Patents

Literature

109results about How to "Improve dynamic stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

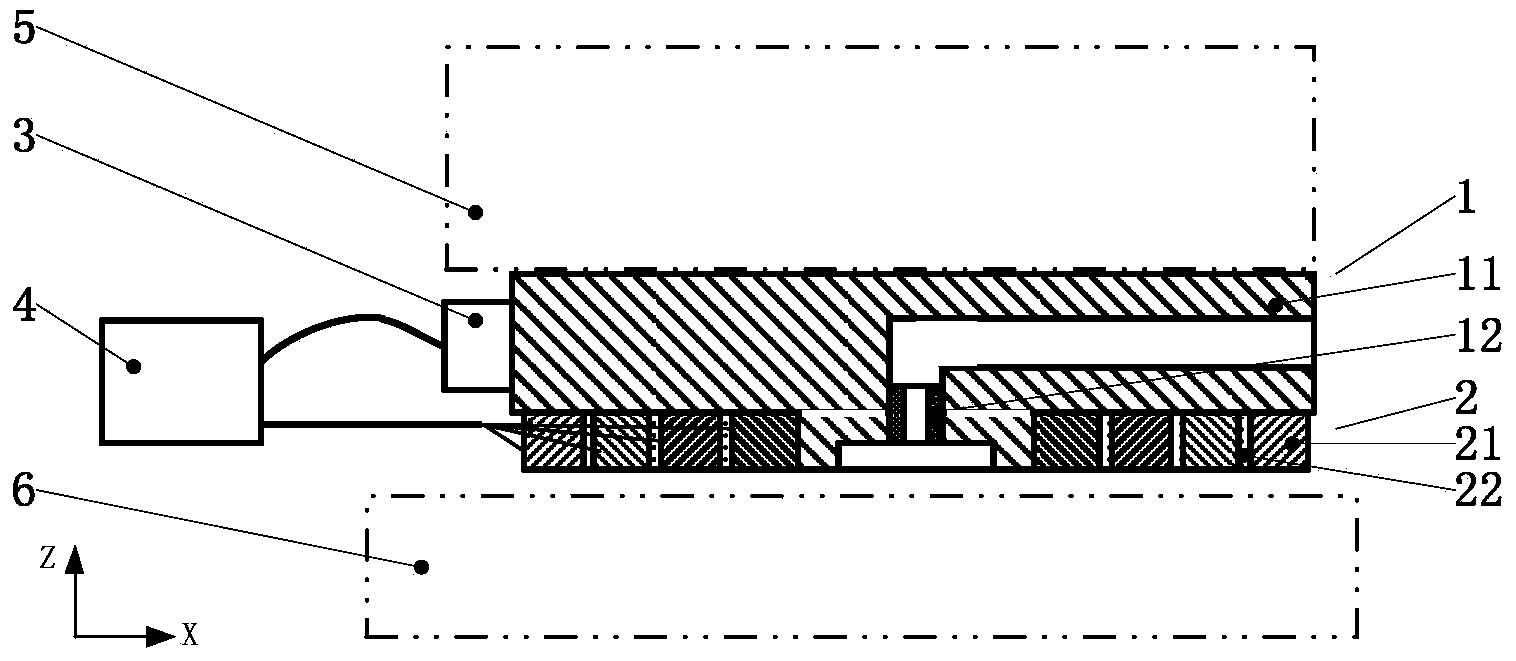

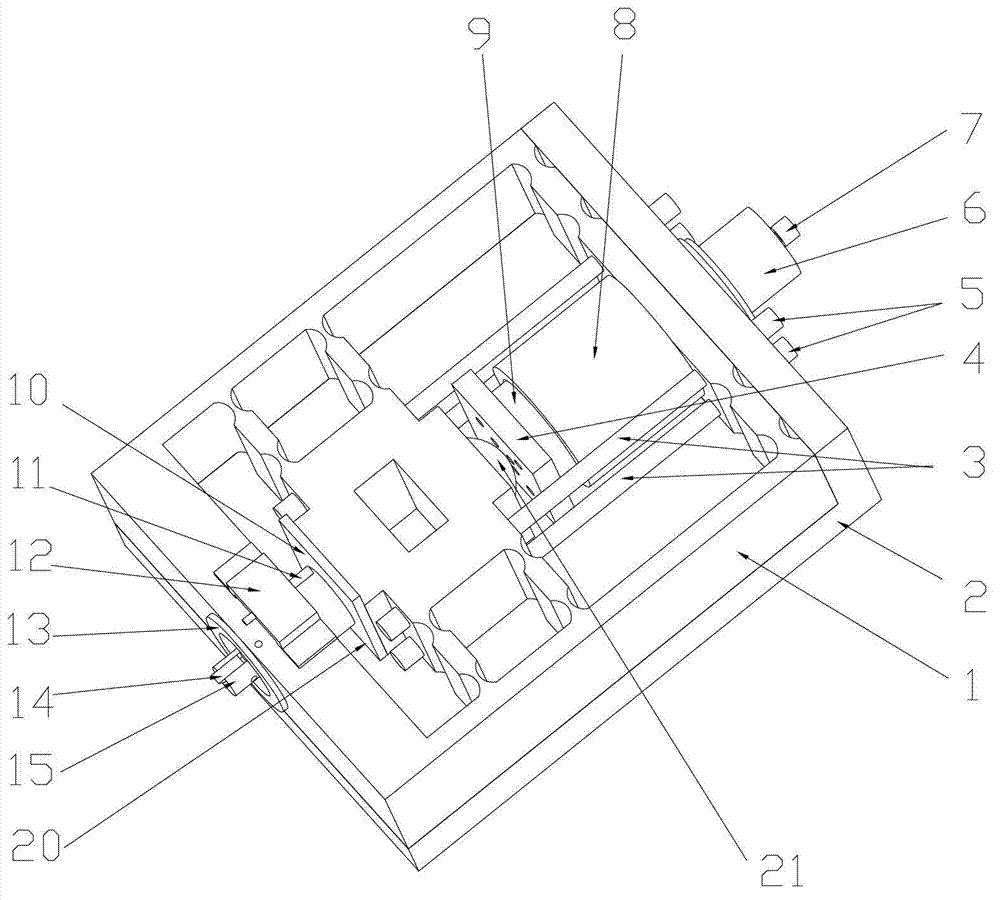

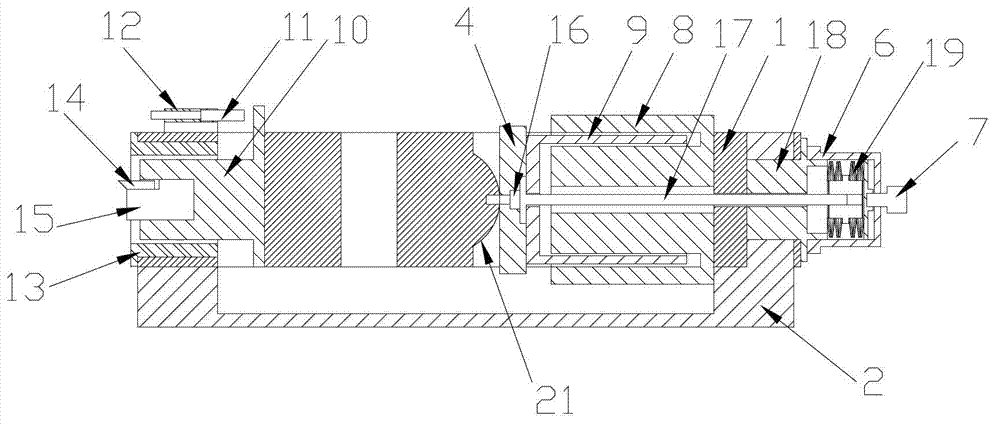

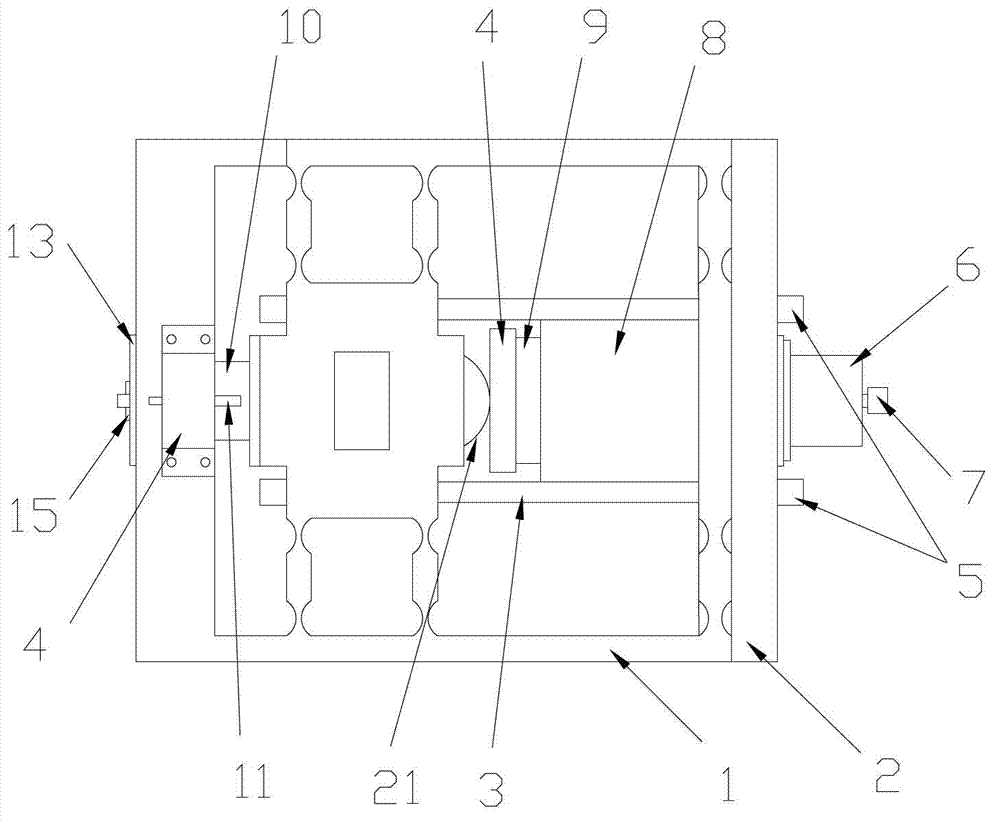

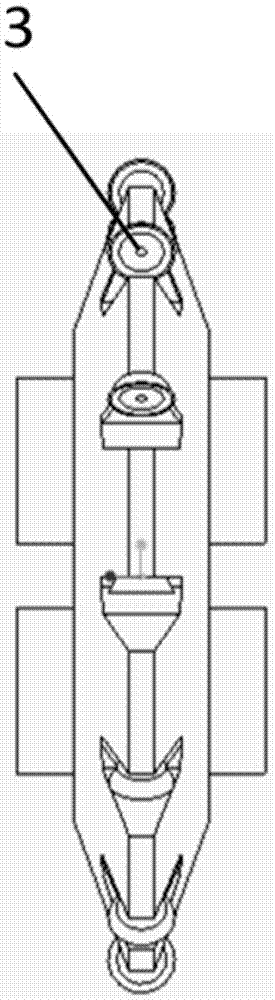

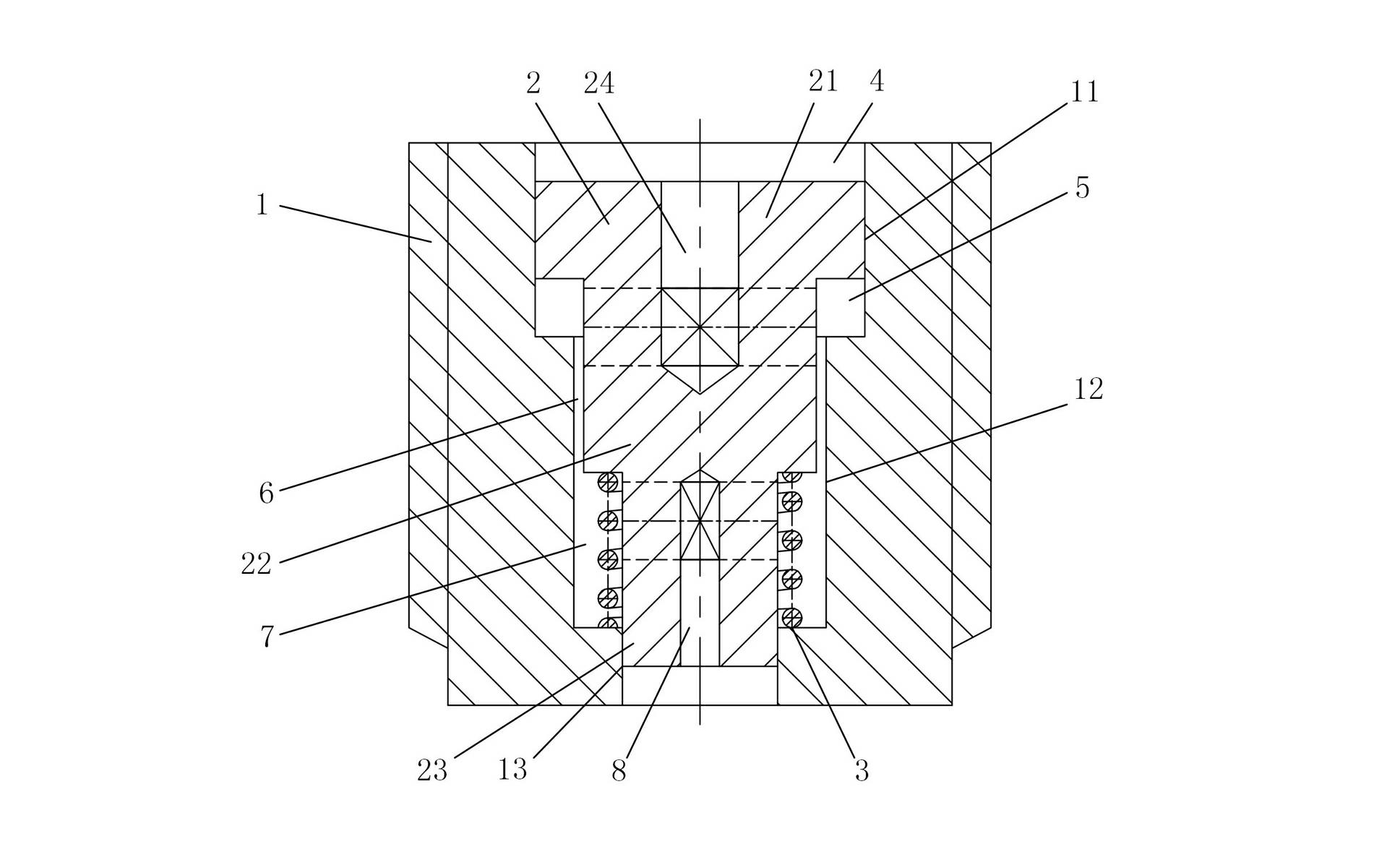

Active air-floatation support device

ActiveCN103836070AImprove dynamic stiffnessImprove dynamic stiffness characteristicsLinear bearingsGas cushion bearingsDynamic stiffnessControl signal

The invention discloses an active air-floatation support device which comprises an air-floatation support body, an air-film active adjustment unit, a support body detecting unit and a drive control unit, wherein the support body detecting unit measures the state of air-floatation support, the drive control unit generates a control signal according to a detection signal to drive and control the air-film active adjustment unit to generate an active role so as to dynamically adjust the air film form of an air-floatation support surface, thereby dynamically adjusting the pressure distribution of air film gaps of the air-floatation support device, and improving the dynamic stiffness characteristic of air-floatation support. According to the active air-floatation support device, the dynamic stiffness characteristic of air-floatation support can be significantly increased, and the purpose of stabilizing air-floatation support is achieved. In addition, the active air-floatation support device also has the characteristics of compact structure, convenience in control and high precision, thus being especially suitable for occasions of ultra-precision machining or with high-speed spindles with a high requirement on support dynamic stiffness.

