Patents

Literature

57results about How to "Improve stiffness performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stiff-feel hair styling compositions

InactiveUS6214328B1Increase stiffnessOptimum hydrophiliclhydrophobic balanceCosmetic preparationsHair cosmeticsMeth-Dicarboxylic acid

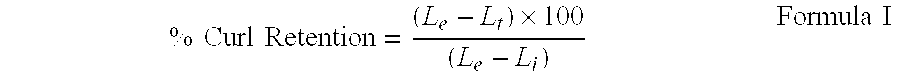

A method for enhancing the performance of hair fixative resins in hair styling compositions by using selected polymers having certain compositions is disclosed. In particular, the present invention involves a method of improving the stiffness performance of hair fixative resins by using polymers containing 5-95% (C1-C10)alkyl (meth)acrylate, 0-70% hydroxyalkyl (meth)acrylate, 0-50% monocarboxylic acid monomer and 1-25% dicarboxylic acid monomer. The selected polymers are particularly useful in aqueous hair styling compositions containing low (80% or less) volatile organic compound (VOC) concentrations.

Owner:ROHM & HAAS CO

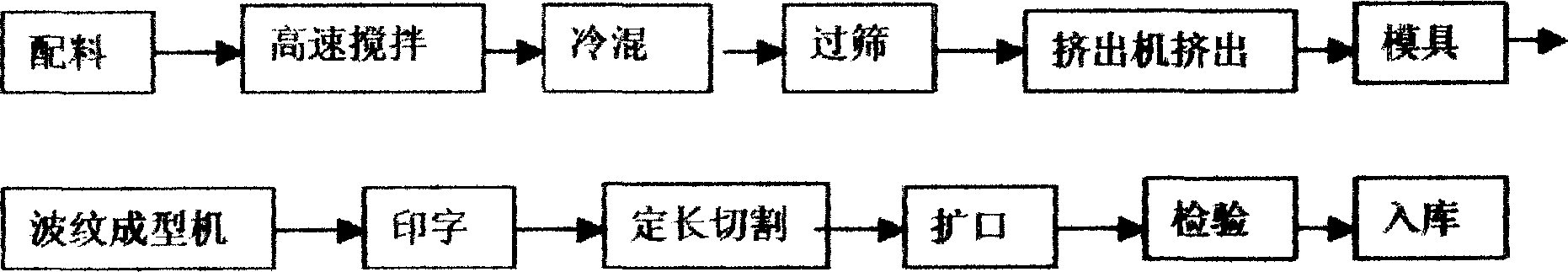

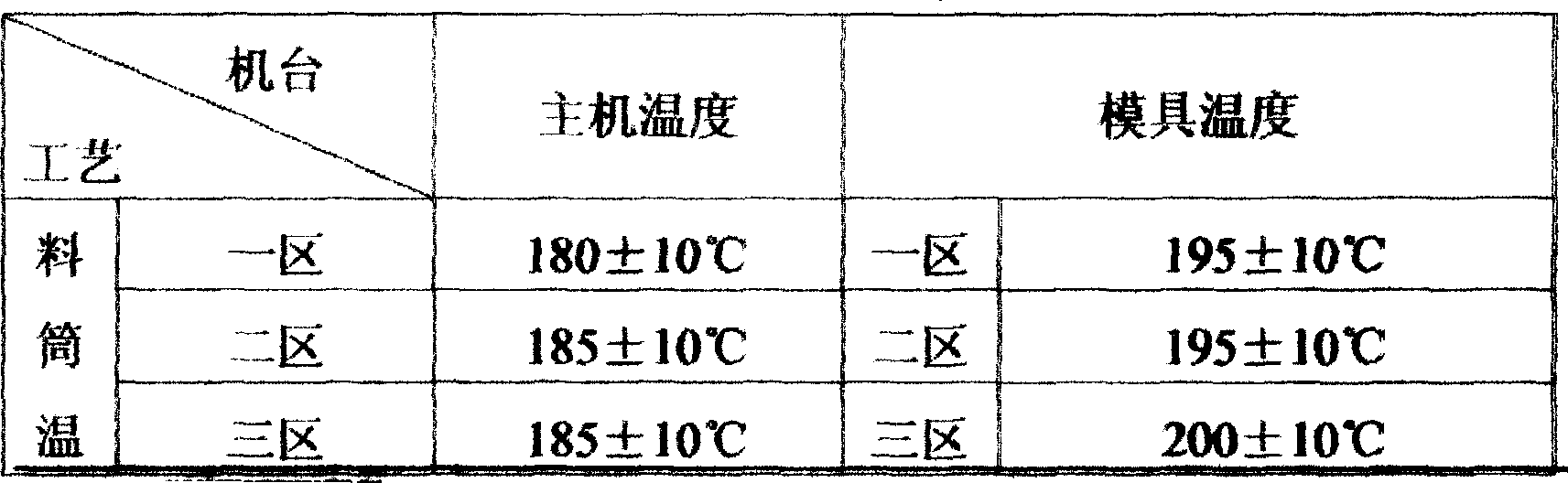

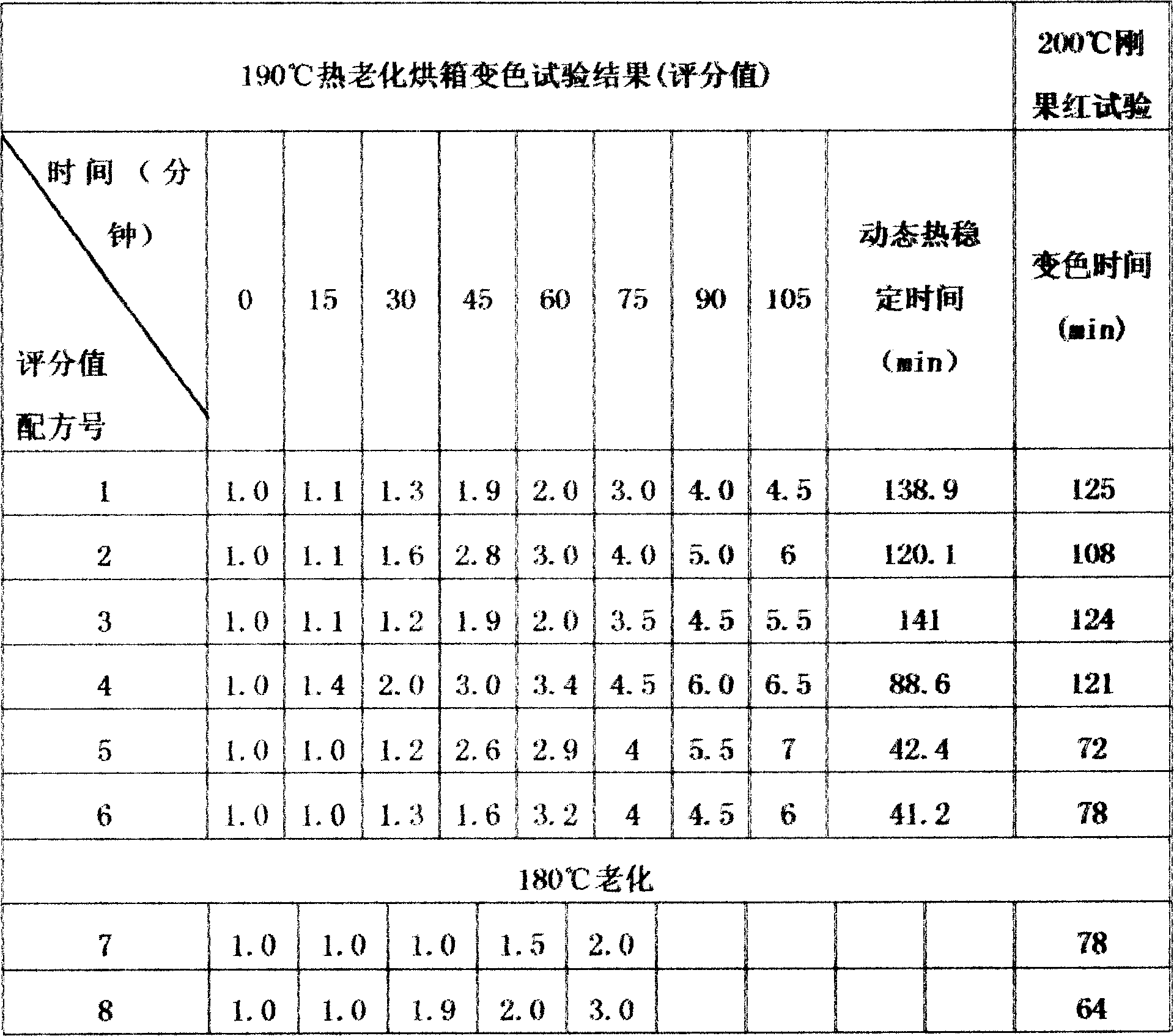

Formula for producing polyvinyl chloride double-wall corrugated pipe

InactiveCN101029160AGood weather resistanceGood light aging performanceRigid pipesChemistryCalcium carbonate

Formula for producing polyvinyl chloride double-wall bellow consists of hard polyvinyl chloride resin 100 proportion, rare-earth thermal stabilizer 3-6 proportion, lubricant 1.5-2.5 proportion, coupling agent 0.5-1.0 proportion, acrylic ester 2-4 proportion, modifier 6-10 proportion, rare-earth modified calcium carbonate 10-25 proportion. It substitutes lead stabilizer and can be used for blow-off pipe and environmental-protection construction.

Owner:郑皓匀

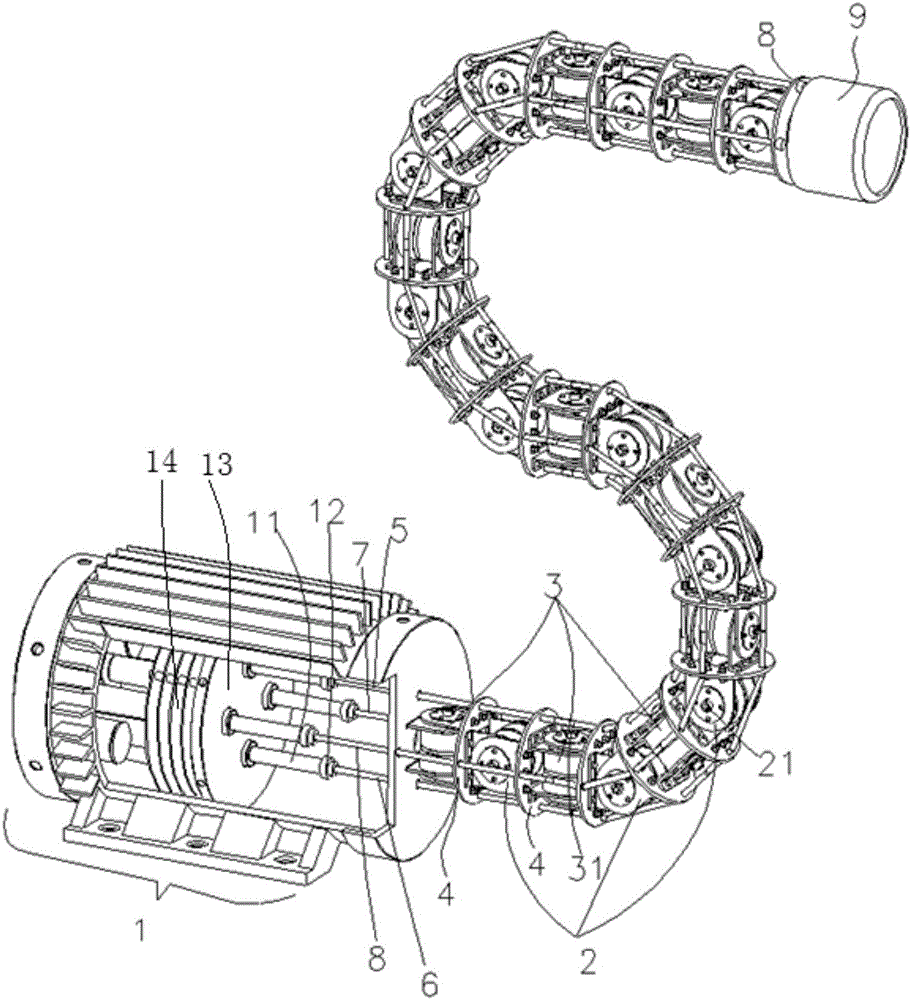

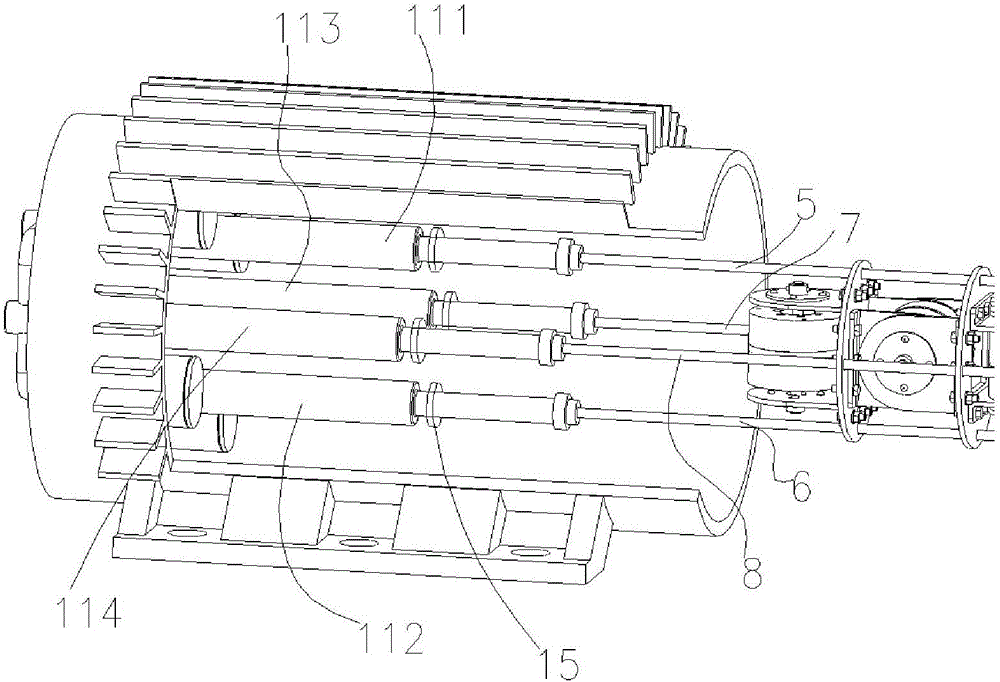

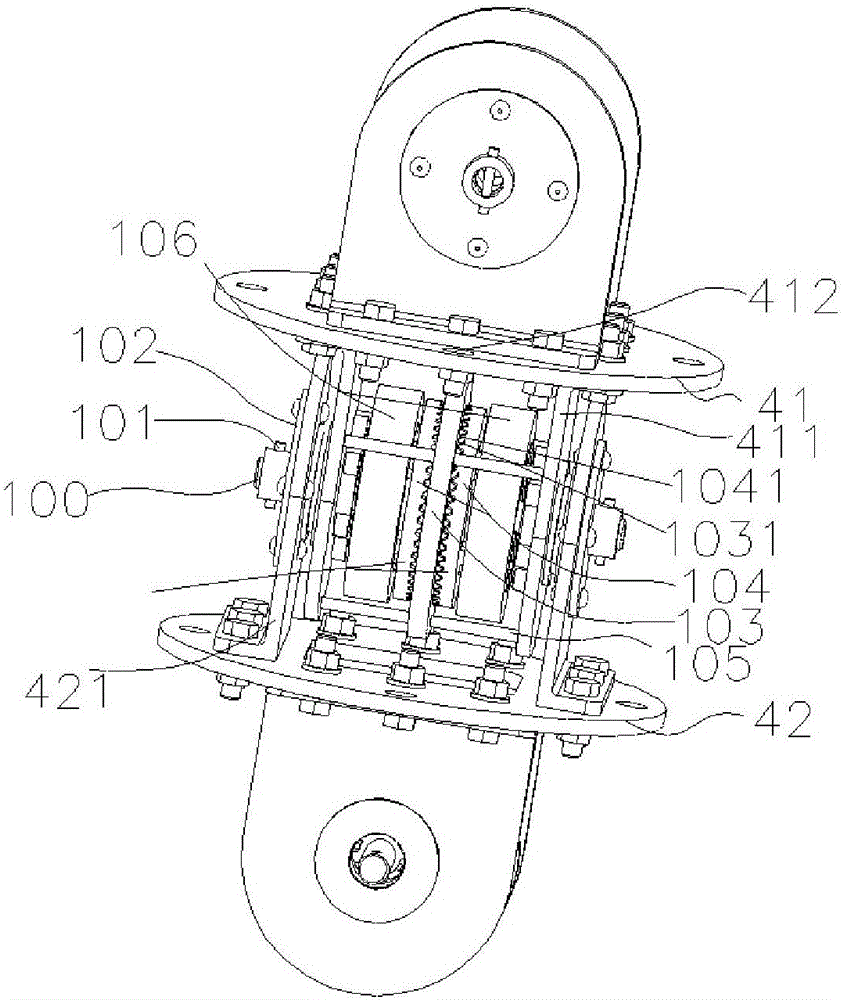

Multi-joint flexible mechanical arm

ActiveCN106113019AUnity of modular designCompact structureProgramme-controlled manipulatorJointsRobotic armReciprocating motion

The invention provides a multi-joint flexible mechanical arm. The multi-joint flexible mechanical arm comprises a driving part, rotating joints, pull wires, brakes and a comprehensive brake, wherein the driving part drives multiple push rods to perform a linear reciprocating motion; the rotating joints include longitudinal rotating joints and transverse rotating joints orthogonally staggered and connected; pivot shafts of the longitudinal rotating joints are perpendicular to pivot shafts of the transverse rotating joints; the longitudinal rotating joints and the transverse rotating joints can rotate and stop around respective pivot shafts; multiple pull wires penetrate through each rotating joint in sequence from the peripheries of the rotating joints; each pull wire is singly connected with the corresponding push rod; the other ends of the pull wires penetrate out of the rotating joint at the most front end for fixing; all the rotating joints are provided with the brakes; and the comprehensive brake uses the linear reciprocating motion of the push rods to tighten or release the pull wires so as to control rotation of the rotating joints. The multi-joint flexible mechanical arm cancels a joint motor, reduces the joint structure complexity and the electric energy consumption, and is provided with a push rod extension detecting device for replacing all joint detecting devices of the arm to reduce the cost.

