Full-automatic cold-folding bagging machine

A folding bagging machine, fully automatic technology, applied in the direction of cloth feeding mechanism, cloth pressing mechanism, sewing machine components, etc., can solve the problems of unfavorable energy saving and consumption reduction, easy deviation of liner position, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

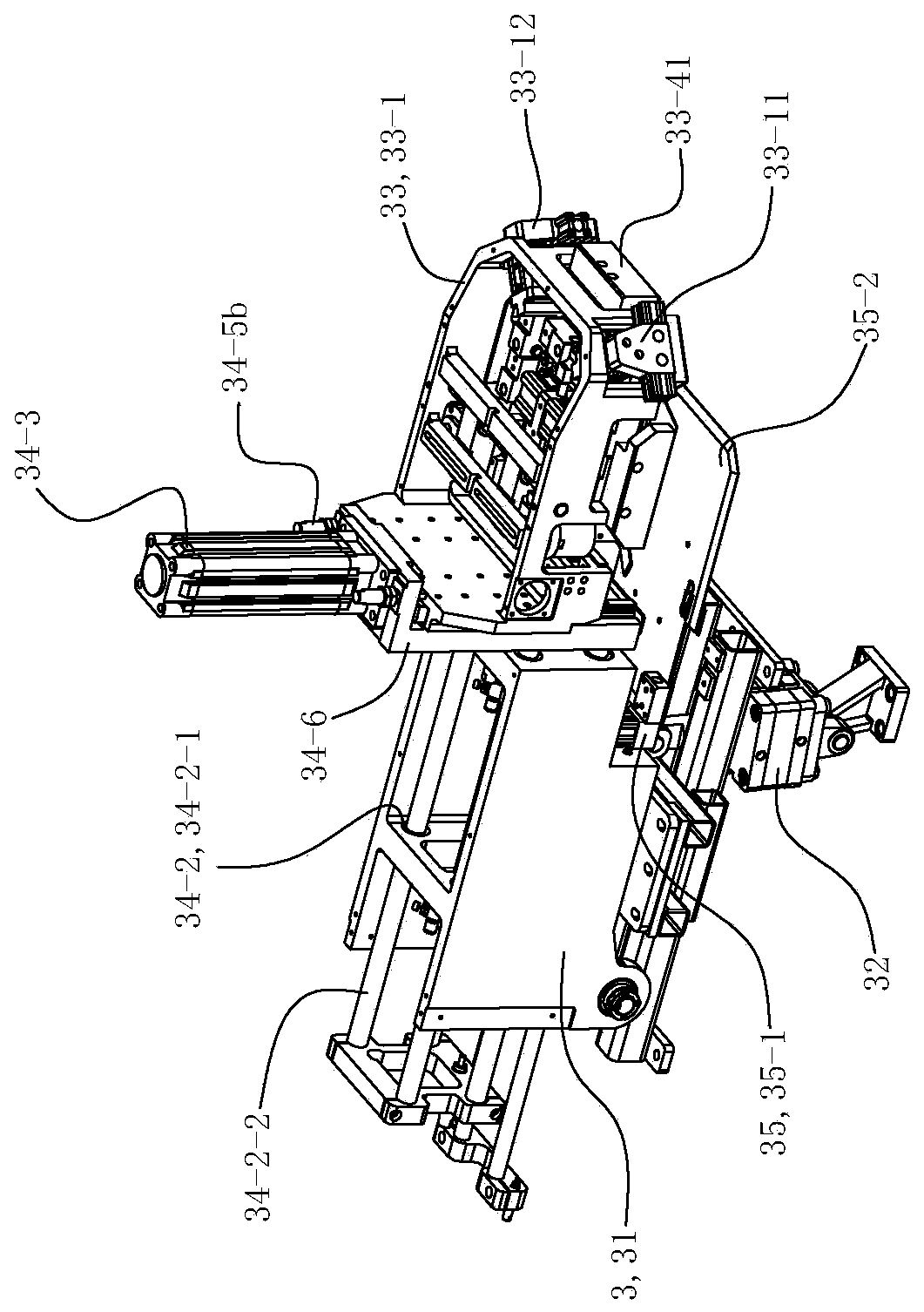

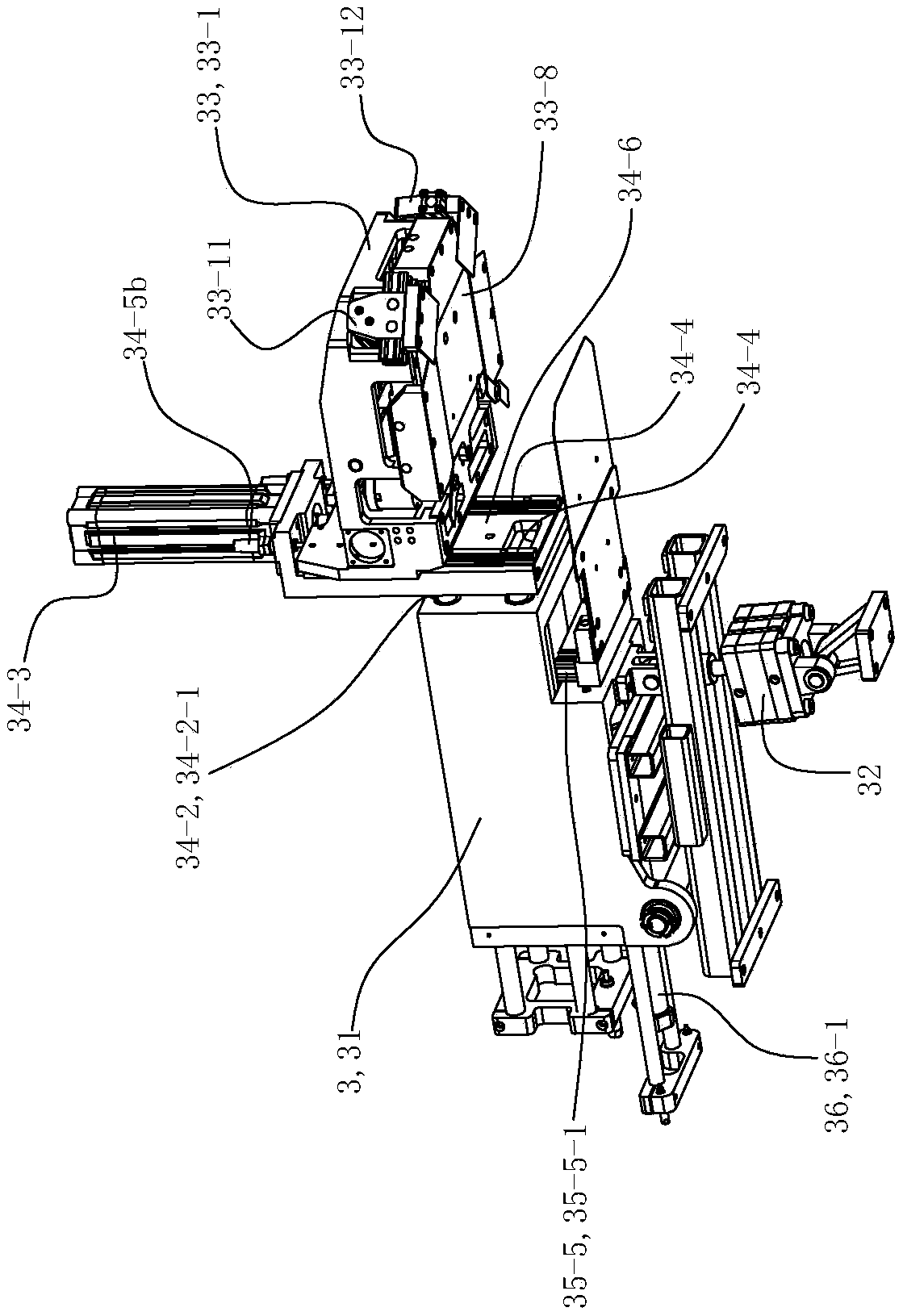

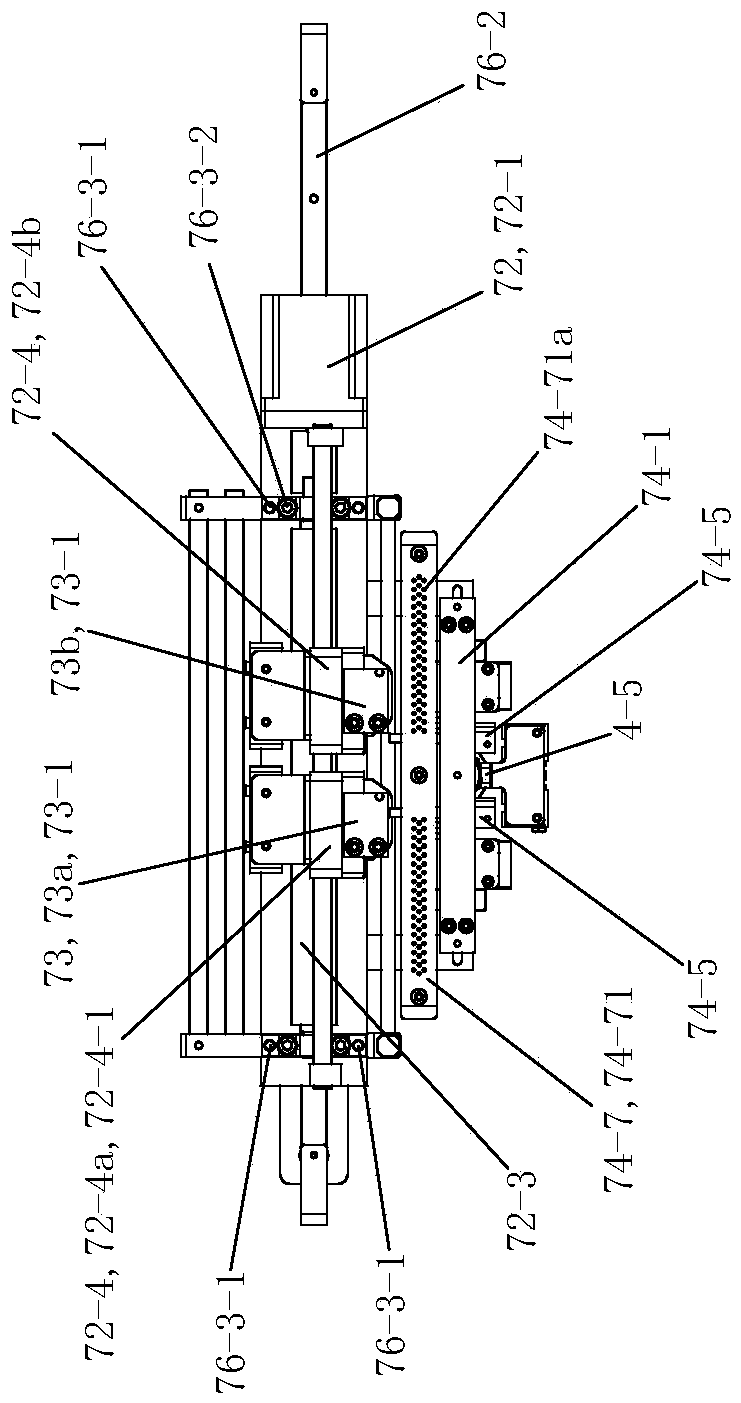

[0140] See Figure 1 to Figure 38 , the full-automatic cold-fold bagging machine of the present invention comprises a workbench assembly 1, a sewing assembly 2, a hemming device 3, an auxiliary positioning adjustment device 4, a feeding device 5, a feeding sewing drive device 6, a liner feeding device 7, a material receiving Device 8 and discharging assembly 9.

[0141] See Figure 1 to Figure 10 with Figure 30 , The worktable assembly 1 includes a frame 1-1, a worktable 1-2, a lifting table 1-3, a table driving assembly 1-4, a protective gear bar 1-5 and a protective cover 1-6. The workbench 1-2 is fixed horizontally on the frame 1-1. The left rear portion of the workbench 