Patents

Literature

137results about How to "Avoid shear force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

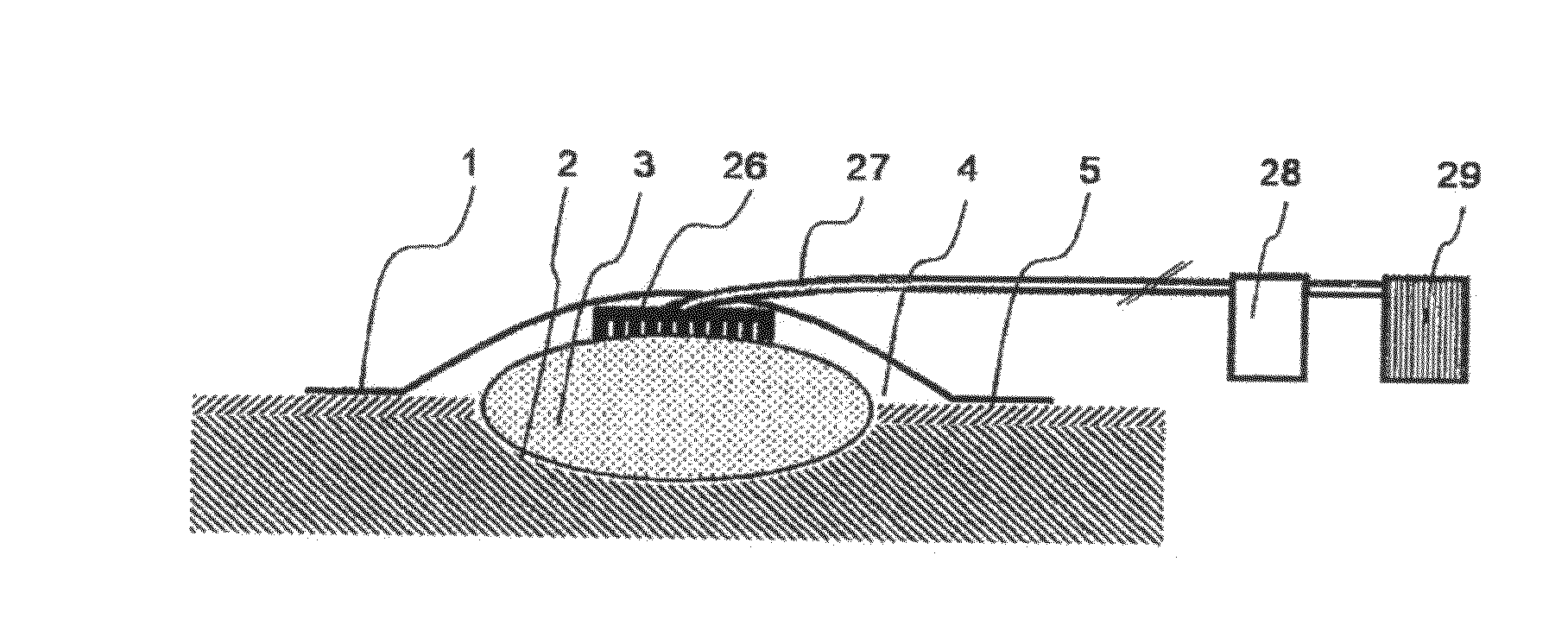

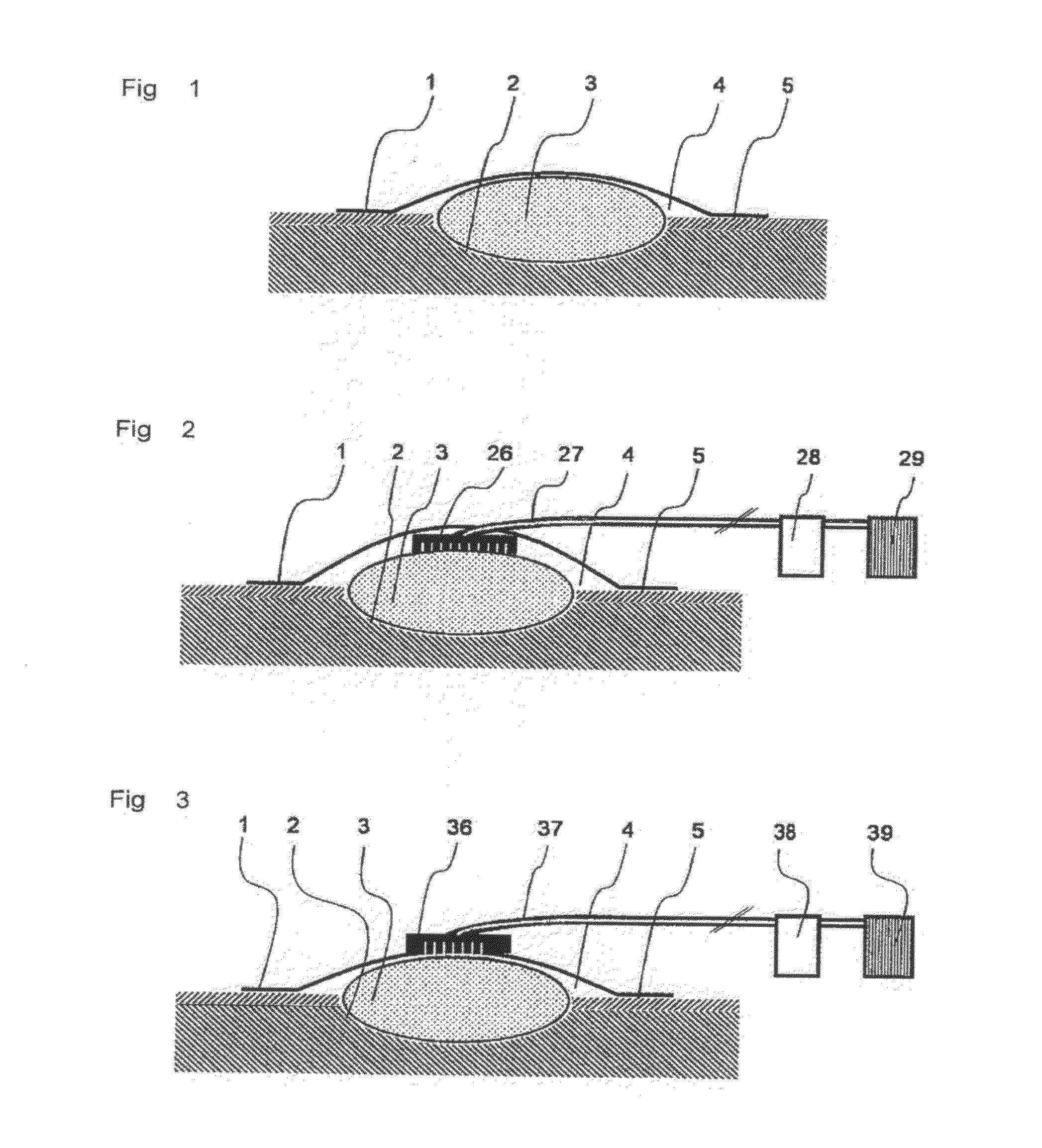

Device for vacuum therapy of wounds

InactiveUS20110004172A1Sufficiently fixedAvoid shear forcePlastersIntravenous devicesSuperabsorbent polymerBiomedical engineering

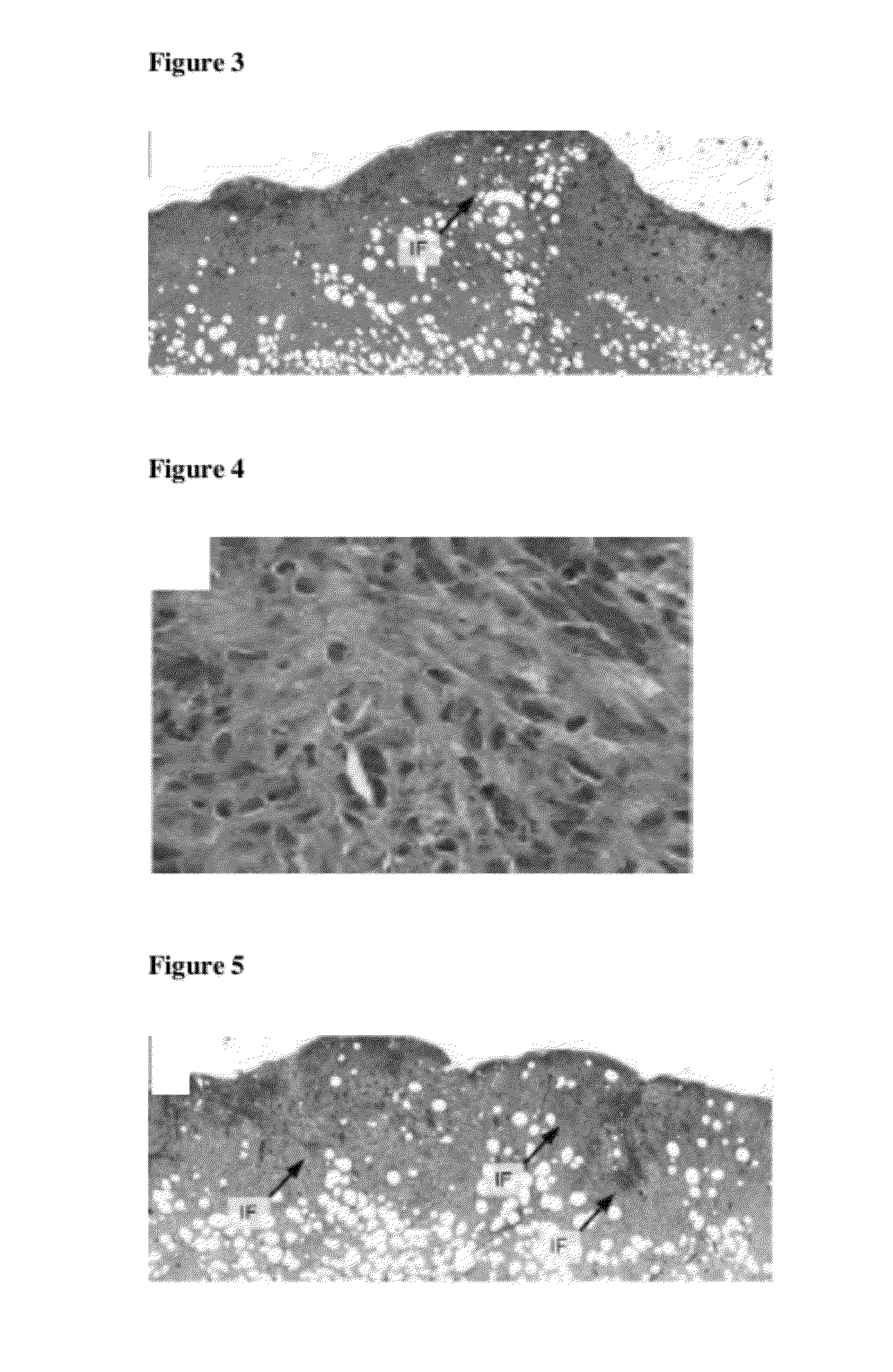

Device for vacuum therapy of wounds comprising a cover material (1) that is impermeable to air, and a means for functional connection of the wound space (4) with a source of vacuum outside the cover material, and at least one activated absorbent / rinsing body (3) that contains at least one superabsorbent polymer.

Owner:PAUL HARTMANN AG

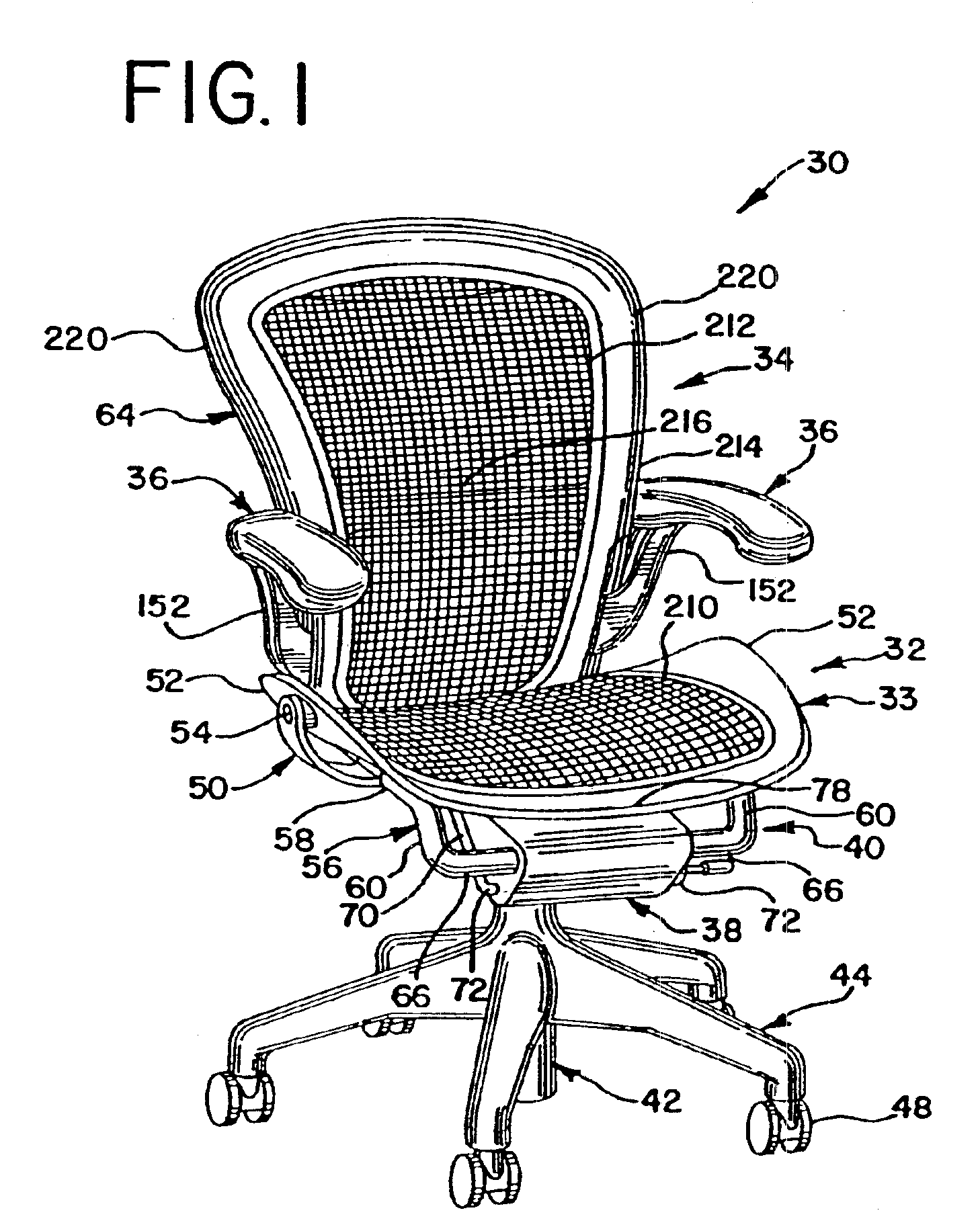

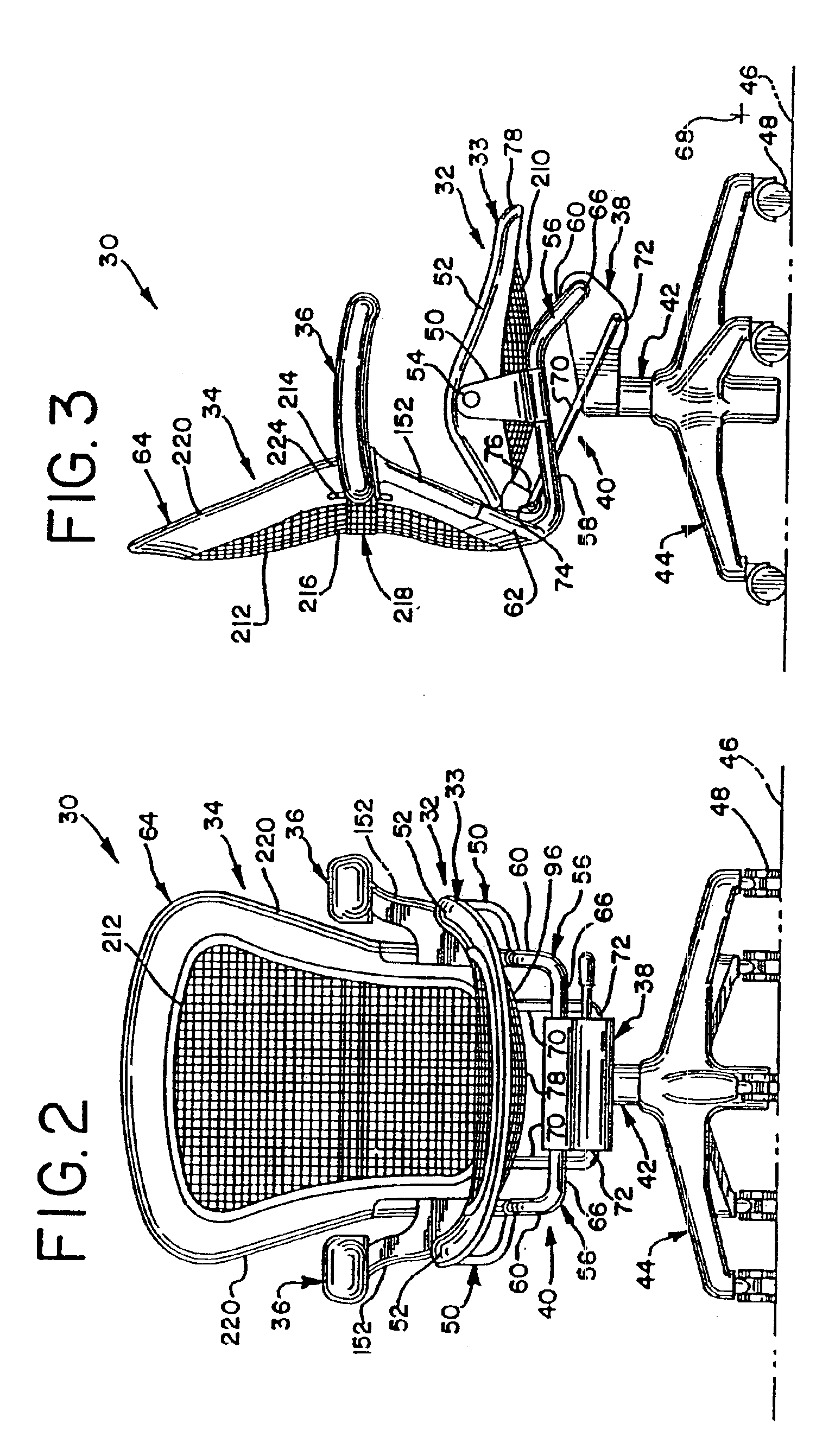

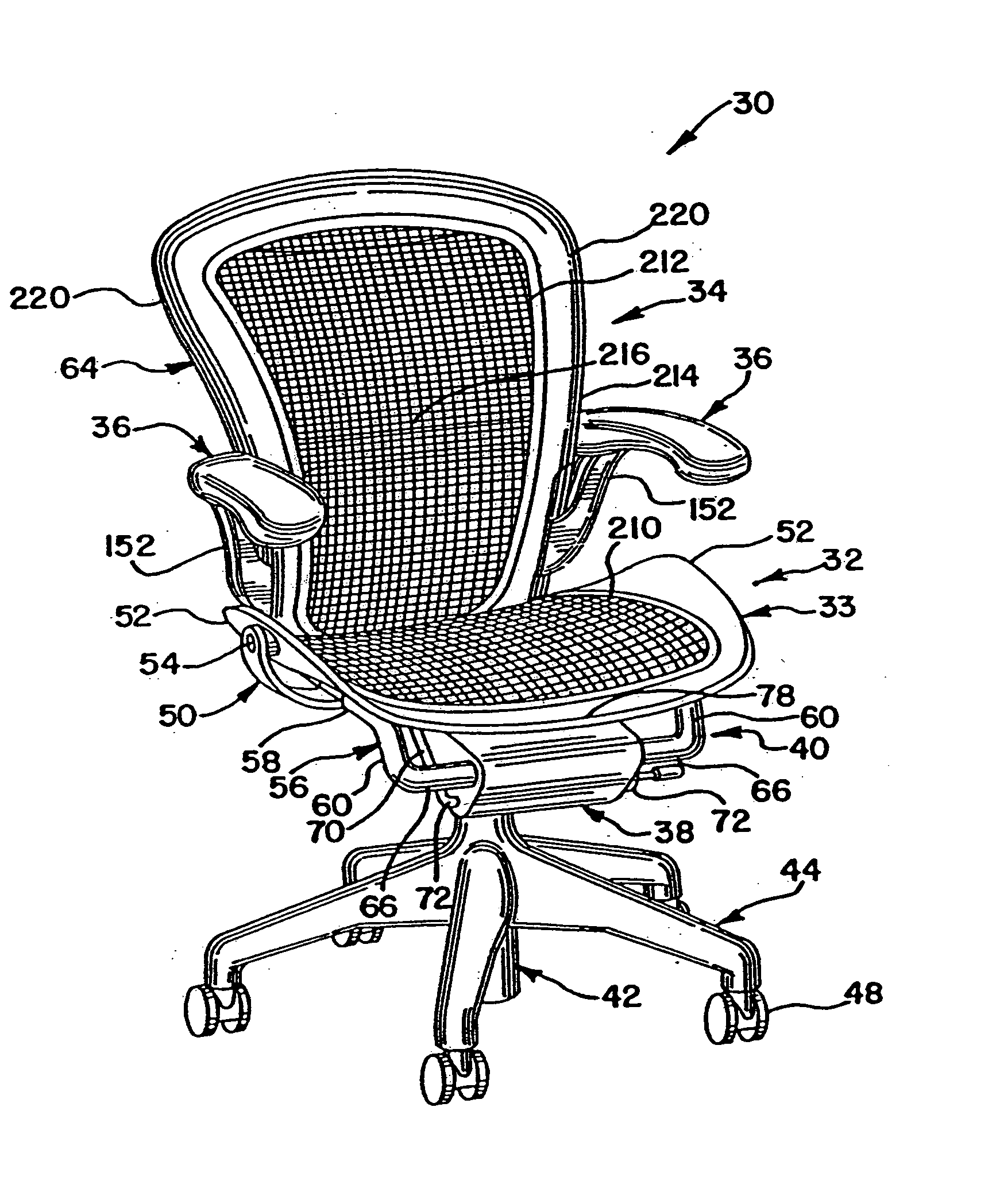

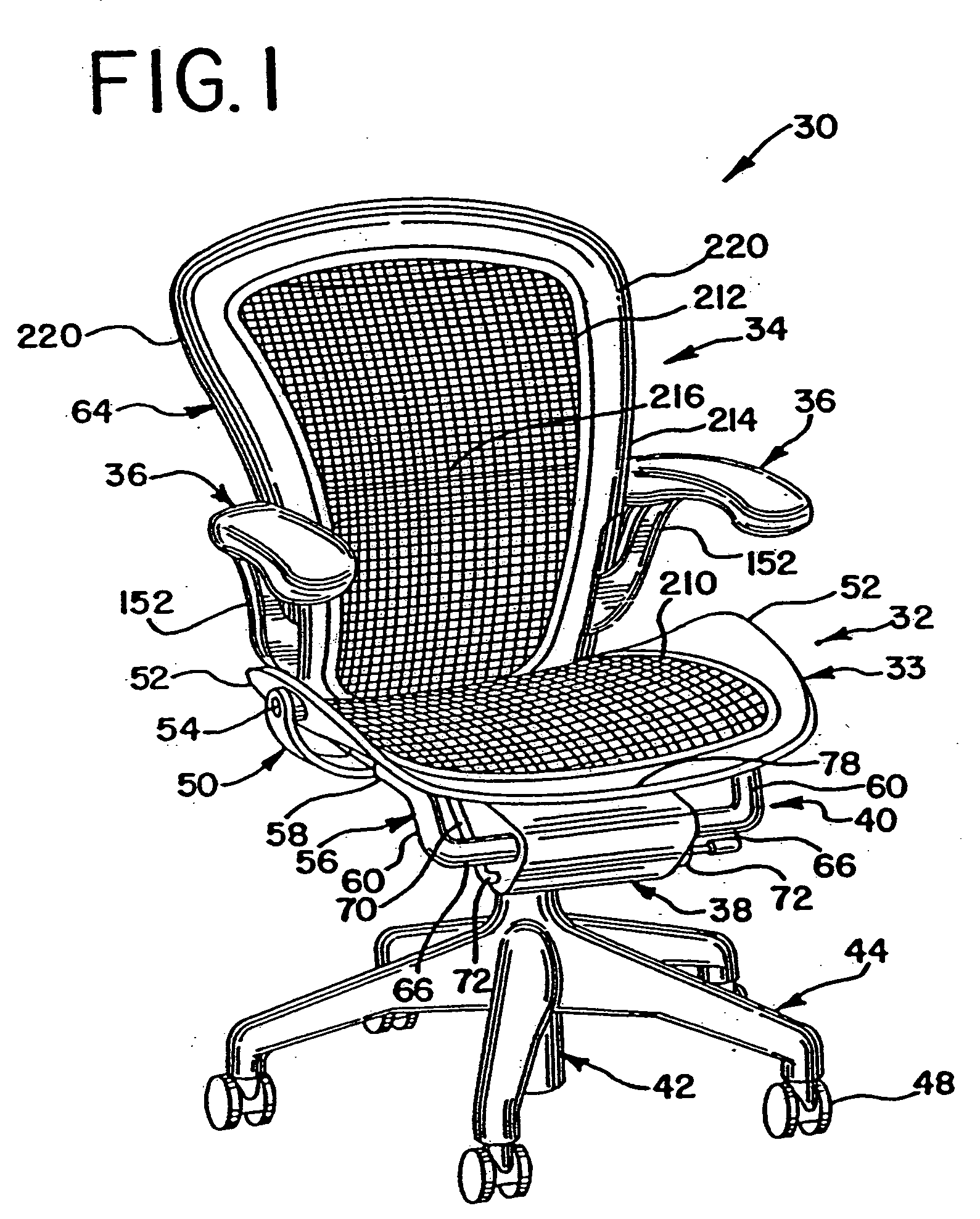

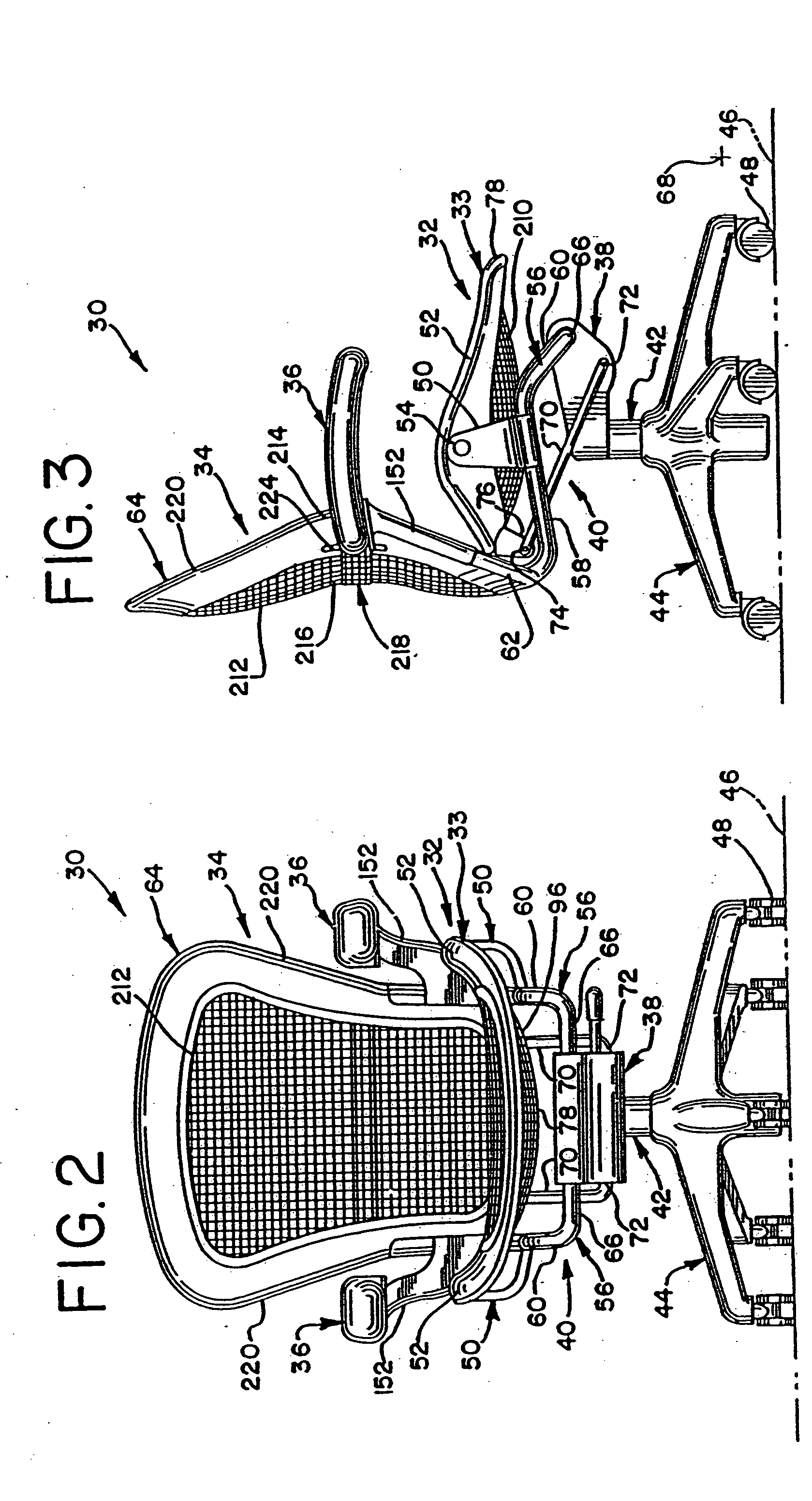

Chair with a linkage assembly

InactiveUS6966604B2Tilt is limitedEffective pointingStuffed mattressesSpring mattressesEngineeringBack support

A chair includes a control housing, a seat and a back support including an upwardly extending upright portion and a link portion extending forwardly from a lower portion of the upright portion. The link portion is pivotally connected to the control housing about a first pivot axis. The seat is connected to the link portion and is pivotable relative thereto. A linkage is coupled to the seat and is pivotally connected to the control housing at a second pivot axis positioned rearwardly and downwardly from the first pivot axis.

Owner:HERMAN MILLER INC

Barking Device and Barking Tool

ActiveUS20070261762A1Designing can be facilitatedExtra stepTree debarkingMulti-purpose machinesEngineeringMechanical engineering

Owner:IGGESUND TOOLS

Office chair

InactiveUS20060071523A1Avoid shear forceTilt is limitedStuffed mattressesSpring mattressesOffice chairEngineering

A chair includes a control housing, a seat and a back support including an upwardly extending upright portion and a link portion extending forwardly from a lower portion of the upright portion. The link portion is pivotally connected to the control housing about a first pivot axis. The seat is connected to the link portion and is pivotable relative thereto. A linkage is coupled to the seat and is pivotally connected to the control housing at a second pivot axis positioned rearwardly and downwardly from the first pivot axis.