Owner:CHANGCHUN UNIV OF SCI & TECH

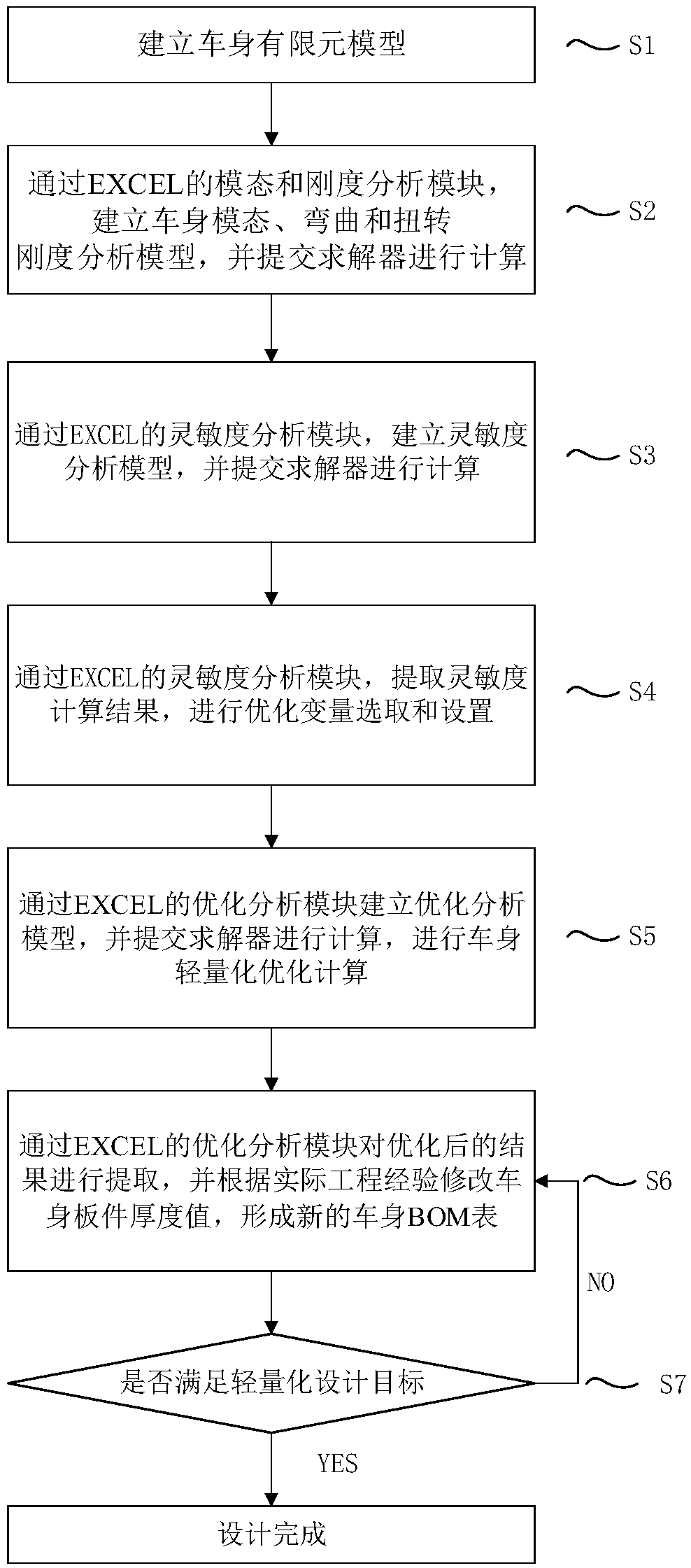

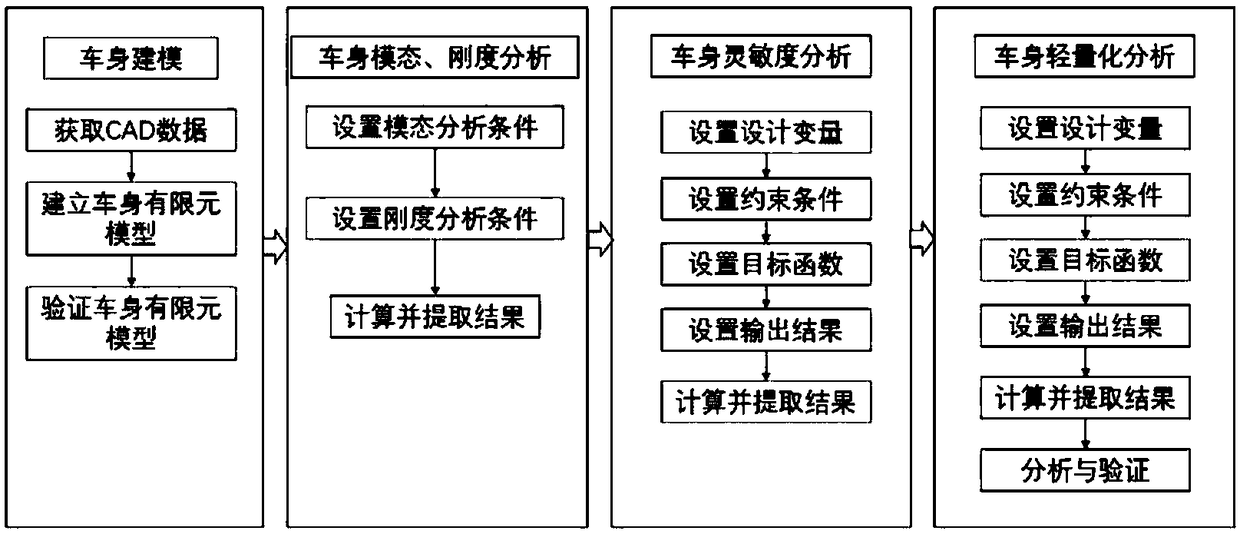

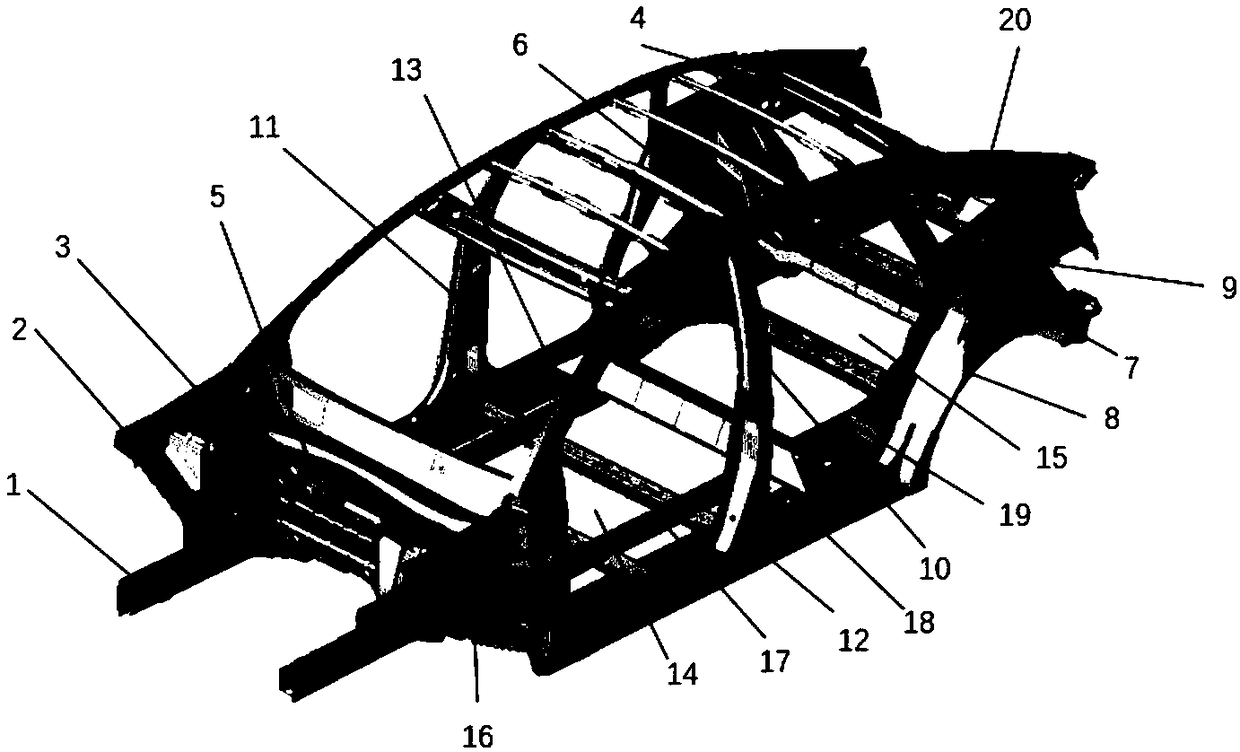

Car body light-weight design method

PendingCN108804857AMeet the stiffness requirementsReduce weightGeometric CADDesign optimisation/simulationElement modelBody weight

The invention relates to a car body light-weight design method. The method comprises the steps of building a car body finite element model; 2, building a car body modal, bending and torsional rigidityanalysis model, and calculating and obtaining modal, bending and torsional rigidity values; 3, building a sensitivity analysis model and performing solution calculation; 4, performing finishing according a sensitivity analysis model calculating result, obtaining a sensitivity analysis result of a car body metal plate corresponding to the design variable; 5, building a car body light-weight optimizing calculation model, and performing solution calculation; 6, performing extraction on the calculation result, and modifying a thickness value of some metal plates so as to meet the requirement forengineering, and forming a novel BOM table; 7, judging whether the BOM table reaches a light-weight design target or not, if yes, completing designing, and if not, repeatedly executing the step 6 tillthe light-weight design goal is reached. Compared with the prior art, the requirement for the car body rigidity is met effectively, the car body weight is lowered, the high engineering practicabilityis achieved, and the applicability is high.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

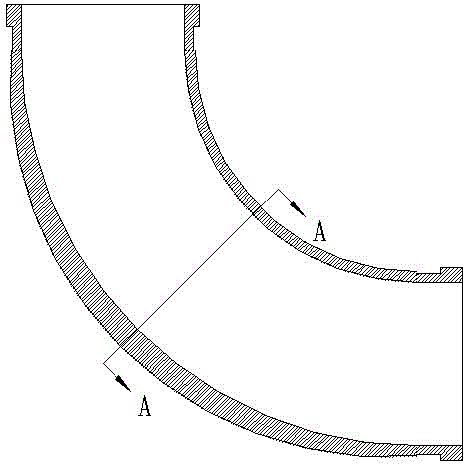

Carbon fiber delivery pipe for delivering concrete, and production method thereof

InactiveCN103256436AReduce quality problemsImprove stiffness performanceRigid pipesPipe protection against damage/wearFiberCarbon fibers

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

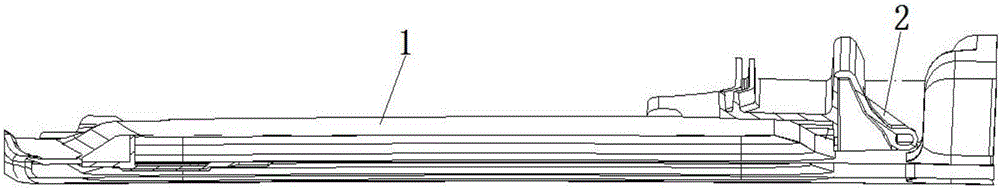

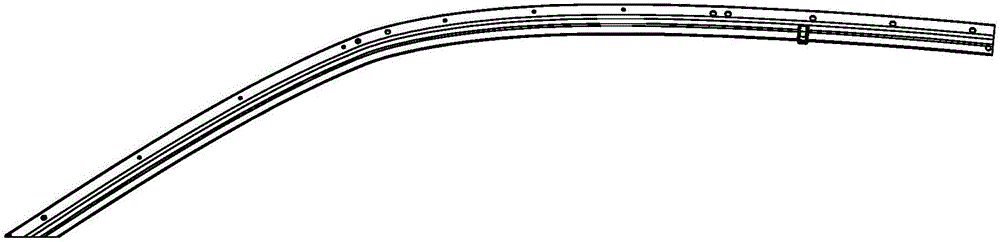

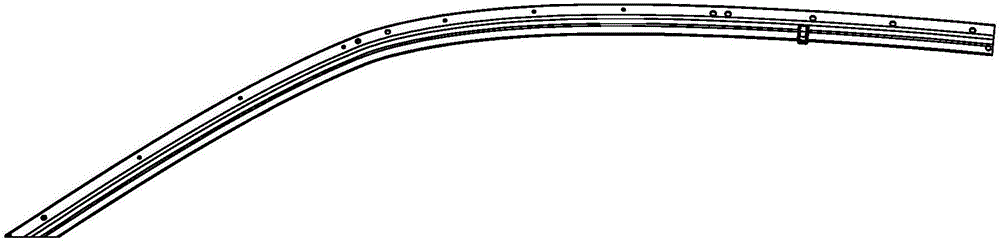

Assembly structure of automobile skylight sun shield and rear drainage groove

An assembly structure of an automobile skylight sun shield and a rear drainage groove comprises the sun shield, the rear drainage groove and a guide rail. The sun shield and the rear drainage groove are arranged on the guide rail in a sliding mode. The rear portion of the sun shield and the rear drainage groove move in a linkage mode. When a skylight is closed to a corresponding position, a skylight sun shield slider and the rear drainage groove are matched for linkage movement, and the skylight sun shield is correspondingly closed along with closing of the skylight. When the skylight is opened to a corresponding position, the rear drainage groove of the skylight and the sun shield are matched for linkage movement, and the skylight sun shield is correspondingly opened along with opening of the skylight. The assembly structure is simple and convenient to use, the sun shield and the rear drainage groove are made to be matched with each other, and practical meaning is large.

Owner:ANHUI DIKUN AUTO SKYLIGHT TECH CO LTD HEFEI

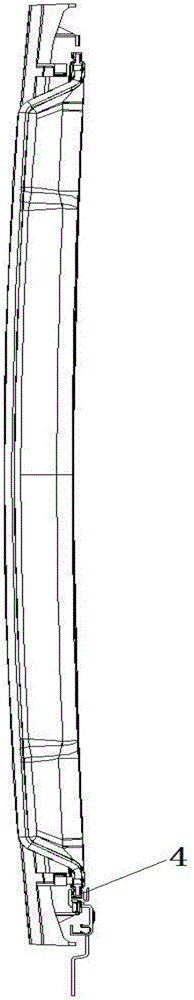

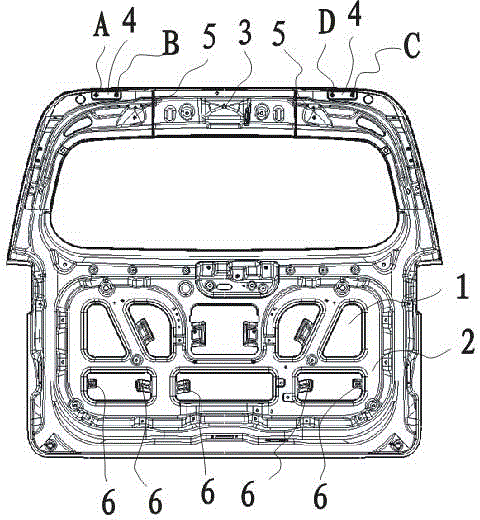

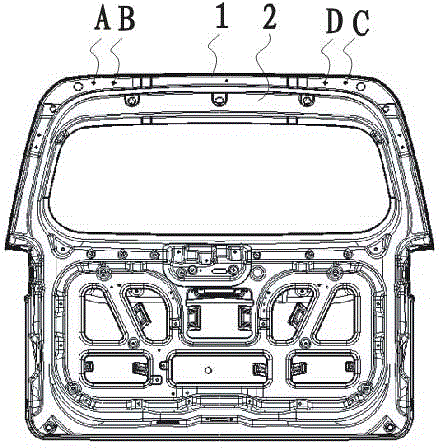

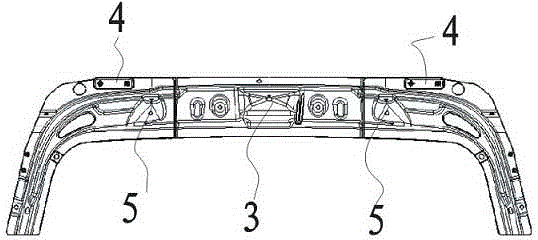

Automobile back door strengthening structure

The invention relates to an automobile back door, in particular to an automobile back door strengthening structure. The automobile back door strengthening structure comprises a back door outer plate and the back door, wherein a back door inner plate and the back door are fixed into a whole. A connecting plate is arranged at the upper portion of an inner cavity formed between the back door outer plate and the back door inner plate, inner plate strengthening plates are fixed to the two ends of the connecting plate, and a strengthening structure is formed by the connecting plate and each inner plate strengthening plate, wherein two face plates of the strengthening structure, the inner plate face of the back door outer plate and the inner plate face of the back door inner plate are welded into a whole. Due to the structure, the modality and lateral rigidity of the back door are improved, and the rigidity performance of a hinge installing point is enhanced.

Owner:北汽瑞翔汽车有限公司

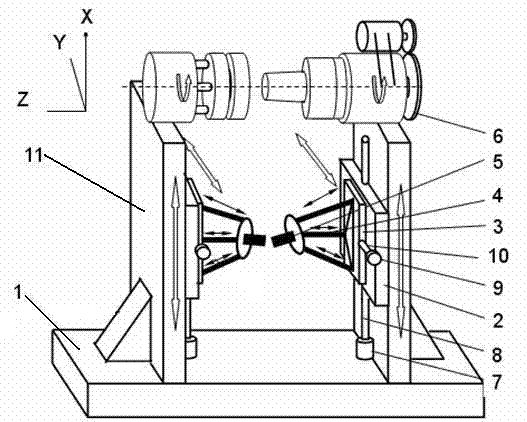

Double-blade and double-faced symmetric machining device of large propellers

InactiveCN102896375AStrong rigidityImprove stiffness performancePrecision positioning equipmentFeeding apparatusPropellerDrive motor

The invention discloses a double-blade and double-faced symmetric machining device of large propellers, and relates to propeller machining devices. The device is provided with a fixed seat; a pair of symmetric propeller machining devices are arranged on the fixed seat; each propeller machining device comprises a supporting frame, an X-direction sliding seat, an X-direction driving screw rod, and a machining power device consisting of an X-direction driving motor, a Y-direction sliding seat, a Y-direction driving screw rod and a Y-direction driving motor; a small-free-degree parallel mechanism is arranged on the Y-direction sliding seat; a machining tool is arranged at the executing end of the small-free-degree parallel mechanism; and dividing mechanisms matched with the propeller machining devices and used for clamping propellers are arranged on the two supporting frames. The device can symmetrically machine the pressure surface and a suction surface of a paddle of the propeller, double-faced symmetric machining can effectively eliminate cantilever beam effect generated during the machining process, simultaneously reduce vibration, and improve the rigidity performance of the machining device, the machining efficiency and the machining accuracy of the propeller are high, and the invisibility and the safety of military submarines are guaranteed.

Owner:HARBIN INST OF TECH AT WEIHAI

Carbon fiber paper reinforced thermoplastic resin sandwich composite material and preparation method thereof

InactiveCN106313782APromote formationPlay a conductive functionSynthetic resin layered productsLaminationCarbon fibersElectromagnetic shielding

The invention discloses a carbon fiber paper reinforced thermoplastic resin sandwich composite material. The composite material is formed through compounding two resin skin layers and a core layer positioned between the two resin skin layers, every resin skin layer is a thermoplastic resin composite material layer, and the core layer is a carbon fiber paper reinforcement. The invention also discloses a preparation method of the composite material. Clamping of the carbon fiber paper reinforcement between resins is similar to the effect of steel bars in concrete, so the carbon fiber reinforcement effect of carbon fiber papers is guaranteed, the continuity and the load transmission and dispersion property of the fiber reinforcement are guaranteed, the material is isotropic, and the integral performances of the composite material are improved; and the continuously distributed carbon fibers are in favor of forming effective channels among the carbon fibers in order to well show the conductive, antistatic and electromagnetic shielding functions.

