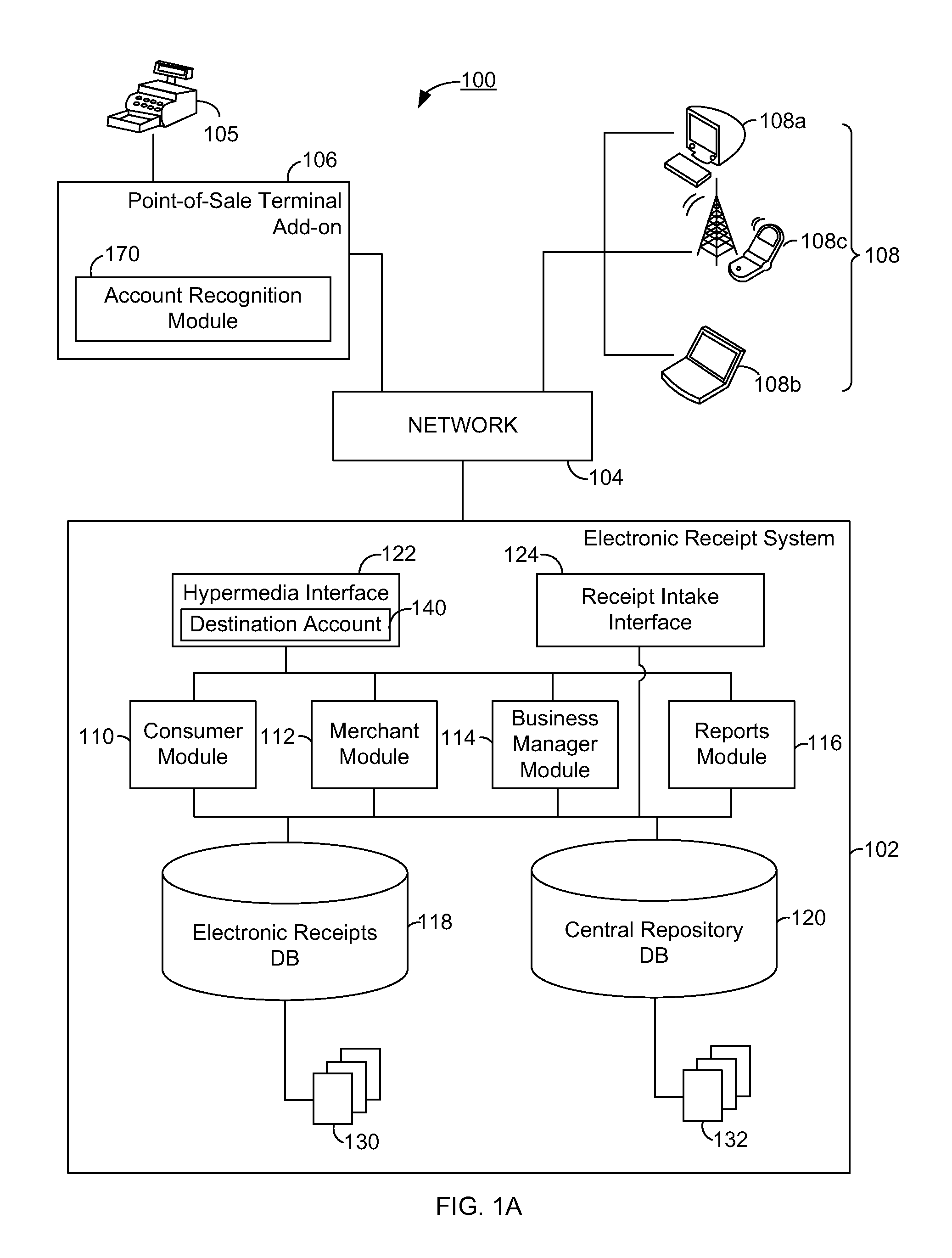

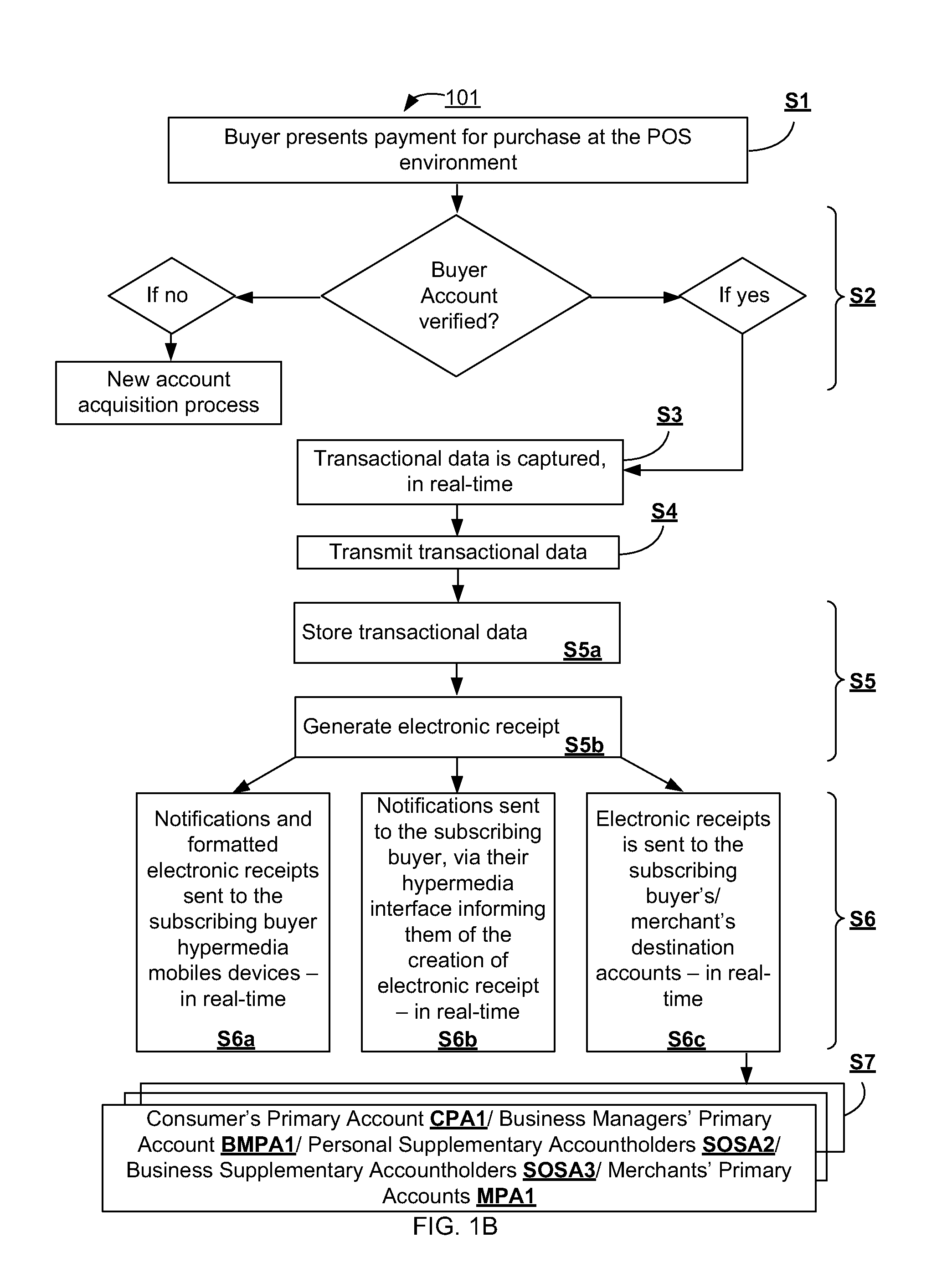

Seamlessly capturing transactional data at the merchant's point of sale environment and creating electronic receipts, all in real-time

InactiveUS20120290422A1Hand manipulated computer devicesPoint-of-sale network systemsPaymentElectronic form

Series of processes and methods designed to seamlessly capture detailed transactional data from merchants' Point of Sale environments and generate final presentments of electronic receipts for both consumers and merchants, is accessible from their destination accounts, all in real time. Objectives are to: migrate all printed paper receipts to electronic forms; enable customer facing post-sales management capabilities; increase self serve; create new shopping and post-shopping experiences and satisfaction rates; significantly reduce administrative and storage requirements and costs, and provide more time for work productivity. Customers and merchants are able to create various reports and are able to directly submit them from their destination accounts for: expenditure accounting and tax purposes, payment processing, and for other company expenses. Further capabilities include creating: supplementary accounts; spend alerts; merchant driven targeted profile marketing initiatives, and business directory listings with mapping capabilities.

Owner:BHINDER MICK M

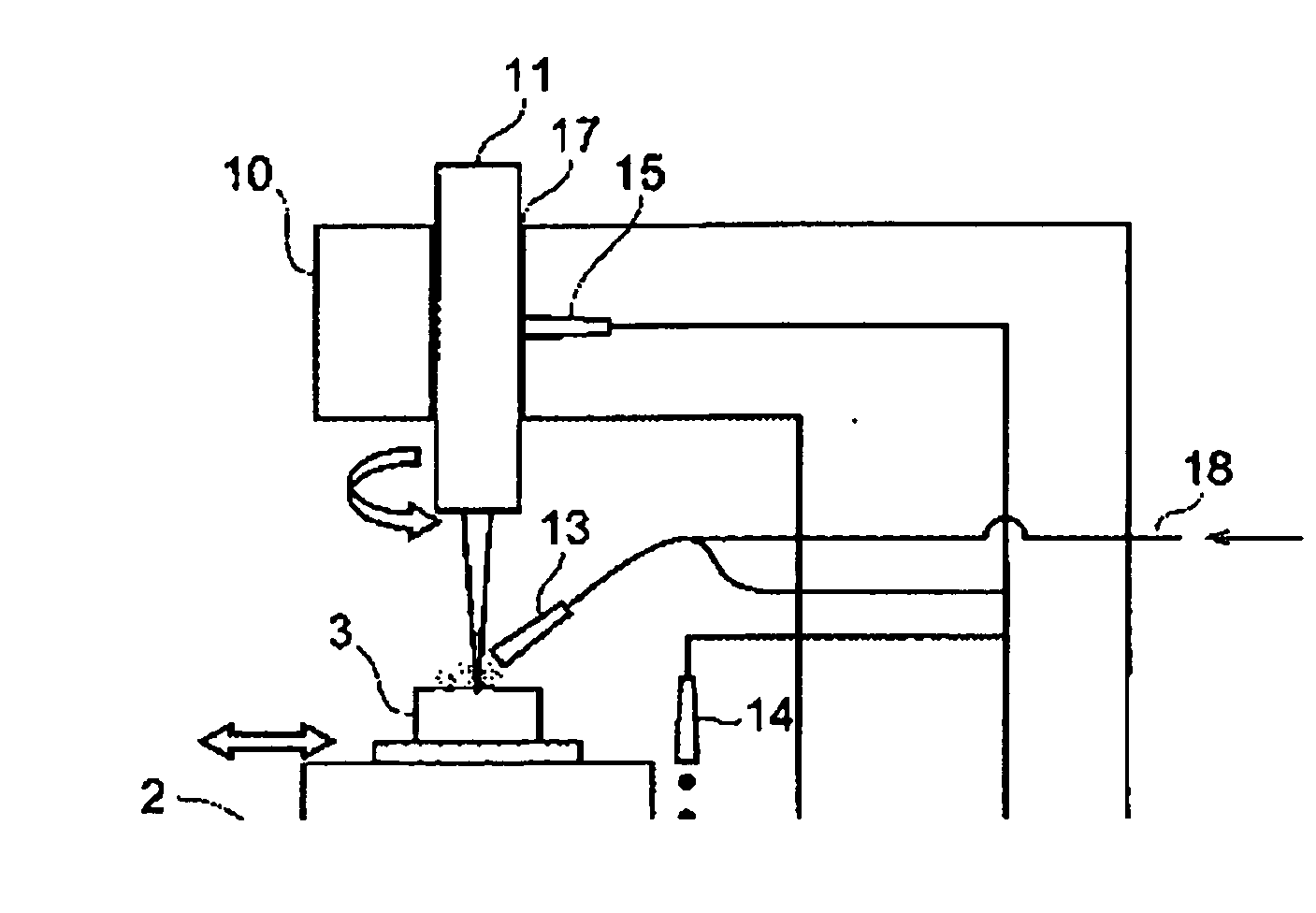

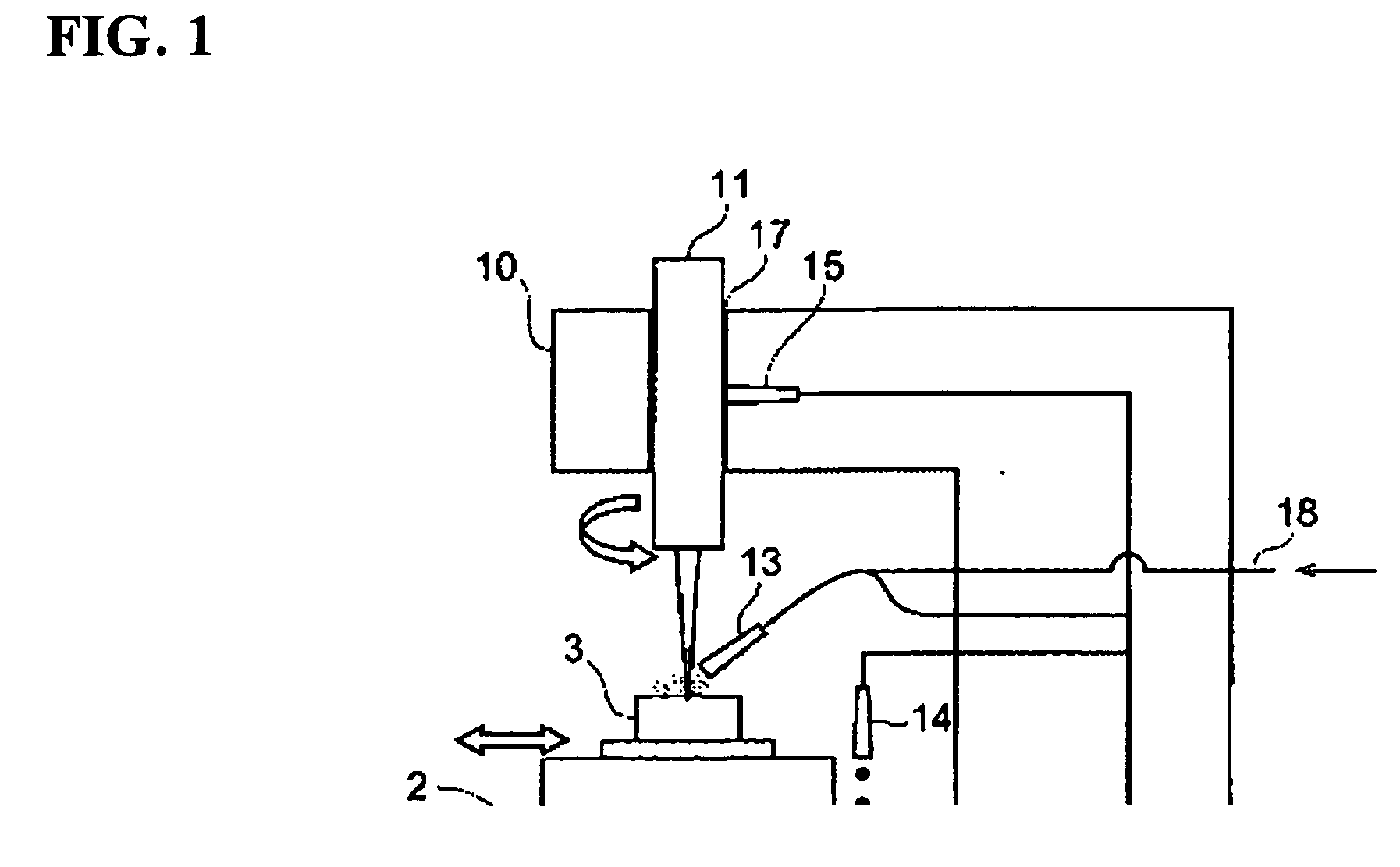

Multifunctional hydrocarbon oil composition

ActiveUS20090111723A1Improve working environmentReduce odorOrganic chemistryOrganic non-surface-active detergent compositionsElectric dischargeMetalworking

A multifunctional, high-performance hydrocarbon composition is demanded. Concretely, a metalworking oil composition having high workability even under a severer lubricating condition while resisting to high productivity, and further capable of suppressing deterioration of working environments or degradation of quality of a product without rise of lubricant cost, a metalworking oil composition for minimal quantitative lubrication system, which is excellent in characteristics as a water-insoluble lubricant for nonferrous metalworking and also in characteristics as a lubricant for cutting / grinding by minimal quantitative lubrication method, and can attain improvement in working efficiency and a further extended tool life, an electric discharge machining oil improved in working environments such as odor or skin roughness and further improved in processing rate, particularly processing rate in high-level finish, a rust preventing oil composition improved in resin compatibility, and a detergent excellent in adaptability with organic material are demanded.Therefore, metalworking oil which contains, as hydrocarbon base oil, hydrocarbon base oil having a density at 15° C. of 0.7 to 0.8 g / cm3, and including a n-paraffin content of 10 to 90% by mass, an aromatic content of 0 to 3% by volume, and a naphthene content of 0 to 20% by volume, a metalworking oil including the above-mentioned base oil and ester oil, and electric discharge machining oil, rust preventing oil, and a detergent composition including the above-mentioned base oil are provided.