Owner:HERMAN MILLER INC

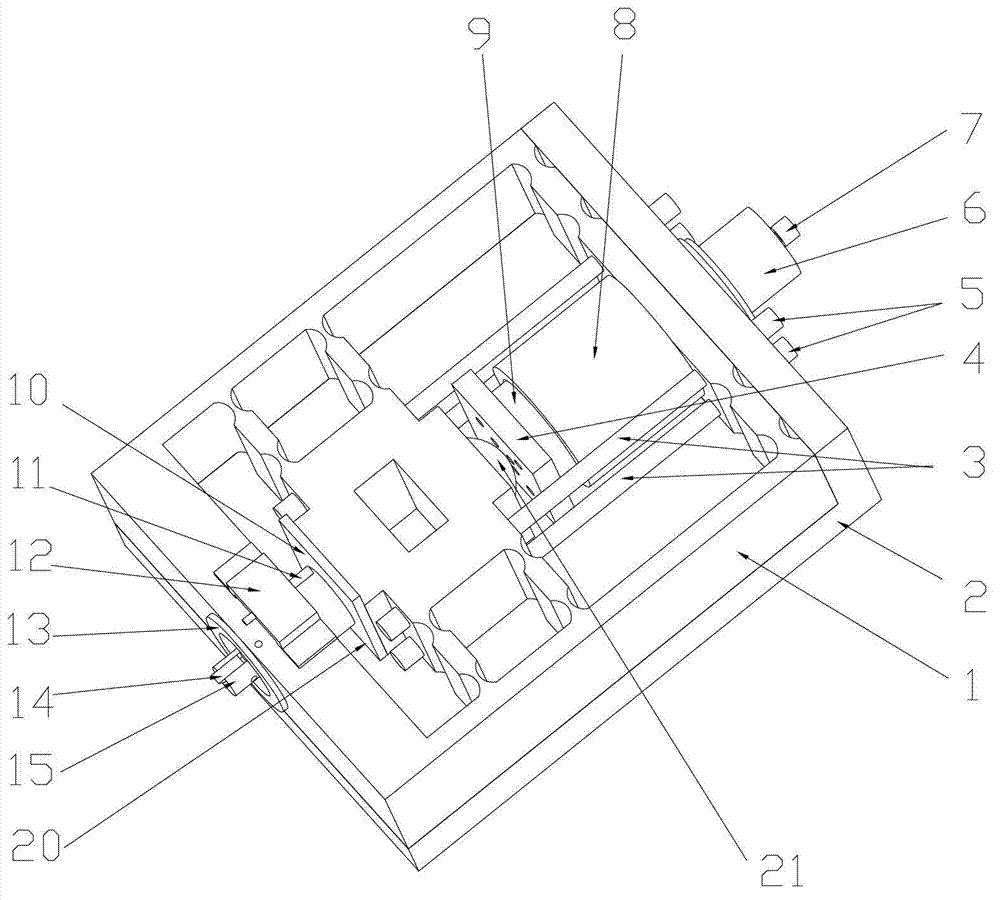

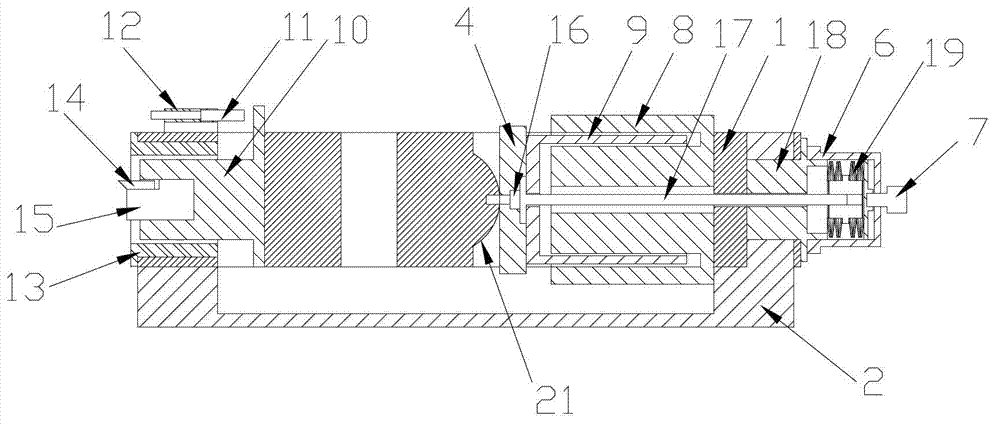

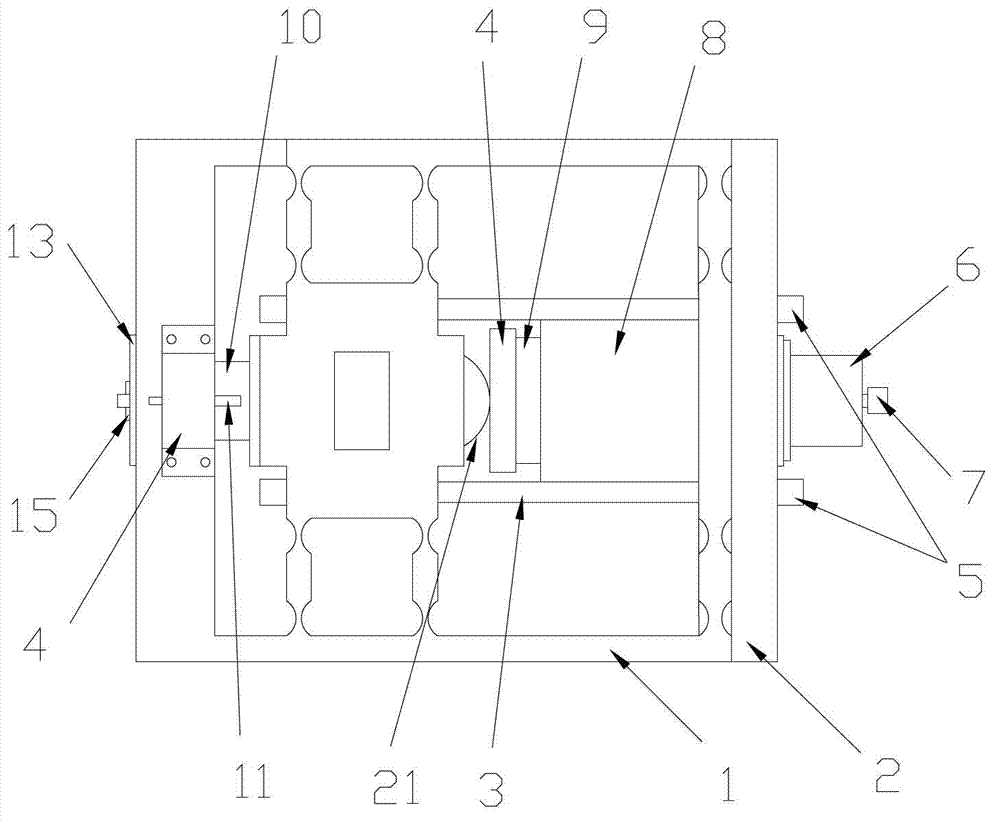

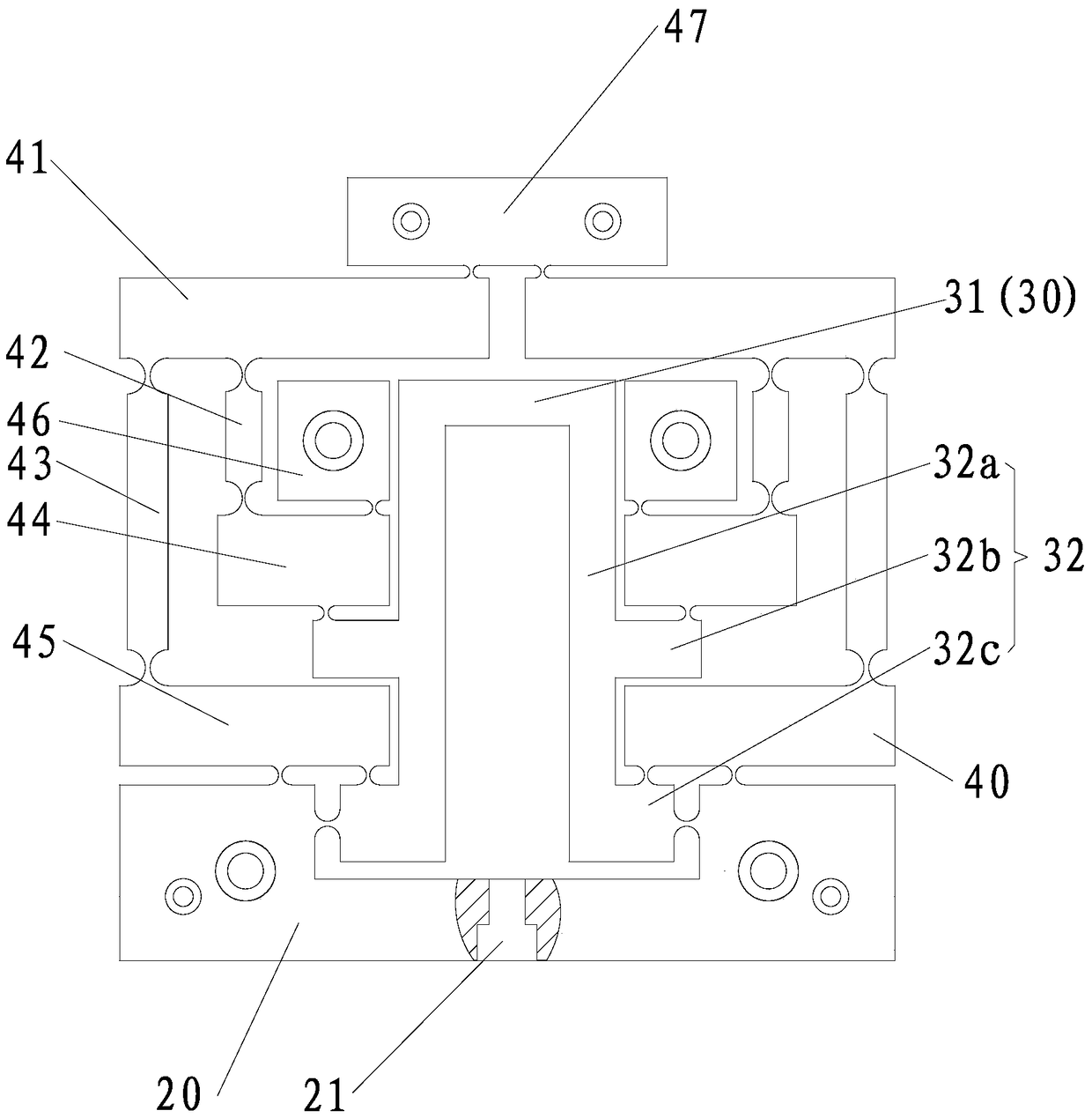

Cutter servo micro-feeding mechanism

InactiveCN102862084AIncrease the itineraryImprove dynamic stiffnessFeeding apparatusMaintainance and safety accessoriesStatorEngineering

A cutter servo micro-feeding mechanism relates to a part processing displacement mechanism, is based on a voice coil motor and is characterized by being fast, high in frequency response and accuracy, large in journey, multiple in shock buffer effect, double in pre-tightening effect and good in cutter cutting rigidity and force conductivity. The cutter servo micro-feeding mechanism is provided with a flexible hinge, a base, an elastic connection rod, an adapter plate, an elastic connection rod adjustment nut, an end cover, a spring adjustment nut, a voice coil motor stator, a voice coil motor rotor, an air hydrostatic guideway inner rail, a capacitance displacement sensor, a sensor support frame, an air hydrostatic guideway outer rail, a lathe tool, a tool bit clamp, a transmission shaft, a pre-tightening nut and a disc spring.

Owner:XIAMEN UNIV

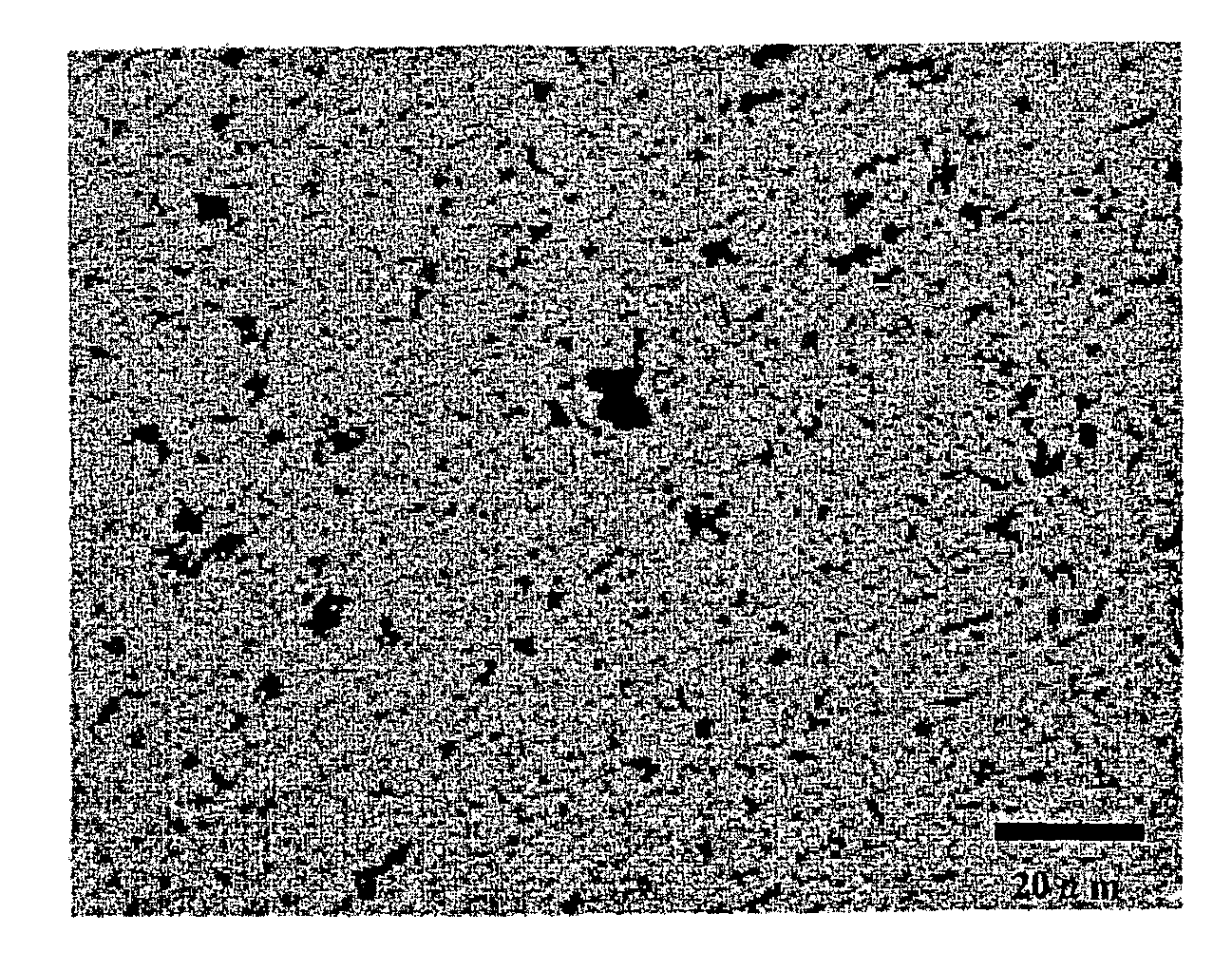

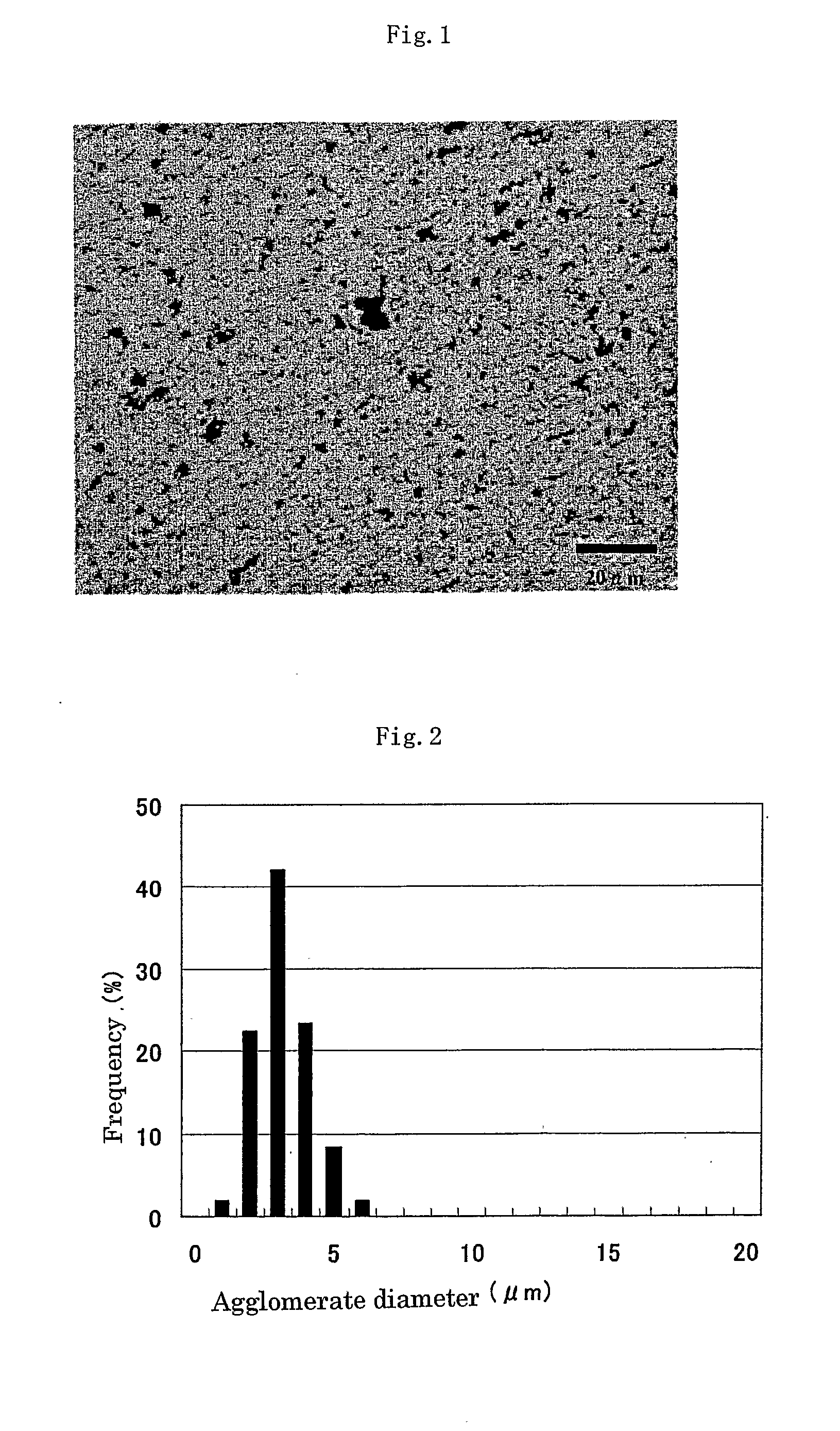

Electroconductive Resin Composition, Production Method and Use Thereof

InactiveUS20080099732A1Good surface smoothnessHigh dimensional accuracyNon-metal conductorsNon-macromolecular adhesive additivesFiberCarbon fibers

The electroconductive resin composition comprising 1 to 30 mass % of carbon fiber having a hollow structure, an average filament diameter of 50 to 500 nm and an average aspect ratio of 50 to 1000 and 99 to 70 mass % of resin, wherein the volume ratio of carbon fiber agglomerate to one carbon fiber filament constituting the agglomerate in the resin composition (volume of carbon fiber agglomerate / volume of a carbon fiber filament) is 1500 or less according to the invention can be uniformly dispersed in resin without agglomeration and therefore, a good electroconductivity can be achieved by addition of small amount of the composition.

Owner:SHOWA DENKO KK

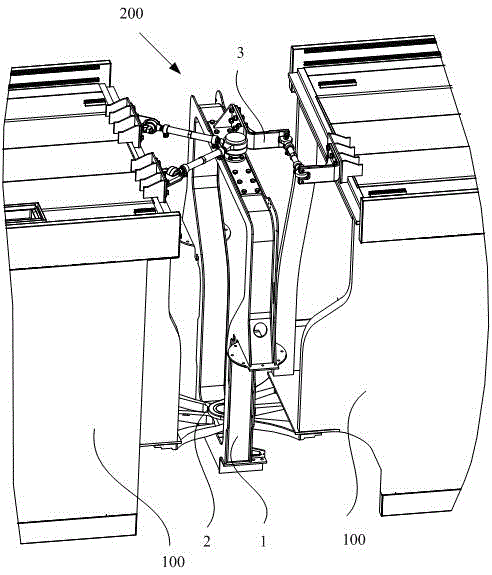

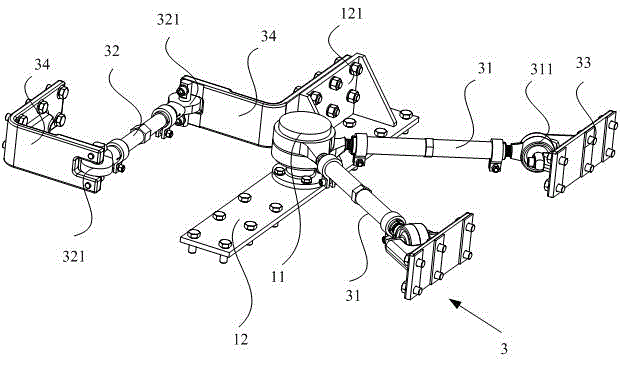

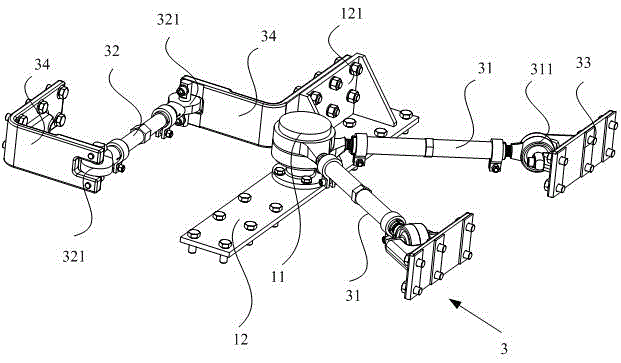

Carriage hinge device and streetcar

ActiveCN105329252AImprove reliabilityHigh torqueRailway couplingsTramway vehiclesEngineeringMechanical engineering

The invention provides a carriage hinge device and a streetcar. The carriage hinge device comprises a loading frame, a lower hinge assembly and an upper hinge assembly. The lower hinge assembly comprises a first oscillating bearing, a second oscillating bearing, a first connecting plate and a second connecting plate, and the connecting plates are hinged to the loading frame through the oscillating bearings. An upper installing shaft is arranged at the upper portion of the loading frame and provided with a rubber bearing. The upper hinge assembly comprises two first connecting rods, a second connecting rod, two first installing bases and two second installing bases; one ends of the first connecting rods are hinged to the loading frame through the rubber bearing, and the other ends of the first connecting rods are hinged to the first installing bases through a third oscillating bearing; the two ends of the second connecting rod are hinged between the two second installing bases through a fourth oscillating bearing, and one of the second installing bases is fixed to the upper portion of the loading frame. The reliability of the streetcar is improved.

Owner:青岛中车四方轨道车辆有限公司

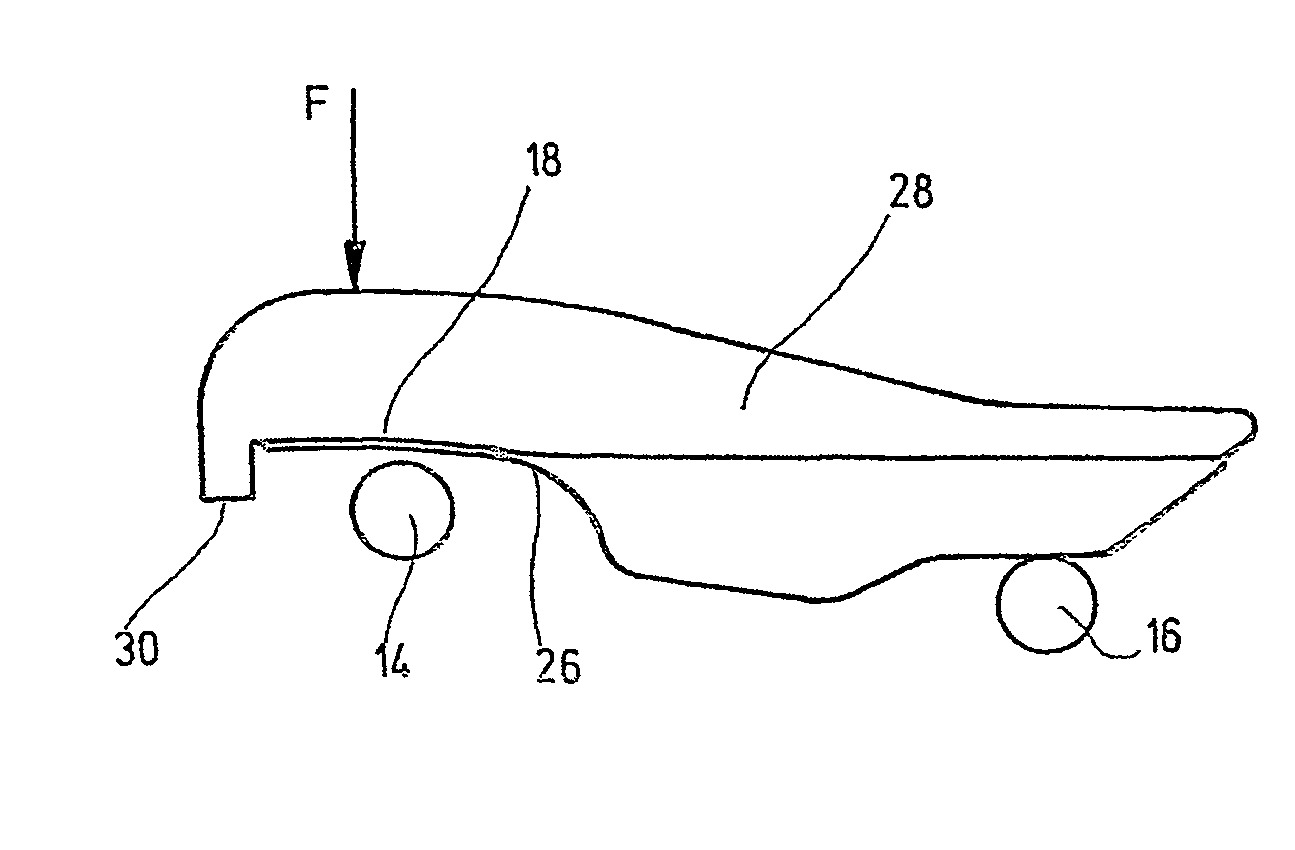

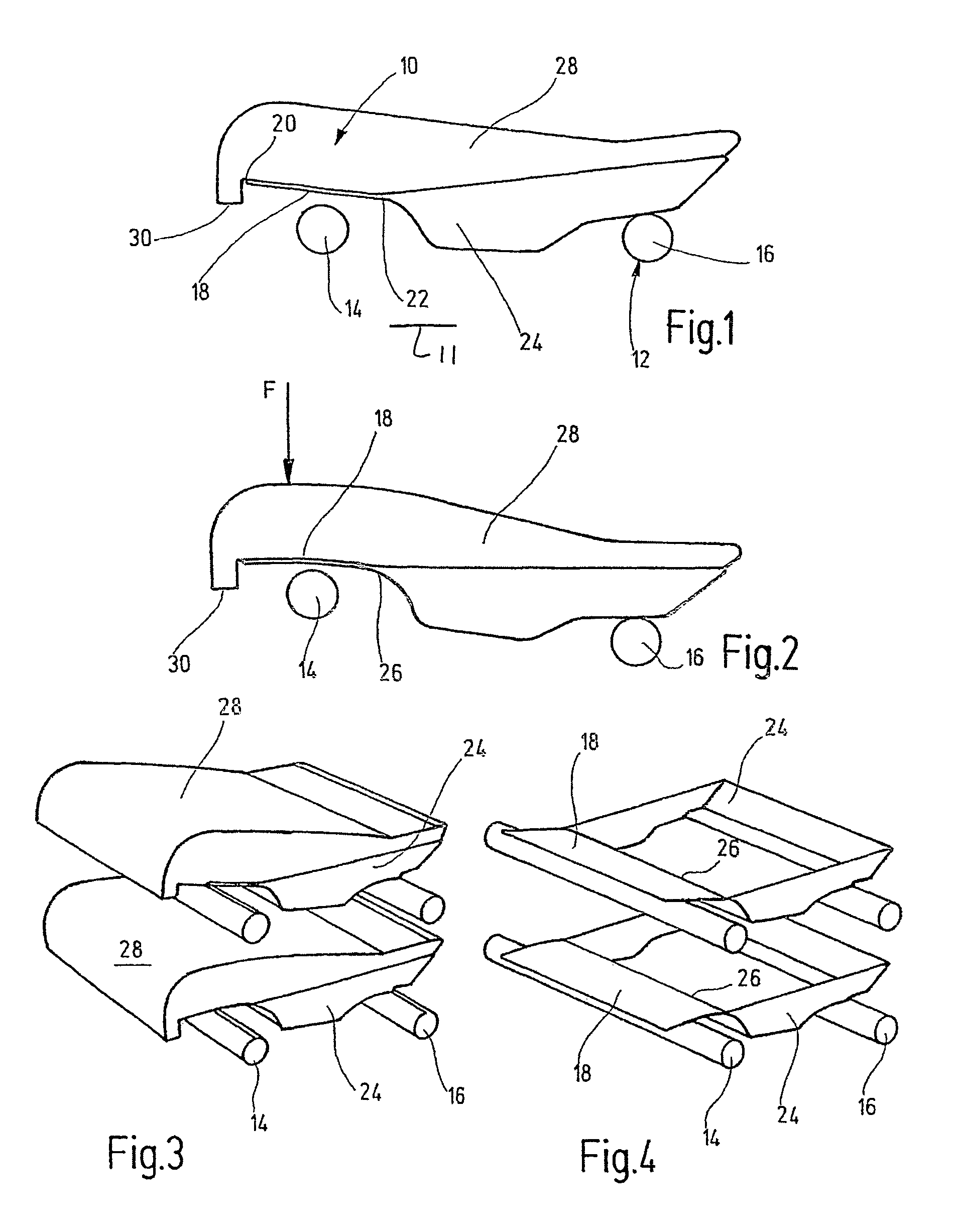

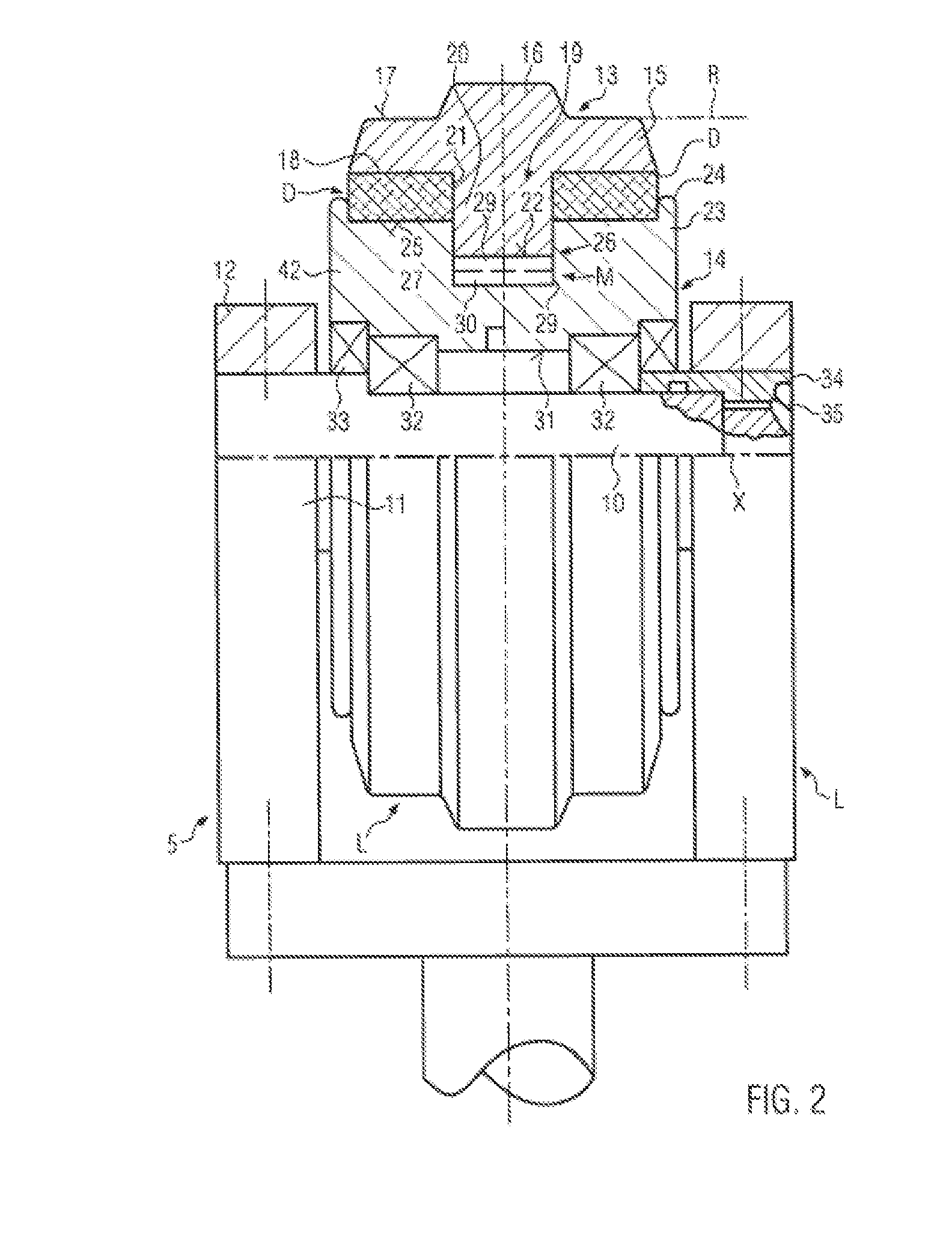

Seat, especially an airplane or vehicle seat

A seat, especially an airplane or vehicle seat, has a seat part placed on the stand-type seat structure (12) in relation to a base and provided with a bearing part (18) on its front side. The bearing part (18) is embodied in a flexible manner and can move in the direction of the seat structure (12) when a predefined seating load is exerted on it. When the load is discharged, it can move back into its initial position in the opposite direction from the seat structure (12). This arrangement creates a seat whose front part is maintained in a flexible manner such that the front area of the seat part yields according to the seating load exerted by the seat user. The pressure forces are limited to the lower side of the upper thighs of the seat user. As a result, the cross-sections of the veins in that region are not reduced, but are maintained such that the circulation of the blood is not impeded, significantly reducing the risk of thrombosis.

