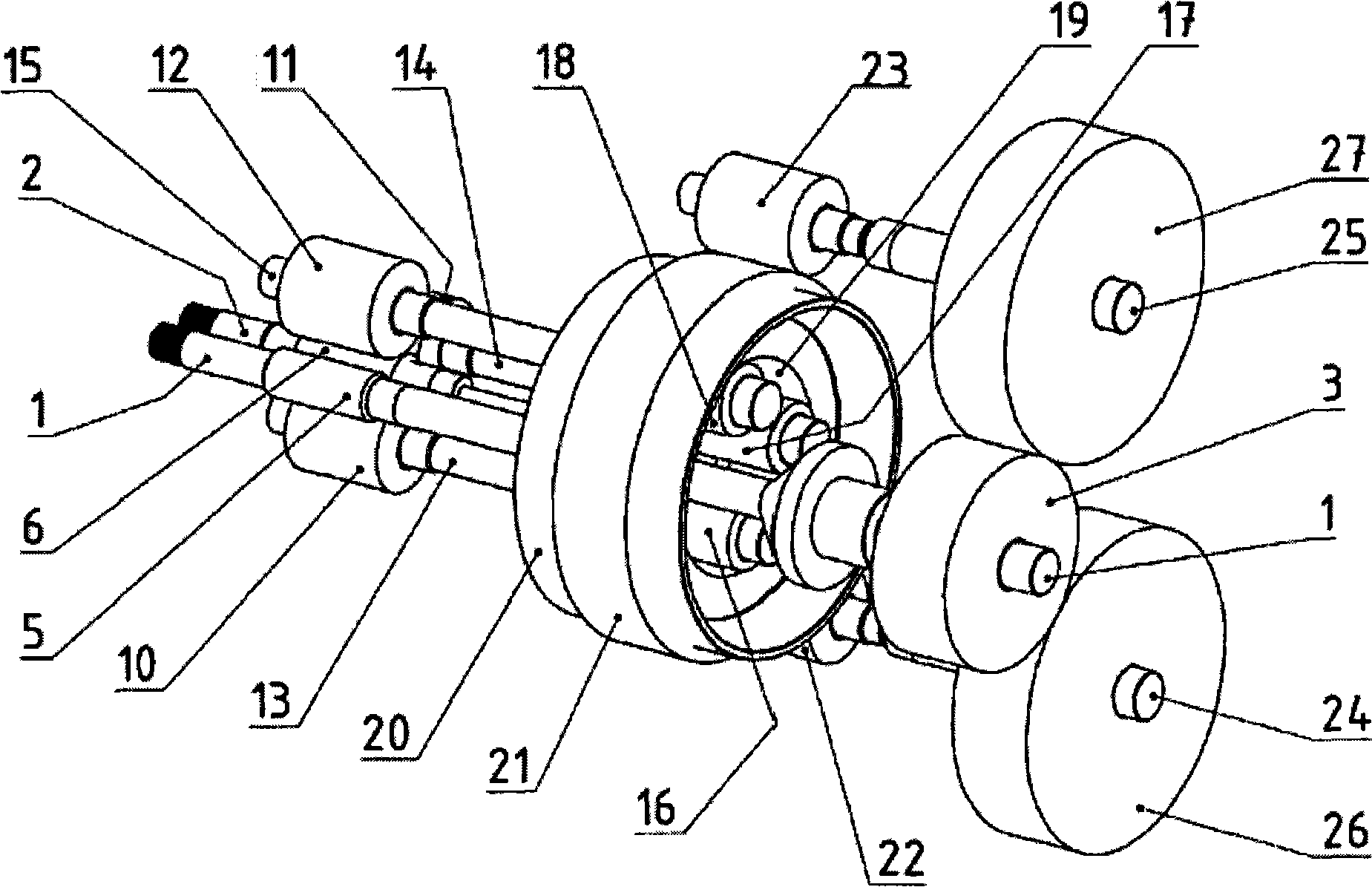

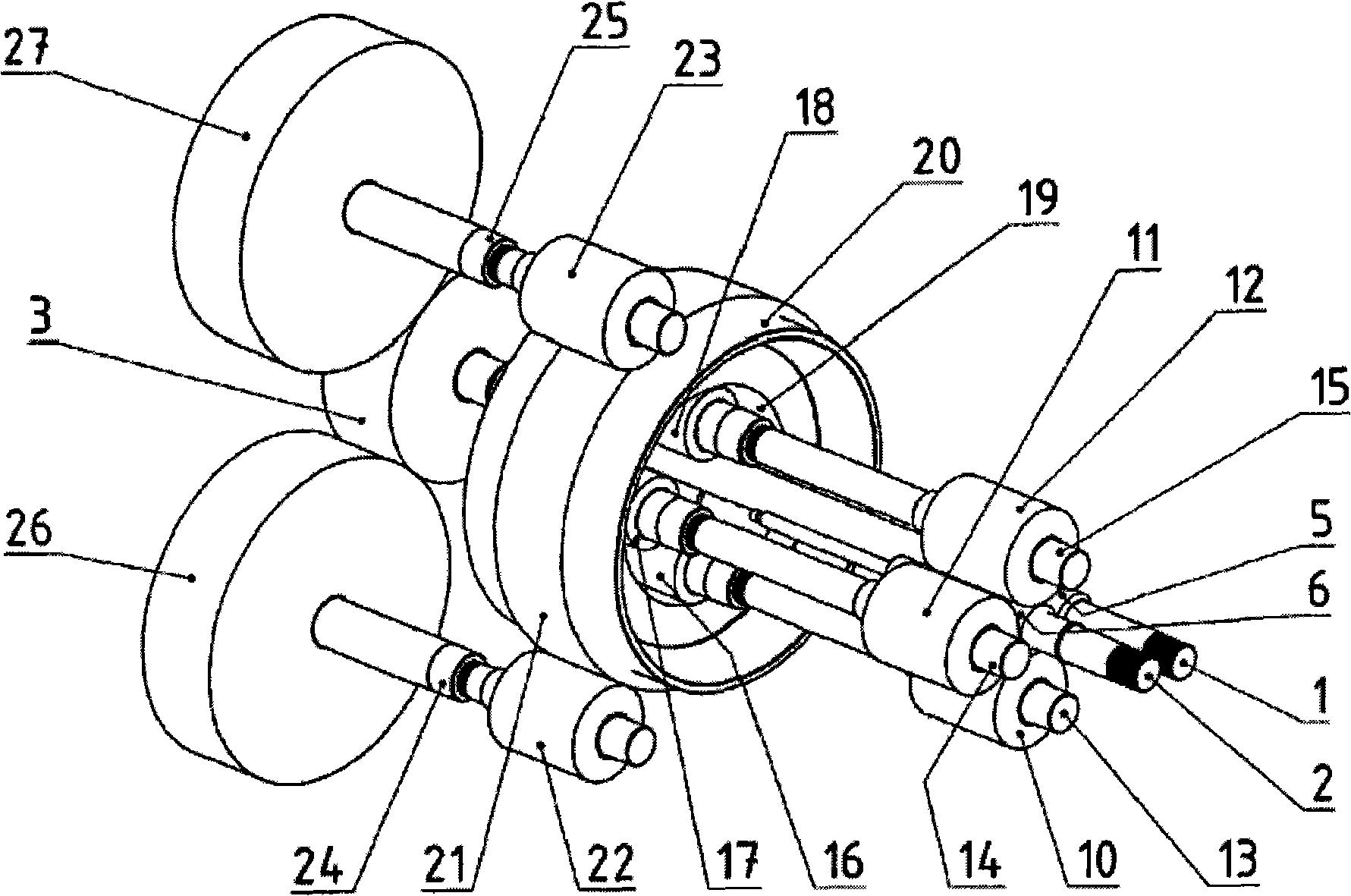

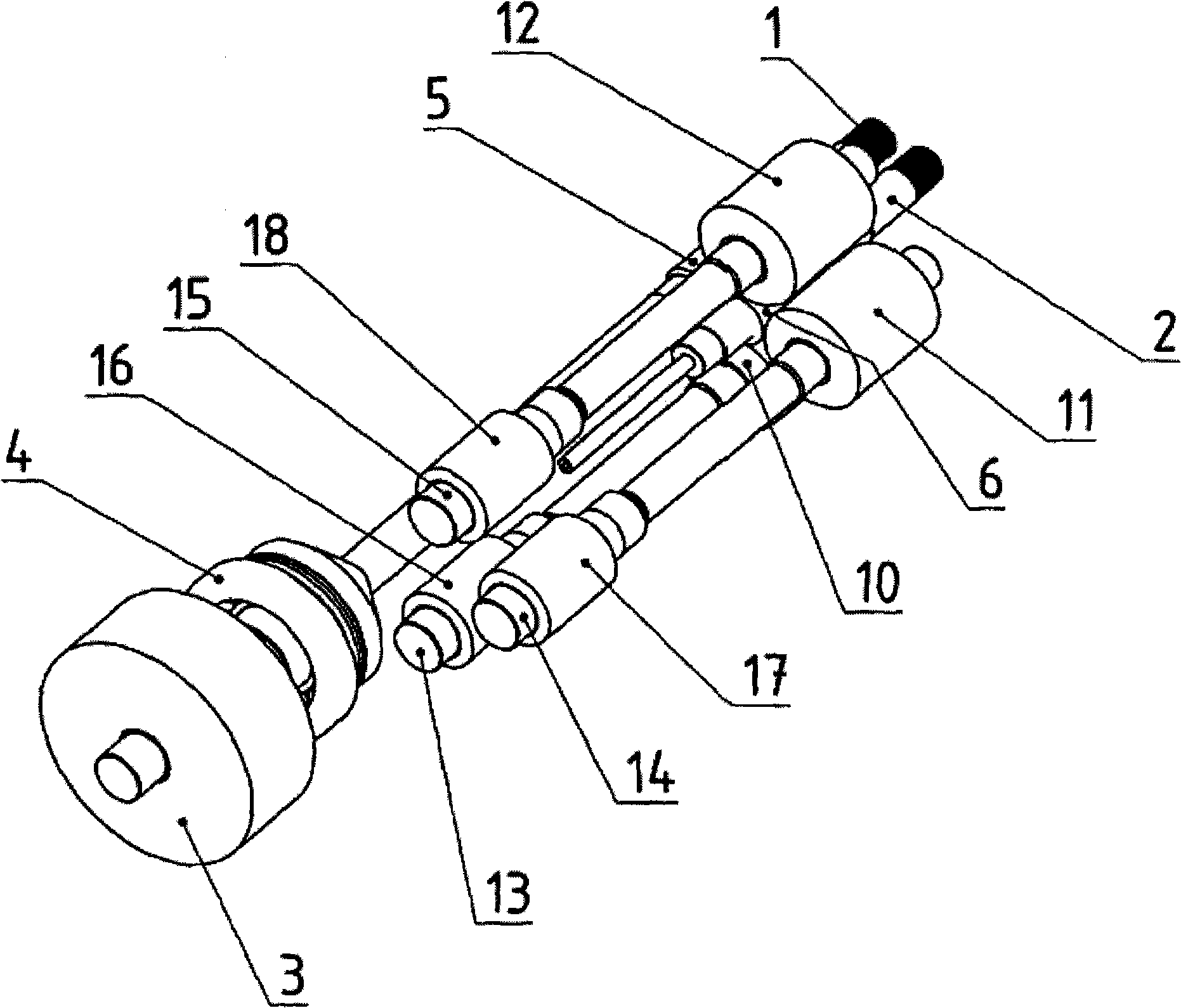

Gear system for a twin-screw extruder

A twin-screw extruder and transmission technology, applied in transmission, gear transmission, mechanical equipment, etc., can solve the problems of ring gear deformation and disadvantage, avoid shear force and elastic deformation, and achieve high operational safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The drive gear 3 is rotatably fixed on the long drive shaft 1 and meshes with the output gear of a motor not shown in the figure, or the long drive shaft 1 is directly connected with the drive motor. In addition, the long drive shaft 1 carries an axial bearing 4 and is rotatably fixed to a gear 5 that meshes with a gear 6 rotatably fixed to the short drive shaft 2. The short drive shaft 2 also has an axial bearing 9. Since the long drive shaft 1 is relatively close, the diameter of the axial bearing 9 is limited, and it is preferably designed as a double row bearing.

[0021] Gear 5 and gear 6 have helical gear teeth. The helical gear transmission is selected so that the short drive shaft 2 is pushed toward the screw, so the axial force acting on the bearing 9 of the short drive shaft 2 decreases proportionally with the increase of the torque. Therefore, the axial force on the long drive shaft 1 does increase, but this is not a problem because the axial bearing 4 can be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com