Owner:NIPPON OIL CORP

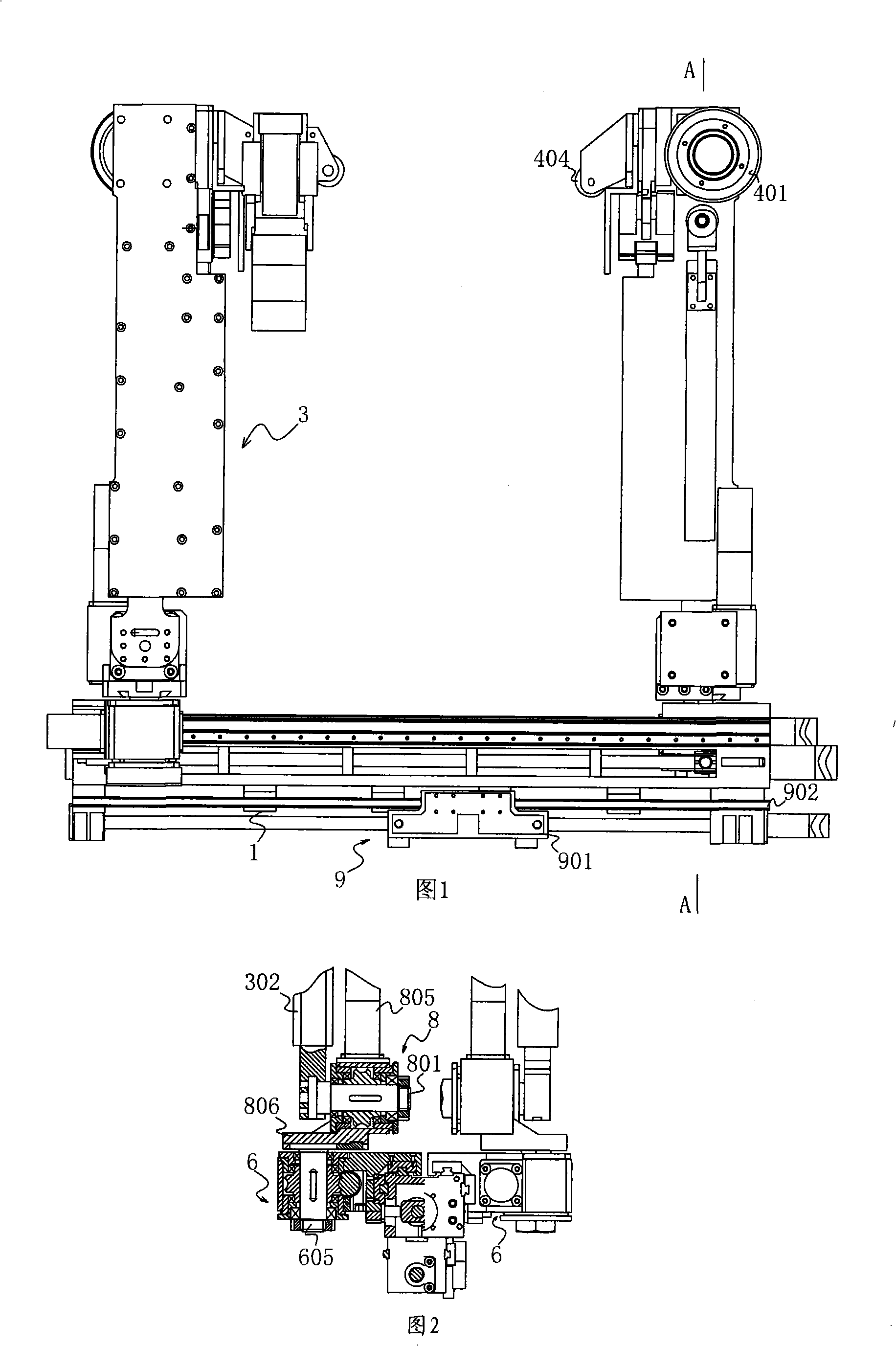

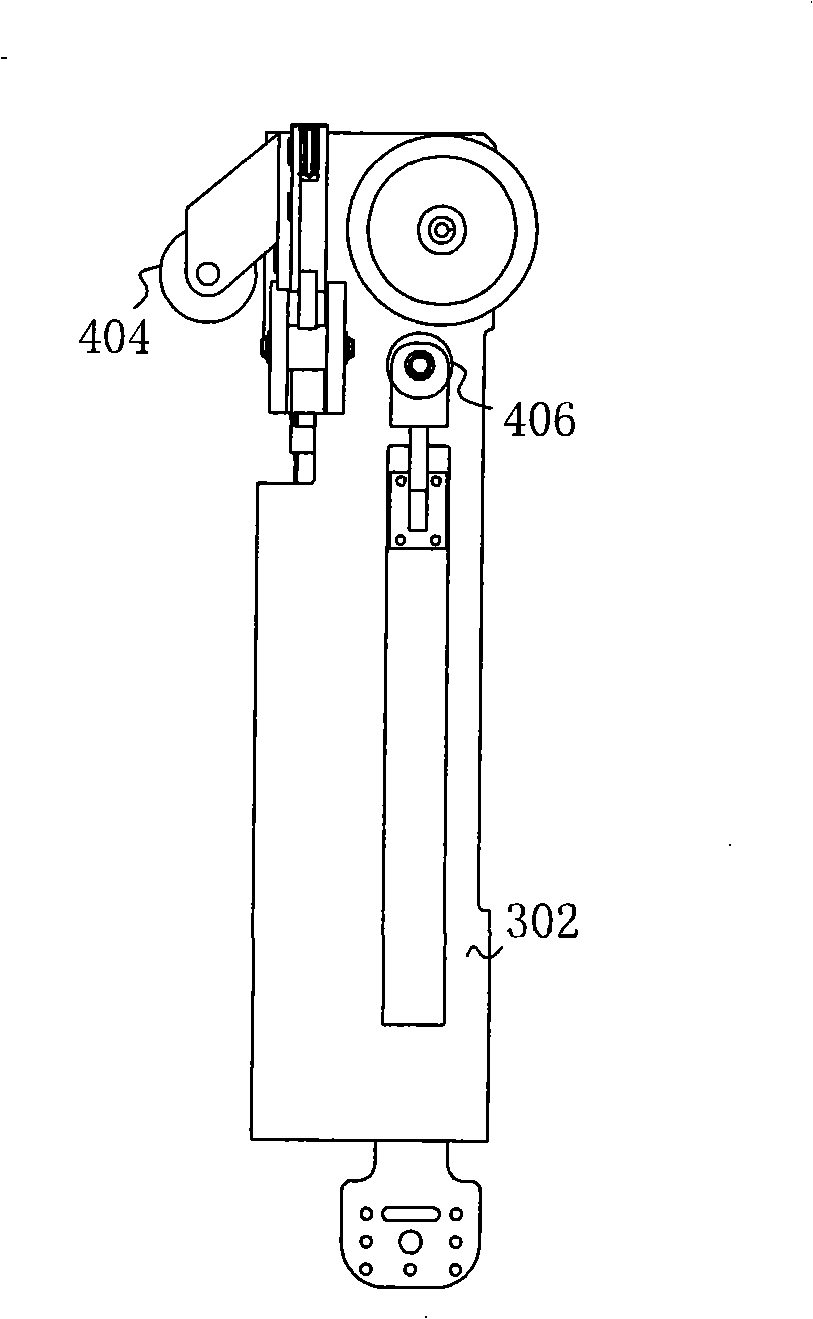

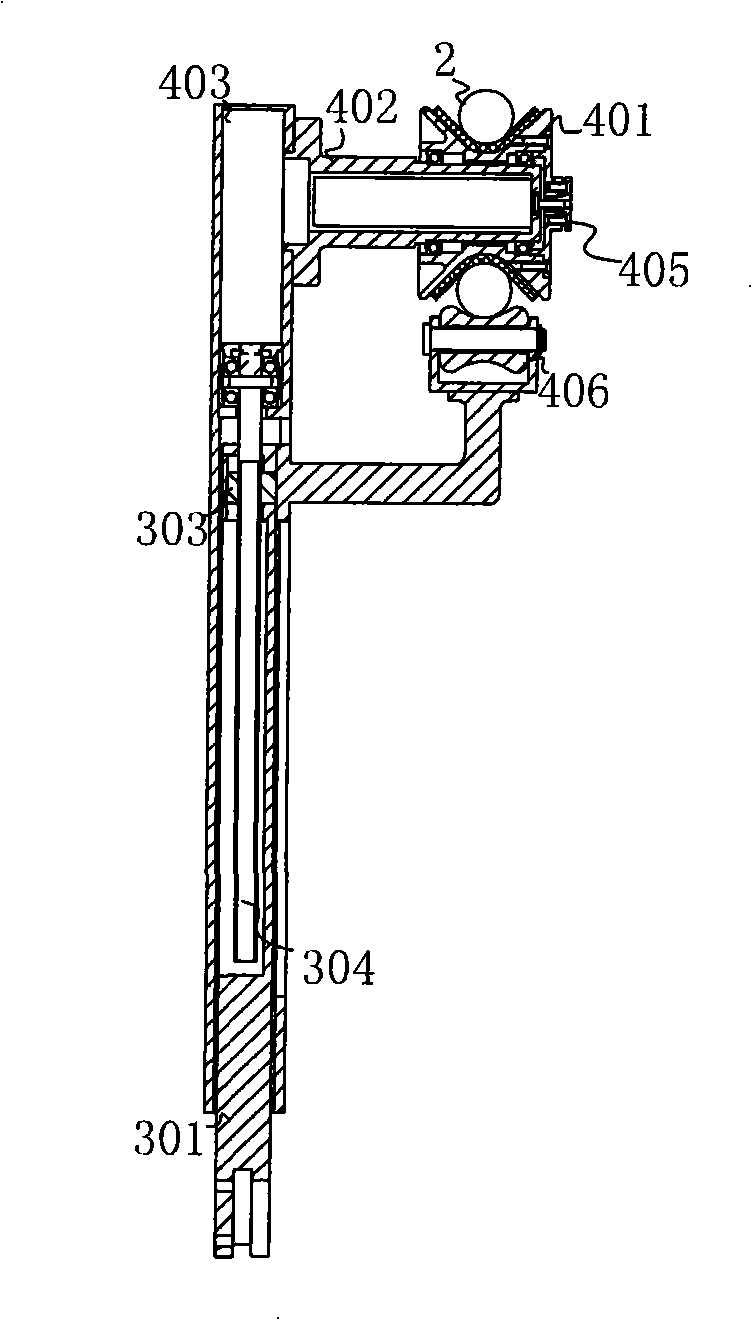

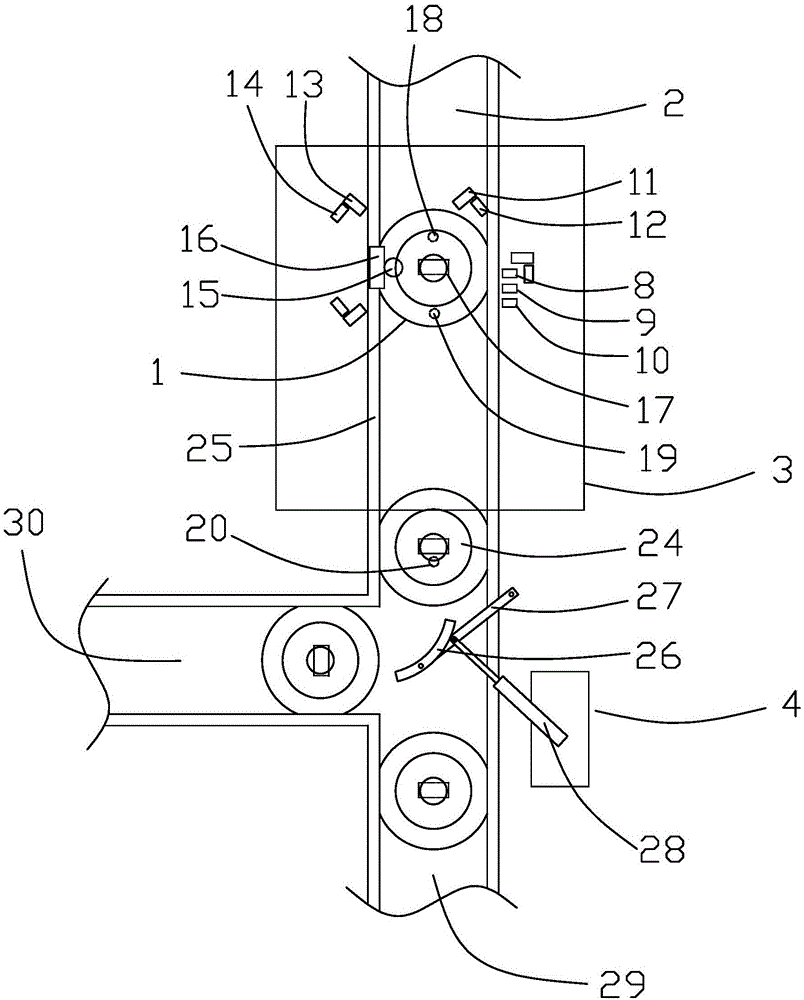

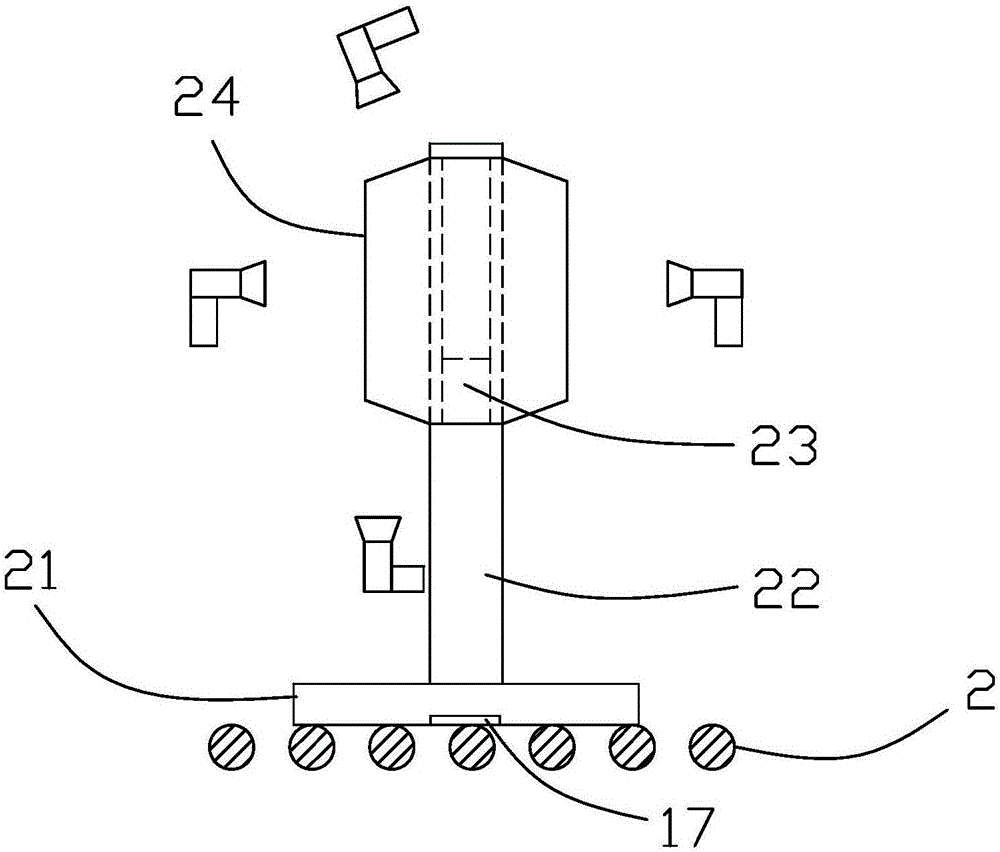

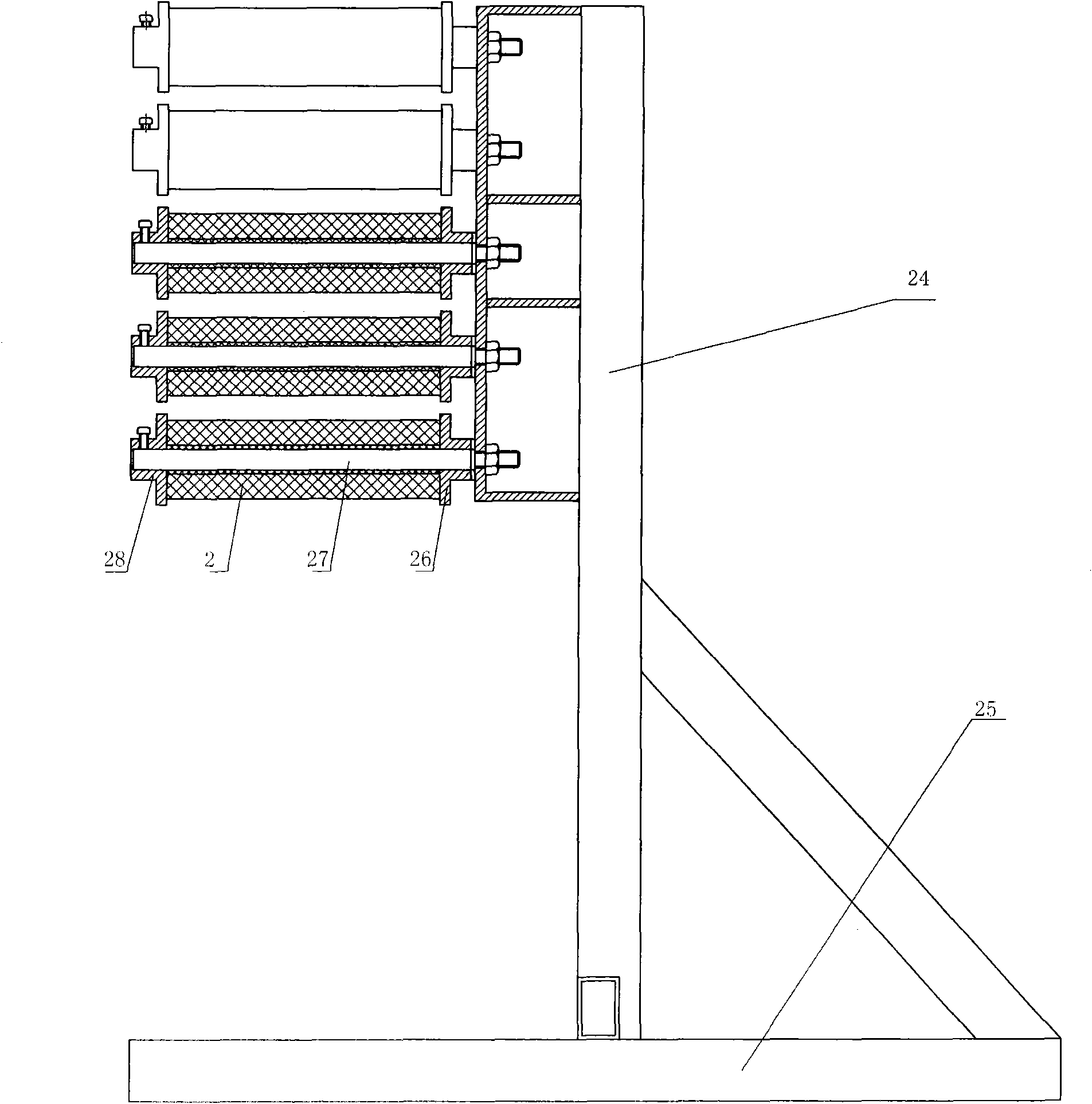

Robot

The present invention relates to a robot which runs along a multi-splitting overhead high voltage transmission line, in particular to the structure improvement of a robot which runs along the whole course of an overhead high voltage transmission line. The present invention creatively connects the lower end of a big arm with a gravity adjusting mechanism by a support frame. The gravity adjusting mechanism has the function of adjusting the gravity of the robot at proper time during the process that the robot moves forwards by two arms in turn, so as to ensure that the robot is stable during the running process, can not cause the gravity excursion of a whole operation vehicle and cause the phenomenon that the operation vehicle can not run stably on a transmission line. In addition, the robot can run along the whole line of the overhead high voltage transmission line and can span over or avoid various kinds of barriers on the line, and the robot is not required to be conveyed from one side of a pole tower to the other side by manpower, thereby greatly shortening the auxiliary time for the robot to operate, improving the work efficiency and ensuring the safety of the detection process.

