Full-automatic stalk removing machine

A fully automatic, reducer technology, used in applications, food processing, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

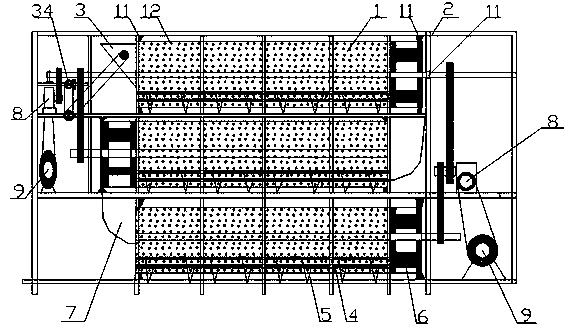

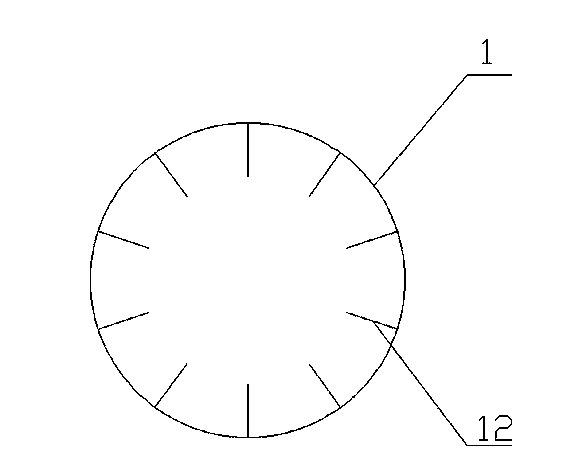

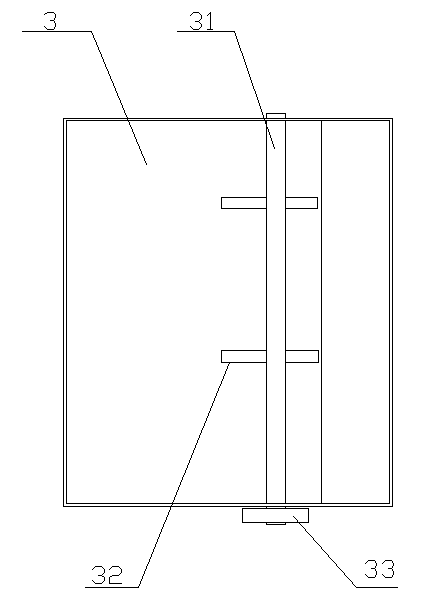

[0023] This embodiment describes in detail the structure designed according to the requirement of removing stems of dried chili peppers, and only illustrates the specific implementation of the present invention, rather than specifically limiting the structure of the present invention.

[0024] Such as figure 1 As shown, it mainly includes three rollers 1 arranged up and down and connected end to end on the support frame 2. The three rollers 1 are divided into an upper roller, a middle roller and a lower roller, and the three rollers are horizontally placed on the support frame 2 , the inclination angle is 0 to 15 degrees, the discharge port of the upper drum is connected with the feed port of the middle drum through the arc funnel 7, and the same design principle is used to design the connection mode of the middle drum and the lower drum; the inclination methods of the three drums are all adopted The inlet end is higher than the outlet end; the reason why the inventor designe...

Embodiment 2

[0034] The installation method is the same as that of Example 1, the difference is that there is only one drum 1 in this embodiment, and the body length of the drum 1 is longer than the three drums in Embodiment 1, and the upper part of one end of the drum is provided with a feed inlet, and the other end is The lower part of the drum is provided with a discharge port; the drum rotates clockwise, and a row of blades is arranged horizontally on the support frame at the bottom of the lower left side of the drum.

[0035] The reducer and the generator are arranged on the supporting frame at one end of the drum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com