Owner:HUAZHONG UNIV OF SCI & TECH

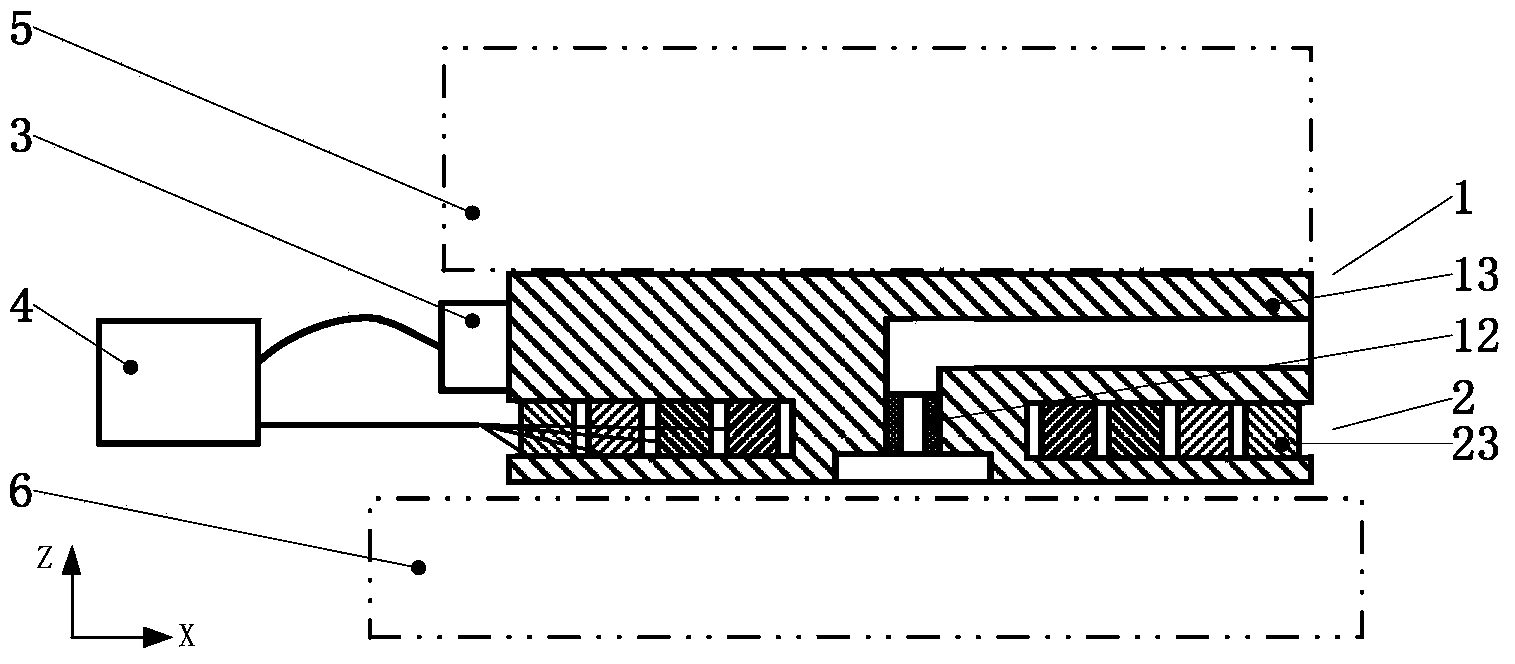

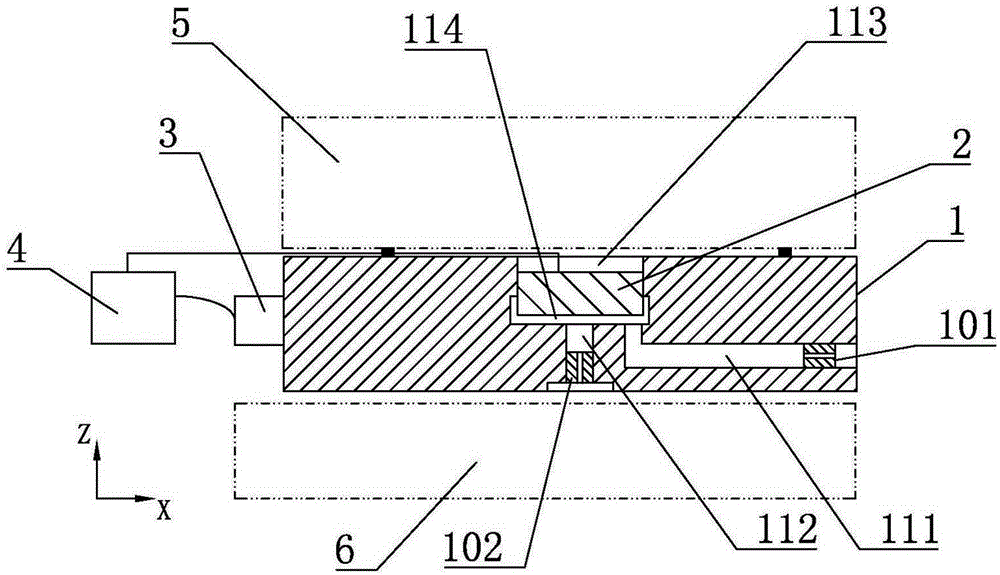

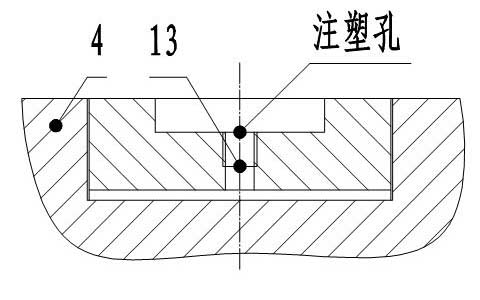

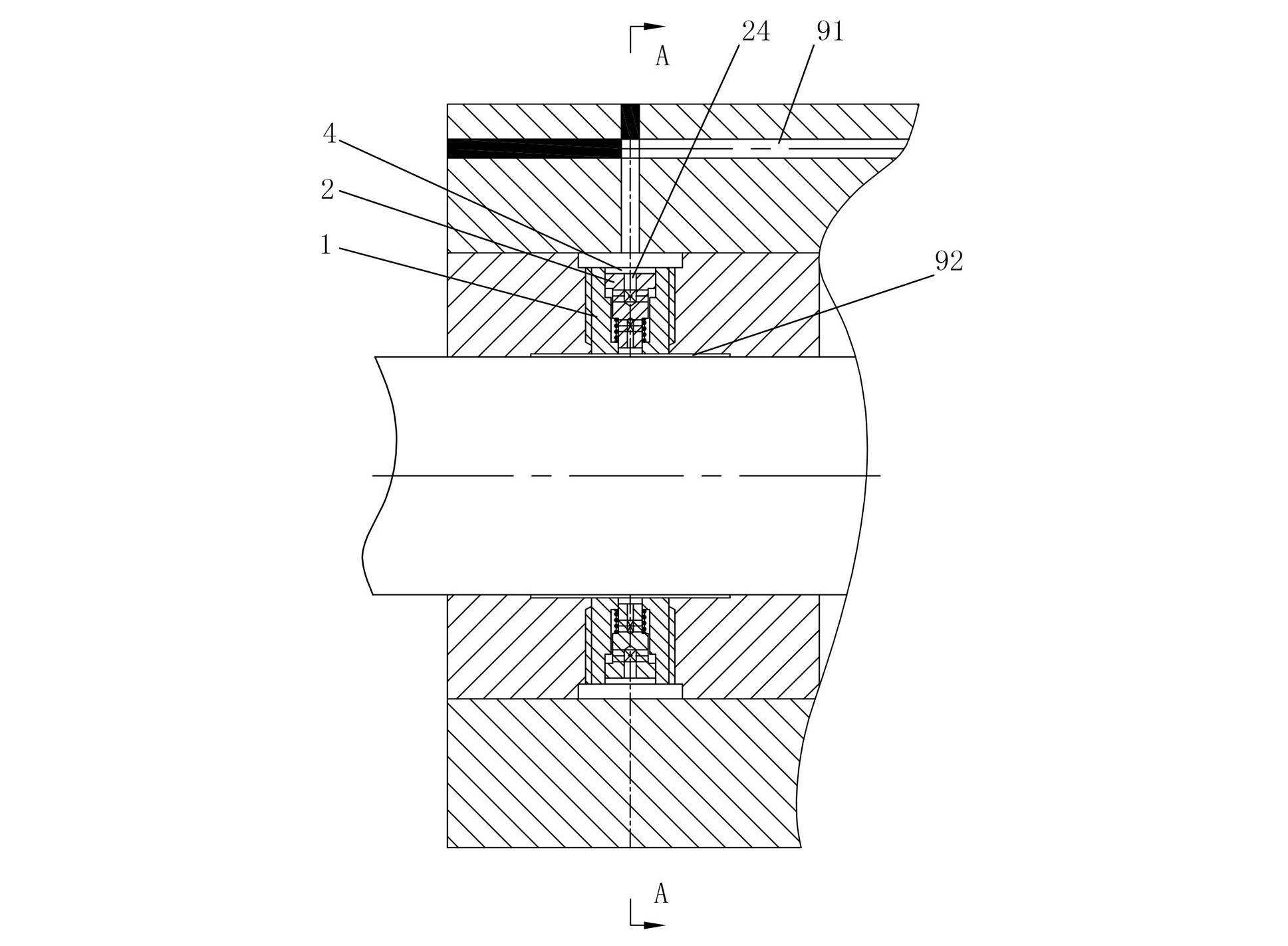

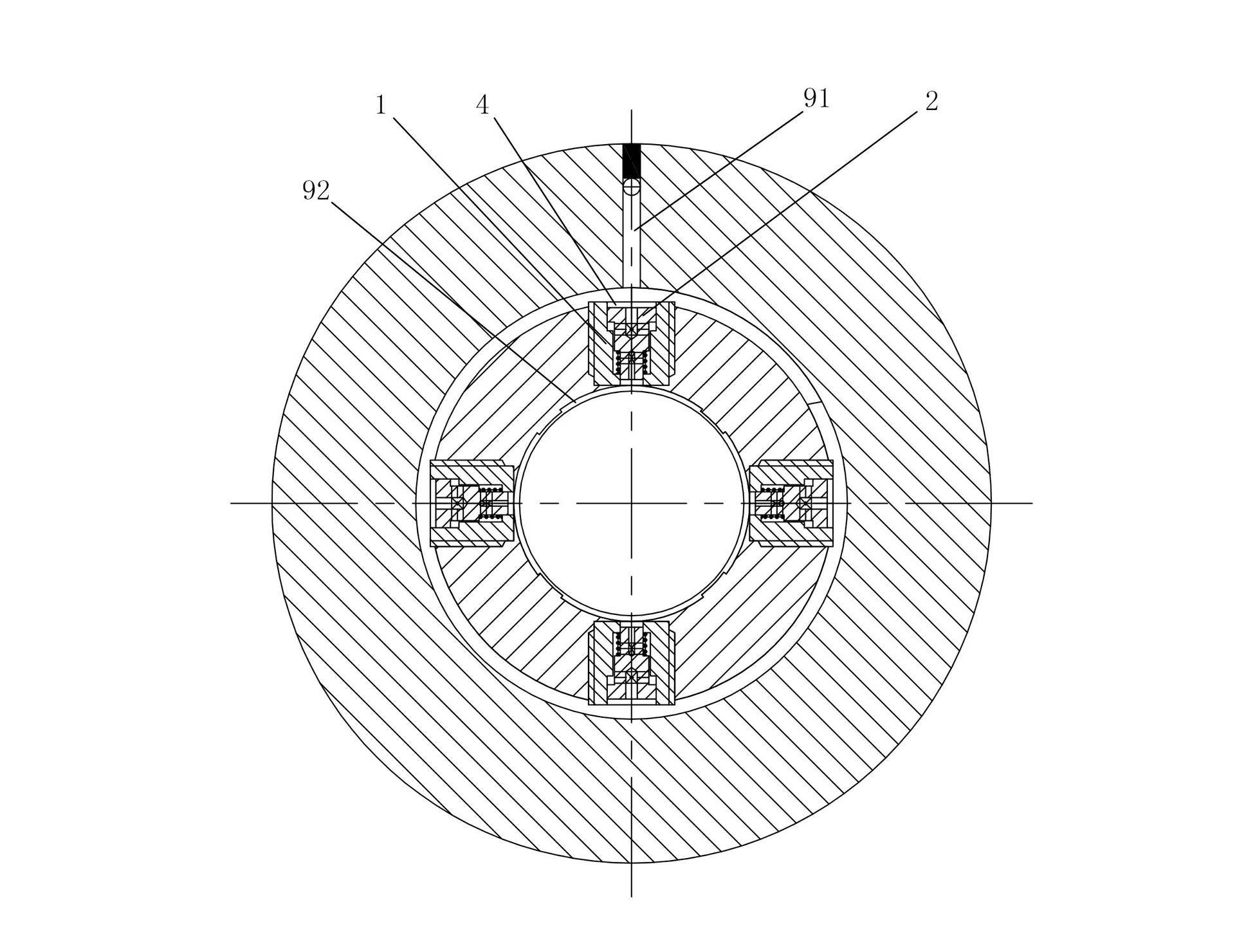

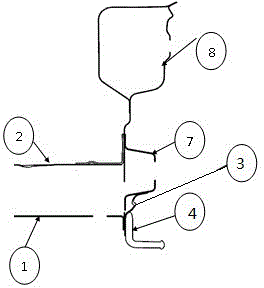

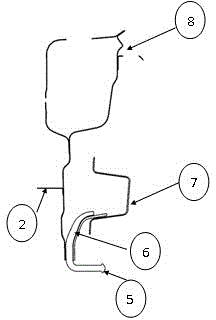

Air-floatation supporting device for actively regulating and controlling air pressure of throttling hole inlet

The invention discloses an air-floatation supporting device for actively regulating and controlling the air pressure of a throttling hole inlet. The air-floatation supporting device comprises an air-floatation supporting body, an active air-pressure regulating unit, a supporting body detecting unit and a driving control unit, wherein an air inlet hole, a throttling hole and a regulating unit mounting hole are formed in the air-floatation supporting body; an air inlet valve and an air outlet valve are arranged at the air inlet of the air inlet hole and the air outlet of the throttling hole respectively; a regulating cavity is formed between the active air-pressure regulating unit and the air-floatation supporting body; the supporting body detecting unit is used for real-time detection of the speed and acceleration of up-and-down motion of the air-floatation supporting body and / or the distance of the air-floatation supporting body relative to an air-floatation guide rail below the air-floatation supporting body; and the driving control unit is used for performing filtering, amplification and data processing of signals detected by a detecting device to generate driving signals to drive the active air-pressure regulating unit to deform to change the volume of the regulating cavity. The air-floatation supporting device can effectively inhibit micro-vibration of air-floatation supporting and meanwhile has the characteristics of compact structure, convenience in control and high precision.

Owner:HUAZHONG UNIV OF SCI & TECH

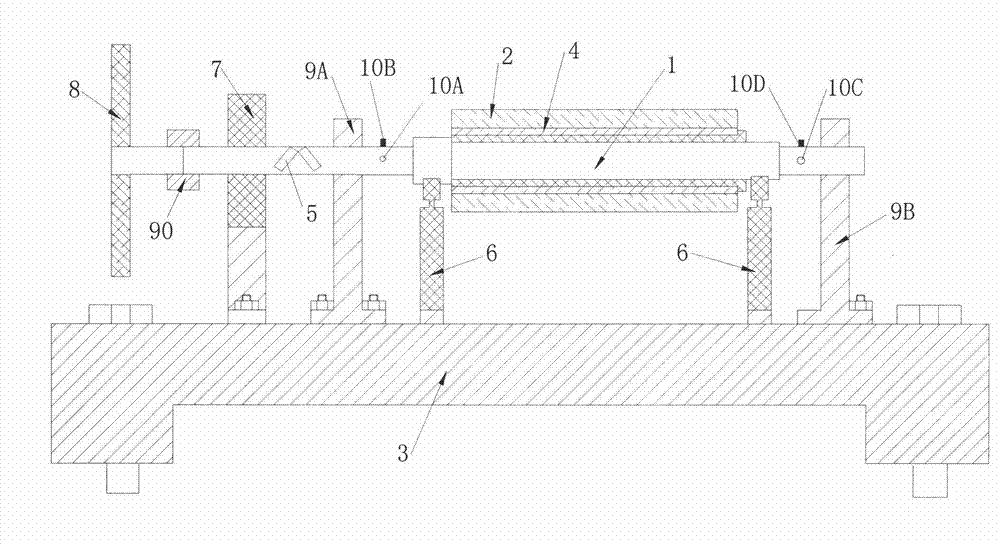

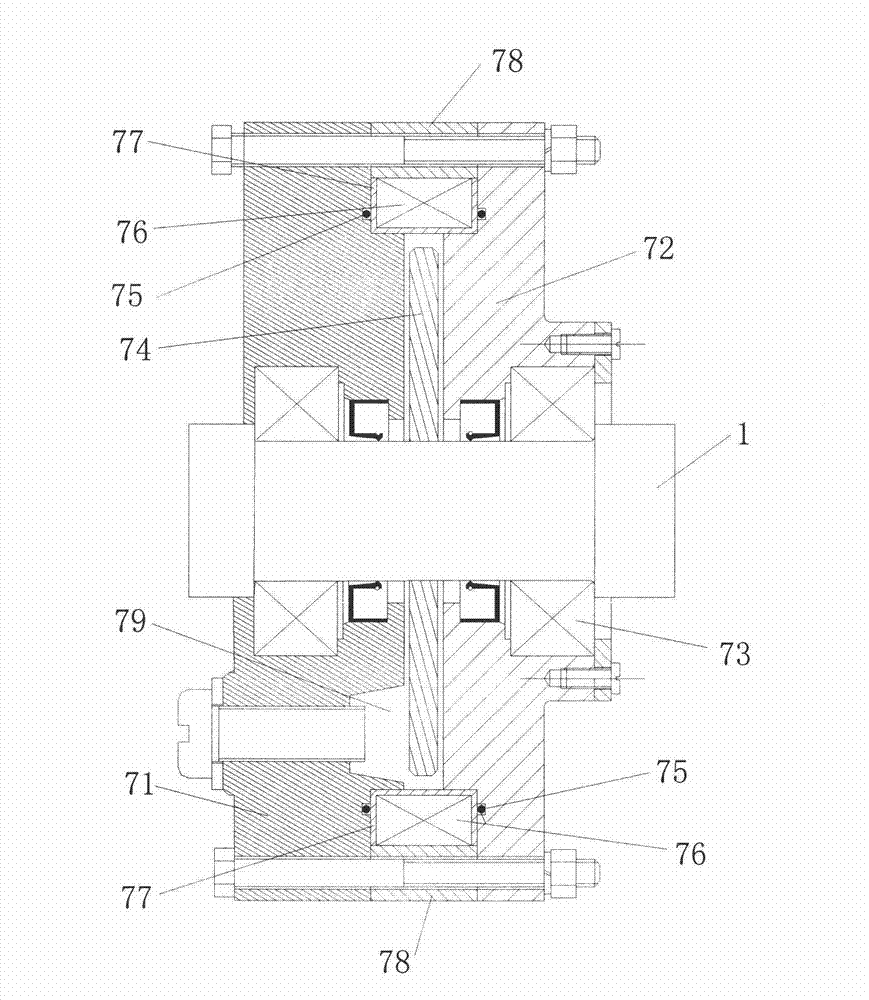

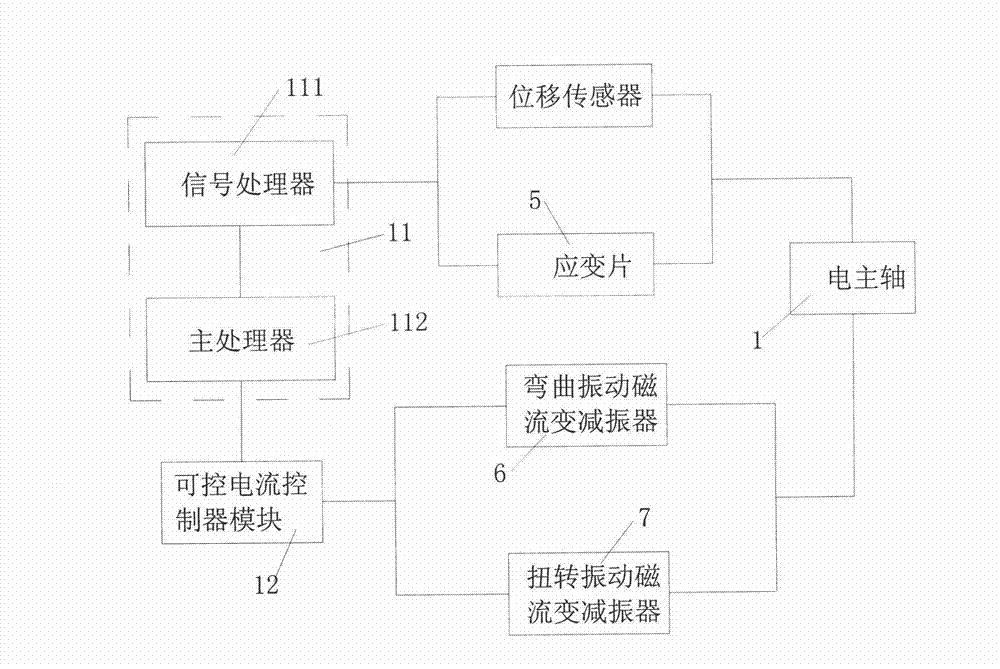

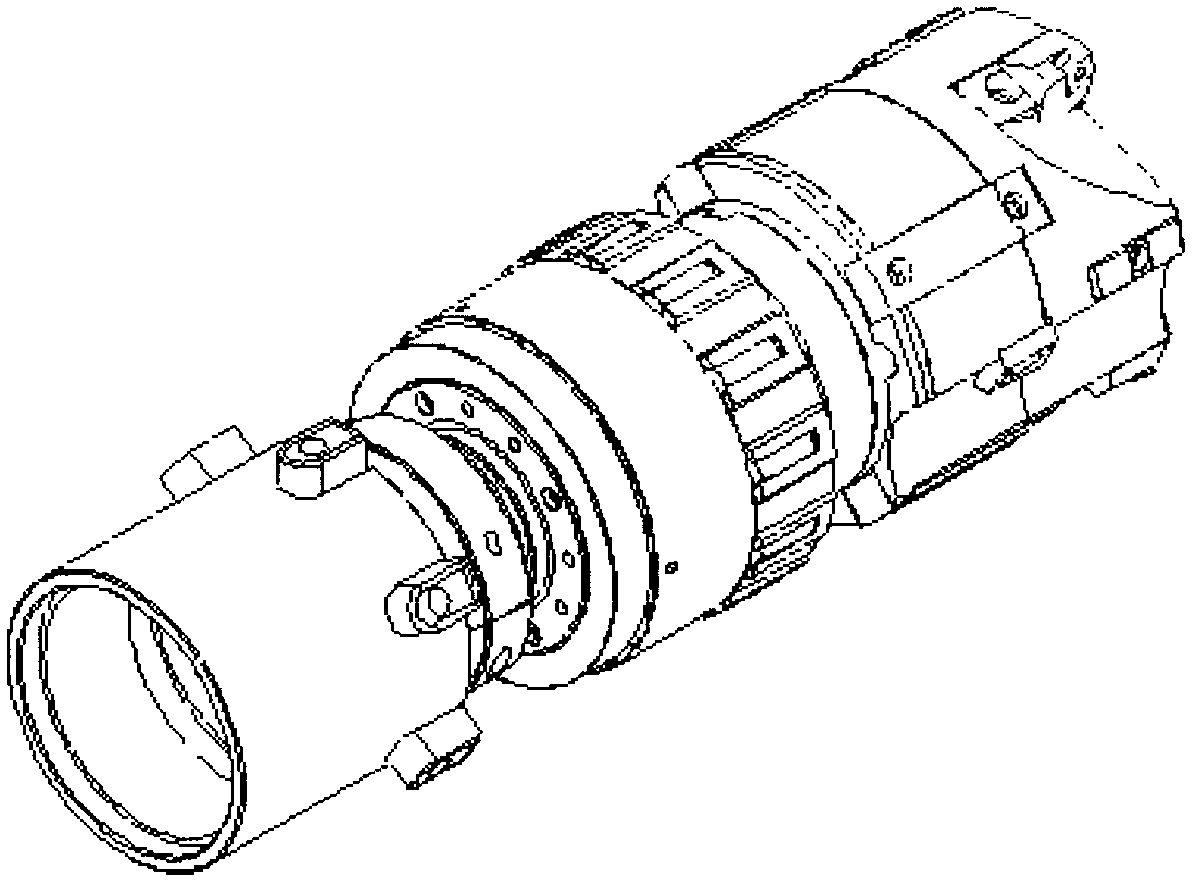

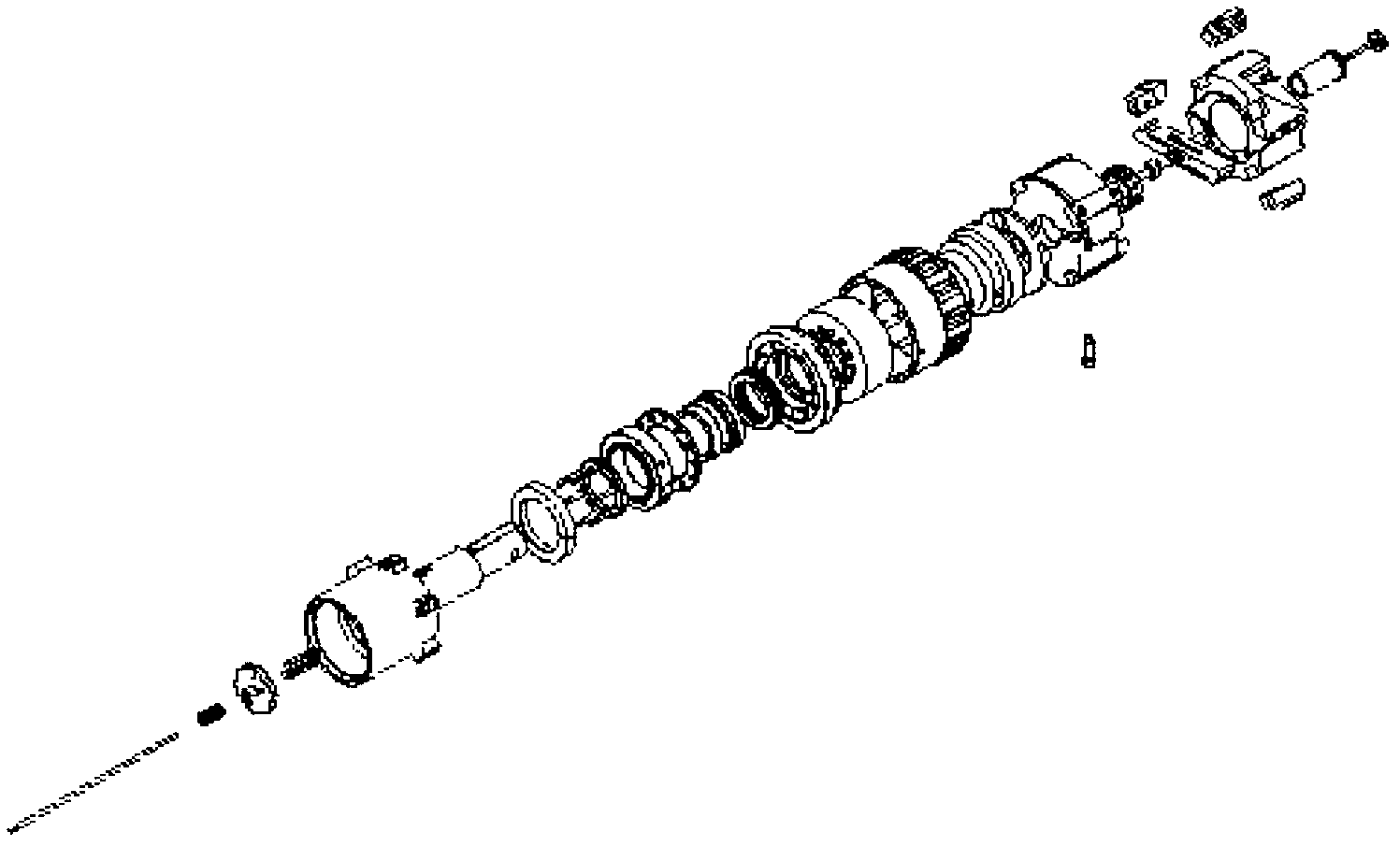

Electric spindle semi-active vibration control test stand, system and electric spindle control method

InactiveCN102853979AImprove vibrationVibrate in real timeMachine part testingVibration testingSemi activeMechanical models

The invention discloses an electric spindle semi-active vibration control test stand, a system and an electric spindle control method, wherein the electric spindle semi-active vibration control method comprises the following steps: through a processor, an electric spindle torsional coupled vibration signal is separated by using an experience modal decomposition and Hilbert transformation method so as to obtain a test frequency and a test phase; through an electric spindle intensive parameter equivalent mechanical model and the design parameter of the electric spindle system, the theory frequency and theory phase of the bending vibration and the torsional vibration of the electric spindle are obtained; through a force synchronizing vibration control model, the testing frequencies of the bending vibration and the torsional vibration of the electric spindle are combined, the test phase, the theory frequency and the theory phase are combined, so that a first pulse-width modulation (PWM) signal of a magneto-rheological absorber used for controlling the bending vibration and a second PWM signal of the magneto-rheological absorber used for controlling the torsional vibration are generated respectively. Therefore the bending vibration and the torsional vibration of the electric spindle can be synchronously controlled.

Owner:JIAXING UNIV

Automatically expanding and shrinking scraping-rolling combined deep hole cutter

ActiveCN102152118AImprove static stiffnessImprove dynamic stiffnessOther manufacturing equipments/toolsBoring headsMatched pairEngineering

The invention discloses an automatically expanding and shrinking scraping-rolling combined deep hole cutter. A scraping part of the cutter comprises at least one pair of scrapers, a top block, and a reset device; the top block is positioned in the centre of a thick boring head body and is provided with a taper structure, and a corresponding conical surface is jacked by an endocentric end of the scraper; and the reset device is arranged between each matched pair of scrapers for resetting the scrapers; and a rolling part of the cutter comprises a rolling path and a keeper. The combined boring head also comprises a manipulating device which comprises a first driving part and a second driving part, wherein the first driving part drives the keeper to move axially along a spindle, and the second driving part penetrates a centre hole and acts on the top block in order to drive the top block to move axially along the spindle. The cutter disclosed by the invention is compact in structure, high in processing precision, convenient to use, and can expand and shrink automatically.