1-2 is provided with a lifting platform hole that runs through it up and down. The middle part of the left part of the workbench 1-2 is also provided with a liner feed hole that runs through it up and down, and the liner feed hole is located at the front side of the lifting platen hole. The left front...

Embodiment 2

[0248] The rest of this embodiment is the same as that of Embodiment 1, the difference is that: the two quick-mounting shafts on the front quick-mounting seat 33-41 of the edge-folding device 33 of the edge-folding device 3 are fixedly arranged at the front along the up and down direction On the upper side of quick mounting seat 33-41. 2 fast loading shafts on the front fast loading seat 33-41 pass through the corresponding through holes on the front connecting plate 33-5-1 respectively from bottom to top and insert the fourth fast loading locking cylinder 33-3-4 and the In the vertical insertion hole 33-311 of the fifth fast loading locking cylinder 33-3-5, then the piston rod of the fourth fast loading locking cylinder 33-3-4 and the fifth fast loading locking cylinder 33-3-5 33-32 stretches into the annular fastening groove on the fast mounting shaft, thereby the fast mounting seat 33-41 at the front is fast fixedly connected on the underside of the edge folder base plate 3...

Embodiment 3

[0253] See Figure 39 with Figure 40 , The remainder of this embodiment is the same as that of Embodiment 1, the difference being that: the upper pressing plate 33-8 of the hemming device of the hemming device 3 is a pentagon corresponding to the shape of the pocket being sewn. The bag-shaped die 35-2 is a pentagon corresponding to the shape of the bag to be sewn. The feeding body presser foot 52 of feeding device 5 is replaced with the pentagon corresponding to the shape of the pocket to be sewn in the shape of the inner side, the left adjustment pressing plate 54-7, the right adjustment pressing plate 54-8 and the front adjustment pressing plate 54-6 The shape of the outside of the body corresponds to the shape of the feeding body presser foot 52 insides. The left front folding knife fast mounting seat 33-11-3, the left front upper folding knife 33-11-4 and the left front lower folding knife 33-11-5 are not installed on the left front flap assembly 33-11. The right front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com