Owner:RECARO AIRCRAFT SEATING

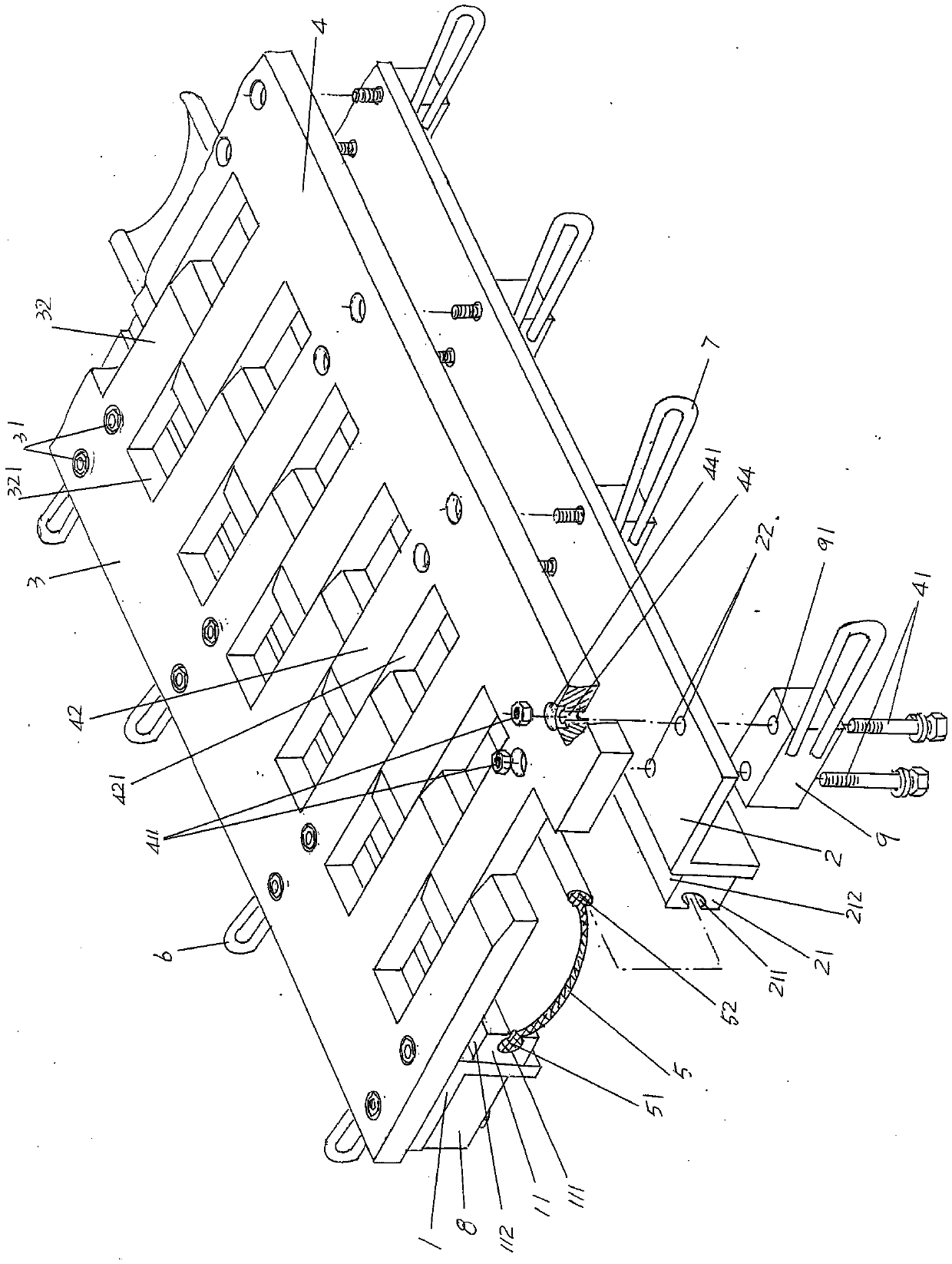

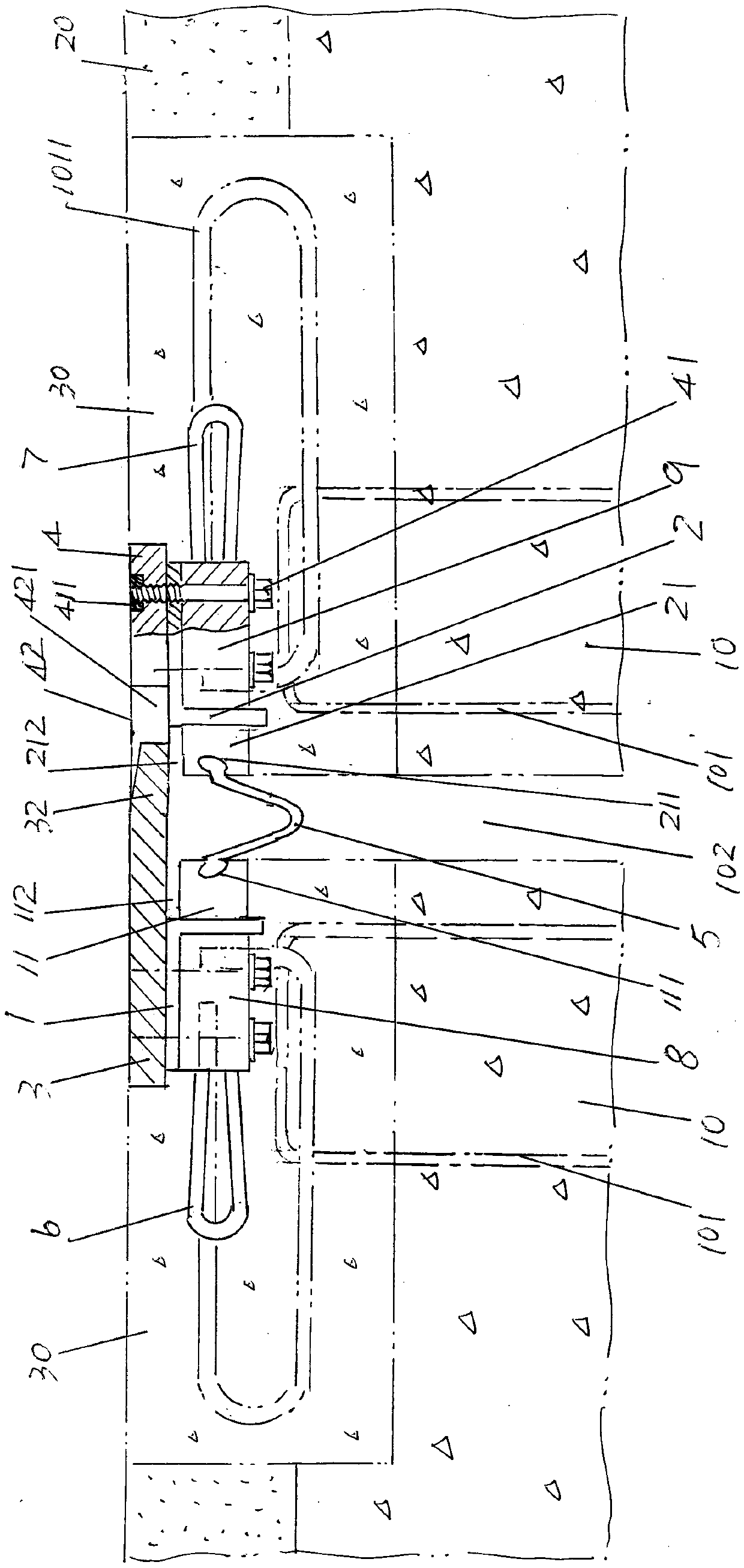

Bridge expansion joint device

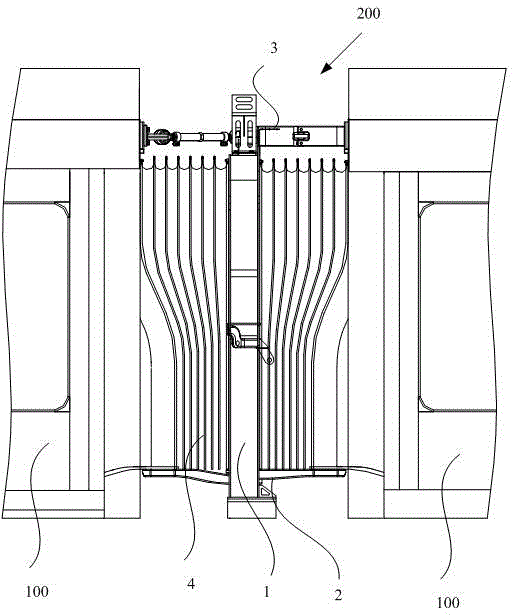

InactiveCN105507141AAvoid shear forceEasy to install and replaceBridge structural detailsWater stopBridge deck

The invention belongs to the technical field of bridge auxiliary members, and relates to a bridge expansion joint device. The bridge expansion joint device comprises left and right comb plate supporting beams, left and right comb plates, a water stop belt, left anchor bars and right anchor bars and further comprises a set of left supporting blocks and a set of right supporting blocks, wherein the set of left supporting blocks are distributed at intervals in the length direction of the left comb plate supporting beam and fixed through left comb plate fixing bolts, and the set of right supporting blocks are distributed at intervals in the length direction of the right comb plate supporting beam and fixed through right comb plate fixing bolts; a left water stop belt embedding base is fixed to one side, facing the right comb plate supporting beam, of the left comb plate supporting beam, a right water stop belt embedding base is fixed to one side, facing the left comb plate supporting beam and corresponding to the left water stop belt embedding base, of the right comb plate supporting beam, and the water stop belt is embedded between the left water stop belt embedding base and the right water stop belt embedding base. It is avoided that shear force on bolts of the left and right comb plates is generated in the heat expansion and cold contraction process of a bridge floor and a bridge abutment, the water stop belt is convenient to install and replace, operation intensity is relieved, and construction efficiency is improved.

Owner:常熟市双惠路桥工程构件有限公司

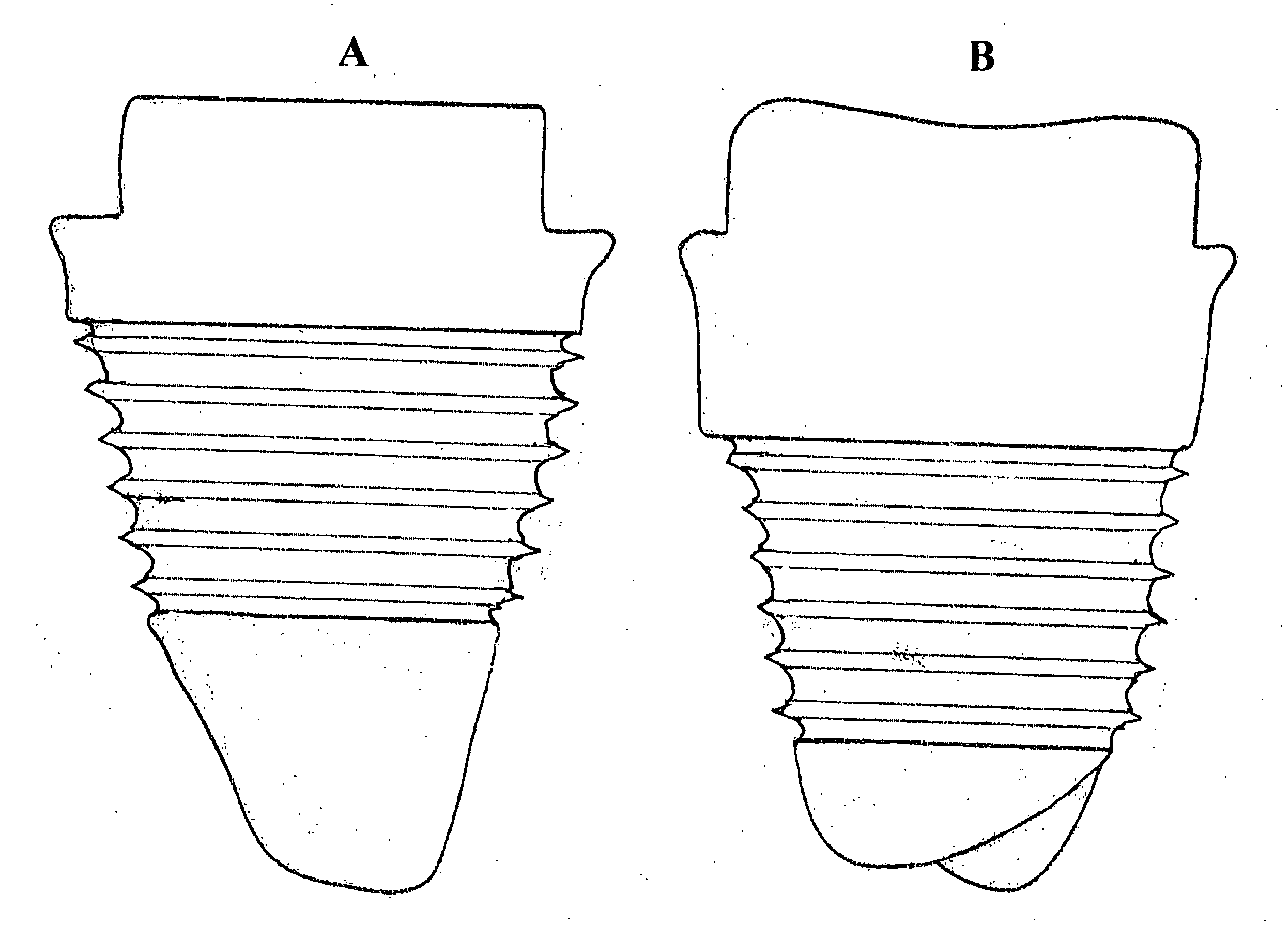

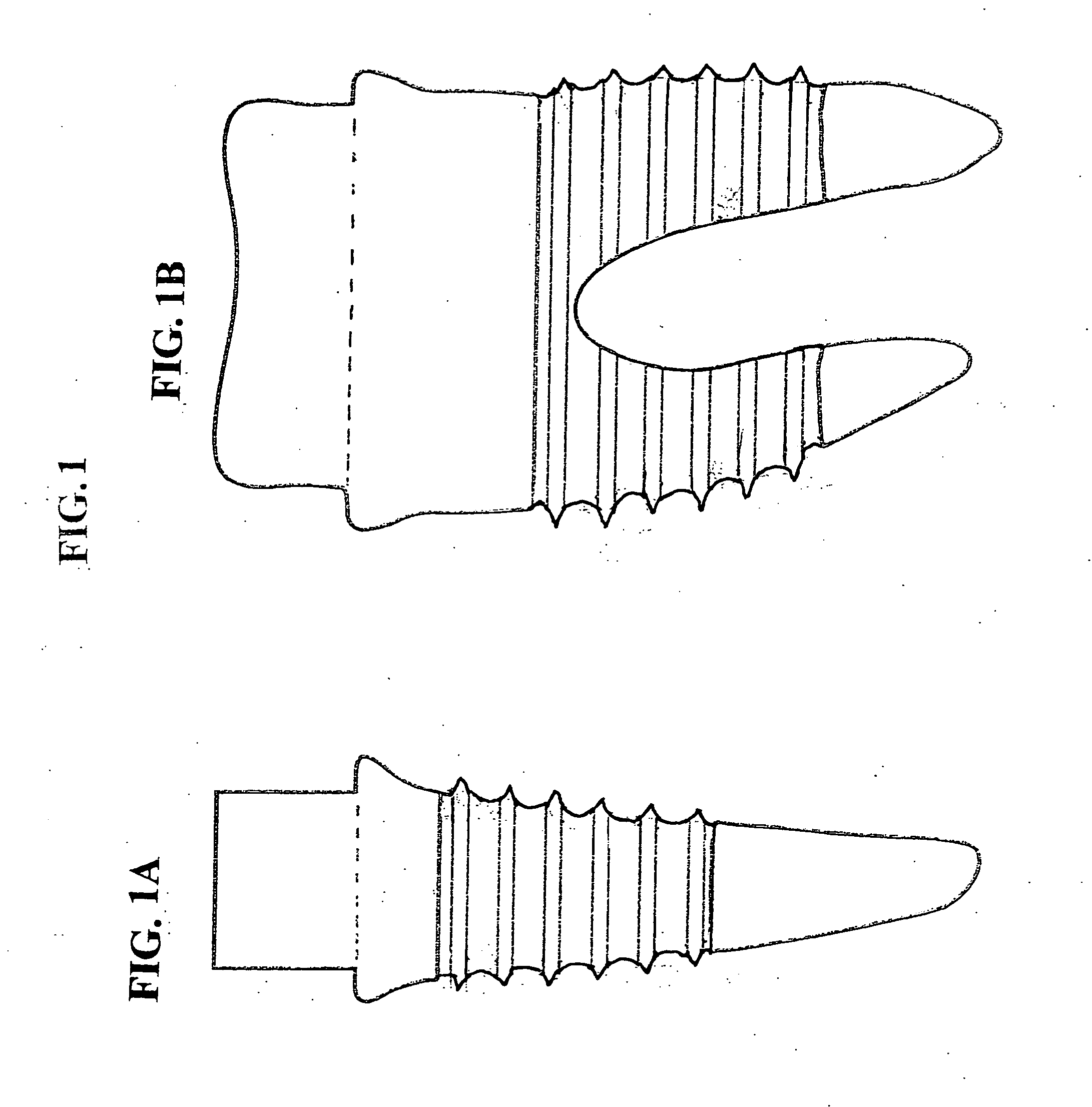

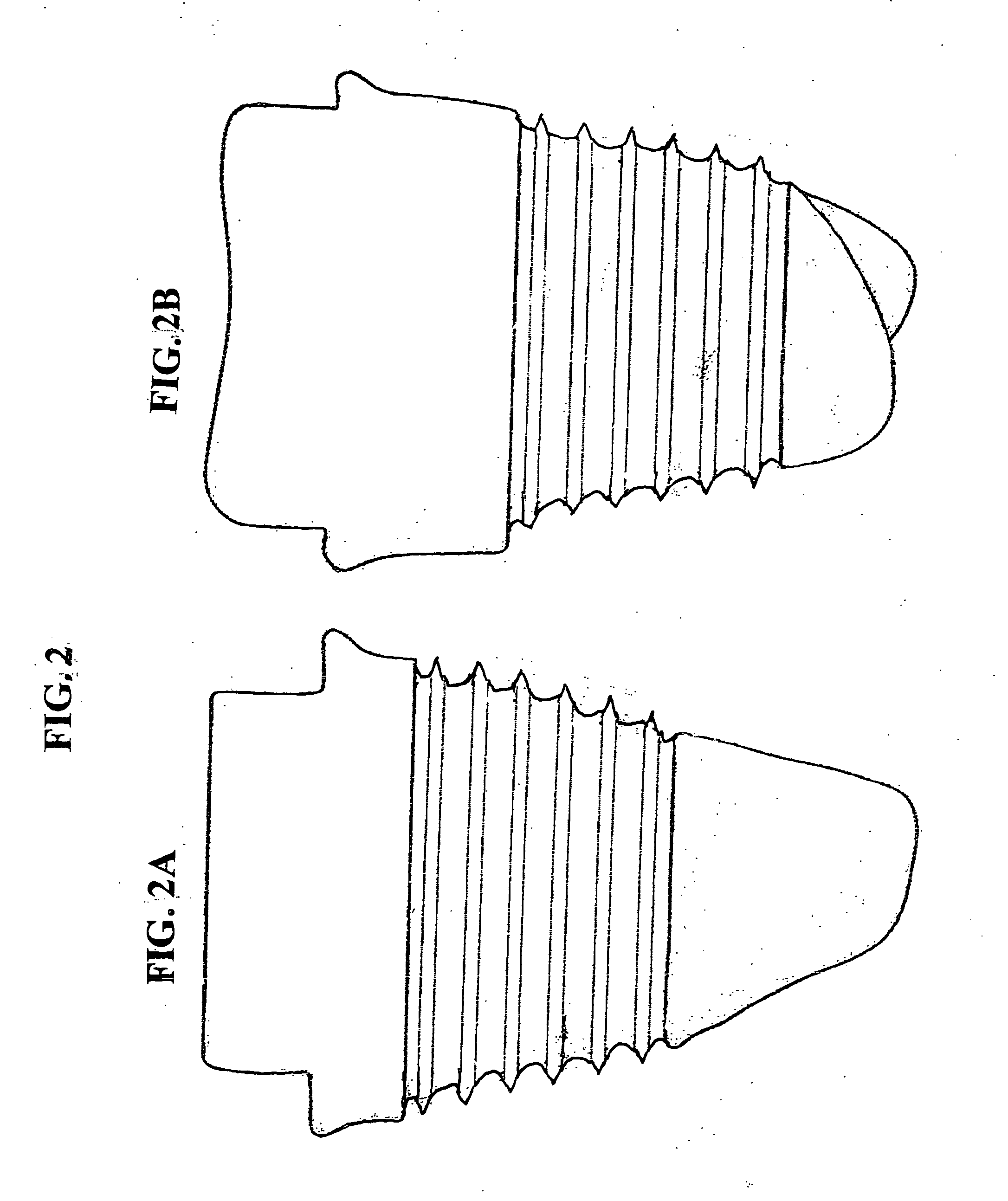

Individualized endosseous dental implant

InactiveUS20130323677A1Minimize functionReduce numberDental implantsDental implantBiocompatible material

The instant invention is an individualized anatomic tooth root implant comprised of zirconia oxide or other biocompatible material, manufactured to very closely approximate an extracted tooth root and the existing extracted tooth root socket morphology. By so doing, invasive drilling and other dental procedures can be avoided. The implant consists of single or multiple root(s), the main implant body, a custom built abutment, and a dental prosthesis (crown), cemented to the abutment once sufficient healing and osseointegration has occurred. The the instant invention will have user defined additions and subtractions with circumferential grooves and ridges cut into the implant body below the coronal lip to insure better fit and retention.

Owner:PEARSON THOMAS STEWART

Use of a polyurethane foam as a wound dressing in negative pressure therapy

ActiveUS8772567B2Sufficiently fixedAvoid shear forceNon-adhesive dressingsCatheterWound dressingMedicine

