Explosion-proof and safety-increased type composite explosion-proof motor with current transformer

A technology for current transformers and explosion-proof motors, which is applied to electrical components, electromechanical devices, and electric components, etc., can solve the problem of high cost of pre-purging devices and positive pressure control devices, high construction materials and labor costs, and reduced motor operation reliability. and other problems, to achieve the effect of light weight, improved connection reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

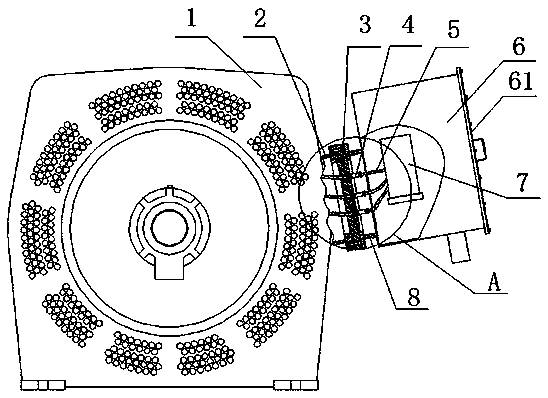

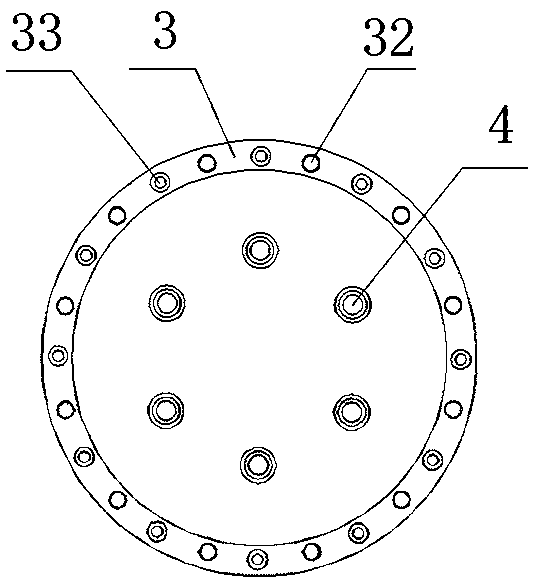

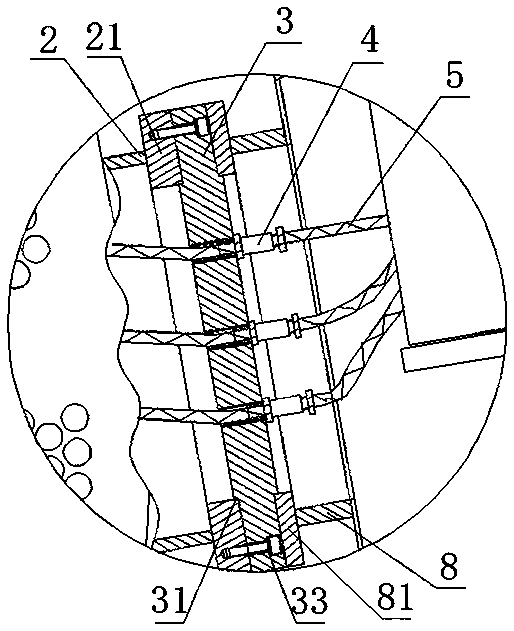

[0019] see Figure 1-3 , the explosion-proof+increased-safety composite explosion-proof motor with current transformer of the present invention includes a flameproof motor body 1, and an annular junction box support 2 is welded on the frame of the flameproof motor body 1, and the junction box supports A flameproof cover 3 is provided on the seat 2, and an increased safety current transformer junction box 6 is connected to the flameproof cover 3 through a junction box seat 8. The flameproof cover 3 is provided with a flameproof gland 4 , the motor lead 5 in the flameproof motor body 1 is connected to the conductive member 7 inside the junction box 6 through the flameproof gland 4, the junction box support 2, the flameproof cover plate 3 and the flameproof The gland head 4 and the machine base together form the flameproof enclosure of the motor, which isolates the inside of the motor from the junction box 6 of the increased safety current transformer, and realizes the effective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com