Owner:HEFEI GENIUS NEW MATERIALS

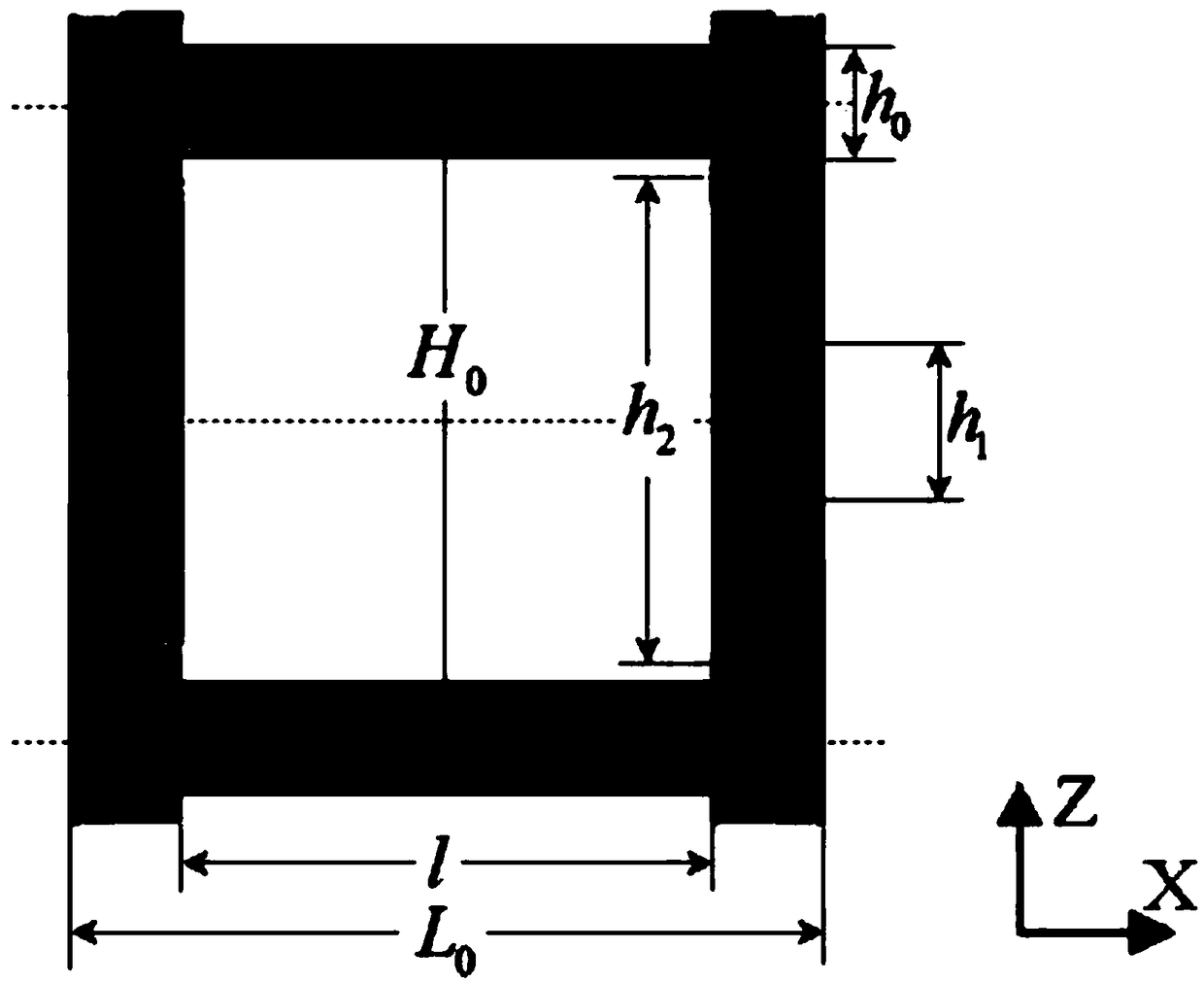

Double-material high-rigidity porous negative-Poisson's-ratio cell and structural component thereof

ActiveCN108389258AImprove stiffness performanceDesign optimisation/simulationSpecial data processing applicationsEngineeringSelf adaptive

A double-material high-rigidity porous negative-Poisson's-ratio cell and a structural component thereof belong to the technical field of elastomeric material science. The cell of a rectangular ambulatory plane structure comprises two lateral sides in mirroring symmetry and two crossbeams in parallel symmetry, the lateral sides made of double materials present a negative Poisson's ratio effect. Thestructural component of the double-material high-rigidity porous negative-Poisson's-ratio cell is of a stereoscopic structure, and is formed by arranging multiple double-material high-rigidity porousnegative-Poisson's-ratio cells in a 3D manner. The finite element value of the structural component is simulated, it is verified that the structural component has the negative Poisson's ratio effectand a higher rigidity compared with a traditional honeycomb structure, the high-rigidity structural design broadens the application range of the negative Poisson's ratio structure, and functions including damping and energy absorbing can be realized according to change of adaptive rigidity performance of the structure.

Owner:NORTHEASTERN UNIV

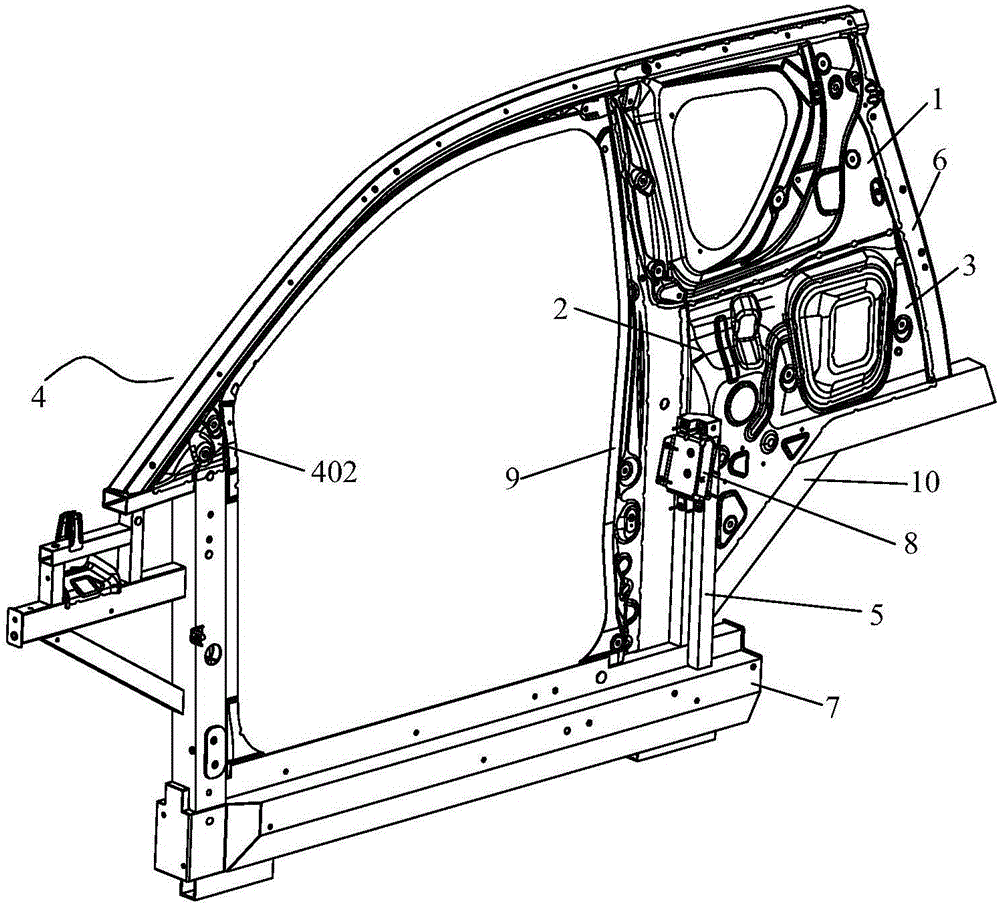

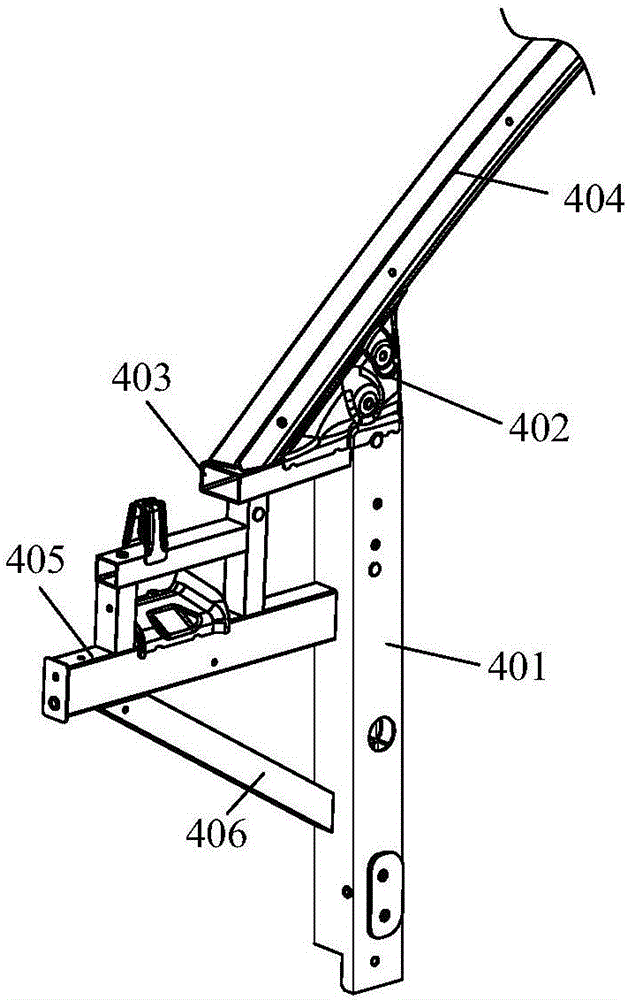

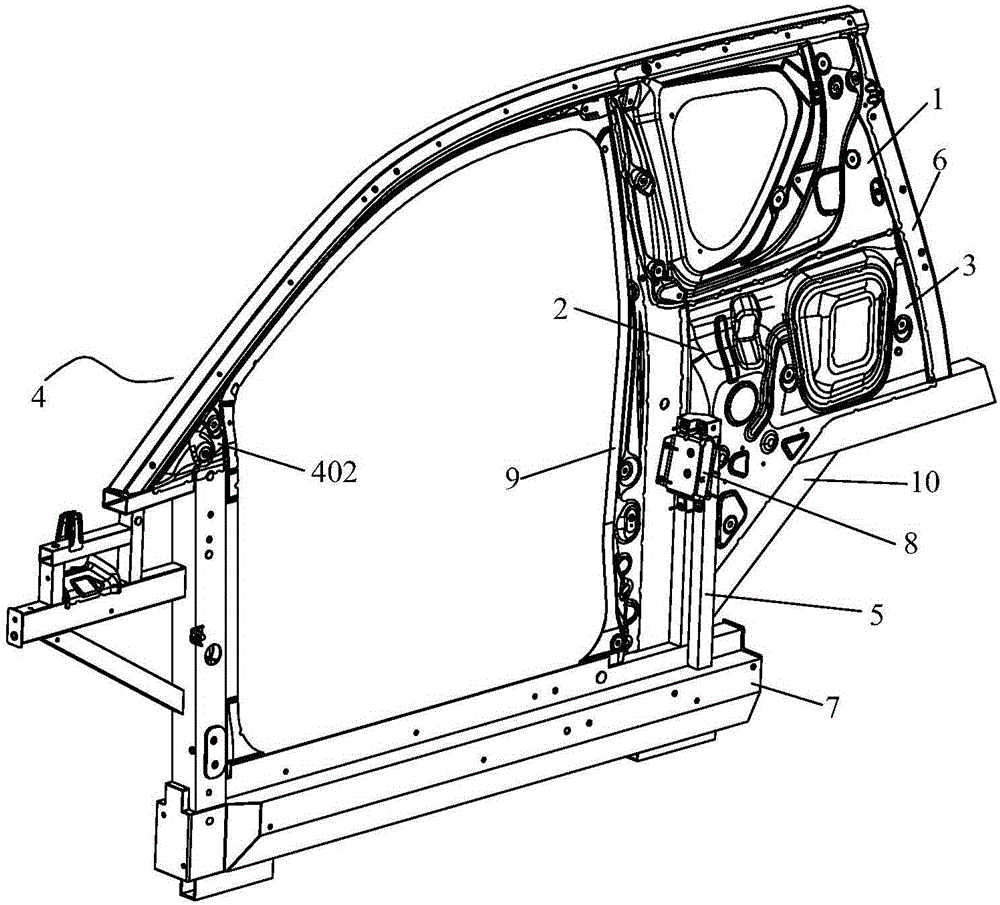

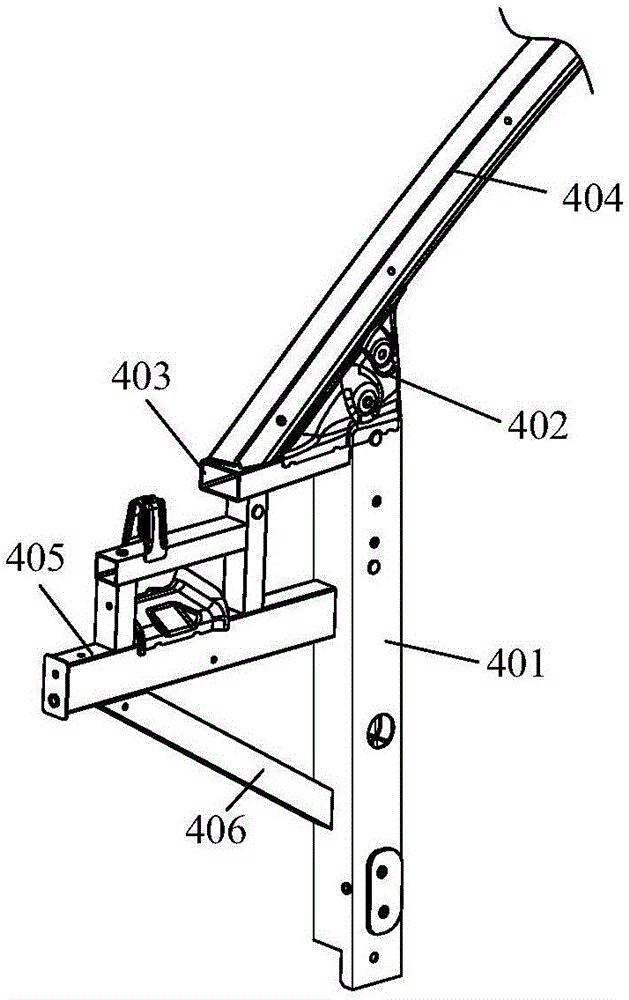

Body-side B column connection structure

ActiveCN106143633AImprove stiffness performanceMiniaturizationSuperstructure subunitsStructural engineeringElectric vehicle

The invention discloses a body-side B column connection structure which comprises a B column assembly, a threshold beam assembly connected with one end of the B column assembly and a top boundary beam connected with the other end of the B column assembly, wherein the top boundary beam is made of an aluminum section, and a cavity is formed inside. The body-side B column connection structure disclosed by the invention is made of a hollow aluminum section, has the advantages of light overall weight, high strength and better crash safety, facilitates the light weight of an electric vehicle and can effectively prolong the endurance mileage of the electric vehicle; and moreover, the top boundary beam is made of the aluminum section, has simple structure and good rigidity and improves the rigidity of the body-side B column connection structure.

Owner:奇瑞新能源汽车股份有限公司

Automobile body side wall rear structure

ActiveCN106184390AMiniaturizationImprove battery lifeSuperstructure subunitsUltimate tensile strengthMechanical engineering

The invention discloses an automobile body side wall rear structure which comprises a column B assembly, a column C assembly and a top edge beam connected with the column B assembly and the column C assembly. The top edge beam is made of aluminum profiles and internally provided with a cavity. The automobile body side wall rear structure is made of the hollow aluminum profiles, the overall weight is small, strength is high, the collision safety performance is more excellent, lightweight of an electric automobile is facilitated, and the cruising mileage of the electric automobile can be effectively increased; and the top edge beam arranged in a penetrating manner is made of the aluminum profiles, the structure is simple, rigidity is good, and the rigidity performance of a side wall assembly is improved.

Owner:奇瑞新能源汽车股份有限公司

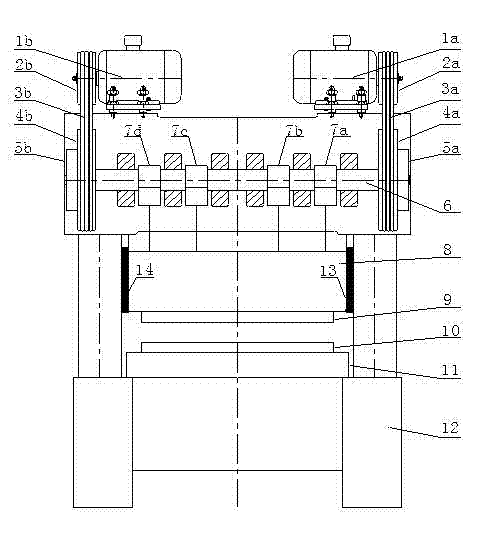

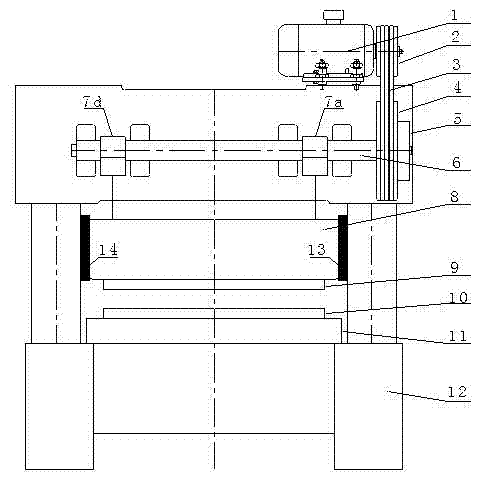

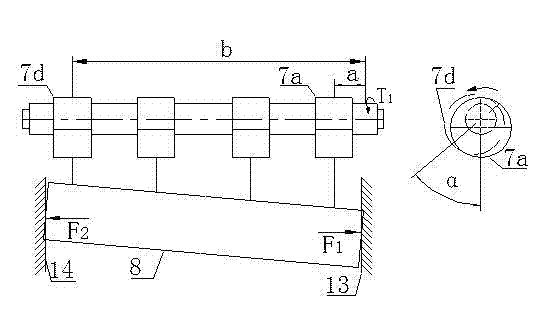

Bilateral drive four-point force press

Bilateral drive four-point force press, which includes: a main shaft, a first eccentric force application point, a second eccentric force application point, a third eccentric force application point, a fourth eccentric force application point, a driver, a first flywheel and a second flywheel, a second eccentric force application point, A clutch and a second clutch, the first eccentric force application point, the second eccentric force application point, the first flywheel and the first clutch are located on one side of the main shaft, the third eccentric force application point, the fourth eccentric force application point, the second flywheel and the second clutch Located on the other side of the main shaft, the driver drives two flywheels to rotate at the same time. The two flywheels drive a main shaft to rotate through the action of two clutches. Four eccentric force application points are installed on the main shaft, and the main shaft drives the slider through the action of four eccentric force application points. It moves up and down, thereby driving the upper mold of the press mold installed on the bottom plane of the slider to reciprocate up and down, and completes the processing of the workpiece between the upper mold and the lower mold. The movement precision, the bottom dead point precision, the guide precision and the precision of the workpiece processing of the slider are improved, and at the same time, it is beneficial to prolong the service life of the press machine and the mold.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