Owner:WUHAN UNIV

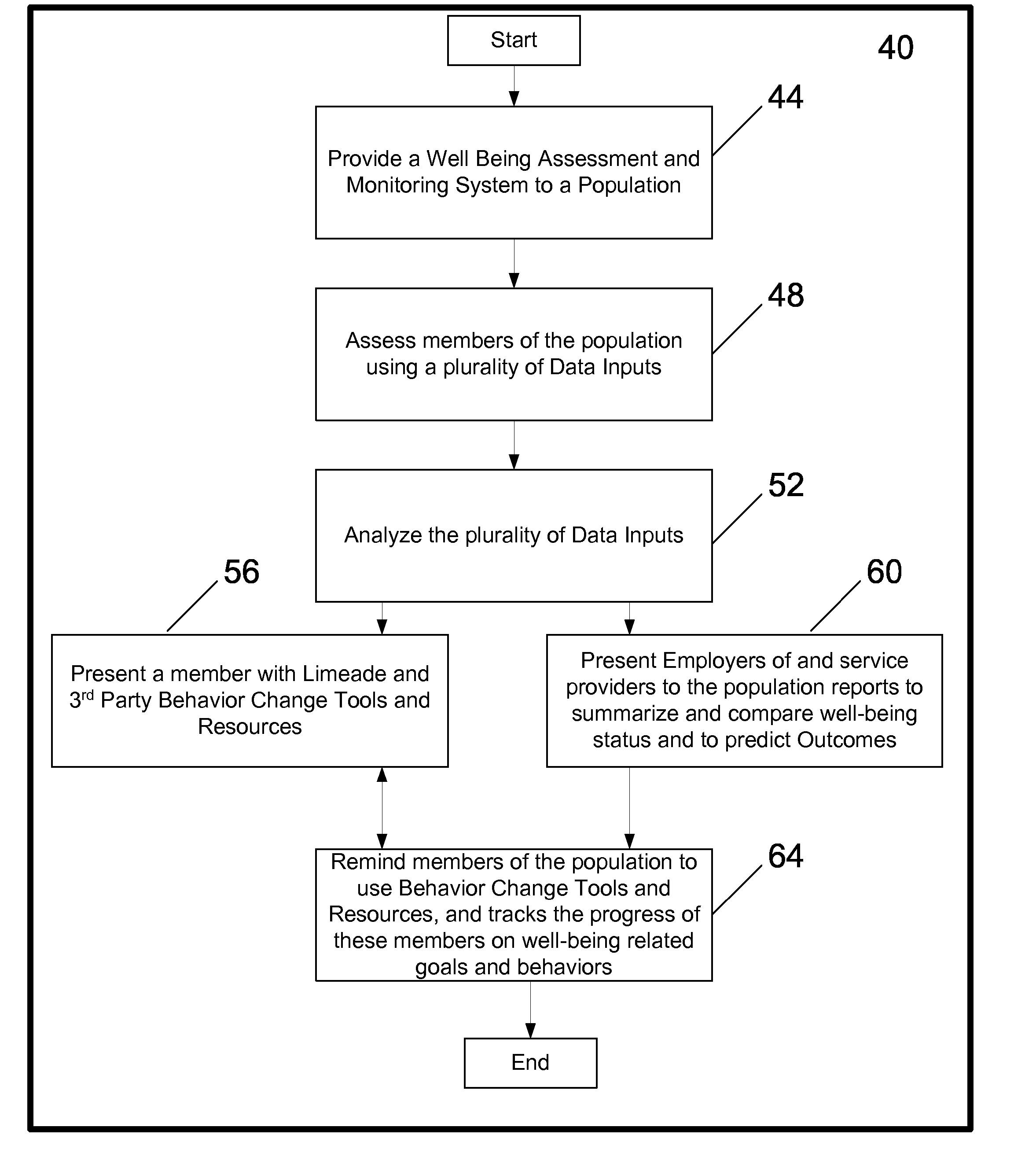

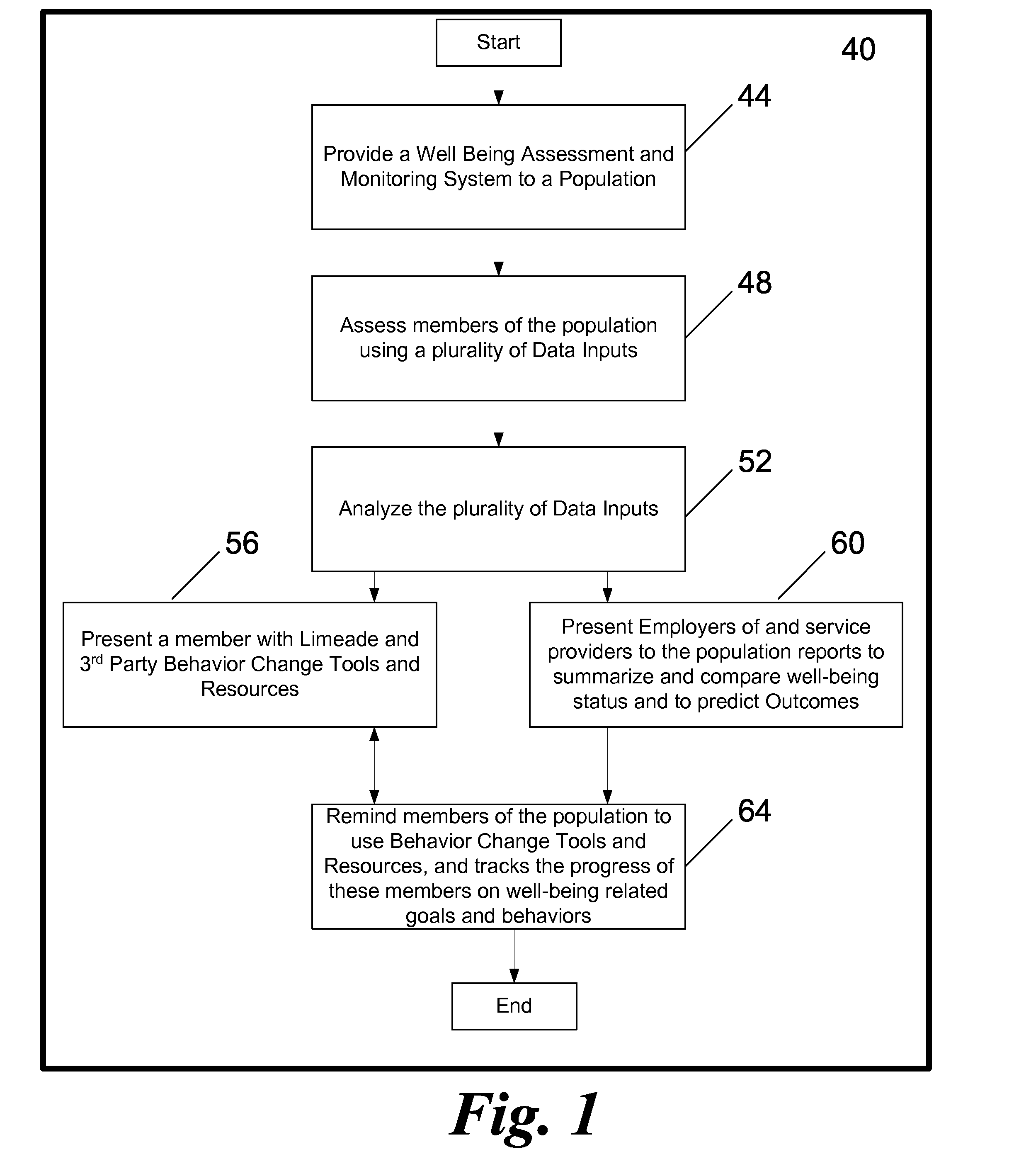

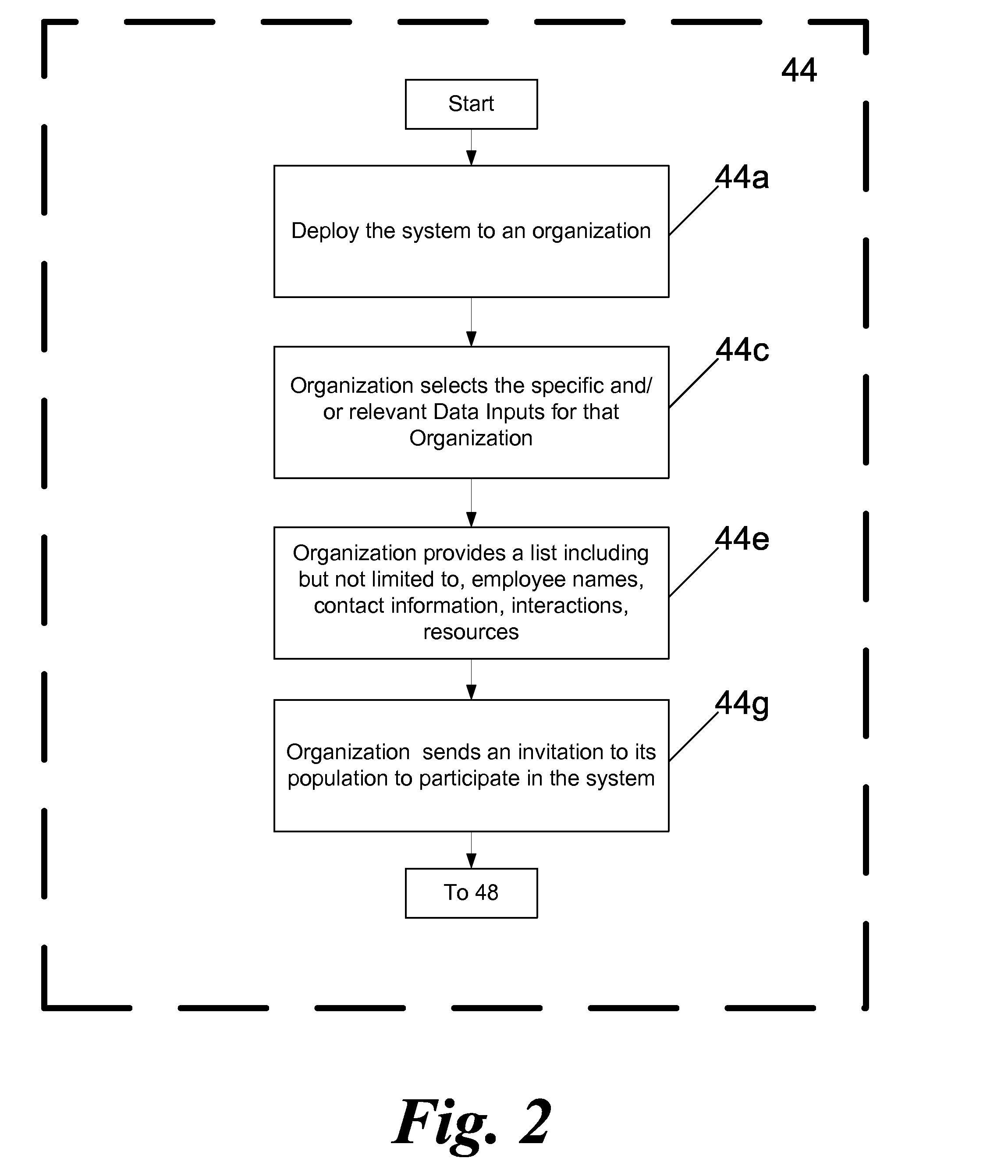

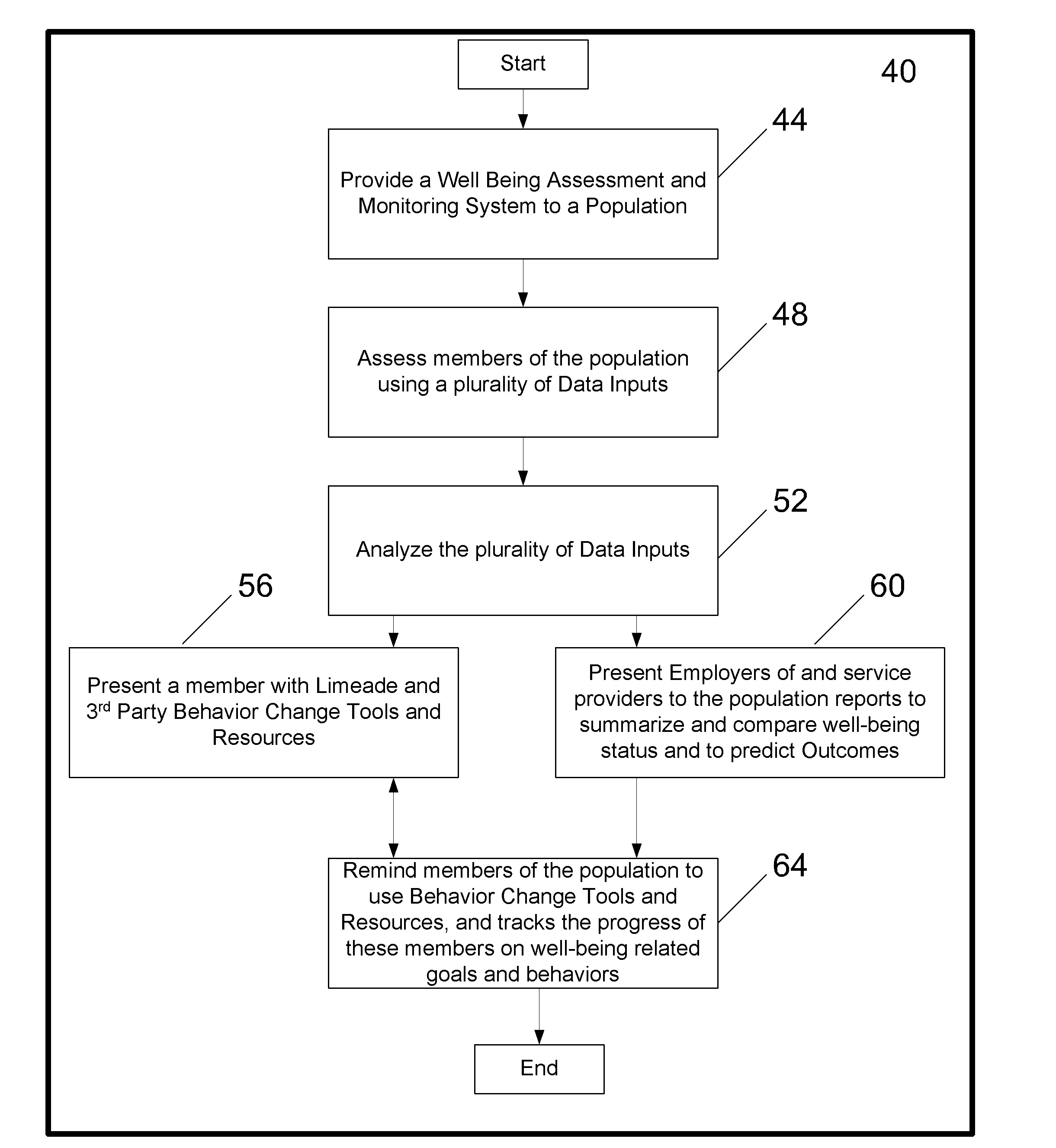

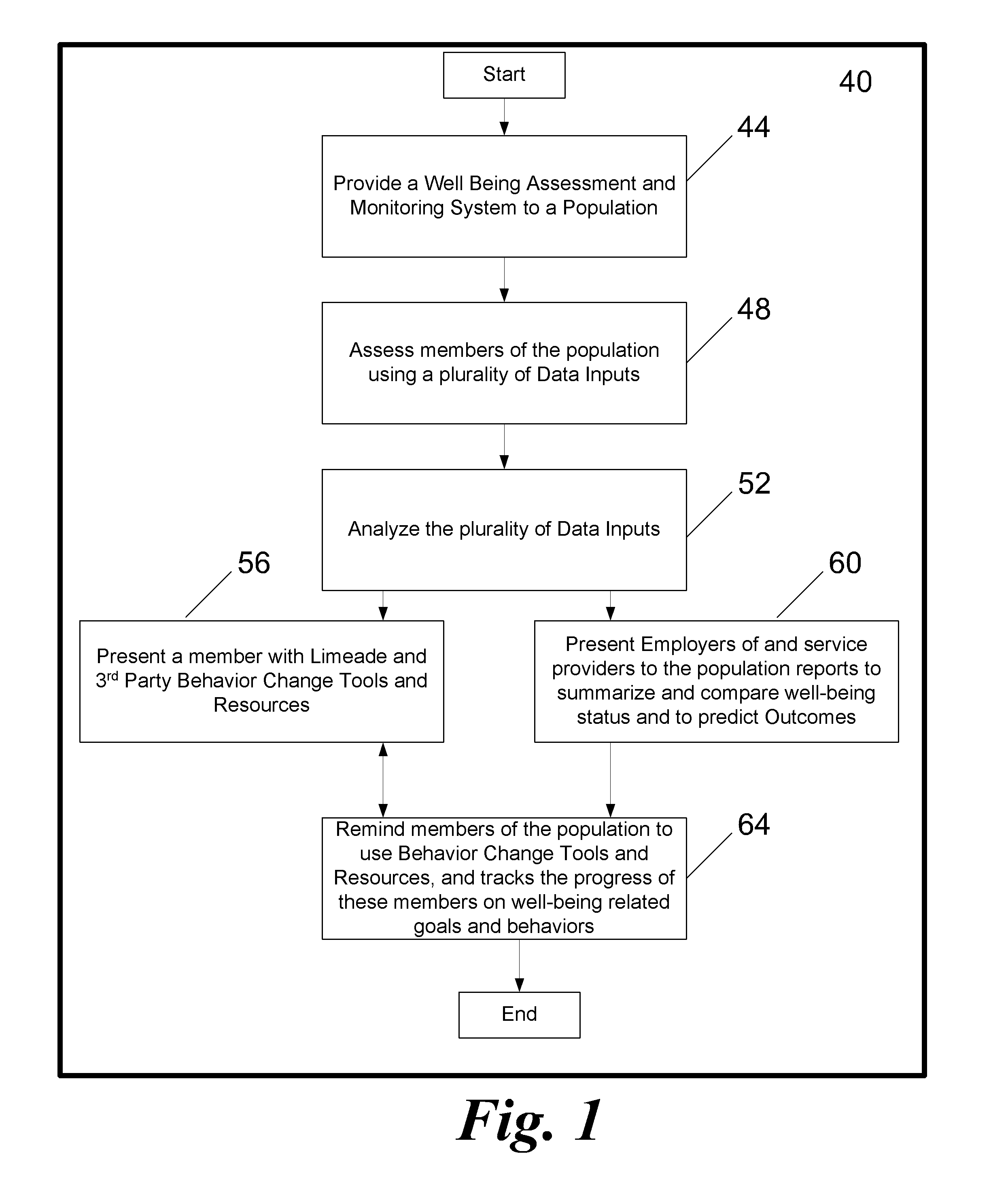

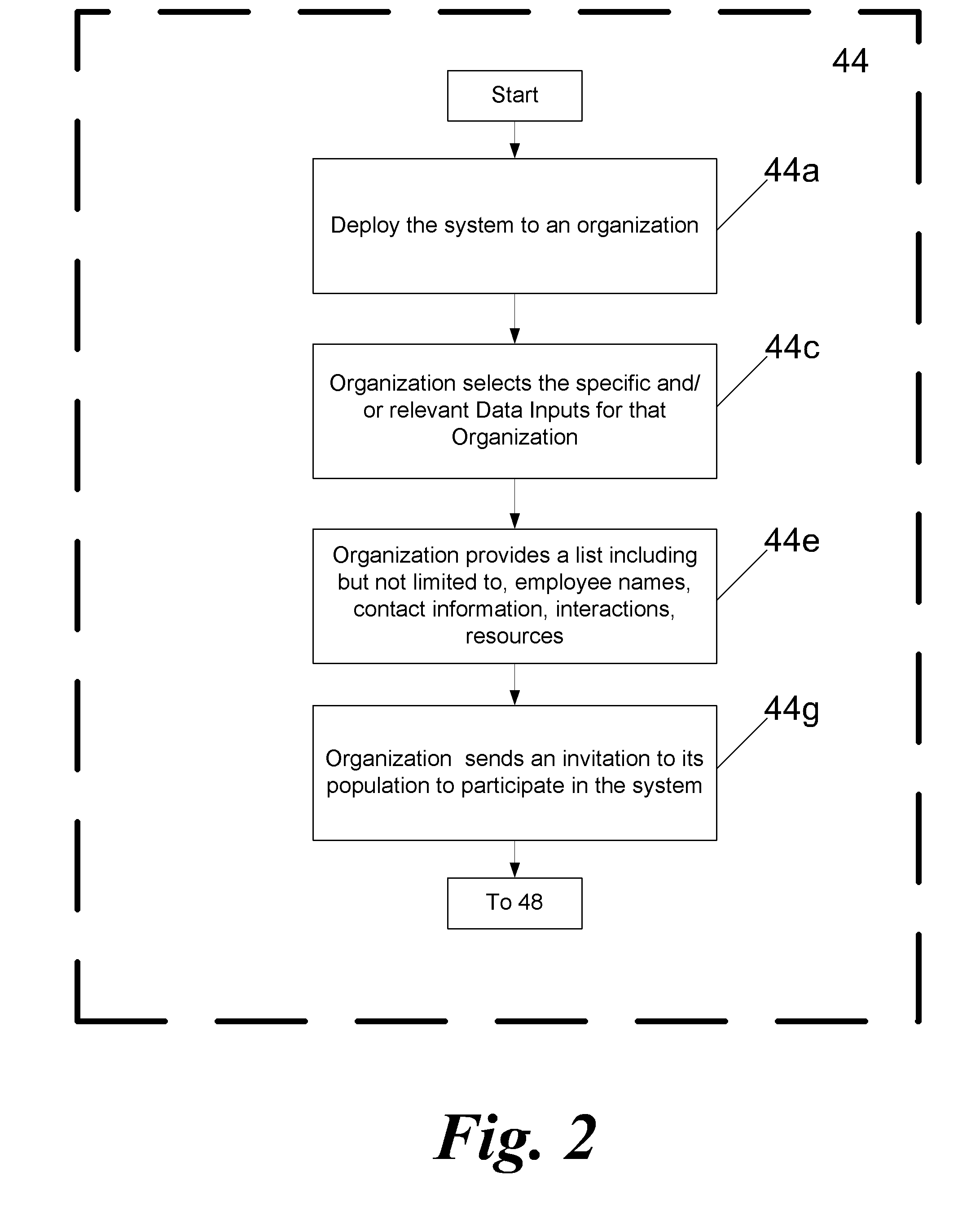

Systems and methods for a holistic well-being assessment

InactiveUS20080109257A1Predictable outcomeEpidemiological alert systemsComputer-assisted medical data acquisitionThird partyThe Internet

Systems and methods are described for an assessment tool built on a holistic well-being improvement model. The model consists of a series of assessments including, but not limited to a well-being improvement assessment, work productivity assessment, and a clinical health risk assessment. A member would complete these assessments through an internet site, on paper, on the phone, and / or on any other medium generally known in the art. After a member participates in the assessment, the assessment is analyzed based on a series of predefined algorithms. A member is then provided with system tools and access to third party behavior change tools and resources. Concurrently the data is compiled for the benefit of an employer and / or a provider in the form of an aggregate report in order to understand the status of the current population's well being and also providing the ability to predict future outcomes. The system further tracks the progress of a member on their well-being goals and behaviors.