Owner:PAUL HARTMANN AG

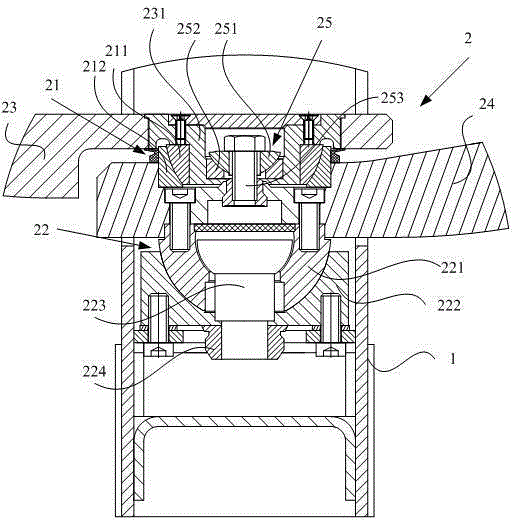

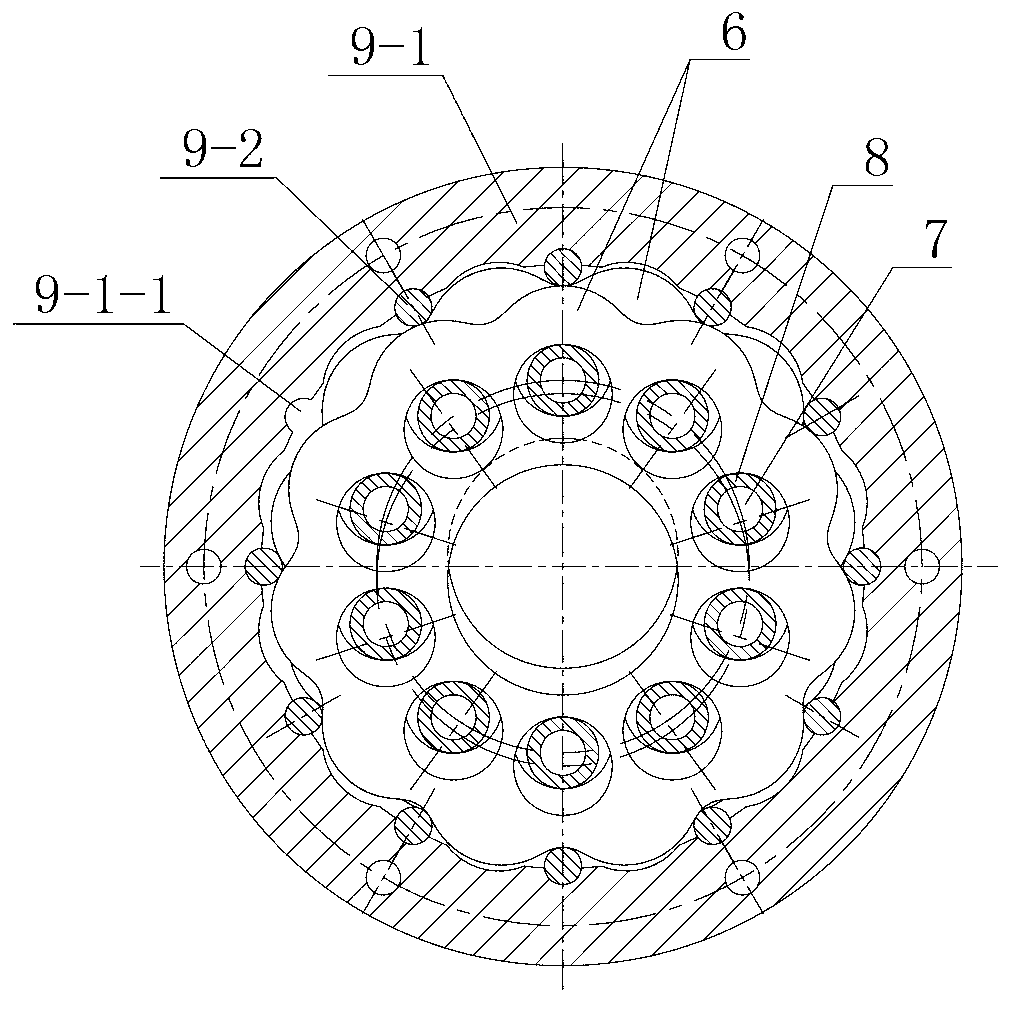

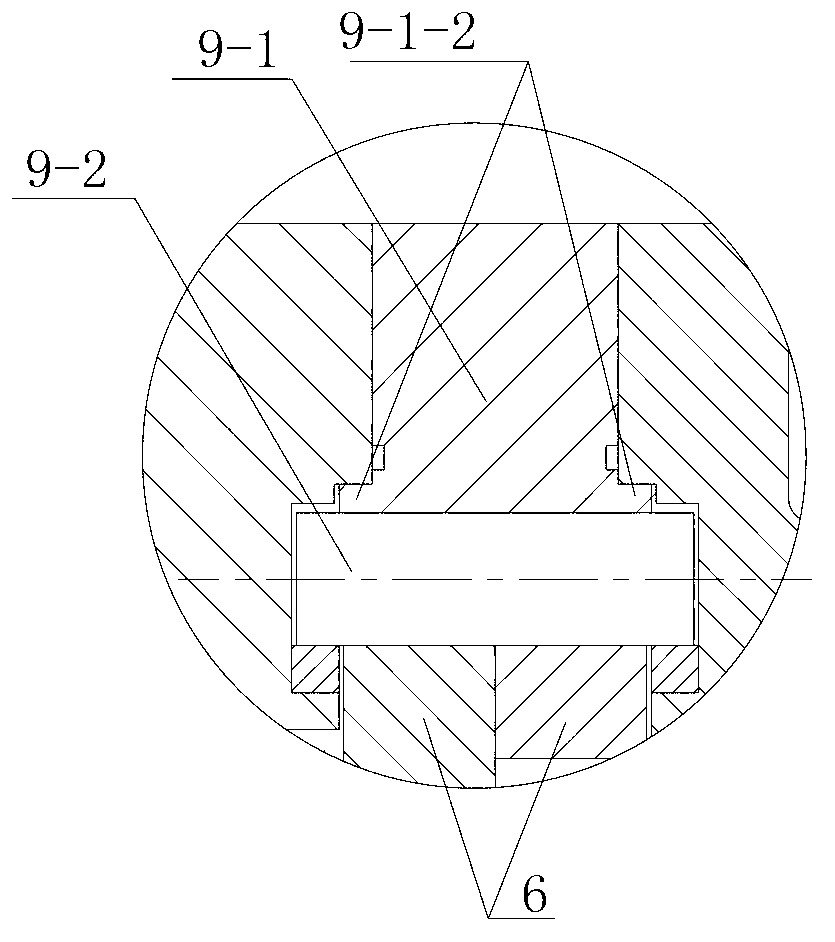

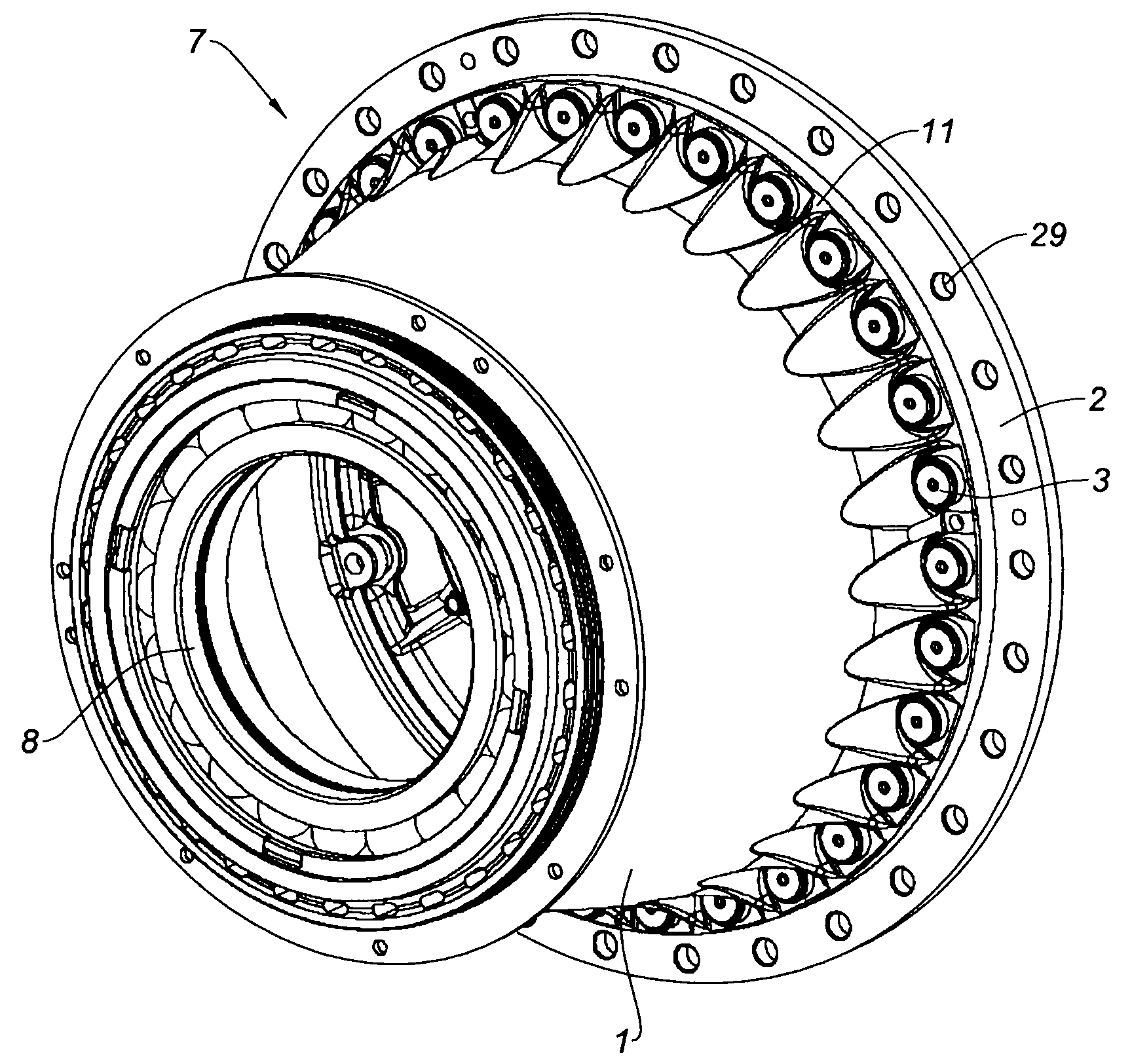

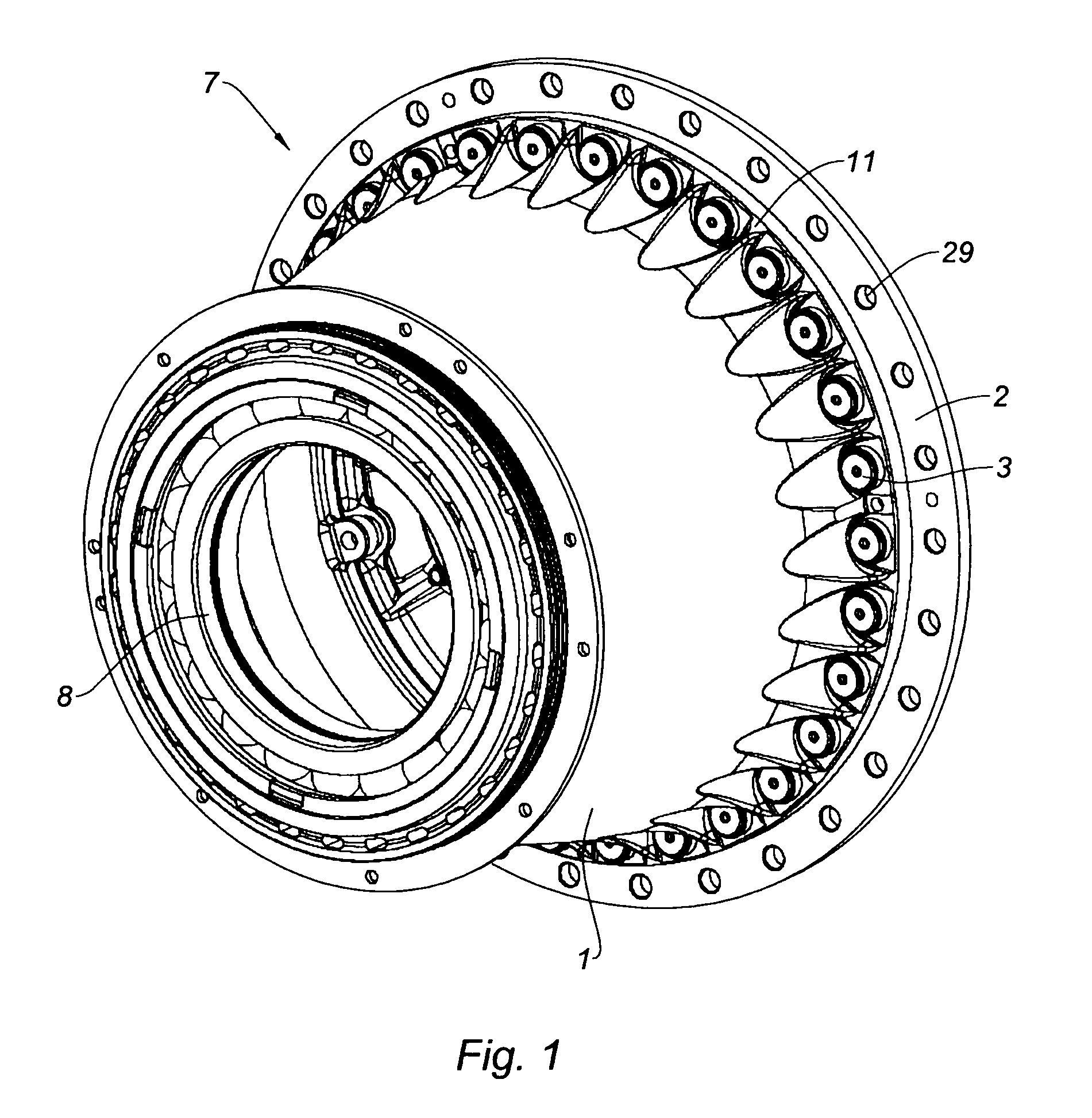

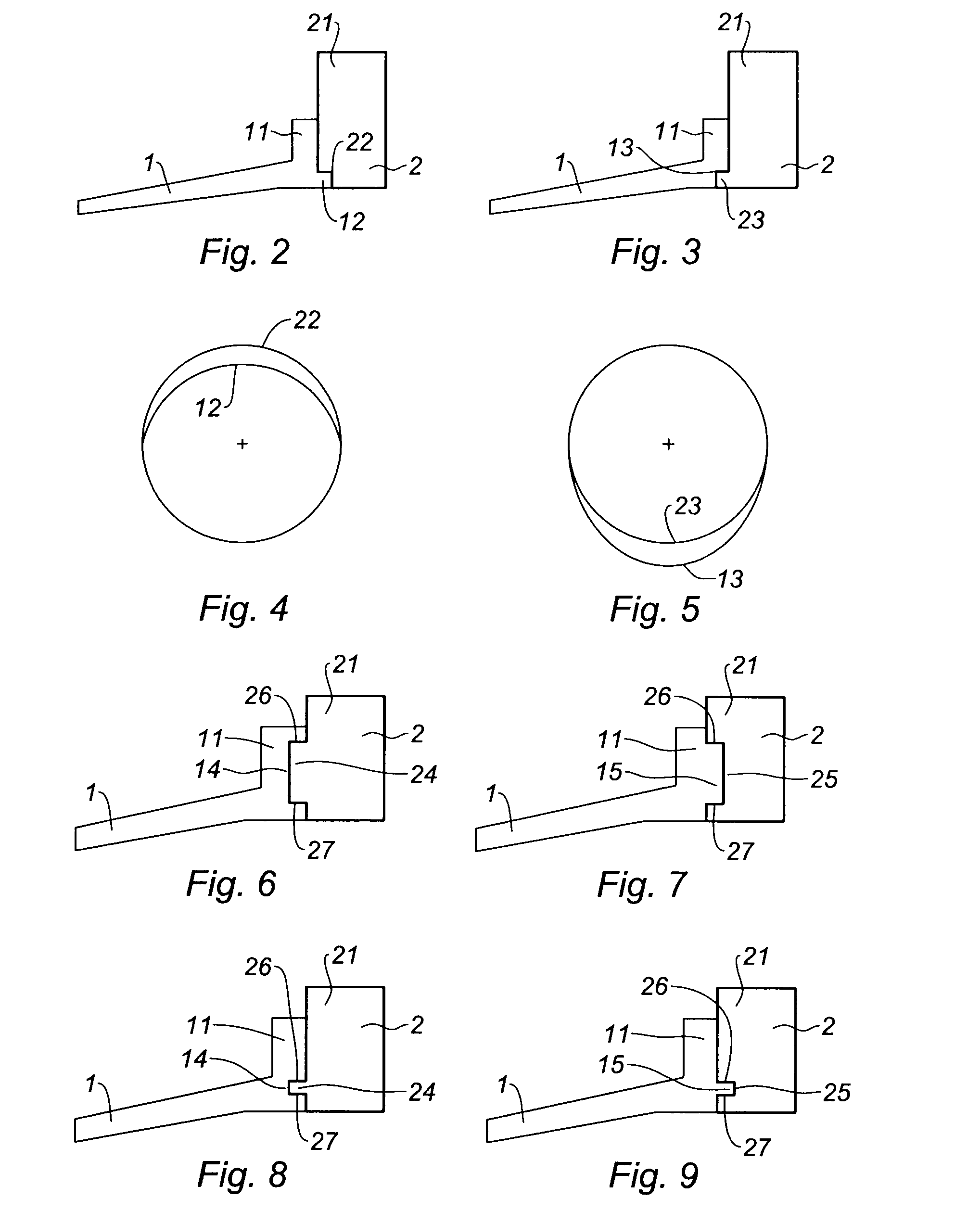

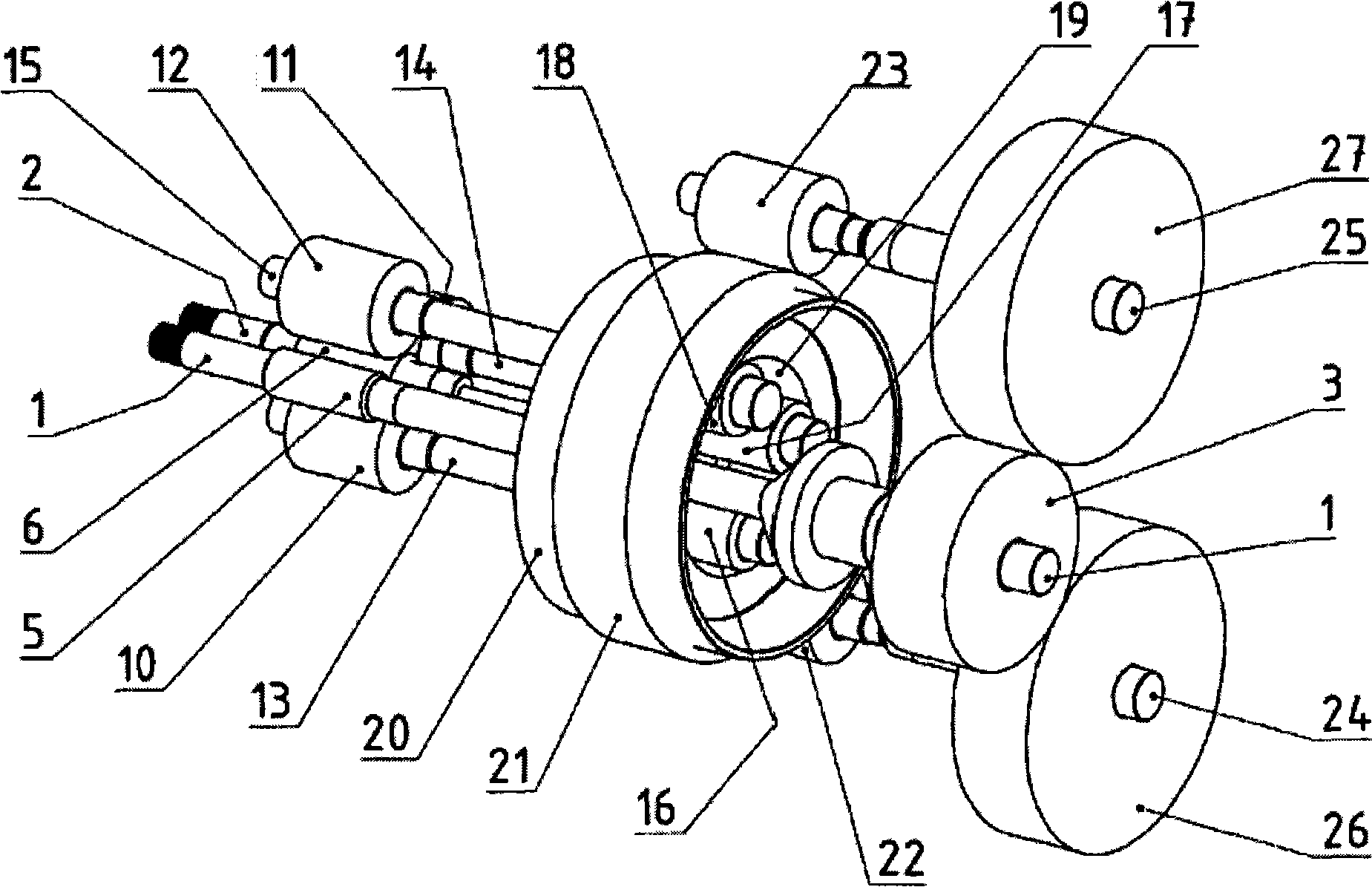

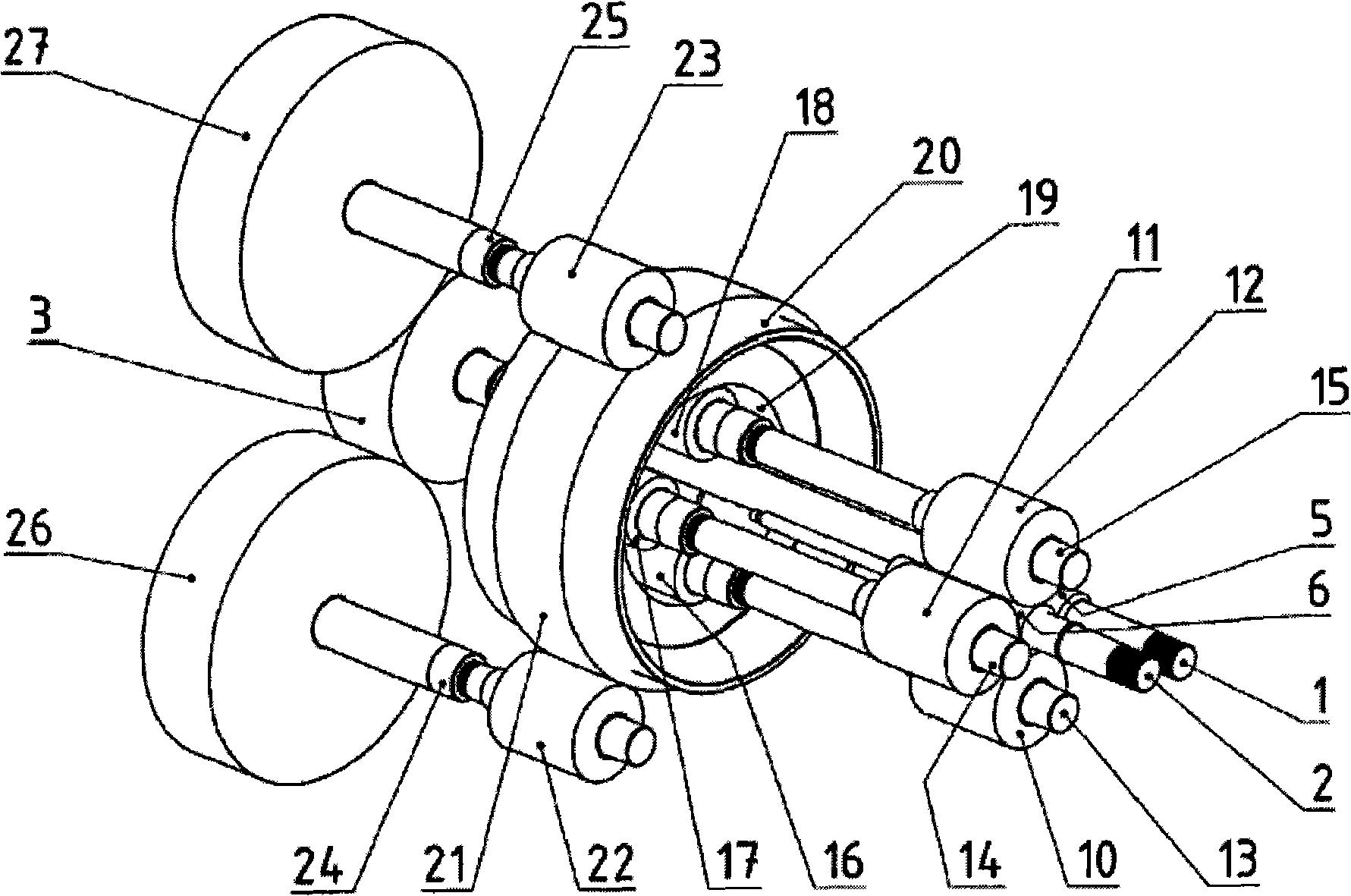

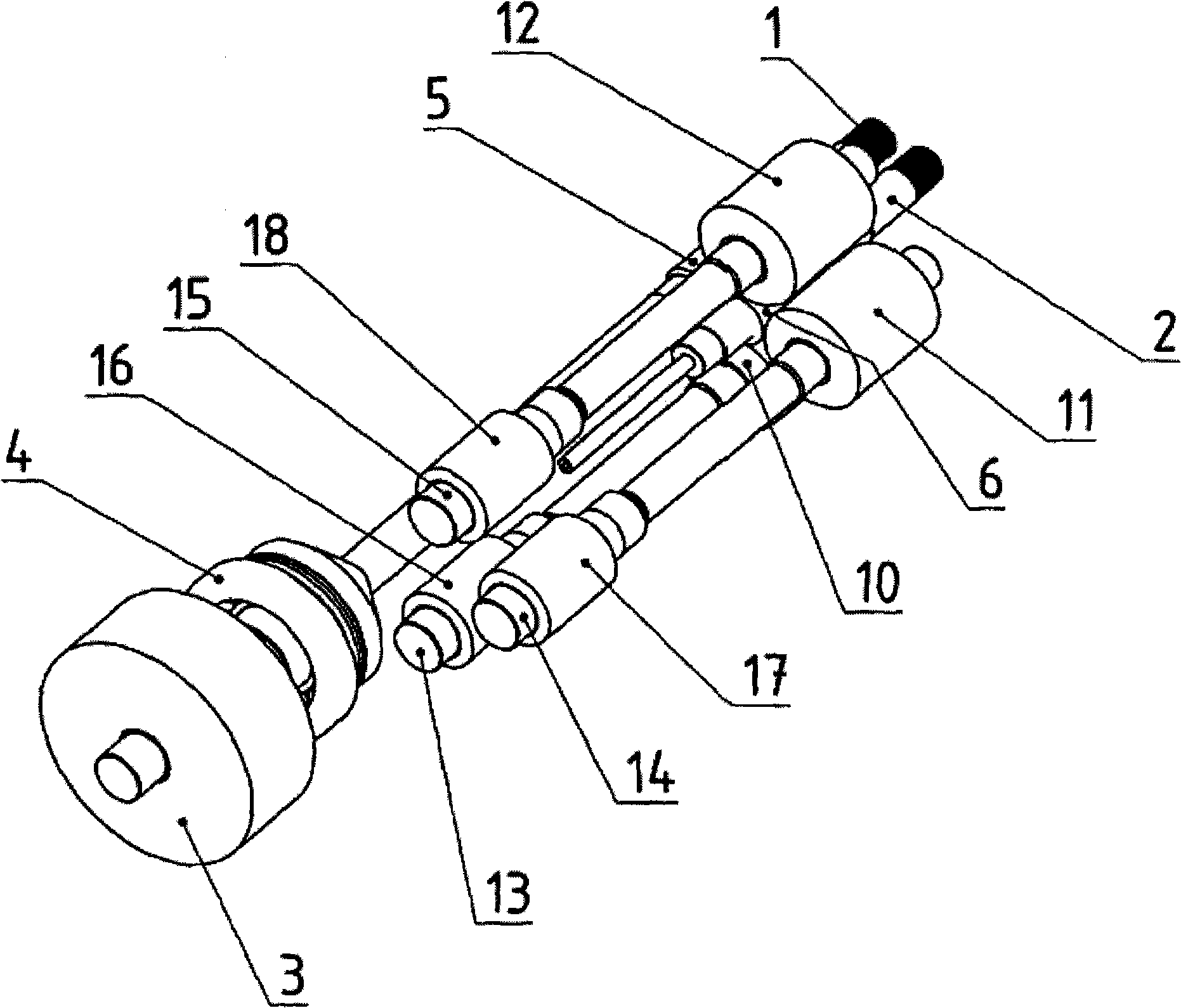

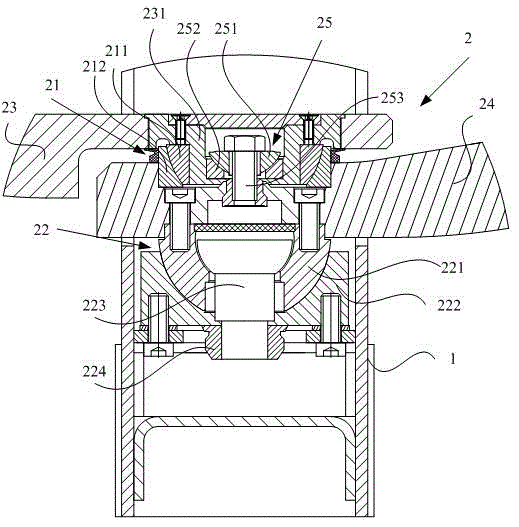

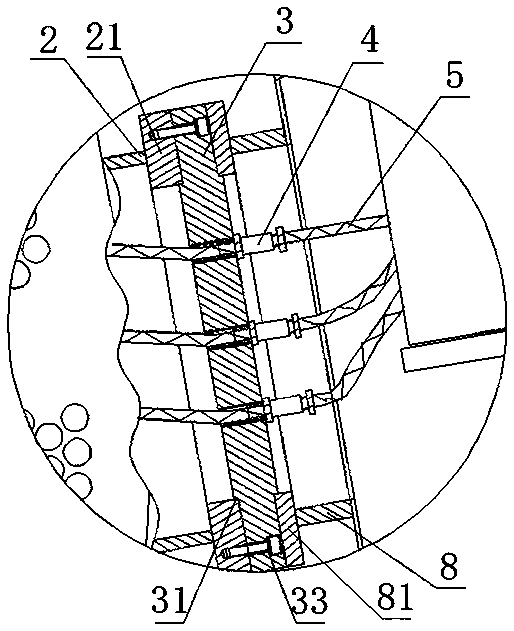

High-bearing-capacity cycloidal pin wheel speed reducer

The invention relates to a high-bearing-capacity cycloidal pin wheel speed reducer. The high-bearing-capacity cycloidal pin wheel speed reducer comprises an input portion, a speed reduction portion and an output portion, wherein the input portion comprises a flange plate and an input shaft; the output portion comprises an engine seat and an output shaft; and the speed reduction portion comprises a 180-degree-staggered double-eccentric support member, two cycloidal wheels and a plurality of pin shafts, a pin sleeve and a pin gear assembly, wherein the pin shafts and the pin sleeve are connected with the cycloidal wheels and the output shaft. The high-bearing-capacity cycloidal pin wheel speed reducer is characterized in that the pin gear assembly consists of a pin gear housing and a plurality of gear pins; two end surfaces of the pin gear housing are respectively compressed with the inner end surfaces of the flange plate and the engine seat, and the pin gear housing, the flange plate and the engine seat are fixedly connected by bolts; and arc-shaped grooves are uniformly formed in the inner circle of the pin gear housing, and the gear pins are mounted in the arc-shaped grooves one by one. By utilizing the technical scheme, the contact areas between the gear pins and the pin gear housing are increased; and compared with the conventional structure, for the high-bearing-capacity cycloidal pin wheel speed reducer, the gear pins are uniformly extruded on the whole axial length, so that the rigidity of the gear pins is substantially increased, the deformation of the gear pins is avoided when an input torque is properly increased, the noise and the temperature rise caused by the deformation are reduced, and finally the bearing capacity of the whole speed reducer is improved.