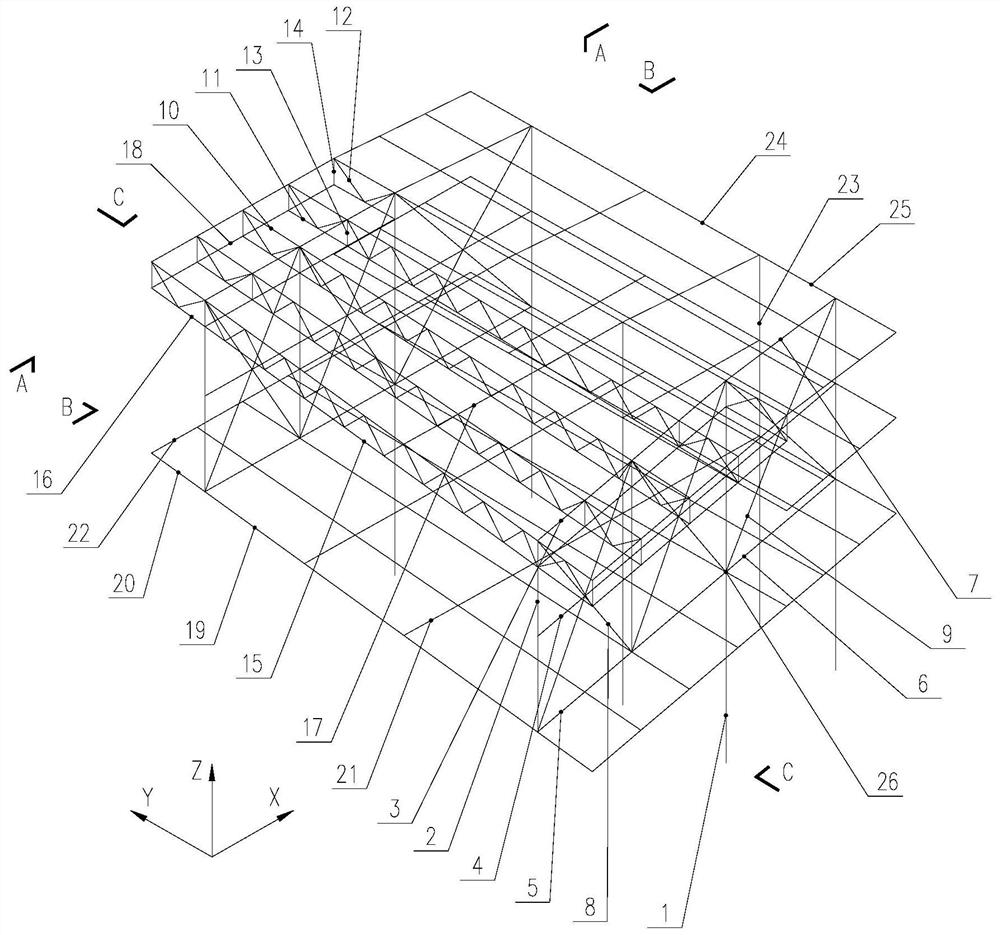

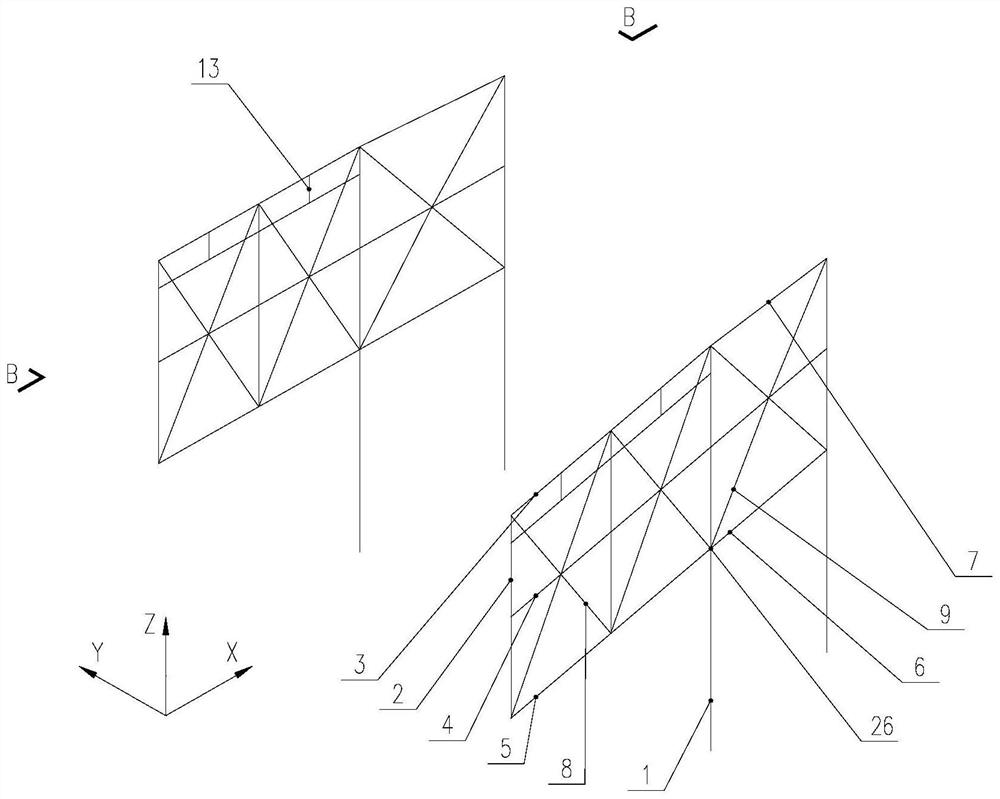

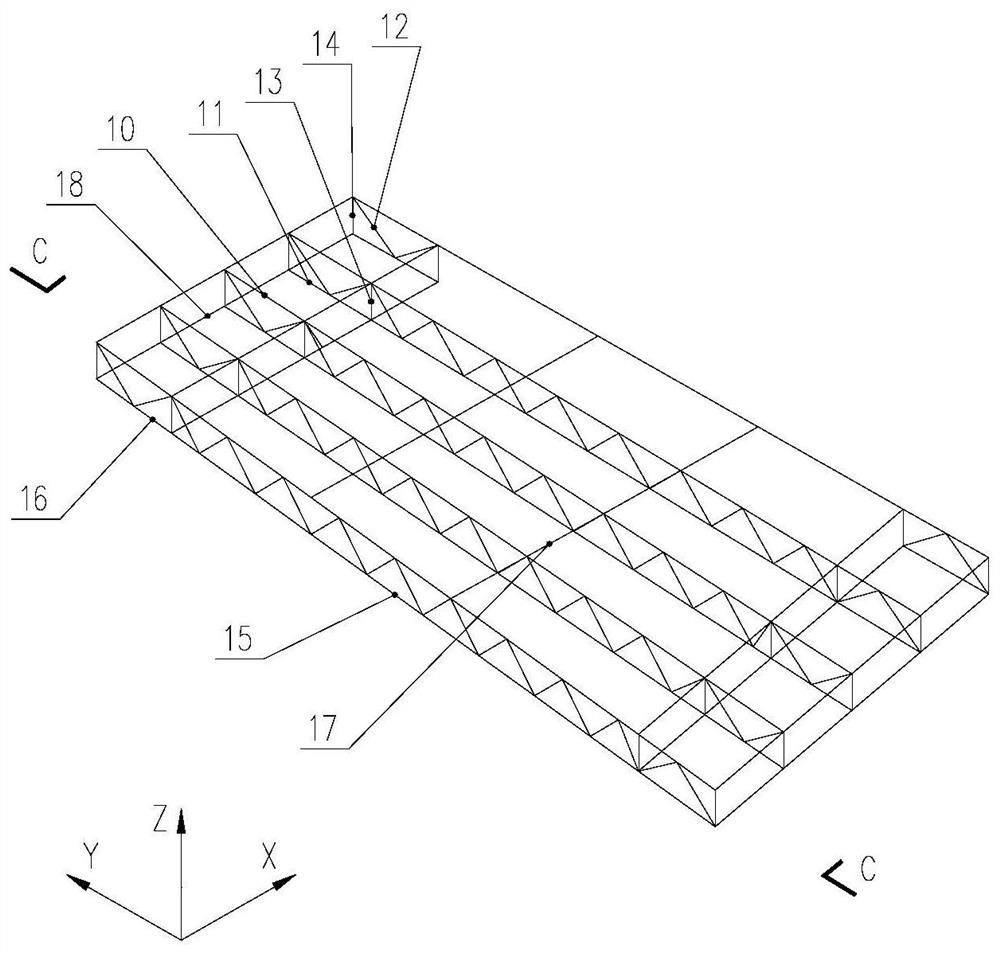

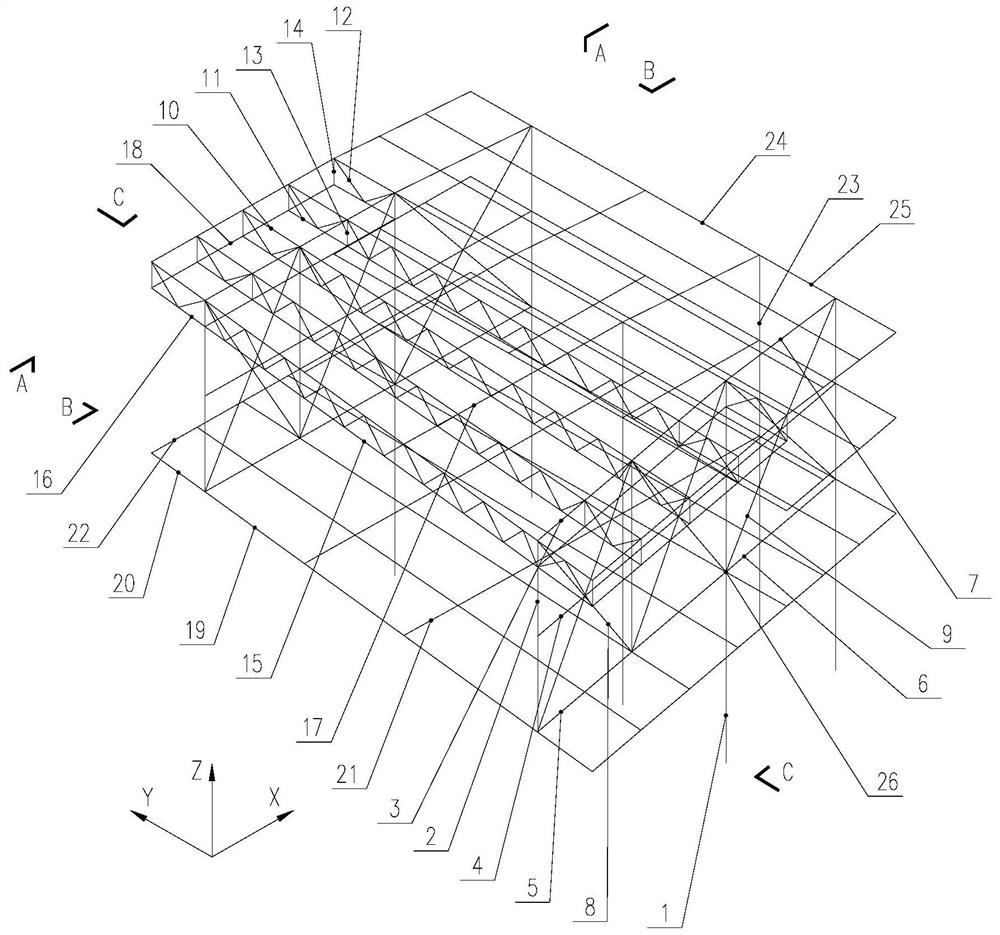

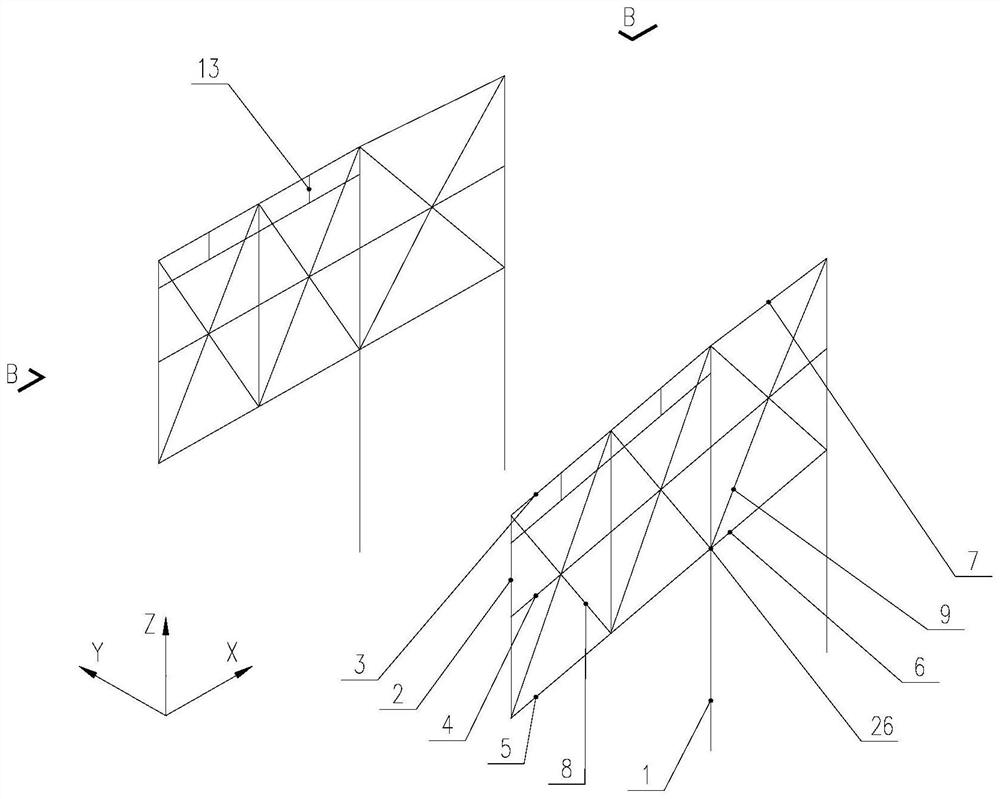

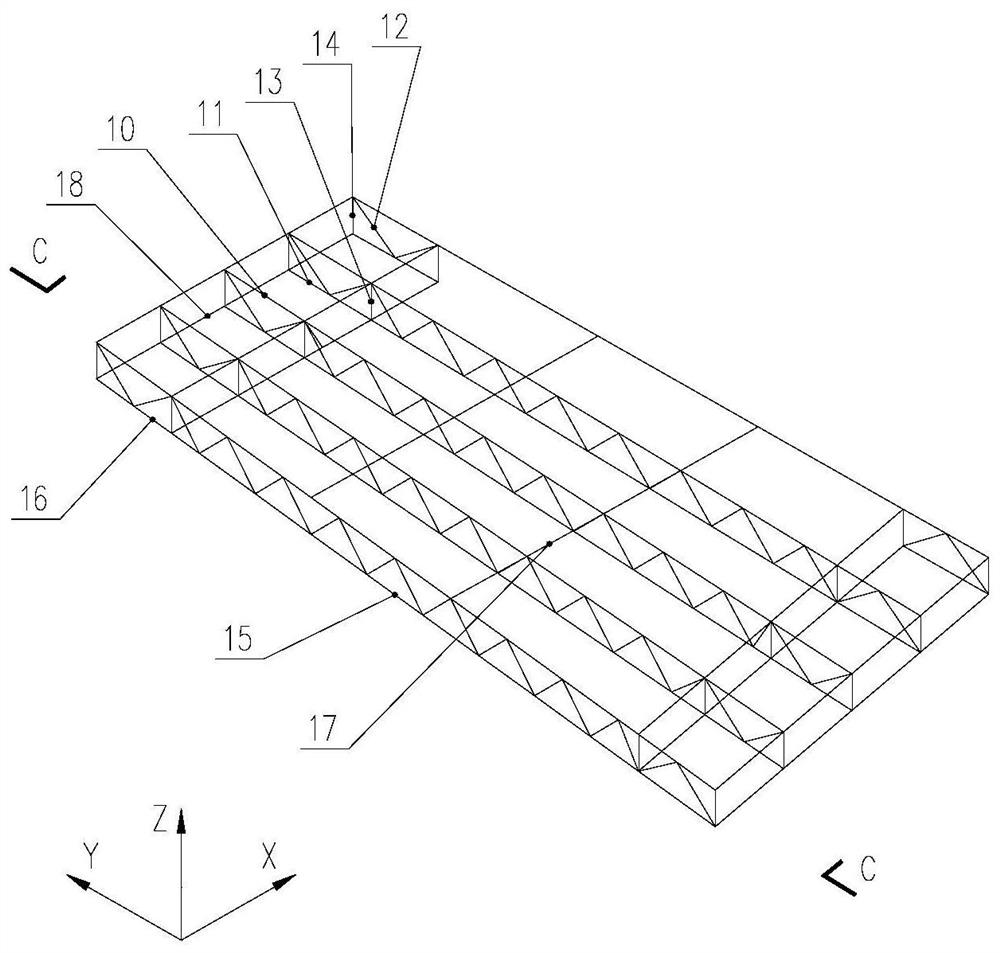

Multi-layer full-height large-space cantilever truss structure with embedded orthogonal small trusses and application

ActiveCN112443043AReasonable structureImprove stiffness performanceGirdersJoistsSteel frameLong span

The invention relates to a multi-layer full-height large-space cantilever truss structure with embedded orthogonal small trusses. The multi-layer full-height large-space cantilever truss structure comprises vertical supporting cantilever trusses, cantilever roof orthogonal small trusses, cantilever floor large-span steel beams and transition area steel frames; the vertical supporting cantilever trusses are located at the ends of the two sides of a multi-layer full-height large space and composed of two X-shaped cross-layer cantilever trusses extending to the transition area; and the cantileverroof orthogonal small trusses are located at the top of a large-space roof and are orthogonal to the vertical supporting cantilever trusses, each cantilever roof orthogonal small truss is composed ofa plurality of large-span small trusses, and the cantilever roof orthogonal small trusses and the vertical supporting cantilever trusses jointly form a center supporting framework. The multi-layer full-height large-space cantilever truss structure with the embedded orthogonal small trusses has the beneficial effects that the structure system is reasonable in structure, and complex steel structural system design and bearing of high-position large-cantilever-area multi-layer full-height large-space building function and modeling can be achieved.

Owner:ZHEJIANG UNIV CITY COLLEGE +1

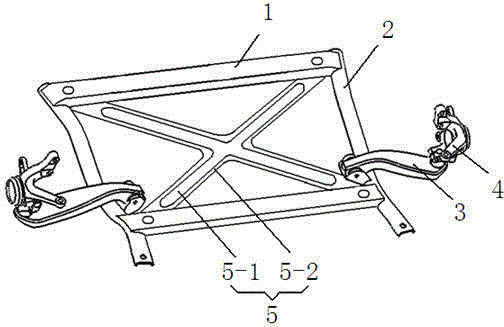

Front auxiliary frame cross reinforcement structure

InactiveCN104590376AIncrease stiffnessSolve the strength problemUnderstructuresVehicle frameJunction point

The invention discloses a front auxiliary frame cross reinforcement structure. The front auxiliary frame cross reinforcement structure comprises two front auxiliary frame longitudinal beams which are welded and fixed to two ends of two front auxiliary frame transverse beams, wherein the two front auxiliary frame transverse beams and the two front auxiliary frame longitudinal beams form a square framework; swinging arms are symmetrically hinged to and mounted on the opposite inner sides of the two front auxiliary frame longitudinal beams; the swinging arms are close to a junction point between the front auxiliary frame transverse beams on the rear sides and the two front auxiliary frame front auxiliary frame longitudinal beams; steering joints are fixed on the upper end surfaces of the swinging arms; X-shaped reinforcing plates are arranged under the two front auxiliary frame longitudinal beams; four ends of each reinforcing plate are fixed to two ends of the corresponding front auxiliary frame transverse beams. According to the front auxiliary frame cross reinforcement structure, an integrated cross reinforcement structure is mounted at four corners of a frame-shaped front auxiliary frame under the condition that arrangement of a power assembly is not influenced, so that the purpose of improving the overall rigidity and strength of the front auxiliary frame is achieved; the reduction of the risk of influence on the automotive performance caused because of insufficient rigidity or strength of the auxiliary frame can be facilitated; meanwhile, the smoothness of the automobiles can be improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