Owner:德州普利森机床有限公司

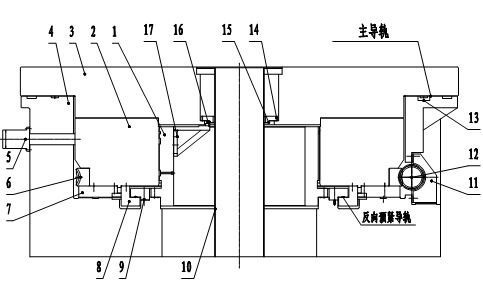

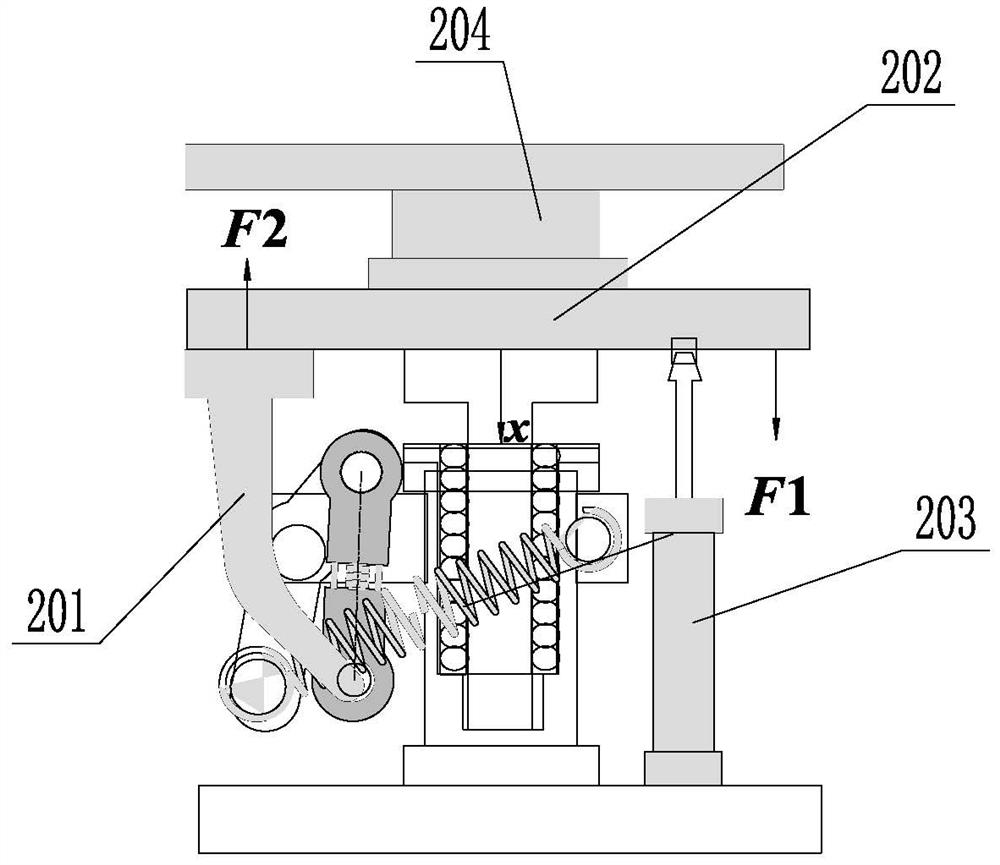

Cutter servo micro-feeding mechanism

InactiveCN102862084AIncrease the itineraryImprove dynamic stiffnessFeeding apparatusMaintainance and safety accessoriesStatorEngineering

A cutter servo micro-feeding mechanism relates to a part processing displacement mechanism, is based on a voice coil motor and is characterized by being fast, high in frequency response and accuracy, large in journey, multiple in shock buffer effect, double in pre-tightening effect and good in cutter cutting rigidity and force conductivity. The cutter servo micro-feeding mechanism is provided with a flexible hinge, a base, an elastic connection rod, an adapter plate, an elastic connection rod adjustment nut, an end cover, a spring adjustment nut, a voice coil motor stator, a voice coil motor rotor, an air hydrostatic guideway inner rail, a capacitance displacement sensor, a sensor support frame, an air hydrostatic guideway outer rail, a lathe tool, a tool bit clamp, a transmission shaft, a pre-tightening nut and a disc spring.

Owner:XIAMEN UNIV

Large and heavy numerical control static-pressure revolving platform

ActiveCN102059558AAccuracy is easy to guaranteeStrong craftsmanshipLarge fixed membersManufacturing cost reductionNumerical control

The invention discloses a large and heavy numerical control static-pressure revolving platform. In the invention, a constant-current static-pressure closed guide rail is used for axial unloading and positioning; a constant-current opposed oil cavity is used for radial positioning; a radial damping oil cylinder is used for locking and applying Coulomb frictional damping; a double-lead worm gear isused for precision scale division; a closed loop control system consists of round gratings; and the revolving platform has high scale division accuracy, repeated location accuracy, heavy load and high rigidity and can realize accurate location at any angles and bear heavy cutting load. The large and heavy numerical control static-pressure revolving platform disclosed in the invention mainly comprises six parts of a supporting part, a scale division rotating part, a closed guide rail part, a worm part, a round grating full closed loop part and a radial locking part. The processing and assembling process of the large and heavy numerical control static-pressure revolving platform can improve the accuracy and the production efficiency of the static-pressure revolving platform, reduce the manufacturing cost and meet the requirement of the industrialization of large high-grate numerical control machine tools in China for large and heavy numerical control static-pressure revolving platforms.

Owner:NANJING GONGDA CNC TECH

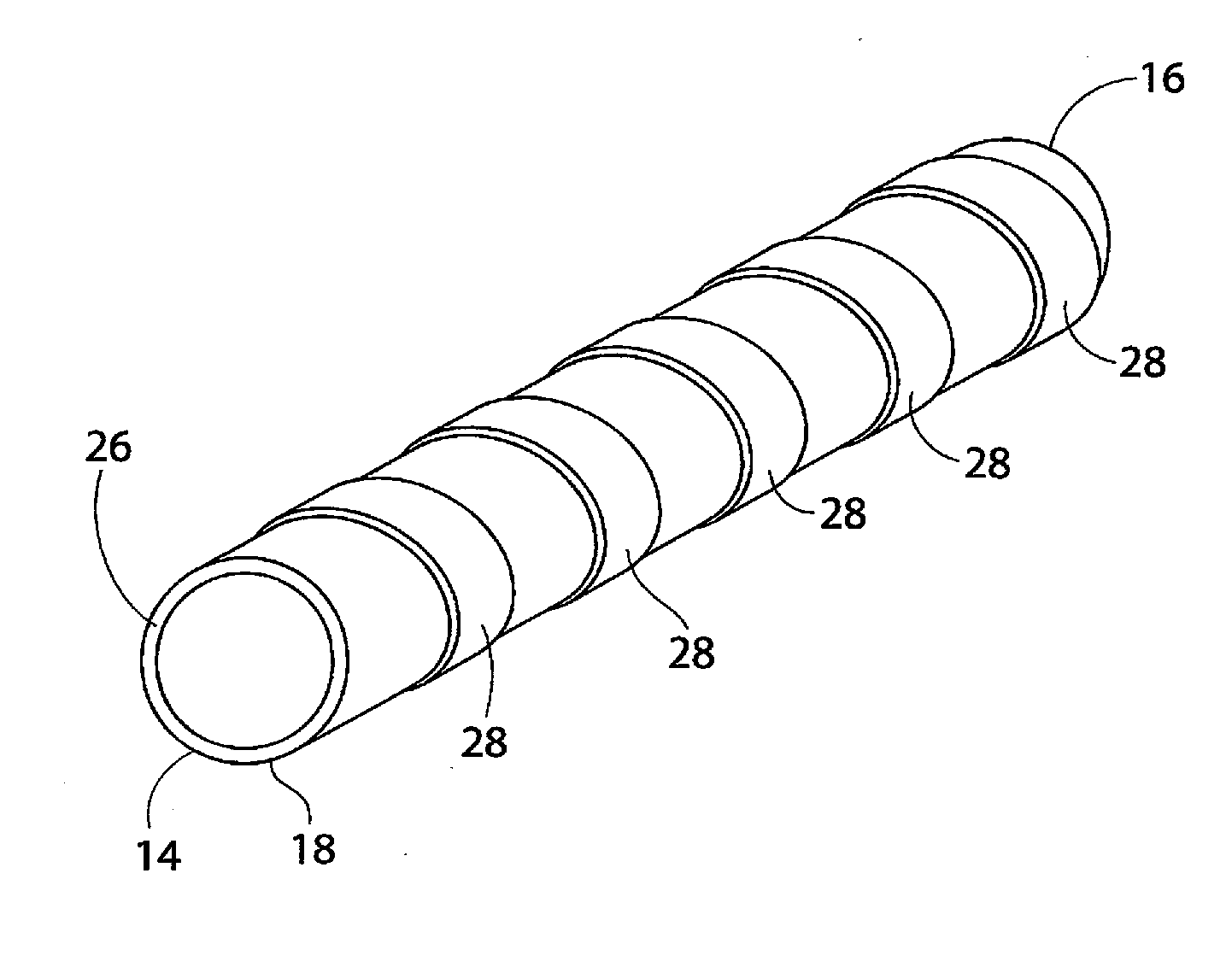

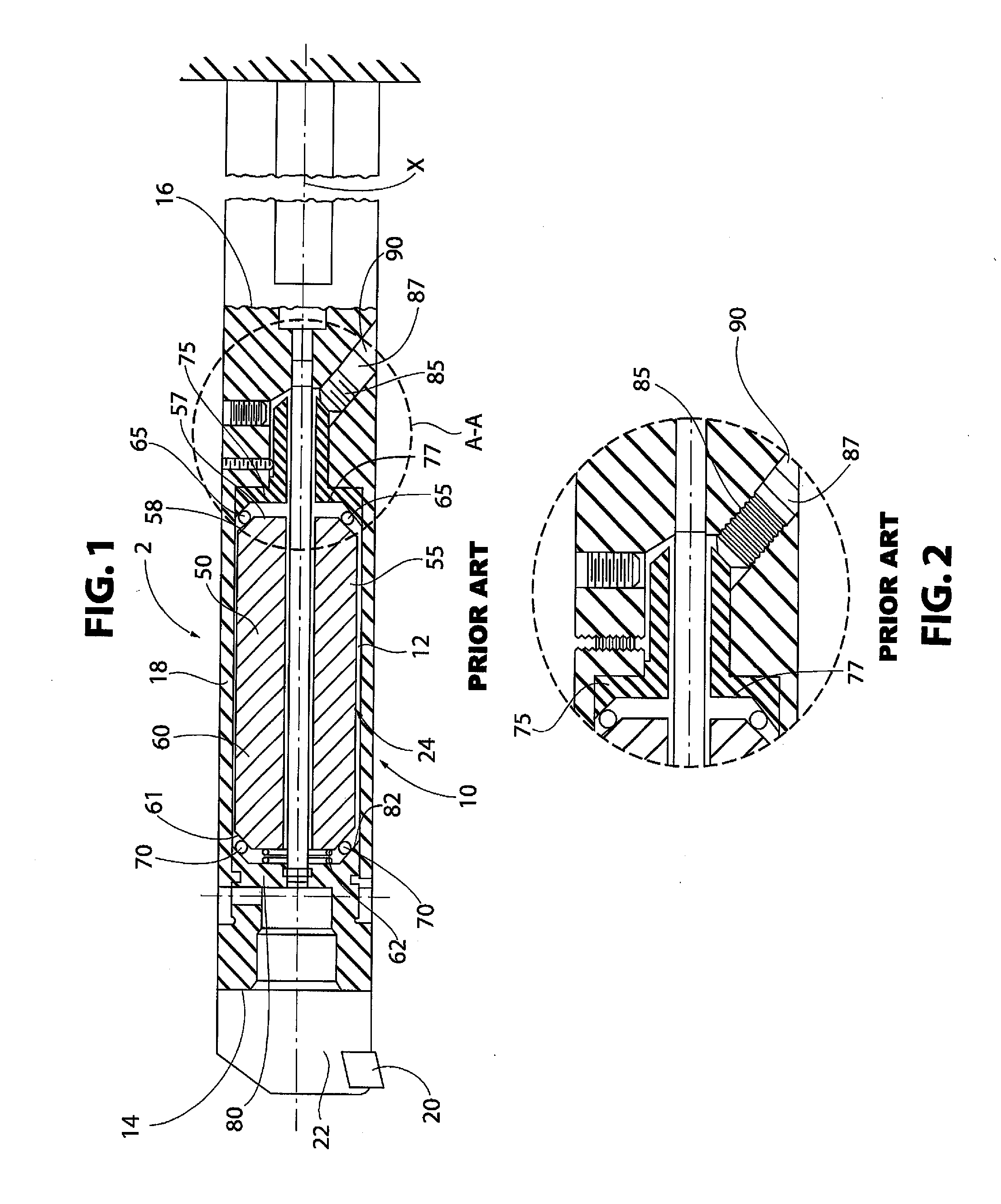

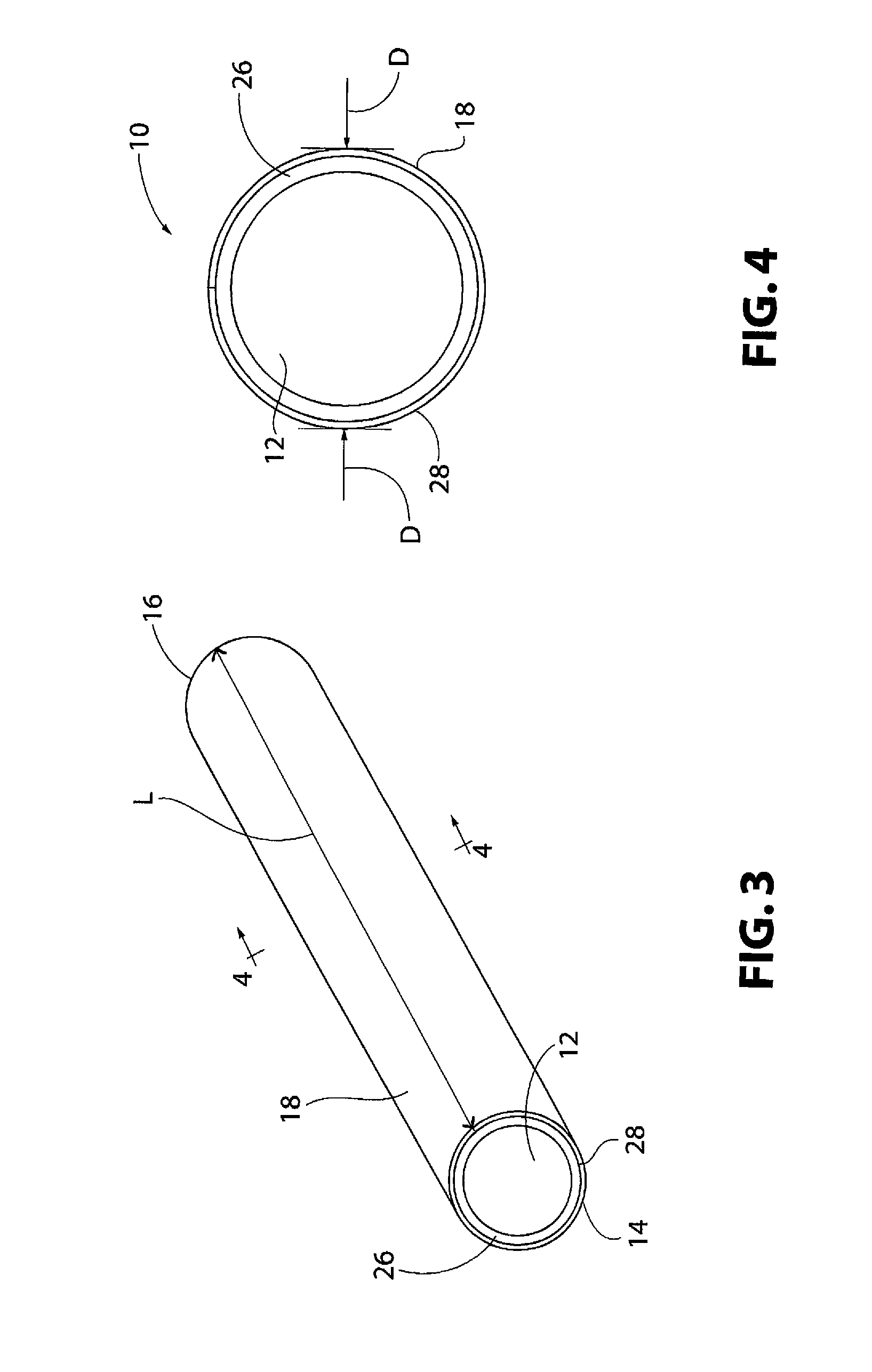

"Boring Bar with Improved Stiffness"

ActiveUS20150258612A1High dynamic stiffnessImprove dynamic stiffnessTransportation and packagingWorkpiecesDistal portionPlasma diffusion

A tunable or tuned boring bar having increased stiffness is provided. Increasing the stiffness of the bar increases the natural frequency, thereby reducing directional deformation of the bar during use. The tunable boring bar includes a distal portion configured to support a tool, a proximal portion configured for attachment to a support structure of a metalworking machine, and a body, which is at least partially tubular, extending between the proximal portion and the distal portion. The tubular portion of the body has an elongated cylindrical cavity. The body of the boring bar includes a core layer formed from a first material and a coating layer formed from a second material. The second material has a higher modulus of elasticity than the first material. In certain configurations, the coating layer is bonded to the core layer by cladding, welding, chemical adhesives, chemical vapor deposition, pulsated plasma diffusion, or combinations thereof.