Owner:LIMEADE

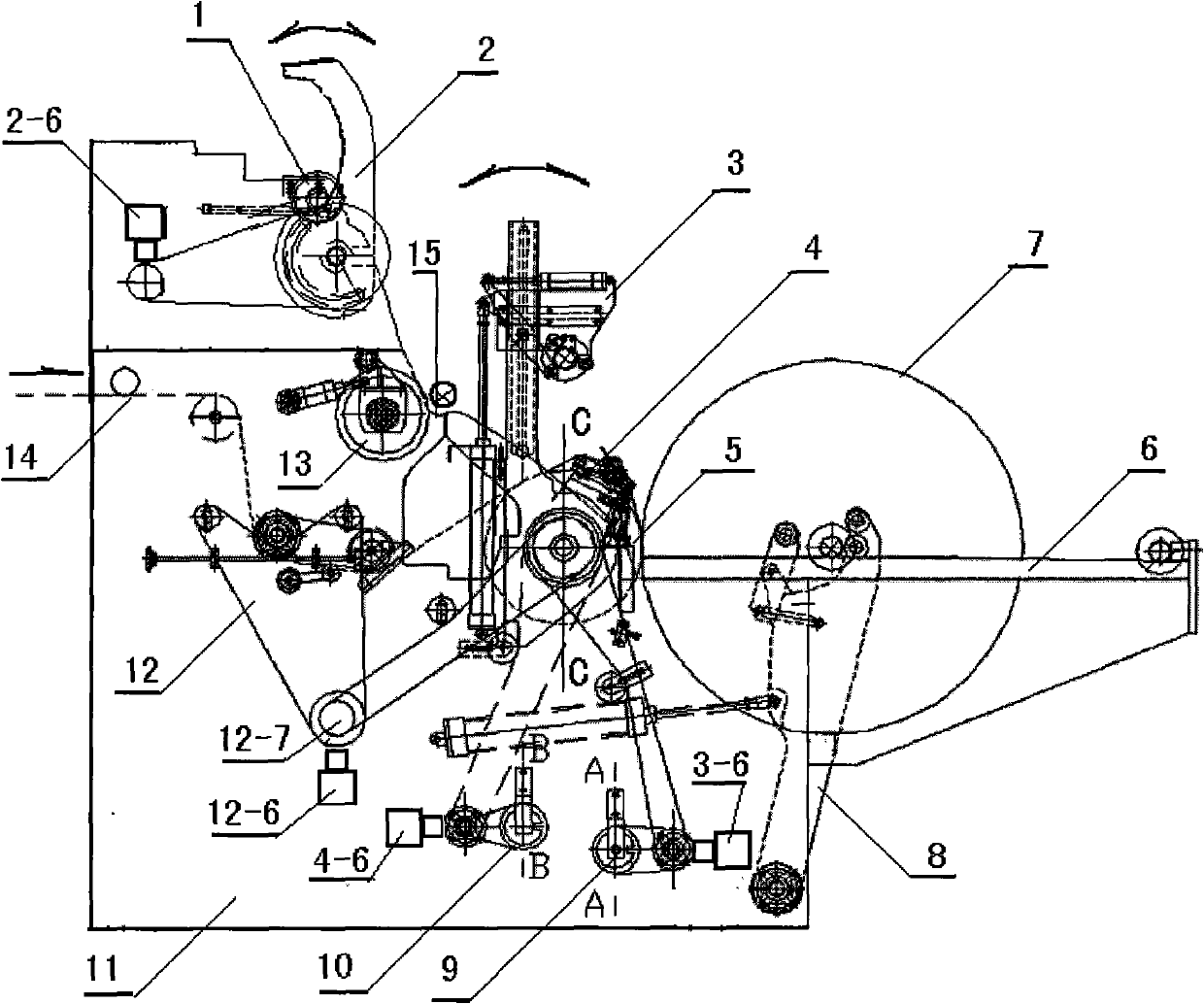

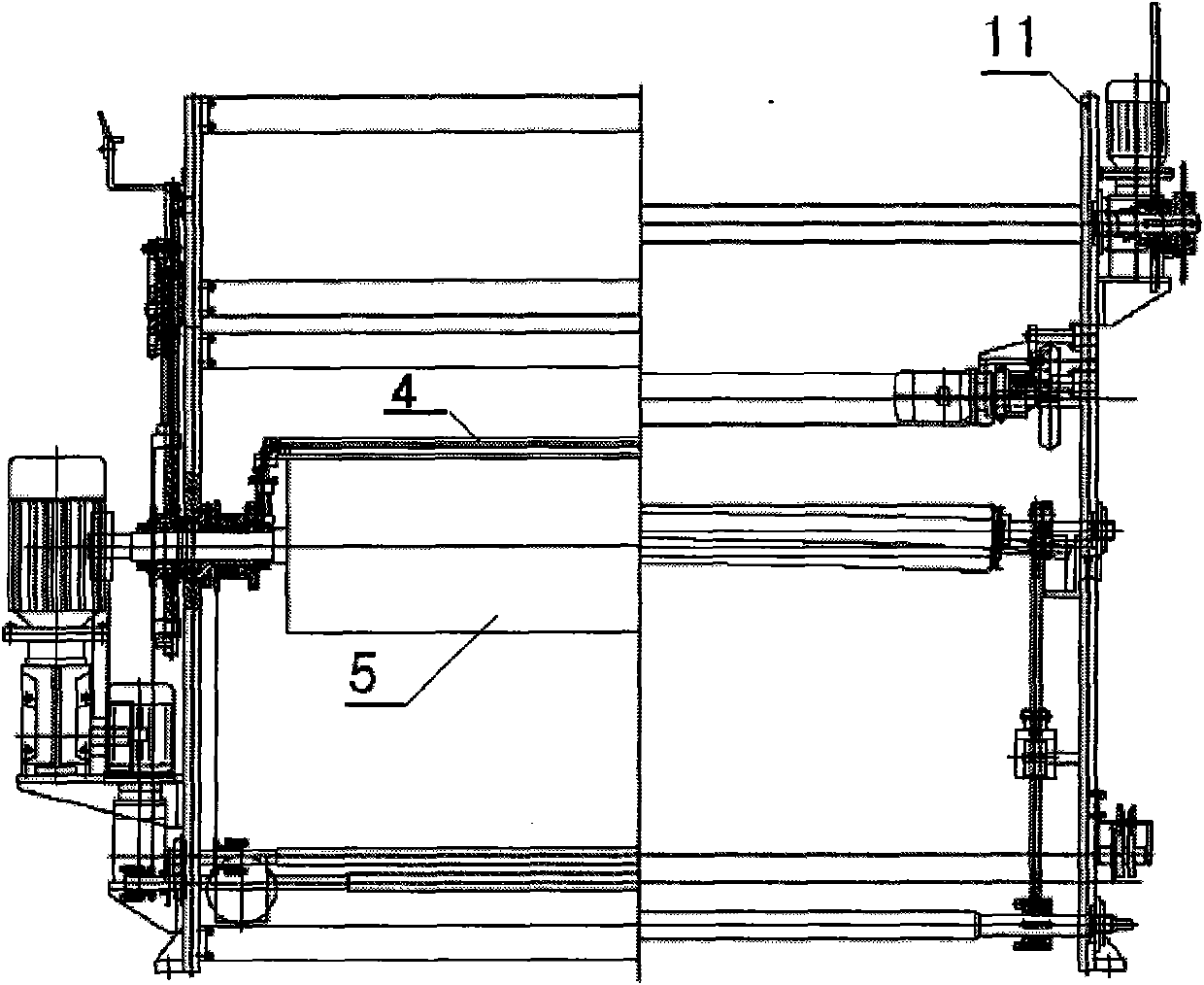

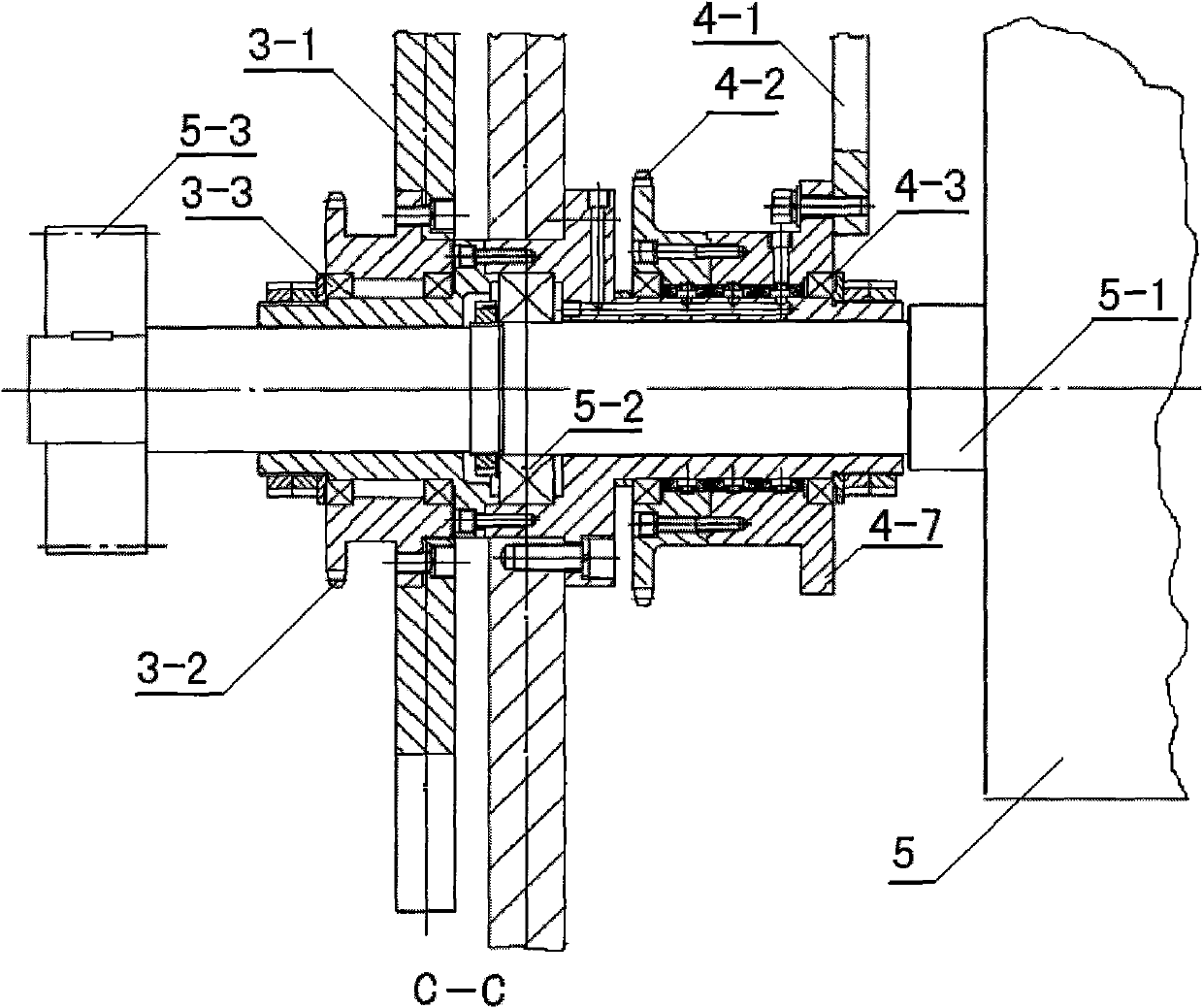

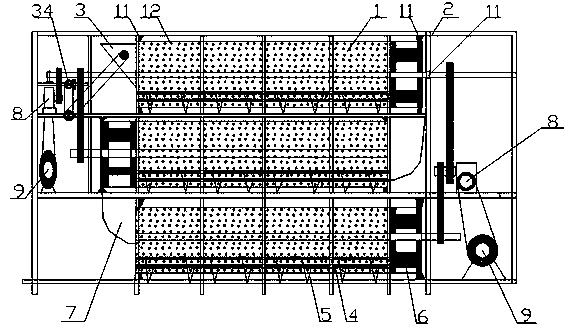

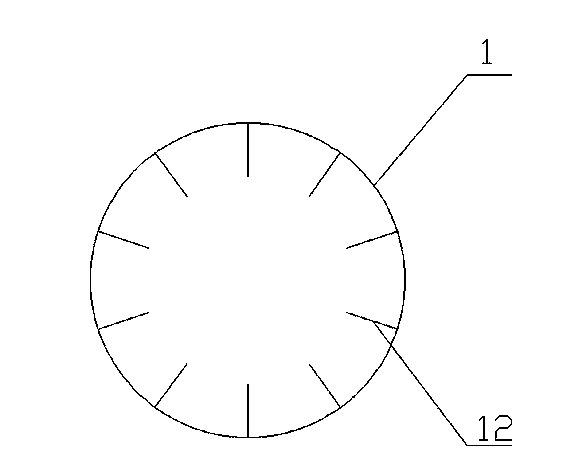

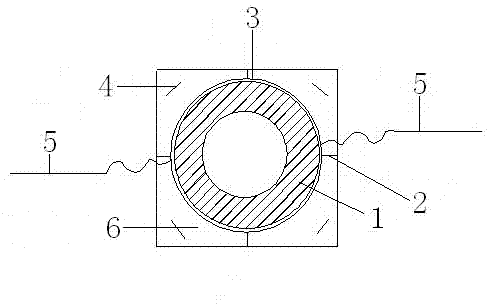

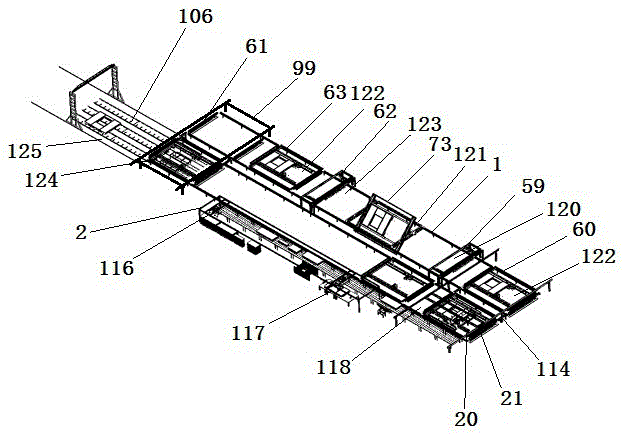

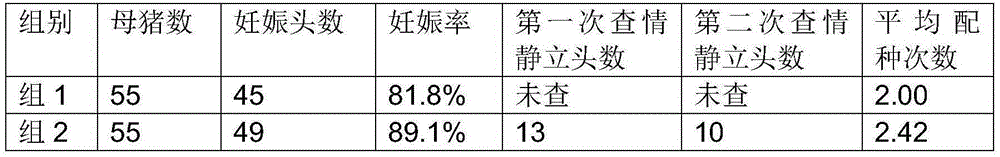

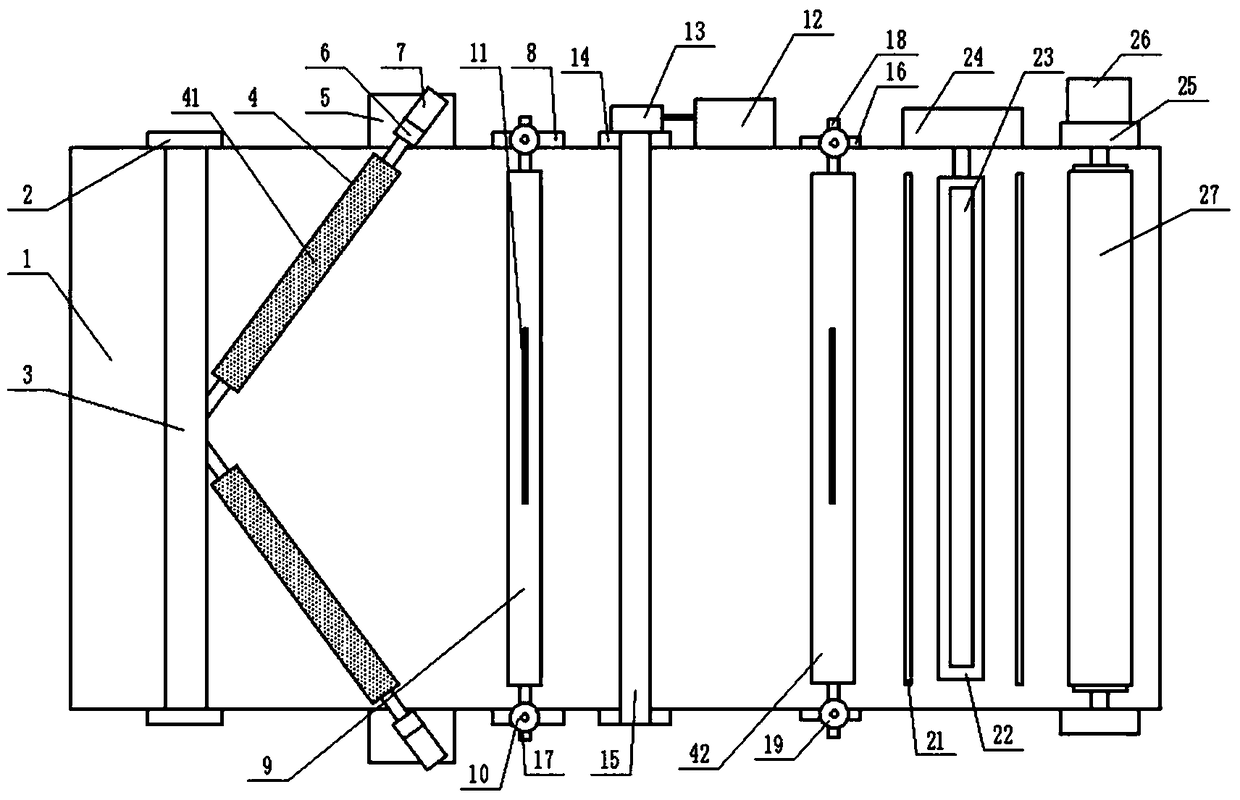

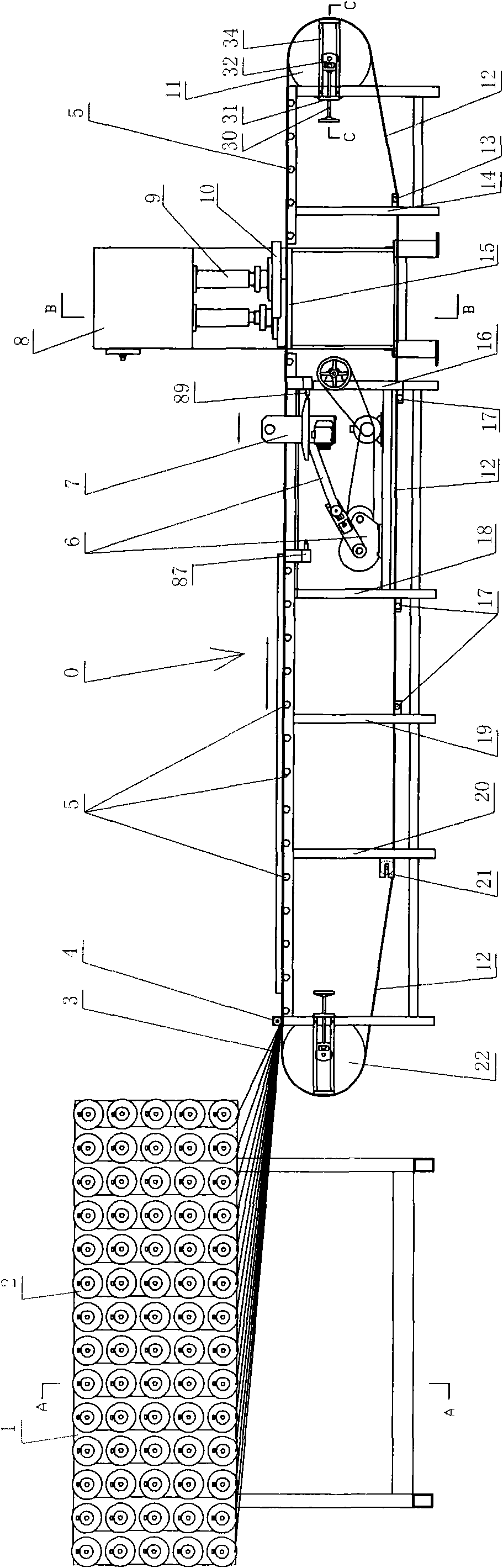

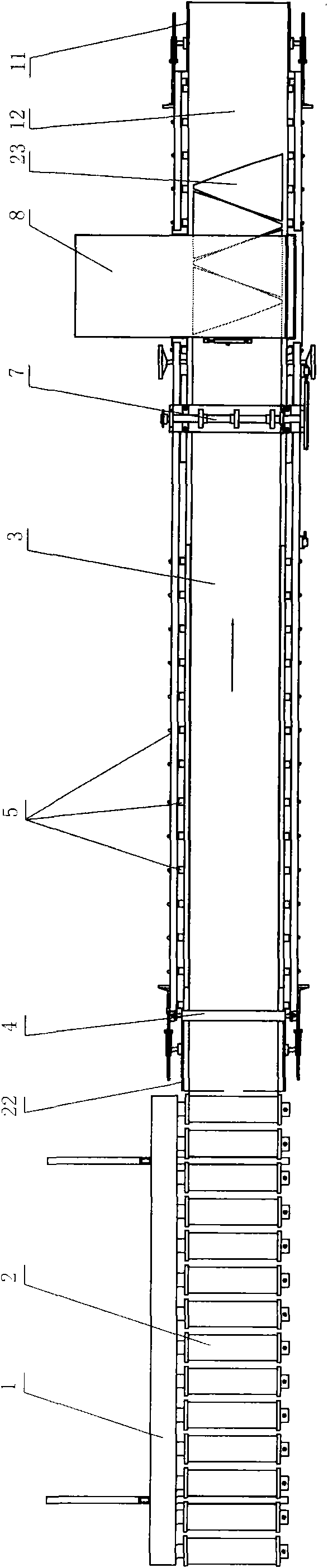

Full-automatic high-speed winder

The invention provides a full-automatic high-speed winder, which realizes the full automation and high speed in the production process of non-woven fabrics. The full-automatic high-speed winder adopts the program control for cooling, cloth cutting and shaft exchanging and realizes automatic regulation for the main indicators of tension, rotating speed and diameter of a cloth roll, thereby adapting to the requirements of high speed and automation of a hot rolling machine, so that the hot rolling machine can keep good running state all the time, and the excellent quality of the produced non-woven fabrics is ensured. The winder is the equipment integrated with the machine, the electric apparatus and the instrument and has the advantages of compact structure, full functions, high speed, high efficiency and accurate measurement. The winder achieves the following indicators: the effective working width is 2,000mm, the mechanical speed is regulated at 20-350m / min, and the maximum winding diameter Phi is 2,200mm, therefore, the winder has high working efficiency and economic efficiency.

Owner:余克

Systems and methods for a holistic well-being assessment

InactiveUS20090319347A1Epidemiological alert systemsComputer-assisted medical data acquisitionThird partyThe Internet

Systems and methods are described for an assessment tool built on a holistic well-being improvement model. The model consists of a series of assessments including, but not limited to a well-being improvement assessment, work productivity assessment, and a clinical health risk assessment. A member would complete these assessments through an internet site, on paper, on the phone, and / or on any other medium generally known in the art. After a member participates in the assessment, the assessment is analyzed based on a series of predefined algorithms. A member is then provided with system tools and access to third party behavior change tools and resources. Concurrently the data is compiled for the benefit of an employer and / or a provider in the form of an aggregate report in order to understand the status of the current population's well being and also providing the ability to predict future outcomes. The system further tracks the progress of a member on their well-being goals and behaviors.

Owner:LIMEADE

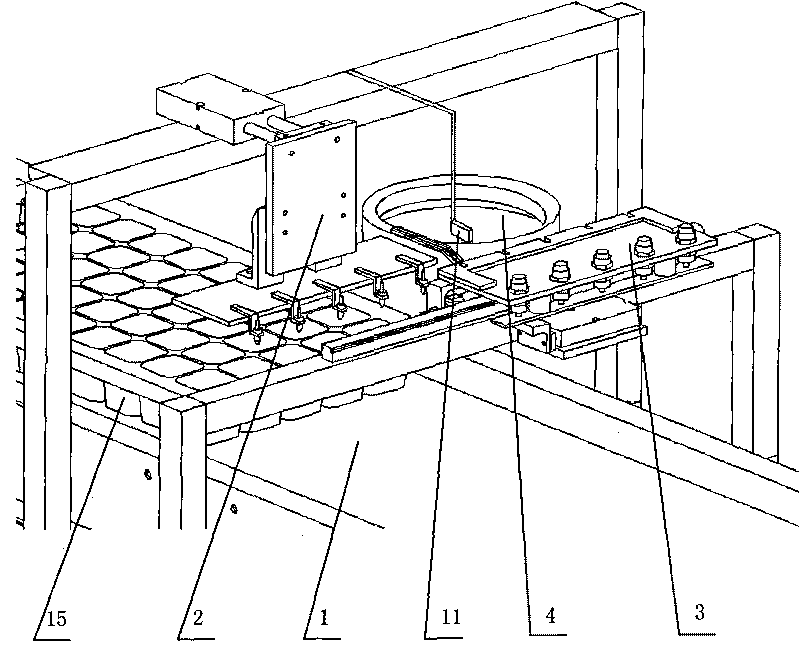

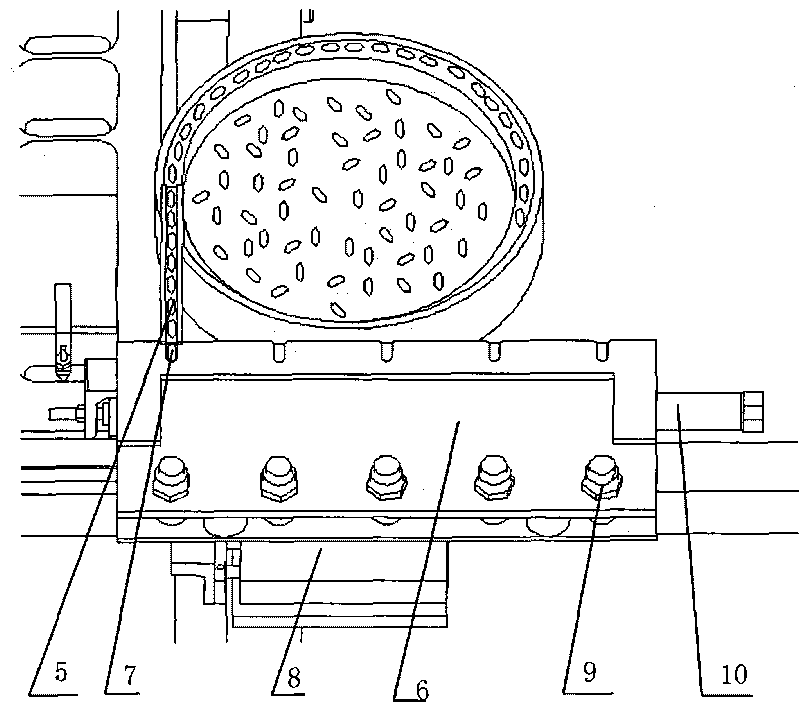

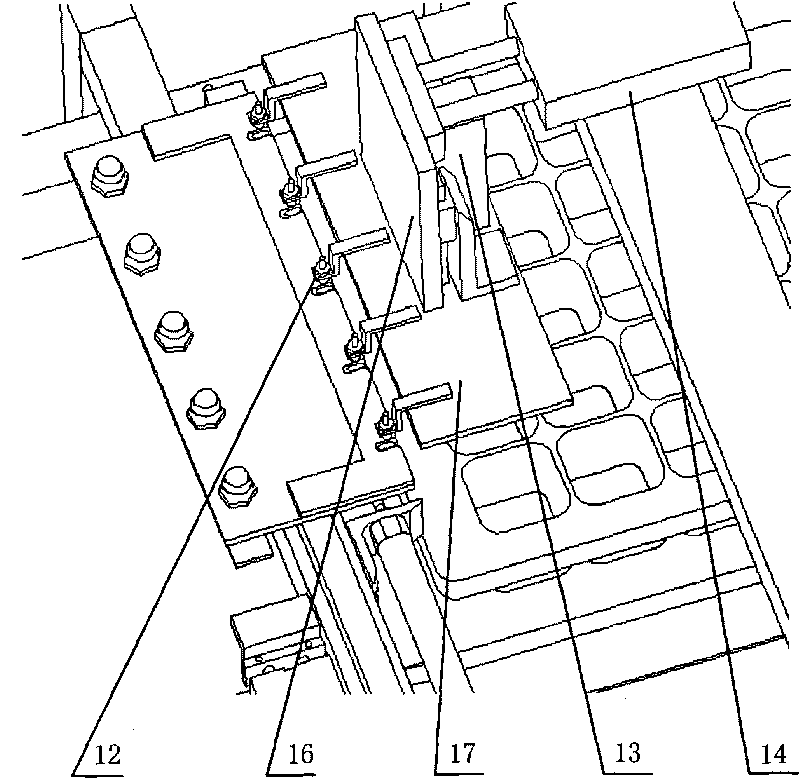

Long grained seed steering precision seeding device and seeding method thereof

InactiveCN101702969ATo achieve the purpose of batch directional seedling cultivationImprove job productivitySeed depositing seeder partsProduction rateEngineering

The invention provides a long grained seed steering precision seeding device comprising a plug conveyer belt, a directional seed delivering device, a directional seed dividing mechanism and an air-aspiration seeding mechanism, wherein the directional seed delivering device and the direction seed dividing mechanism are connected and are arranged at the same side of the plug conveyer belt; the air-aspiration seeding mechanism is arranged above the plug conveyer belt; a seed delivering slide way is arranged in the tangential direction of the edge of the directional seed delivering device; the seed delivering slide way and the directional seed dividing mechanism are connected; and the plug conveyer belt, the directional seed delivering device, the directional seed dividing mechanism and the air-aspiration seeding mechanism are fixed on a stand. The invention also provides a seeding method for realizing the seeding device; long grained seeds are delivered and absorbed into the hole of a plug respectively by the directional seed delivering device, the directional seed dividing mechanism and the air-aspiration seeding mechanism, thereby realizing precision seeding. The invention can provide seedlings with even germination and uniform cotyledon direction for melon crop full automatic engrafting devices and other equipment and has the advantages of high work productivity, stable work quality and the like.

Owner:SOUTH CHINA AGRI UNIV

Monocrystal silicon-rod butting technique

InactiveCN101664970AImprove work efficiencyEasy to cutFine working devicesPolishing compositions with abrasivesAdhesiveEngineering

The invention relates to a monocrystal silicon-rod butt technique, comprising the following steps: selecting a round monocrystal silicon rod of which the length is 220-500 mm and the diameter is 153-160 mm, and vertically sticking the silicon rod to crystal support of a butting machine with adhesive; putting the crystal support of the butting machine and the round monocrystal silicon rod on a magnetizing workbench, numbering and recording, and magnetizing to fix the crystal support and the round monocrystal silicon rod; calibrating the positioning table, setting the cutting parameters, and starting the butting machine to carry out the sand-bearing cutting; degumming the cut semifinished product, removing the side skin and separating the crystal support; and inspecting whether the semifinished product is qualified or not. The technique has favorable cutting effect and greatly increases the qualification rate and improves the working efficiency of the machine; and after the space of theguide wheels is corrected, even if the sand during the cutting is not enough, the technique can ensure the whole dimension within the range of the tolerance value.

Owner:无锡尚品太阳能电力科技有限公司

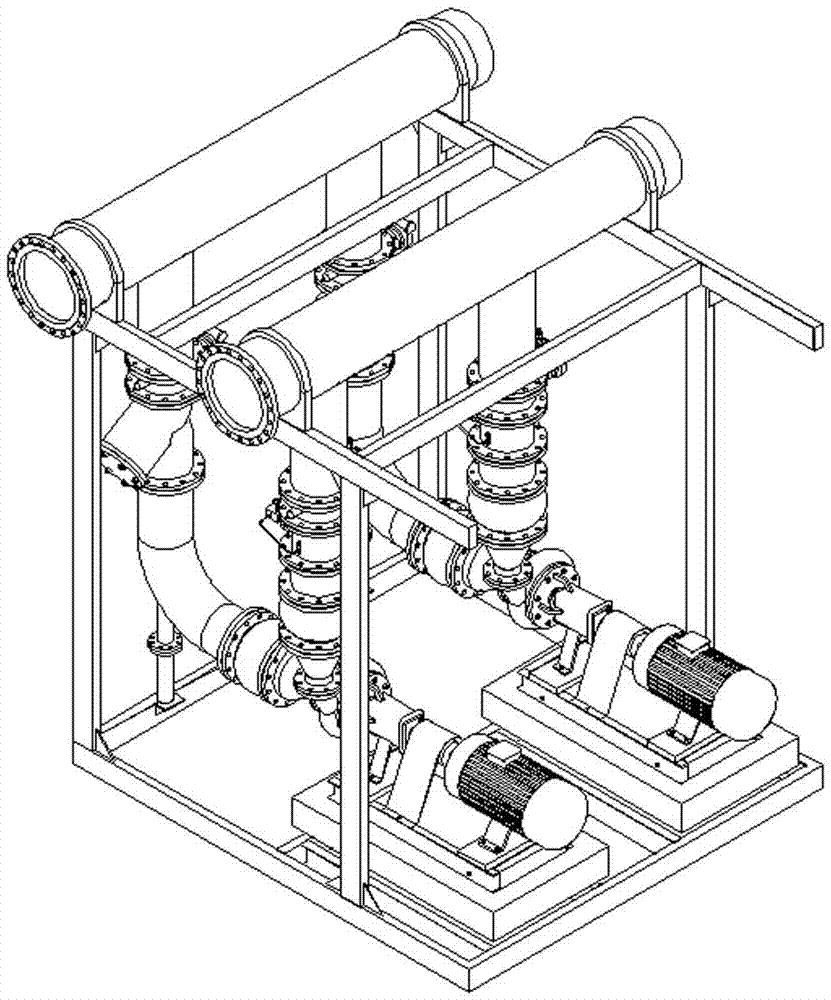

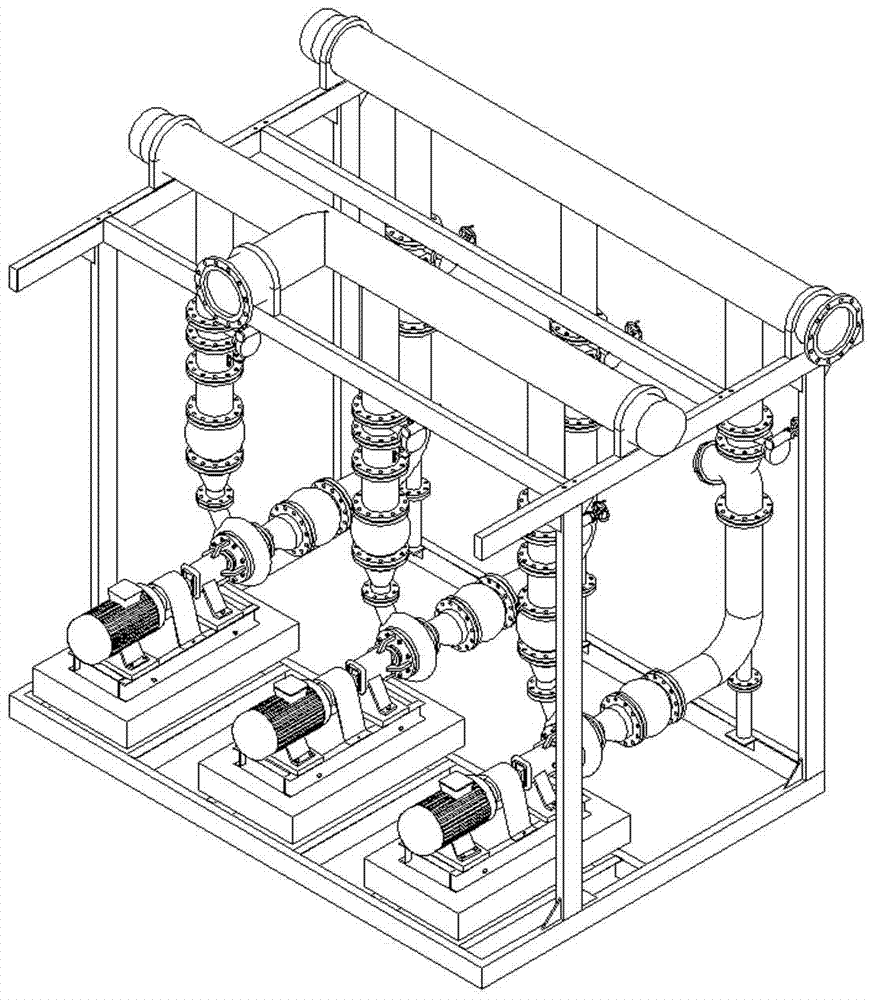

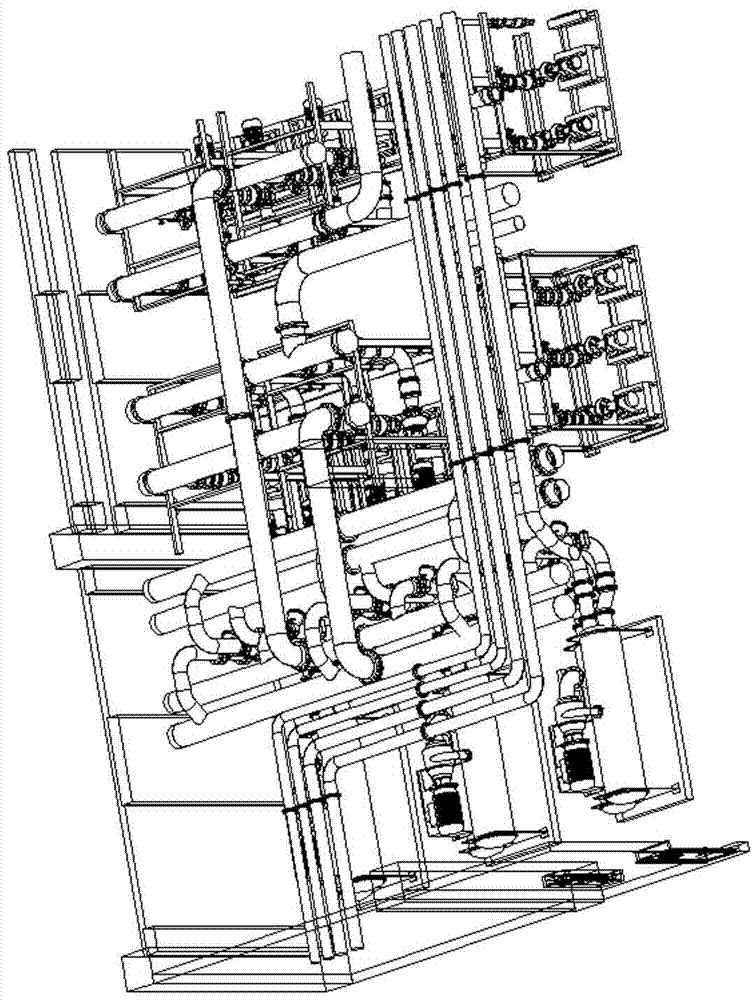

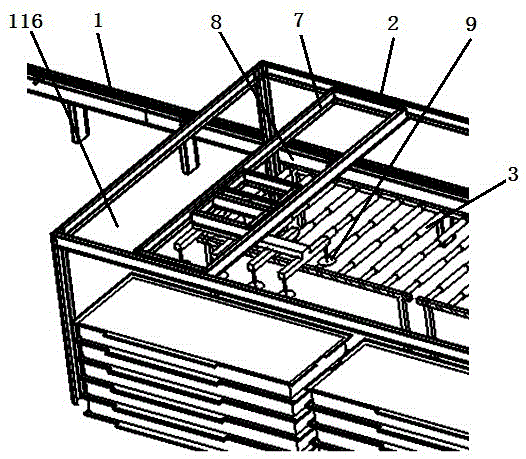

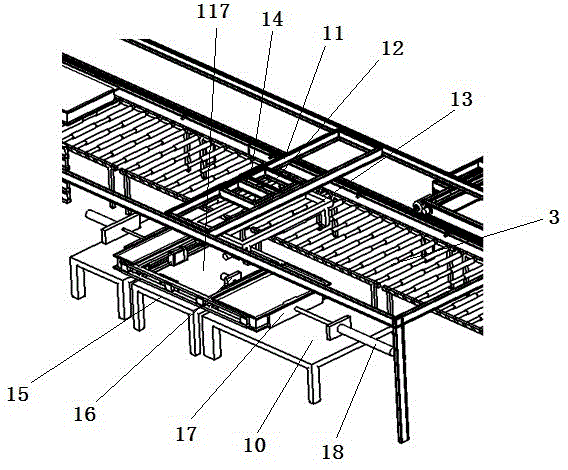

BIDA integral engineering technology system

InactiveCN107542161AEfficient transportImprove transportation efficiencyBuilding constructionsTechnological systemResource saving

The invention provides a BIDA integral engineering technology system, and belongs to the technical field of construction engineering. According to the technical system, a BIM model is used, refined family library building according to a construction sample, BIM model building for deep design, prefabricated processing segmentation and grouping, processing detailed diagram drawing, factory prefabrication processing, field assembly and debugging and acceptance check are performed. The BIM technology is used in the whole process for guiding the application. The technical system is favorable for engineering construction efficiency improvement and labor release. Through the standardized design, preassembled part factorized production and mechanical construction, the construction period is greatly shortened; in addition, the construction people number is reduced to a great degree; the work productivity is improved; the labor cost is reduced; and the energy source saving, resource saving and environment pollution reduction are facilitated. The engineering quality and construction safety improvement is facilitated; and the industrialization level improvement is facilitated.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