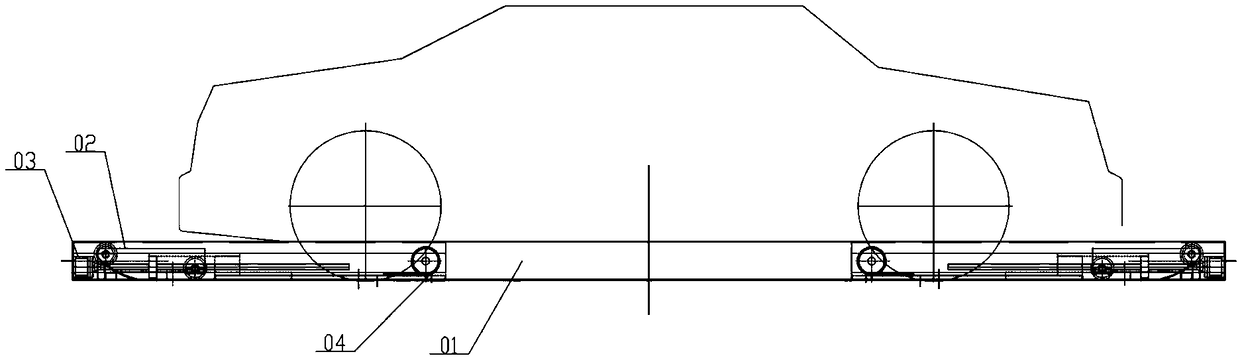

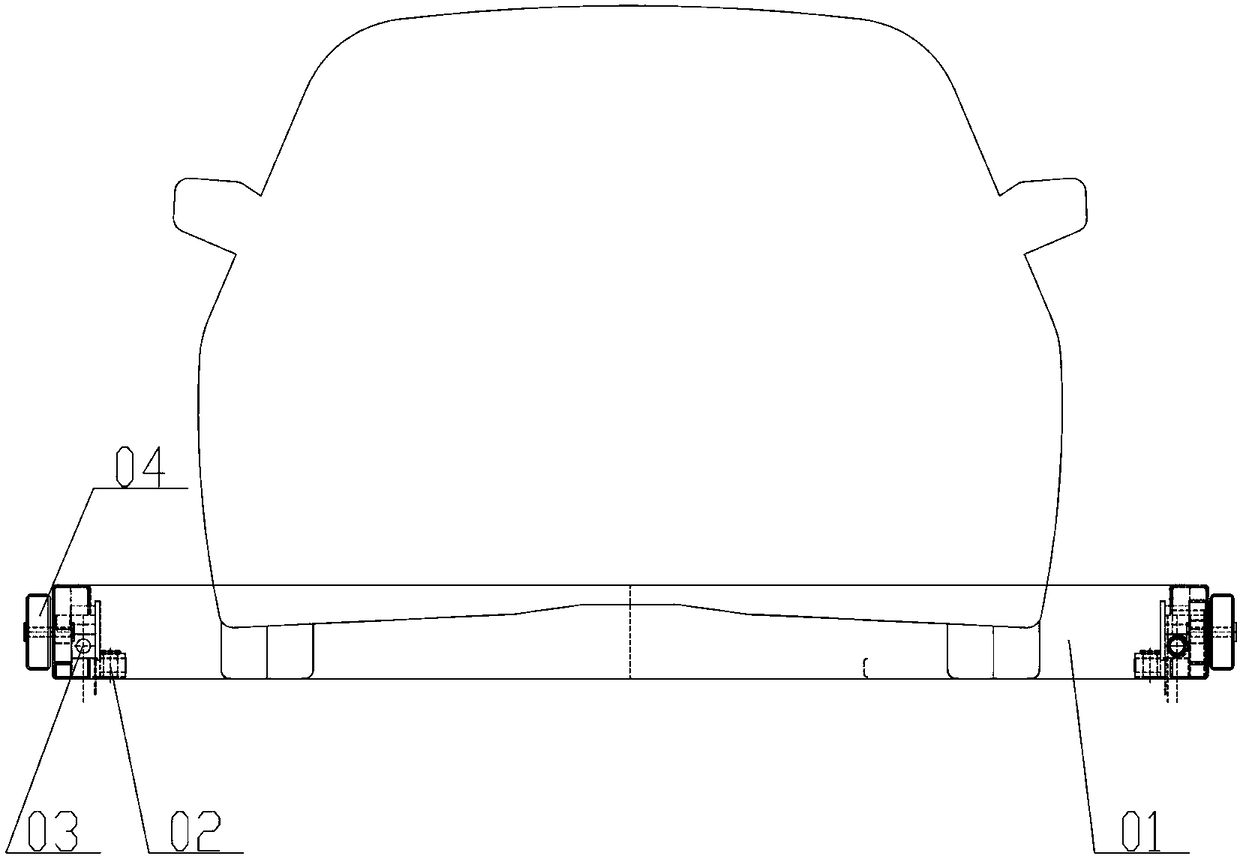

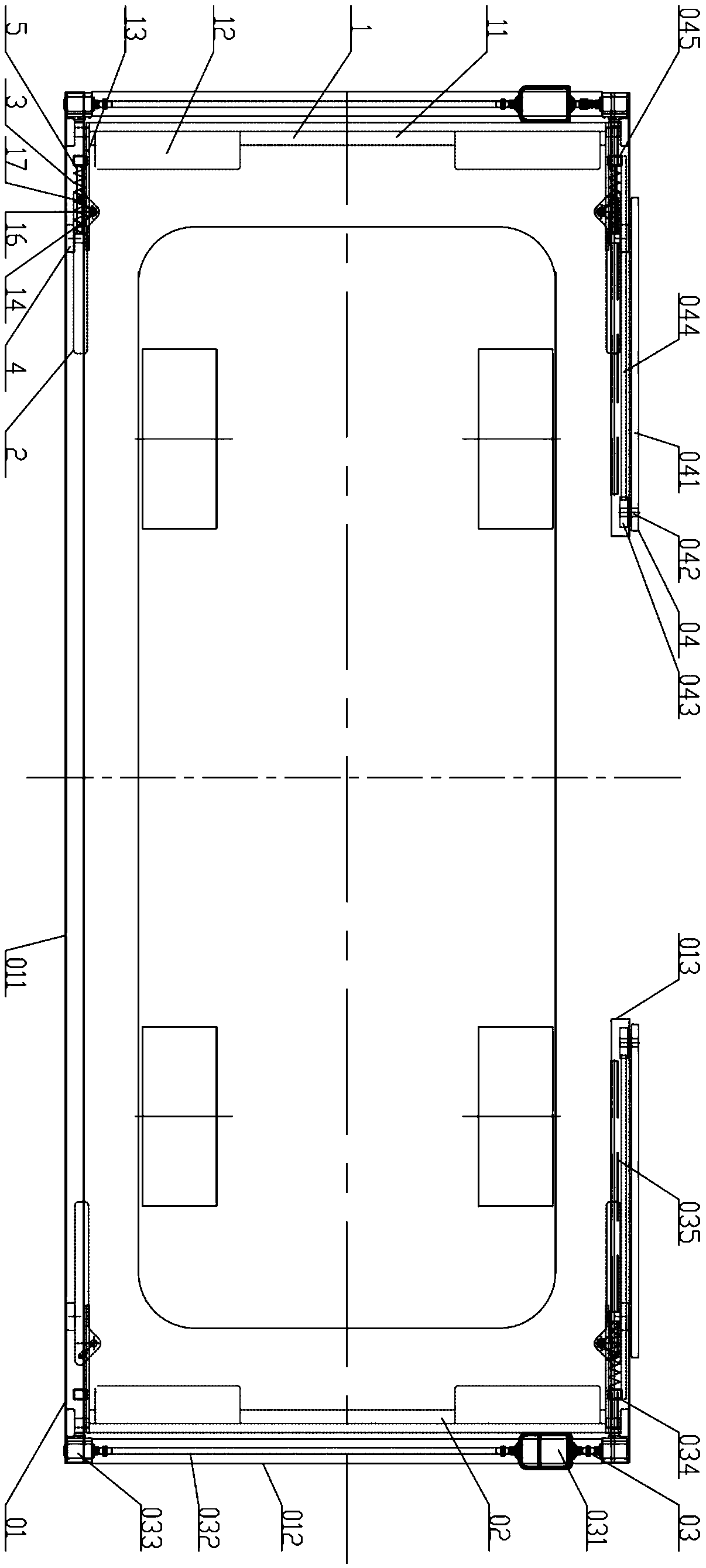

Opened pickup device with locking devices

InactiveCN109252725AFlexible and reliable rotationIngenious structureParkingsLocking mechanismEngineering

The invention discloses an opened pickup device with locking devices, comprising a pickup frame and locking mechanisms. A clamping mechanism and a pushing device are arranged at each of two inner endsof the pickup frame. The pushing devices push the clamping mechanisms to close and hold wheels inward; the pickup frame is of single-side-opened rectangular frame structure; each locking mechanism includes a locking arm, a rotary shaft, a rotary gear, a rack and a push rod, the rotary shaft is rotationally mounted at the cantilever end of a short rail beam, the locking arm and the rotary gear arein bond connection with the two ends of the rotary shaft and are placed in the inner lower portion of the short rail beam, the push rod helps connect the rack and a nut of the corresponding pushing device, and the locking arm is driven to rotate by 180 degrees. The opened pickup device allows a vehicle to enter directly and conveniently, vehicle accessing efficiency is improved, clamping effect is good, and the locking mechanisms help improve the rigidity of the frame.

Owner:WUXI CITY COLLEGE OF VOCATIONAL TECH

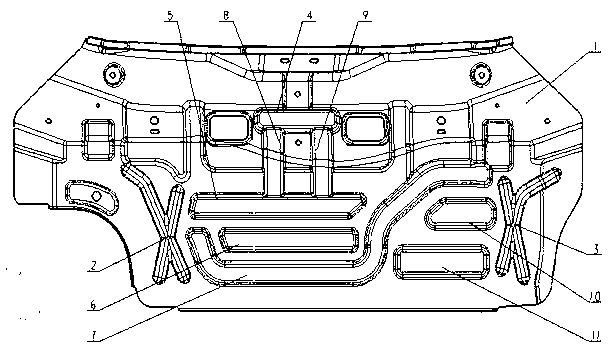

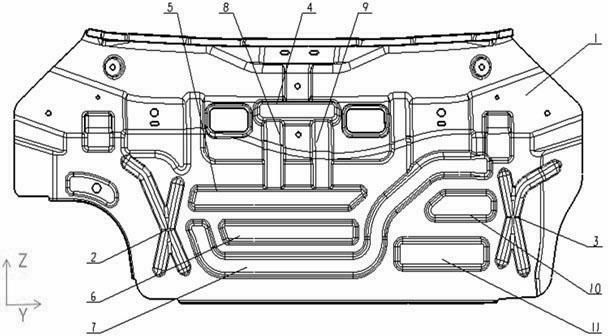

Rear apron board of automotive body

InactiveCN102700616AReduce weightImprove local stiffnessSuperstructure subunitsEngineeringSquare Shape

The invention relates to a rear apron board of an automotive body. The rear apron board comprises a board body and is characterized in that the left lower part of the board body is provided with a first X-shaped reinforcing rib, and the right lower part of the board body is provided with a second X-shaped reinforcing rib; the middle upper part of the board body is provided with a first horizontal reinforcing rib, the middle lower part of the board body is sequentially provided with a second horizontal reinforcing rib, a third horizontal reinforcing rib and an S-shaped reinforcing rib from top to bottom; and a first vertical reinforcing rib and the second vertical reinforcing rib are arranged between the first horizontal reinforcing rib and the second horizontal reinforcing rib. Because the rear apron board is provided with the first X-shaped reinforcing rib and the second X-shaped reinforcing rib, local rigidity of the point of the reinforcing ribs is improved, the additional arrangement of a reinforcing plate at the reinforcement point is avoided, the weight of the automotive body is reduced, and the cost is saved. Because the two horizontal reinforcing ribs and the two vertical reinforcing ribs are connected in a square shape, the static rigidity and the dynamic rigidity of a metal plate at the point are obviously improved, and the vibration resistance is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

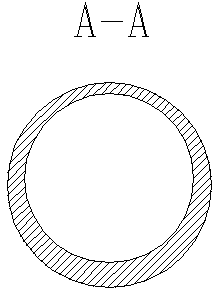

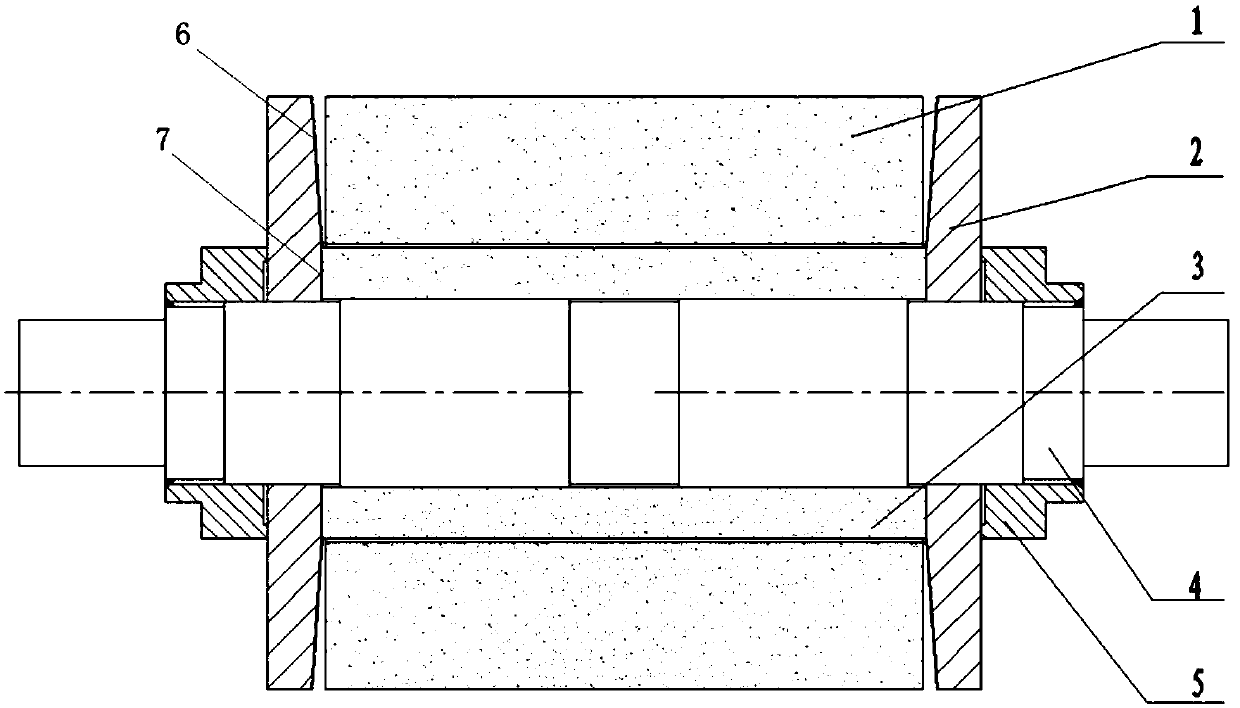

High-reliability closed spool type dynamic pressure bearing

ActiveCN109578433AImprove stiffness performanceIncrease stiffnessBearing componentsSliding contact bearingsBoron carbideEngineering

The invention relates to a high-reliability closed spool type dynamic pressure bearing. The high-reliability closed spool type dynamic pressure bearing comprises a spindle, a bearing rotor installed on the spindle in a sleeving mode, a spindle sleeve located between the spindle and the bearing rotor and thrust plates installed at the two ends of the spindle in a sleeving mode respectively. According to the dynamic pressure bearing, the spindle sleeve is additionally arranged on the spool bearing structure, the spindle sleeve is fixed to the spindle and forms a closed spool type structure withthe bearing rotor, the thrust plates each adopt a special slope structure, external air flow is pumped into an axial bearing body and a radial bearing body through the thrust plates with the special slopes, pressure distribution is formed in a bearing working clearance, the pressure in the bearing maintains the dynamic stability after the rotation speed is stable, and the bearing rigidity problemand the axial bearing body starting and stopping friction problem are solved; an axial compressing nut adopts an elastic compressing structure, and therefore it is guaranteed that the bearing axial clearance keeps stable at different temperatures; and a radial bearing friction pair adopts a boron carbide-boron carbide mode, a thrust axial friction pair adopts a boron carbide-structural steel mode,and therefore the bearing contact friction and wear problems are further solved.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