Owner:KENNAMETAL INC

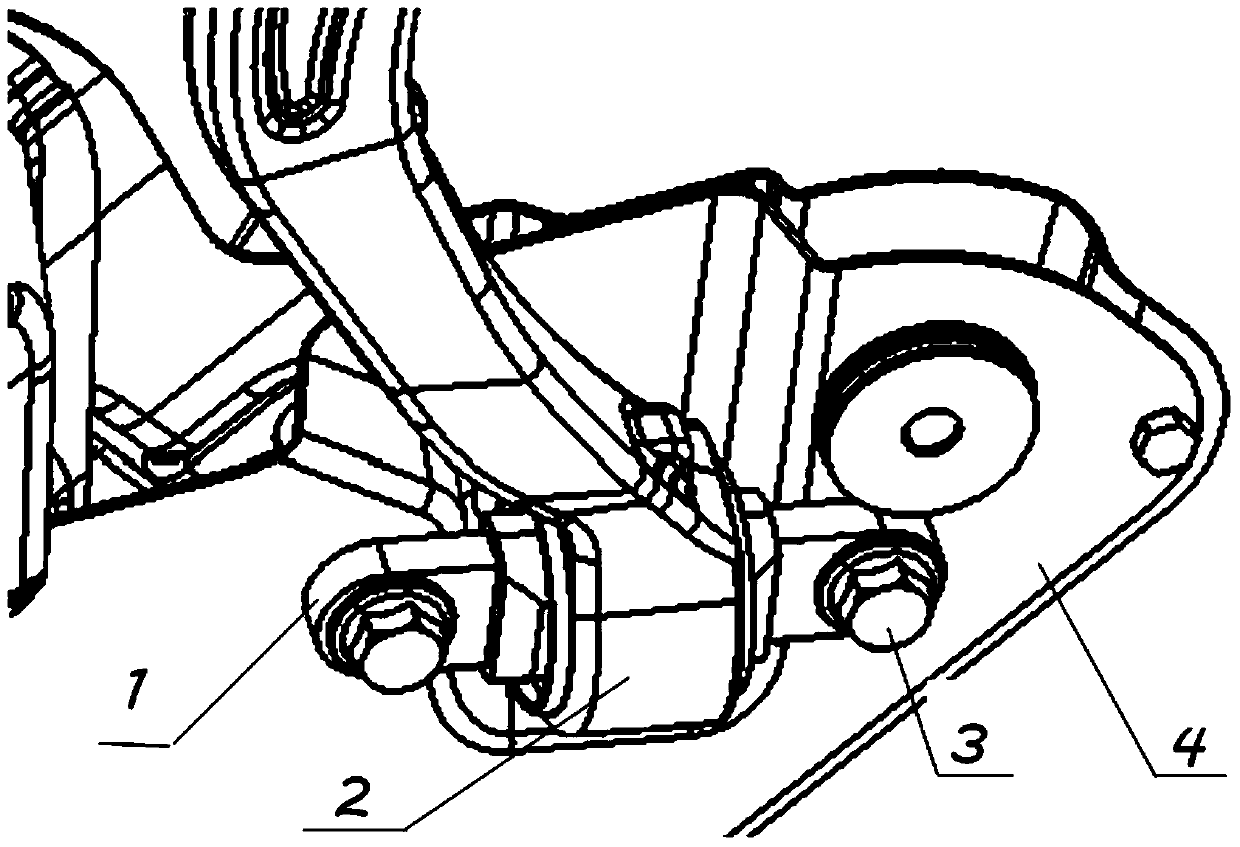

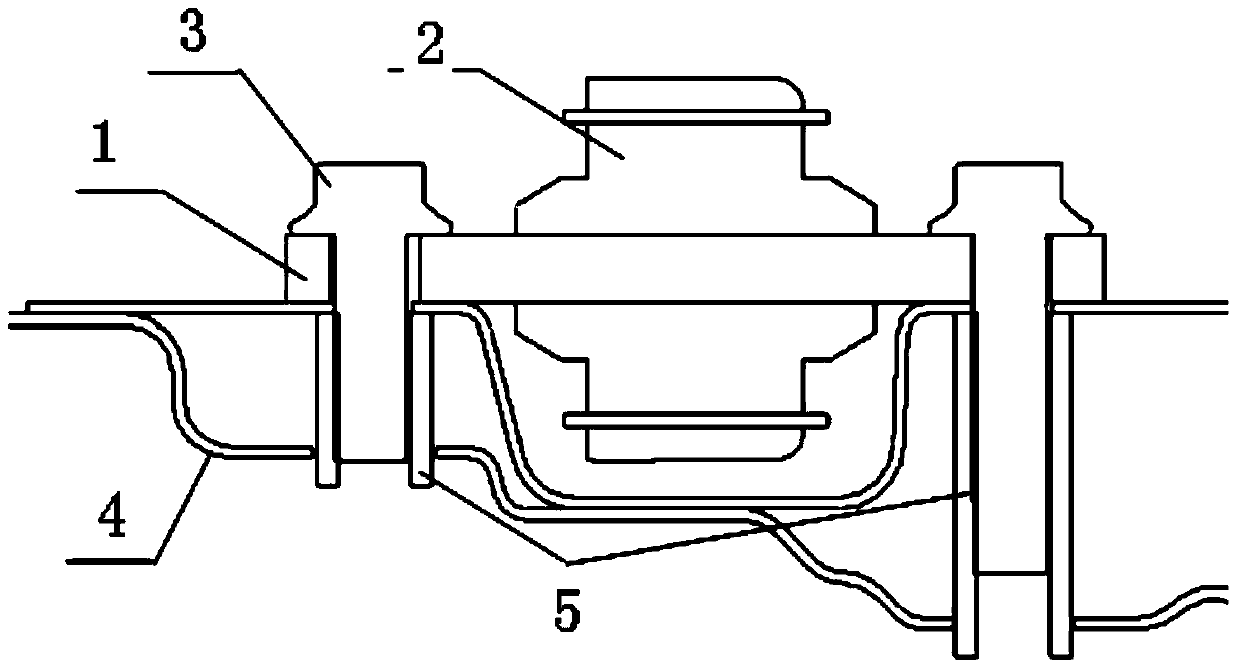

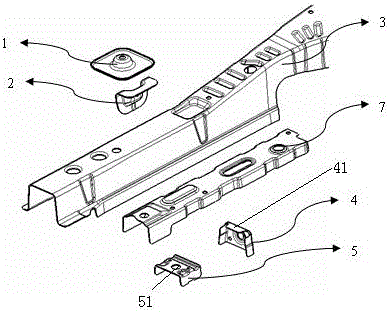

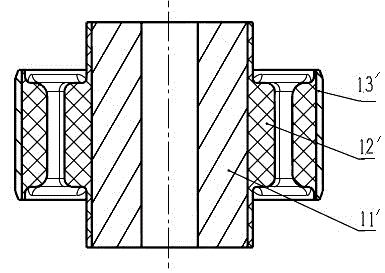

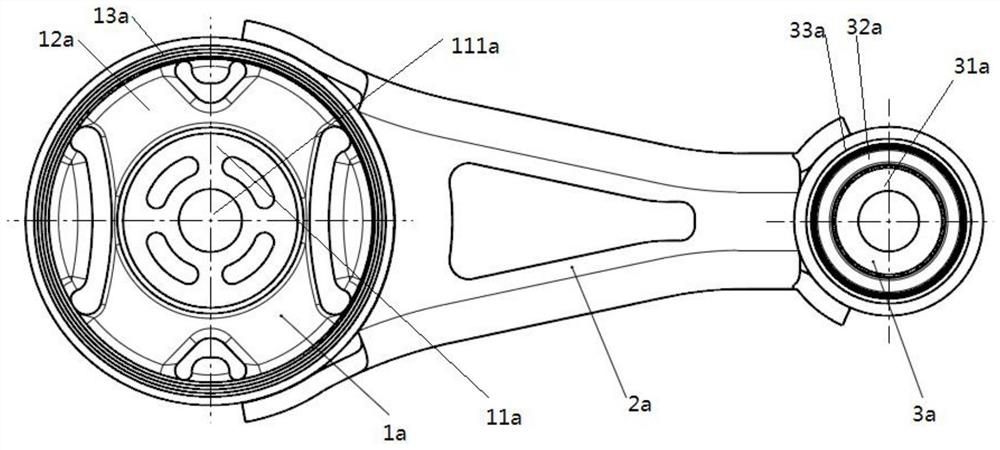

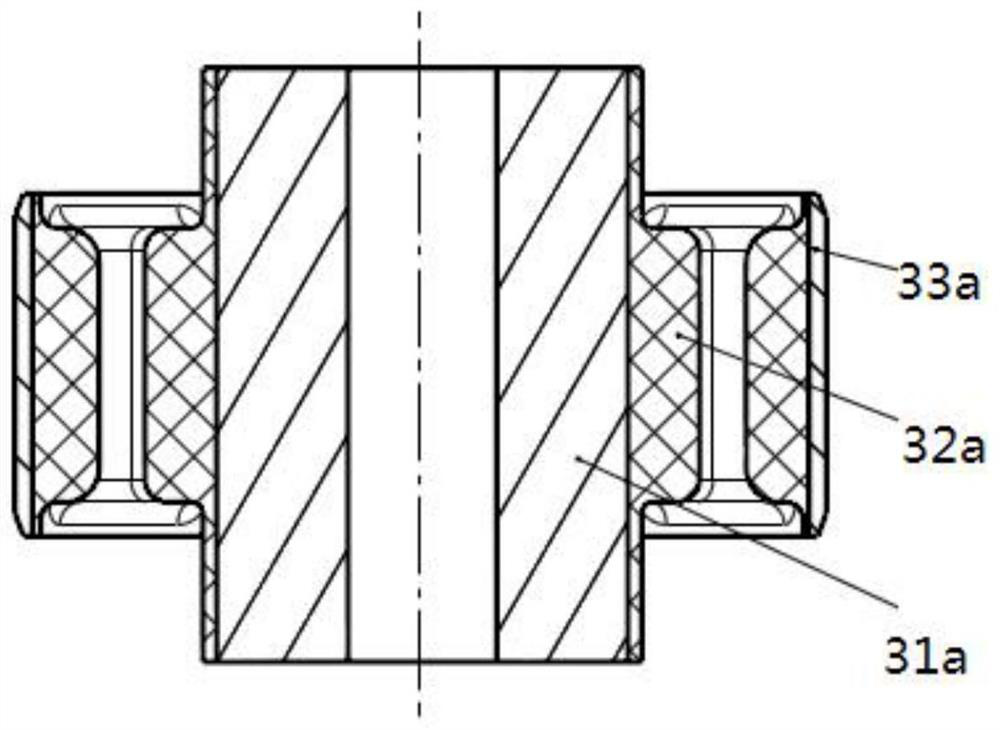

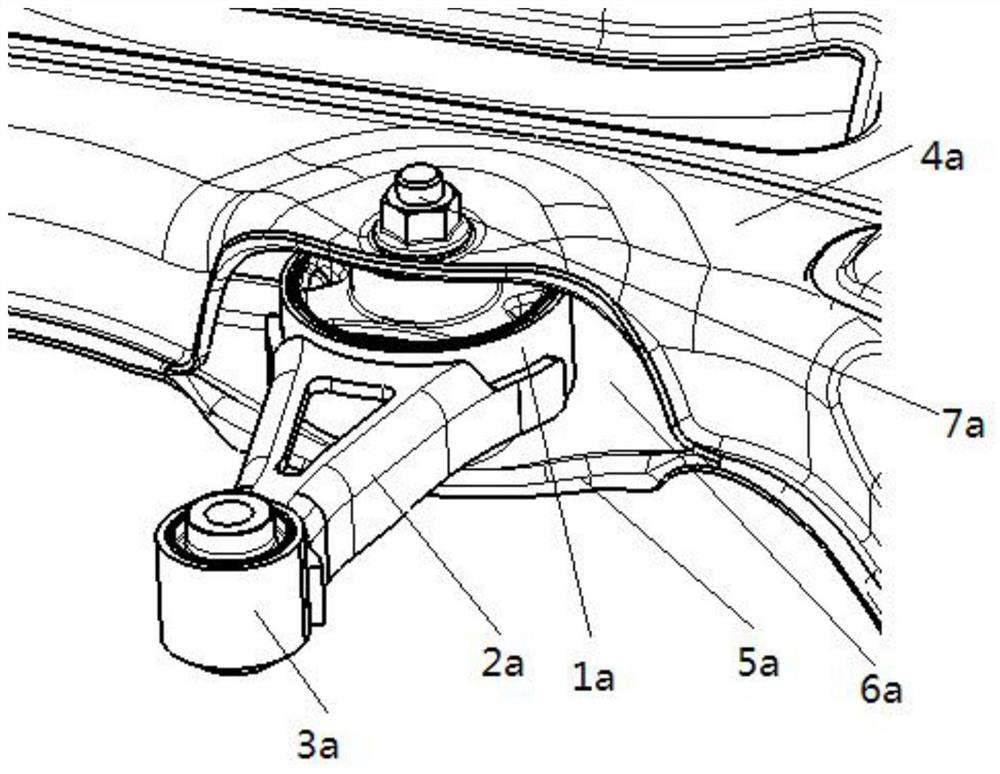

Structure for connecting swing arm lining with sub vehicle frame

ActiveCN104210322AImprove dynamic stiffnessEasy assemblyUnderstructuresPivoted suspension armsVehicle frameNoise, vibration, and harshness

The invention relates to a structure for connecting a swing arm lining with a sub vehicle frame. The inner framework of the swing arm lining is flat; the two ends of the swing arm lining are protruded out of a middle rubber body and a lining outer pipe; a bolt hole is formed in each of the two ends of the swing arm lining; a through hole is formed in a sub vehicle frame; a threaded casing pipe is arranged in the sub vehicle frame; the bolt holes, the through hole and the threaded casing pipe are communicated with one another; a sink which is toward the inner side is formed in the part, corresponding to each of the middle rubber body and the lining outer pipe, on the sub vehicle frame; the swing arm lining is fixedly connected with the sub vehicle frame in the way that a bolt is matched with the threaded casing pipe. In the technical scheme, due to the fact that the sub vehicle frame is flatly stuck to the inner framework, abnormal sound caused when the inner framework of the swing arm lining moves in the manner of being relative to a gear-starting structure is avoided, and the promotion of NVH (Noise Vibration and Harshness) is benefited; due to the fact that secondary welding of the frame is not required, the rigidity of a mounting part is high, and meanwhile, the mounting space is saved; due to the fact that the sub vehicle frame is molded by drilling and casting a complete plate, the drilling precision is high, and the production is easy to control; due to the fact that the threaded casing pipe is adopted, the assembling process is simple.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

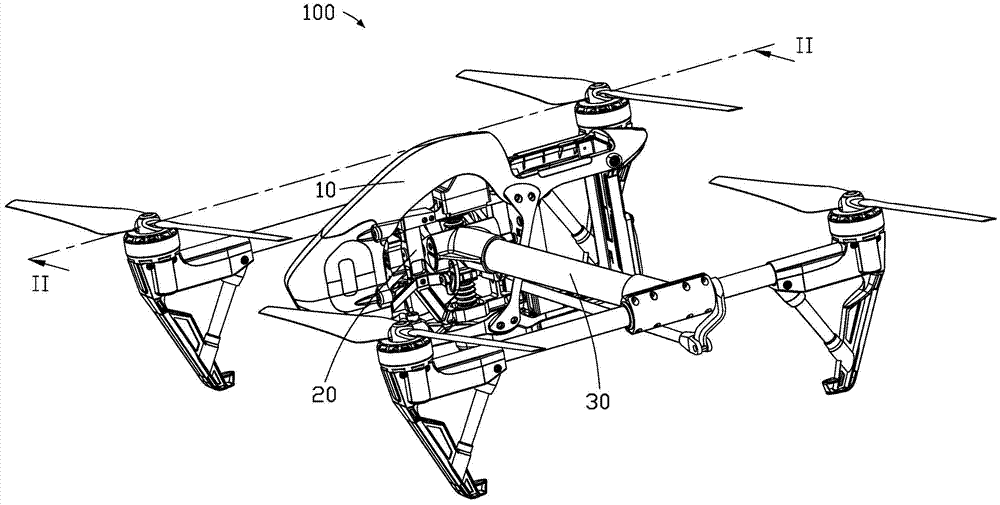

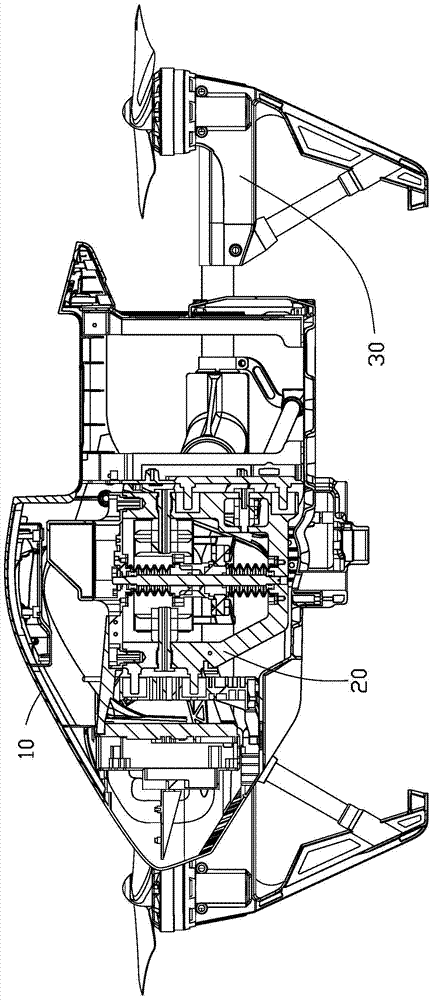

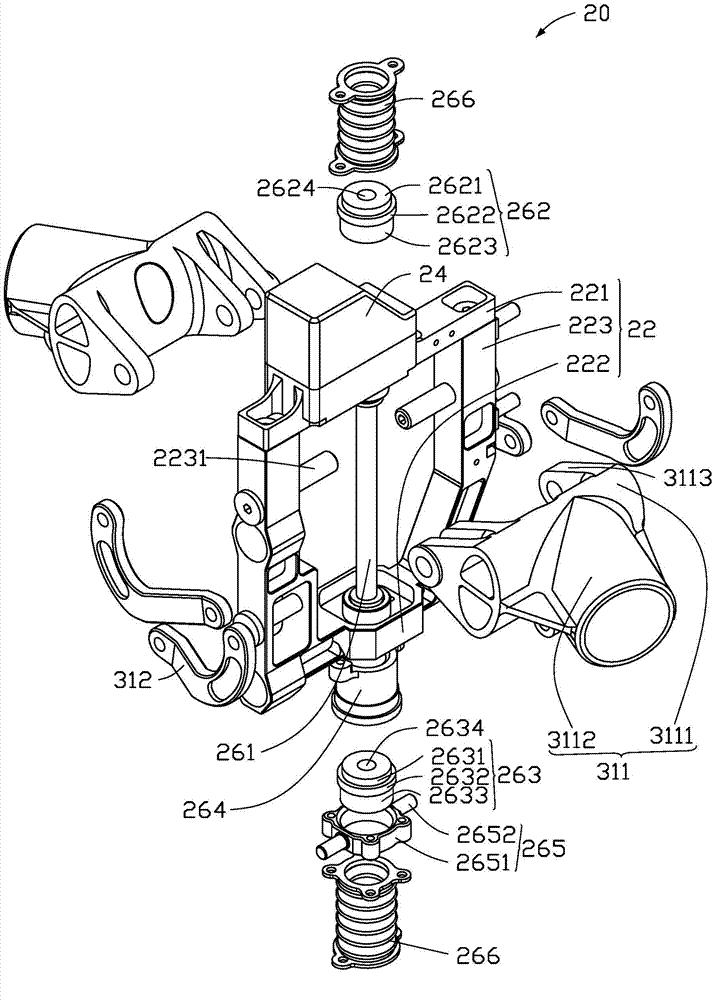

Morphing aircraft

InactiveCN104507800AImprove dynamic stiffnessDynamic stiffness meetsAircraft componentsRemote controlled aircraftMorphingDynamic stiffness

A morphing aircraft (100) includes a body (20) and a frame (30) connected to the body. The body (20) includes a transmission mechanism (26). The frame (30) includes a main supporting arm (31), a cross rod (33) and a spiral power mechanism (34). The main supporting arm (31) is connected to the transmission mechanism (26) of the body (20). The cross rod (33) is connected to the main supporting arm (31). The spiral power mechanism (34) is arranged on the cross rod (33). The transmission mechanism (26) includes a screw (261), at least two nuts (262, 263) screwed to the screw (261), and a nut adaption connector (265) that sleeves one of the nuts. The at least two nuts (262, 263) are connected mutually. The main supporting arm (31) is connected to the nut adaption connector (265). The dynamic stiffness of the whole aircraft is improved, the dynamic stiffness of the morphing aircraft during morphing and flying is achieved, the flying performance is improved, and also costs are reduced.

Owner:SZ DJI TECH CO LTD

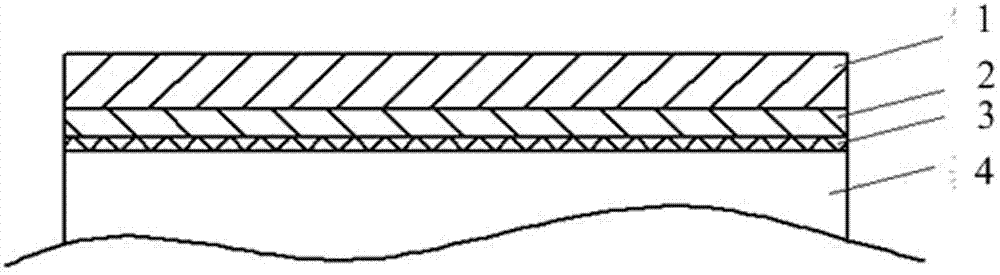

Method for manufacturing soundproof cushion board for floor

InactiveCN101691049AImprove dynamic stiffnessLarge internal dampingMixing operation control apparatusCeramic shaping apparatusSurface layerPolymer science

The invention provides a method for processing a soundproof cushion board for a floor, which comprises processes of manufacturing a surface layer and a soundproof layer, wherein the surface layer is made of cement mortar; the soundproof layer is formed by pressing a slurry mixture wrapped on the surface of polyphenyl granules serving as a main material, wherein the slurry mixture comprises high polymer adhesive, cement, fly ash and swelling agent; and then the surface layer and the soundproof layer are pressed and shaped. The method has the advantages of having simple operation and low cost of required raw materials, reducing the production cost, and effectively solving the problem of poor sound insulation of hard tiles of a concrete floor.

Owner:CHINA ACAD OF BUILDING RES

Automobile rear suspension spring installation point structure

InactiveCN105966185AIncreased durabilityStrong torsional rigidityResilient suspensionsVehicle springsDynamic stiffnessEngineering

The invention provides a structure of an automobile rear suspension spring installation point with strong dynamic rigidity, high durability and light weight. The structure includes a rear suspension spring seat mounting plate, a support plate and a rear floor side longitudinal beam body, and also includes a first partition plate and a second partition plate. The rear floor side longitudinal beam body is a U-shaped channel steel beam in section, and the support plate It is an L-shaped support plate, the side of the L-shaped support plate is fixedly connected with the side of the rear floor side longitudinal beam body, and the top surface of the L-shaped support plate is respectively connected with the bottom surface of the rear suspension spring seat mounting plate and the groove top of the rear floor side longitudinal beam body The surface is fixed, the first partition and the second partition are respectively arranged on the sides of the rear floor side longitudinal beam body corresponding to the installation point of the L-shaped support plate, and the first partition and the second partition are both U-shaped in cross section channel steel, the groove tops of the first partition and the second partition are respectively vertical and flush with the groove tops of the side longitudinal beam body of the rear floor, and the sides of the first partition and the second partition are vertically aligned with the side longitudinal beams of the rear floor The sides of the beam body are fixed.

Owner:CHERY AUTOMOBILE CO LTD

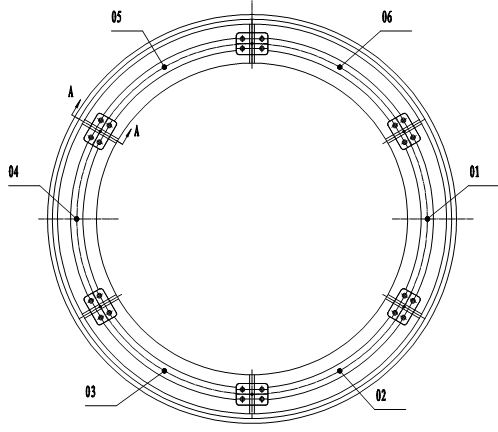

Bidirectional multi-arch large-caliber space reflector

InactiveCN103207440AImprove dynamic stiffnessRaise the natural frequencyMountingsBack reflectorEngineering

The invention discloses a bidirectional multi-arch large-caliber space reflector, and belongs to the technical field of precision machinery of optical systems. The reflector comprises a reflector surface and a back matrix, wherein open lightweight holes and supporting holes are formed in the back matrix, and the back matrix has a stiffened plate type structure; and grooves are formed in the back matrix, and the back matrix is in a bidirectional multi-arch shape formed by multiple radial arches and multiple annular arches. By adjusting the arrangement of the grooves and changing the mass distribution of the reflector along two directions, the mass of the matrix is lightened under the condition that the stiffness of the structure of the reflector is not reduced, the specific stiffness of the structure is improved, the structure is reasonable, and great lightweight is realized. The specific design examples show that the mass of the reflector can be reduced by 24.5 percent compared with a flat-back reflector. The reflector has the advantages of low self-weight deformation, reasonable stiffness distribution and light mass, and is suitable for a large-caliber space telescope system.