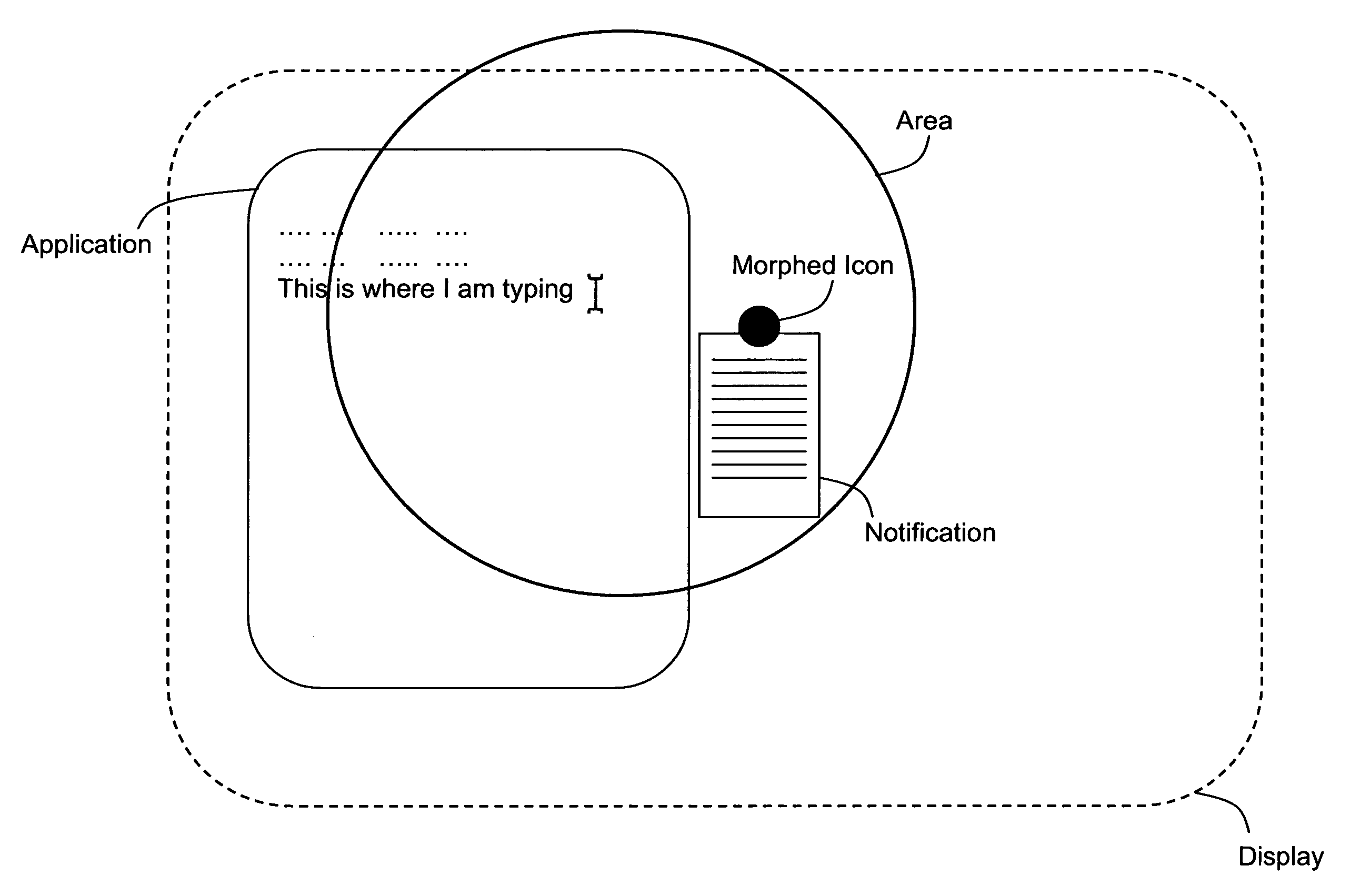

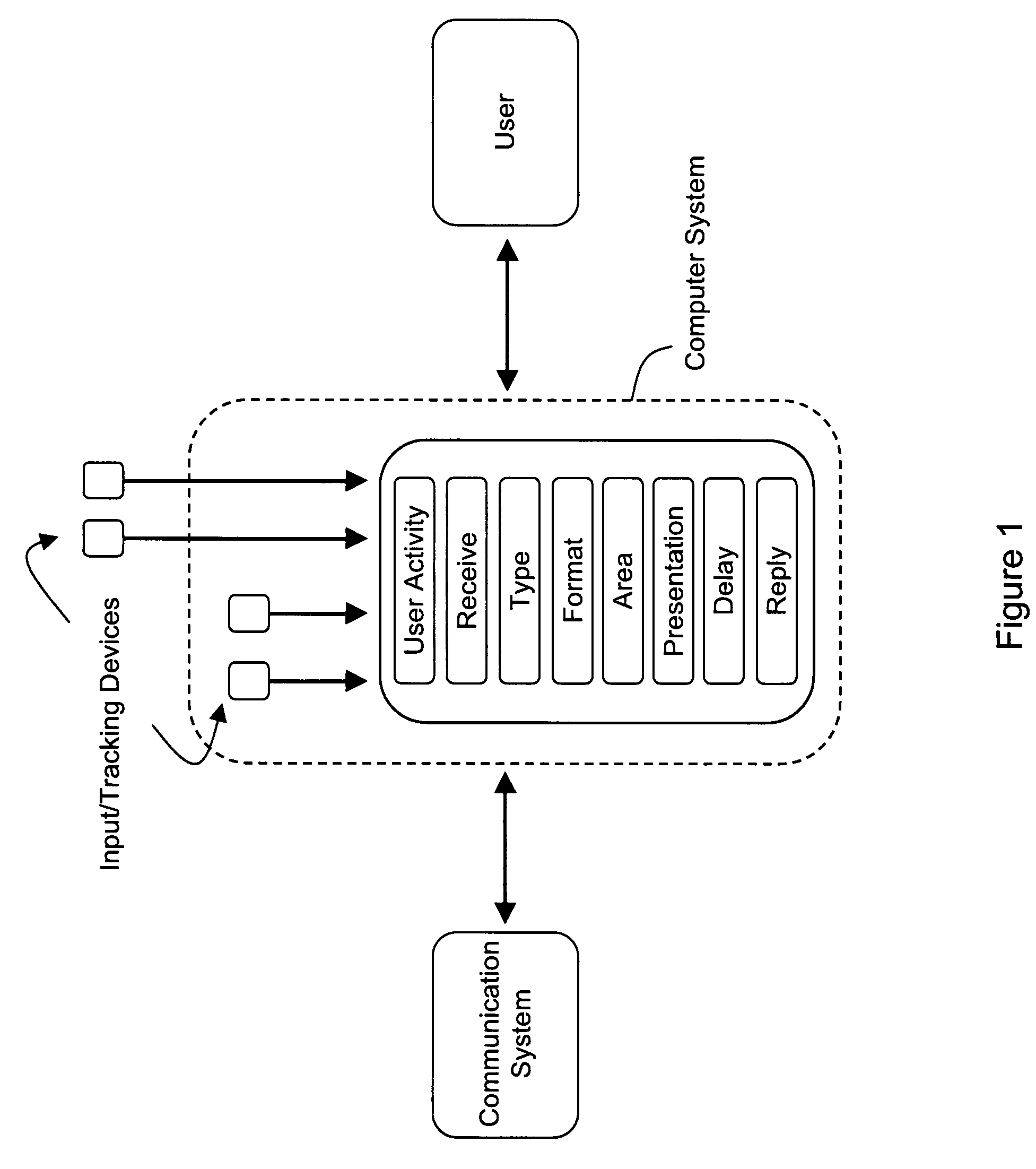

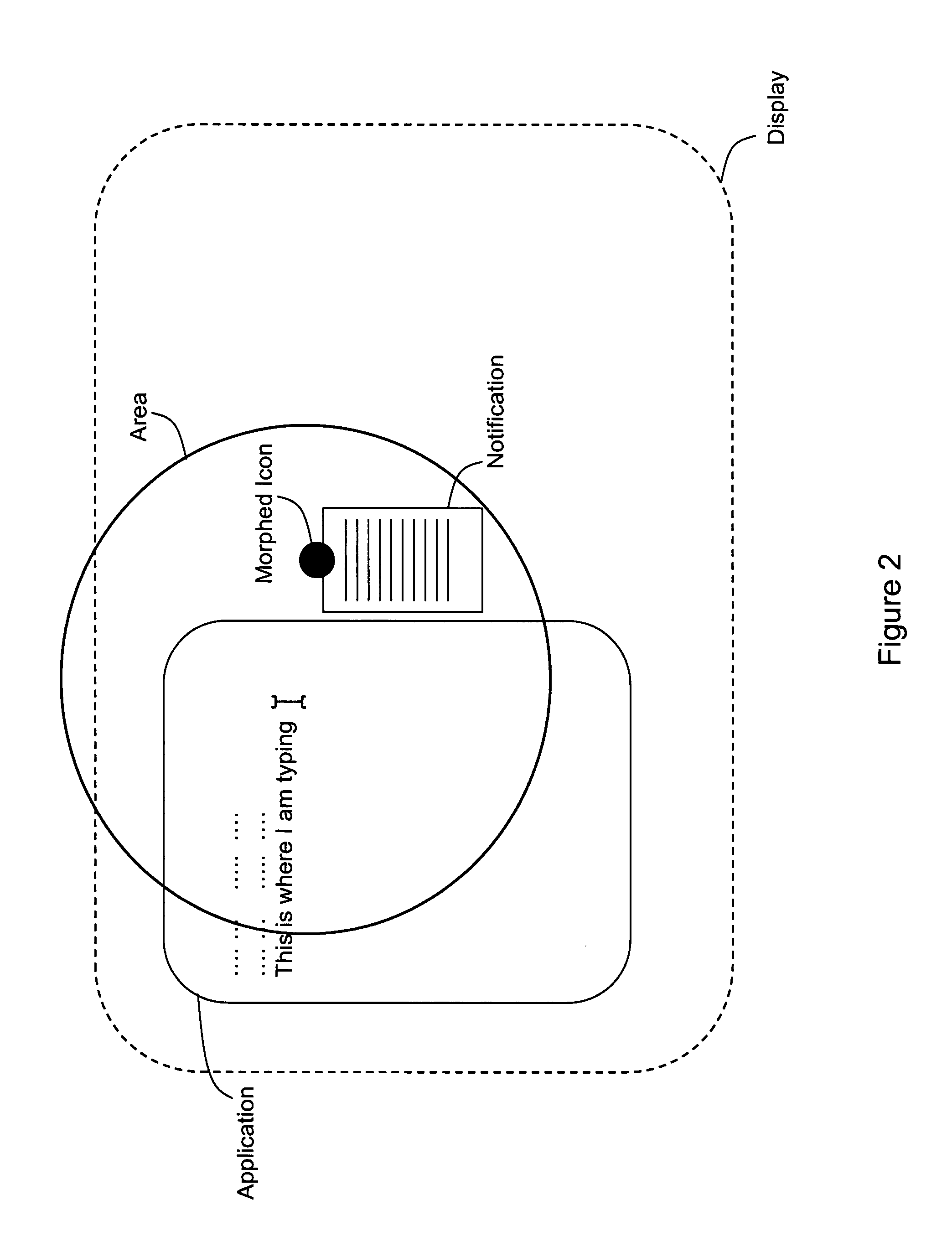

Automatic communication notification and answering method in communication correspondance

ActiveUS20090089716A1Reduce distractionsImprove work efficiencyInput/output for user-computer interactionMultiple digital computer combinationsDistractionDisplay device

A communication correspondence notification and reply method is provided. The method is implemented as a software program with the objective to be less distractive and to increase work productivity compared to prior methods. In particular, a notification format for incoming communication correspondences is determined, without any guidance / input from the user, taking into account (i) monitored user activity and (ii) the type of incoming correspondence, i.e. the notification format is a function of tracked / monitored user activity and the message type with the objective to minimize distraction to the user. To further minimize user distraction, the software program determines an area on the display of the computer system where the incoming correspondence can be presented to the user. Once presented, the user then has the ability to reply with minimal effort by making a pointer-device gesture movement in reply to the presented notification.

Owner:VSEE LAB

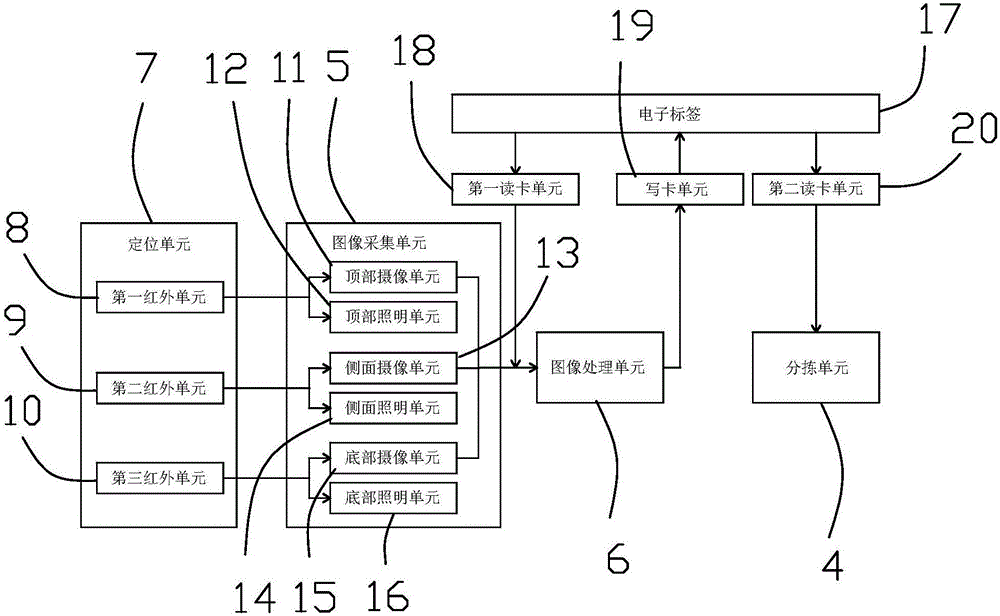

Self-learning chemical fiber spindle intelligent appearance detection system and method based on big data

ActiveCN106841209AAdd automatic classification functionSave human effortOptically investigating flaws/contaminationSortingFiberEngineering

The invention relates to an automatic classifying type spindle appearance detection system and method, which solve the problems of waste of labor, material and cost, lack of position and light source control, influence to subsequent appearance detection result, and low efficiency and accuracy on appearance defect detection of the spindle during sorting of spindles with appearance defects in a manual manner. The system comprises a tray and a conveying unit, wherein a dark box is arranged on the conveying unit; a sorting unit is arranged on the conveying unit behind the dark box; an image collection unit is arranged in the dark box; the appearance defect of the spindle is analyzed by collecting an image of each surface of the spindle, and the spindle is automatically classified according to the analysis result. Compared with the manual manner, the system has the advantages that a large amount of labor, material and cost is reduced; compared with common check system, the function of automatically classifying the defective spindles is added, the workload is reduced, and the working efficiency is improved; by providing a self-learning function, the accuracy of oil dirt detection is further improved.

Owner:杭州慧芯智识科技有限公司

Full-automatic stalk removing machine

ActiveCN103689760ACut off smoothlyReduce processing costsFood treatmentAgricultural engineeringEconomic benefits