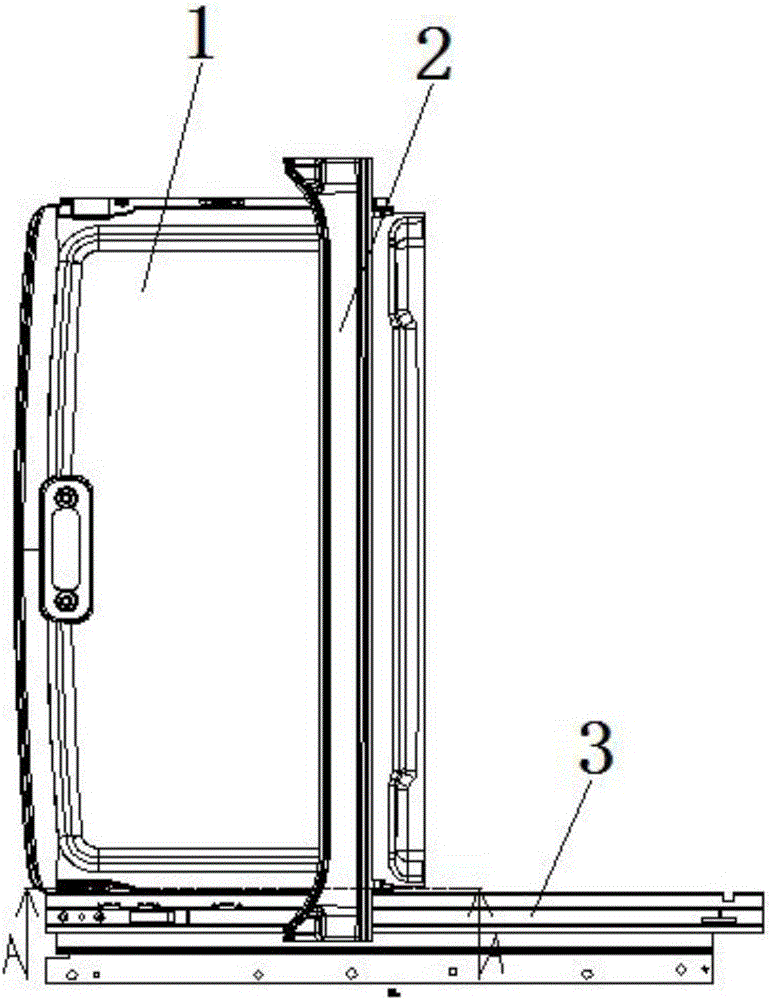

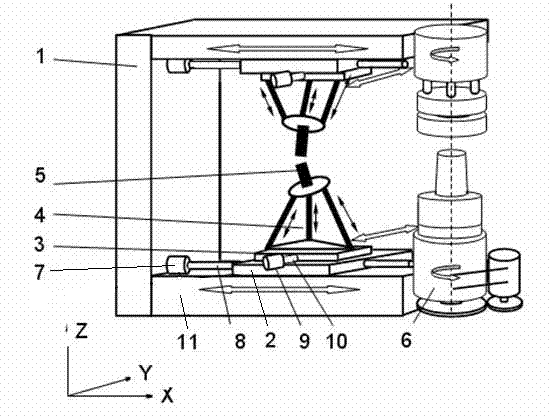

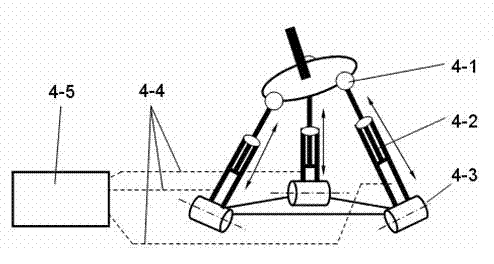

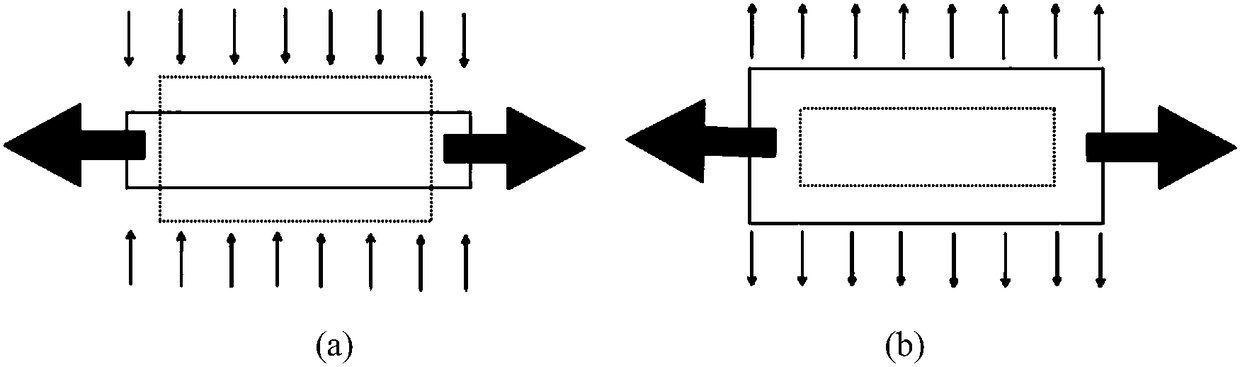

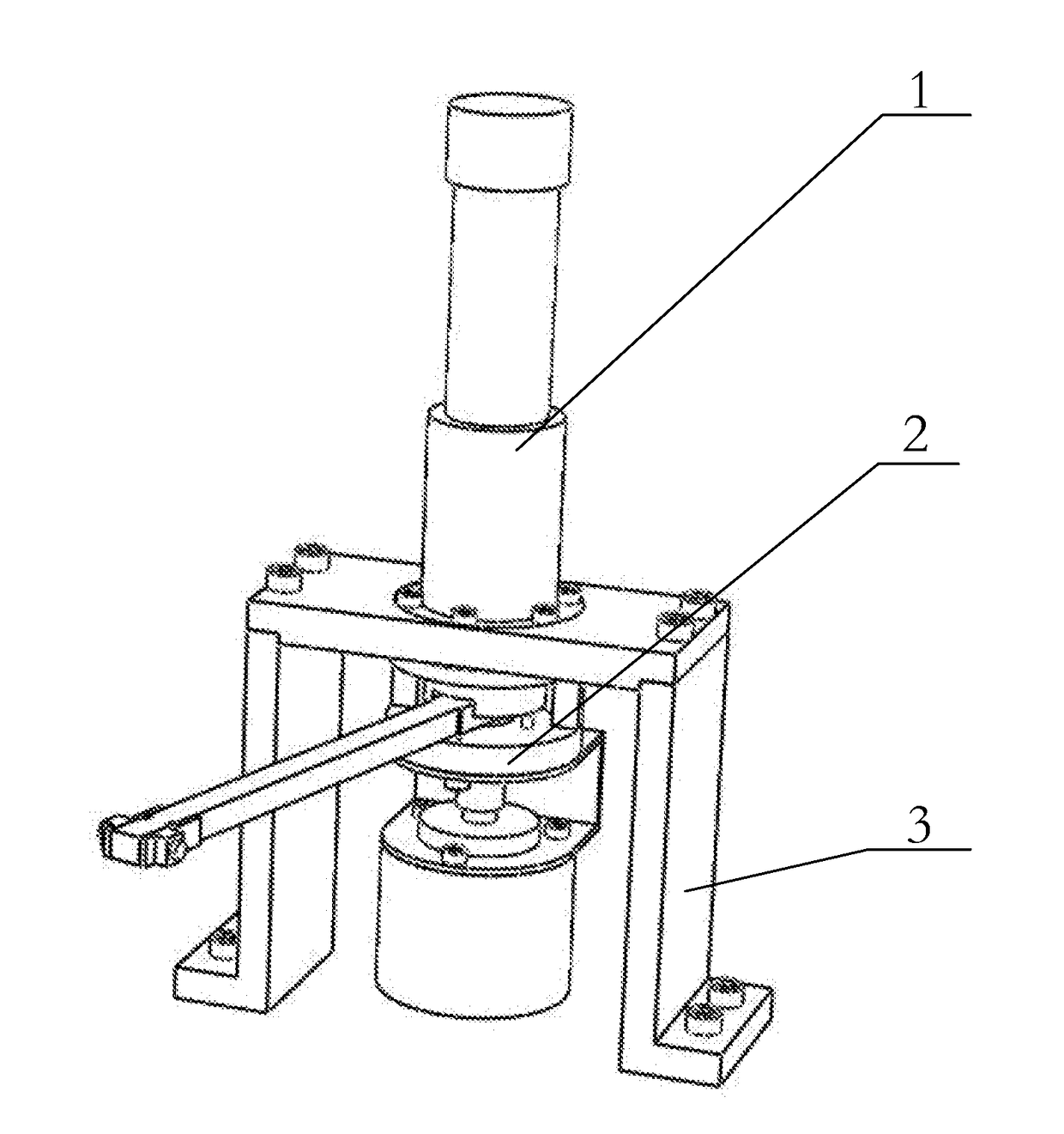

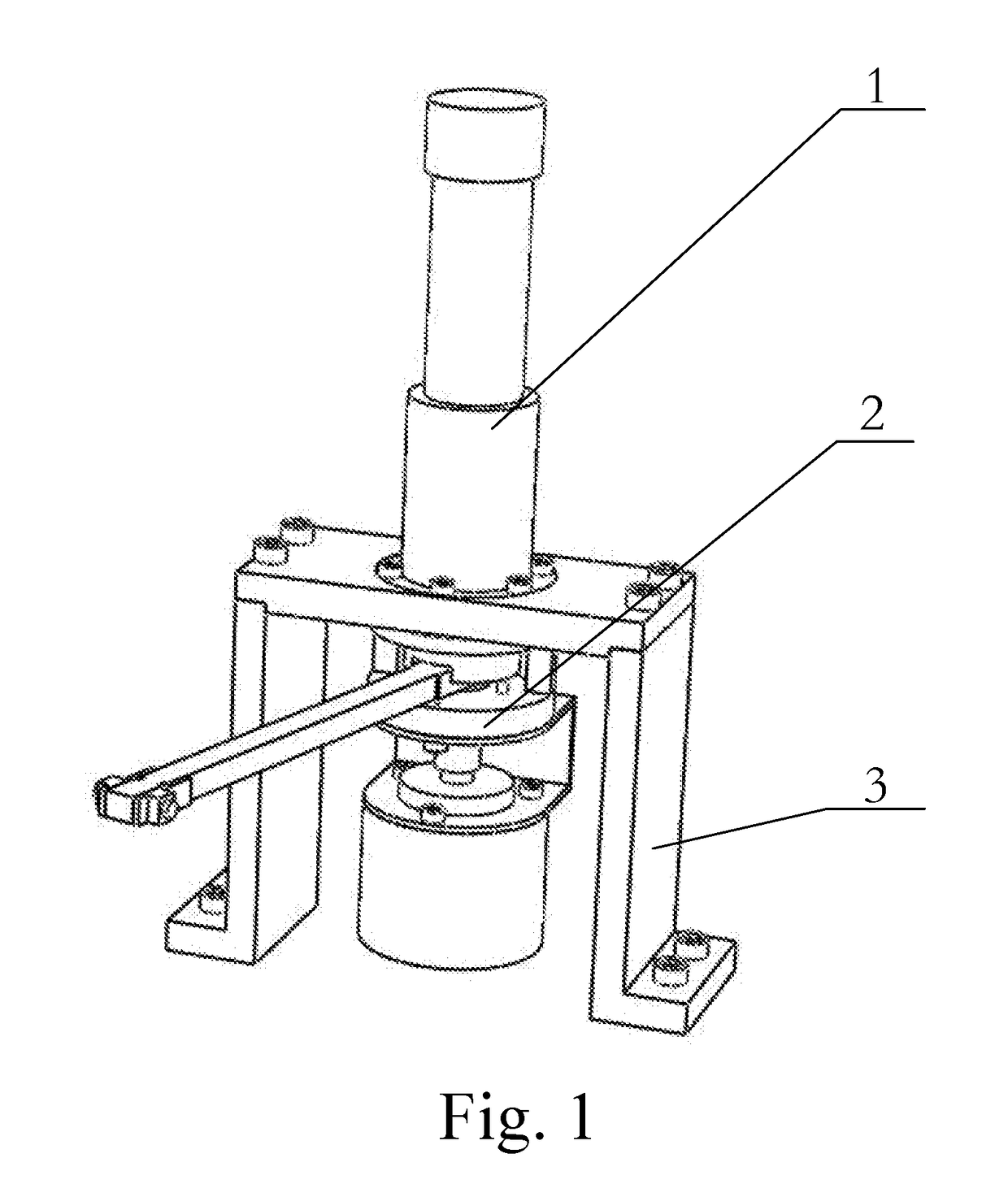

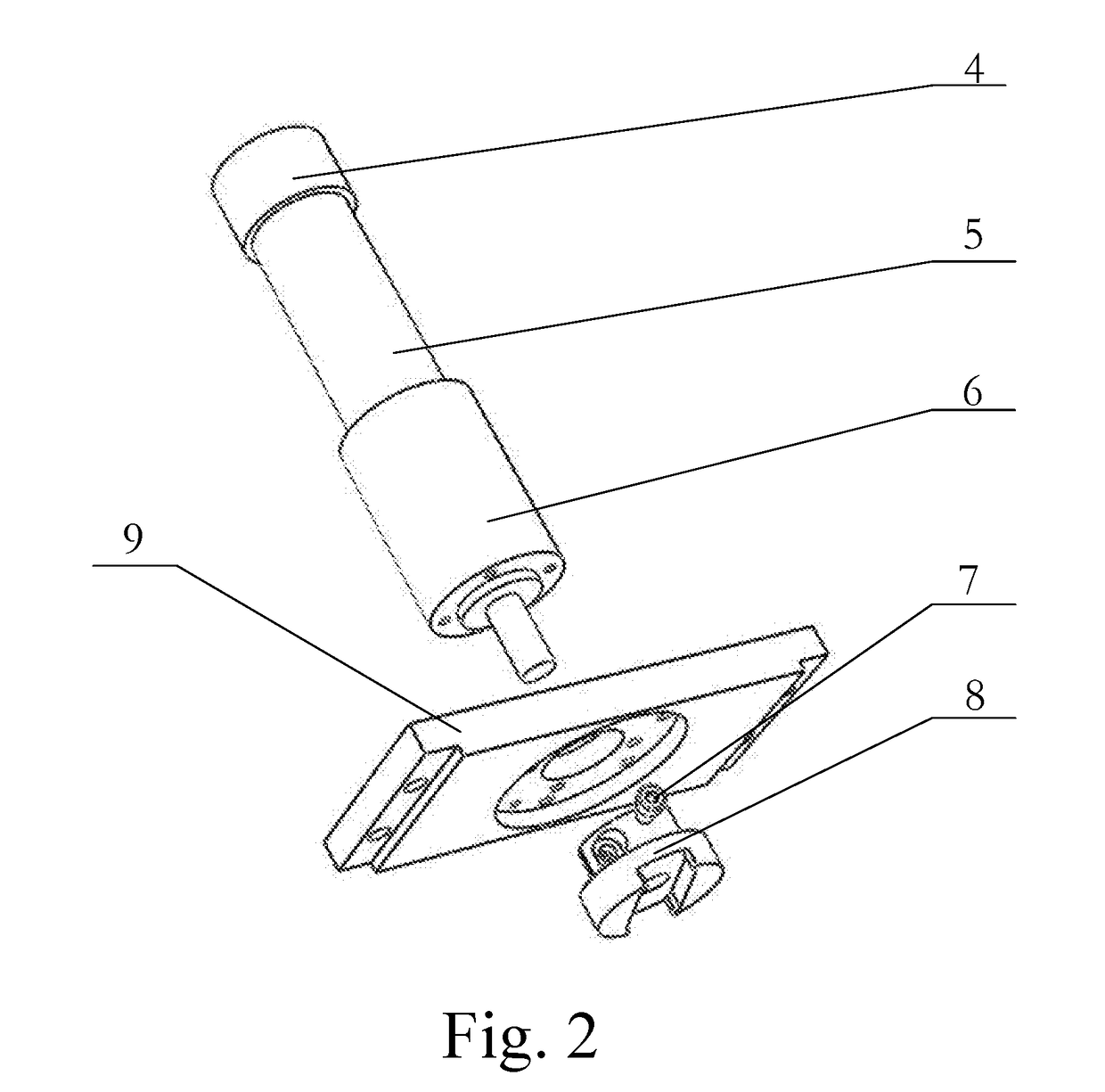

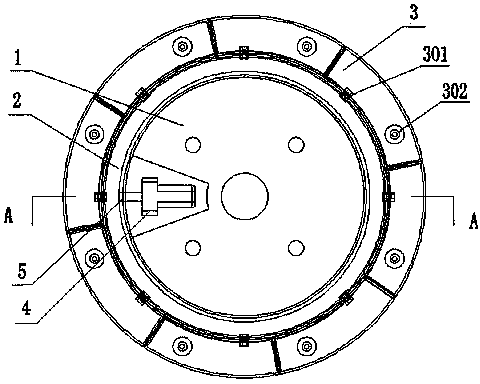

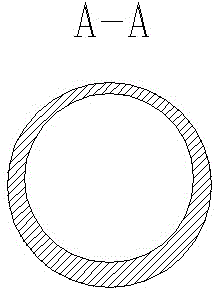

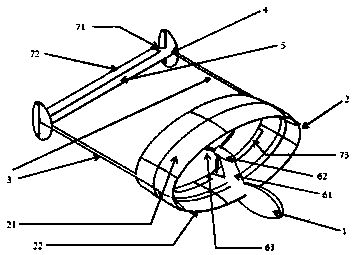

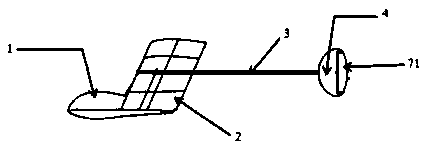

Force feedback handle device with a degree-of-freedom and working method thereof

ActiveUS20170235327A1Overcome the small stiffnessSlight frictionControlling membersLimiting/preventing/returning movement of partsHigh stiffnessDegrees of freedom

A force feedback handle device with a degree-of-freedom includes: a driving part (1), a link part (2) and a frame part (3); wherein the driving part (1) and the link part (2) are both installed on a top board (9), and a rotation axis of the link part (2) coincides with a rotation axis of the driving part (1); the driving part (1), the link part (2) and the frame part (3) are fixed and connected by bolts. A working method of the force feedback handle device includes four steps. The force feedback device of the invention has low inertia and high stiffness performance, which improves overall interaction performance of the force feedback device. The structure is simple and a manufacturing cost is low.

