Latch component, locking mechanism and vehicle

A locking mechanism and locking technology, applied in the field of automobile manufacturing, can solve the problems of sharp and harsh door closing sound, low strength of side wall outer panels, and low low frequency components, so as to increase static and dynamic stiffness, improve the quality of door closing sound, The effect of increased low frequency components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

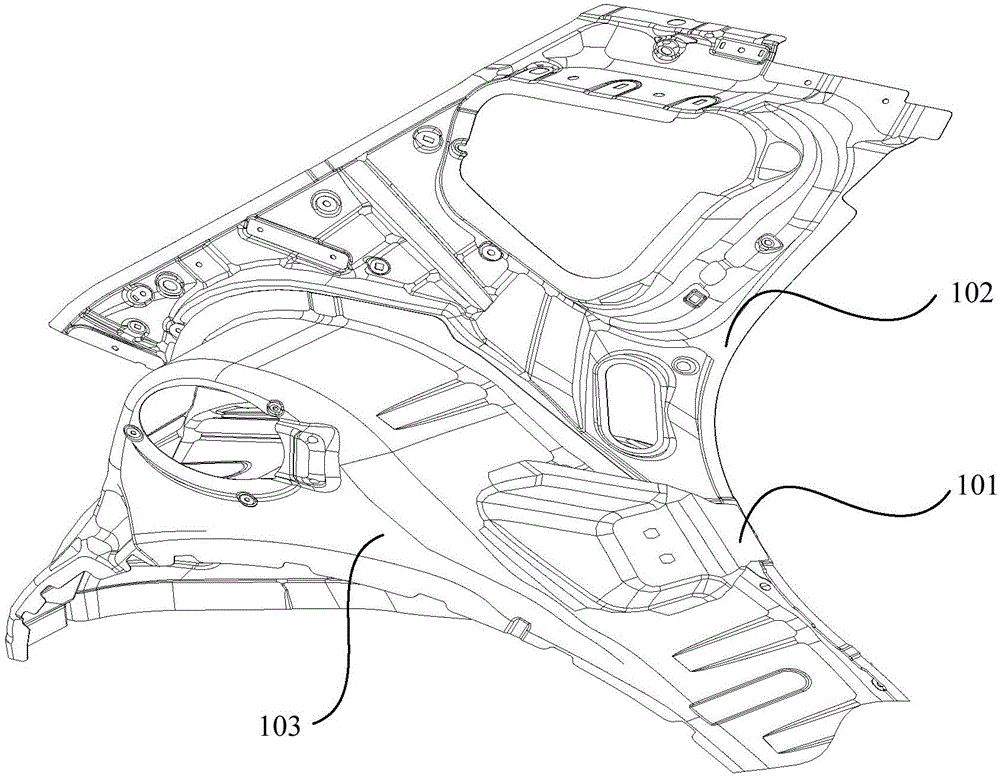

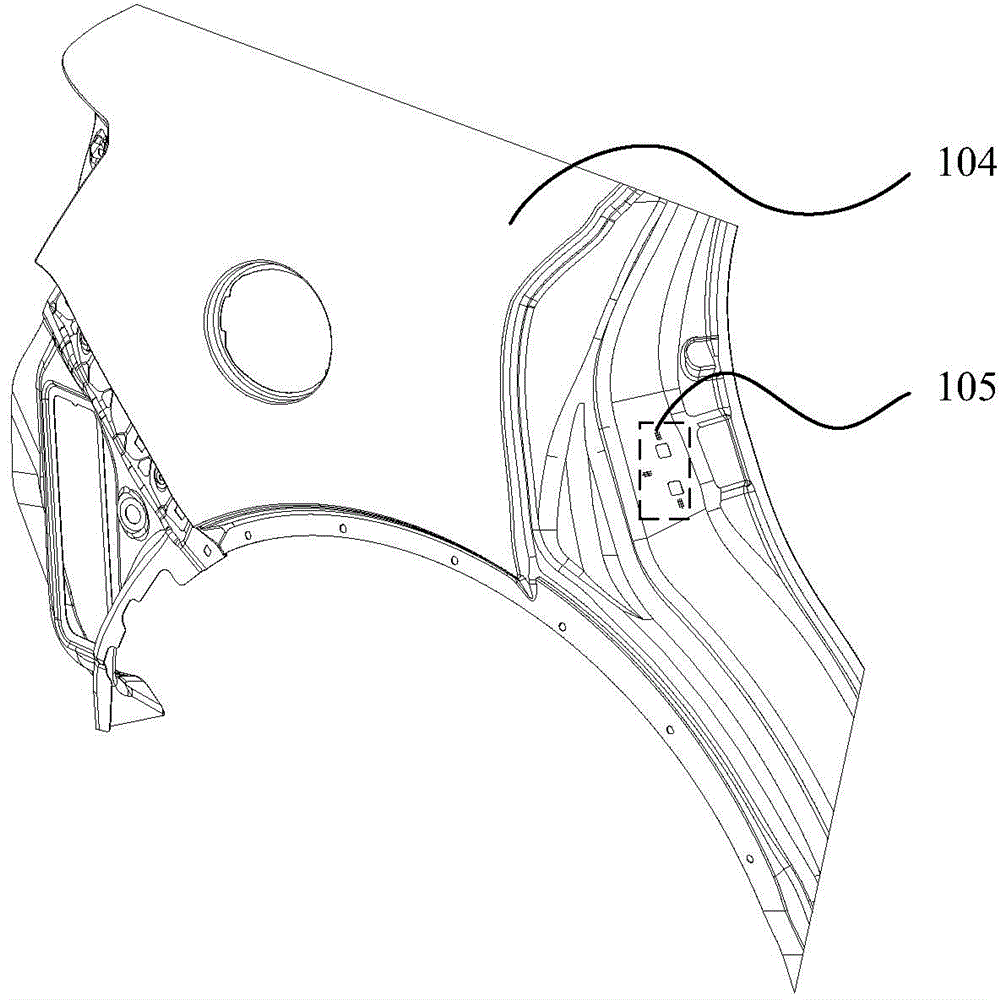

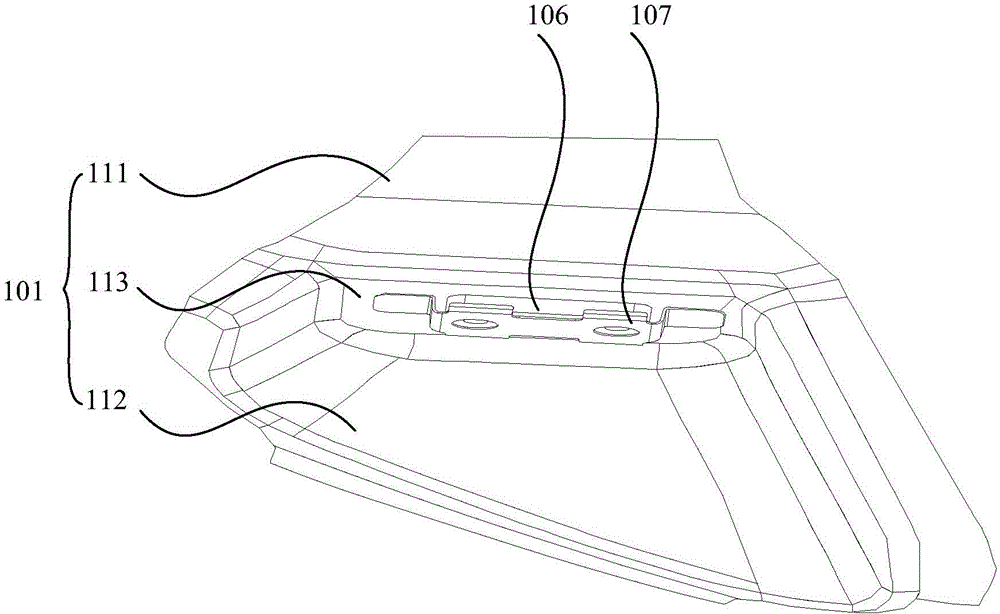

[0039] see figure 1 with figure 2 , the embodiment of the present invention provides a lock assembly, including: a reinforcement plate 101 fixedly installed in a set area of the vehicle body, and a reinforcement plate 101 arranged in the area opposite to the reinforcement plate 101 of the vehicle body, connected to the reinforcement plate by at least two bolts 101 is fixedly connected to the buckle, and the reinforcing plate 101 is located on the inside of the vehicle body, and the lock buckle is located on the outside of the vehicle body.

[0040] During specific implementation, first, the reinforcing plate 101 is installed on the set area inside the vehicle body. The set area mentioned here includes but not limited to the side wall outer panel 104 of the vehicle body, the C-pillar inner panel 102, and / or the outside of the rear wheel house. plate 103, and then install the buckle on the outside of the vehicle body, and be fixedly connected with the reinforcing plate 101 b...

Embodiment 2