Owner:DALIAN UNIV OF TECH

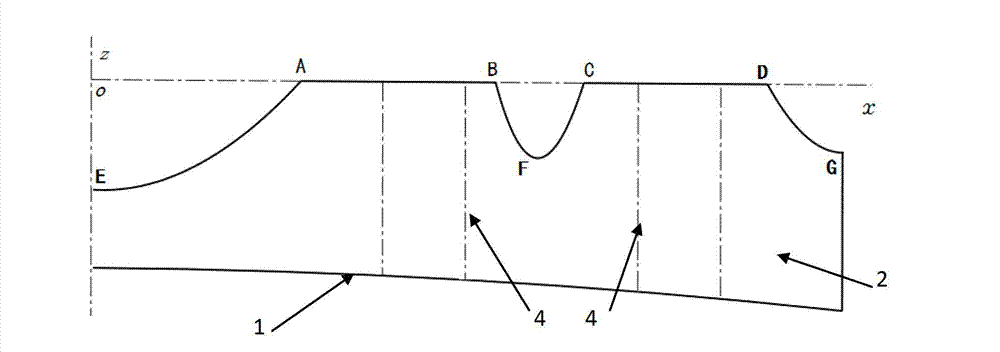

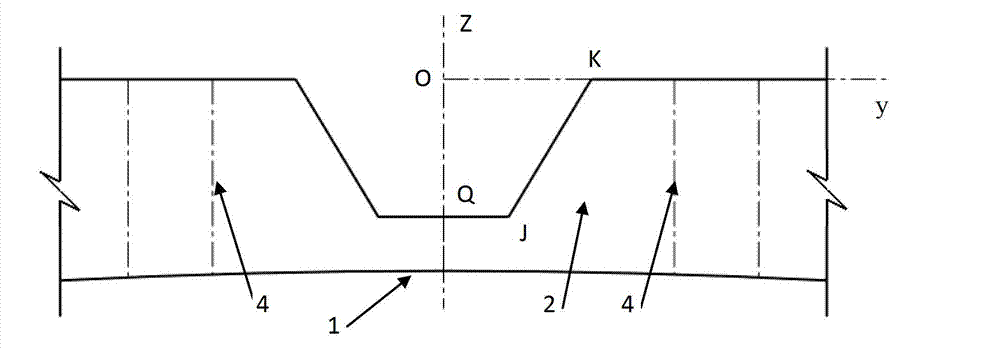

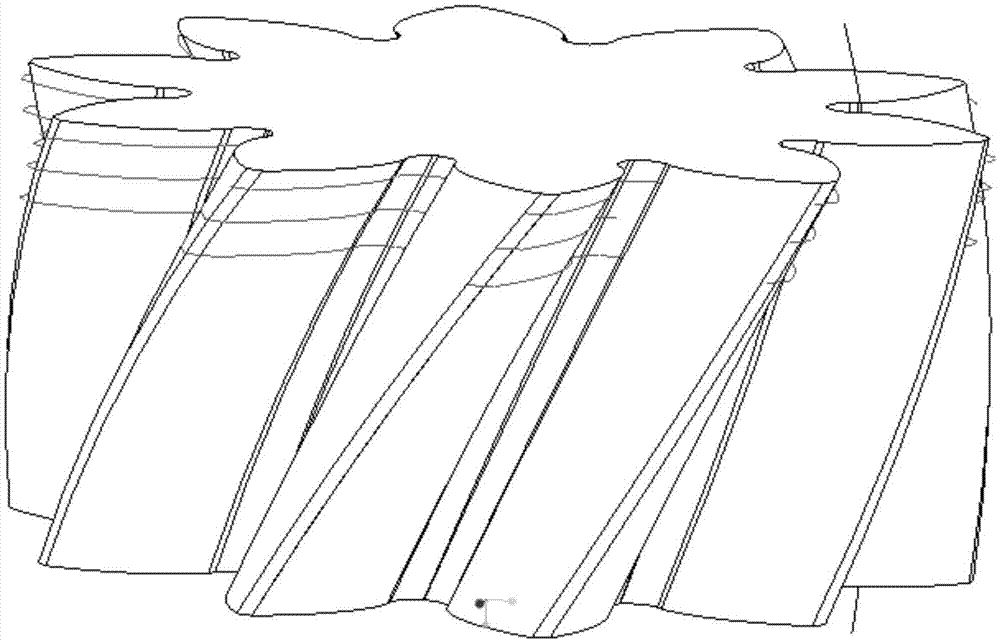

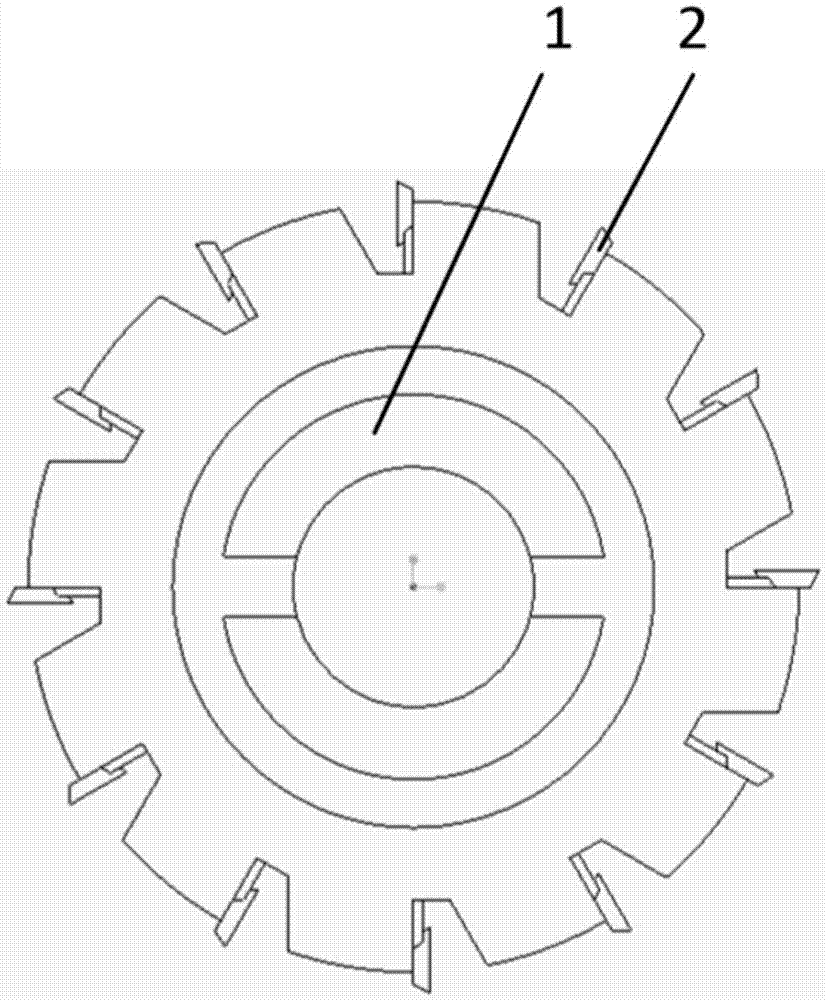

Method for processing hard tooth surface of medium-precision large-modulus cylindrical gear

ActiveCN105436623AGood fixationImprove cutting rigidityGear teeth manufacturing toolsGear teethDynamic stiffnessHelical line

A method for processing a hard tooth surface of a medium-precision large-modulus cylindrical gear is characterized in that a double-parameter non-instantaneous-pole enveloping method is carried out to perform tooth surface generating enveloping and hard milling, namely, a cutter is used for performing weft enveloping along the circumference contour direction of the gear and then performing warp enveloping along a helical line direction of the tooth surface of the gear. According to the method, a large-diameter disc milling cutter, which is provided with a large-space chip storing groove and is high in cutting stiffness and convenient and reliable in blade fixing manner, is utilized, so that a cutter disc is outstanding in comprehensive high-speed hard milling performance; a coated carbide blade is used for achieving high-speed hard milling of hardened steel; the form of the geometric structure of the blade can effectively improve the dynamic stiffness and thermal stiffness and can also reduce the influence of force and heat on a workpiece and the blade, and as a result, the durability of the blade can be improved.

Owner:NANJING GONGDA CNC TECH +1

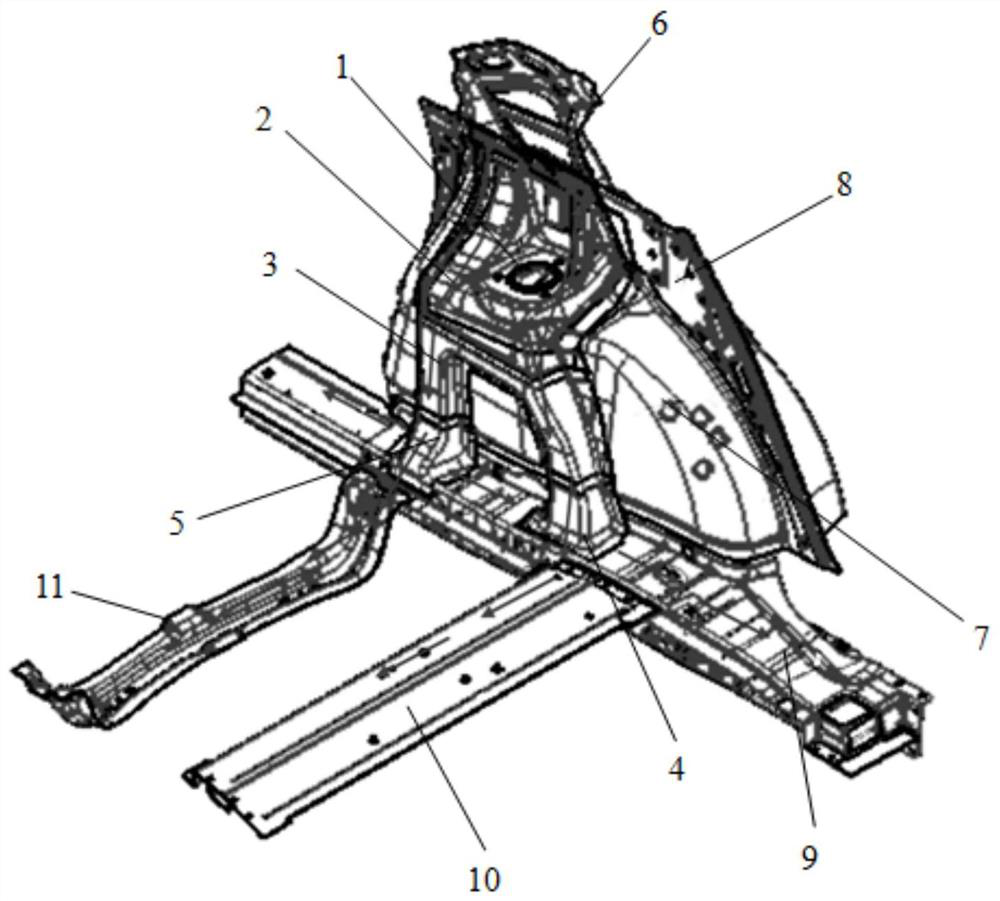

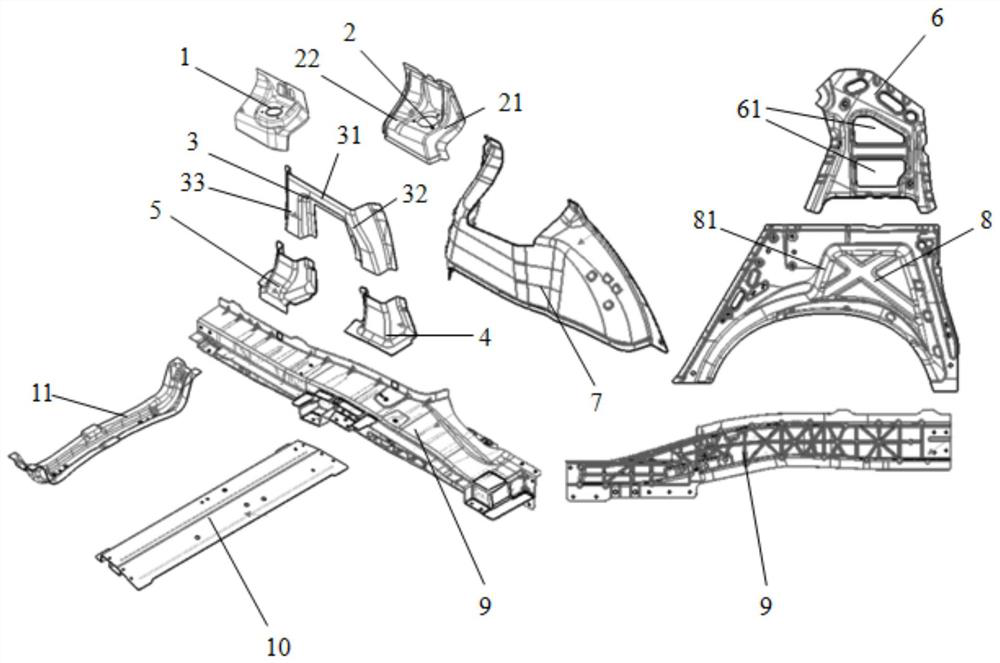

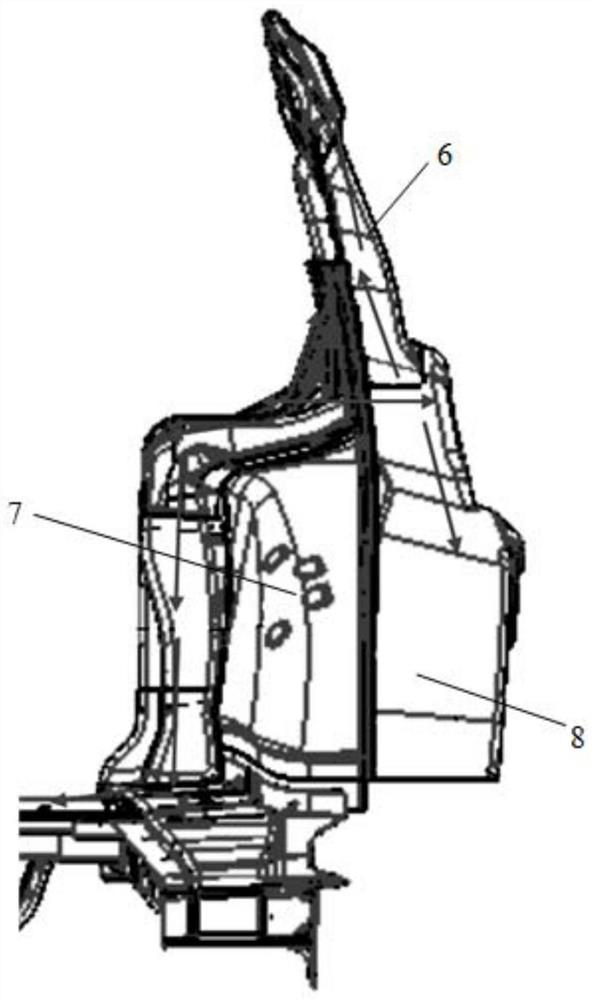

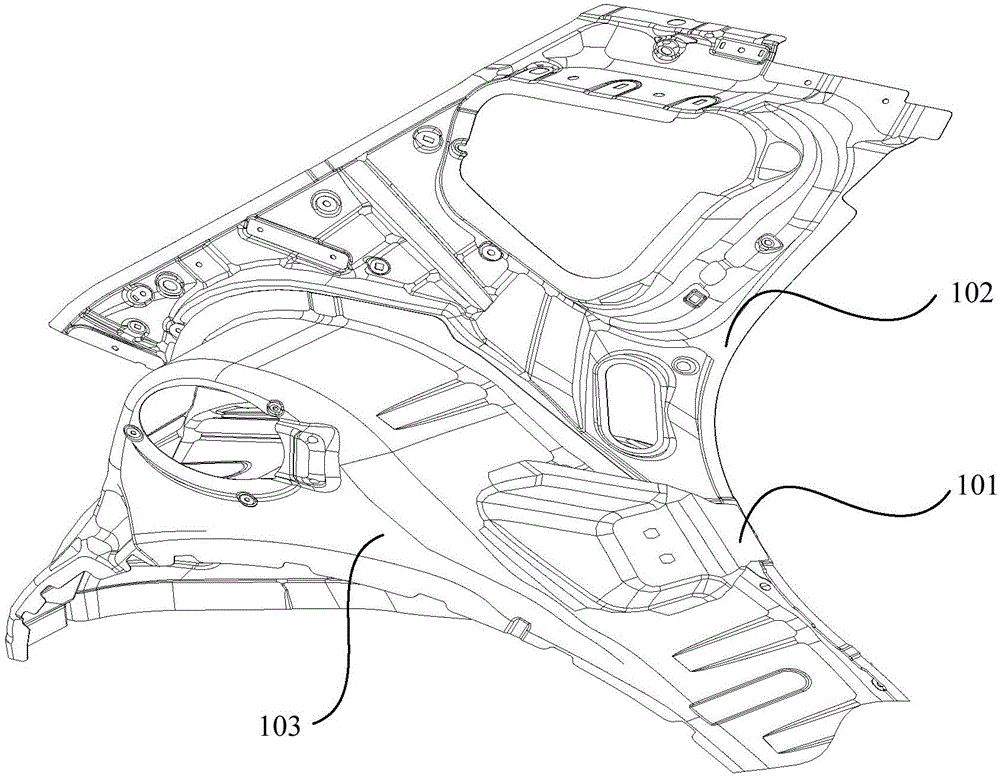

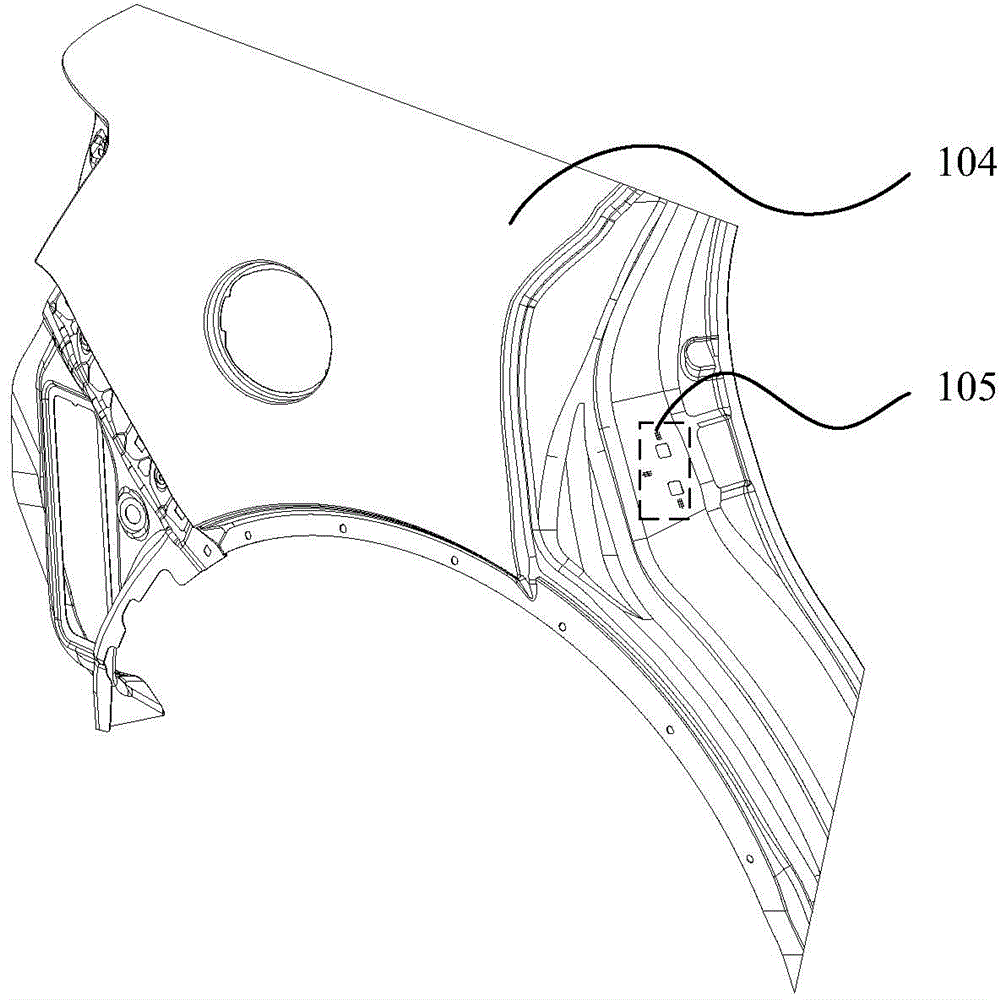

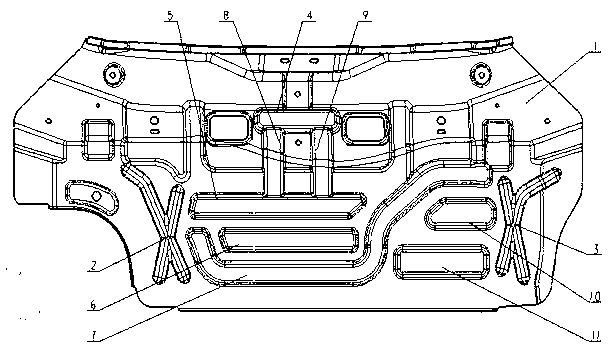

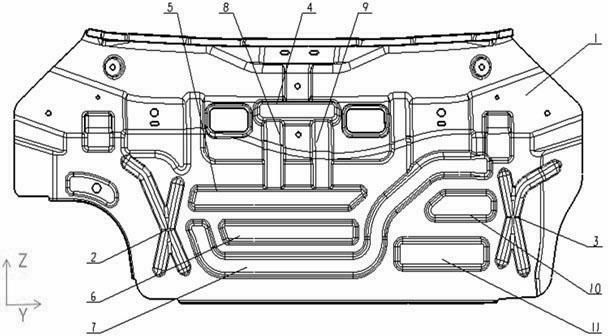

Automobile body rear force transmission structure and automobile

ActiveCN112339861AReduce weightImprove hard jog stiffnessUnderstructuresSuperstructure subunitsControl theorySpare tire

The invention belongs to the technical field of automobile bodies, and relates to an automobile body rear force transmission structure and an automobile, and the automobile body rear force transmission structure comprises a rear suspension mounting piece, a rear wheel cover internal reinforcing plate, a rear wheel cover front joint, a rear wheel cover rear joint, a rear wheel cover external reinforcing plate, a rear wheel cover inner plate, a rear wheel cover outer plate and a rear longitudinal beam joint. According to the automobile rear force transmission structure, an H-shaped force transmission channel in the inner side covers the rear suspension stress area and dispersedly transmits force to the rear longitudinal beam joint, the rear floor cross beam, a spare tire pool cross beam andthe upper portion of the rear side wall, and the force transmission efficiency of the rear suspension area (especially a three-connecting-rod rear suspension area) is greatly improved; and the dynamicstiffness, the NVH performance and the fatigue durability of a rear shock absorber area are improved. The automobile body rear force transmission structure is suitable for an automobile model with asteel-aluminum hybrid automobile body matched with a three-connecting-rod rear suspension. Under the condition that a floor frame beam structure is not added, after the automobile body rear force transmission structure is adopted, the weight of the automobile body can be reduced by about 3 kg.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

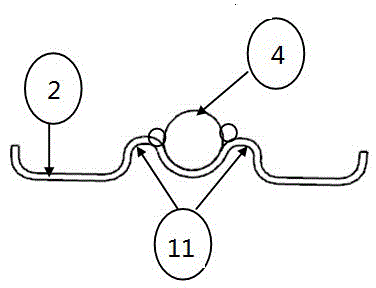

Built-in variable throttler

A built-in variable throttler comprises a throttler seat, a throttling post and a spring. A stair-step centre hole is arranged on the throttler seat and composed of a big diameter hole, a middle diameter hole and a small diameter hole, the big diameter hole is communicated with the small diameter hole through the middle diameter hole, the throttling post is formed by connecting a big diameter post, a middle diameter post and a small diameter post, the throttling post is installed in the throttler seat, the big diameter post is tightly matched with the big diameter hole, an oil storage chamber is defined by the top end of the big diameter post and the inner wall of the big diameter hole, an oil inlet chamber is formed between the middle diameter post and the big diameter hole, an oil inlet channel for communicating the oil storage chamber and the oil inlet chamber is arranged on the throttling post, a throttling gap communicated with the oil inlet channel is formed between the middle diameter post and the middle diameter hole, an oil collecting chamber is formed between the small diameter post and the middle diameter hole, the small diameter post is tightly matched with the small diameter hole, an output channel communicated with the oil collecting chamber is arranged on the small diameter post, and a spring abuts against and is arranged between the bottom end of the middle diameter post and the bottom end of the middle diameter hole. The built-in variable throttler is simple and compact in structure, and rapid in changing dynamic response of external loads.

