Internal and external thread grinding machine capable of realizing in-situ modification of grinding wheel

A technology of internal and external threads and grinding wheels, applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve problems such as affecting thread grinding accuracy, reducing the rigidity of grinding wheel headstock, and repeating positioning errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

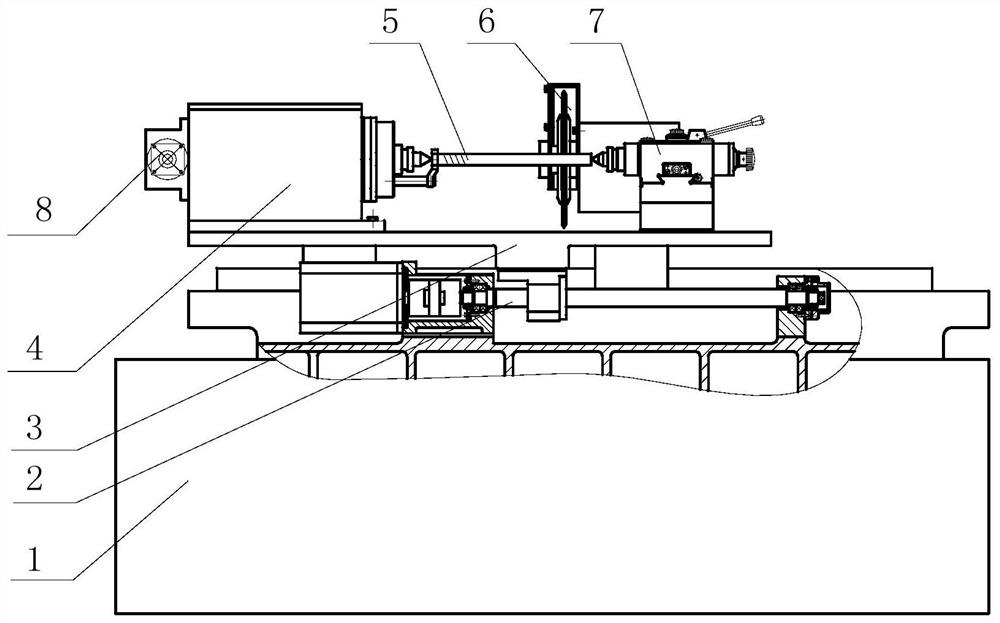

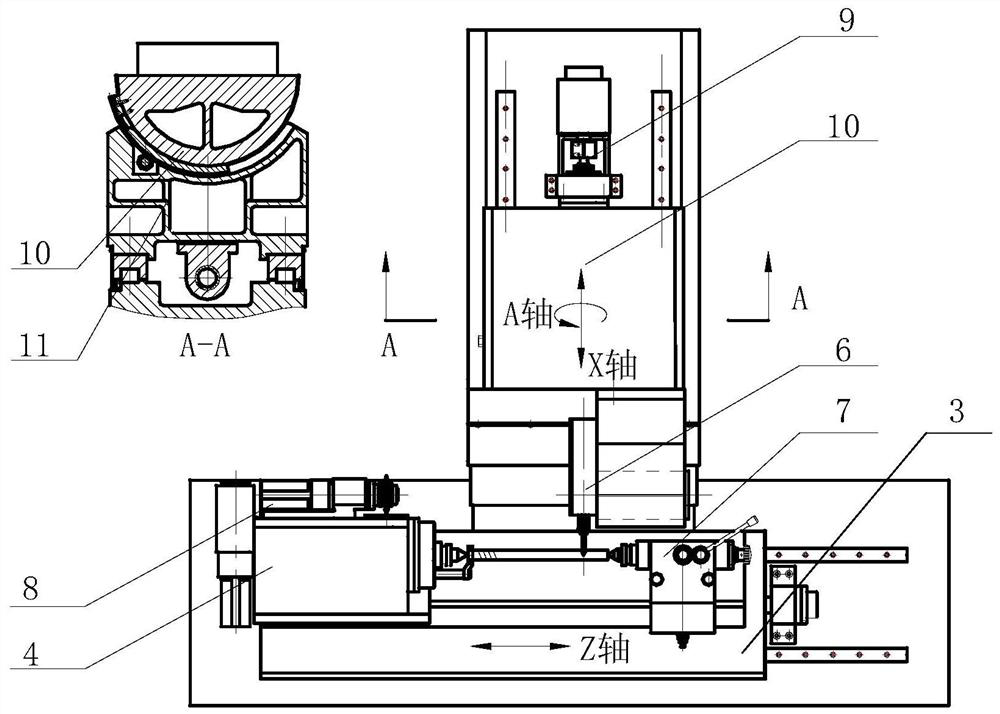

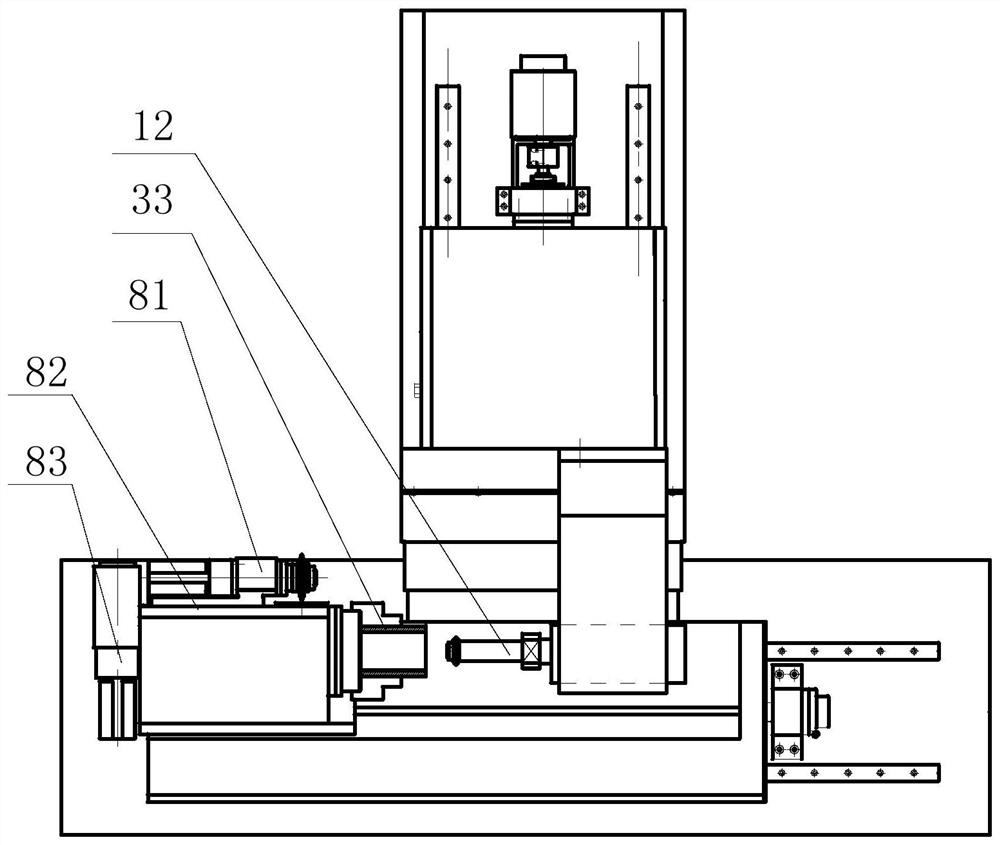

[0052] The present invention is an internal and external thread grinding machine with in-situ modification of the grinding wheel. The A-axis rotary table 10 is arranged on the turntable base 11. The A-axis rotary table 10 can rotate on the turntable base 11. The rotation axis is defined as the A axis, and the rotation axis revolves Rotate in the X-axis direction; large-diameter grinding wheels can be installed on the grinding wheel head frame 6, and the angle adjustment of large-diameter grinding wheels or small-diameter grinding wheels can be realized through the rotation axis A; the swingable angle dresser 8 is fixed on the side of the workpiece head frame 4 to realize self-generation A certain swing angle, the swing angle trimmer 8 is made up of a roller rotation mechanism 81, a swing angle guide mechanism 82, and an angle drive mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com