[0049] An embodiment of the present invention also provides a locking mechanism, including: a door lock, matching with the door lock, and the lock assembly mentioned in Embodiment 1. During specific implementation, the door lock is installed on the door opening side of the rear door, and the lock assembly is installed on the set position of the vehicle body; when the rear door is closed, the door lock cooperates with the lock assembly to lock the rear door on the vehicle body. Utilizing the reinforcing plate in the above-mentioned lock assembly can increase the static stiffness and dynamic stiffness of the connection area between the vehicle body and the lock, so that the high-frequency components in the door-closing sound issued when the door is closed are reduced, the low-frequency components are increased, and the door-closing sound becomes muffled, thereby Improved the sound quality of closing doors.

Embodiment 3

[0051] The embodiment of the present invention also provides an automobile, including: a vehicle body, a door installed on the vehicle body, and the locking mechanism mentioned in Embodiment 2, wherein the door lock of the locking mechanism is installed on the door opening side of the vehicle door, and the locked The locking assembly of the mechanism is installed in the set area of the vehicle body. For example, when the above-mentioned locking mechanism is used at the rear door of the automobile, after the rear door is closed, the door lock of the locking mechanism cooperates with the latch assembly to lock the rear door on the vehicle body. Utilizing the reinforcing plate in the above-mentioned lock assembly can increase the static stiffness and dynamic stiffness of the connection area between the vehicle body and the lock, so that the high-frequency components in the door-closing sound issued when the door is closed are reduced, the low-frequency components are increased, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com