Owner:HUNAN UNIV

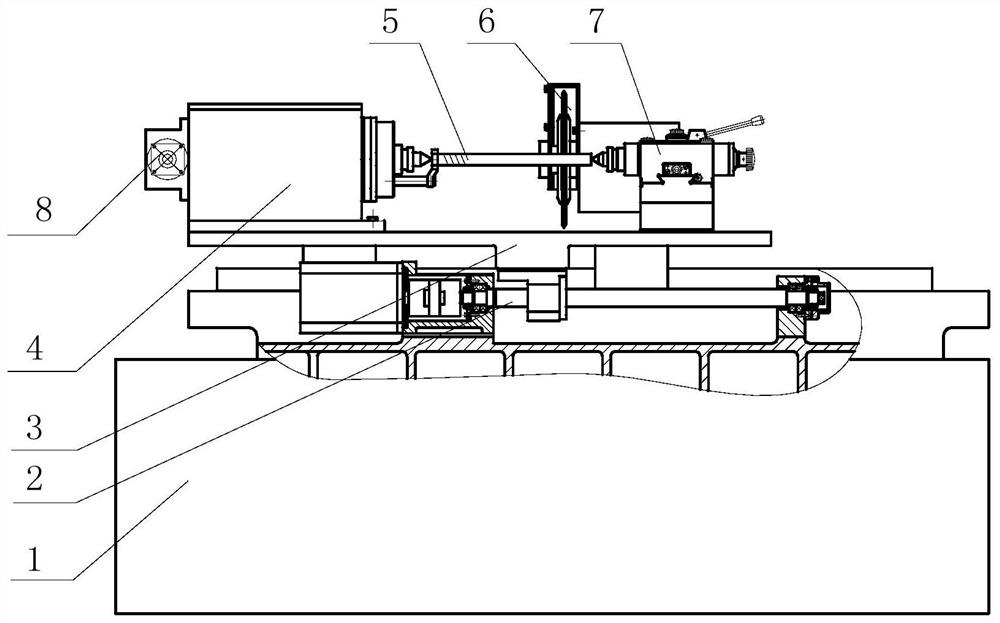

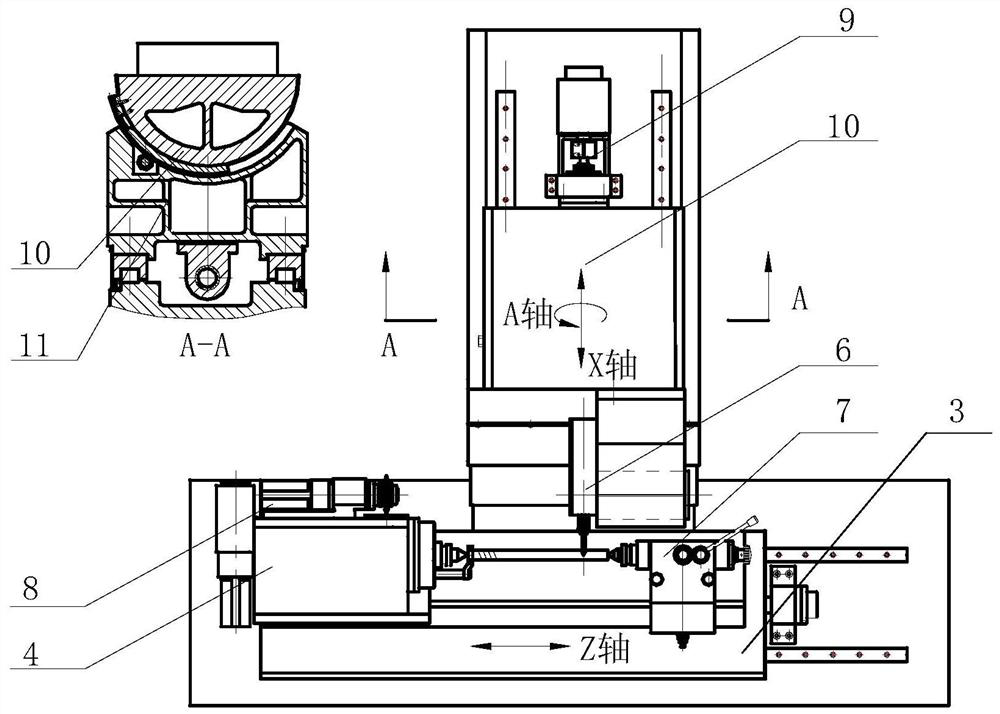

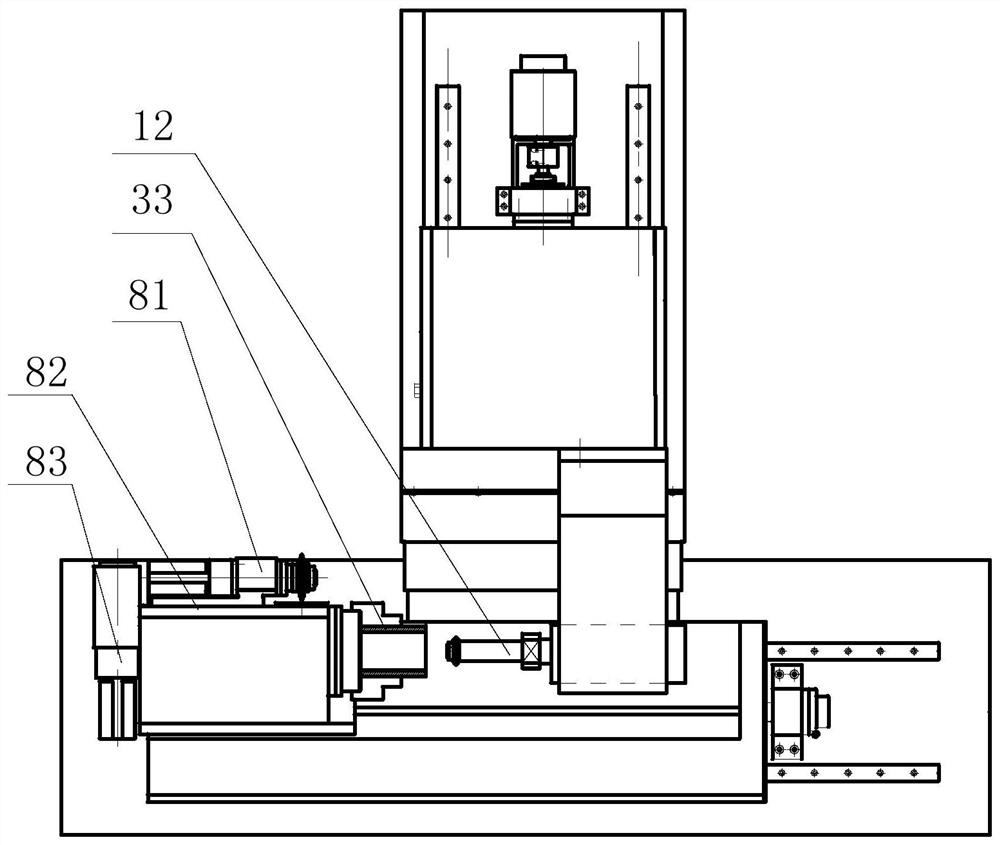

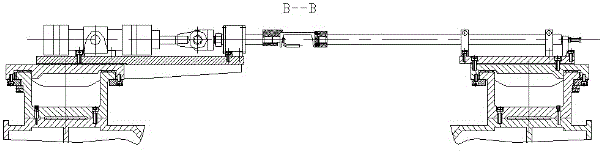

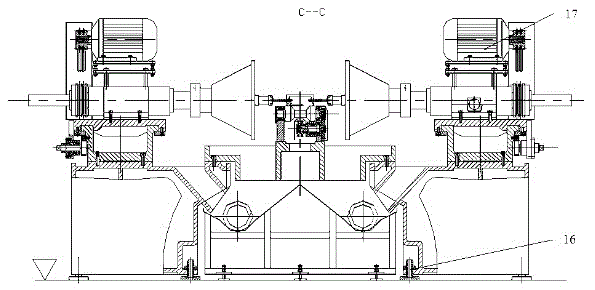

Internal and external thread grinding machine capable of realizing in-situ modification of grinding wheel

PendingCN112059327ASolve the accuracy problemSolve the stiffness problemThread cutting machinesRotational axisEngineering

The invention provides an internal and external thread grinding machine capable of realizing in-situ modification of a grinding wheel. An A-shaft rotary table (10) is arranged on a rotary table base (11); the A-shaft rotary table (10) can rotate on the rotary table base (11); a rotating shaft is defined as a shaft A and rotates in the X-axis direction; a large-diameter grinding wheel can be installed on a grinding wheel headstock (6); angle adjustment of the large-diameter grinding wheel or a small-diameter grinding wheel is achieved through the rotating shaft A; a shakable angle dresser (8) is fixed to the side surface of a workpiece headstock (4) and is used for generating a certain oscillation angle; the shakable angle dresser (8) consists of a rolling wheel rotating mechanism (81), anoscillation angle guide mechanism (82) and an angle driving mechanism (83); the oscillation angle guide mechanism (82) and the angle driving mechanism (83) are both installed at the side surface of the workpiece headstock (4); the rolling wheel rotating mechanism (81) is installed on the oscillation angle guide mechanism (82); the angle driving mechanism (83) can be used for driving the oscillation angle guide mechanism (82) to rotate; and the rolling wheel rotating mechanism (81) can be used for trimming a large-diameter grinding wheel installed on the grinding wheel headstock (6) or a small-diameter grinding wheel installed on an inner grinding head component (12) to realize in-situ modification of the grinding wheel.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

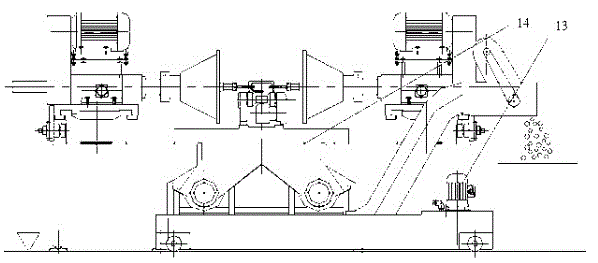

Belt conveyor roller frame vertical beam drilling device and method

InactiveCN104028797AImprove dynamic stiffnessReasonable designMetal working apparatusPositioning apparatusElectric machineryEngineering

The invention relates to the field of machining, in particular to a belt conveyor roller frame vertical beam drilling device and method. A belt conveyor roller frame vertical beam drilling device is characterized by comprising a machining portion. The machining portion comprises bases. The bases comprise a left base, a right base and a middle base. Guide rails are arranged on the left base and the right base, each guide rail is provided with a sliding seat capable of moving along the guide rail, and a power head is installed on each sliding seat. A conveying device is arranged on the middle base, a motor for providing power for rotating of a drill bit is arranged on the upper portion of each power head, a multi-shaft device is installed at the front end of each power head, and a drill bit is installed on each multi-shaft device. The left base, the right base and the middle base are connected through bolts. The device has the structure advantages of being reasonable in design, high in whole machine dynamic rigidity, high in accuracy, long in service life, safe and reliable, convenient to maintain and the like, and has the production advantages of being convenient to operate, high in efficiency, low in labor intensity and high in automation.

Owner:西安重装韩城煤矿机械有限公司

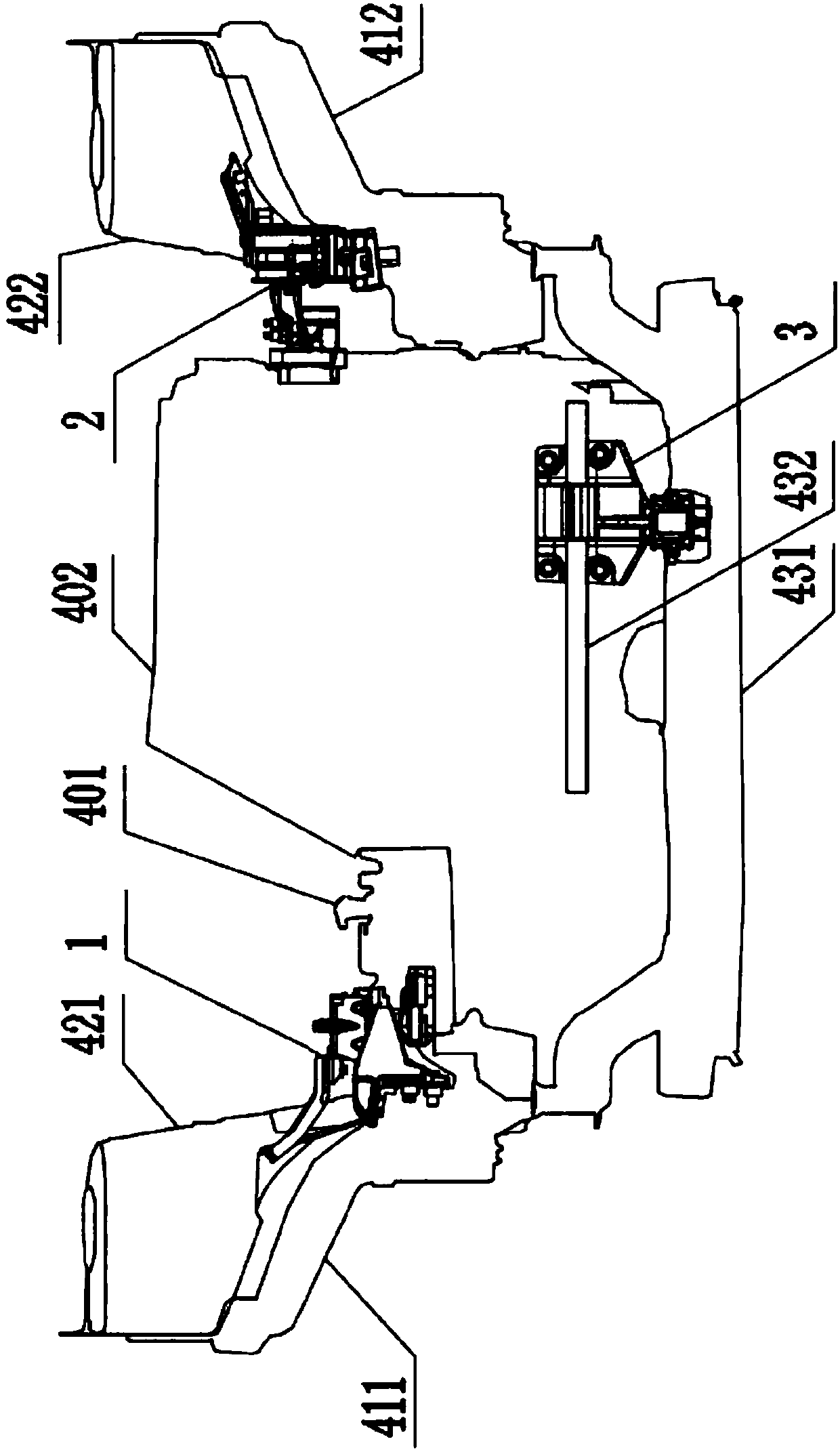

Three-point suspension-mounting system and suspension-mounting method for front-arranged front-driven car power assembly

ActiveCN107901747AFirmly connectedImprove stabilityJet propulsion mountingInternal combustion mountingDrive shaftEngineering

The invention relates to the technical field of cars, in particular to a three-point suspension-mounting system and suspension-mounting method for a front-arranged front-driven car power assembly. Thethree-point suspension-mounting system comprises a left suspension-mounting assembly, a right suspension-mounting assembly and a rear suspension-mounting assembly. The power assembly is suspended-mounted in a car through the left suspension-mounting assembly, the right suspension-mounting assembly and the rear suspension-mounting assembly, so that the problems that an existing rear suspension-mounting connector is separated from a transmission shaft bearing seat, the connection structure is complex, the rear suspension-mounting connector is directly connected with a left suspension-mounting part and a right suspension-mounting part as well as the positions between a car body wheel cover, the car body wheel cover is complex in structure, and the right suspension-mounting part is difficultto arranged are solved.

Owner:北京长城华冠汽车技术开发有限公司

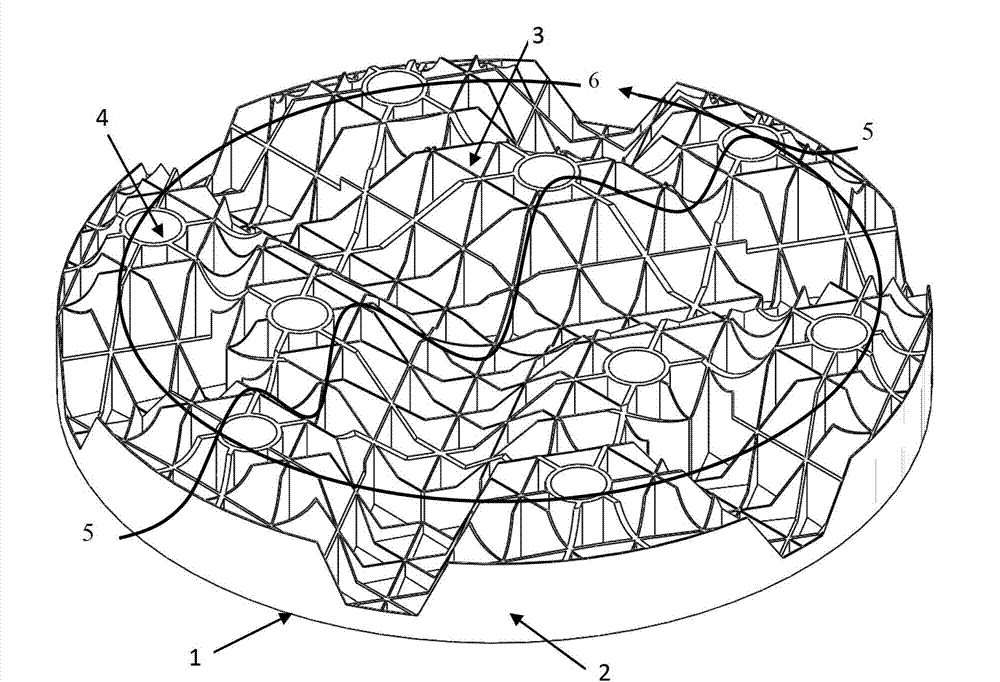

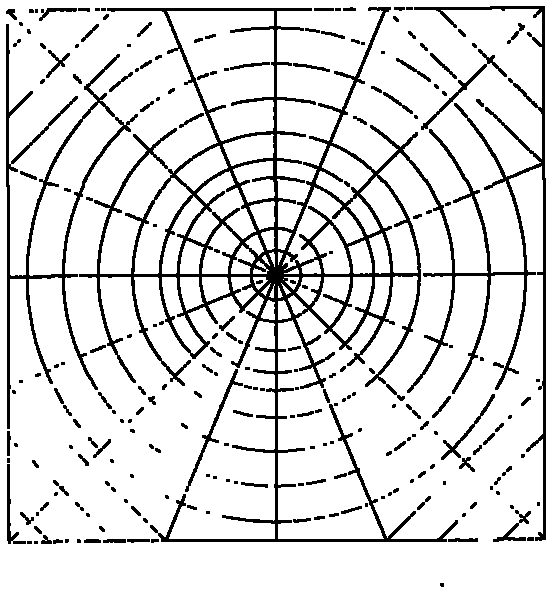

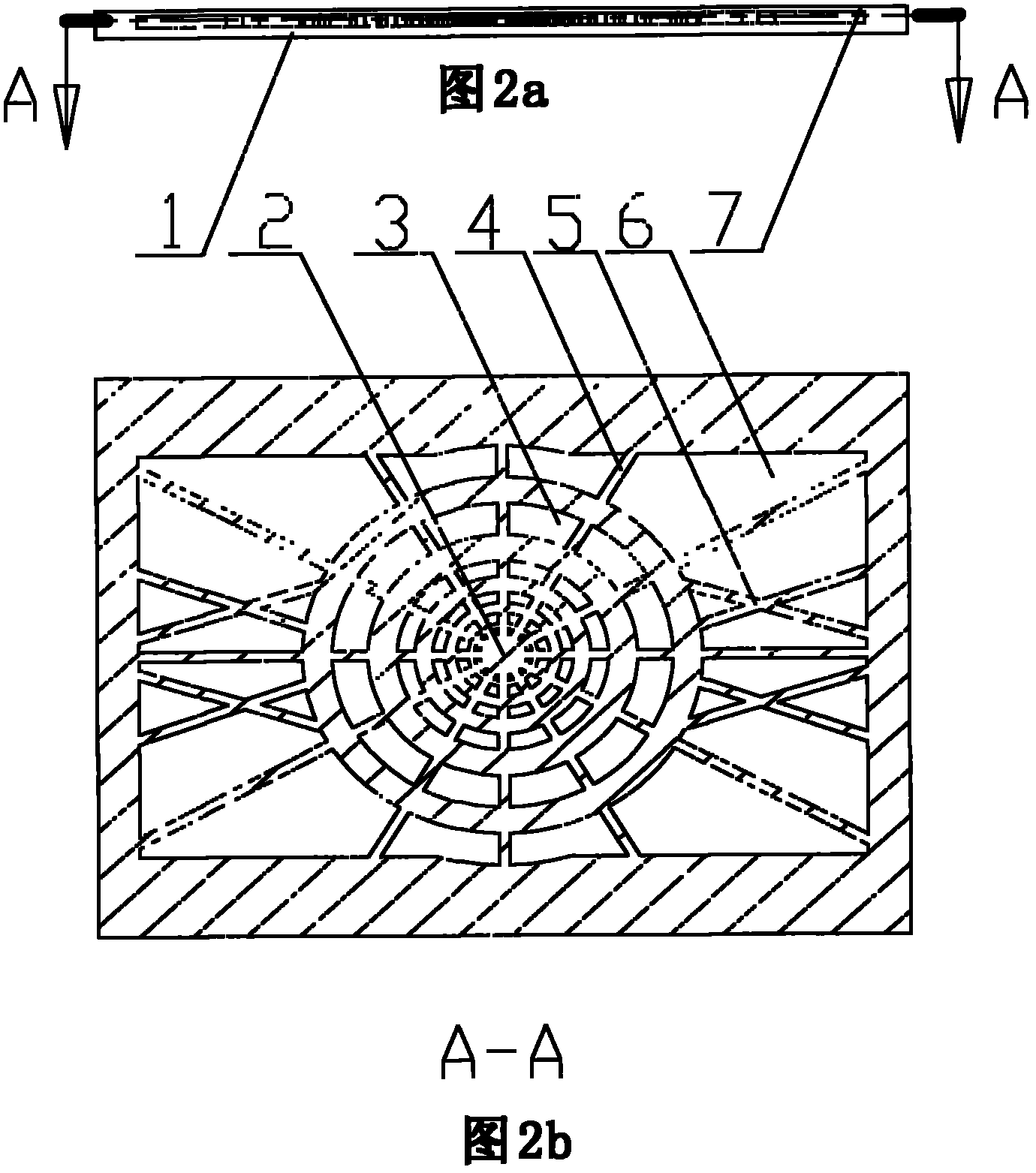

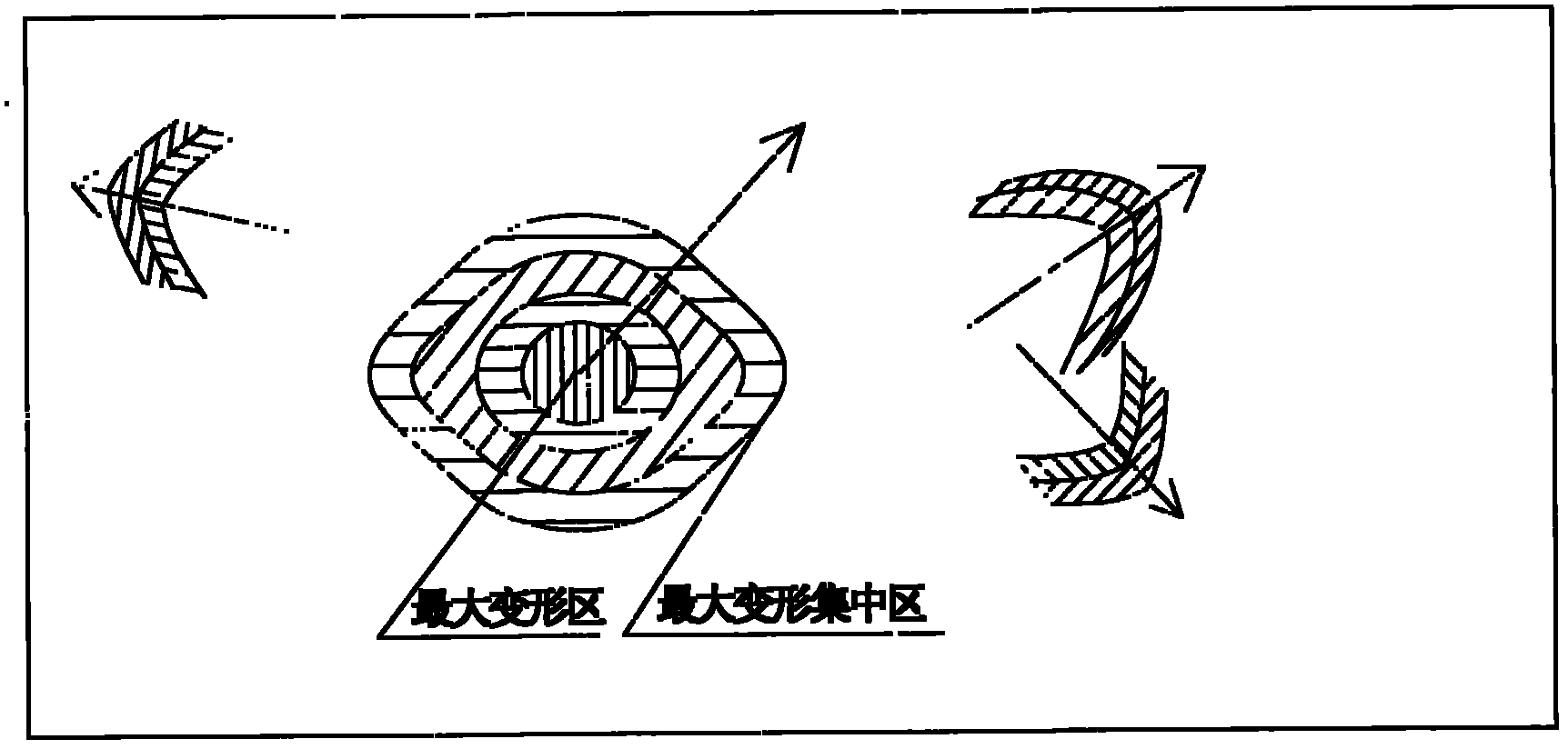

Topology optimization-based cobweb-like interlayer rib plate composite structure design method

