Rear apron board of automotive body

A technology for automobile body and rear apron, which is applied to vehicle parts, upper structure, upper structure sub-assembly, etc. It can solve problems such as easy vibration and noise, weak rear apron stiffness, etc., so as to improve local stiffness and rigidity performance , The effect of reducing the weight of the vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the present invention will be further explained below in conjunction with the drawings.

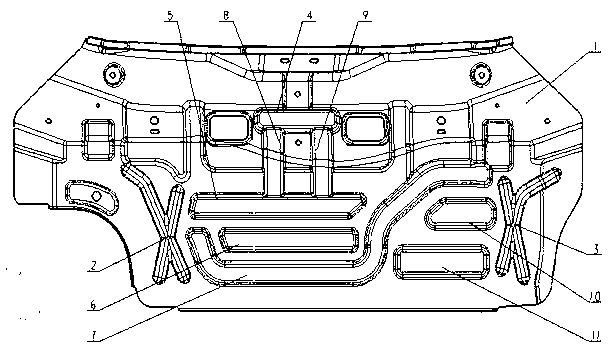

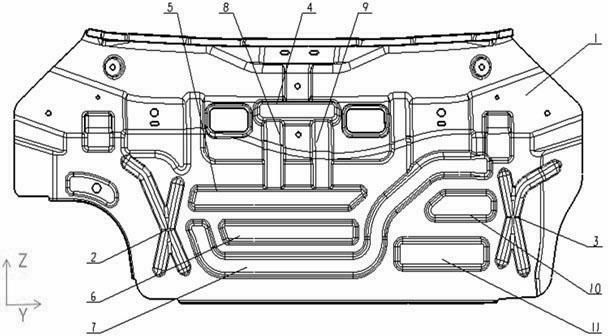

[0016] See figure 1 A rear apron of an automobile body is shown. The plate body is a sheet metal member. A first "X"-shaped reinforcing rib 2 is provided on the lower left part of the plate body 1, and a second "X" shaped stiffener 3;

[0017] The middle and upper part of the plate body 1 is provided with a first transverse stiffener 4, and the middle and lower part of the plate body 1 are successively arranged with a second transverse stiffener 5, a third transverse stiffener 6 and an "S"-shaped stiffener from top to bottom. Tendons 7;

[0018] Between the first horizontal reinforcing rib 4 and the second horizontal reinforcing rib 5, a first vertical reinforcing rib 8 and a second vertical reinforcing rib 9 are provided. These two vertical reinforcing ribs and two horizontal reinforcing ribs are connected to form a " Mouth" shaped structure.

[0019] Furthermore, betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com