Owner:天津百利天星传动有限公司

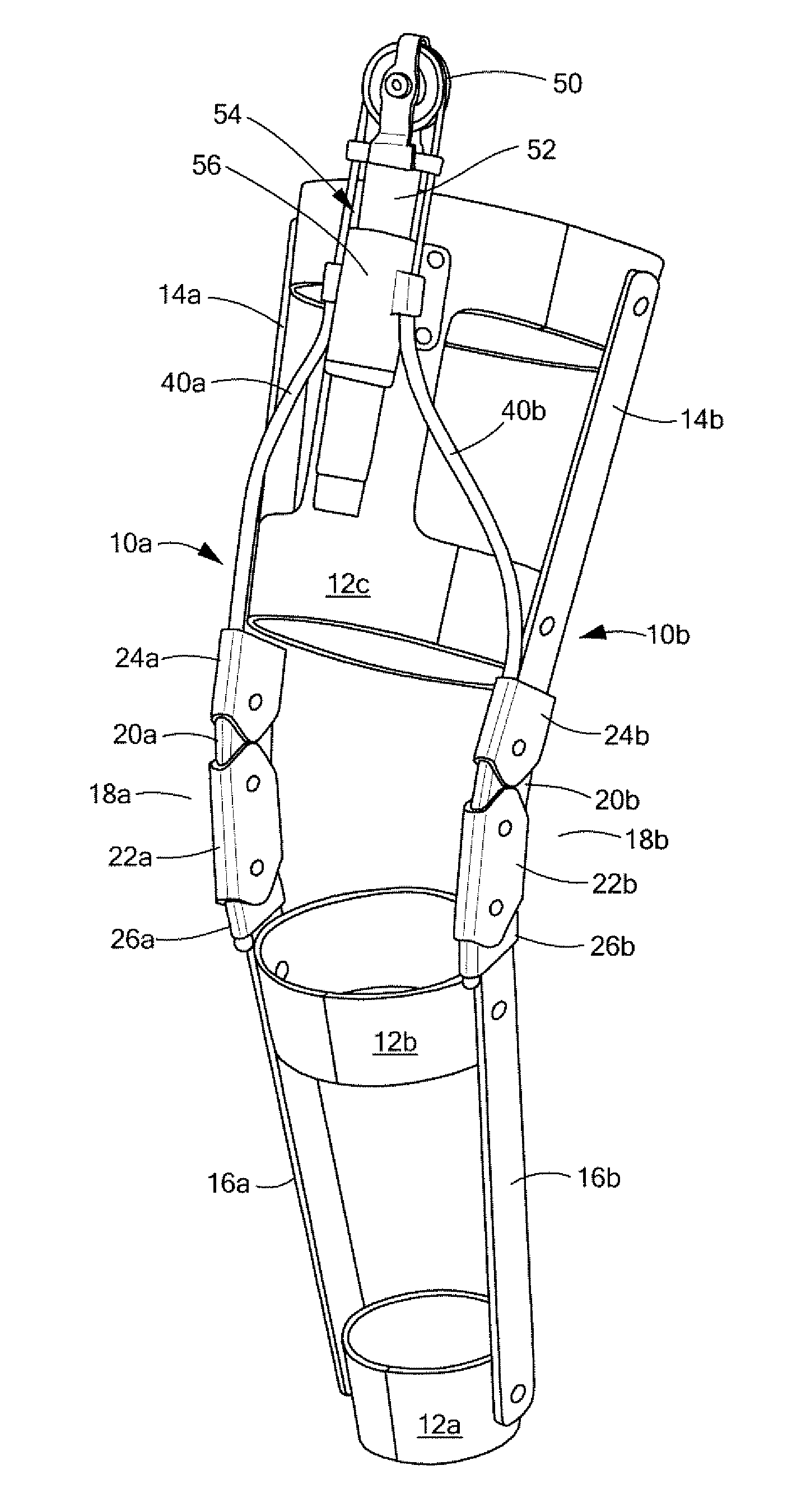

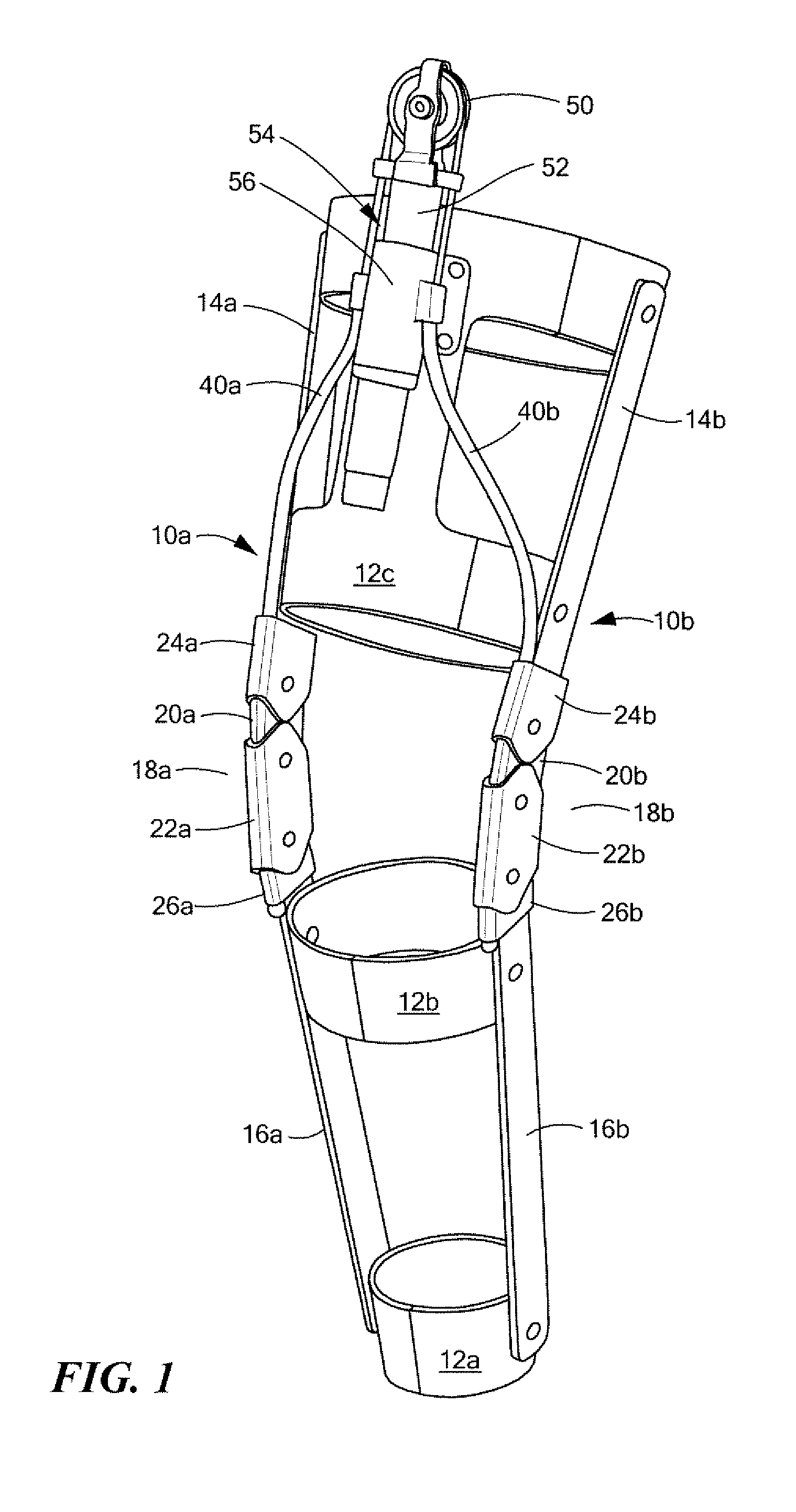

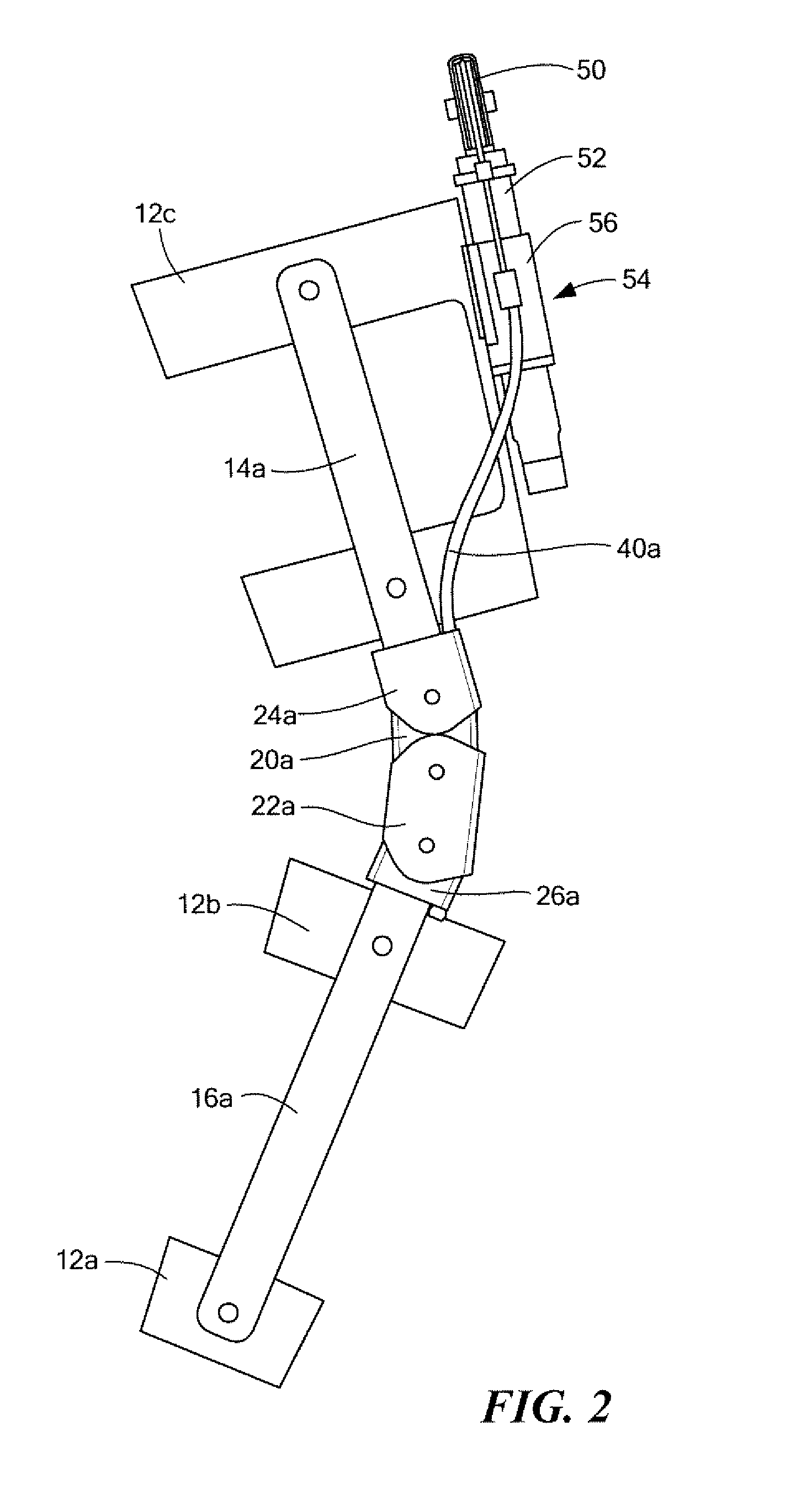

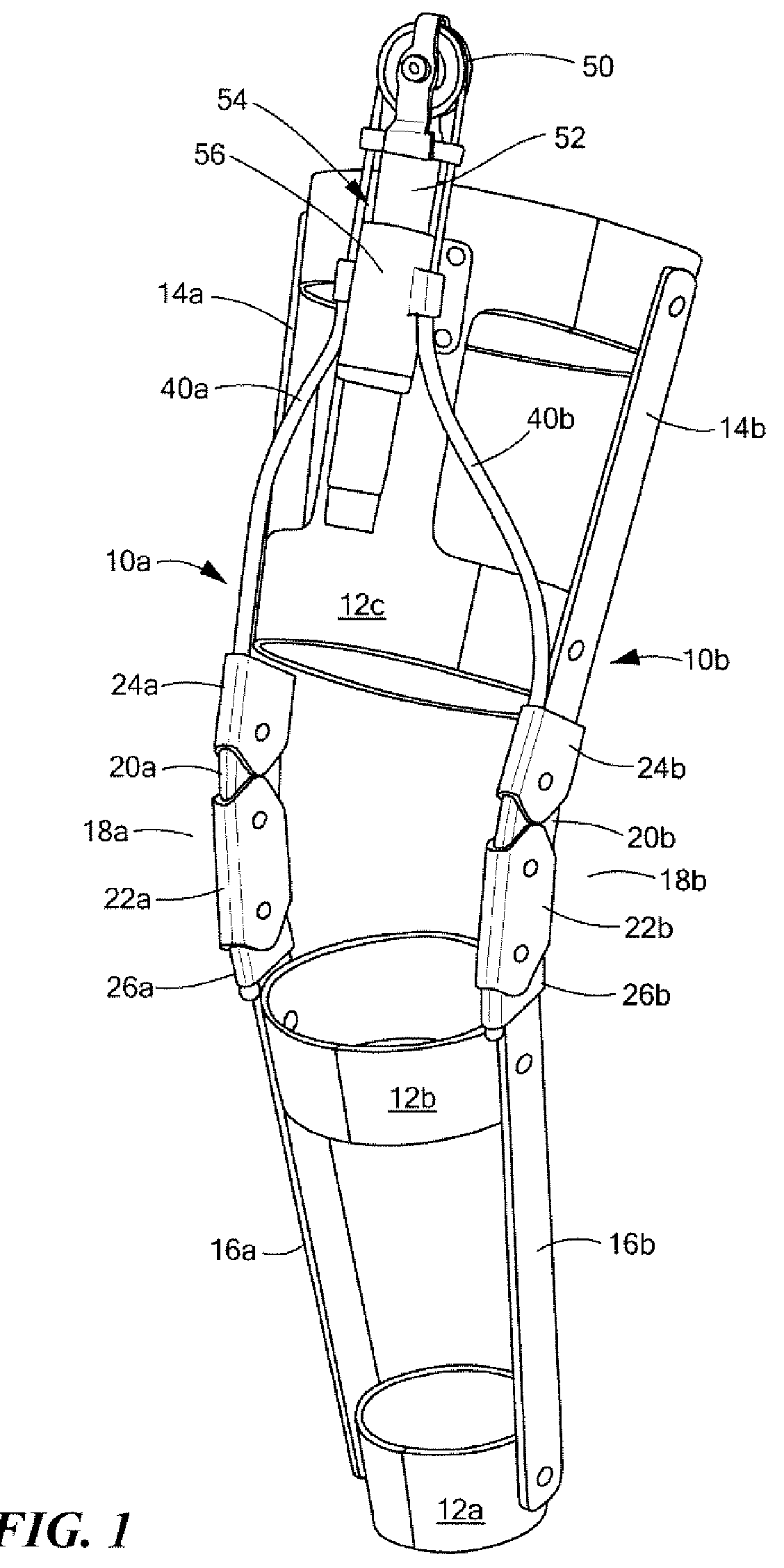

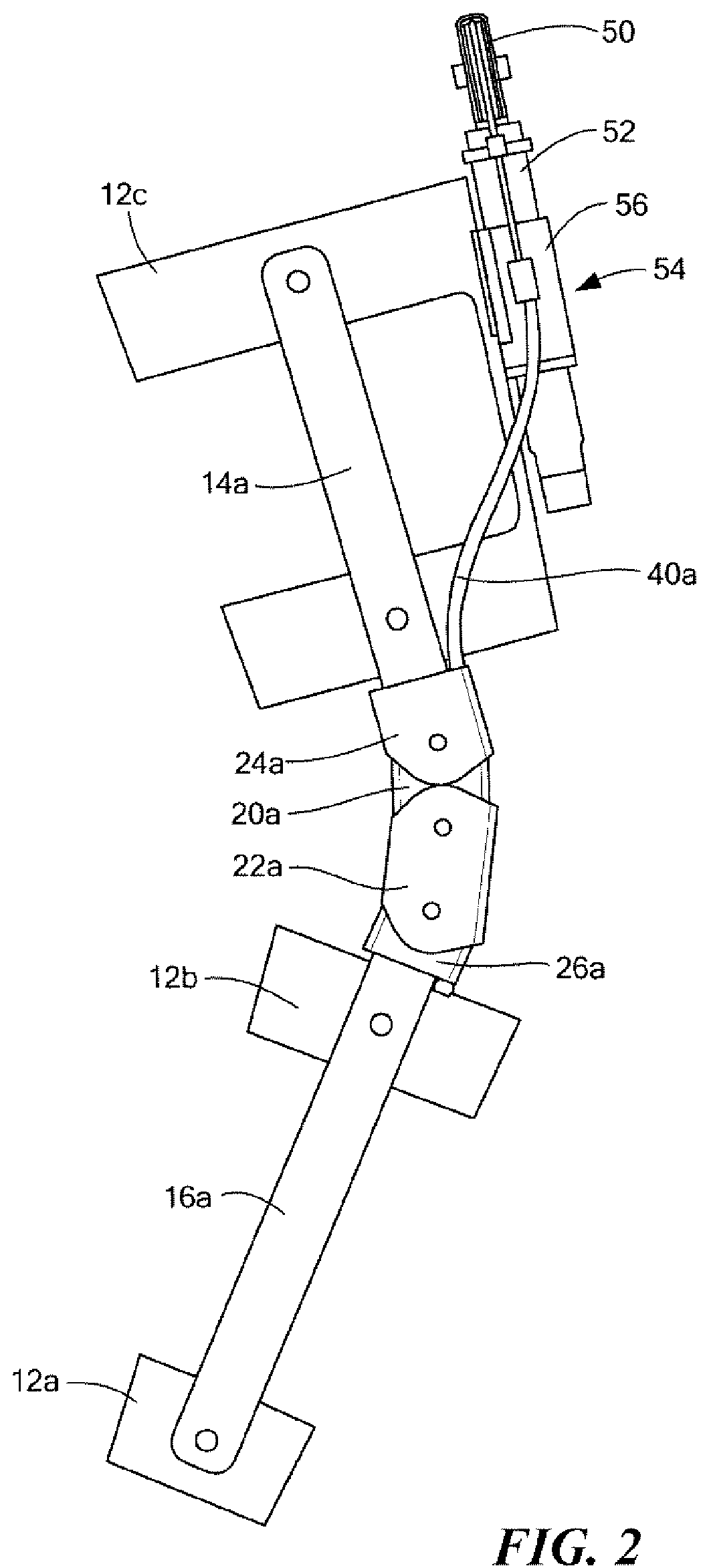

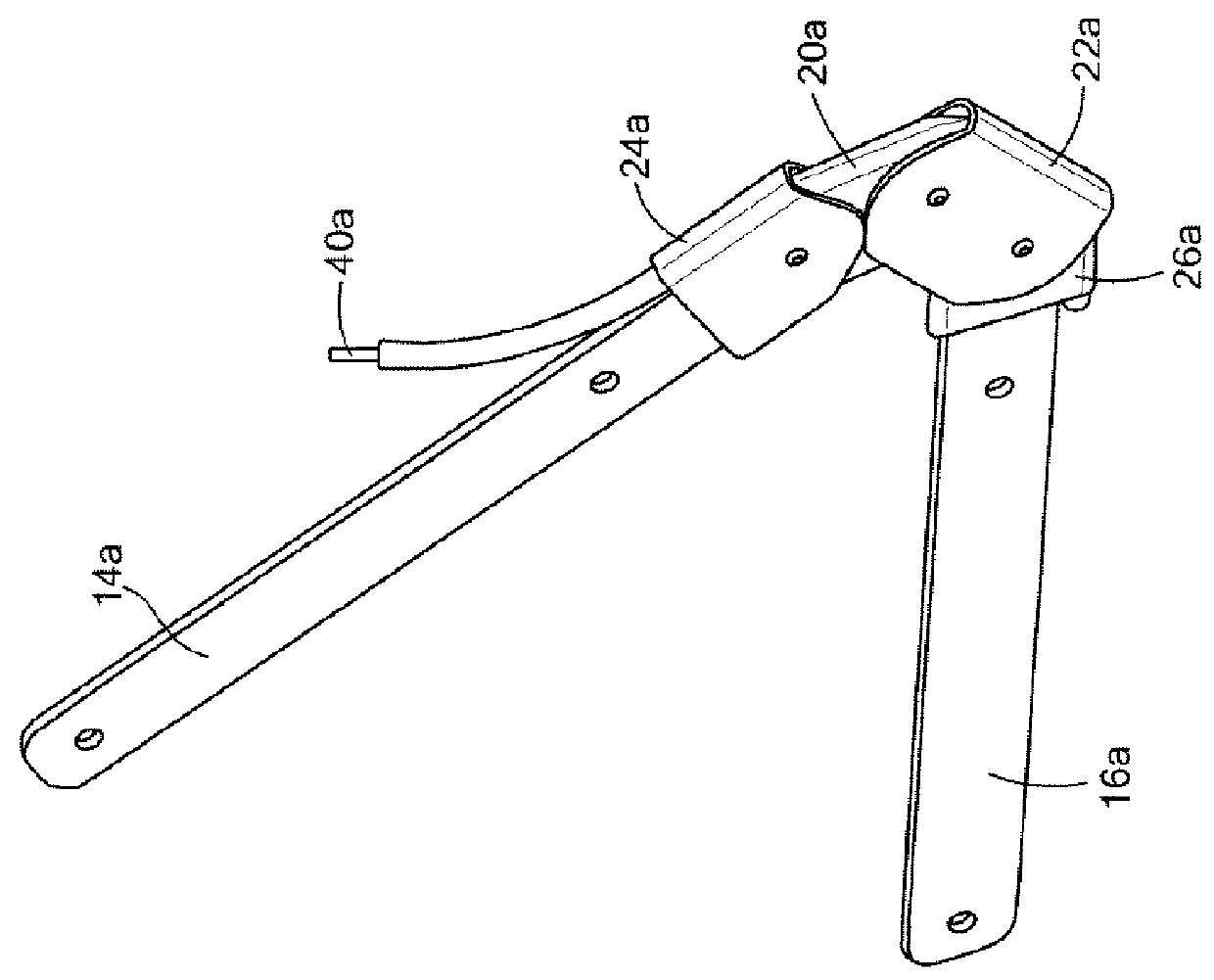

Brace system

ActiveUS9333107B2Avoid shear forceInsensitive to alignmentChiropractic devicesWalking aidsEngineering

Owner:BOSTON DYNAMICS INC

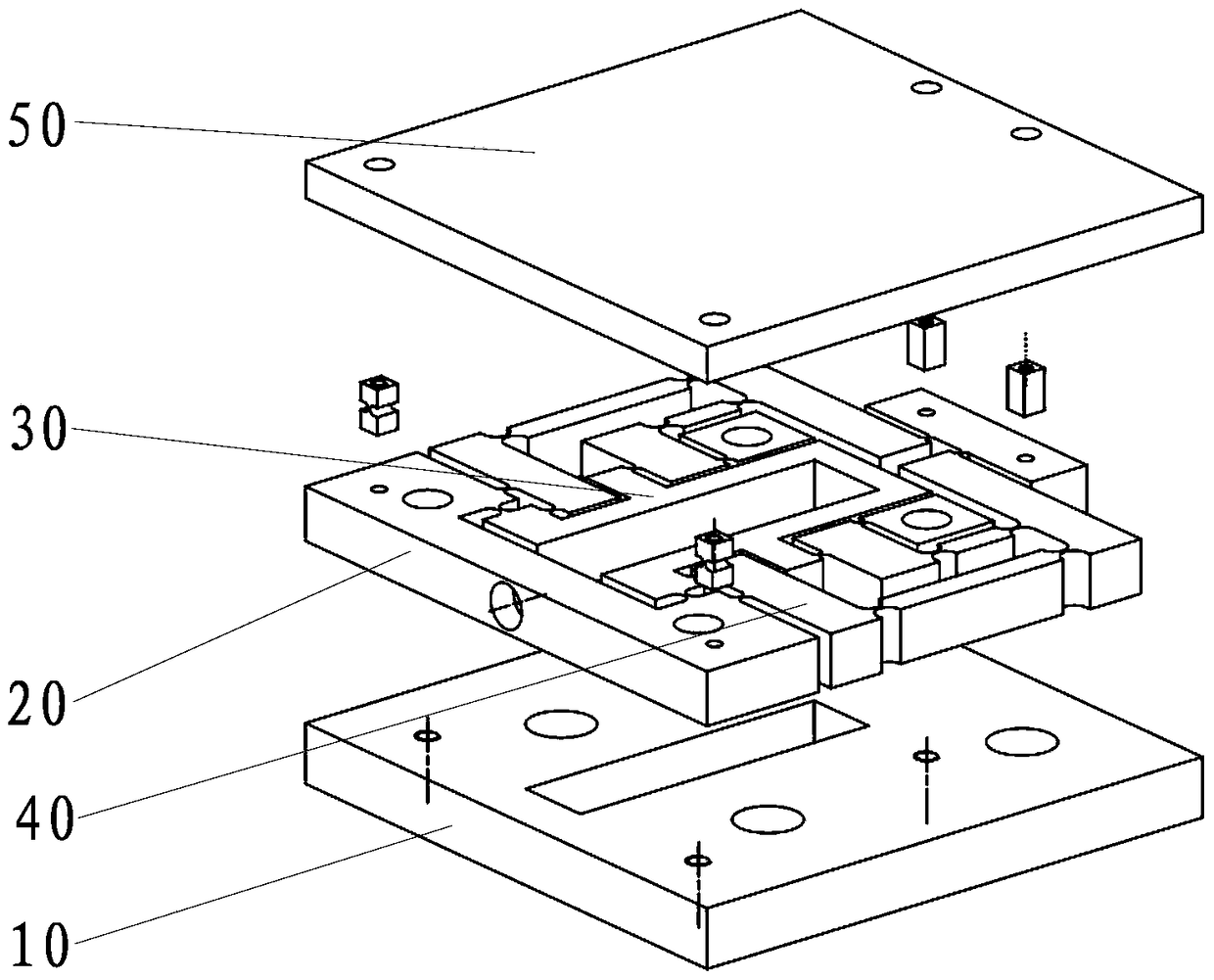

A Symmetrical Differential Lever Micro-displacement Amplifying Device

ActiveCN104900573BAvoid large gapsLarge displacement magnificationSemiconductor/solid-state device manufacturingElectricityFriction force

Provided in the invention is a symmetric differential-lever micro displacement amplification apparatus comprising a pedestal, a base plate fixed on the pedestal, a piezoelectric block. The piezoelectric block and the substrate are located at the same plane. The piezoelectric block has a top pressing part and two transmission parts that are respectively arranged at the two ends of the top pressing part and are arranged symmetrically by using the midperpendicular of the top pressing part as the center; each of the two transmission parts is respectively connected with one group of lever assemblies located at the same plane as the substrate; and the two lever assemblies are arranged symmetrically by using the midperpendicular of the top pressing part as the center. A piezoelectric ceramic driver abutted against the top pressing part is arranged between the two transmission parts. With the lever assemblies, a large displacement enlargement factor can be realized based on a differential lever amplification principle; and the stroke is also large. Meanwhile, because of connection based on flexible hinging, gaps and friction forces among all levers are small, thereby reducing the error and improving the precision.

Owner:HUAQIAO UNIVERSITY

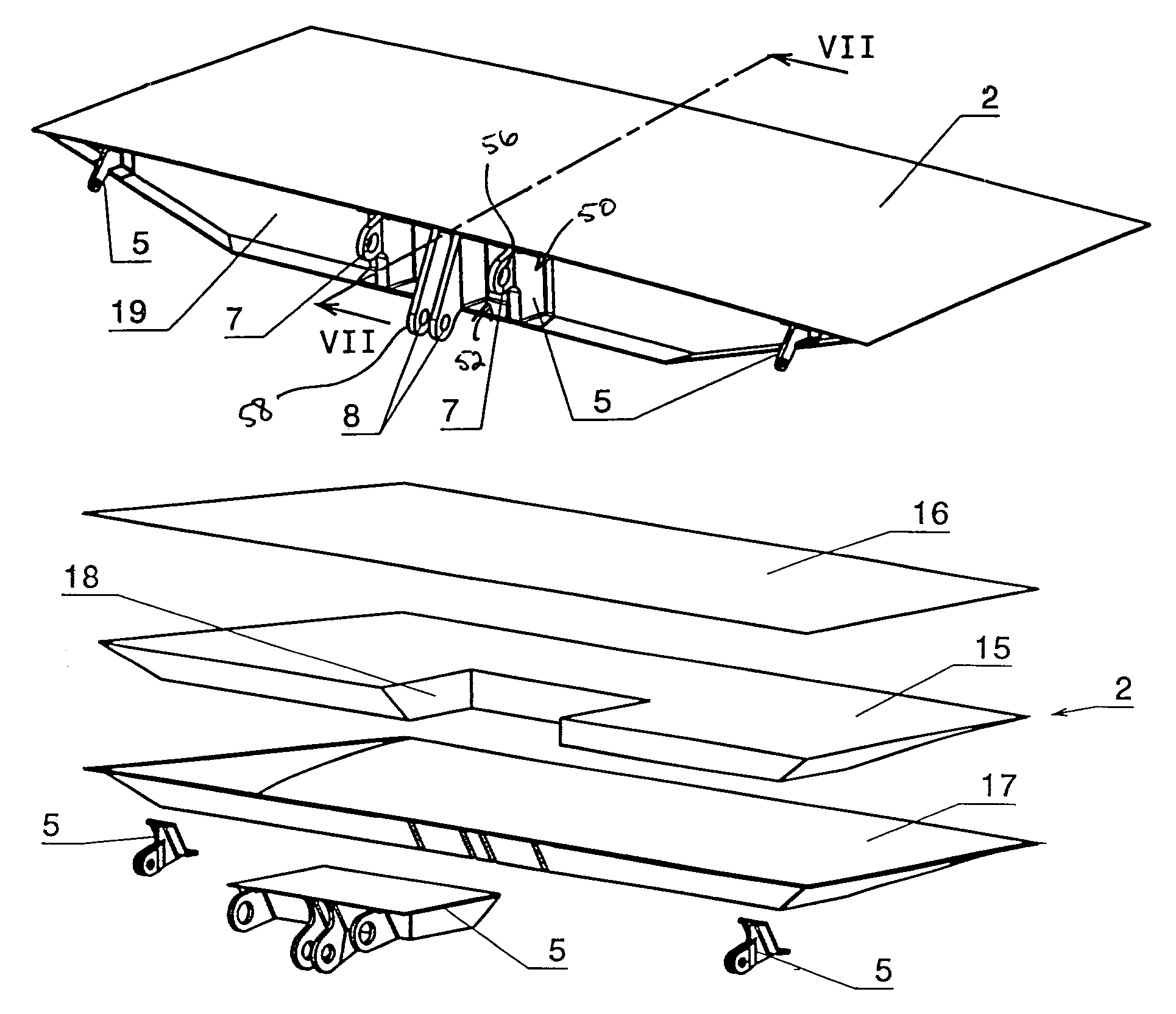

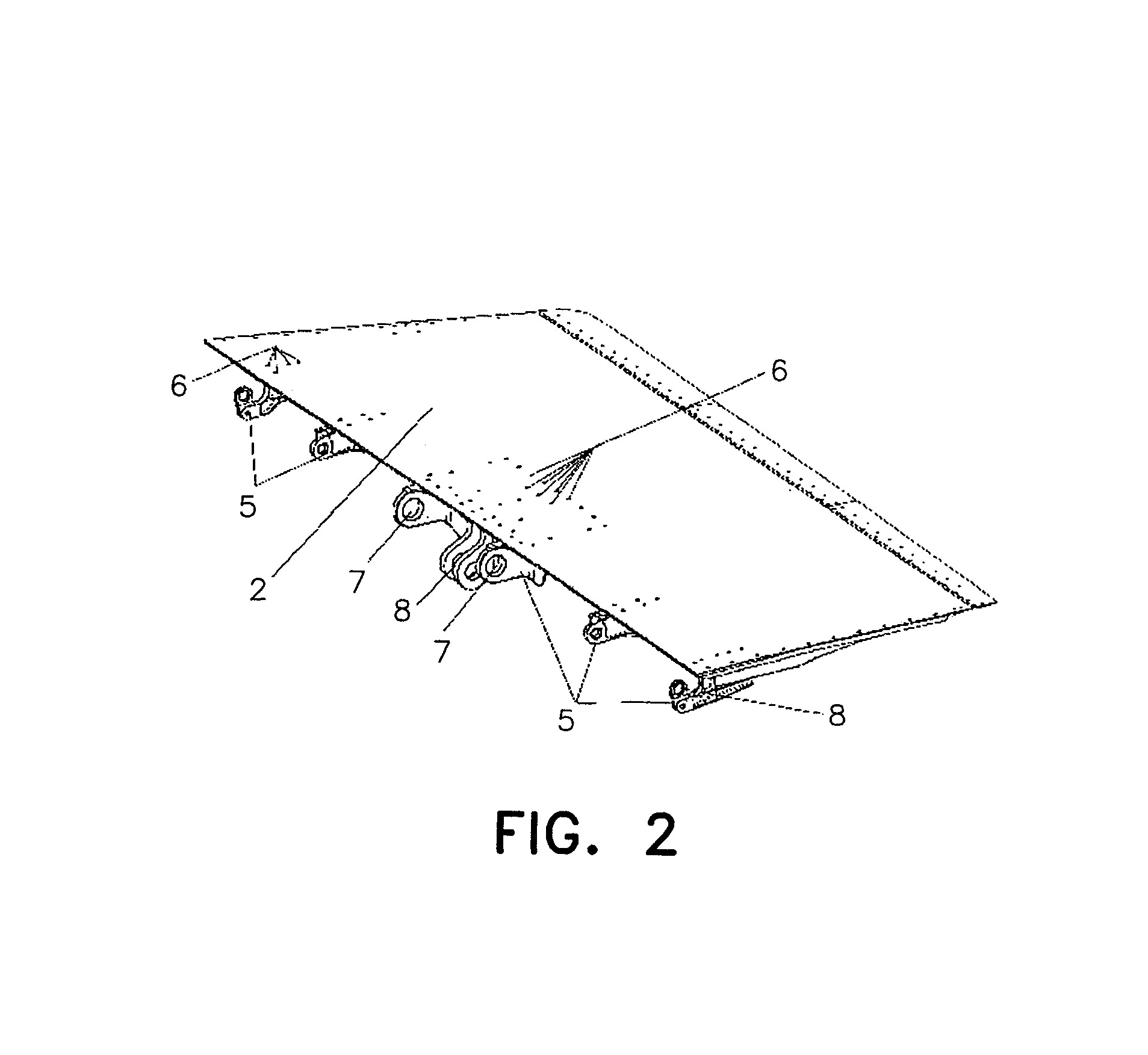

Device for connecting movable parts with structural elements of airplanes or the like

InactiveUS8453972B2Reduce weightGood for long termFuselage framesAircraft stabilisationJet aeroplaneSynthetic materials

A device for connecting movable parts with structural components of airplanes or other high-speed vehicles, including at least one fitting provided with at least one bearing. In order to provide such a device exhibiting low thermal stresses, a low weight, a high bearing capacity and a producibility as simple as possible, it is provided that the at least one fitting is made of a synthetic material and glued with the movable part. The resin transfer molding (RTM)-method is particularly suitable to produce the fitting.

Owner:FACC

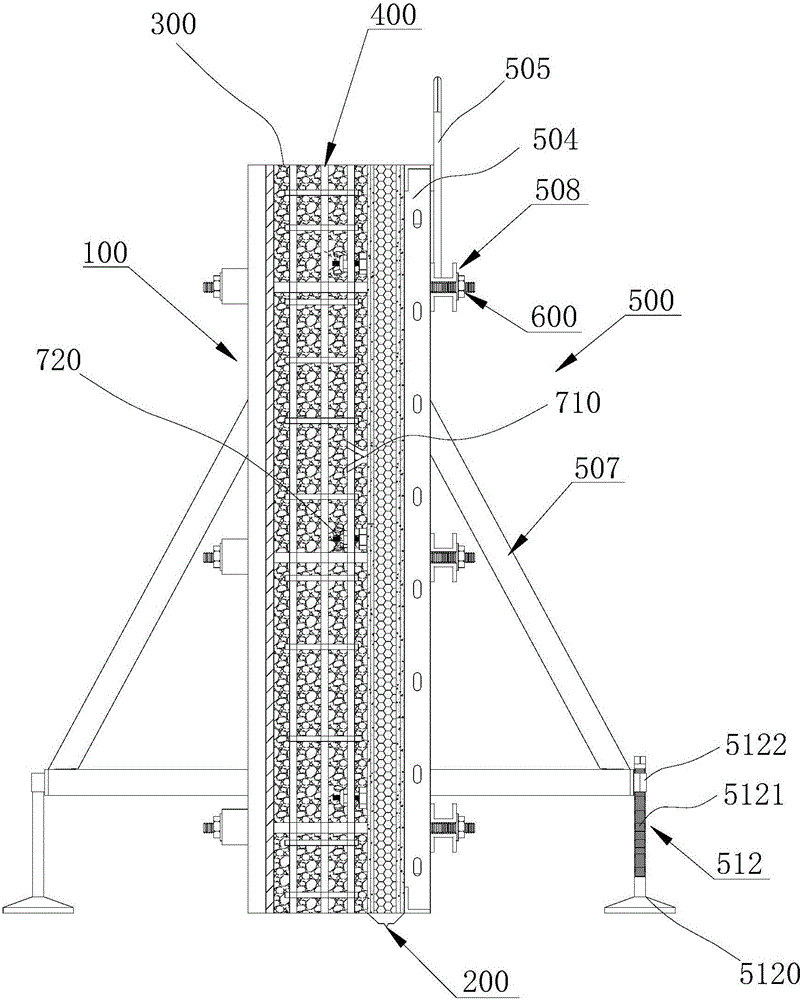

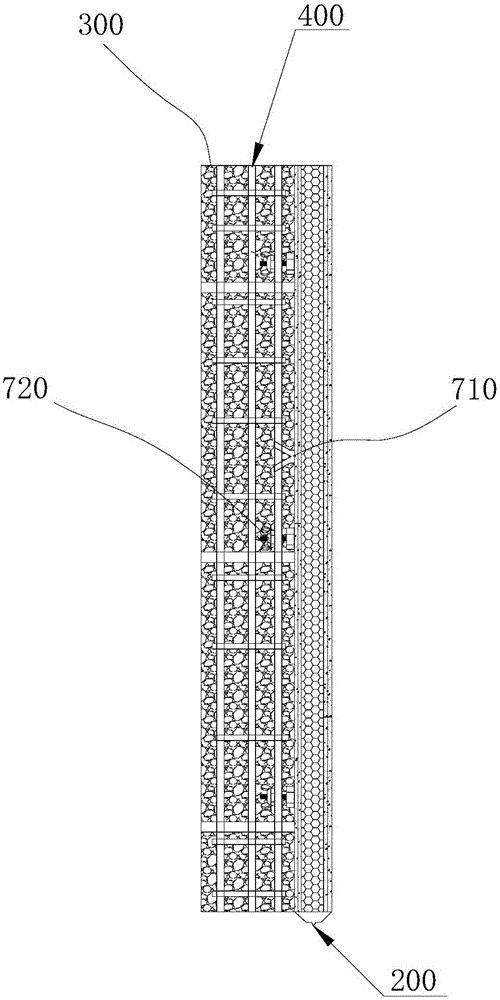

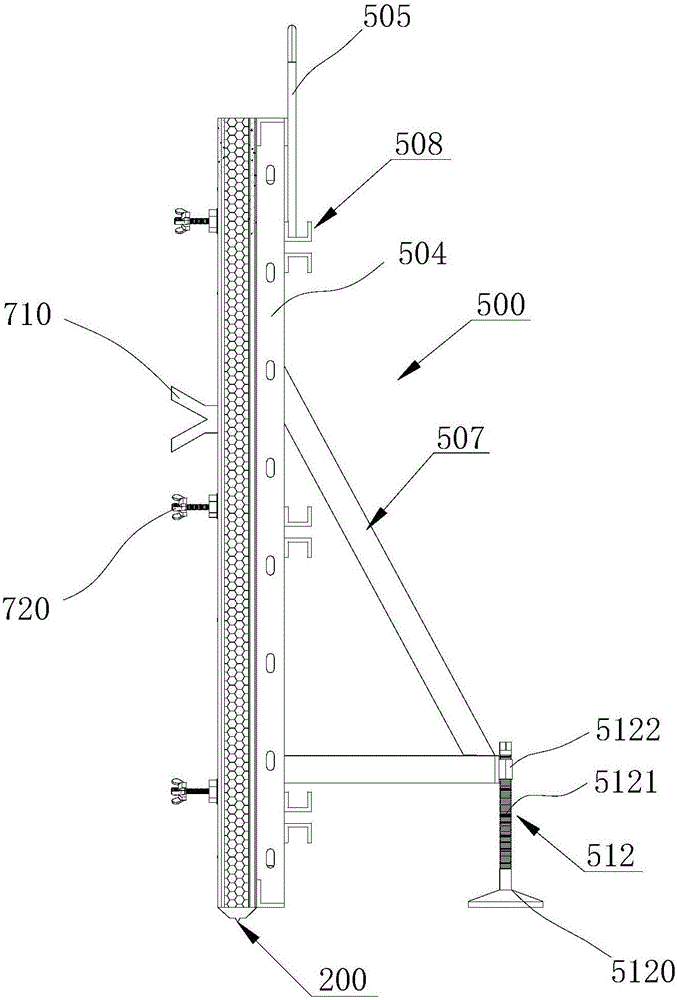

External wall system of cast-in-situ prefabricated dismantling-free integral assembling heat-preservation external formwork and construction method

InactiveCN105714962AReduce secondary constructionImprove insulation effectWallsHeat proofingFalseworkRebar

The invention relates to an external wall system of a cast-in-situ prefabricated dismantling-free integral assembling heat-preservation external formwork and a construction method.The external wall system comprises an internal formwork, a prefabricated integral assembling heat-preservation external formwork formed by splicing prefabricated external wall composite heat-preservation formwork single bodies and wall body rebars; a cast-in-situ shear wall is formed by conducting cast-in-situ by taking the prefabricated integral assembling heat-preservation external formwork and the internal formwork as supports; the prefabricated integral assembling heat-preservation external formwork is fixedly mounted on a prefabricated external wall heat-preservation external formwork frame, the prefabricated external wall heat-preservation external formwork frame and the prefabricated integral assembling heat-preservation external formwork are integrally hoisted on the outer sides of the wall body rebars and correspond to the internal formwork on the inner sides of the wall body rebars, and an opposite-pull bolt assembly which transversely penetrates through the wall body rebars, the prefabricated external wall heat-preservation external formwork frame and the internal formwork is arranged in the wall body rebars.Compared with the prior art, integral prefabricating hoisting is adopted, and secondary construction of the heat-preservation layer is omitted; a heat-preservation layer and the main body structure are integral and same in service life, and the durability of the heat-preservation layer is increased; the building wall heat-preservation performance can be improved, and the construction quality is improved; by means of the system, construction of the external formwork and an external scaffold can be omitted and the construction efficiency can be improved.