Owner:QINGDAO LULU AGRI EQUIP CO LTD

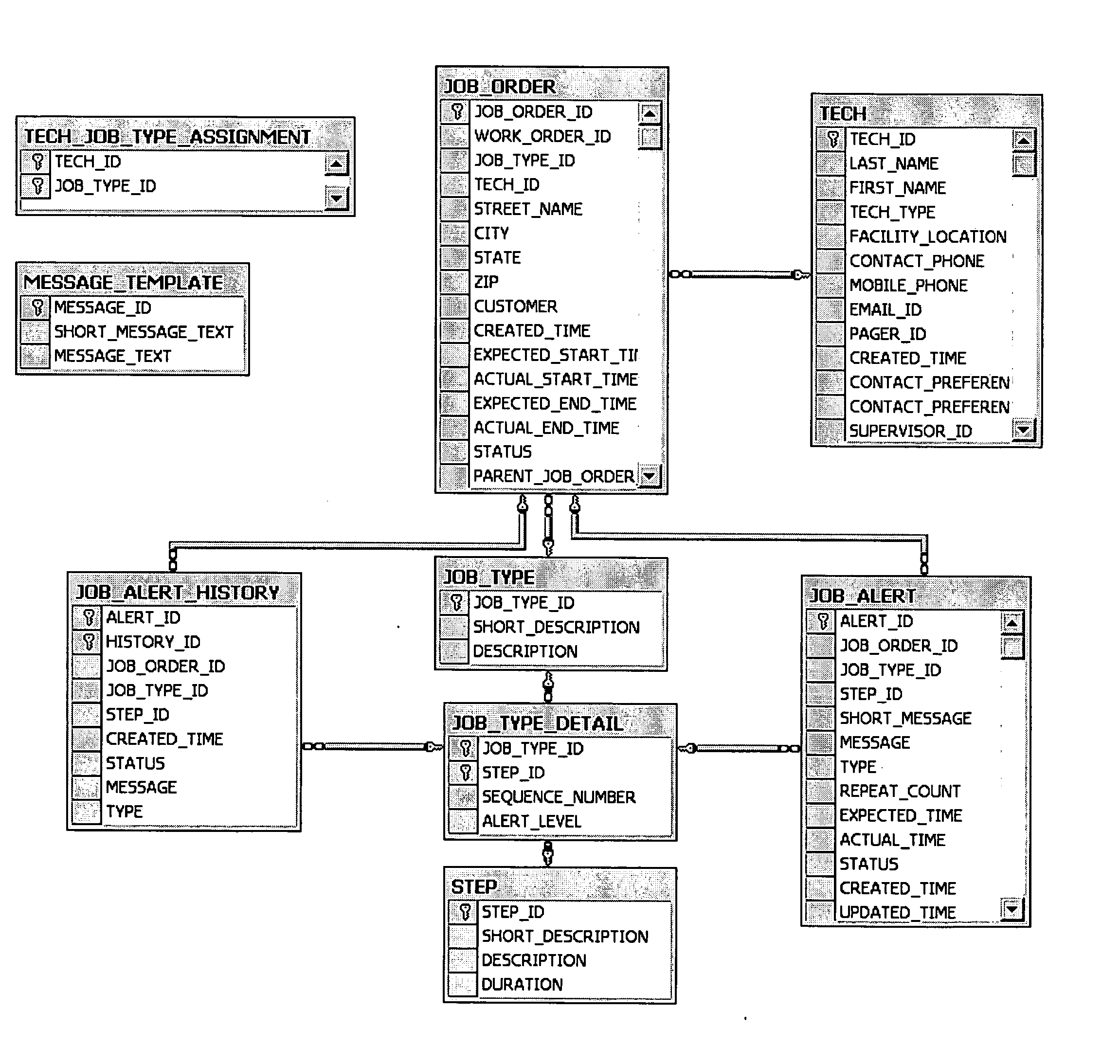

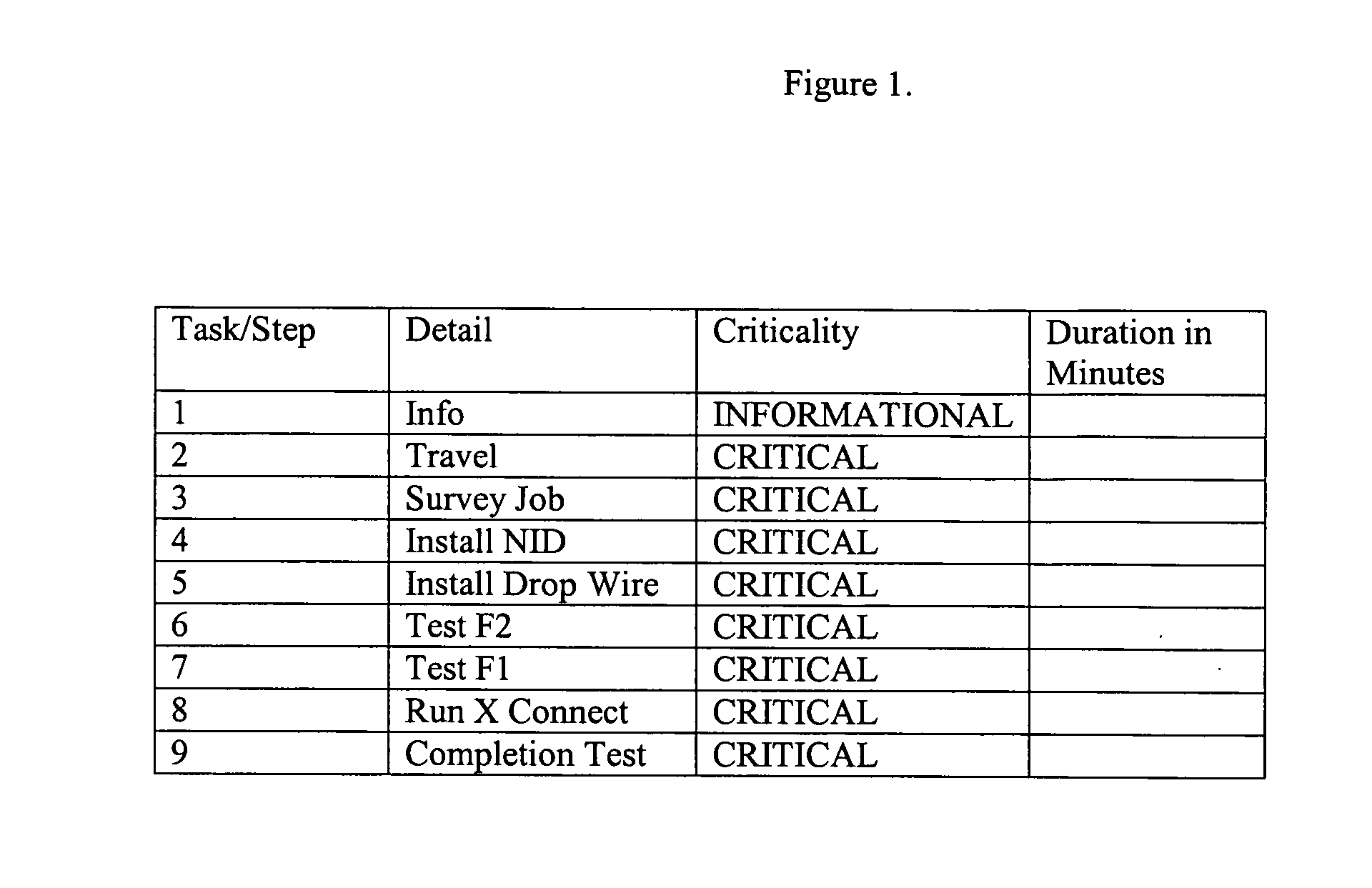

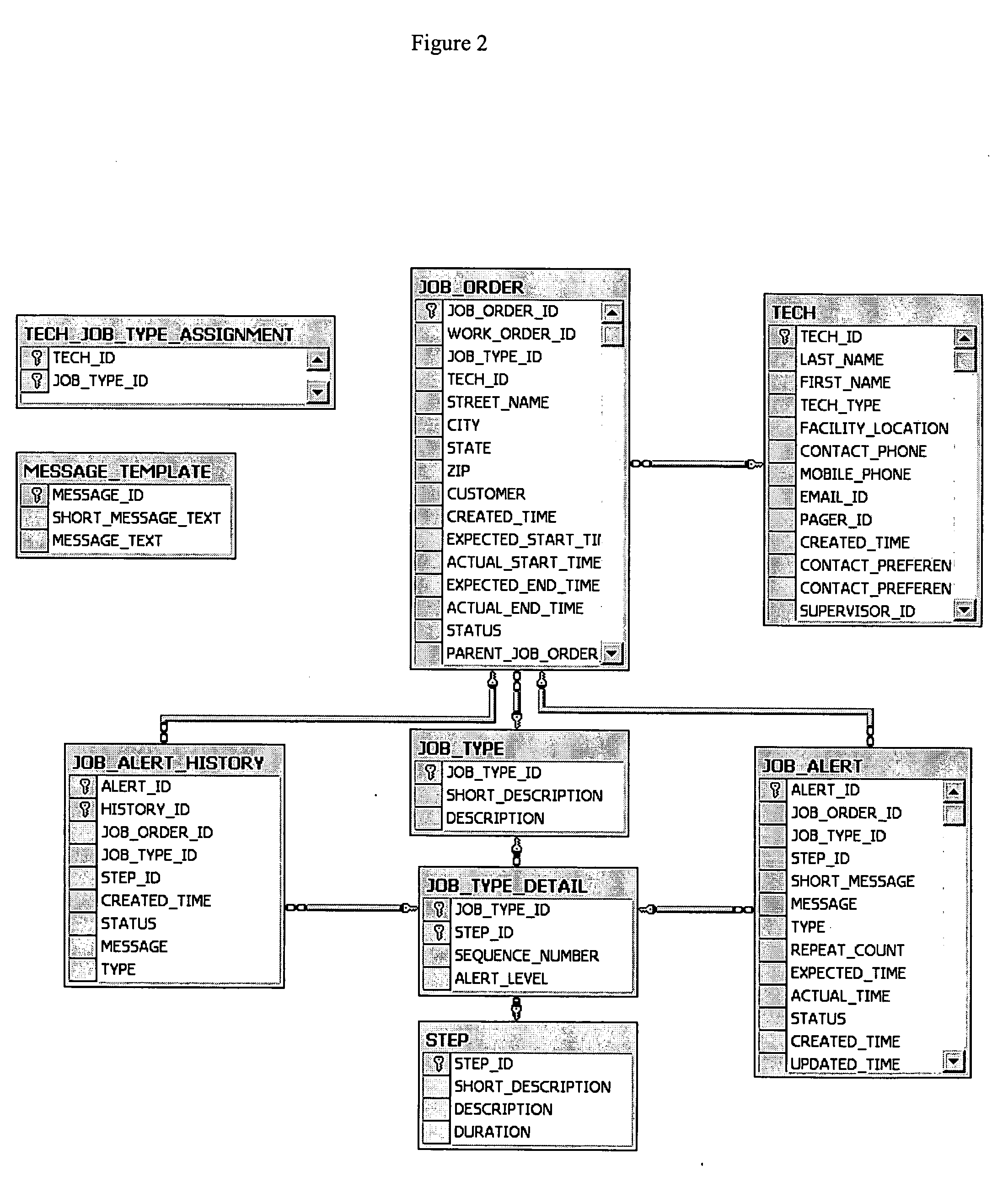

Method and system for measuring work productivity

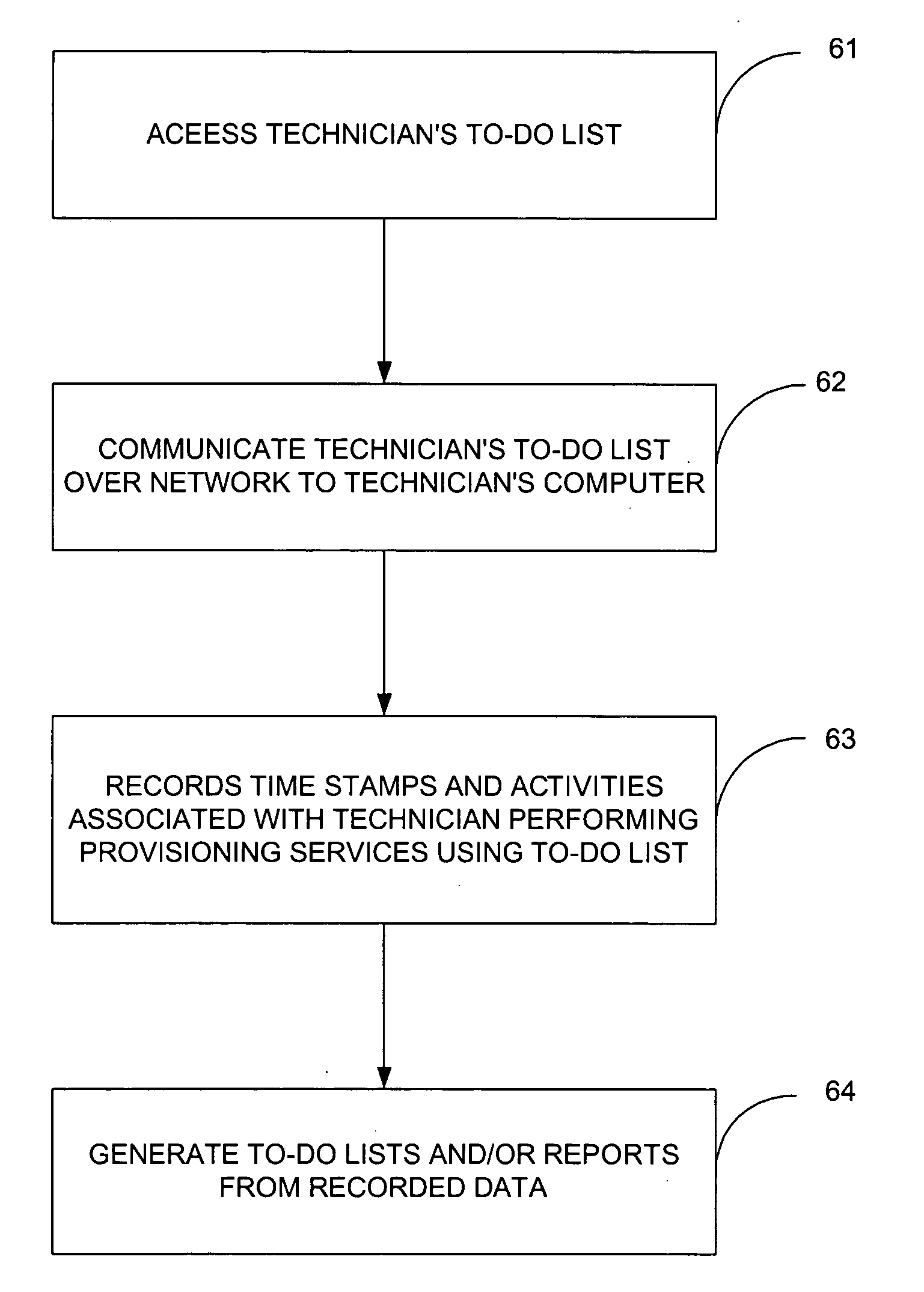

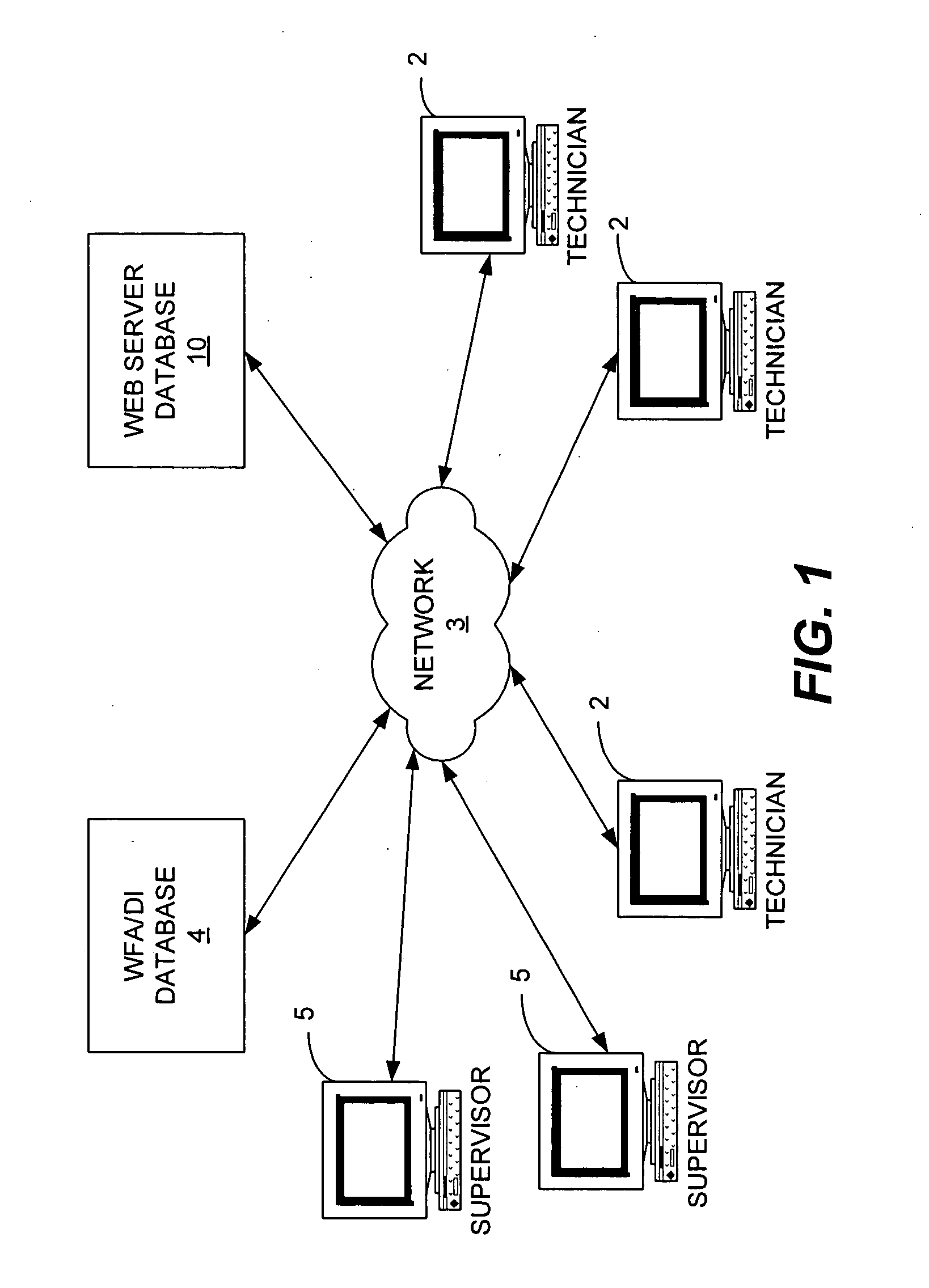

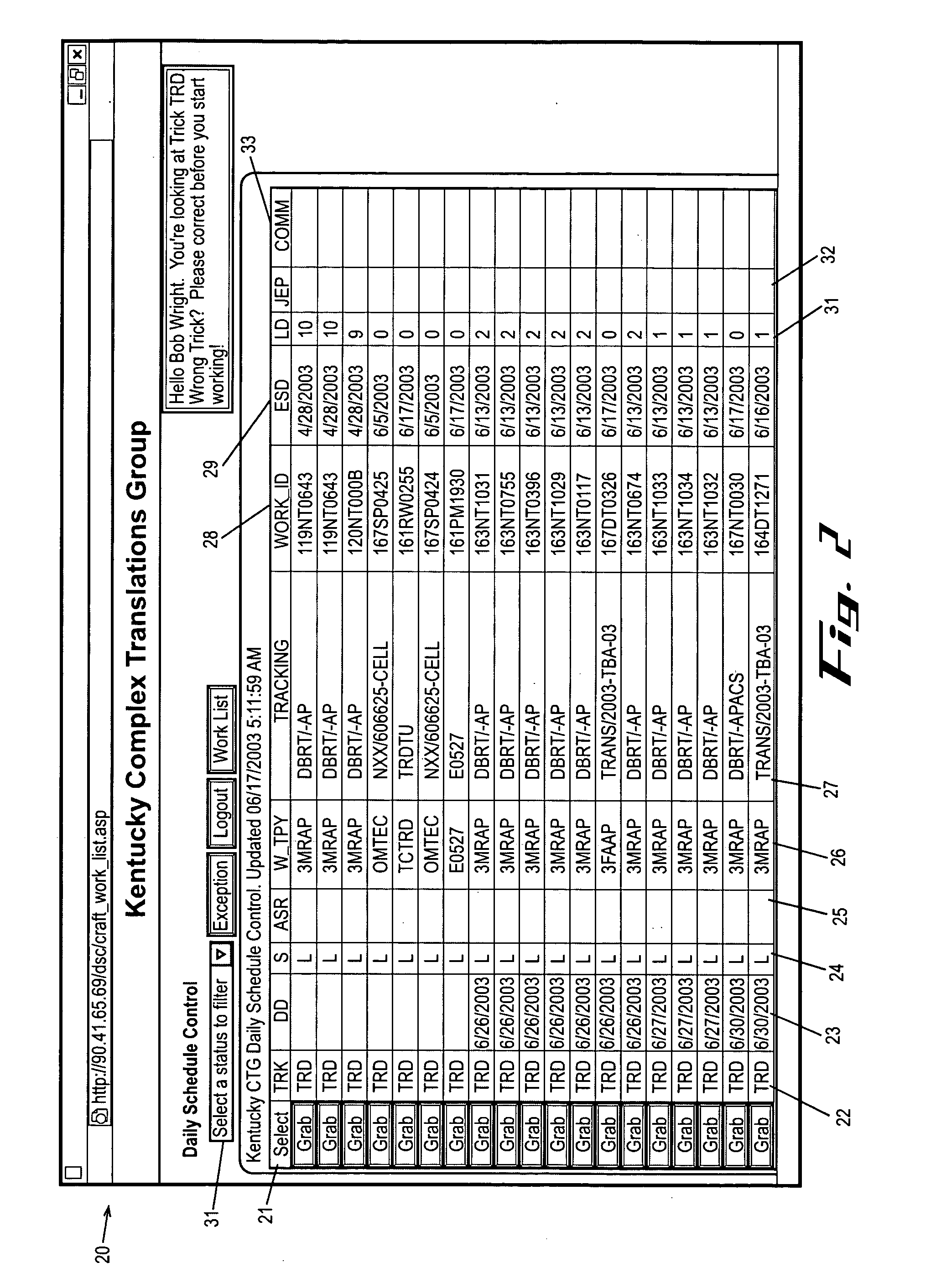

InactiveUS20050125275A1Provisioning scheduling is made easier and more accurateOffice automationSpecial data processing applicationsRelevant informationWork productivity

A productivity measurement method and system in which work item status, exceptions, work item jeopardy and related information are automatically recorded and updated in a database in real-time as tasks are being performed. To-do lists are displayed on the worker's computer so that when the worker selects an item to begin working on it, an indication that the item has been selected is stored in an activities table in a database along with an indication of the time of the selection. As exceptions are encountered, the worker makes selections from the display to indicate that an exception has been encountered and the type of exception. An indication of the type of exception and the time that the exception selection was made are stored in the activities table. All of this activity information is automatically processed in real-time. Productivity reports can be automatically generated at any time from this information.

Owner:BELLSOUTH INTPROP COR

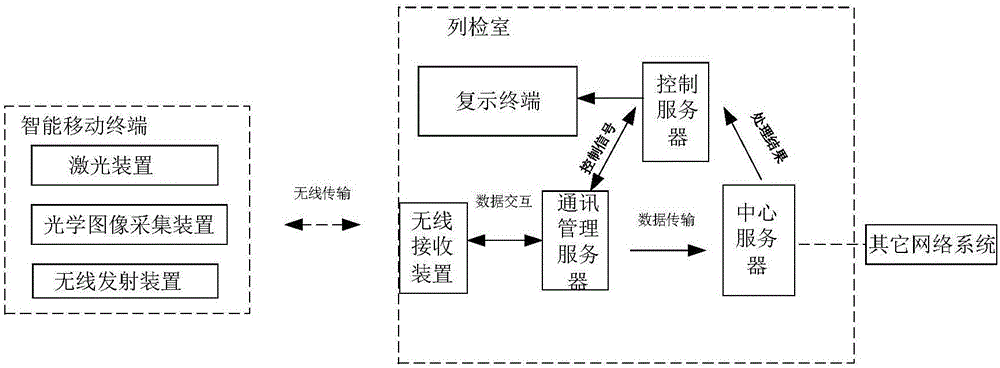

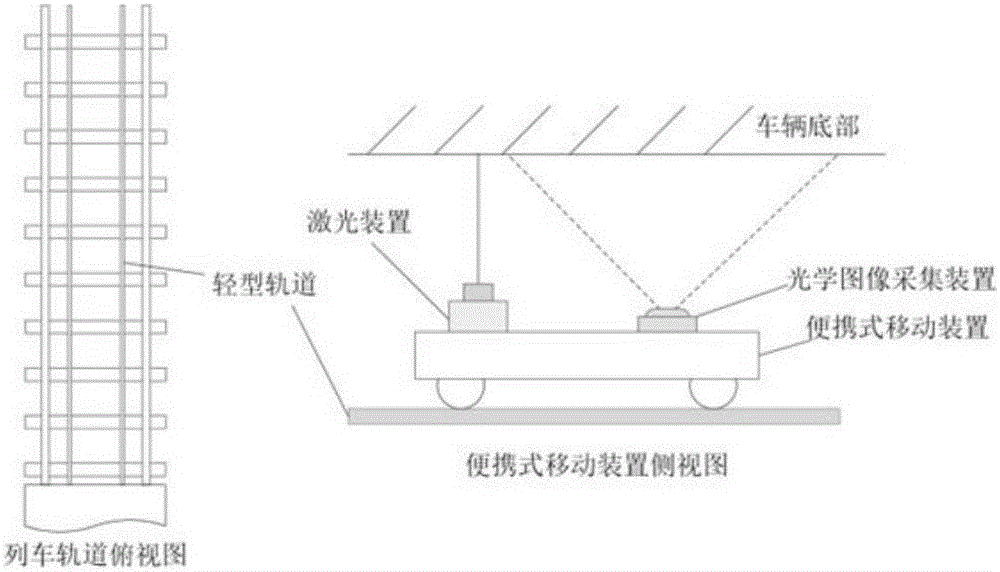

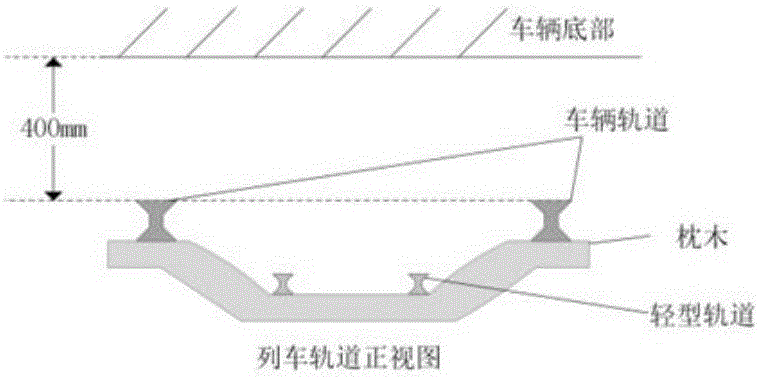

Machine vision based technical inspection and detection system and method for railway trains

ActiveCN105882683AQuality improvementImprove accuracyImage enhancementImage analysisMachine visionFreight trains

The invention discloses a machine vision based technical inspection and detection system and method for railway trains and belongs to the field of technical inspection on railway freight trains. According to the system, a light-duty rail, a portable moving device, a laser device, an optical image acquisition device and a wireless transmitting device are arranged outside a train inspection room; a wireless receiving device, a communication management server, a control server and a central server are arranged in the train inspection room. According to the system and the method, the automation and the intellectualization of technical inspection on the railway trains are achieved through controlling the portable moving device running on the light-duty rail, automatically acquiring image and video data on the bottom of a vehicle, carrying out data processing and outputting a current state of each component of the vehicle, an air testing test result and a repair processed result. According to the system and the method, manpower can be replaced for outdoor vehicle guarding operation, and the high quality, the accuracy and the reliability of train inspection can be guaranteed; the system and the method can adapt to various climatic conditions and natural environments and high-strength operation, so that the work efficiency of train inspection is increased.

Owner:BEIJING CTROWELL INFRARED TECHN

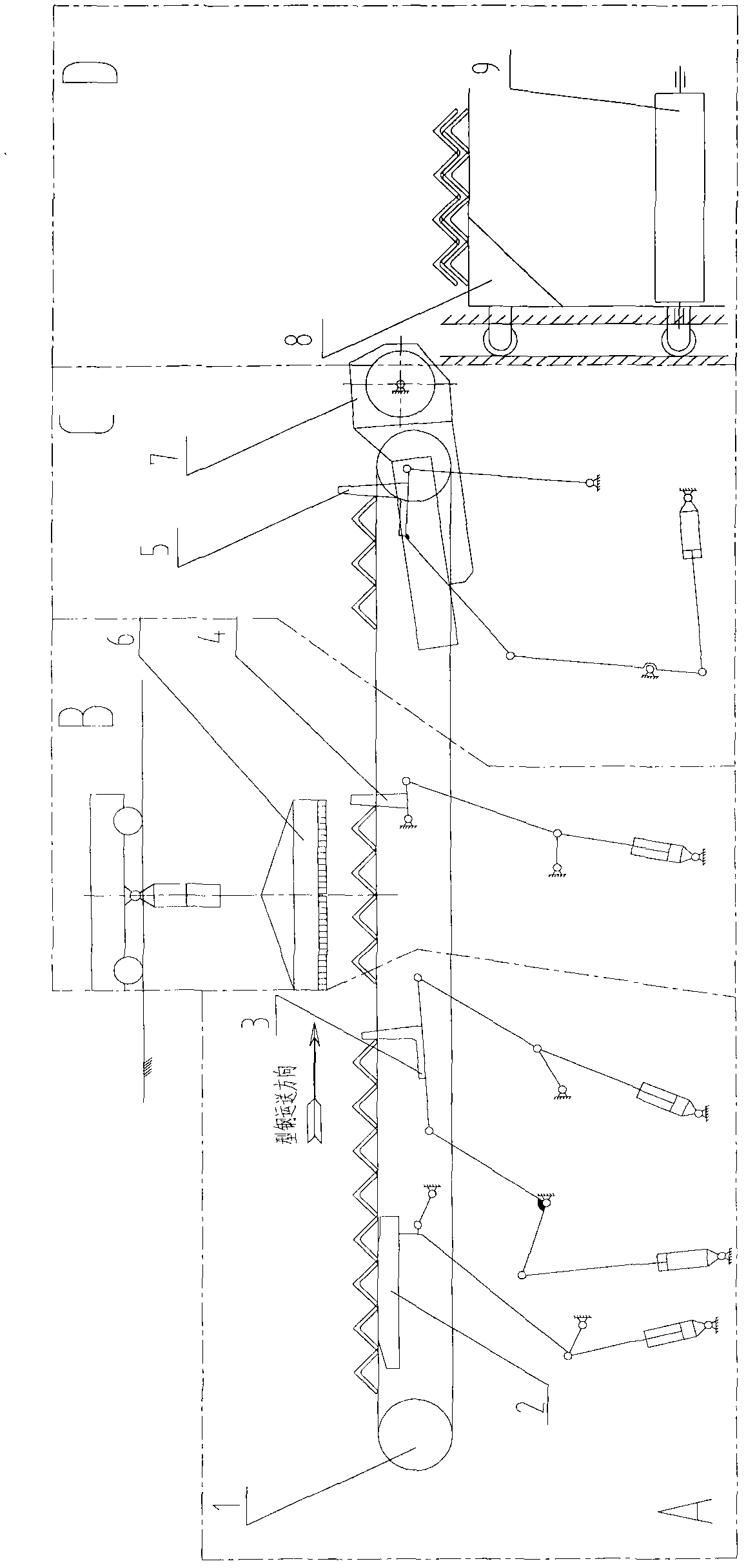

Profile steel stacking device

ActiveCN103010759AReduce labor intensityMeet bundling quality requirementsStacking articlesEngineeringUltimate tensile strength

The invention provides a profile steel stacking device, which comprises a transporting steel bar splitting unit (A), wherein the steel bar splitting unit also comprises a chain conveyer (1), a first driving device, a steel bar splitting device (2) and a first baffle plate, the steel bar splitting device (2) is driven by the first driving device, the first baffle plate is driven by the first driving device and the second driving device, the steel bar splitting device is arranged at the front end of a transporting frame, can be bounced and is projected out of the upper surface of a transporting machine, the first baffle plate (3) can do lifting movement under the driving of the second driving device, when the first baffle plate (3) is projected out of the upper surface of the transporting machine, profile steel on the transporting machine is prevented from continuously advancing, when the number of the blocked profile steel reaches the required number, and the steel bar splitting device (2) is bounced, so the profile steel between the steel bar splitting device (2) and the first baffle plate (3) is combined into one group. The profile steel stacking device with the steel bar splitting unit can meet the stacking of large-cross-section profile steel in different shapes, in addition, the work productivity can be greatly improved, and the work intensity of workers is lightened.

Owner:BERIS ENG & RES CORP

Reinforced concrete inspection well whole prefabricated hoisting construction method

ActiveCN103088844AGuaranteed spacingGuaranteed thicknessArtificial islandsUnderwater structuresSocial benefitsWork period

The invention relates to a construction method for an inspection well, in particular to a reinforced concrete inspection well whole prefabricated hoisting construction method. The method comprises that a formwork of a base plate is firstly erected, then reinforcing steel bars of the base plate are bound, finally concrete is poured on the base plate and burrs need to be removed thoroughly between the reinforcing steel bars in the inner circle and the outer circle; reinforcing steel bars of a well body are bound through the reserved bars of the base plate, after binding, a crane hoists inner steel formworks in the crane with cooperation of manual power, outer steel formworks are installed, finally the concrete is poured, after the formworks are disassembled, the formworks are wound by plastic thin films and water is sprayed on the formworks to cure the formworks; and a drawing method of double cross is adopted in hoisting process. Compared with the prior art, the reinforced concrete inspection well whole prefabricated hoisting construction method has the advantages of effectively solving the quality problem caused by insufficient construction space, greatly improving work efficiency, shortening work period, having good social benefit and economic benefit and being wide in application space in concrete inspection well engineering and high in popularization value.