InactiveCN101980222AReduce quality problemsSave materialSpecial data processing applicationsTopology optimizationThin layer

The invention discloses a topology optimization-based cobweb-like interlayer rib plate composite structure design method, which comprises the following steps of: 1, performing a static analysis on an original structural component to obtain a deformation cloud chart; 2, performing a topological optimization design on the structural component to obtain a topological optimization unit pseudo-density diagram; 3, finding the position of a largest deformation zone from the deformation cloud chart of the structural component; 4, arranging annular regular parallels and regular meridian lines of the structural component; 5, determining the arrangement density of the regular meridian lines; 6, arranging irregular meridian lines on some parts of the component; 7, combining the topology optimization to obtain a hollow component structure; 8, making a thin layer plate on the upper layer of the cobweb-like interlayer rib plate to fully envelope the cobweb-like rib plate, so that the middle interlayer becomes a composite structure of the cobweb-like rib plate; and 9, repeatedly improving the original component according to the steps. The invention has scientific concept and a novel structure, can meet the requirement of aerospace on light weight design, and has good practical value and wide application prospect in the engineering and technology field.

Owner:BEIHANG UNIV

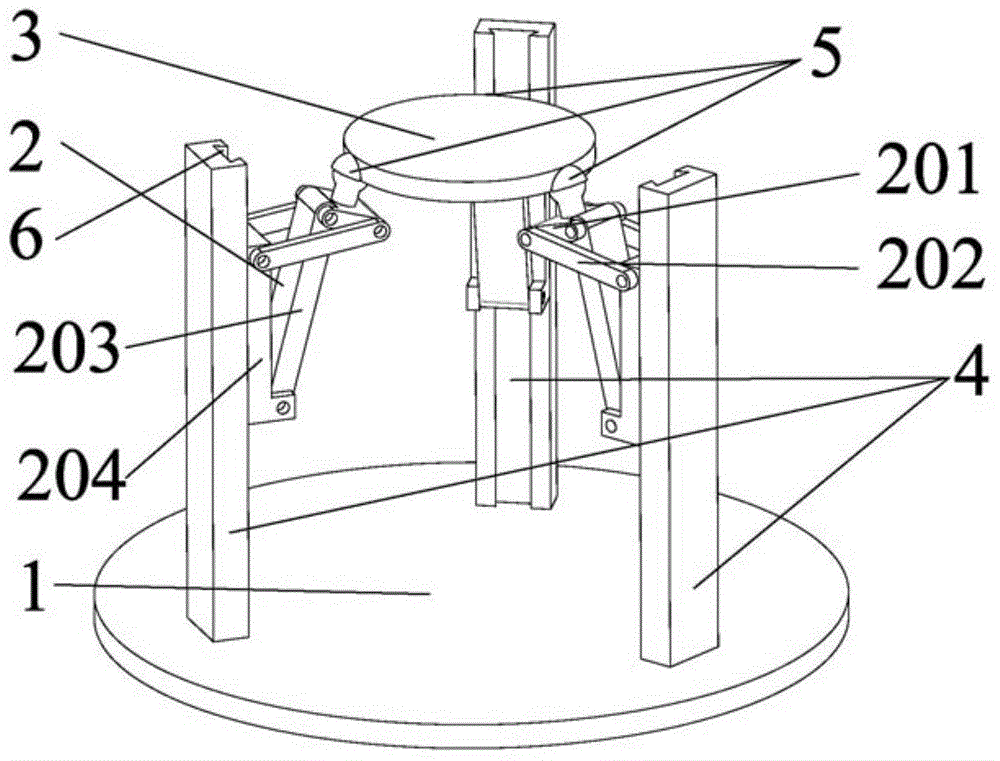

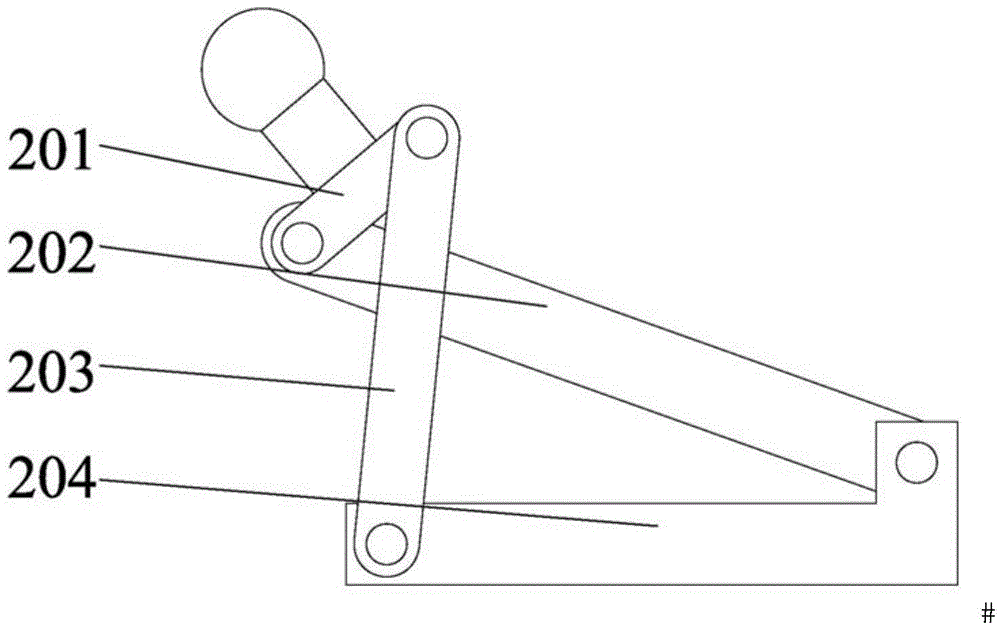

Parallel main shaft head mechanism based on four-bar mechanisms

ActiveCN104400446ALarge working spaceImprove dynamic performanceLarge fixed membersIsoetes triquetraEngineering

The invention discloses a parallel main shaft head mechanism based on four-bar mechanisms, and belongs to the technical field of mechanical production. The mechanism comprises a base, three frames and a movement platform, wherein the three frames are fixedly mounted on the base in an equilateral triangle form; a linear guide rail and a four-bar mechanism are arranged on each frame; each four-bar mechanism comprises a first connecting rod, a second connecting rod, a third connecting rod and a slide block; the rods are interconnected through rotating pairs; and the side edges of the movement platform are connected with the first connecting rods through movement pairs. The movement form of two-rotation and one-movement of the movement platform is realized, and the position and the posture of the movement platform can be easily controlled, so super-precise processing of complex curved surfaces is achieved.The parallel main shaft head mechanism has such characteristics as simple and compact structure, high rigidity, high loading capacity, small mass of the movement part, increase of a working space of the movement platform and facilitation of high-speed movement.

Owner:TSINGHUA UNIV

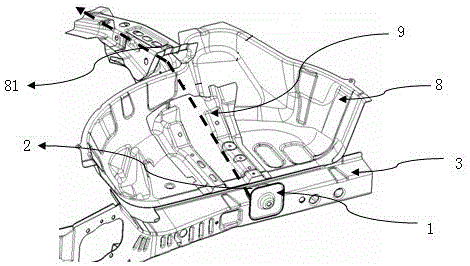

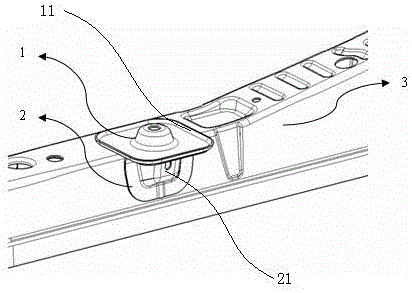

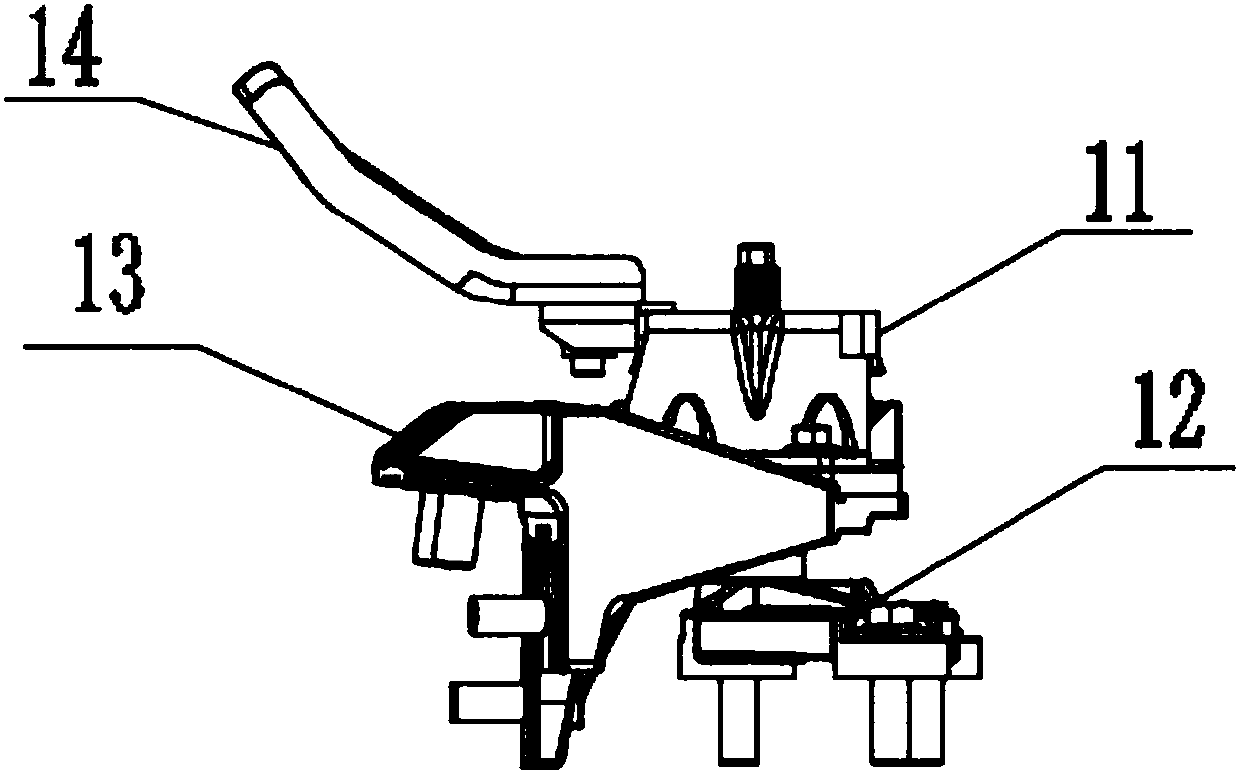

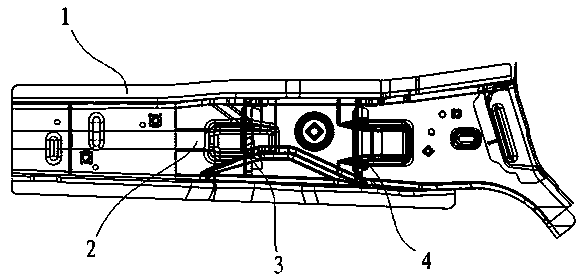

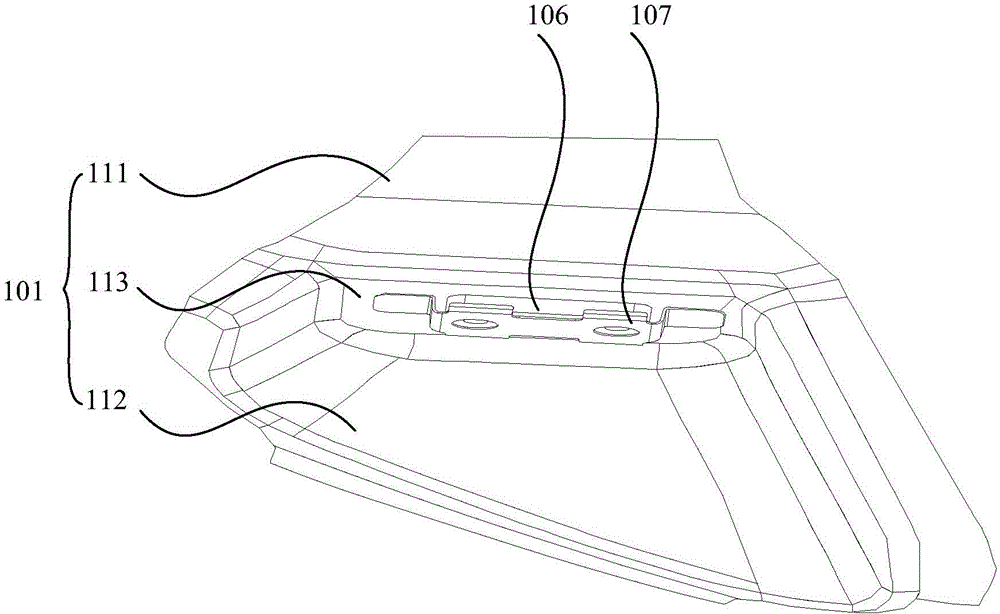

Reinforcing structure of suspension installation points for automobile

ActiveCN103738152AFirmly connectedReduce in quantityJet propulsion mountingInternal combustion mountingDynamic stiffnessResonance

The invention provides a reinforcing structure of suspension installation points for an automobile. On the premise of ensuring the installation intensity and stiffness, the achievement difficulty of the process is lowered, and the platform requirement is met. The reinforcing structure of the suspension installation points for the automobile comprises a reinforcing board of a front longitudinal beam inner board body, a suspension supporting board and the front longitudinal beam inner board body, wherein the reinforcing board of the front longitudinal beam inner board body and the suspension supporting board are welded to be a suspension reinforcing board subassembly, the suspension reinforcing board subassembly is provided with at least three full-closed or semi-closed box-shaped units; each box-shaped unit is provided with the installation points; the suspension reinforcing board subassembly and the front longitudinal beam inner board body are welded and fixed. As the box-shaped units are formed inside the structure and the multiple suspension installation points can be provided at the same time, the platform design requirement of a front longitudinal beam is met, the dynamic stiffness and the static stiffness of the suspension installation points are improved, resonance between the suspension installation points and the vibration frequency of an engine is avoided effectively, and the durability and the NVH performance of the installation points are improved; compared with the prior art, the reinforcing structure has the advantages that the number of parts is reduced, and the process is easy to implement.

Owner:CHERY COMML VEHICLE ANHUI

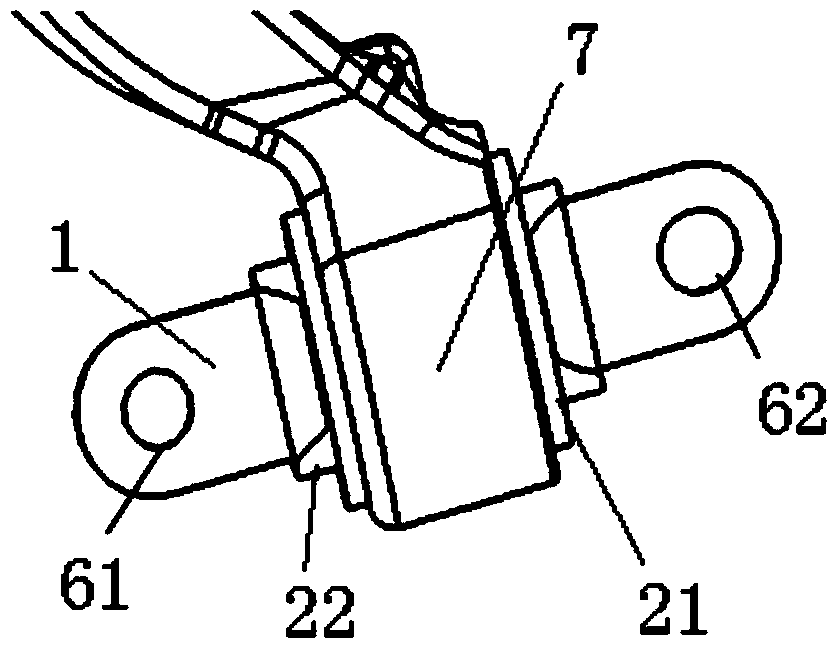

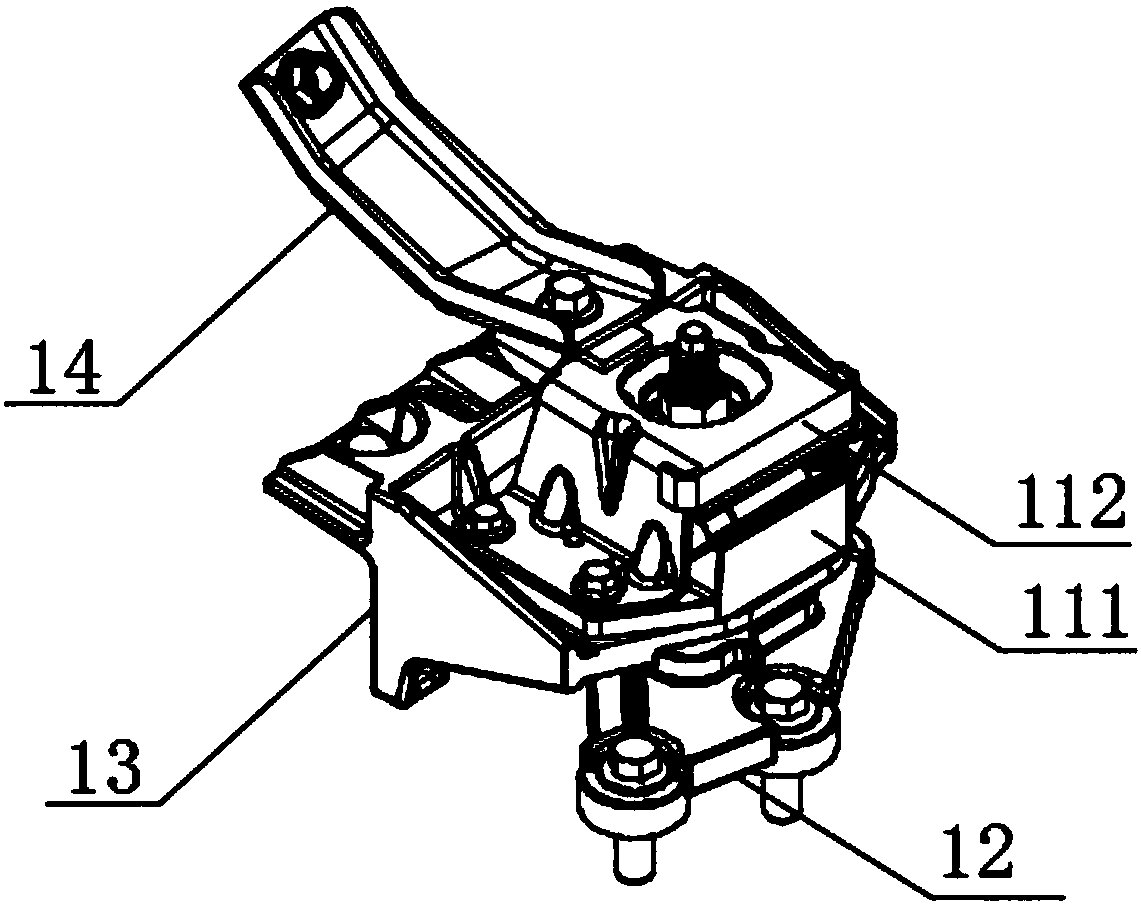

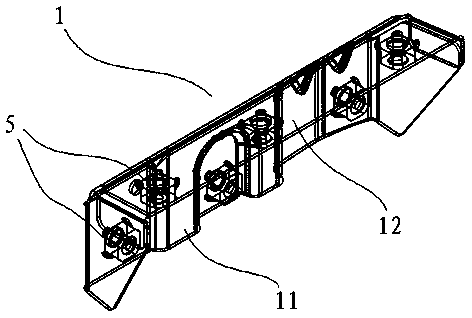

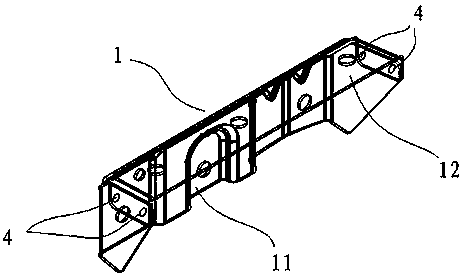

Latch component, locking mechanism and vehicle

InactiveCN104405223AImprove static stiffnessImprove dynamic stiffnessVehicle locksDynamic stiffnessLocking mechanism

The invention provides a latch component, a locking mechanism and a vehicle, and relates to the technical field of vehicle manufacturing. The latch component comprises a reinforcement plate fixedly mounted in a set area of a vehicle body, and a latch arranged in an area, opposite to the reinforcement plate, of the vehicle body and fixedly connected with the reinforcement plate through at least two bolts, wherein the reinforcement plate is positioned at the inner side of the vehicle body; and the latch is positioned at the outer side of the vehicle body. The latch component, provided by the invention, can improve static stiffness and dynamic stiffness of the connected area of the vehicle body and the latch, so that high-frequency components in door closing sound generated in the closing of a vehicle door are decreased, low-frequency components are increased, the door closing sound is deep, and the quality of the door closing sound is improved. The locking mechanism comprises the latch component provided by the invention; and the vehicle comprises the locking mechanism provided by the invention.

