Top thread keeping device of sewing machine

A technology of holding device and sewing machine, applied in the direction of thread cutting mechanism, sewing machine components, sewing equipment and other directions in sewing machines, can solve problems such as poor aesthetics, and achieve the effect of improving aesthetics and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

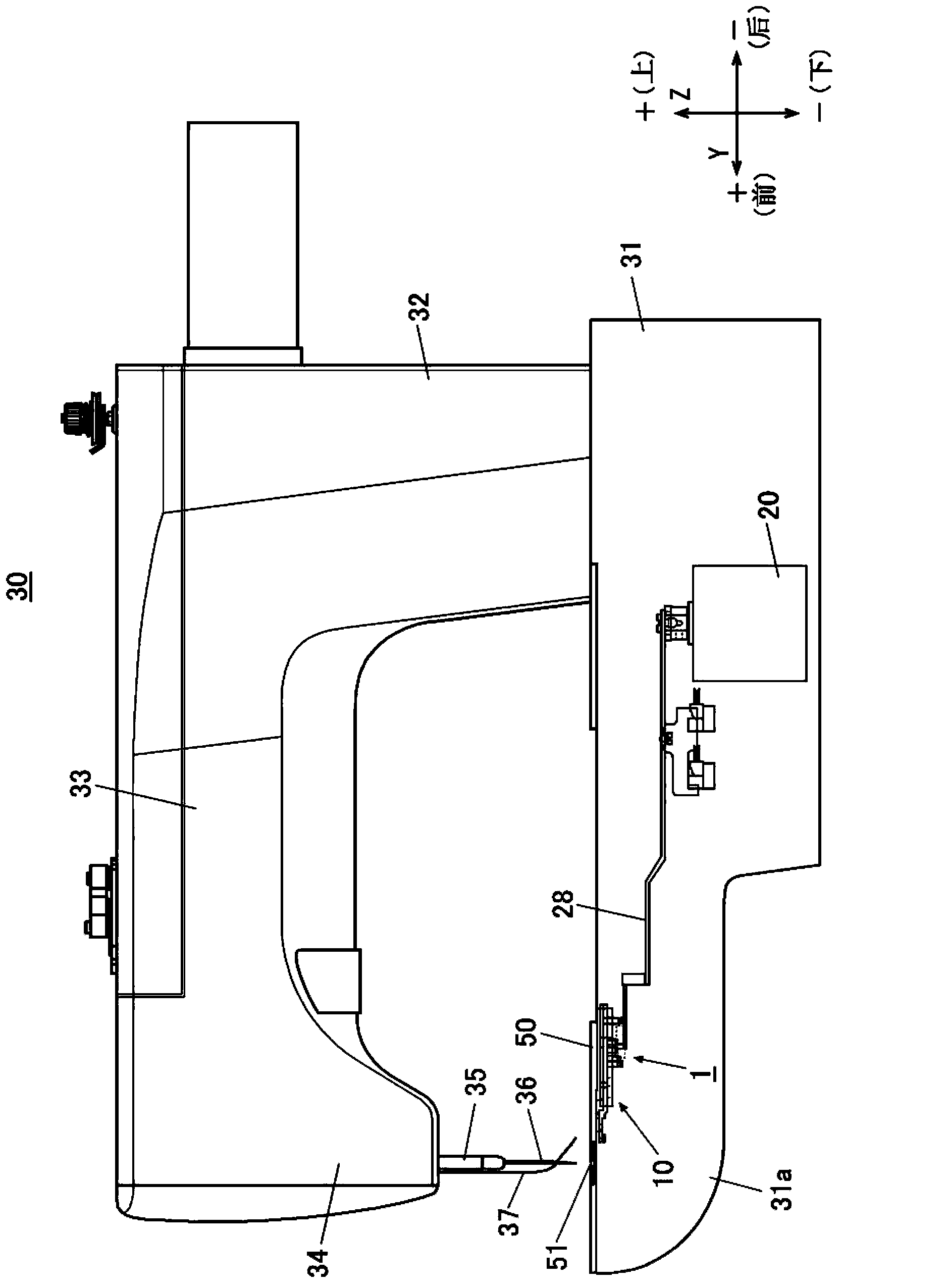

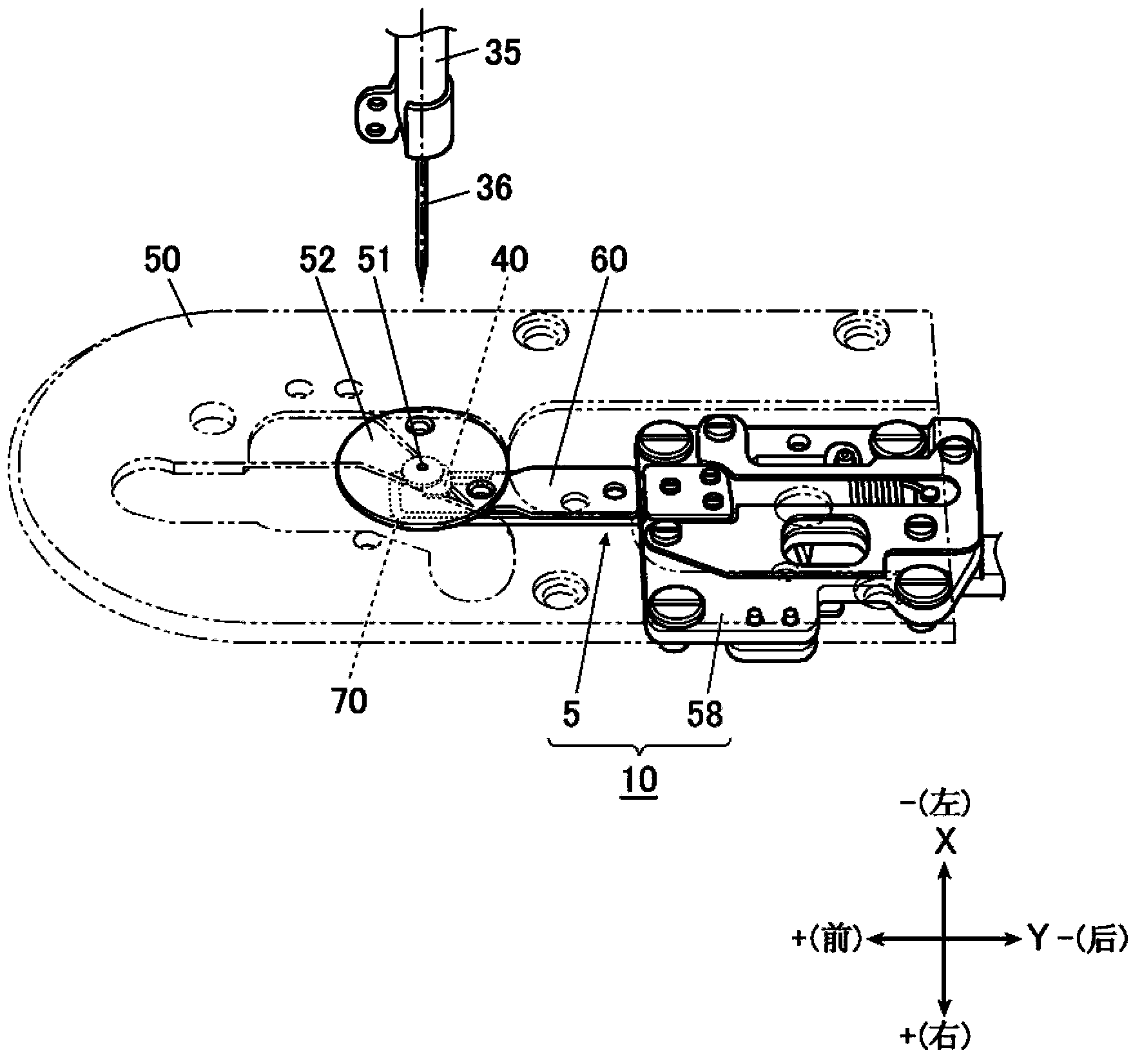

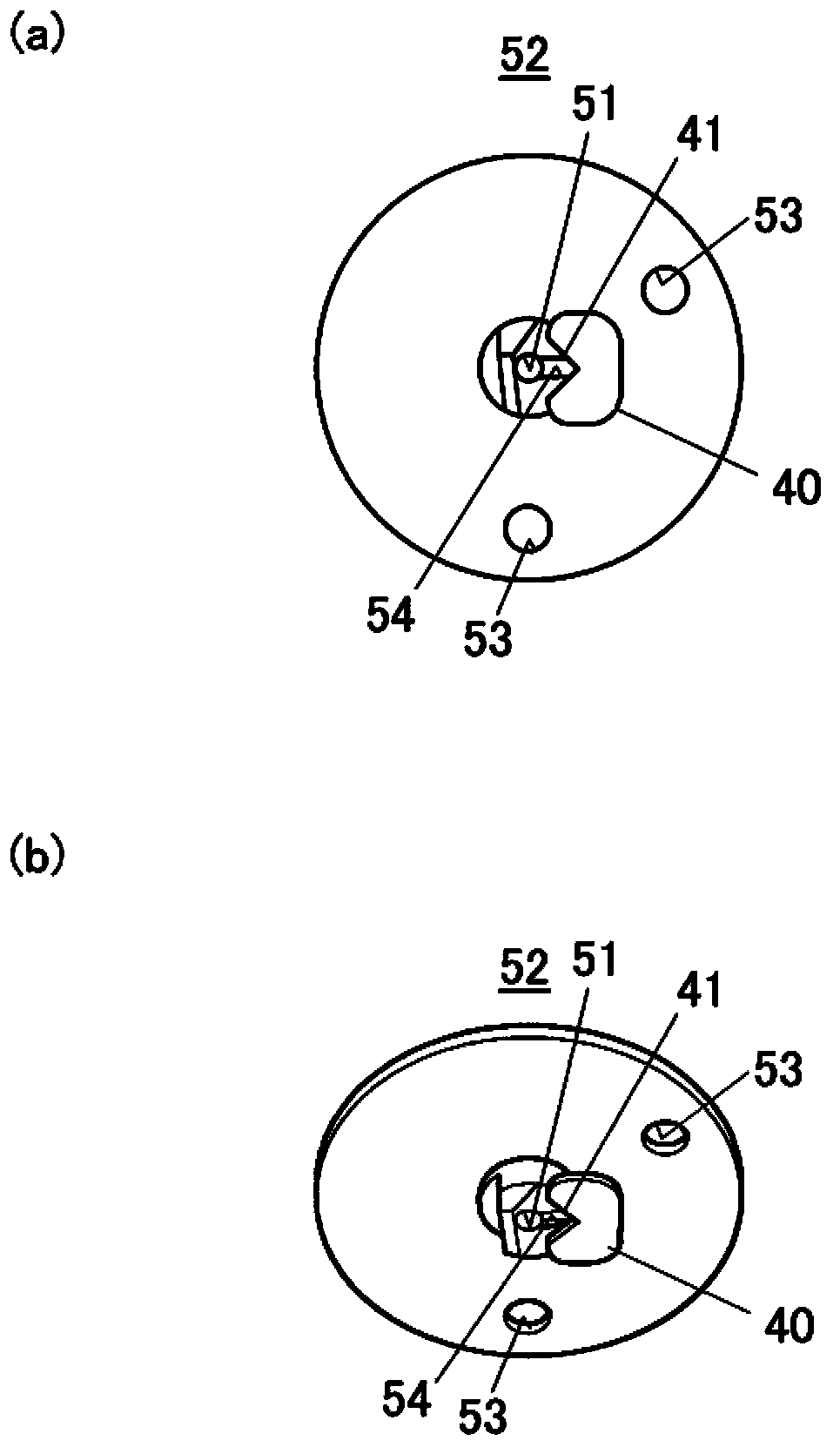

[0098] Next, embodiments of the needle thread holding device according to the present invention will be described with reference to the drawings. In addition, when describing the structure of each component of the sewing machine body including the needle thread holding device of the present invention, in this embodiment, each direction is determined by the XYZ axes shown in the figure, and the sewing machine width direction is defined as the X direction, The longitudinal direction of the arm portion 33 perpendicular to the X direction is defined as the Y direction, and the direction perpendicular to both the X direction and the Y direction is defined as the Z direction. In particular, the + side in the X direction is represented as right, and the − side is represented as left; the + side in the Y direction is represented as front, and the − side is represented as rear; the + side in Z direction is represented as up, The - side is represented as down.

[0099] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com