Owner:JINAN URBAN CONSTR GRP

Monitoring and controlling work progress

InactiveUS20050240561A1Improve consistencyImprove predictabilityDigital data processing detailsResourcesWorking environmentWork productivity

The invention relates to products for, and methods of, monitoring and controlling work progress, and improving work productivity and work management, for example in highly variable and / or unpredictable work environments, and to products for, and methods of, interactive data processing particularly adapted for systems comprising a handheld mobile component

Owner:ARICENT INC

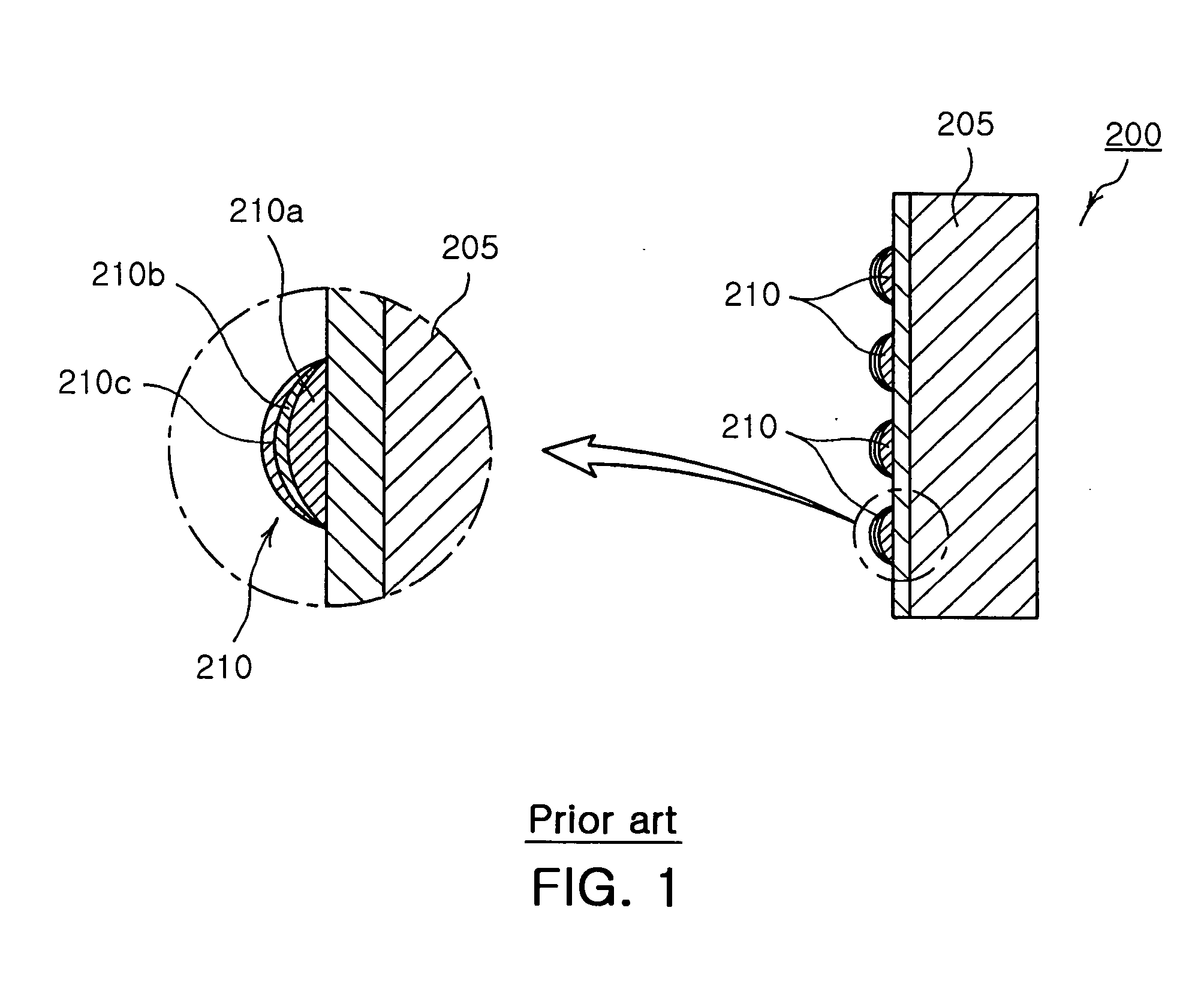

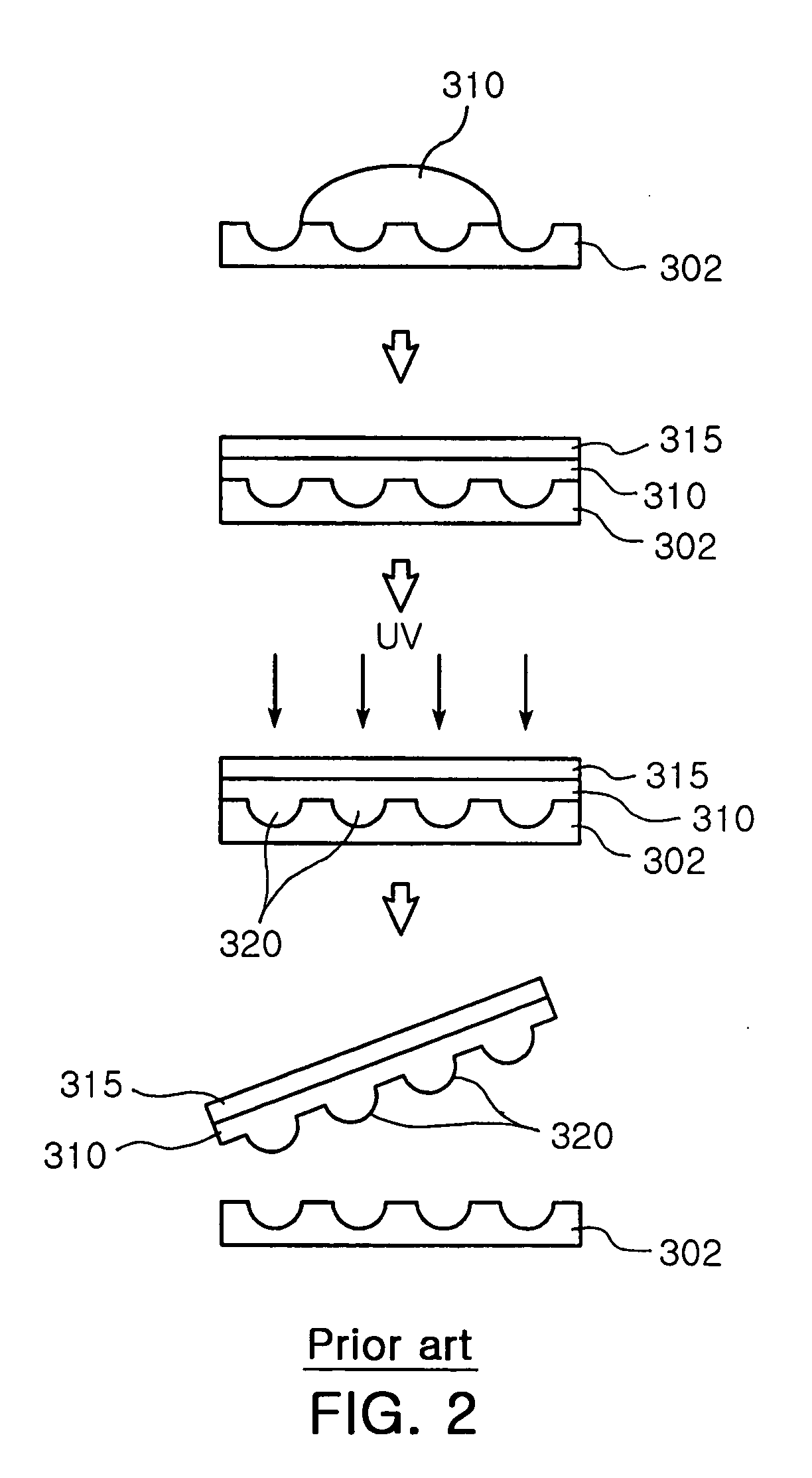

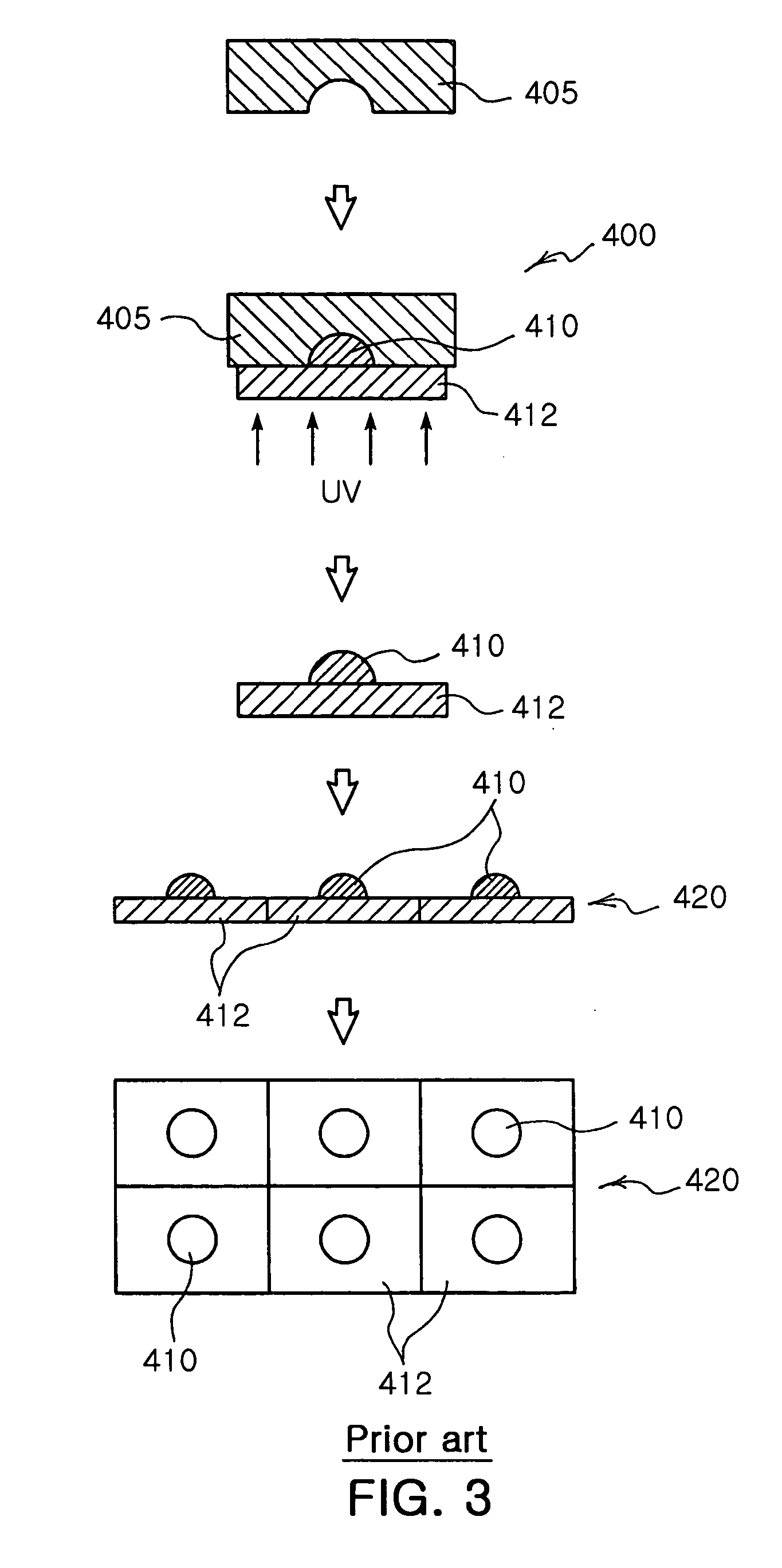

Method of manufacturing a high sag lens and a lens manufactured by using the same method

InactiveUS20060273478A1Improve lens qualityHigh sagOptical articlesLensReplication methodOptoelectronics

The invention provides a method of manufacturing a high sag lens and a lens manufactured thereby. According to the invention, in manufacturing a lens, a polymer lens section made of ultraviolet cured resin is formed on a substrate. Polymer is injected into a mold having a plurality of grooves and then cured by ultraviolet ray to form a plurality of lens sections. Thereafter, a substrate is adhered integrally to a back side of the lens section. Finally, the mold is released from the lens section to produce a lens array. The invention eliminates a need to correct a lens surface resulting from polymer shrinkage and enhances quality of the lens. Also, the invention allows manufacture of the lens without repeating a replication method and dramatically increases work productivity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Wall assembling production line

The invention relates to the technical field of building equipment, in particular to a wall assembly production line. The wall assembling production line is characterized in that the wall assembling production line comprises a production line rail, a material distribution rail and a control system, one side of the production line rail is provided with the material distribution rail, a wallboard conveying line is arranged below the material distribution rail, the wallboard conveying line is provided with a vacuum cup mechanical arm material distribution station and a preassembling station, and the production line rail is sequentially provided with an assembling station, a positive nailing preparation station, a positive nailing station, an overturning station, a reverse nailing preparation station and a reverse nailing station. By the adoption of the structure, the wall assembly production line has the advantages of being novel in structure, convenient to operate, high in work efficiency, low in manufacturing cost, low in labor intensity, high in assembling accuracy, large in throughput and the like.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Efficient short-flow pre-treating process for high-grade high-density cotton fabrics

InactiveCN101725031AEmission reductionReduce consumptionDry-cleaning apparatus for textilesBleaching apparatusFiberHigh density

The invention provides an efficient short-flow pre-treating process for high-grade high-density cotton fabrics in order to remove the impurity and slurry from cotton woven. The process comprises the steps of feeding cloth, hot washing, padding enzyme solution, steaming, hot washing, warm washing, padding floating solution, wet steaming, hot washing, warm washing and drying. The specific step is to desize with wide-temperature enzyme on a pre-treated desizing section, boiling, whitening a whitening section with alkali oxygen technique and a wet short steaming device in order to remove the impurity and slurry from cotton fibers, for the purpose of shorting the process flow and decreasing the consumption. The invention has the advantages that (1) the process flow is shortened, the working efficiency is promoted and the product quality is promoted, (2) the harmful wastes are decreased and the environment is protected, and (3) the consumption of water, steam and energy is decreased and the manufacturing cost is lowered.

Owner:天津三环纺织印染公司

Laboratory glassware detergent

InactiveCN101368139AEase of handling emissionsMeet the protection requirementsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPhosphateWater soluble

The invention provides a cleaner for glassware in a laboratory, comprising phosphate, surface active agent, pH value regulator and deionized water; the weight percentage of all the components is as follows: 5 percent to 10 percent of the phosphate, 5 percent to 10 percent of the surface active agent, 0.5 percent to 2 percent of the pH value regulator and the rest is the deionized water; the pH value of the mixing liquid of the components is 8 to 10; the cleaner has the functions of high efficiency and easy cleaning to the glassware in the laboratory, can clean the oil stain and spots on the plastic surface completely, can prevent stain on the surface of glassware in the laboratory, also can shorten the cleaning time and improve the working efficiency; the cleaner is a water-soluble cleaner, does not contain harmful material to the human body, meets the requirements of environment protection, has low corrosion to the equipment, effectively reduces the production cost and has safe and reliable use; and the cleaned waste liquid is convenient to be treated and discharged.

Owner:JIANGSU HAIXUN IND GROUP SHARE

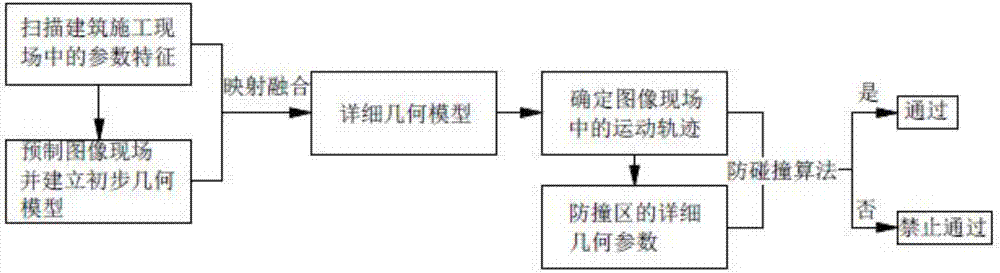

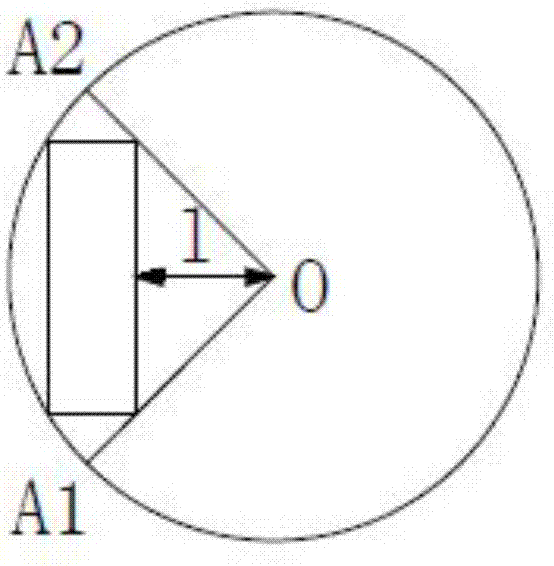

Anti-collision method of collision avoidance early warning system based on tower crane

ActiveCN107285206ARealize all-round full-space anti-collision protectionAnti-collision automatic control realizationDesign optimisation/simulationSpecial data processing applicationsVirtualizationEarly warning system

The invention relates to an anti-collision method of a collision avoidance early warning system based on a tower crane. A building construction site of the tower crane is virtualized to a controllable and operable image site and is integrated into an anti-collision automatic control module of the corresponding system to realize collision prevention. Specifically, the anti-collision method comprises the following steps: mapping parameter characteristics including a relative obstacle, a target crane jib and a relative environment in the building construction site to the image site one by one; and after calculating motion occurring in the building construction site through an anti-collision algorithm of the image site, sending a control command for executing the motion of the building construction site. According to the anti-collision method provided by the invention, a space anti-collision method is solved after an entity space and a virtual space are mapped one by one and an anti-collision region with a geometrical model is set; after actual parameters are subjected to geometrical virtualization, an algorithmic research is carried out; after a result is obtained, command manipulation is carried out; the all-directional reliability of corrosion prevention is realized, the potential safety hazards are reduced, the working efficiency is improved and the production cost is reduced; and the reliability and flexibility of independent work of the tower crane are ensured.

Owner:WUHAN ESPECIAL EQUIP SUPERVISE TEST INST

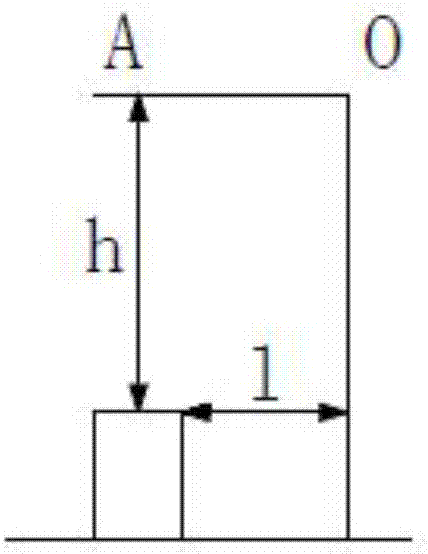

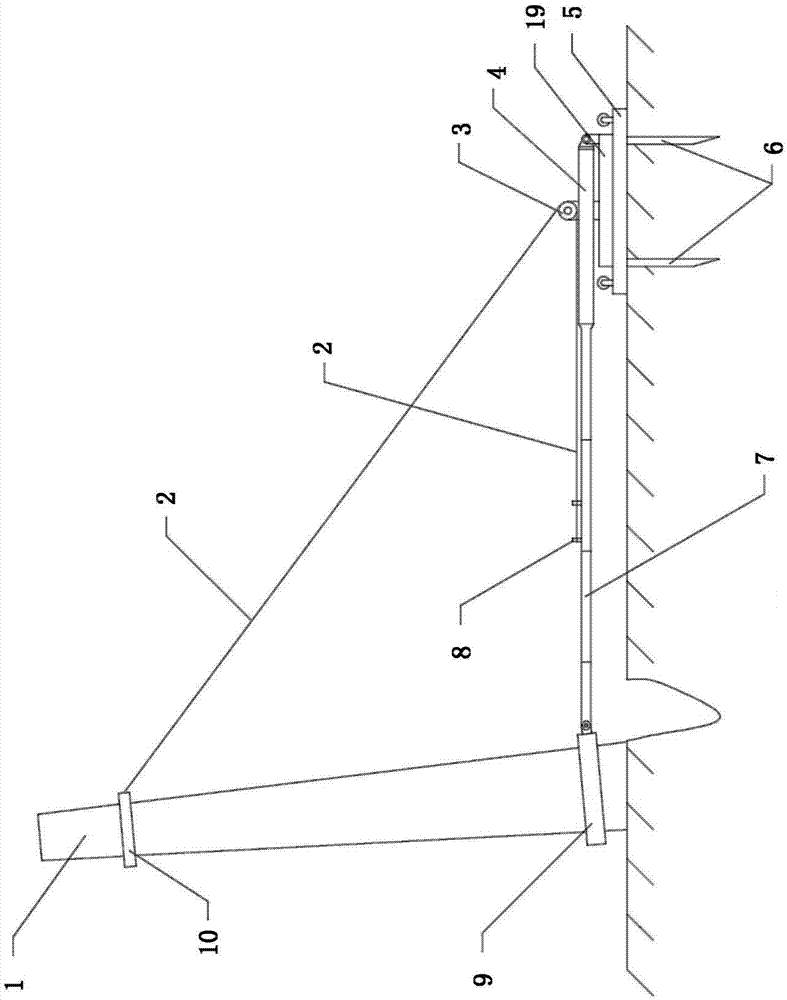

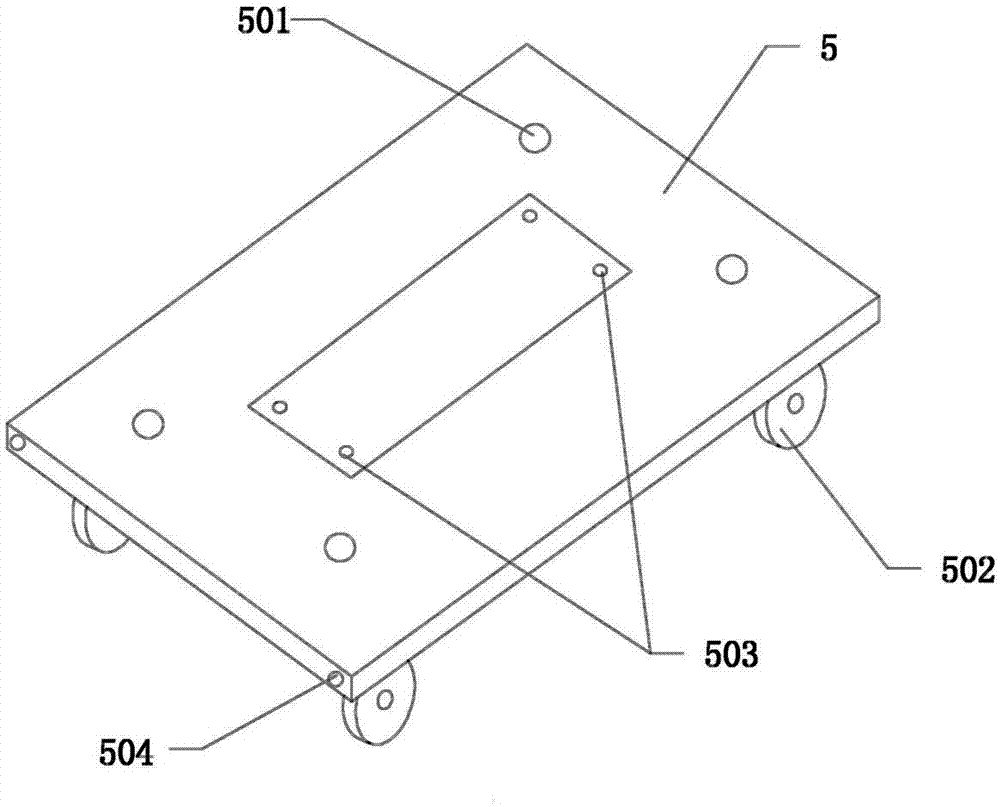

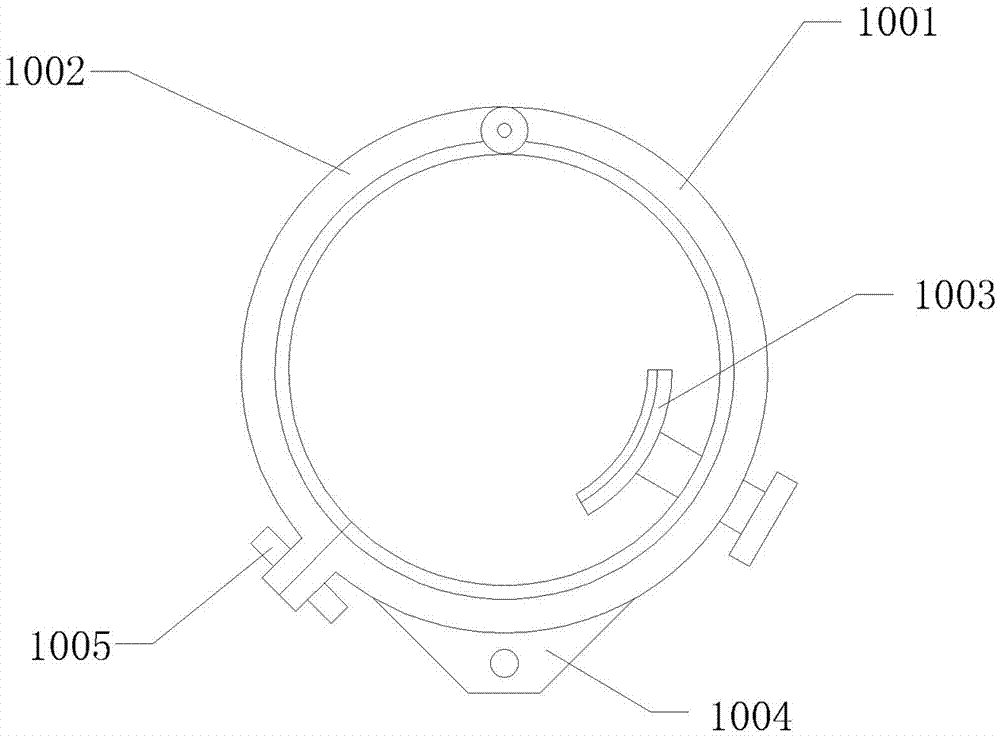

Two-way torque cement pole corrector

The invention discloses a two-way torque cement pole corrector. The two-way torque cement pole corrector comprises a base. A jack is arranged on the base and connected with a supporting rod. A first hoop is arranged on the supporting rod. The supporting rod is provided with a pull rope. A second hoop is arranged on the pull rope. A pulley is arranged on the base. The direction of the pull rope is changed through the pulley. Due to the adoption of the technical scheme, the two-way torque cement pole corrector is suitable for correction work of all cement poles and is small in size, small in weight and convenient to carry and operate; cement poles can be maintained in an inclined mode without power outage, the safety coefficient is high, the cement pole correction work can be completed by a single person, the labor intensity of workers is lowered, time and labor are saved, and the work efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO QINGZHOU POWER SUPPLY CO +2

3D printing false tooth ceramic material and preparation method thereof

InactiveCN108751951AImprove performanceReduce wearAdditive manufacturing apparatusTissue regenerationHardnessVolumetric Mass Density

The invention discloses a 3D printing false tooth ceramic material and a preparation method thereof. The 3D printing false tooth ceramic material is prepared from the following components in parts bymass: 75-90 parts of porous ceramic micropowder, 9-22 parts of photocurable resin, 0.2-1.0 part of photoinitiator and 0-2.0 parts of dispersant. According to the 3D printing false tooth ceramic material, the porous ceramic micropowder is used as a substrate and is matched with the photocurable resin to prepare the 3D printing false tooth ceramic material with excellent properties; the hardness ofthe ceramic false teeth is reduced; the abrasion degree of occlusion of the teeth is reduced; the prepared 3D printing false tooth ceramic material is matched with a 3D printing device to prepare false tooth products with accurate size; a large amount of processing time is reduced; the accuracy is high; the workload of doctors is reduced, so that the working efficiency can be effectively improved;the main properties of the 3D printing false tooth ceramic material are as follows: the volume density is 2.0-2.5g / cm<3>, the normal-temperature compression strength is 100-200MPa, the Vickers hardness is 8.0-10GPa, and the bending strength is 1100-1300MPa.