Owner:GREAT WALL MOTOR CO LTD

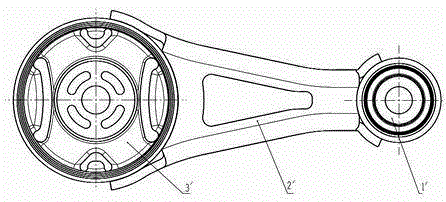

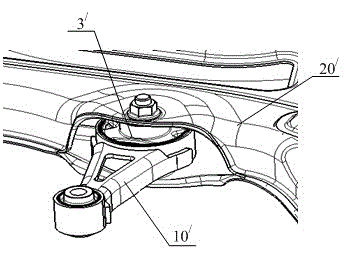

Connection structure of anti-torque pull rod and auxiliary frame and automobile

ActiveCN104924887AAvoid roaring noises in the carImprove NVH performanceJet propulsion mountingInternal combustion mountingVehicle frameFastener

The present invention provides a connection structure of an anti-torque pull rod and an auxiliary frame. The connection structure comprises the anti-torque pull rod and an auxiliary frame installation part; the anti-torque pull rod comprises large and small bushes and a pull rod support; the large and small bushes are installed inside first and second installation holes in the pull rod support; the large bush comprises a large bush inner tube, a large bush rubber body and a large bush outer tube; the large bush inner tube penetrates through the first installation hole, two large bush assembling parts stretch sideward along the axial direction of the hole, and each assembling part is provided with a large bush installation hole whose axis is perpendicular to the hole axis; the auxiliary frame installation part comprises a recess; upper plates, lower plates and support inner tubes disposed between installation plates and the lower plates are disposed at two sides of the recess; the installation plates are also provided with installation plate through holes; the large bush is installed in the recess, and fasteners penetrate through the large bush installation holes and the installation plate through holes and are connected with the support inner tubes. According to the embodiments of the present invention, excellent dynamic stiffness is maintained in all directions of the anti-torque pull rod and the auxiliary frame installation part, and automobile noise, vibration, harshness (NVH) performance can be raised.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

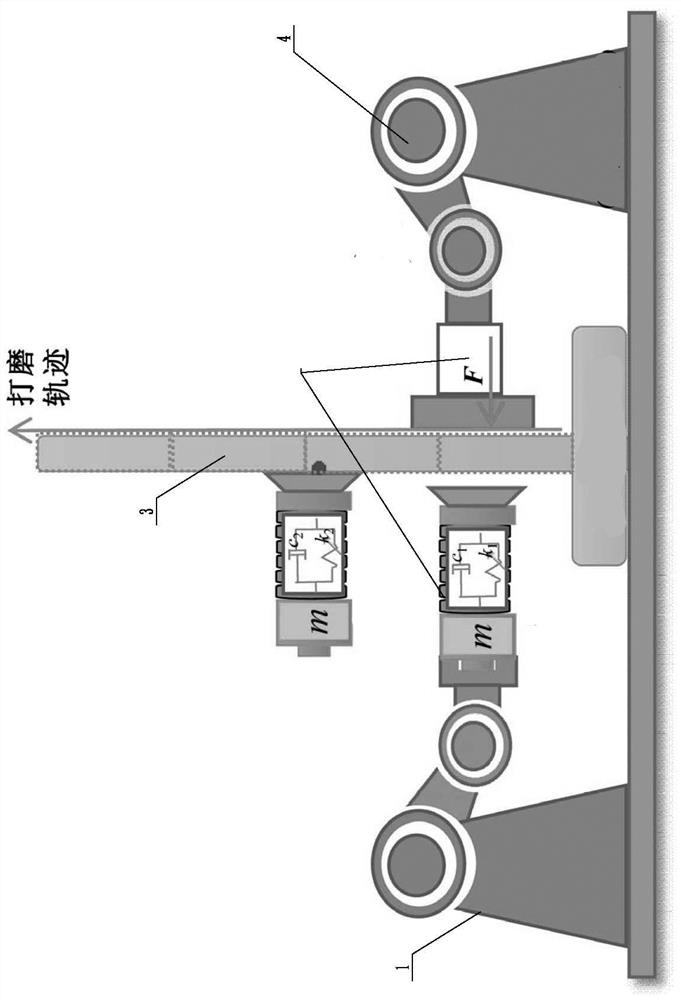

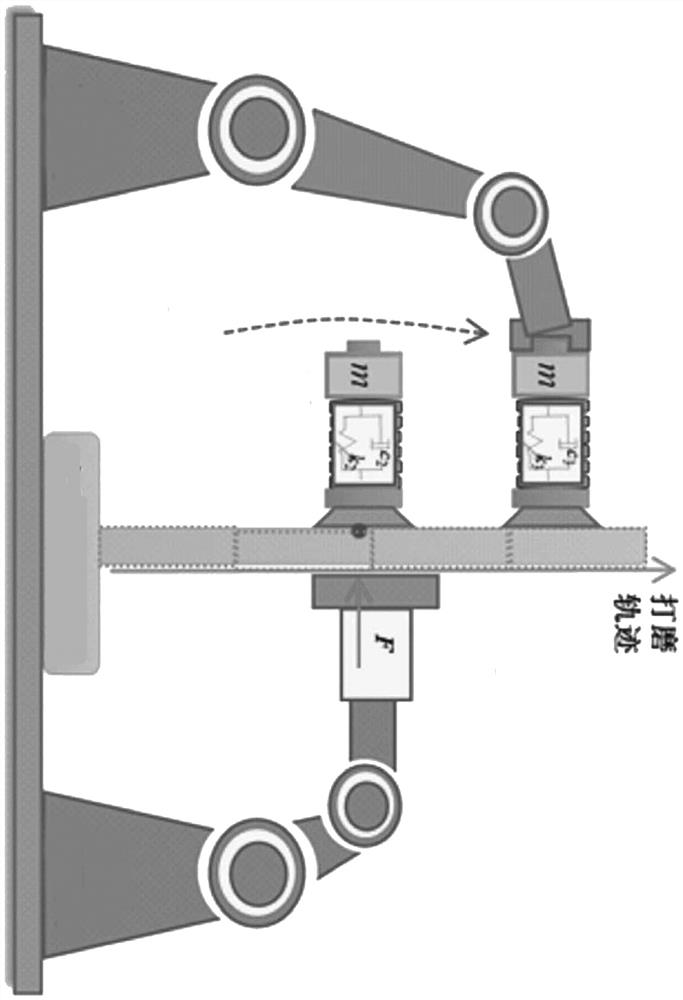

Robot end effector suitable for large thin-walled workpiece grinding and grinding system

ActiveCN112223296AFunction as a shock absorberImprove dynamic stiffnessProgramme-controlled manipulatorRobot end effectorThin walled

The invention provides a robot end effector suitable for large thin-walled workpiece grinding and a grinding system, and belongs to the technical field of machining. The effector comprises a base connected to a robot, a driver is connected to the base, a movable seat is connected to the end, away from the base, of the driver, a length-adjustable connecting rod is arranged above the base, and the upward extending end of the connecting rod is connected with the movable seat. The grinding system comprises a carrying robot and a grinding robot which are arranged at the left end and the right end of a thin-walled workpiece respectively, the output end of the carrying robot is connected with an end effector with a force control function, the grinding robot is connected with an end executor witha vibration reduction function, the upper end and the lower end of the thin-walled workpiece are fixed, and the left end and the right end of the thin-walled workpiece are free. According to the robotend effector, grinding of large thin-walled workpieces can be achieved, and vibration during grinding is reduced.

Owner:BEIHANG UNIV

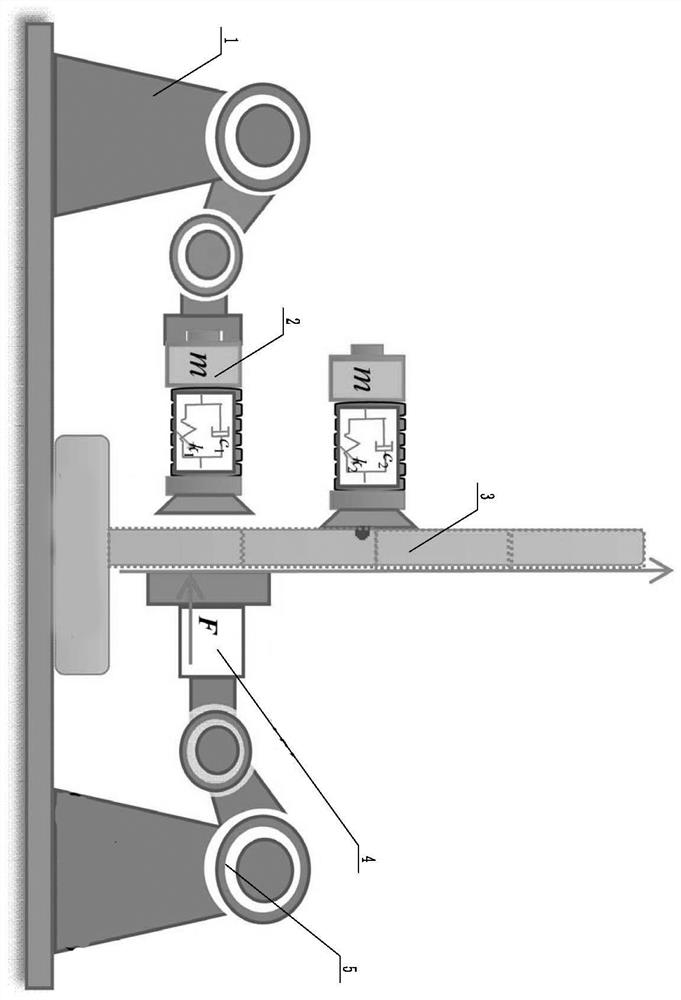

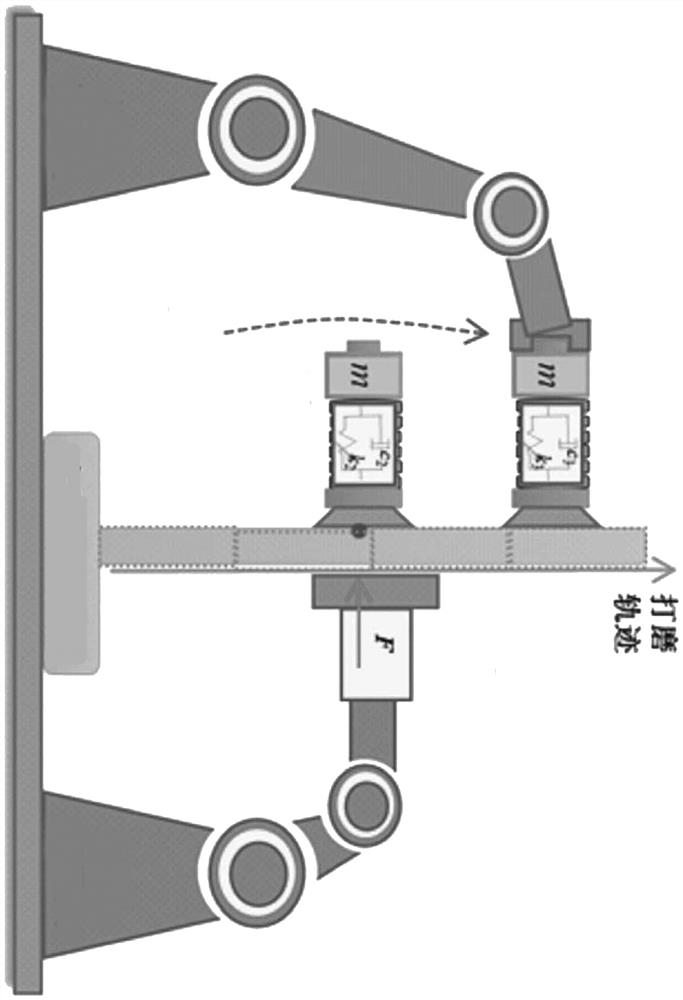

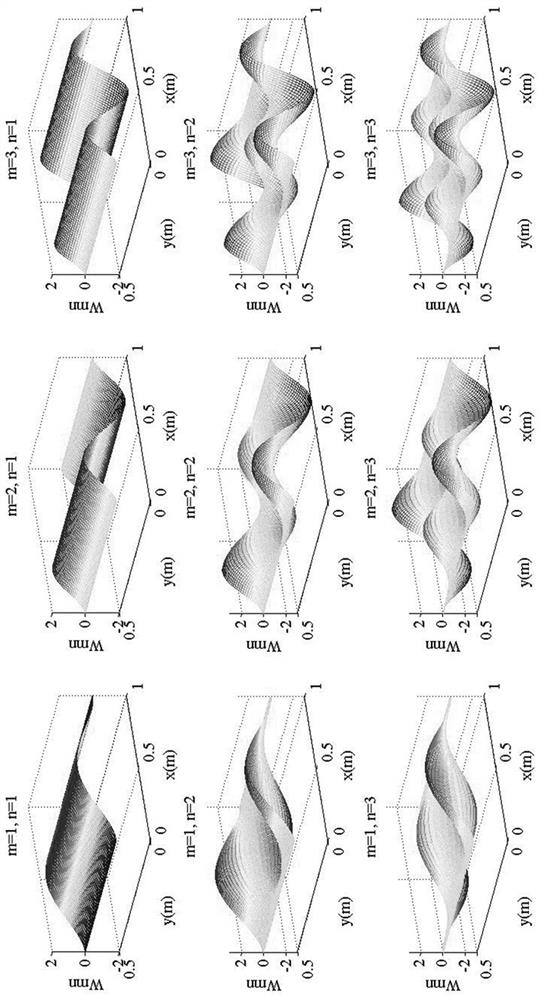

Double-arm robot cooperative vibration reduction method for grinding large thin-walled workpiece

ActiveCN112264852AImprove dynamic stiffnessReduce vibration responseGrinding work supportsPlane surface grinding machinesModal testingClassical mechanics

The invention provides a double-arm robot cooperative vibration reduction method for grinding a large thin-walled workpiece in the technical field of machining. The method comprises the following steps that (1) a steady-state response model of forced vibration of the thin-walled workpiece is analyzed and established; (2) modal testing is carried out on the thin-walled workpiece with two fixed sides and two free sides; (3) an initial value of i is set, and i is equal to 1; (4) the position of a grinding end is input, whether the position of the grinding end is the end point of the grinding track or not is judged, if yes, grinding is finished, and if not, operation turns to the step (5); (5) a target modal is selected, and a vibration absorber is controlled to move to the maximum amplitude position {xi, yi} under the selected target modal; and (6) the position of the next grinding end is input, the maximum modal amplitude position under the target modal at the next grinding position is predicted, if the maximum modal amplitude position of this time is the same as the last maximum amplitude position, a transfer robot does not move, and if the maximum modal amplitude position of this time is different from the last maximum amplitude position, a transfer task is established, and the transfer robot acts. By means of the method, vibration generated when the thin-walled workpiece is ground is reduced.

Owner:BEIHANG UNIV

Fixing structure for exhaust pipes

ActiveCN104670002AImprove dynamic stiffnessReduce in quantityPropulsion unit gas exhaustDynamic stiffnessResonance

The invention provides a fixing structure for exhaust pipes, comprising a rear longitudinal beam, a rear floor, a first exhaust pipe mounting support, a first exhaust pipe mounting hook, a second exhaust pipe mounting hook, a second exhaust pipe mounting support and a rear anti-collision beam. The rear anti-collision beam is connected with the rear longitudinal beam and the rear floor. The first exhaust pipe mounting support and the second exhaust pipe mounting support are both connected with the rear anti-collision beam. The first exhaust pipe mounting hook is disposed on the first exhaust pipe mounting support. The second exhaust pipe mounting hook is disposed on the second exhaust pipe mounting support. The fixing structure has the advantages that dynamic stiffness of the fixing structure is greatly improved, the problem that shaking of the exhaust pipe easily causes resonance and shaking of the floor during running of a vehicle is avoided, electro-coating is sufficient, and the sufficient electrophoretic paint film ensures rust resistance of the fixing structure.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

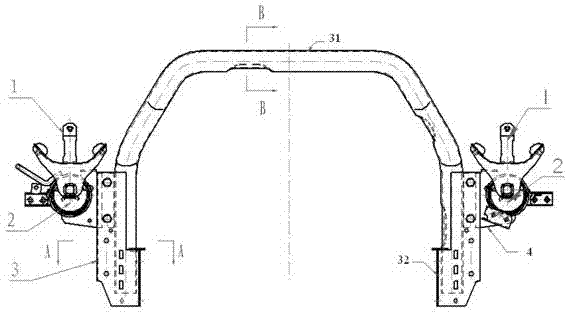

Rear supporting structure of cab

ActiveCN103043116AImprove bending abilityImprove stabilityLoading-carrying vehicle superstructuresVehicle frameRubber mat

The invention provides a rear supporting structure of a cab. The rear supporting structure comprises a pipe beam support, a rubber mat supporting frame, a rubber mat and a small boat support. The pipe beam support comprises a U-shaped pipe and base leg supports, and the base leg supports are fixed at two ends of the U-shaped pipe to have a supporting effect. The rubber mat supporting frame comprises a circular pipe and a supporting frame. One end of the supporting frame is fixedly connected with the circular pipe, and the other end of the supporting frame is fixedly connected with the base leg supports. The rubber mat is fixed on the circular pipe. The small boat support is fixed on the rubber mat. The rear supporting structure adopts a whole pipe beam structure and guarantees that a gap between a left rear support and a right rear support is not affected by vehicle frame extension. The rear supporting structure provides a new suspension liquid charging rubber mat to replace a traditional suspension rubber mat of an automobile cab and achieves shock absorption and noise reducing of the automobile cab. Low-frequency large amplitude vibration of the cab can be effectively restrained by using the liquid charging rubber mat. Simultaneously high-frequency noise in the cab is removed, and riding comfortableness of an automobile is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Rear apron board of automotive body

InactiveCN102700616AReduce weightImprove local stiffnessSuperstructure subunitsEngineeringSquare Shape

The invention relates to a rear apron board of an automotive body. The rear apron board comprises a board body and is characterized in that the left lower part of the board body is provided with a first X-shaped reinforcing rib, and the right lower part of the board body is provided with a second X-shaped reinforcing rib; the middle upper part of the board body is provided with a first horizontal reinforcing rib, the middle lower part of the board body is sequentially provided with a second horizontal reinforcing rib, a third horizontal reinforcing rib and an S-shaped reinforcing rib from top to bottom; and a first vertical reinforcing rib and the second vertical reinforcing rib are arranged between the first horizontal reinforcing rib and the second horizontal reinforcing rib. Because the rear apron board is provided with the first X-shaped reinforcing rib and the second X-shaped reinforcing rib, local rigidity of the point of the reinforcing ribs is improved, the additional arrangement of a reinforcing plate at the reinforcement point is avoided, the weight of the automotive body is reduced, and the cost is saved. Because the two horizontal reinforcing ribs and the two vertical reinforcing ribs are connected in a square shape, the static rigidity and the dynamic rigidity of a metal plate at the point are obviously improved, and the vibration resistance is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Anti-torque pull rod and mounting structure thereof

PendingCN111845313AStable supportImprove scalabilityJet propulsion mountingInternal combustion mountingVehicle frameBush rubber

The invention provides an anti-torque pull rod, which comprises a large-end bushing, a small-end bushing and a pull rod bracket, wherein the large-end bushing comprises a large-end bushing inner pipe,a large-end bushing rubber body and a large-end bushing outer pipe; the large-end bushing outer pipe is provided with a notch, one end of the pull rod bracket penetrates through the notch to be connected with the large-end bushing inner pipe, the other end of the pull rod bracket is connected with the small-end bushing, the large-end bushing outer pipe is provided with a first fixing hole, and the first fixing hole is used for allowing a fixing piece to penetrate through and fixing the large-end bushing outer pipe to an auxiliary frame. The invention further discloses an anti-torque pull rodmounting structure. The anti-torque pull rod of the anti-torque pull rod mounting structure is the anti-torque pull rod; the anti-torsion pull rod mountingstructure further comprises an auxiliary frame, the auxiliary frame comprises an upper layer plate and a lower layer plate, the upper layer plate and the lower layer plate form a mounting opening, second fixing holes are formed in the upper layer plate and the lower layer plate, the large-end bushing is arranged in the mountingopening, and the fixing piece penetrates through the first fixing hole and the second fixing hole to fix the large-end bushing outer pipe to the auxiliary frame.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Method for preparing damping vibration attenuation composite coating on surface of rotary machine thin-shell component

InactiveCN103572221AGood bindingImprove dynamic stiffnessVacuum evaporation coatingSputtering coatingThin shellsRotary machine

The invention provides a method for preparing a damping vibration attenuation composite coating on the surface of a rotary machine thin-shell component, and belongs to the technical field of materials. The method comprises the following steps of (1) by utilizing the rotary machine thin-shell component as a base body, putting the base body in a vacuum chamber of a filtering electric arc ion plating machine; (2) preheating the base body after vacuumizing; (3) charging argon, starting the filtering electric arc ion plating machine, and depositing a titanium coating on the surface of the base body; (4) depositing a Ni60Cr33.7Al4.5Y1.8 alloy coating on the surface of the titanium coating; (5) depositing a magnesium aluminum alloy coating on the surface of the Ni60Cr33.7Al4.5Y1.8 alloy coating to prepare the damping vibration attenuation composite coating on the surface of the base body. The method for preparing the damping vibration attenuation composite coating further has the following characteristics that the pretreatment on the base body does not break the surface structure of a blade; the influence of the low preheating temperature on the structural characteristics of the material of the blade is small; the selected materials of the coating are common without being limited by conditions, such as purchase; the technique is simple, the stability is high, and no pollutants, such as dust and waste gas, in a cleaning process are generated.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com