Bridge expansion joint device

A technology of expansion joints and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of broken bolts, non-existence, old ones and new ones, increased bridge maintenance costs, etc., and achieves the effect of convenient installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

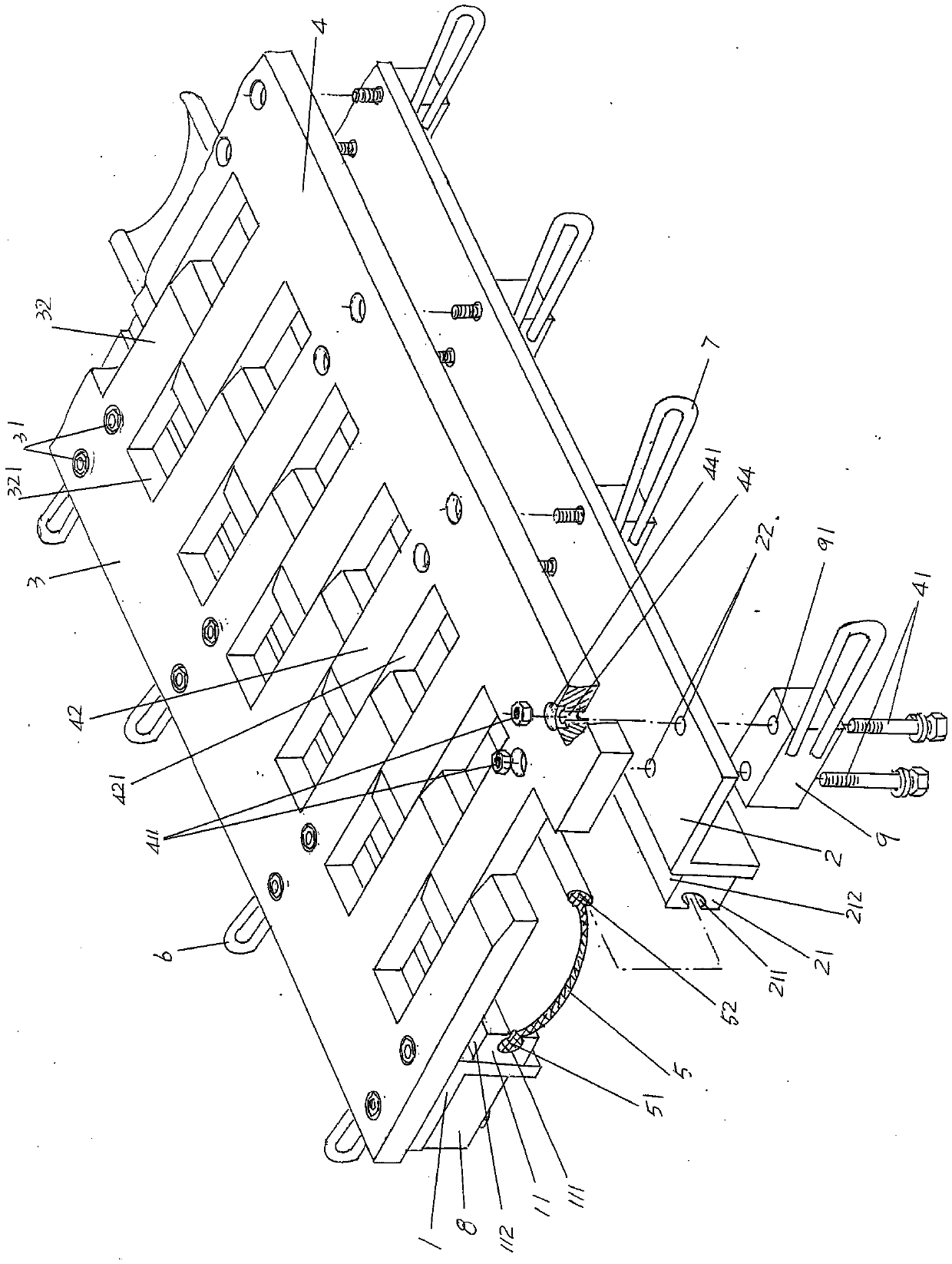

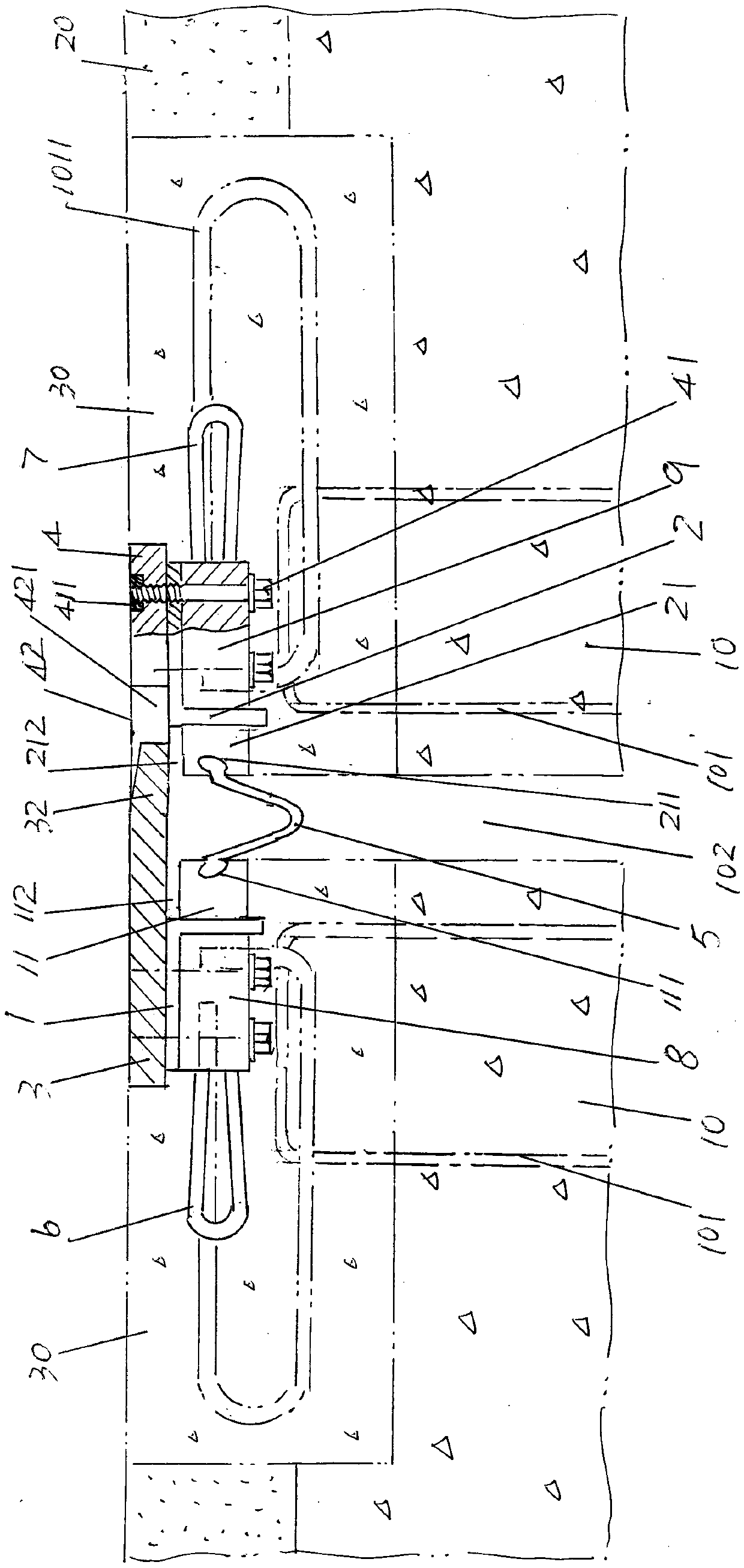

[0021] See figure 1 , showing the left comb plate support beam 1, the right comb plate support beam 2, the left comb plate 3, the right comb plate 4, the water stop 5, the left anchor rib 6 and the right anchor rib 7, the left comb The plate support beam 1 and the right comb-tooth plate support beam 2 are kept parallel to each other in the length direction, and the left comb-tooth plate 3 is fixed to the left comb-tooth plate support beam 1 by two rows of left comb-tooth plate fixing bolts 31 distributed at intervals. The length direction of the left comb tooth plate 3 is formed with left comb teeth 32, and the space between each two adjacent left comb teeth 32 constitutes a right comb tooth matching cavity 321, and the right comb tooth plate 4 is distributed by two rows in an interval state. The right comb tooth plate fixing bolt 41 is fixed with the right comb tooth plate support beam 2, and the right comb tooth 42 is formed in the length direction of the right comb tooth pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com