Owner:BEIHANG UNIV

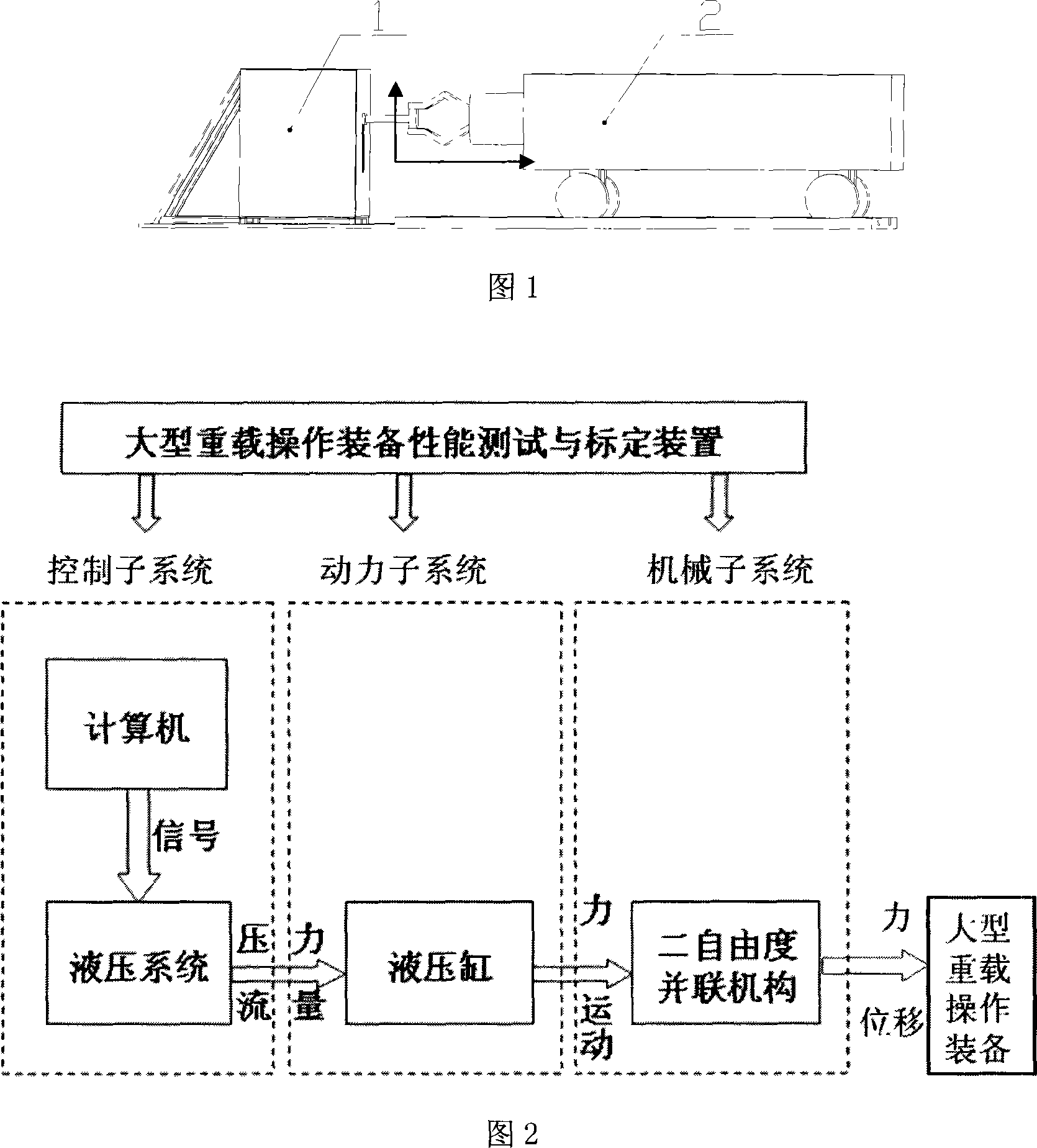

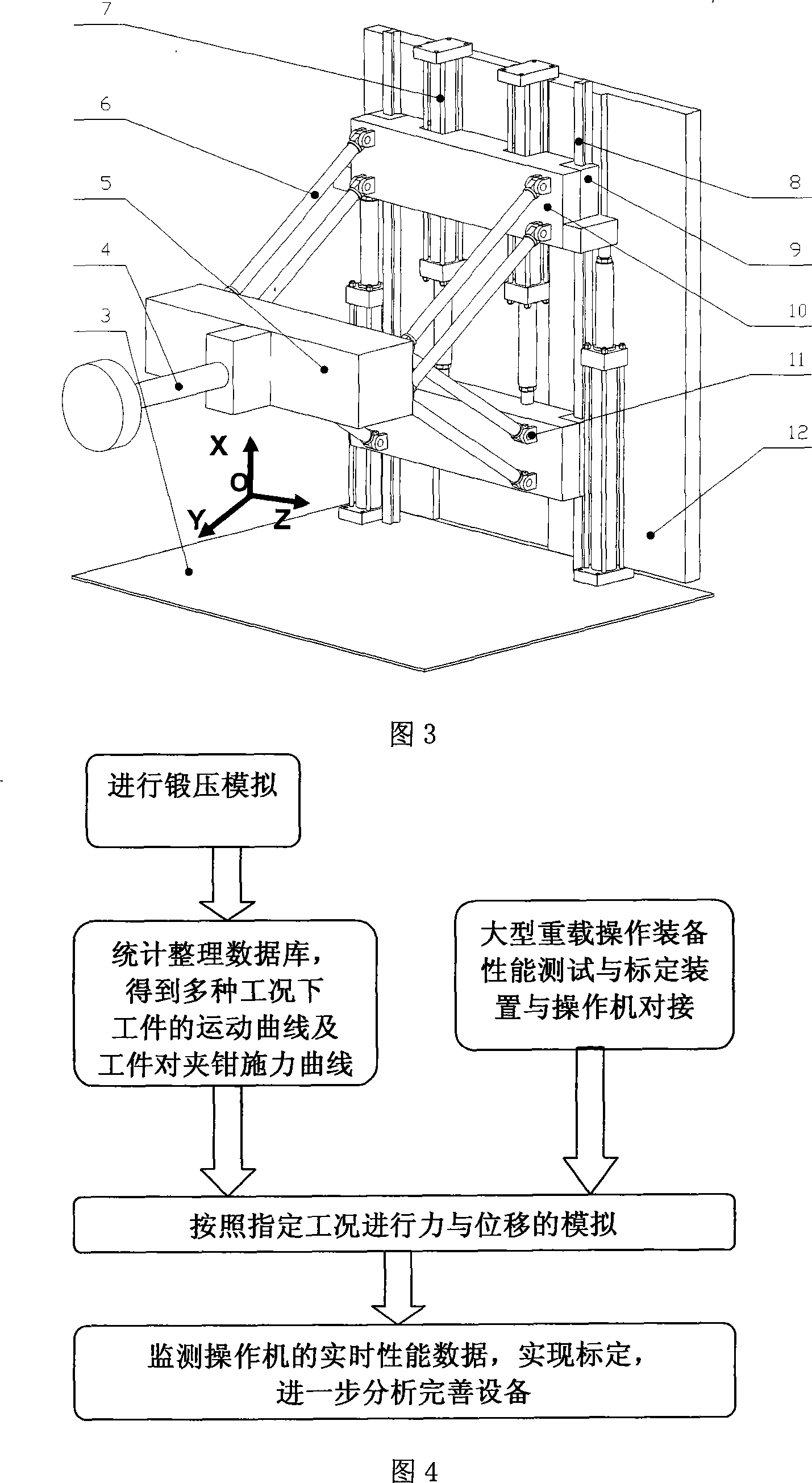

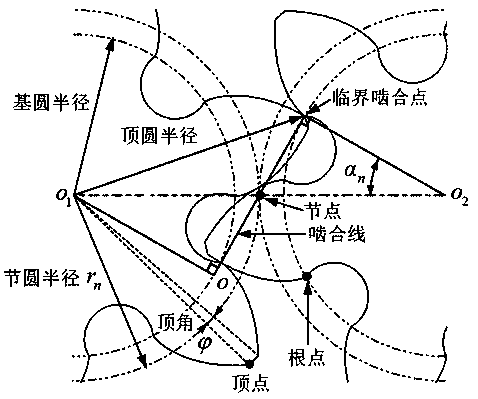

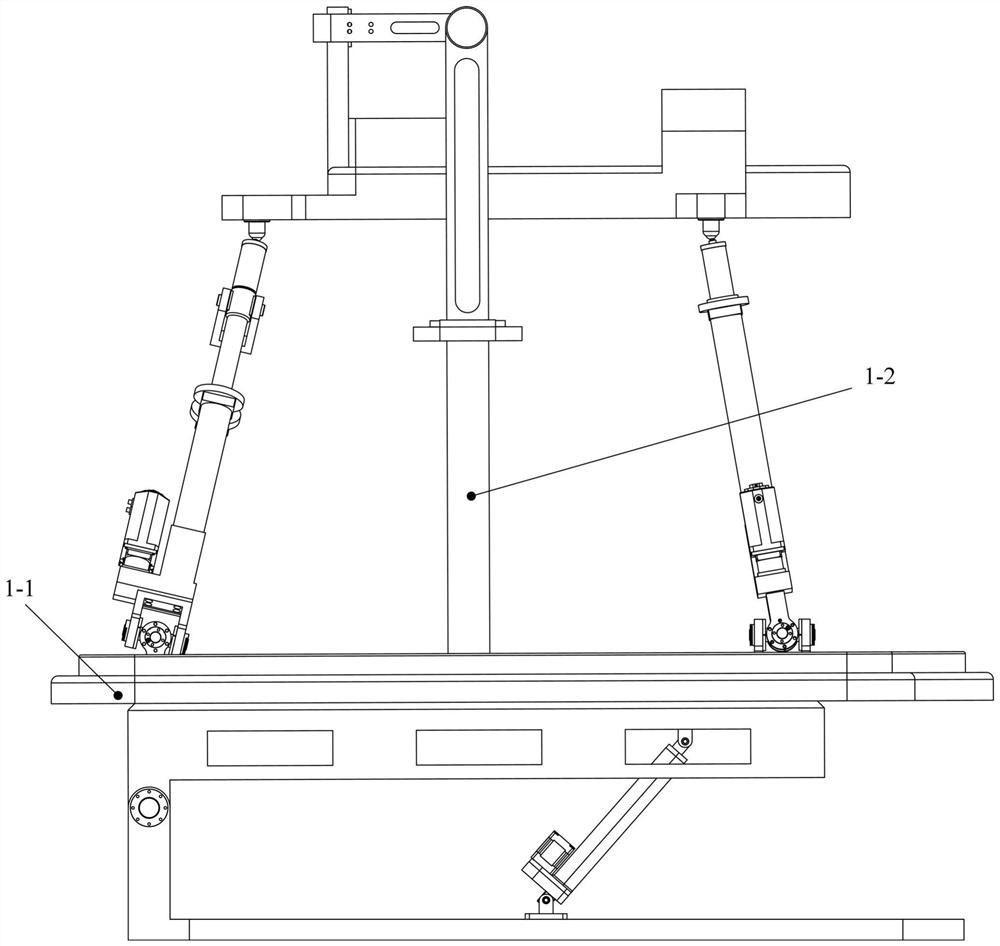

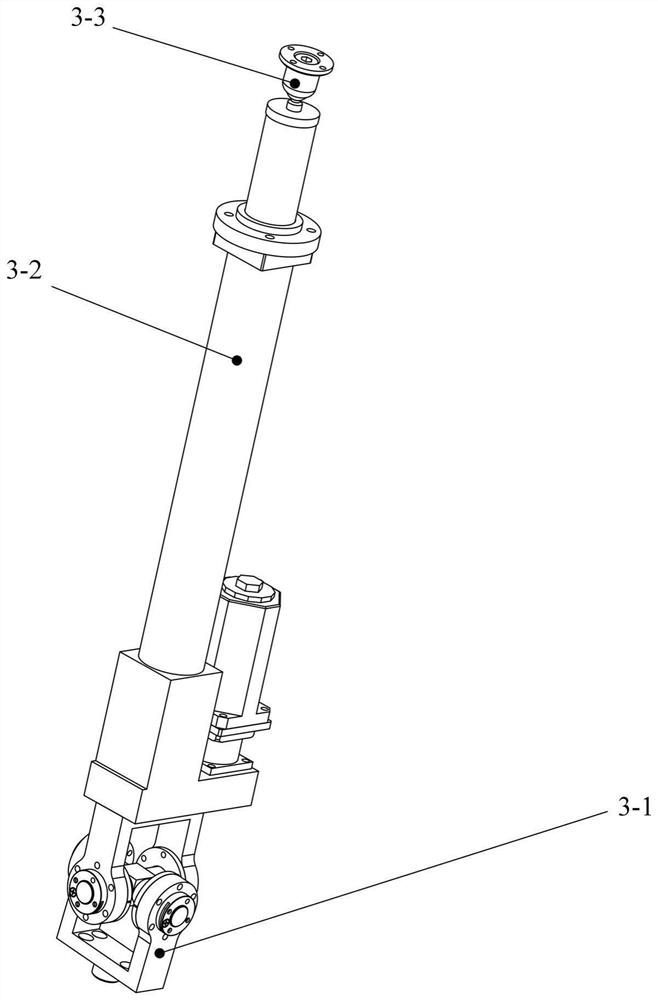

Device and method for testing and standardizing performance of macrotype over-loading operation equipment

InactiveCN101206164AQuick Performance TestQuick checkStructural/machines measurementHydraulic cylinderEngineering

The invention relates to a performance test and calibration device and method for large-scale heavy-load operating equipment in the mechanical technology field. The device comprises a control subsystem, a power subsystem, and a mechanical subsystem, wherein the mechanical subsystem is a two-freedom-degree motion parallel mechanism, the control subsystem consists of a computer and a hydraulic system, and the power subsystem consists of four hydraulic cylinders. The invention simulates the operating condition of large-scale heavy-load operating equipment through the performance test and calibration device of large-scale heavy-load operating equipment and a computer simulation analysis method, and then butts with the large-scale heavy-load operating equipment or the model of the large-scale heavy-load operating equipment, thereby testing the performance of the equipment, calibrating the parameters of the equipment and testing the capacity of the equipment. The invention realizes the semi-physical simulation and performance test and calibration of large-scale forging operating equipment in a way of combining virtual and real situations, thereby greatly boosting the developing process of large-scale heavy-load operating equipment.

Owner:SHANGHAI JIAO TONG UNIV

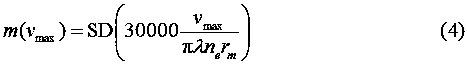

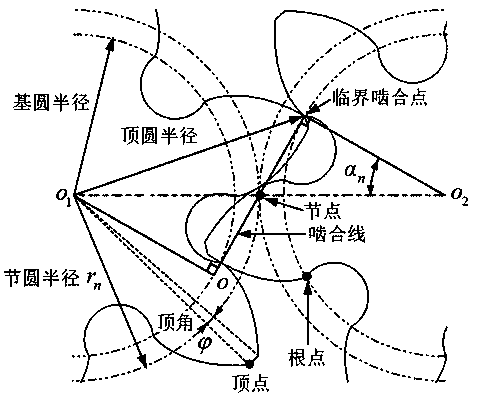

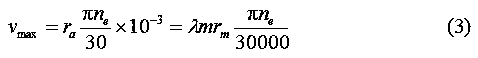

Critical meshing gear pair under light gear pump unit modulus

ActiveCN109372743AHigh strengthImprove stiffness performanceRotary piston pumpsRotary piston liquid enginesCavitationGear pump

The invention relates to a critical meshing gear pair under light gear pump unit modulus. The critical meshing gear pair comprises driving and driven involute gears of a pair of same-tooth-shape parameters under the unit modulus; the meshing position of tooth peaks is a critical point on a theoretic meshing line; a traditional shape parameter and size parameter mixing parallel design method for gear pump lightening is changed to a serial design method, the serial design method is characterized in that based on the tooth number determined by sensitivity analysis of critical meshing and shape parameters, the shape parameters of the addendum coefficient and the tip clearance coefficients and the calculated corresponding shape parameters; single needed maximum modulus is determined by a modulus upper limit and the standardization thereof determined by an addendum maximum peripheral speed not causing cavitation, and actual sizes including a tooth width of the gear pair are finally determined; and the modulus is the allowed maximum value, so that the gear strength and rigidity performances are improved, the axial leakage being about 85% of total leakage of the pump is reduced, and the light design requirements of the gear pump can be efficiently met with high quality.

Owner:SICHUAN WUHUAN PETROCHEM EQUIP CO LTD

Hub type energy-saving vibration-reducing pneumatic power generating device

ActiveCN103863111AAchieve vibration reductionSimple combinationAuxillary drivesIn vehicleInlet valve

The invention discloses a hub type energy-saving vibration-reducing pneumatic power generating device, comprising a hub, at least two compressed air bags and a pneumatic generator, wherein the periphery of the hub is connected with an annular air collector, the compressed air bags are uniformly distributed at the periphery of the air collector, and are isolated from each other, the compressed air bags are communicated with the air collector through valves, the outer sides of the compressed air bags are provided with air inlet valves, the radial direction of the hub is provided with the pneumatic generator, and the pneumatic generator is communicated with the air collector through air hole connecting parts. The invention aims to provide the energy-saving hub vibration-reducing pneumatic power generating device, which is used for converting vibration in vehicle movement and partial energy generated by self weight, electric energy generated through the power generating device is charged into a storage battery of the vehicle, so that the service life of the storage battery is prolonged, and the working time of electric car series is greatly prolonged. The hub type energy-saving vibration-reducing pneumatic power generating device is simple and reliable in structure and has a small influence on the rigidity of the hub.

Owner:湖南亿尚清洁工程有限公司

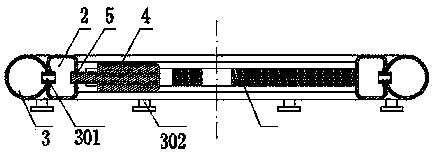

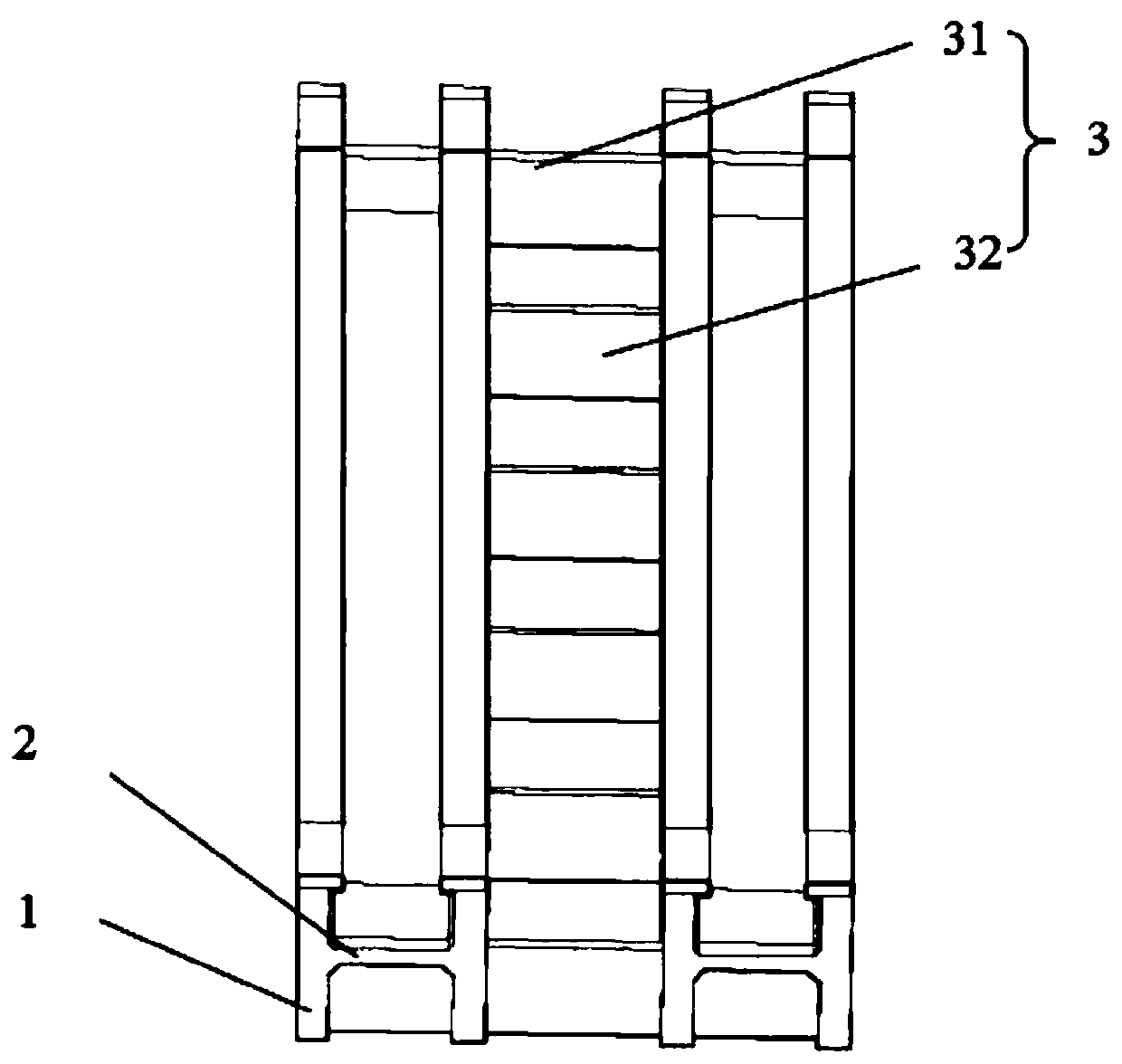

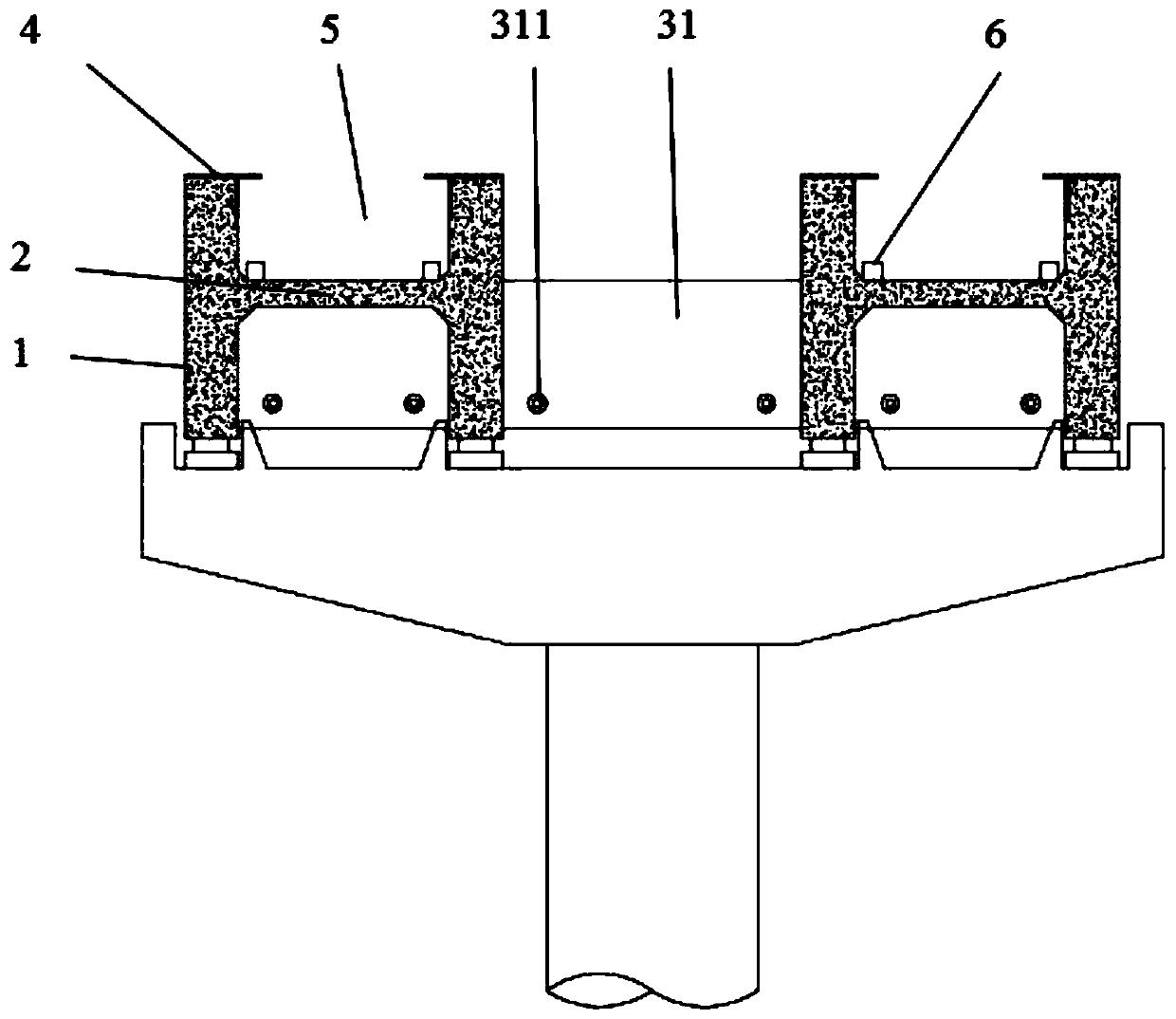

High-performance redundant drive parallel ankle joint rehabilitation mechanism

PendingCN114366561AImprove stiffness performanceIncrease flexible workspaceChiropractic devicesControl engineeringControl theory