Owner:TIANJIN GOLDEN VIRTUE ENERGY SOURCES TECH DEV

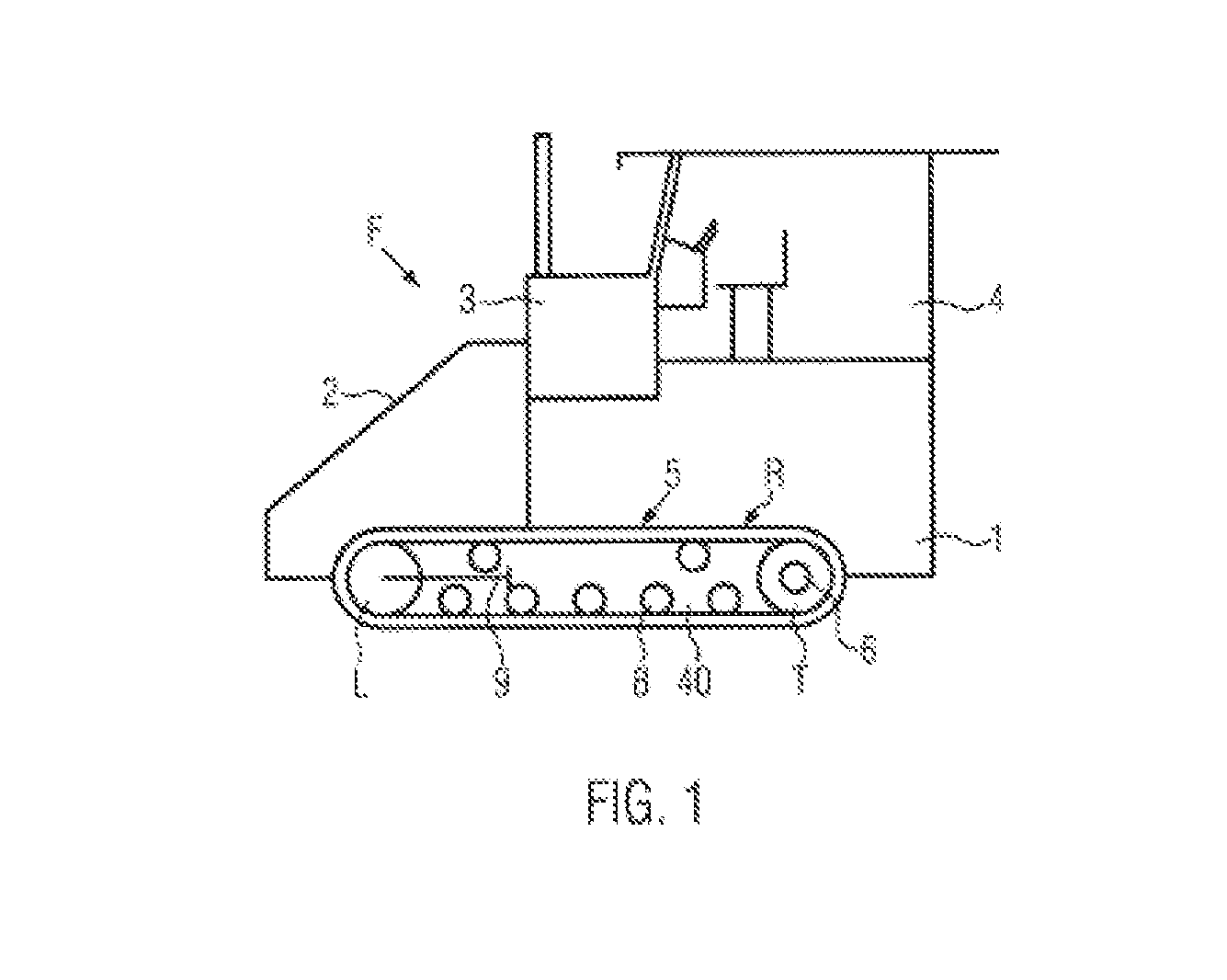

Tracklaying gear

ActiveUS20130020860A1Stable and directed runningEffective inner dampingPortable liftingEndless track vehiclesFree rotationGear wheel

In a tracklaying gear of a road finishing machine or a feeder with a drive chain wheel comprising circumferential teeth and being rotatably driven about an axis, and at least one idler wheel freely rotating about an axis inside a caterpillar track damping layers having damping material and exclusively radial sliding guides are integrated in the drive chain wheel and / or the idler wheel between the axis and the caterpillar track.

Owner:JOSEPH VOEGELE AG

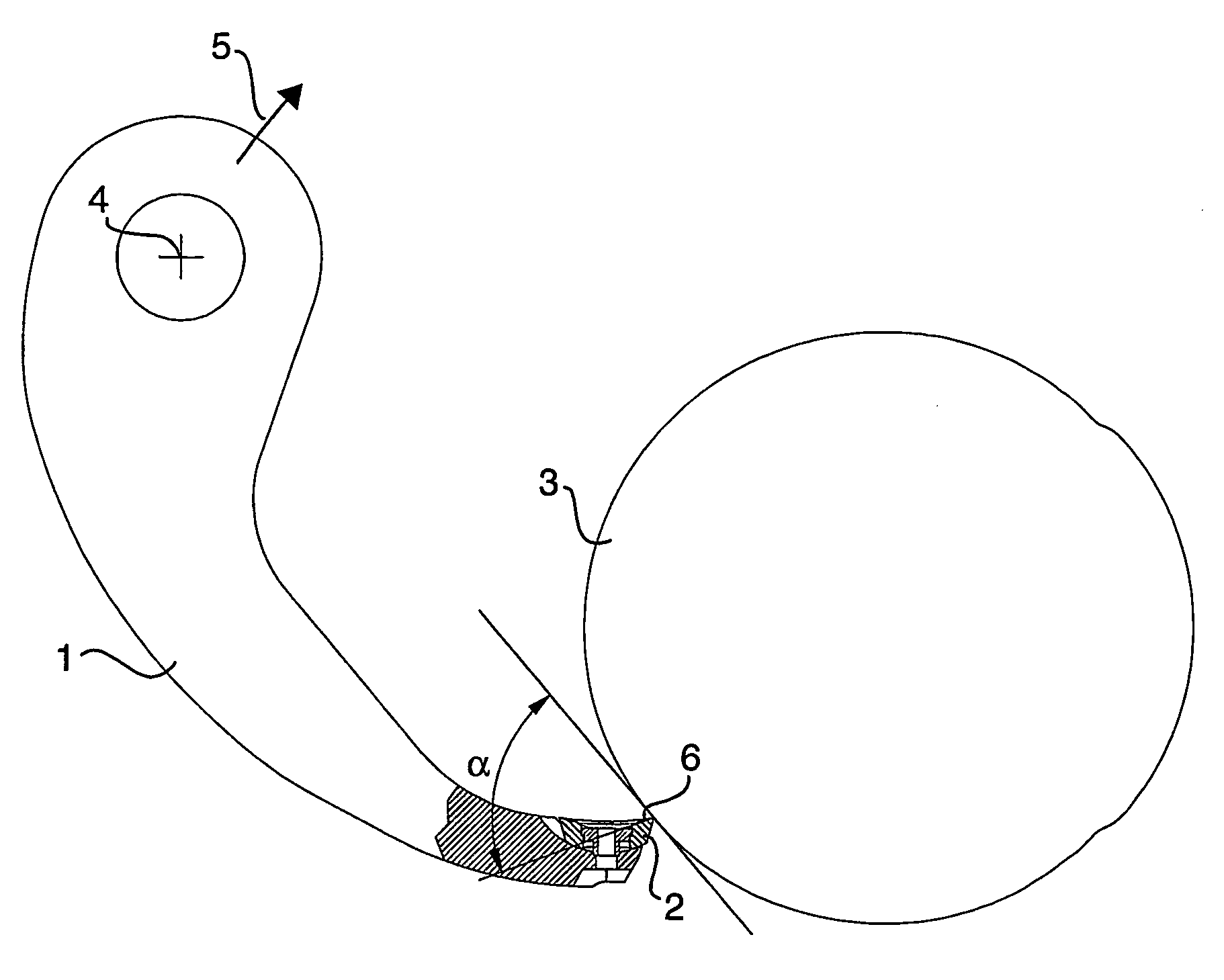

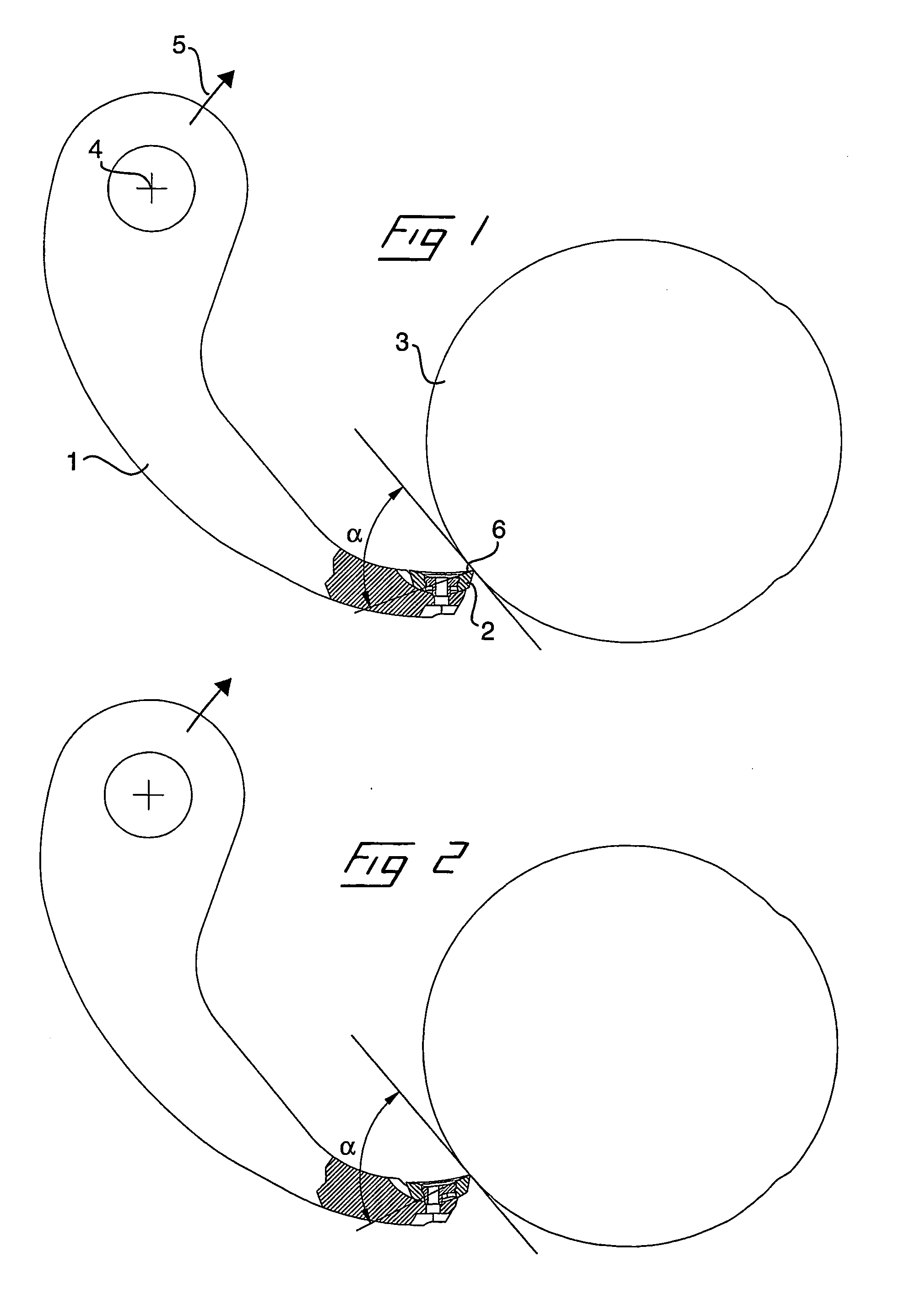

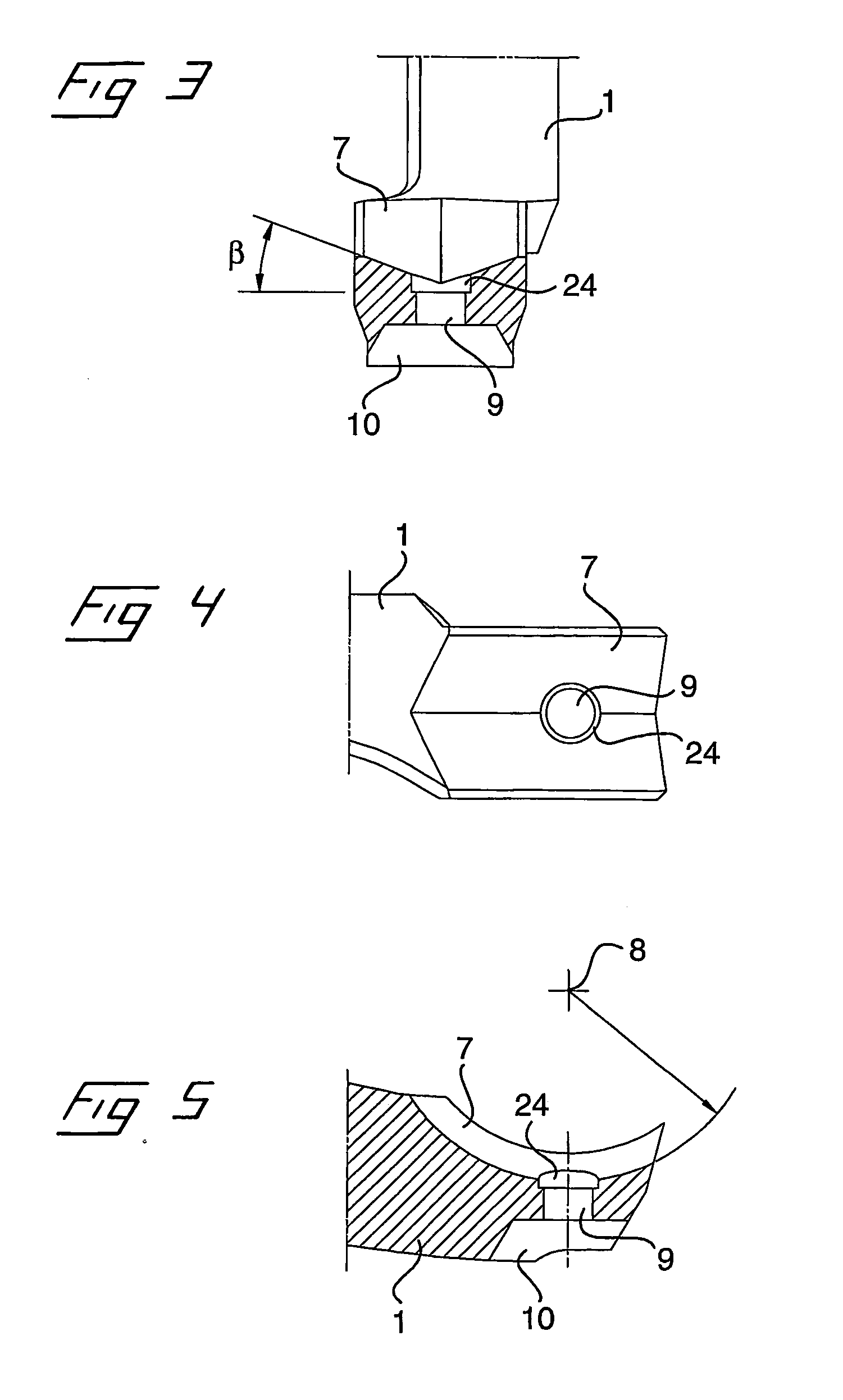

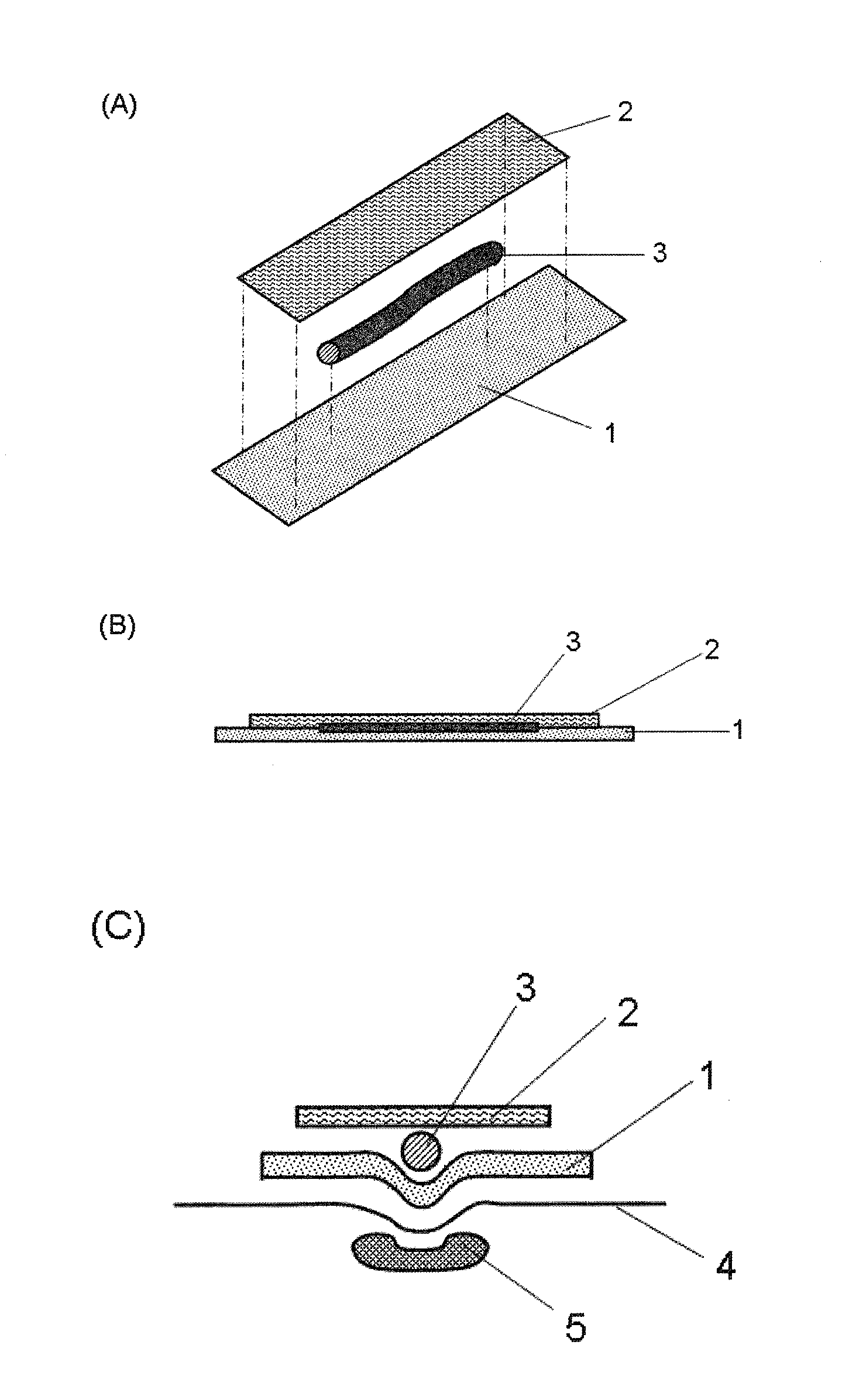

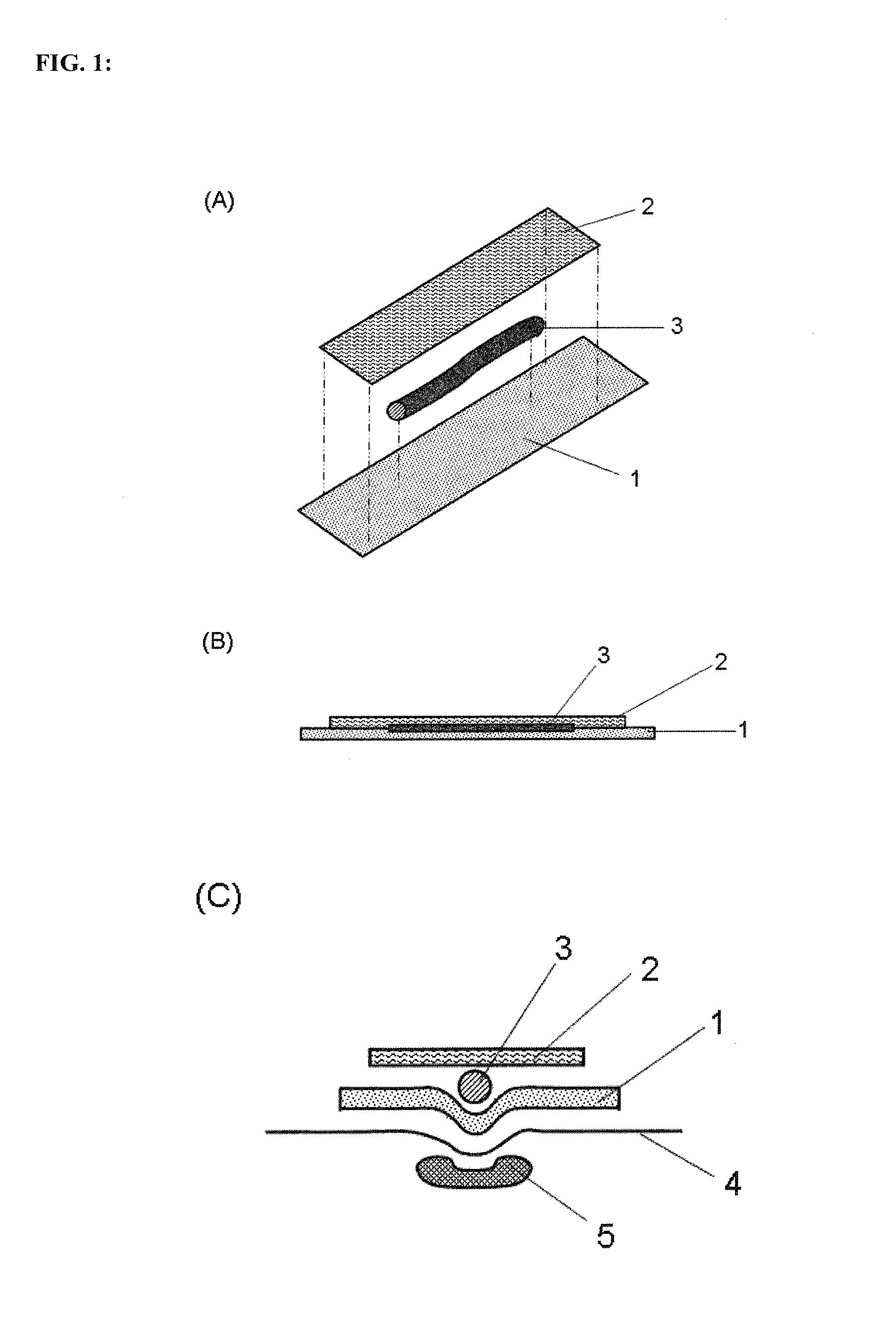

Adhesive patch or bandage for use in treating blood vessel diseases

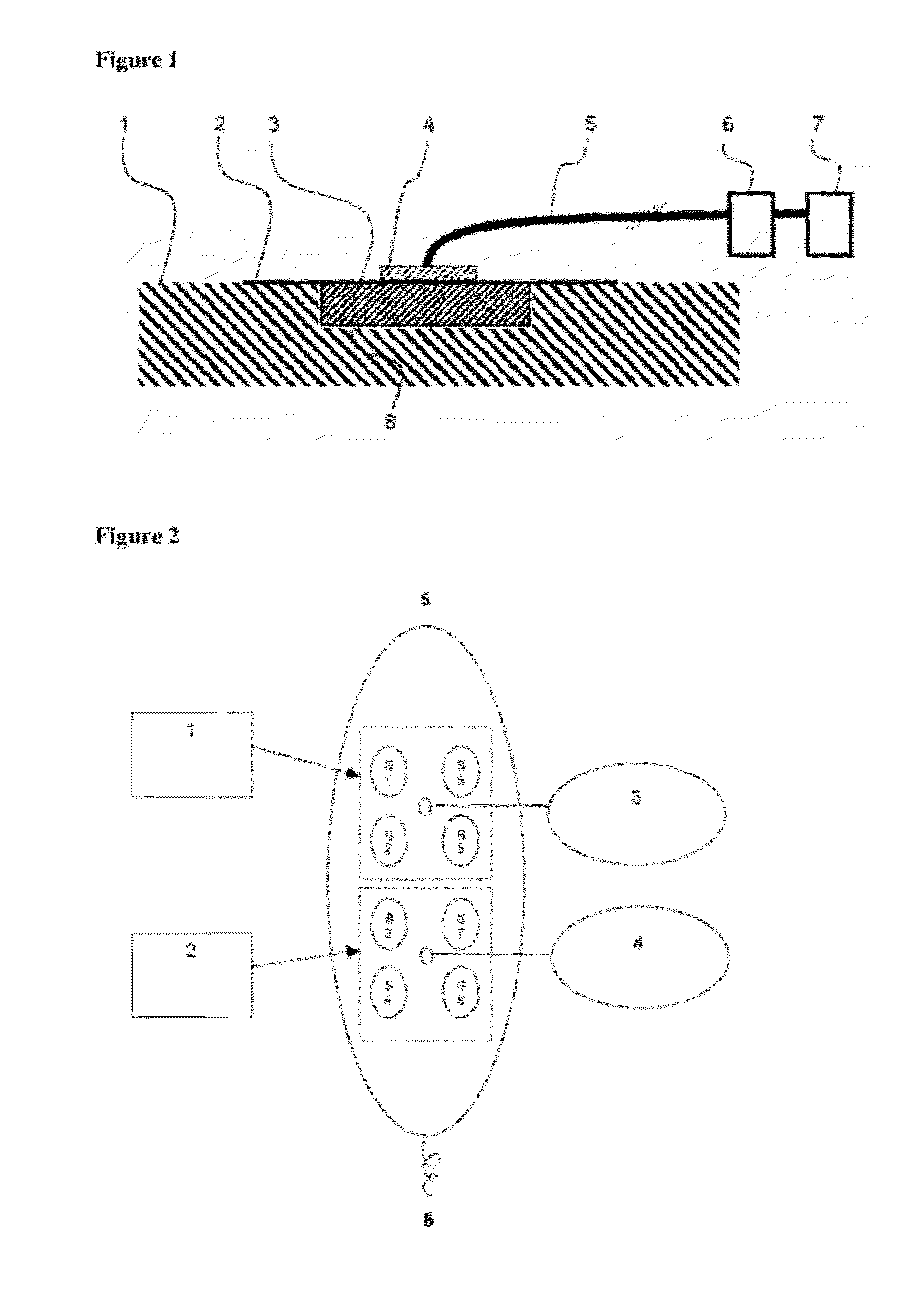

The present invention relates to an enhanced adhesive bandage sandwich (FIG. 1) for compressing blood vessels and a kit for assembling said bandage sandwich. Moreover, the invention relates to a bandage or kit for use as a medicament, particularly, for use in treating varicose veins. The invention also relates to the use of a bandage sandwich or kit for compressing veins or arteries and a method to produce said bandage sandwich. Furthermore, the invention relates to a bandage sandwich obtainable by the inventive method.

Owner:ANGIOCLINIC

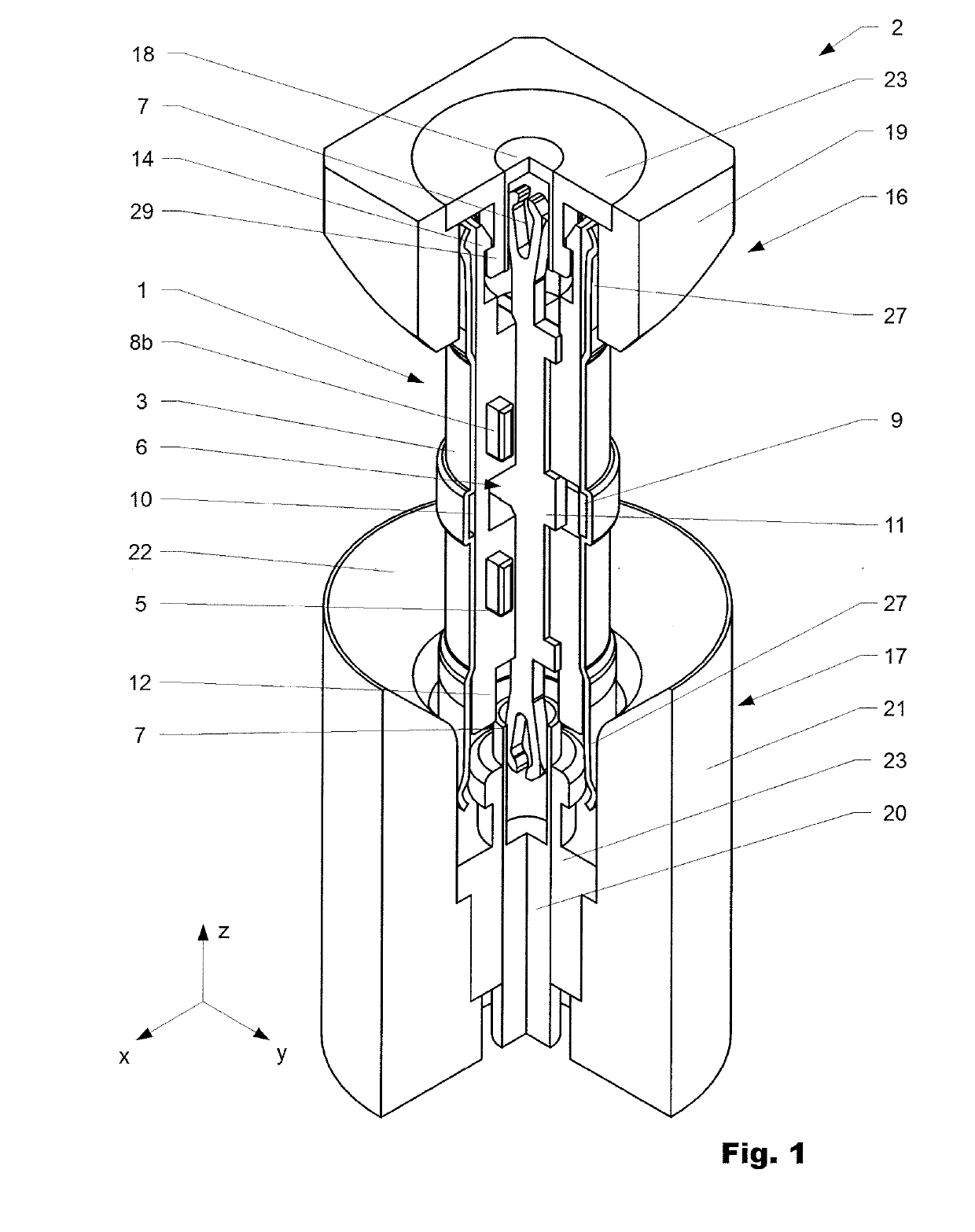

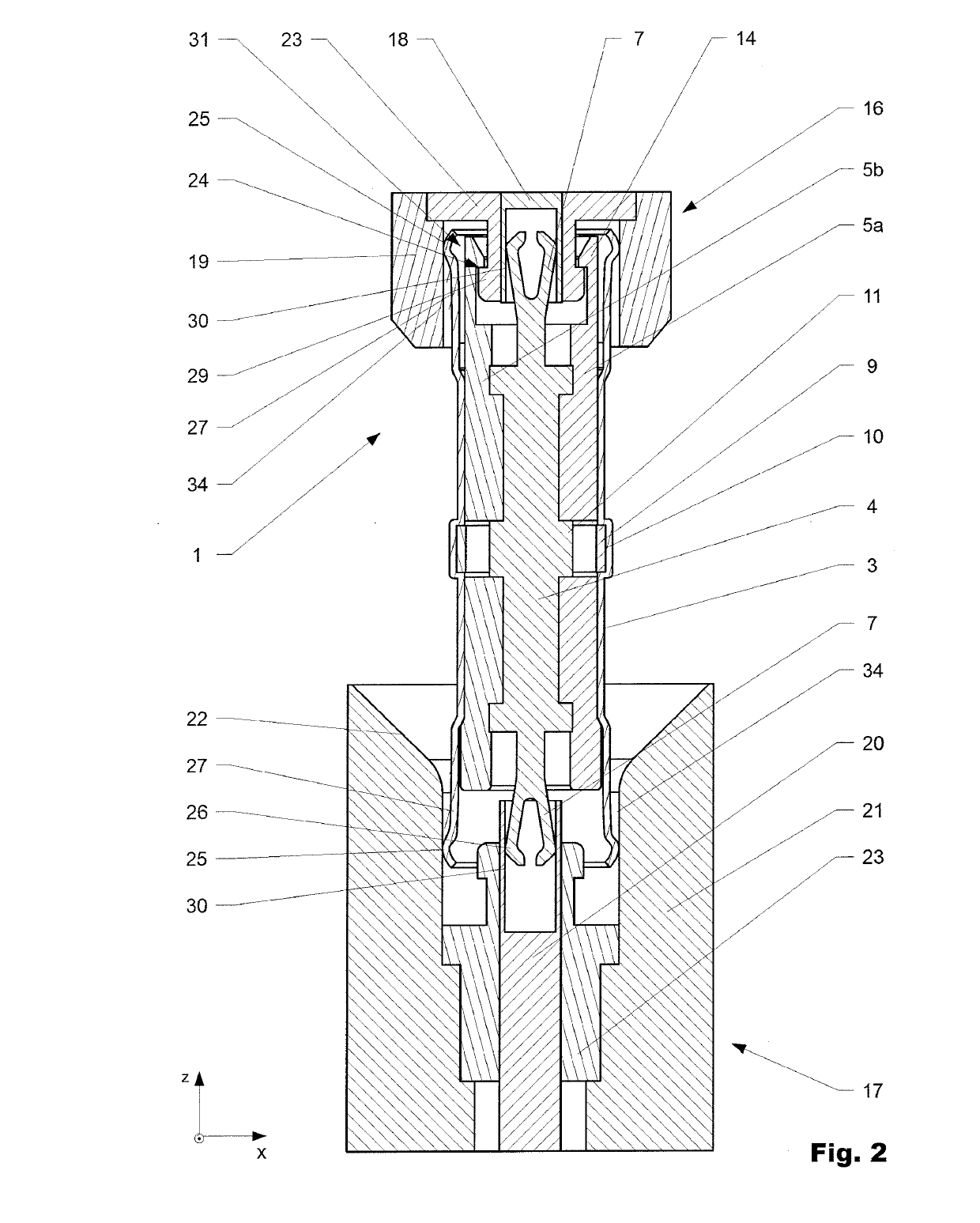

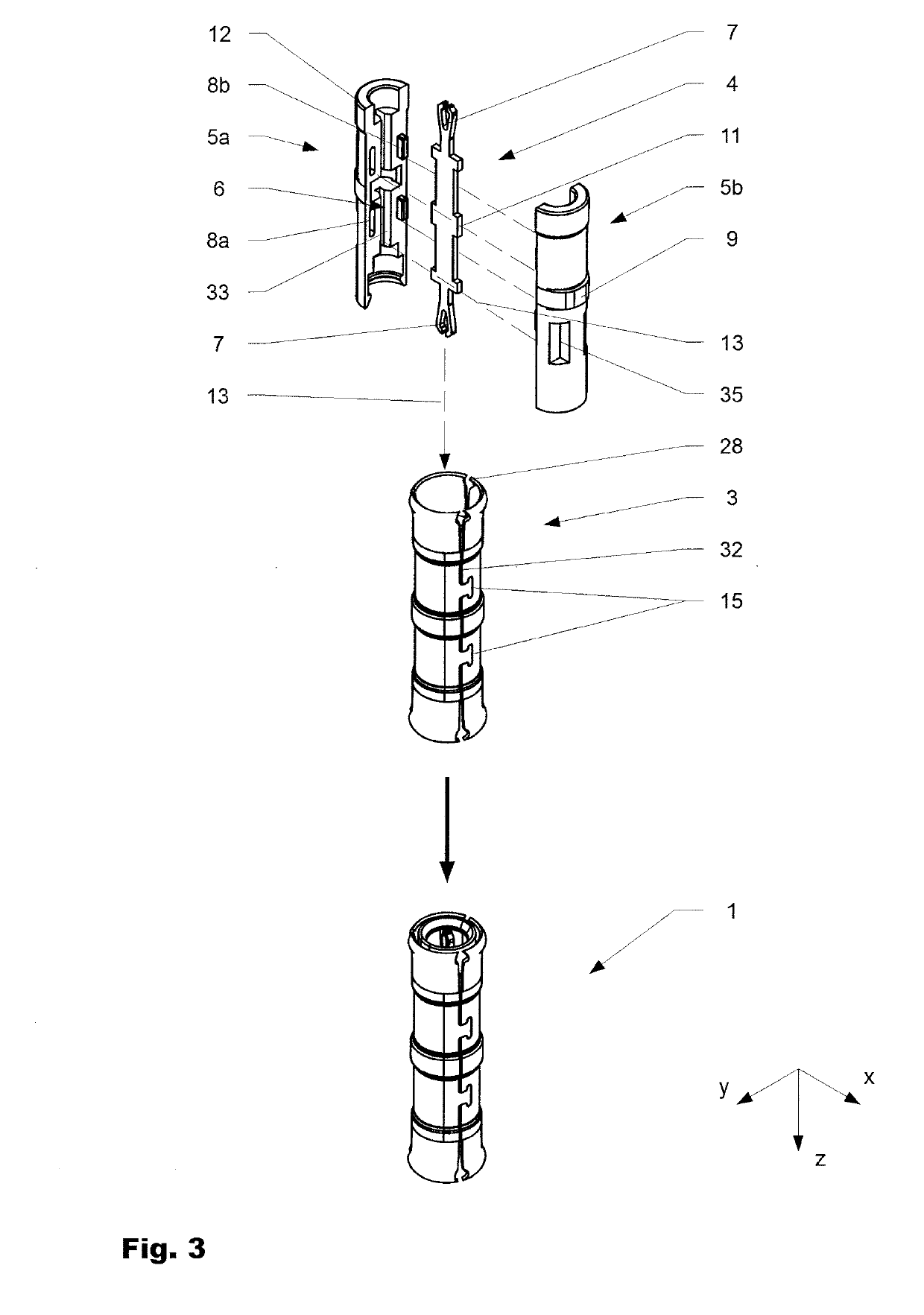

Circuit board coaxial connector

ActiveUS20190165525A1Easy to assembleImprove transmission qualitySecuring/insulating coupling contact membersTwo-part coupling devicesElectrical conductorEngineering

