Tramcar

A technology for trams and carriages, which is applied in the direction of motor vehicles, railway car bodies, vehicle parts, etc., and can solve the problems of complex stress in the middle compartment, low reliability of trams, poor fatigue resistance, etc., and achieve the connection mode Reliable, good cushioning effect, and the effect of improving anti-fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

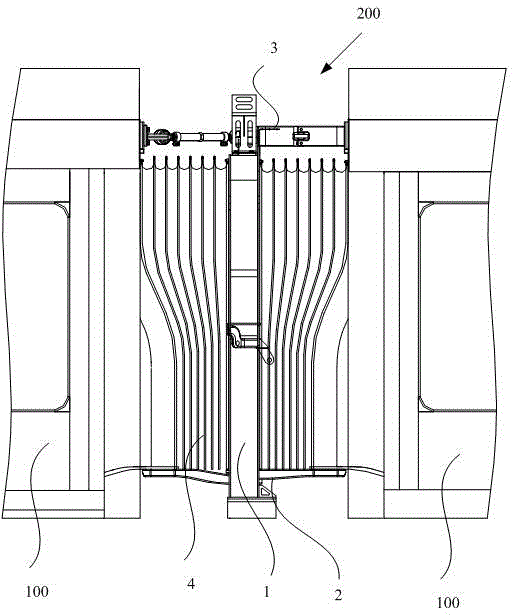

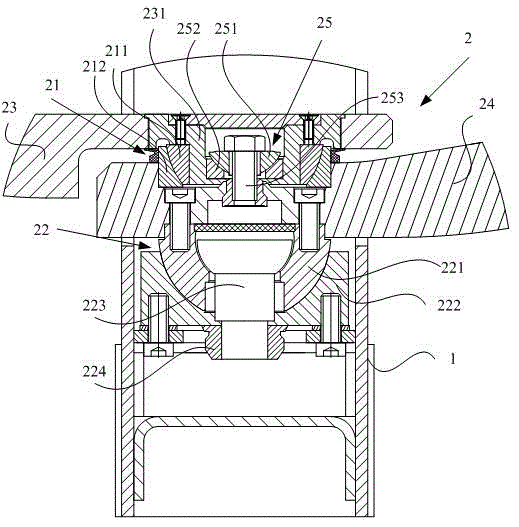

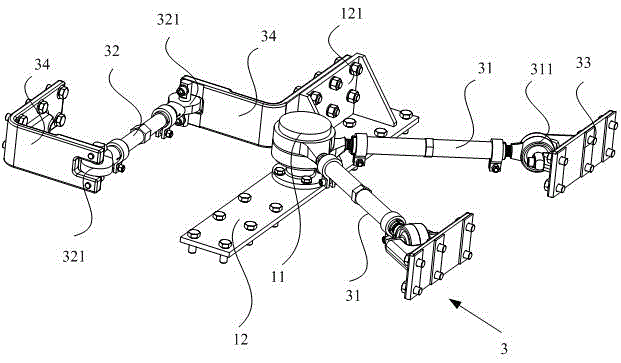

[0018] Such as Figure 1-Figure 3 As shown, the tram in this embodiment includes at least two carriages 100 and also includes a carriage hinge device 200 through which two adjacent carriages 100 are connected. Specifically, the compartment hinge device 200 includes a load frame 1, a lower hinge assembly 2, an upper hinge assembly 3 and a bellows windshield 4, and the lower hinge assembly 2 includes a first joint bearing 21, a second joint bearing 22, a first connecting plate 23 and the second connecting plate 24, the first joint bearing 21 and the second joint bearing 22 are coaxially arranged at the bottom of the bearing frame 1 up and down, and the first connecting plate 23 passes through the first joint bearing 21 is hinged on the second connecting plate 24, and the second connecting plate 24 is hinged on the carrying frame 1 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com