The invention provides a high-performance redundant drive parallel ankle joint rehabilitation mechanism, which comprises a fixed platform, a movable platform, a first driving branch, a second driving branch, a third driving branch, a middle constraint branch chain and an inclination angle adjustable support device, the first driving branch and the second driving branch are respectively provided with a driving unit, the third driving branch is provided with two driving units, and the middle constraint branch chain is provided with a middle constraint branch chain. The three driving branches are connected with the fixed platform through hooke joints and connected with the movable platform through spherical hinges, the middle constraint branch chain is connected with the fixed platform and the movable platform through three rotating pairs which are orthogonal in space, the intersection center of the rehabilitation mechanism coincides with the rotating center of ankles, the bottom of the fixed platform is connected with the inclination angle adjustable supporting device, and the inclination angle adjustable supporting device is connected with the middle constraint branch chain. The inclination degree of the rehabilitation mechanism can be changed. Three rotational degrees of freedom of the movable platform can be achieved in a redundant drive mode, the reachable working space of the mechanism is increased, high flexibility and movement-force transmission performance are achieved, the comfort degree of the lower limbs of a patient can be adjusted, and therefore the optimal training effect is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

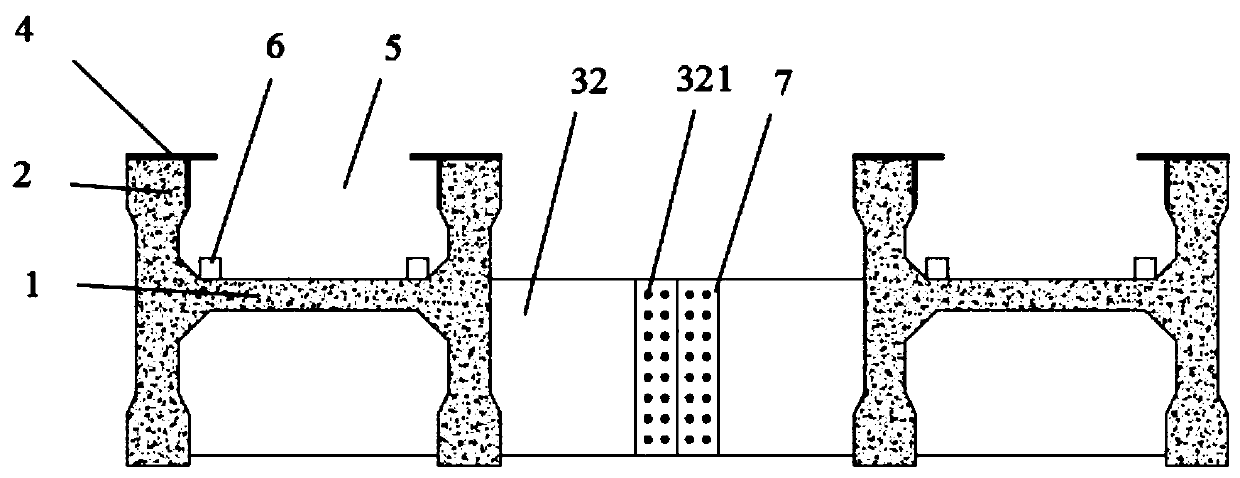

Double-H-shaped concrete rail beam of rubber-tyred tram and construction method thereof

PendingCN111424477AGood driving comfortIncreased durabilityRailway tracksArchitectural engineeringStructural engineering

The invention discloses a double-H-shaped concrete rail beam of a rubber-tyred tram and a construction method threof. The double-H-shaped concrete rail beam is arranged on piers and comprises a plurality of guide rail beam span sections, and every two adjacent guide rail beam span sections are connected in a chaining mode. Each guide rail beam span section comprises four webs, two bottom plates and a transverse partition plate; the four webs and the two bottom plates are combined into a double-H-shaped structure and are connected and combined into an integrated structure through the transversepartition plate; each web plate is of a structure with an I-shaped cross section, and embedded wear-resistant steel plates are arranged at the top end of each web plate and one side end of the top ofeach web plate; each transverse partition plate is located below the bottom plates and comprises two end transverse partition plates and a plurality of middle transverse partition plates. The two endtransverse partition plates are located at the two ends of each guide rail beam span section, and the multiple middle transverse partition plates are sequentially arranged. Compared with an existingsteel guide rail beam, the double-H-shaped concrete rail beam is large in overall rigidity, good in driving comfort, low in noise, good in durability of a concrete structure and small in later maintenance amount.

Owner:中交铁道设计研究总院有限公司

A cantilevered truss structure with multi-storey high-height and large space embedded with small orthogonal trusses and its application

ActiveCN112443043BReasonable structureImprove stiffness performanceGirdersJoistsClassical mechanicsLong span

Owner:ZHEJIANG UNIV CITY COLLEGE +1

A critically meshing gear pair in unit modulus of a light-weight gear pump

ActiveCN109372743BHigh strengthImprove stiffness performanceRotary piston pumpsRotary piston liquid enginesCavitationGear pump

The invention relates to a critical meshing gear pair under the unit modulus of a light-weight gear pump, which includes a pair of driving and driven involute gears with the same tooth shape parameters under the unit modulus, and the meshing position of the tooth apex is the theoretical meshing line At the critical point above, the gear pump lightweight existing mixed parallel design method of shape parameters and size parameters is changed to the number of teeth, addendum height coefficient and The shape parameters of the top clearance coefficient and the corresponding shape coefficient are calculated, the upper limit of the modulus determined by the maximum peripheral speed of the addendum that does not cause cavitation and its standardization, determine the single maximum modulus required, and finally determine the gear The serial design method of the actual size of the pair including the tooth width, and the modulus takes the maximum value allowed, which is conducive to improving the strength and stiffness of the gear and reducing the axial leakage accounting for about 85% of the total leakage of the pump. Realize the lightweight design requirements of gear pumps with high quality and high efficiency.

Owner:SICHUAN WUHUAN PETROCHEM EQUIP CO LTD

A kind of manufacturing method of carbon fiber conveying pipe for conveying concrete

InactiveCN103256436BReduce quality problemsImprove stiffness performanceRigid pipesPipe protection against damage/wearFiberCarbon fibers

The invention relates to a carbon fiber delivery pipe for delivering concrete, and a production method thereof. Ingredients of the carbon fiber delivery pipe for delivering the concrete include 100% of carbon fiber materials; pipe wall thickness of a standard straight pipe is more than 4mm, and the pipe wall thickness of a thickened straight pipe is more than 7mm; and the thinnest position of the pipe wall of a bended pipe is more than 7mm, and the thickest position is more than 14mm. The production method of the carbon fiber delivery pipe for delivering the concrete includes S1, performing oxidation treatment to obtain pre-oxidation carbon dioxide; S2, performing carbonization including two sequential stages of high temperature carbonization and low temperature carbonization to obtain graphitized carbon fibers; S3, netting to obtain a piece of carbon fiber clothing; and S4, bonding and shaping to obtain products of carbon fiber pipes. The carbon fiber delivery pipe produced by the method has the advantages of light weight, long service life, small impact, small pressure lose and the like; the diameter of the delivery pipe can be increased, and production efficiency can be improved.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

High-stability double-tail-support vertical annular wing unmanned aerial vehicle

PendingCN110217393AExcellent flight stabilityImprove survivabilityHeat reducing structuresUndercarriagesPropellerMountain forest

The invention discloses a high-stability double-tail-support vertical type annular wing unmanned aerial vehicle. The high-stability double-tail-support vertical type annular wing unmanned aerial vehicle comprises a fusion type vehicle body, vertical type annular wings, double tail supports, a vertical tail, a horizontal tail, a propeller propelling system and a control system. The vertical annularwing comprises an upper elliptical wing and a lower elliptical wing; the propeller propelling system comprises a propelling system supporting frame, a propelling system driving device and a propeller; and the control system comprises a rudder, an elevator and ailerons. The unmanned aerial vehicle has excellent wind resistance, the flight resistance of which is improved by more than 8% compared with a conventional layout, and the unmanned aerial vehicle is suitable for high-precision aerial survey aerial photography, mountain forest important material putting and the like and has excellent flight stability.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

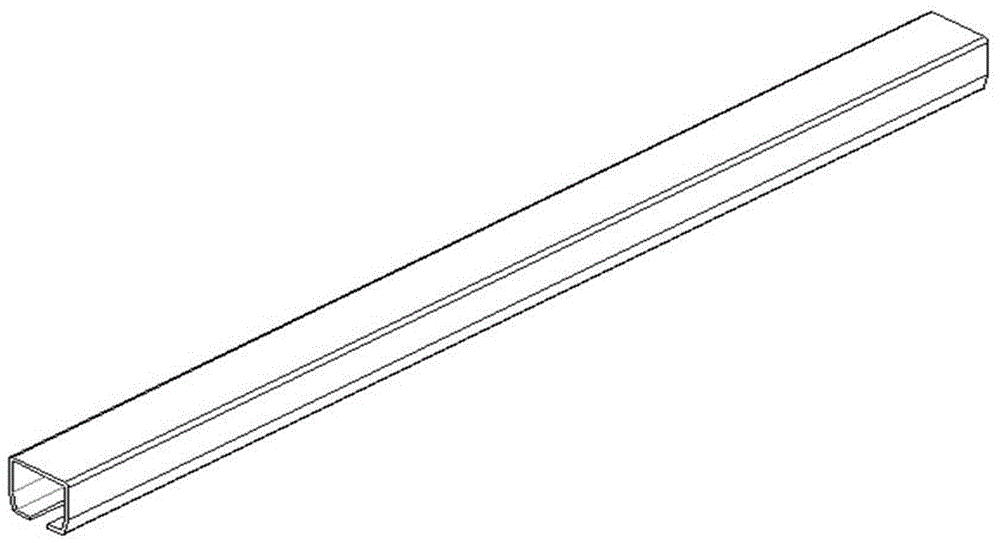

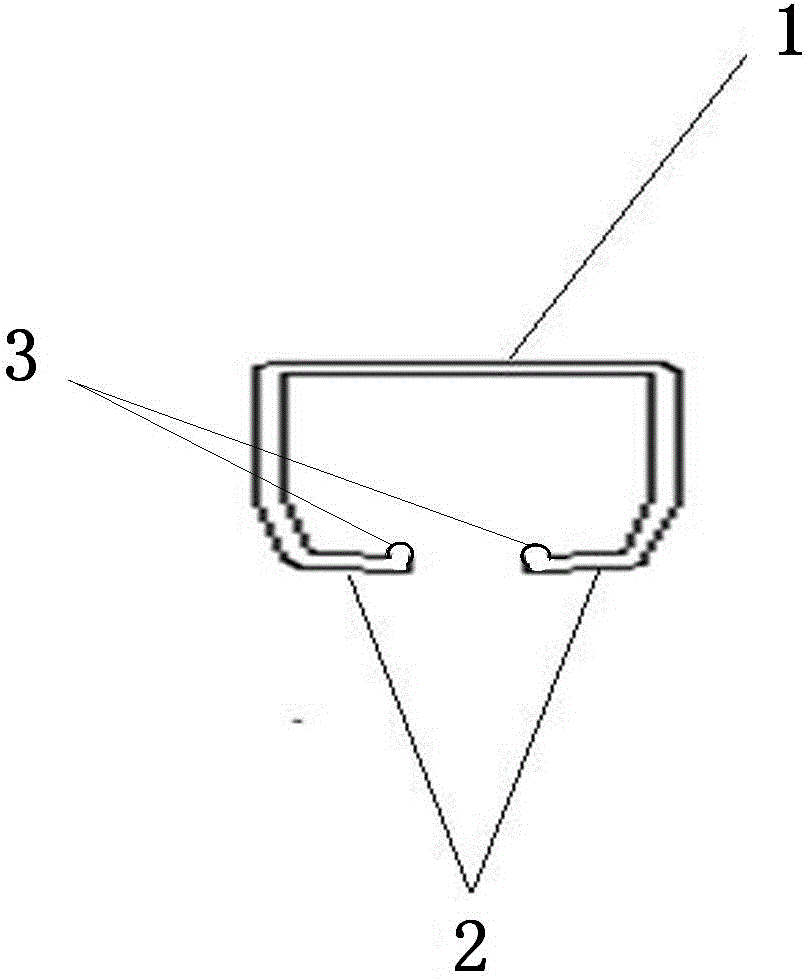

Improved electric hoist rail of crane

InactiveCN105731254ARealize the automatic correction route functionPrevent prolapseRunwaysJunction pointEngineering

The invention discloses an improved electric hoist track of a crane. The cross section of the track is in a "U" shape with the opening facing downwards. Lower edges for carrying electric hoist pulleys are arranged on both sides of the opening, and the lower edges face toward the center of the opening. and the horizontal plane are inclined downward, and the inclination angle is 1-5 degrees. The track of the present invention replaces the traditional splicing and welding process. This invention technology is direct roll forming. Its rigidity performance is further enhanced. The lower edge of the track has a small bevel angle with the plane, which can realize the automatic correction route function of the gourd trolley in the process of traveling in the track, so that the gourd always walks in the center of the track. In the process of use, a large-span connection point can also be realized. Compared with the traditional track, the technology of the present invention integrates the market demand to achieve a large-span, easy installation, high-load working process and low-cost processing process.

Owner:KUNSHAN KLUKE MACHINARY CO LTD

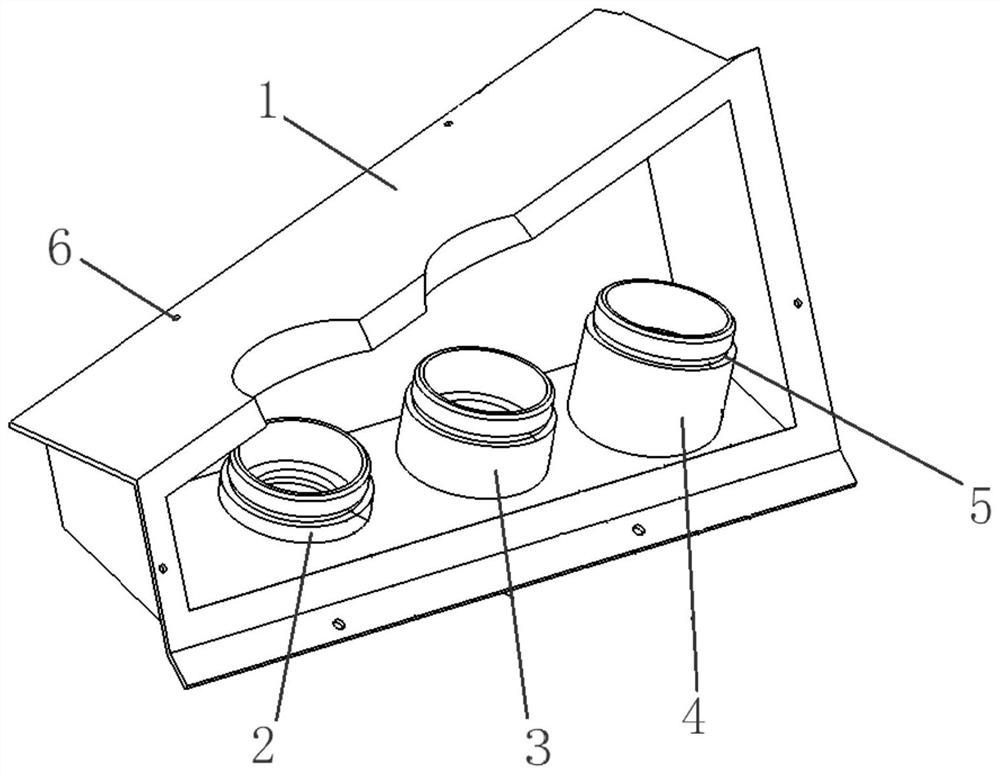

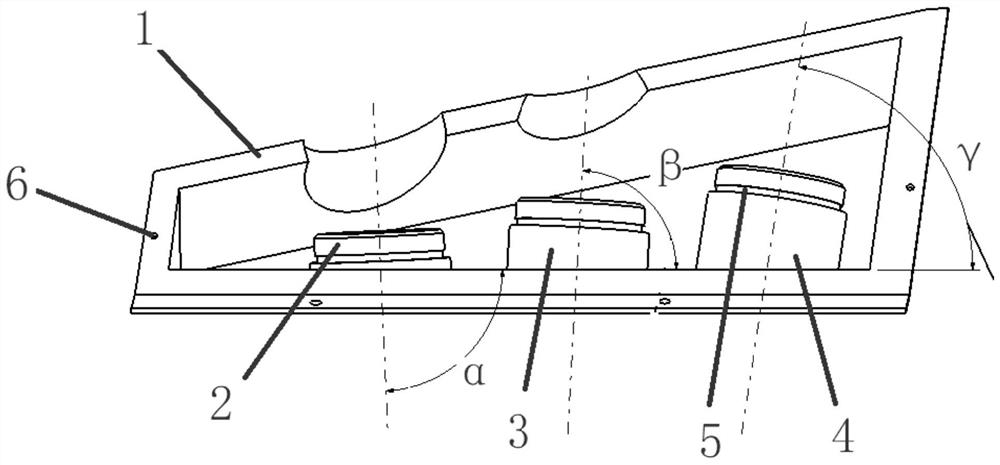

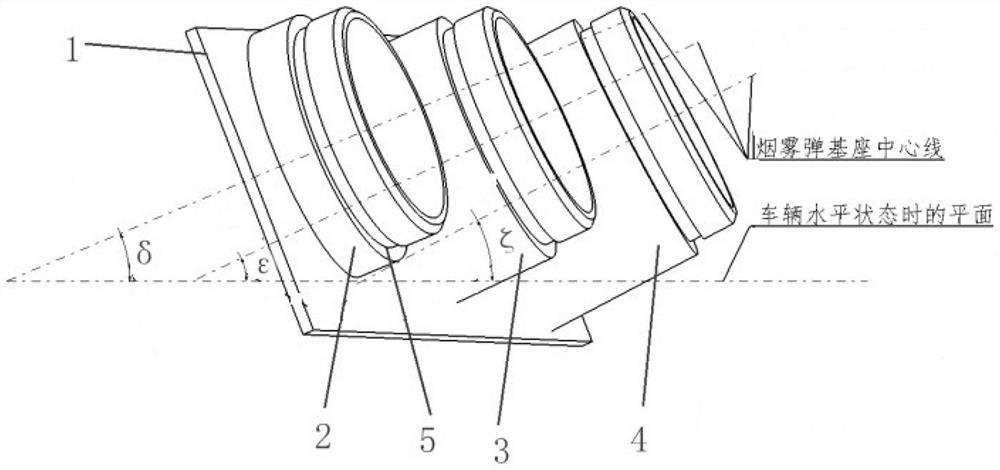

Smoke bomb base for combat vehicle turret outer cover and combat vehicle turret outer cover

PendingCN113324441AEasy maintenanceFirmly connectedAmmunition projectilesArmoured vehiclesSmoke bombStructural engineering

The invention discloses a smoke bomb base for a combat vehicle turret outer cover and the combat vehicle turret outer cover. The smoke bomb base for the battle vehicle turret outer cover comprises a smoke bomb base shell matched with a smoke bomb base containing cavity reserved in the turret outer cover, and an opening is formed in one side of the smoke bomb base shell; a first smoke bomb containing barrel, a second smoke bomb containing barrel and a third smoke bomb containing barrel with upward openings are arranged on a bottom plate in the smoke bomb base shell, and projections of the first smoke bomb containing barrel, the second smoke bomb containing barrel and the third smoke bomb containing barrel in the respective axis directions are not on a top plate of the smoke bomb base shell; and an included angle formed between the axis of the first smoke bomb containing barrel and the bottom plate of the smoke bomb base shell is 87.3 degrees to 87.7 degrees, an included angle formed between the axis of the second smoke bomb containing barrel and the bottom plate of the smoke bomb base shell is 86.6 degrees to 87.0 degrees, and an included angle formed between the axis of the third smoke bomb containing barrel and the bottom plate of the smoke bomb base shell is 79.9 degrees to 81.3 degrees. According to the smoke bomb base for the combat vehicle turret outer cover and the combat vehicle turret outer cover, the problem that the launching angle and the azimuth angle cannot meet the launching requirement when a smoke bomb is launched can be solved.

Owner:BEIJING BEIFANG CHANGLONG NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com