The present invention relates to an adapter (1) for a coaxial connector assembly (2) comprising a tubular outer conductor (3) and a pin-shaped inner conductor (4) both extending in a mounted position in a longitudinal direction (z) and a spacer (5) which in the mounted position is arranged inside the outer conductor (3) encompassing the inner conductor (4) at least partially and by which the inner conductor (4) is positioned with respect to the outer conductor (3). The spacer (5) comprises a first half (5a) and a second half (5b) which are interconnectable to each other along a separation plane extending in the longitudinal direction (z), wherein the first and / or the second half (5a, 5b) comprise at least one holding means (6) to hold the inner conductor (4) in the mounted position.

Owner:HUBERSUHNER AG

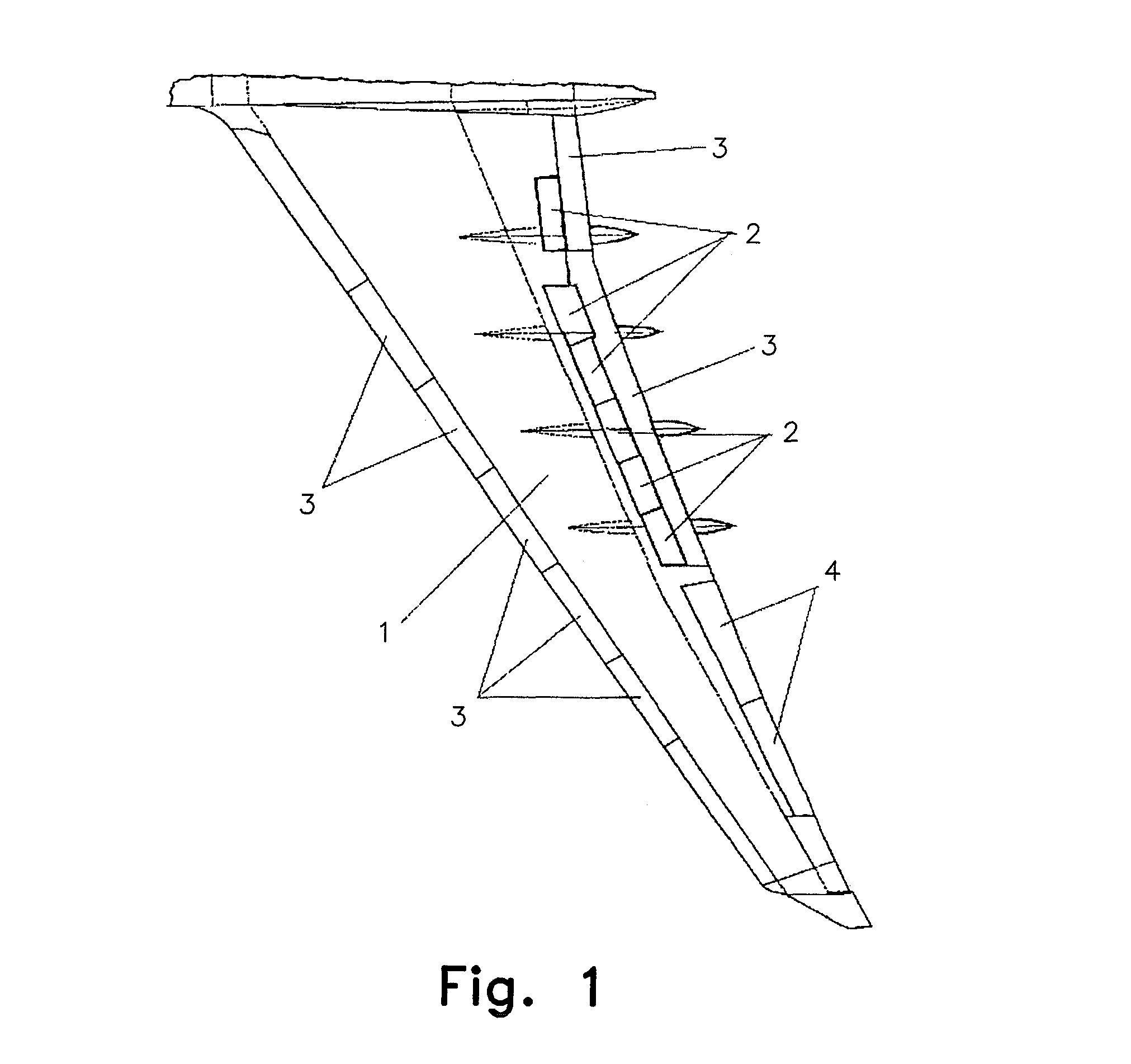

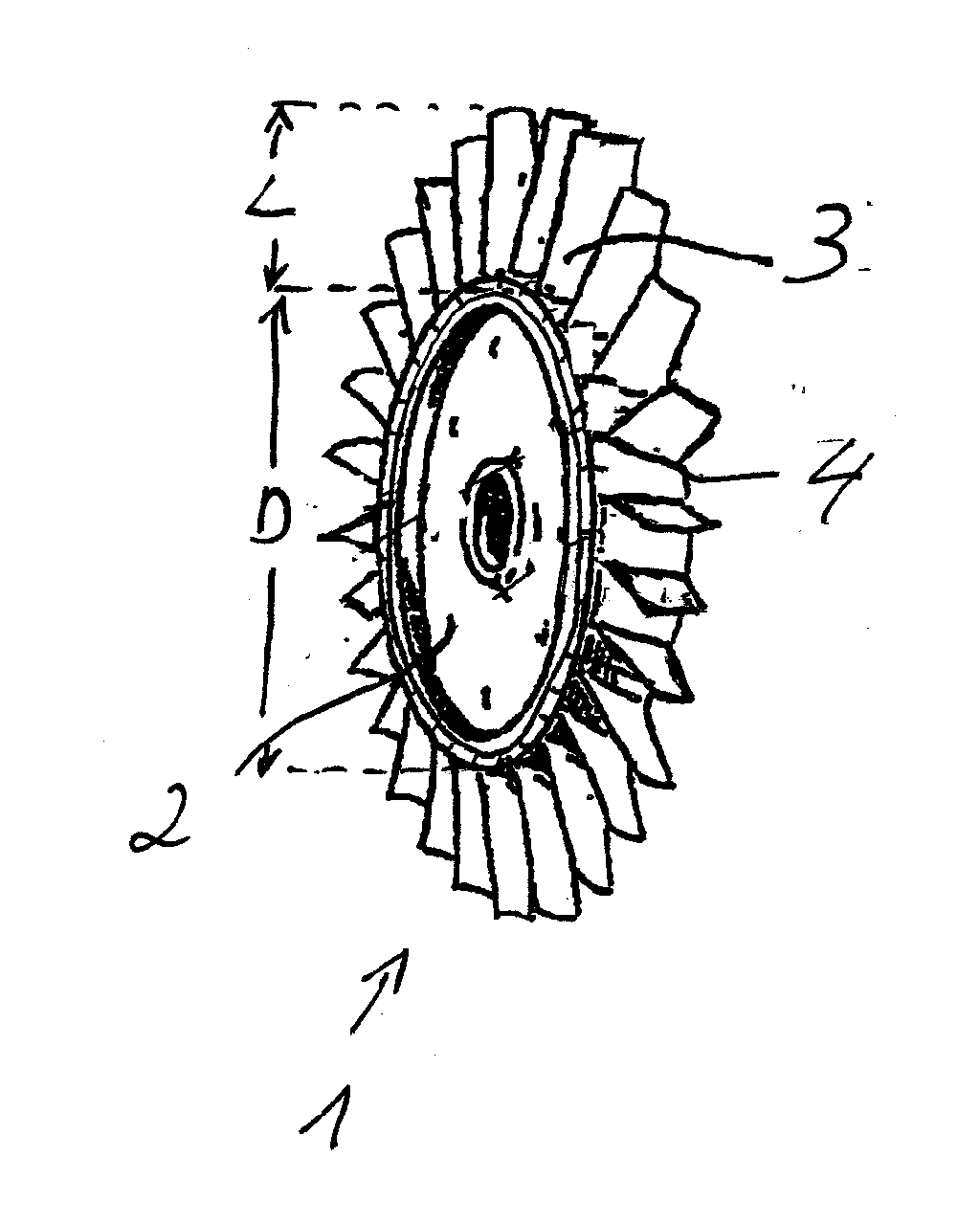

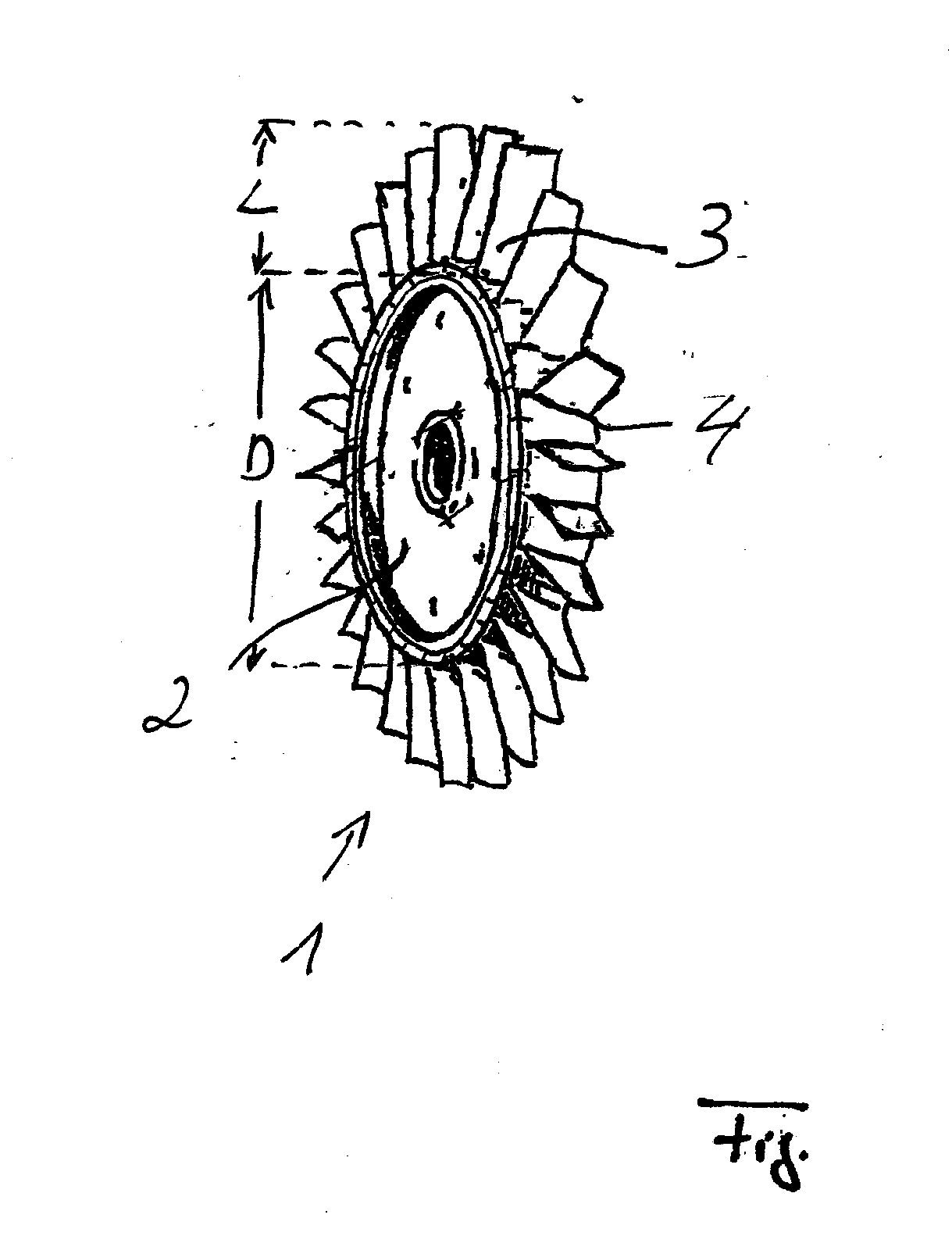

Dual blisks in the high-pressure compressor

The invention relates to a high-pressure compressor of a gas turbine having at least one blisk, specifically a disk with a plurality of blades that are disposed on the disk, wherein the blisk has at least one titanium material from the group that comprises Ti-6246 and Ti-6242, wherein the materials of the disk and the blades of the blisk differ in their chemical composition and / or their microstructure. The blades are welded to the disk, in particular, by means of a pressure welding method supported by high-frequency current, whereby the current is conducted through the joint surfaces and leads to local limited melting therein.

Owner:MTU AERO ENGINES GMBH

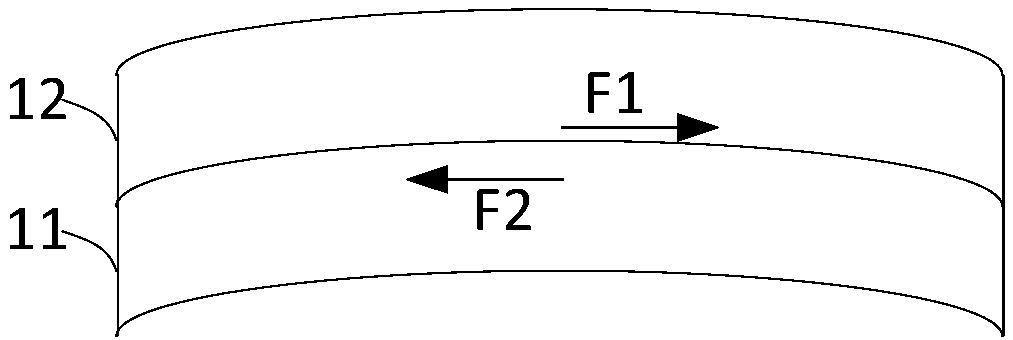

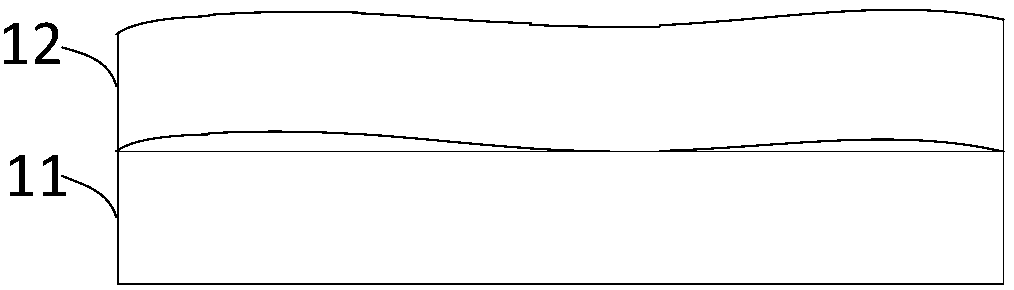

Flexible module and flexible display device

InactiveCN108346376AIncreasing the thicknessAvoid debondingIdentification meansFlexible displayFriction force

The invention discloses a flexible module and a flexible display device. The flexible module comprises a first membrane layer and a second membrane layer which are bonded to each other, and a first coarse structure is formed on the part of the surface of the side, facing towards the second membrane layer, of the first membrane layer; a second coarse structure is formed on the part of the surface of the side, facing towards the first membrane layer, of the second membrane layer; the first and second coarse layers are oppositely arranged and bonded with each other without the existing of clearances. The friction force between the first membrane layer and the second membrane layer is enhanced after the first and second membrane layers are bonded with each other due to the fact that the firstcoarse structure on the first membrane layer is in contact with the second coarse structure on the second membrane layer, and therefore the phenomenons of debonding and layering due to the fact that the first membrane layer and the second membrane layer slide towards each other in the bending process can be avoided.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

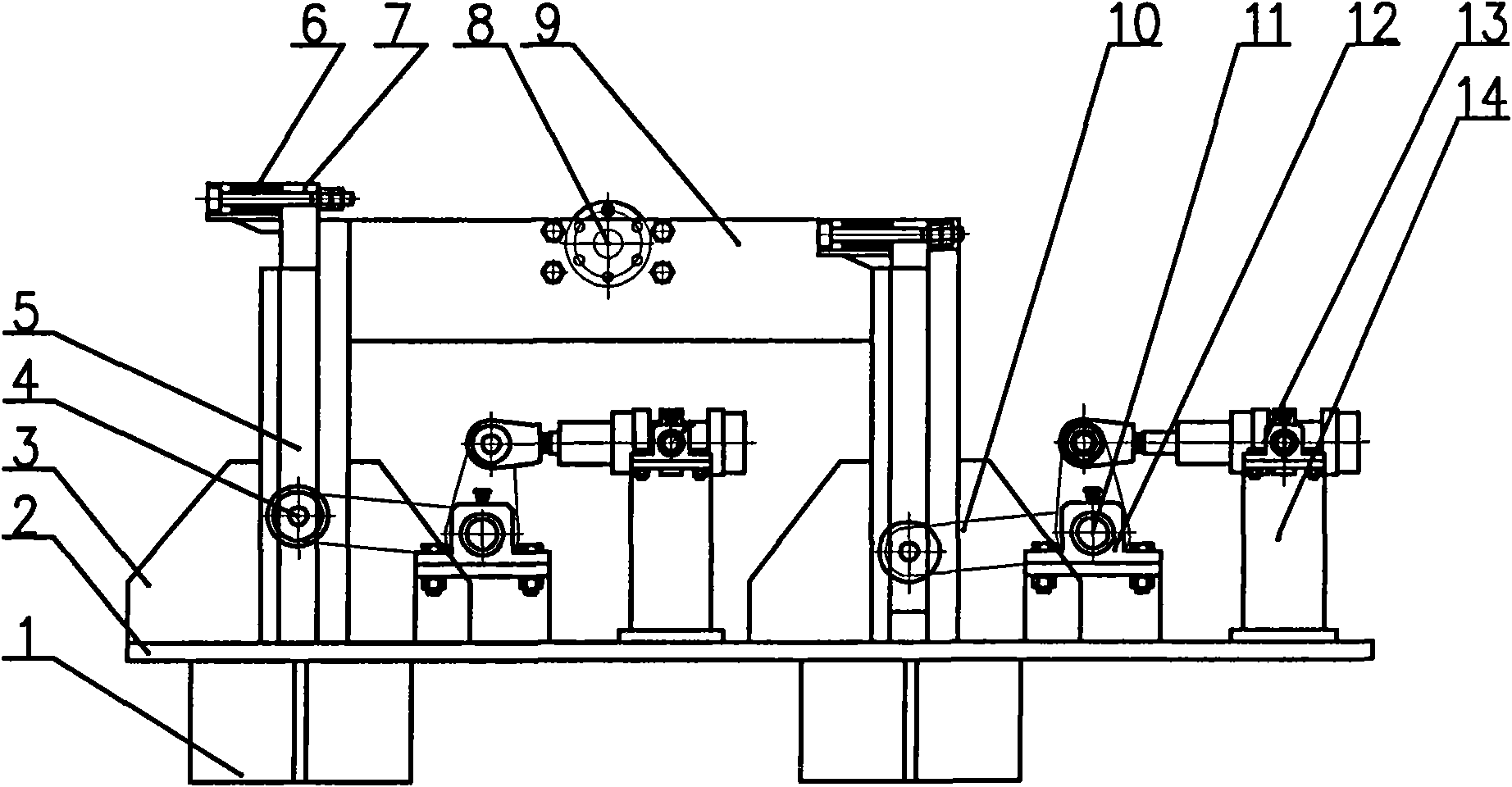

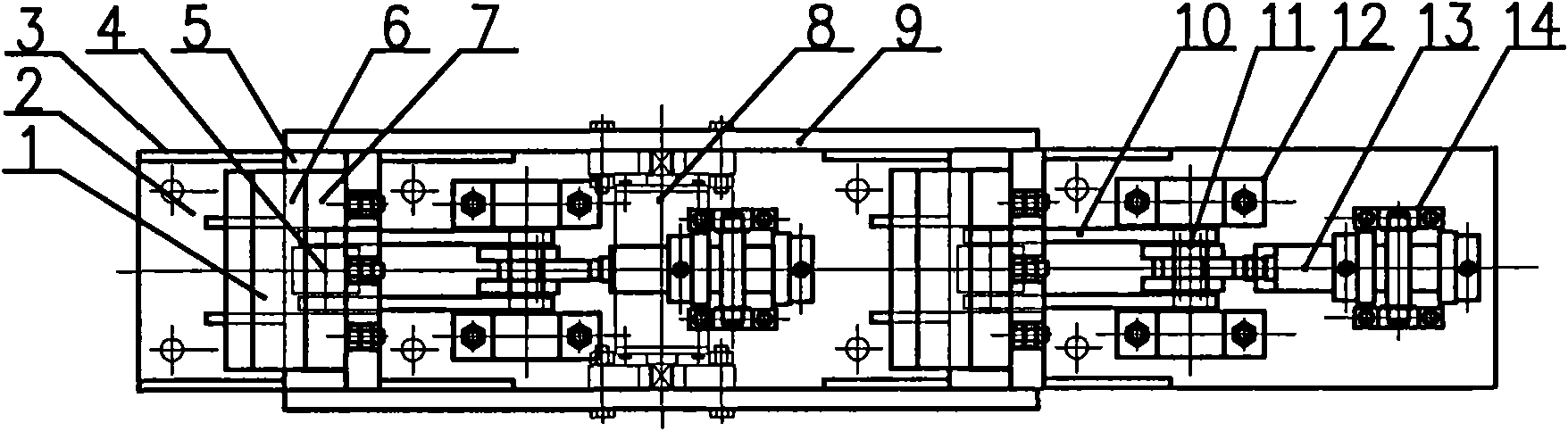

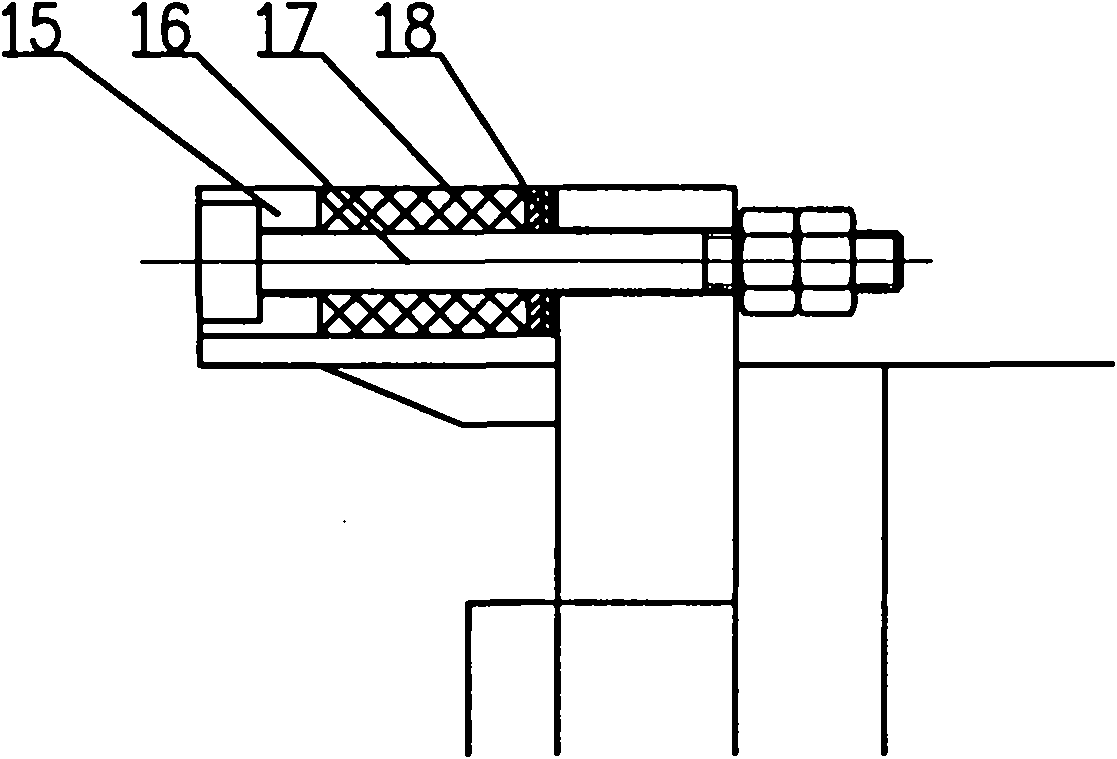

Heavy rail scaling apparatus and method

ActiveCN102039537AExtended service lifeAvoid damageMetal working apparatusPositioning apparatusEngineeringTransmission system

The present invention provides a heavy rail scaling apparatus and a method therefor. The apparatus is a single-set or double-set mechanical scaling apparatus comprising a striking head elevating system, a transmission system, a frame and a detection switch. According to the invention, an electrohydraulic push rod is taken as power source to drive a swing rod to swing, a top wheel arranged at the front of the swing rod is employed to control the rise and fall of a lifter plate to allow the striking head arranged at the top end of the lifter plate to be located at either a working position or as top position and cooperate with a scaling saw to realize accurate scaling of the heavy rail. By employing a front detection switch and a damping and thickness-adjusting striking head having a polyurethane bumper pad and an adjusting gasket unit, impact to the striking head can be reduced while the speed of a frequency-changing roller-way is controlled, the service life of the scaling apparatus can be prolonged, the precision of heavy rail scaling can be improved, and the tolerance of the length of the heavy rail is kept between +4mm and -4mm. The apparatus has a simple structure and is easy to operate and convenient to maintain. The method is reasonable, and enables stable system running process, high operation rate, and low accident rate. In addition, the apparatus can increase the yield of heavy rail. The present invention is particularly suitable to be used for the scaling of 95, 96, 99,100 meter heavy rails.

