Self-learning chemical fiber spindle intelligent appearance detection system and method based on big data

An appearance inspection and self-learning technology, which is applied in the fields of optical testing defects/defects, measuring devices, scientific instruments, etc., can solve problems such as affecting the shooting effect, waste of manpower, material resources, financial resources, and inefficient and accurate detection of appearance defects of silk ingots. To achieve the effect of reducing workload and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

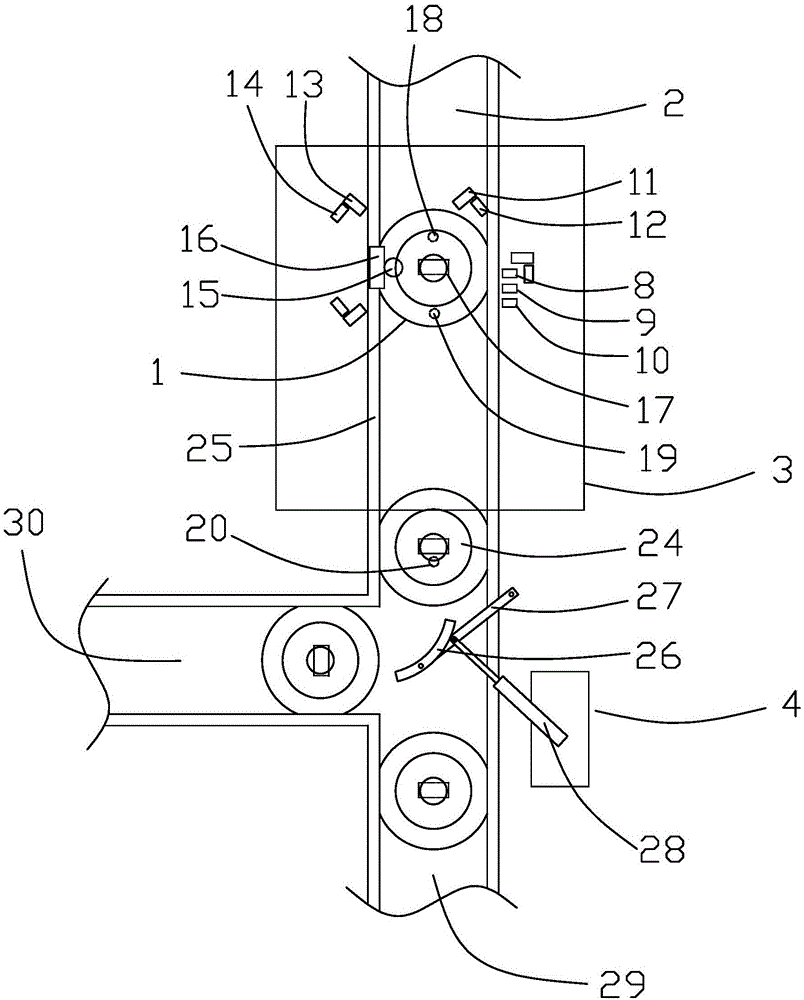

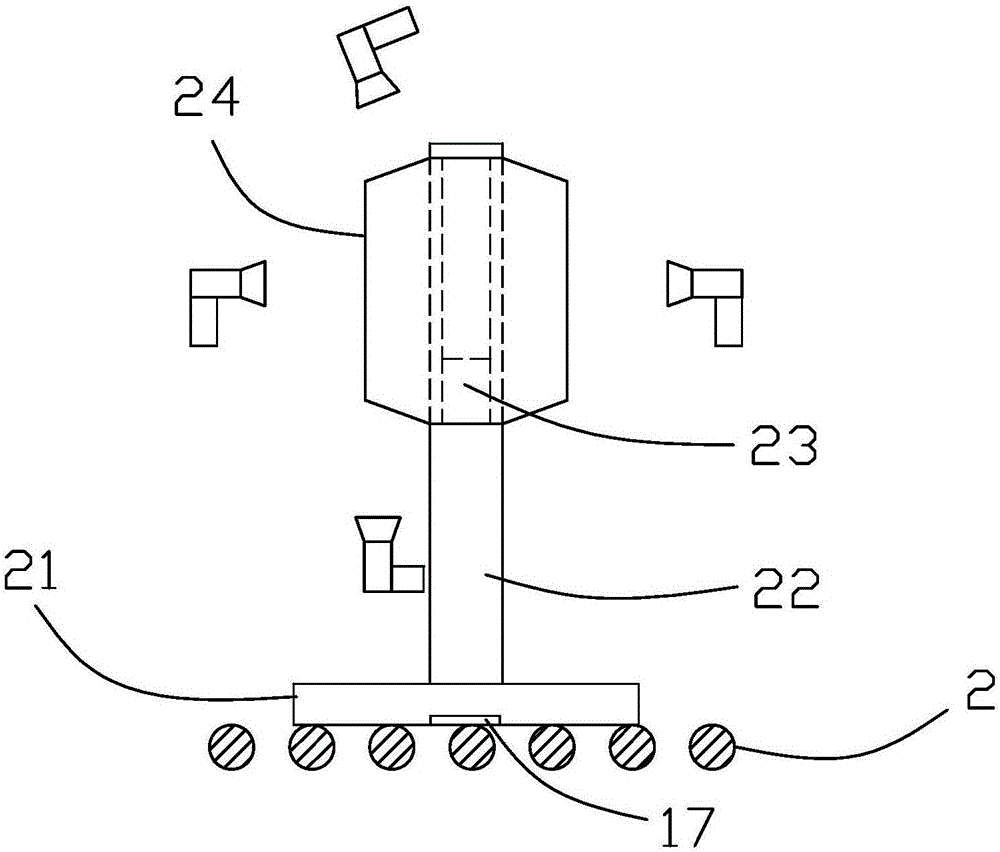

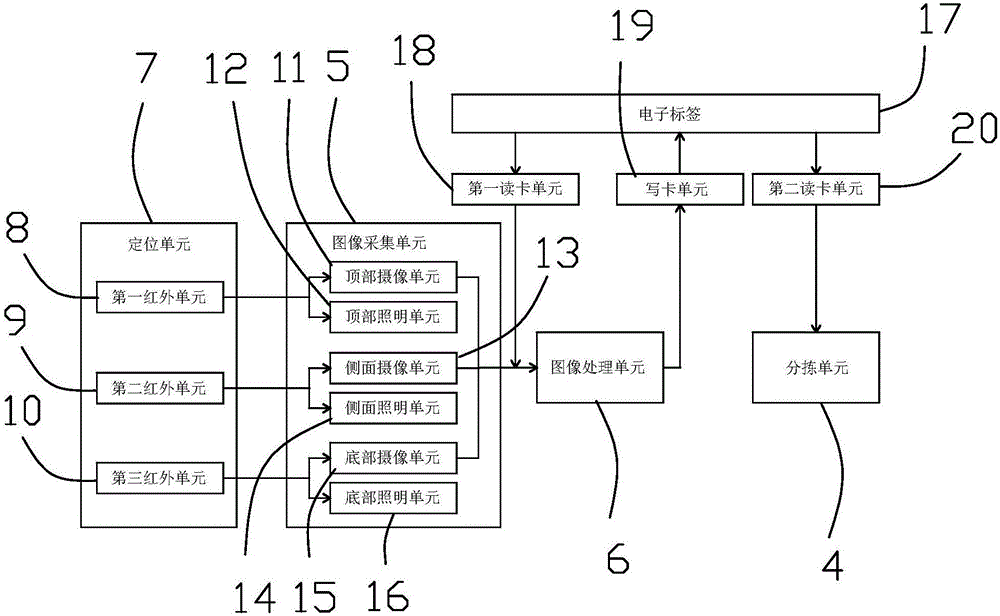

[0097] In this embodiment, an intelligent appearance detection system for chemical fiber ingots based on big data self-learning, such as figure 1 As shown, it includes a tray 1 for loading silk ingots, and a transfer unit 2 for transporting the trays. A dark box 3 is arranged on the conveying unit, and the dark box is provided with an entrance and an exit. The image acquisition unit 5 for image acquisition of the bottom surface and the bottom surface respectively, the image acquisition unit sends the acquisition information to the image processing unit 6 of the system for defect analysis, and the positioning unit for locating the shooting position of the silk ingot. Among them, the sorting unit receives the defect analysis results and sorts the output silk ingots; the image processing unit adopts the differential method to locate the wire detection area on the collected images, and performs oil pollution detection on the detection area.

[0098] like figure 1 and image 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com