Owner:湖南鹏登生物科技股份有限公司

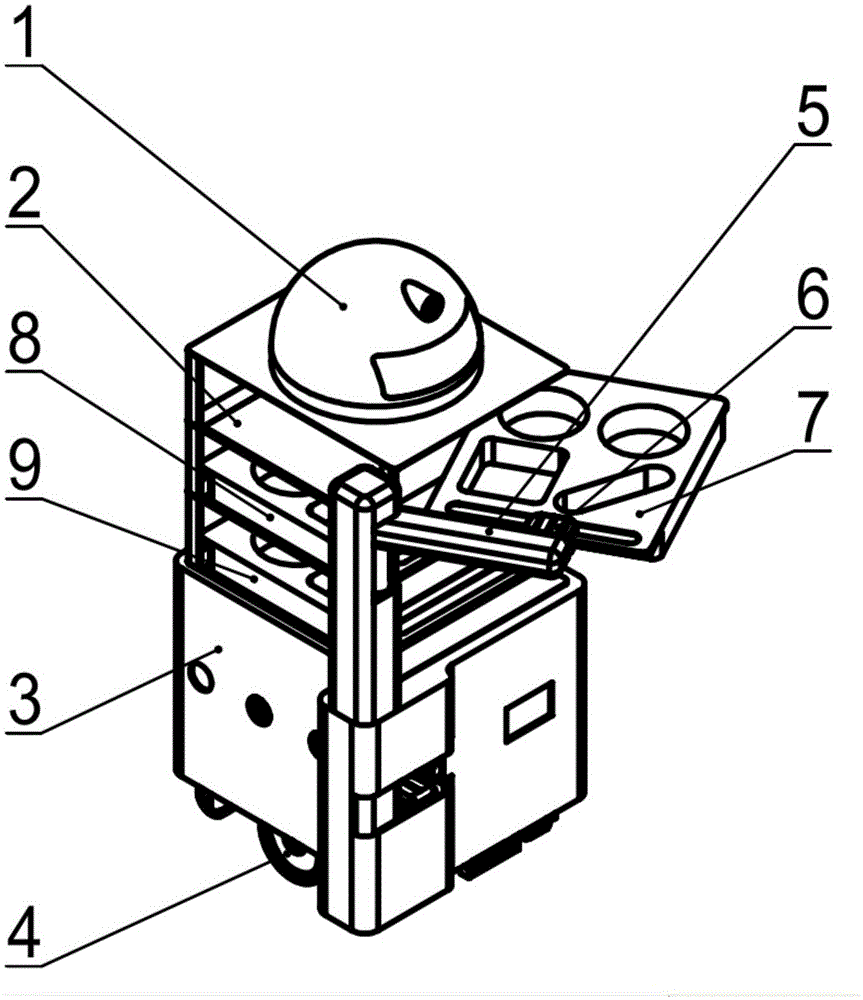

Restaurant robot

InactiveCN106584468AImprove food deliveryImprove efficiencyTable equipmentsManipulatorEngineeringManipulator

The invention relates to the field of robots and particularly discloses a restaurant robot which comprises a movable chassis, a lifting service plate rack, an intelligent manipulator, and a visual system positioned on the robot, wherein the movable chassis is used for driving the robot to move; a plurality of sensing devices and a control device are arranged in the movable chassis, and the control device is used for receiving signals of the sensing devices to control the robot; the lifting service plate rack is positioned on the movable chassis and comprises a multi-layer placement platform which is liftable and used for placing tableware; the intelligent manipulator is positioned on the movable chassis and is used for taking and putting down tableware; and the visual system is used for positioning tableware. The restaurant robot can transport a plurality of service plates, grab the service plates, send meals and recover the service plates, so that the working efficiency is greatly improved, the labor cost is reduced, and services can be provided for a customer more conveniently.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

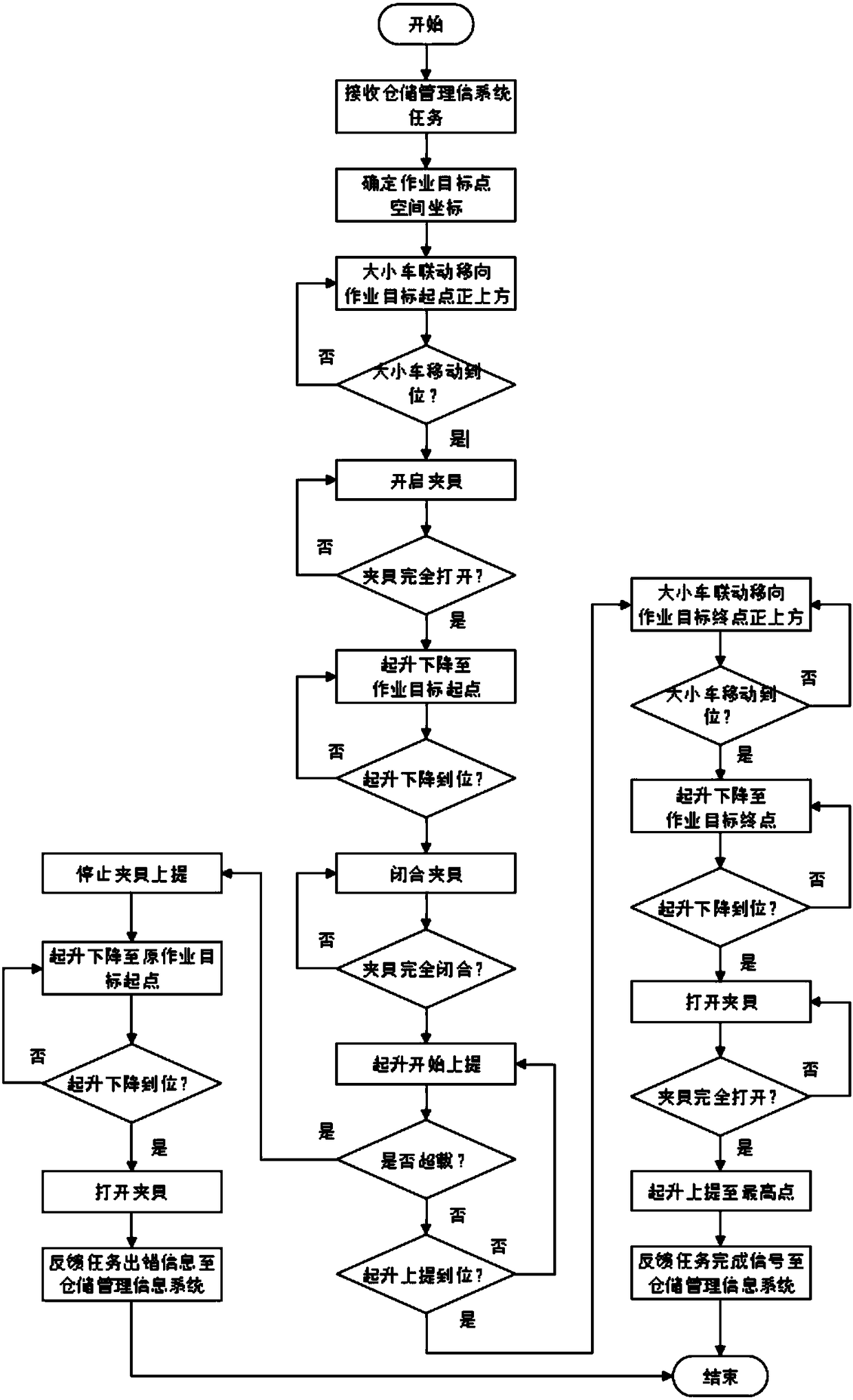

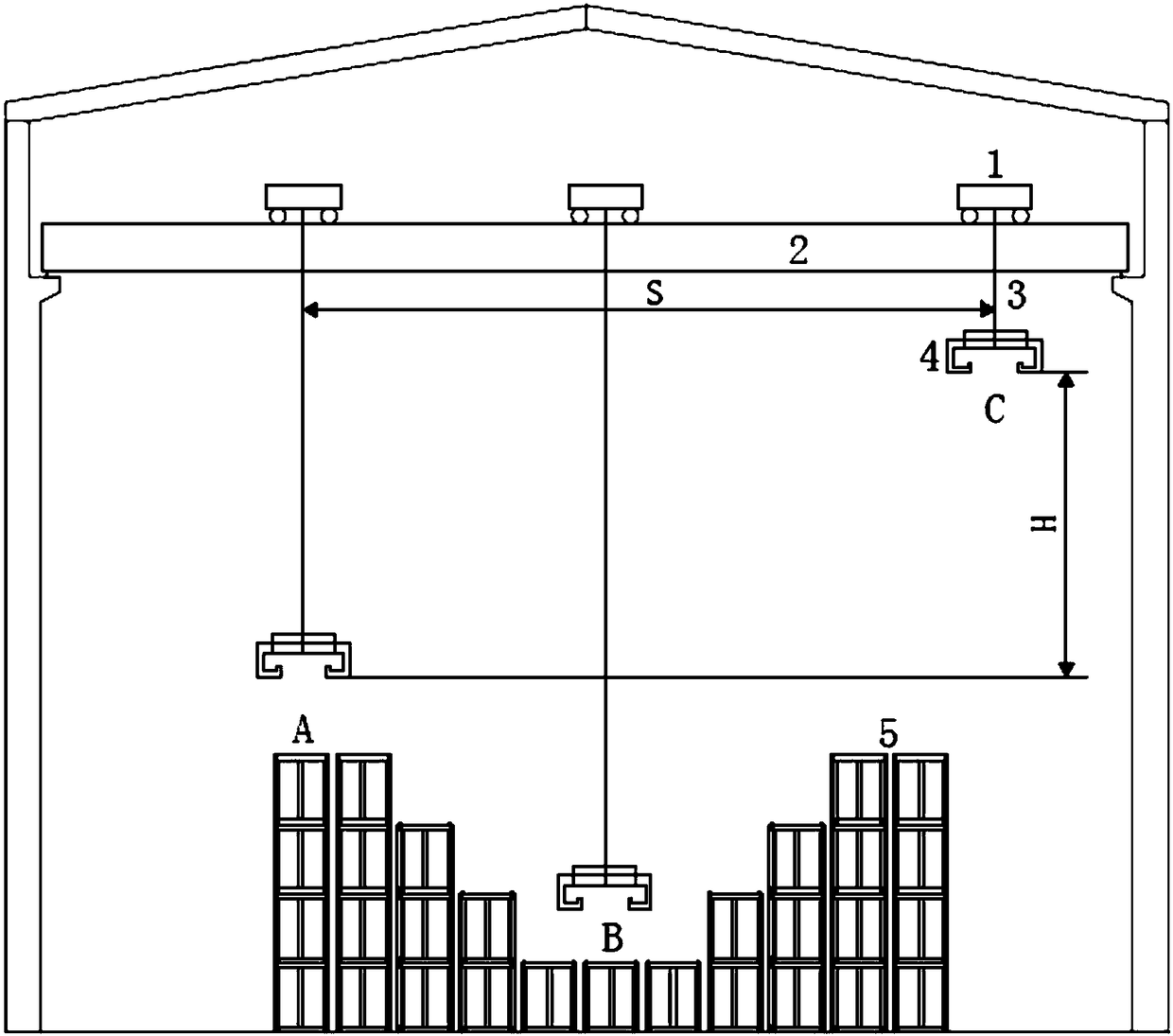

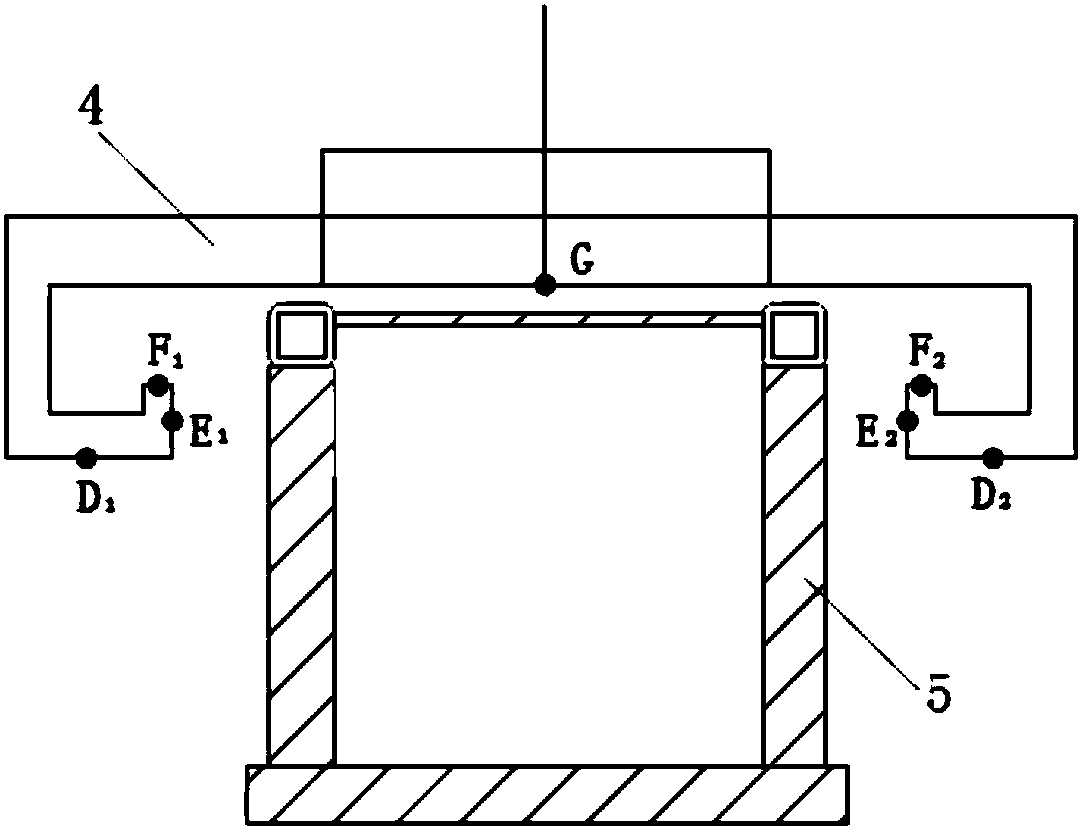

Automatic operation control method for full-automatic bridge-type storage crane

InactiveCN108545614AFully automatedAchieve mutual coordinationGeometric CADSpecial data processing applicationsAutomatic controlCost Controls

The invention discloses an automatic operation control method for a full-automatic bridge-type storage crane, the automatic operation control method comprises the following steps: space coordinates ofa working target point can be determined, a control system is used to realize automatic positioning of a big car, a trolley and a lifting mechanism, a clamp clamps goods, a proximity sensing sensor performs reliable clamping detection, the goods are lifted up and put down, the lifting mechanism automatically raises the clamp to a highest point, and a crane control system feeds back a completion signal of the operation to an upper storage management information system. The automatic operation control method can realize automatic speed planning of the full-automatic bridge-type storage crane, aflexible speed planning algorithm with jerk limitation can ensure the smooth running of each mechanism, thereby reliably realizing the automation of addressing operation points; at the same time, mutual coordination of the lifting mechanism and the clamp can be realized, and the automation of clamping or stacking of the goods can be realized; the working efficiency and reliability of the storagecrane can be improved, working conditions can be improved, energy consumption can be saved, and the automatic operation control method helps enterprises to control cost.

Owner:WUHAN UNIV OF TECH

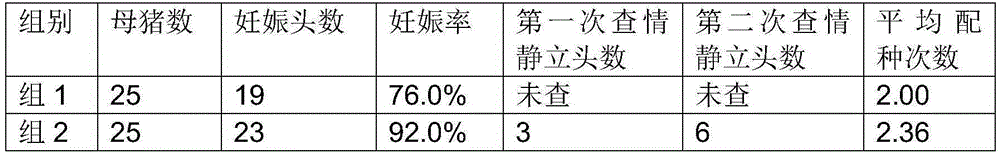

Efficient heat detection and synchronous fertilization method of replacement gilts and multiparous sows

The invention provides an efficient heat detection and synchronous fertilization method of replacement gilts and multiparous sows. The method has the advantages that mating of the multiparous sows and that of the added replacement gilts can be synchronized to allow batch management for sow's production; utilization and mating productivity of sows can also be increased; non-productive days for sows are fewer; work efficiency of mating staff can be improved; the purpose of all in and all out is easily obtainable, and sows can be imparted same reproductive statuses, health statuses and immune statuses.

Owner:NINGBO SANSHENG PHARMA

Cloth spreading machine for garment making and use method thereof

ActiveCN108914433AReduce labor intensitySimple structureLiquid/gas/vapor removal by gas jetsTextile treatment by spraying/projectingAgricultural engineeringPre compression

The invention relates to the field of garment making and specifically relates to a cloth spreading machine for garment making and a use method thereof. The machine comprises a working platform; the working platform is provided with a flattening device; a pre-compression device is arranged, at the right side of the flattening device, on the working platform; a humidifying device is arranged on theworking platform on the right side of the pre-compression device; an ironing device is arranged on the working platform on the right side of the humidifying device; a drying device is arranged on theworking platform on the right side of the ironing device; a winding device is arranged on the working platform on the right side of the drying device. The invention has the advantages of simple structure, convenient operation, high automation degree, can save manpower, reduce labor intensity of workers, can carry out drying treatment on the ironed cloth, and has high working efficiency and the mildew phenomenon after the cloth is placed for a long time is avoided.

Owner:濮阳黑蚂蚁服饰有限公司

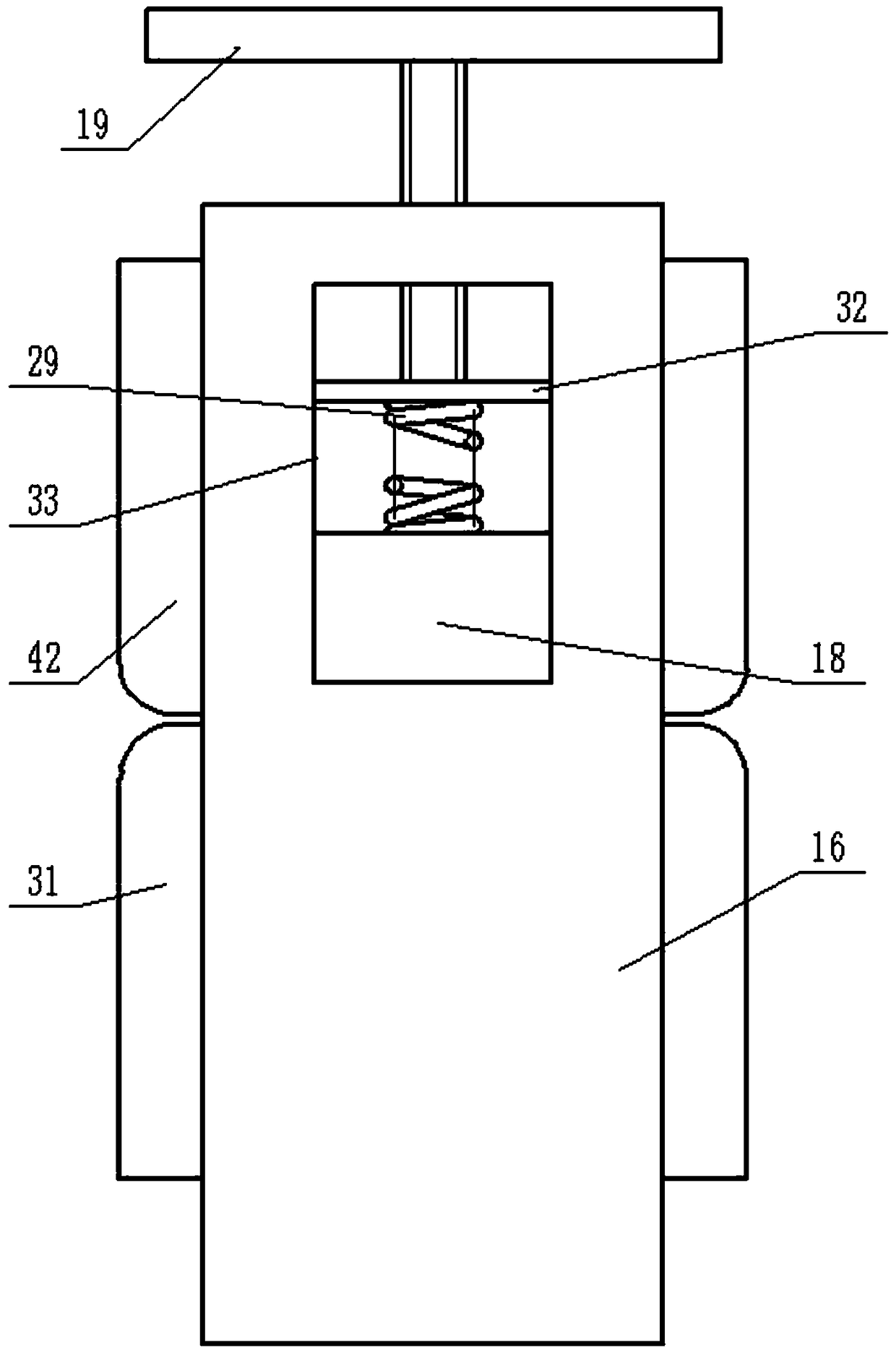

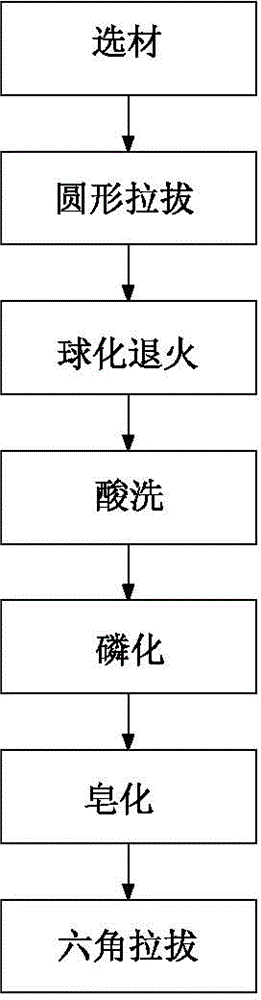

Production process of alloy steel material for high-strength internal hexagonal wrench

The invention discloses a production process of an alloy steel material for a high-strength internal hexagonal wrench. The production process comprises the following steps of 1, material selecting, wherein a material with the trade mark of 50CrVa is selected as a base material; 2, round drawing; 3, spheroidizing annealing; 4, acid pickling; 5, phosphating; 6, saponifying; 7, hexagon drawing. By selecting specific material and adopting specific matched drawing process and spheroidizing process, a wire made according to the invention has relatively high plastic deformation capability, meets the bending forming requirements of customers, is uniform in annealed structure grains, is high in rate of spheroidization and is free of abnormal structures; the product size is stable, the precision is high, the tolerance of opposite sides is + / -0.02mm, and the tolerance of opposite angles is + / -0.03mm; the material meets the use requirements of the customers, after the material is subjected to quenched-tempered heat treatment, the hardness HRC of the obtained wrench is greater than or equal to 55, the wear resistance is good, and the service life is long; meanwhile, the softening time in the spheroidizing annealing working procedure is shortened by a larger margin, and the goals of shortening the production cycle, reducing energy consumption, raising work productivity, reducing the production cost, protecting the environment and the like are achieved.

Owner:DONGGUAN KELEE STEEL WIRE

Semi-automatic double-pole umbrella fabric pressure cutting machine

ActiveCN101575797AImprove delivery efficiencyUniform waste edgeWalking sticksToothed gearingsPunchingSemi automatic

The invention relates to a fabric cutting tool in the process of producing an umbrella, in particular to a semi-automatic double-pole umbrella fabric pressure cutting machine which comprises a stander, a fabric stand which can load a plurality of rolls of fabric, a punching mechanism which cuts the fabric to be cut into umbrella pieces, and a feeding system which sends the fabric to be cut to the punching mechanism. The feeding system consists of conveyor belts which are sheathed on feed rolls on the front and back parts of the stander as well as a compacting feeding mechanism. The compacting feeding mechanism mainly comprises a reciprocating compacting feeding trolley and a reciprocating dynamic system of the compacting feeding trolley. The punching mechanism is equipped with two pressing cutter rows. In the invention, the feeding system for automatically spreading and sending umbrella fabric is designed, thus not only improving the fabric spreading and sending efficiency, but also having the machine spreading and sending accuracy higher than that of manual work, significantly reducing the chances of scrapped slitting, having well-distributed fabric slitter edge, and reducing fabric waste. Moreover, the arrangement of two pressing cutter rows simplifies the operational procedures of the punching mechanism and has more significance for improving the working efficiency of the machine.

Owner:HANGZHOU PARADISE UMBRELLA GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com