Owner:ANGANG STEEL CO LTD

Device for decoupling a bearing bracket

InactiveUS20090154863A1Easy to controlEliminate shear forcePump componentsEngine fuctionsStress limitMechanical engineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

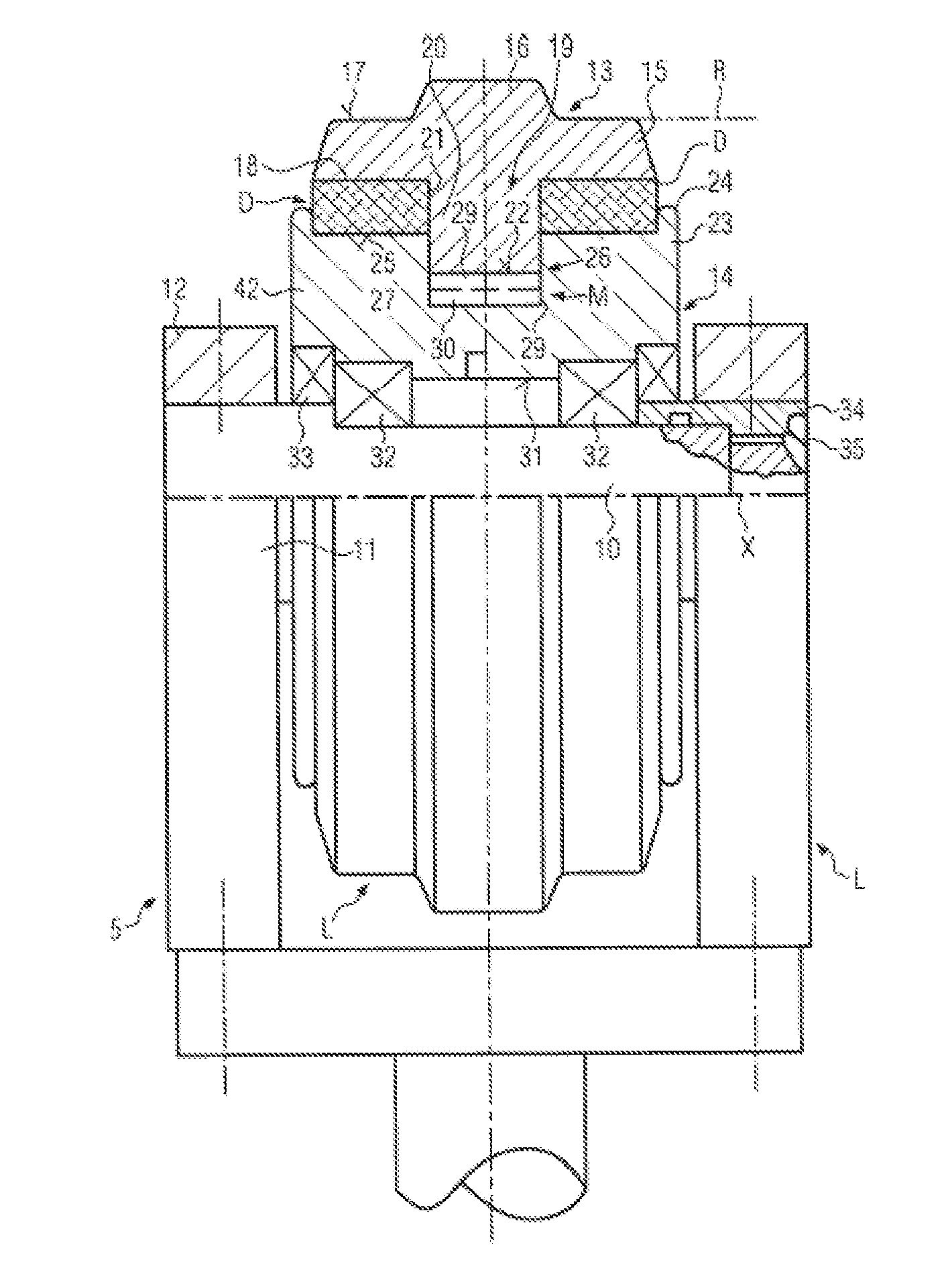

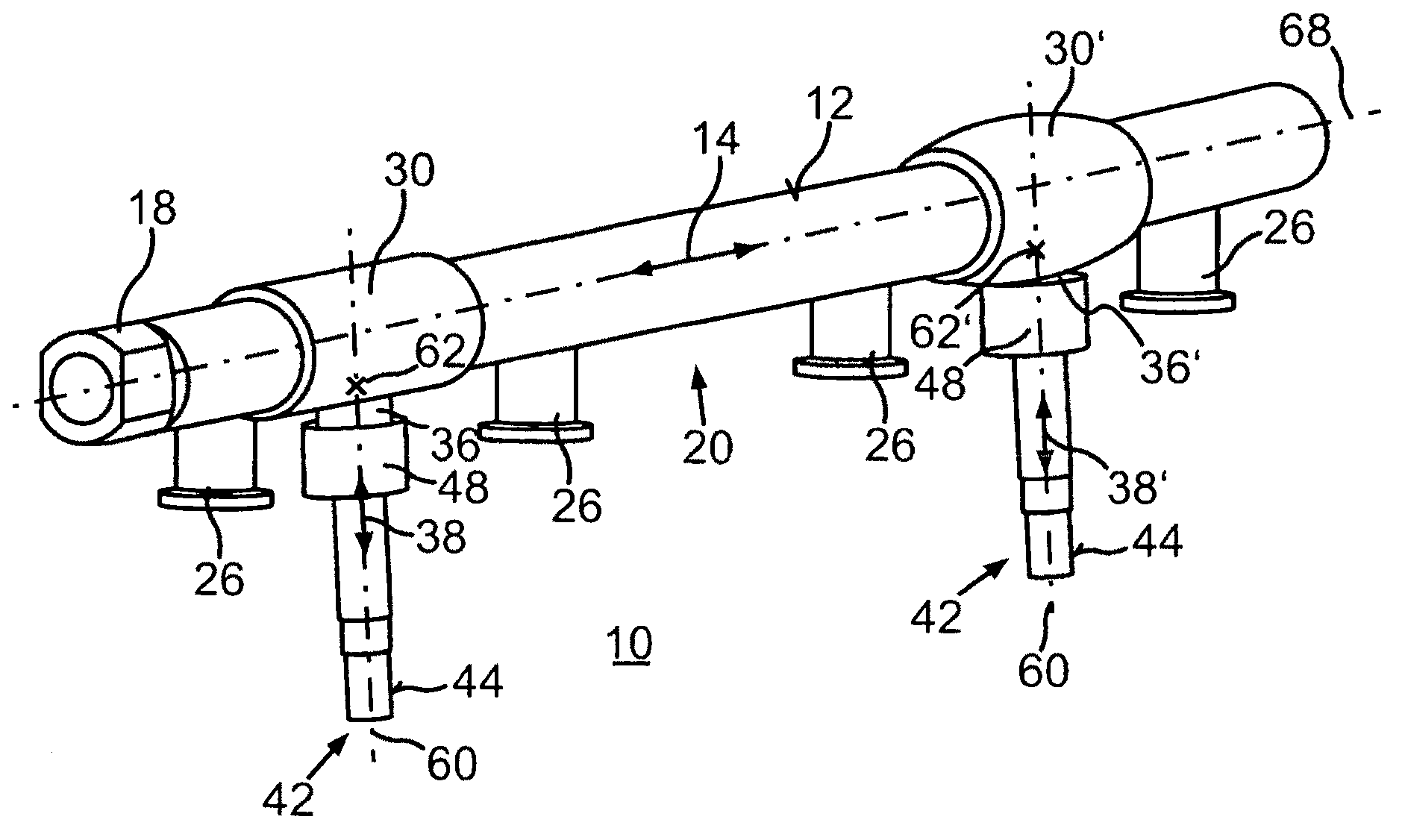

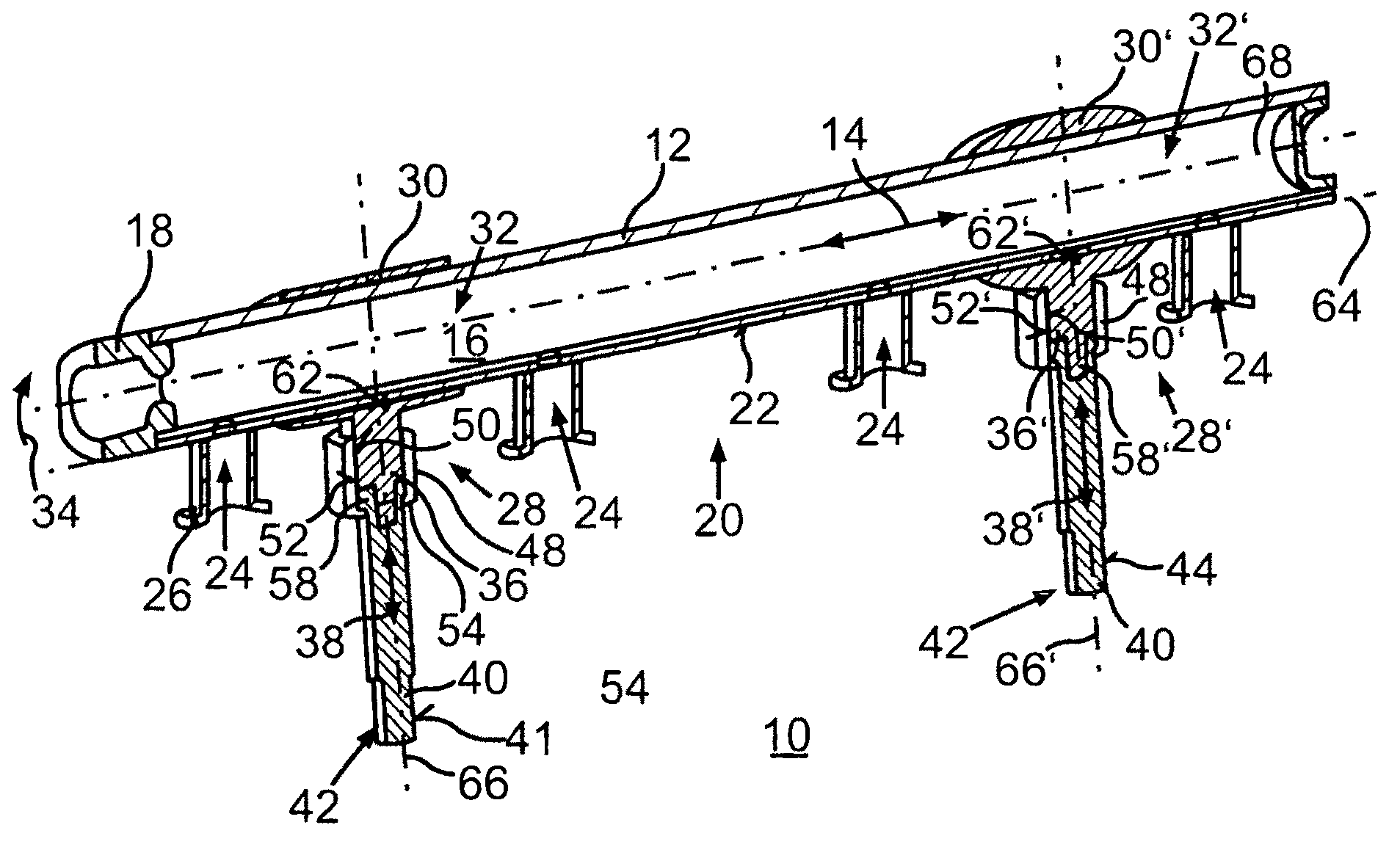

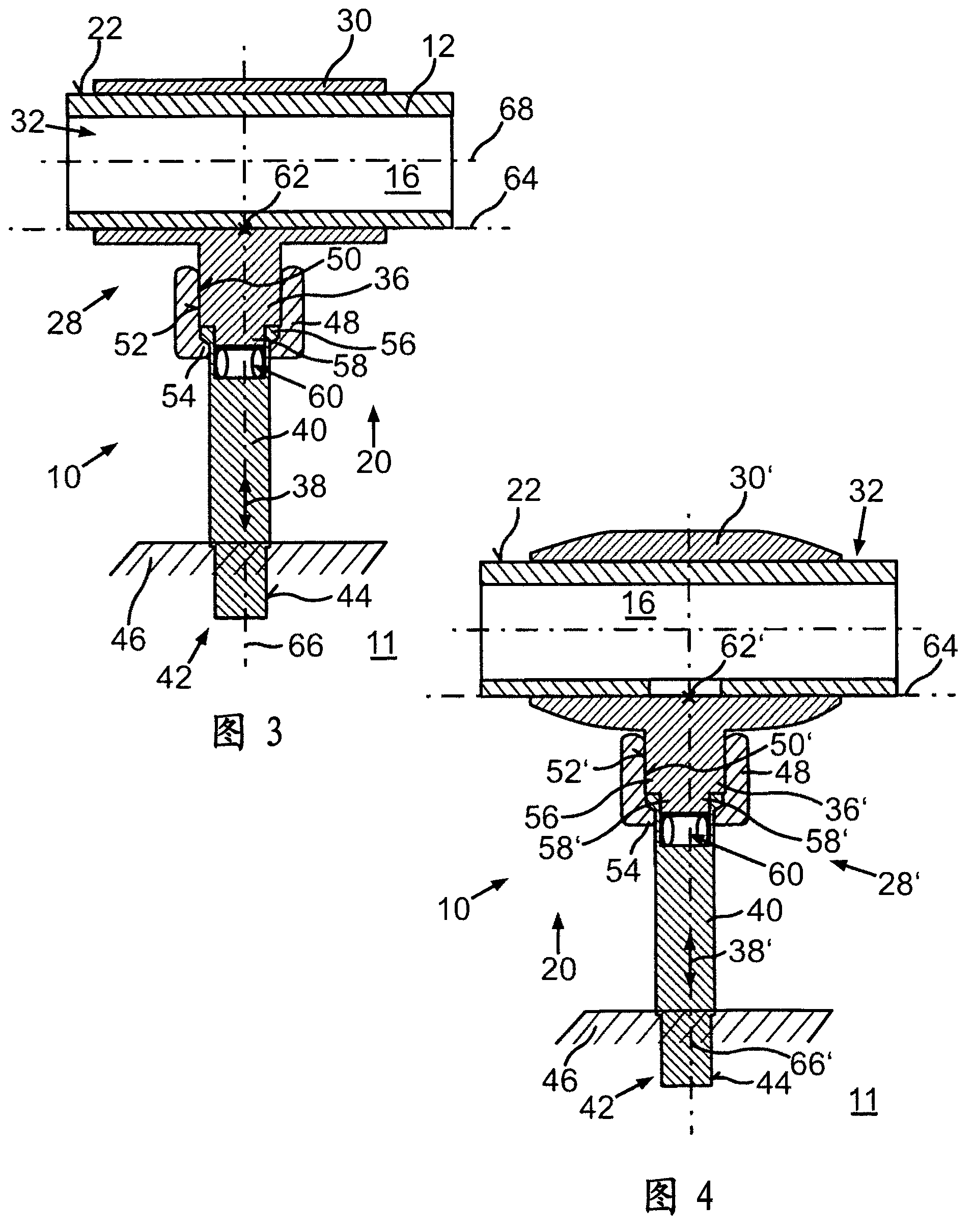

A fastening arrangement of a fuel supply device on an internal combustion engine, and a method for fastening a fuel supply device to the internal combustion engine

ActiveCN103210204AShorten the timeLow costLow-pressure fuel injectionMachines/enginesExternal combustion engineEngineering

The invention relates to a fastening arrangement (11) of a fuel supply device (10) on an internal combustion engine, and also relates to a method for fastening the fuel supply device (10) of said type to the internal combustion engine. In the fastening arrangement (11), at least one fuel distributing element (12) which runs along a longitudinal direction (14) and which has at least two connection openings (24) for connecting a respective fuel injection device is fastened to the internal combustion engine by means of at least one connecting part (36, 36'), wherein the connecting part (36, 36') is connected to the fuel distributing element (12) via a holding part (30, 30') which has a receptacle (32, 32') which completely surrounds at least one outer circumferential region of the fuel distributing element (12) and in which at least one portion of the fuel distributing element (12) is held, and wherein a point (62, 62'), which is situated in an elongation of the connecting element (36, 36') in a direction of extent (38, 38'), of the fuel distributing element (12) lies on a straight line (64) which connects the two connection openings (24).

Owner:AUDI AG

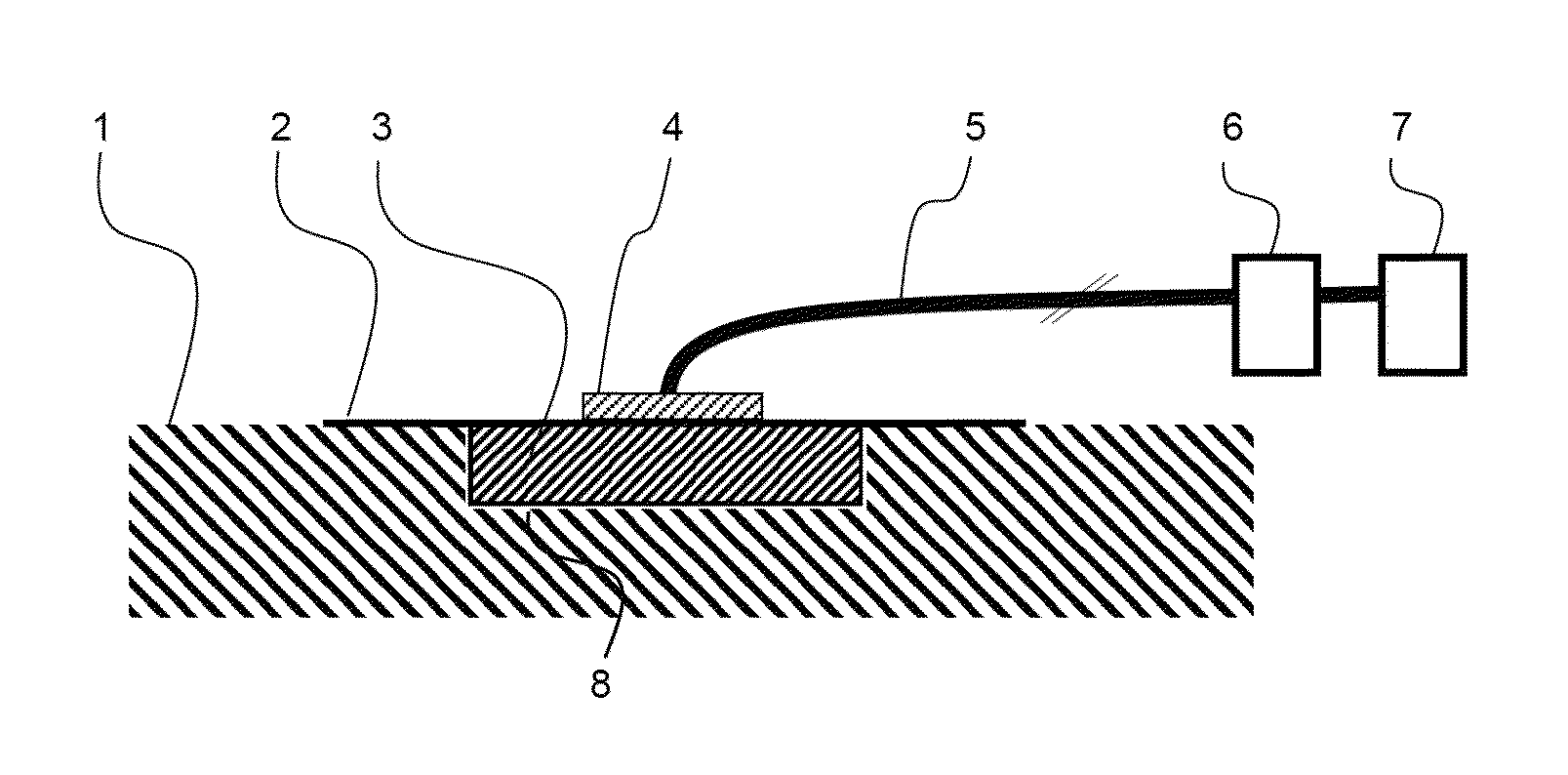

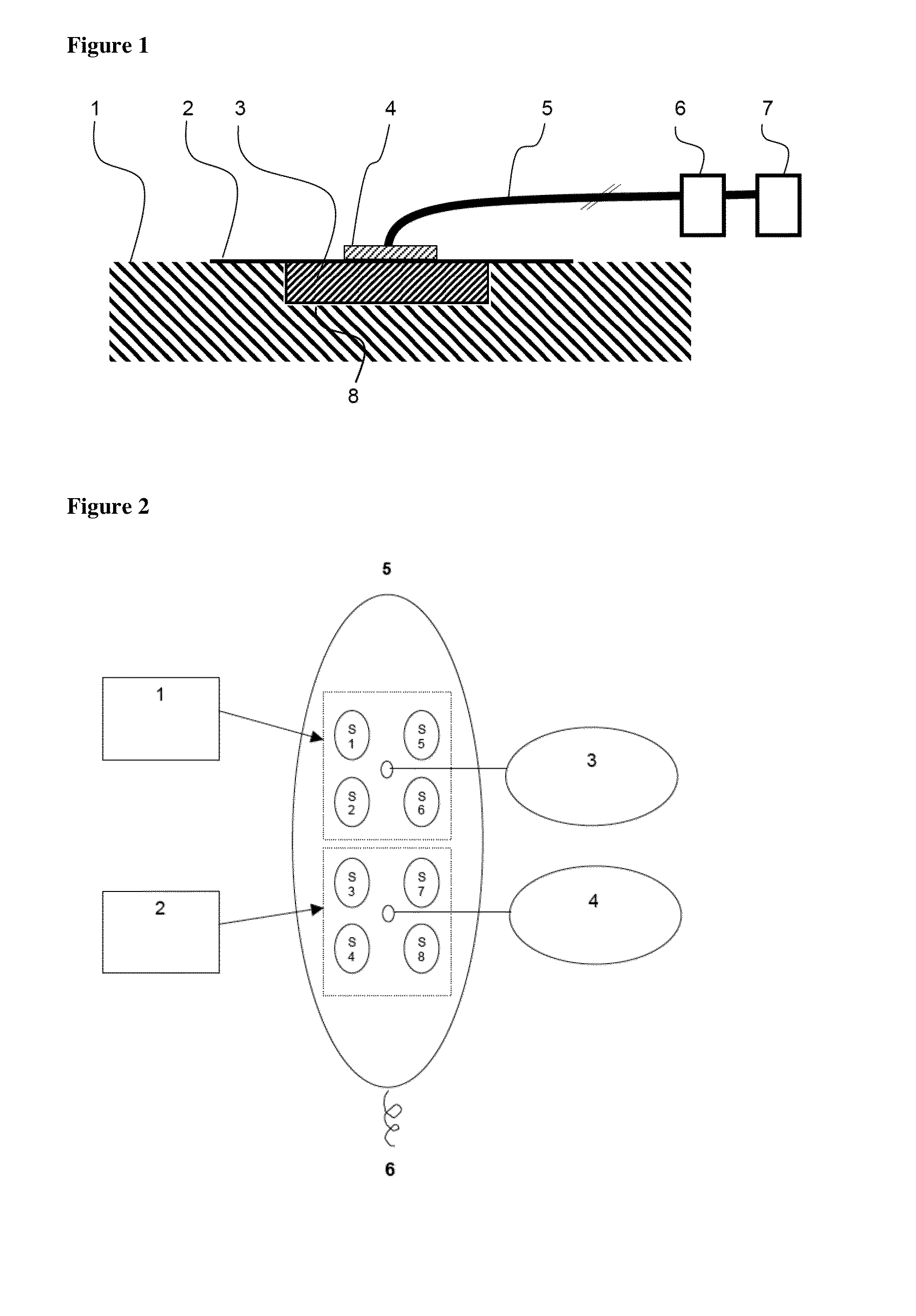

Use of a polyurethane foam as a wound dressing in negative pressure therapy

ActiveUS20120046588A1Improve matchAvoid shear forceNon-adhesive dressingsAbsorbent padsWound dressingMedicine

The invention relates to a device for negative pressure wound therapy comprising (a) a cover material for air-tight sealing of the wound space; (b) as applicable, a means for the connection of a negative pressure source; and (c) a wound dressing comprising an open-cell polyurethane foam whereby the open-cell polyurethane foam has special properties, in particular a tensile strength after three days of storage in bovine serum, measured in accordance with DIN 53571, between 80 kPa and 300 kPa. The invention further relates to the use of said open-cell polyurethane foam for use as a wound dressing in negative pressure wound therapy.

Owner:PAUL HARTMANN AG

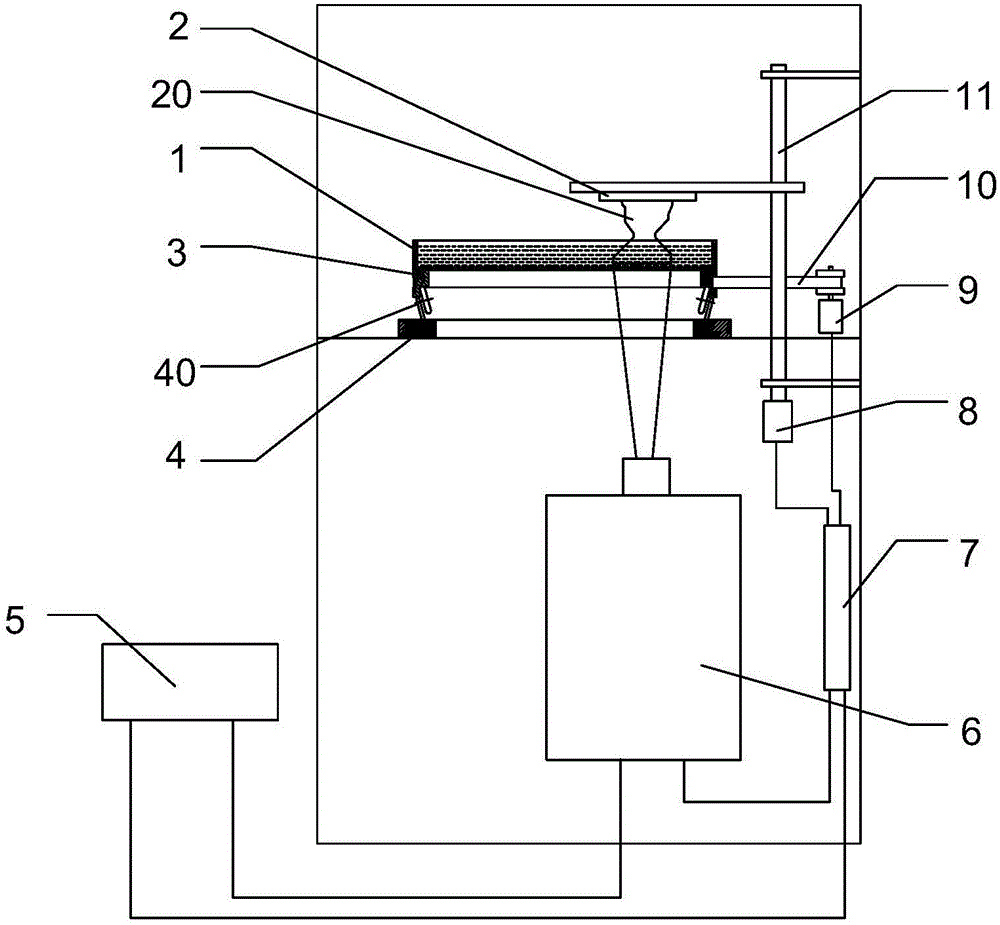

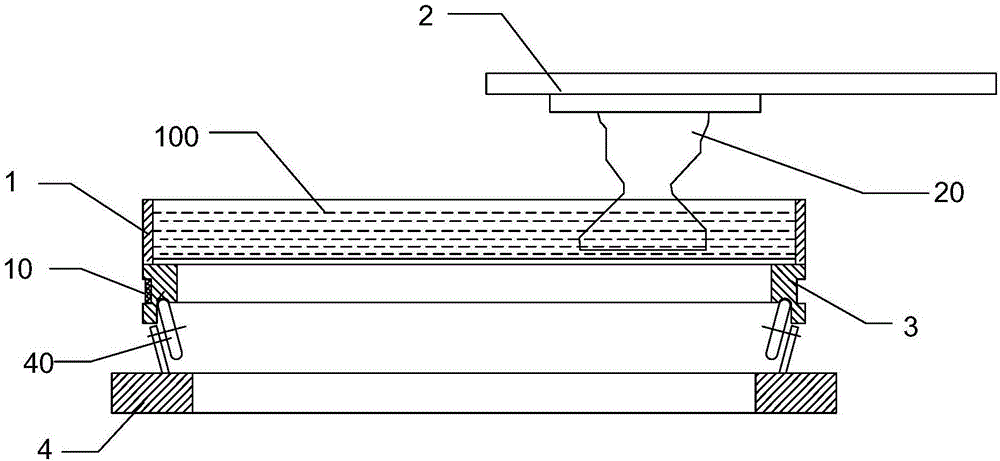

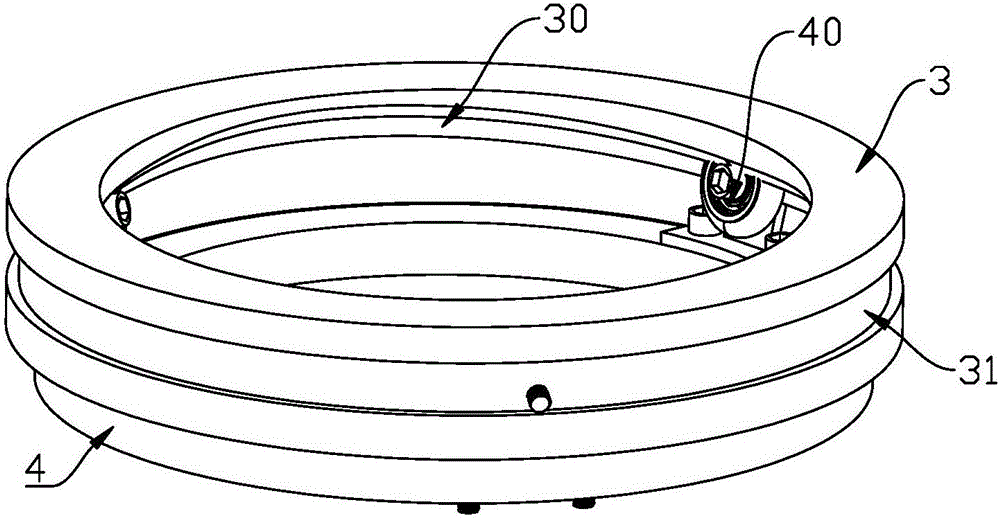

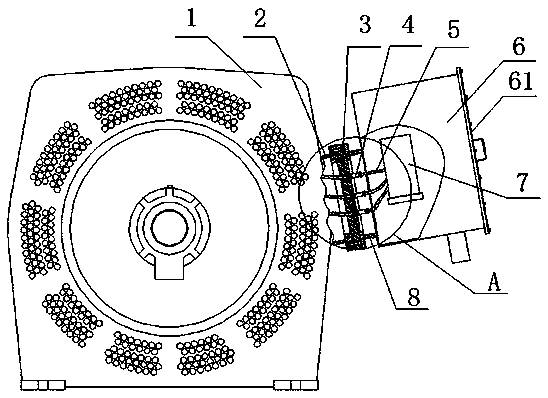

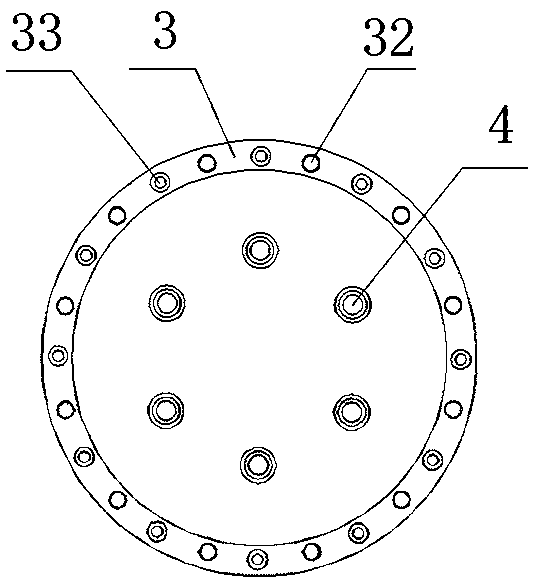

Photo-sensitive material solidification layer forming method in 3D (three-dimensional) printing and structure for implementing such method

InactiveCN106476267ARealize layer-by-layer moldingReduce distortionManufacturing platforms/substrates3D object support structuresIrradiationDislocation

The invention relates to a photo-sensitive material solidification layer forming method in 3D (three-dimensional) printing and a structure for implementing such method. The method includes disposing a photo-sensitive material in a horizontally rotatable container, and rotating the container when the photo-sensitive material forms a solidification layer under irradiation of a light source, wherein the container moves downwards while rotating so as to be separated from the solidification layer and then moves upwards to restore so as to achieve solidification of next solidification layer. The structure comprises a light source component, a liftable printout lifting plate and the round container mounted on a rotatable seat, and a specially designed orbital groove in the rotatable seat controls the round container to ascend and descend. The photo-sensitive material solidification layer forming method in 3D printing and the structure for implementing such method have the advantages that one-by-one forming of the solidification layers is achieved through ascending and descending of the container for holding the photo-sensitive material during rotating, so that shear force and frictional force generated by horizontal movement are avoided, and printout deformation, printout layer shedding and printed layer dislocation are reduced.

Owner:深圳市鑫创盈科技有限公司

Gear system for a twin-screw extruder

Owner:THEYSOHN EXTRUSIONSTECHNIK GMBH

Tramcar

ActiveCN105667528AImprove reliabilityImprove fatigue resistanceTractor-trailer combinationsAxle-box lubricationAgricultural engineeringRubber bearing

The invention provides a tramcar. The tramcar comprises at least two carriages, wherein a carriage hinging device is arranged between every two adjacent carriages; each carriage hinging device comprises a bearing framework, a lower hinging assembly, an upper hinging assembly and a vestibule windshield; each lower hinging assembly comprises a first joint bearing, a second joint bearing, a first connecting plate and a second connecting plate; each connecting plate is hinged to the corresponding bearing framework through the corresponding joint bearing; an upper mounting shaft is arranged at the upper part of each bearing framework; a rubber bearing is arrange on each upper mounting shaft; each upper hinging assembly comprises two first connecting rods, a second connecting rod, first mounting bases and two second mounting bases; one end part of each first connecting rod is hinged to the corresponding bearing framework through the corresponding rubber bearing; the other end part of each first connecting rod is hinged to the corresponding first mounting base through a third joint bearing; two ends of each second connecting rod are hinged between the two second mounting bases through fourth joint bearings; and one second mounting base is fixed at the upper part of the corresponding bearing framework. The reliability of the tramcar is improved.

Owner:青岛中车四方轨道车辆有限公司

Explosion-proof and safety-increased type composite explosion-proof motor with current transformer

ActiveCN105515258AReduce weightImprove security levelSupports/enclosures/casingsShort circuit protectionControl theory

The invention discloses an explosion-proof and safety-increased type composite explosion-proof motor with a current transformer. An annular junction box support is welded on the base of an explosion-proof motor body. The annular junction box support is provided with an explosion-proof cover plate. The explosion-proof cover plate is connected with a safety-increased type current transformer junction box via a terminal box base. The explosion-proof cover plate is provided with an explosion-proof cable joint. The terminal box base, the explosion-proof cover plate, the explosion-proof cable joint and the base together form an explosion-proof housing of the motor. In this way, through arranging the current transformer as a measurement element on the explosion-proof motor body for realizing the differential protection, the interphase short-circuit protection function is effectively realized. Therefore, the security level of the explosion-proof motor is effectively realized. The motor is simple in structure, convenient to install and maintain, good in security and reliability and high in explosion-proof level. The technical scheme of the invention can be effectively applied to the explosion-proof motor with the power thereof larger than 2000 kW. The cost of the motor is greatly reduced.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com