Multi-layer full-height large-space cantilever truss structure with embedded orthogonal small trusses and application

A technology of tall space and truss structure, applied in the direction of truss structure, girders, trusses, etc., can solve the problems of complex assembly of components, complex mechanical performance of the structure, complex node connection structure, etc., to achieve a reasonable and effective guarantee and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

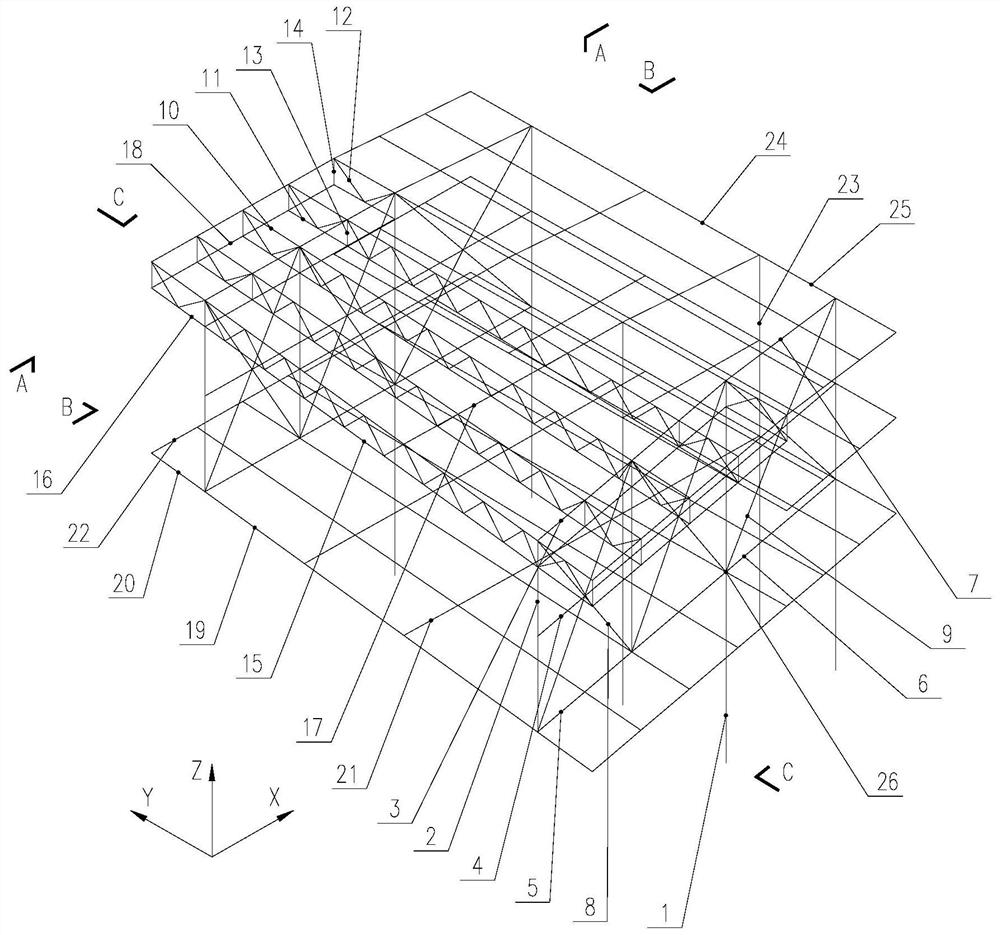

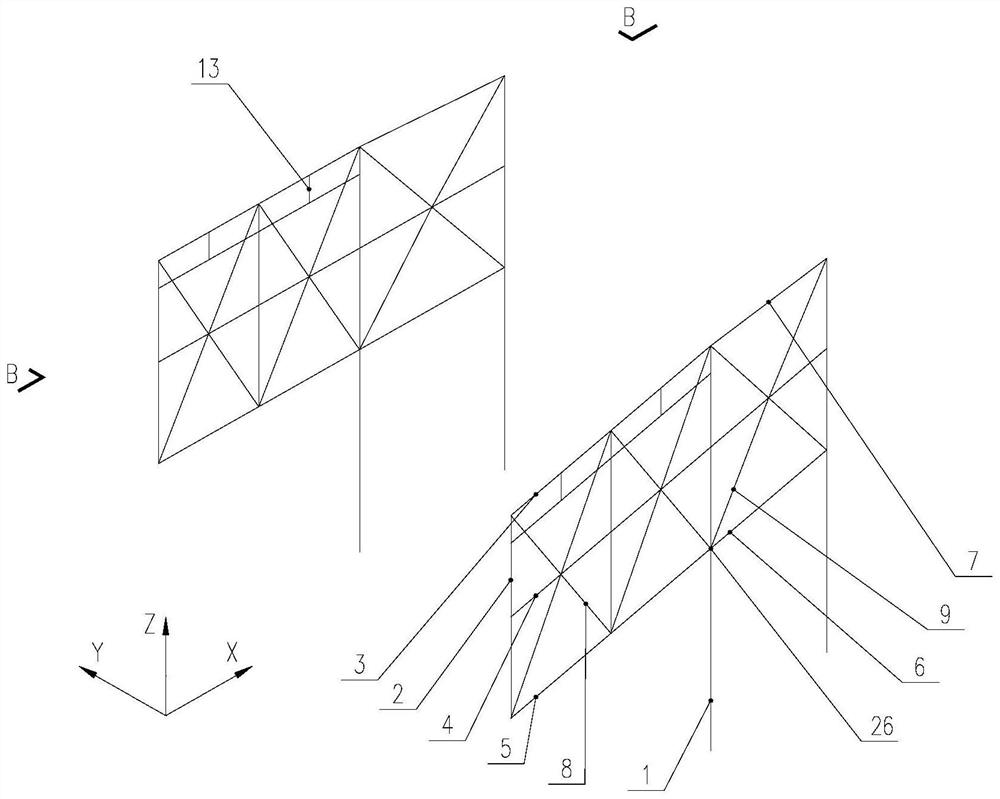

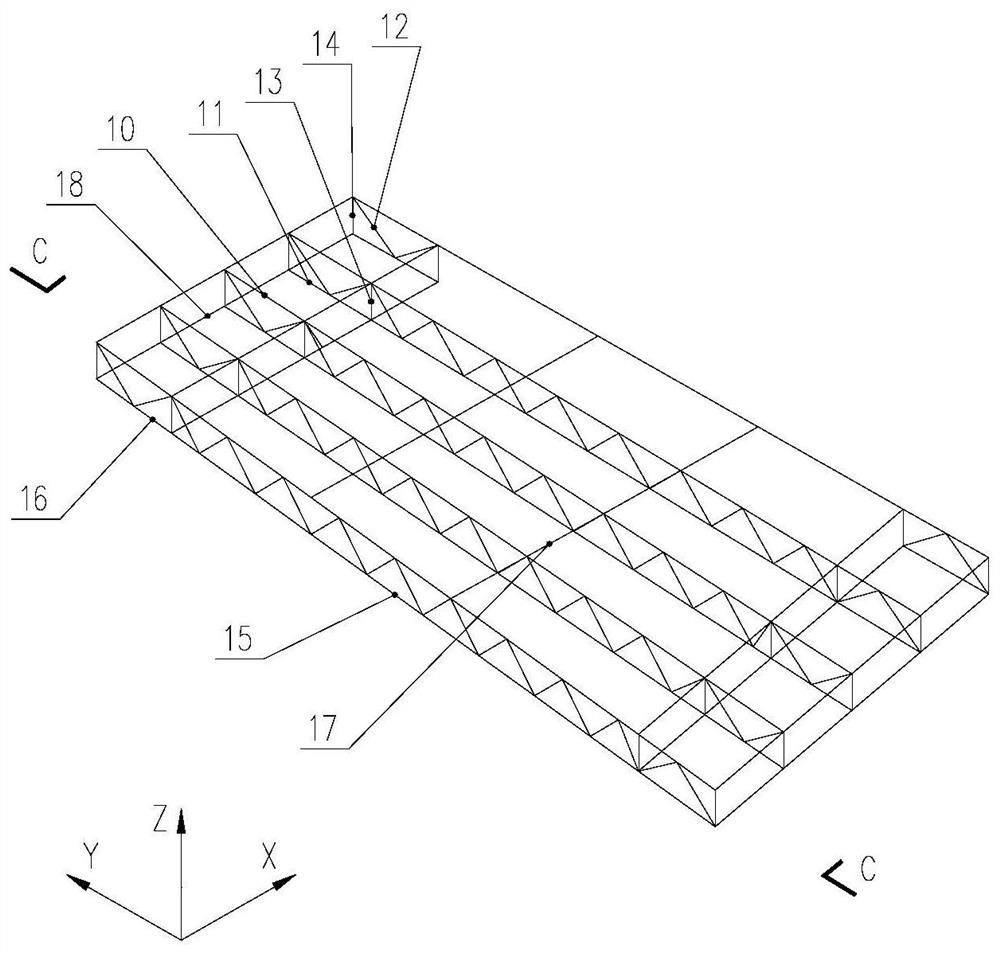

[0052] Such as Figures 1a-1e as well as Figure 2-Figure 4 As shown, the multi-storey high-height large space cantilever truss structure embedded with small orthogonal trusses includes vertical support cantilever trusses, cantilevered roof orthogonal small trusses, cantilevered floor large-span steel beams, transition Area steel frame. The vertical support cantilever truss ( Figure 1b ) is located at the ends of both sides of the multi-storey high-rise space, and is composed of cantilevered trusses composed of two "X-shaped" cross-layer diagonal bracing extending to the transition area, which is a core structure for vertical support and lateral force resistance; the cantilevered Picking the roof orthogonal to small trusses ( Figure 1c ) is located on the top of the roof of the large space, perpendicular to the vertical support cantilever truss and arranged at a certain distance, and is composed of multiple large-span small trusses, which together form the central support ...

Embodiment 2

[0072] Such as Figure 9 As shown, the specific component assembly process of the multi-layer high-height large-space cantilever truss structure embedded with small orthogonal trusses is as follows:

[0073] (1) The upper chord cantilever beam supporting the cantilever truss vertically 3, the middle chord cantilever beam supporting the cantilever truss vertically 4, the lower chord cantilever beam supporting the cantilever truss vertically 5, the cantilever beam vertically supporting the cantilever truss The floor chord beam 6 in the transition area and the roof slope chord beam 7 in the transition area supporting the cantilever truss vertically form the chord part, which is then connected with the oblique support 8 in the cantilever area vertically supporting the cantilever truss, and the vertical support cantilever The oblique support 9 in the transition area of the truss, the landing frame column 1 vertically supporting the cantilever truss and the truss column 2 vertical...

Embodiment 3

[0081] This patent also provides the application of a multi-storey high-height large-space cantilever truss structure embedded with orthogonal small trusses in the design and load-bearing of complex steel structure systems with multi-layer high-height large-space building functions and shapes in high-position and large overhang areas. The large cantilevered space is a large-span architectural functional space with a cantilever not less than 10 meters and a span not less than 20 meters.

[0082]Compared with the deficiencies of the prior art, the present invention provides a multi-layer high-height large-space cantilever truss structure embedded with small orthogonal trusses based on the combination of vertically supported cantilever trusses and cantilevered roof orthogonal small trusses. The central support frame realizes the large-space building function through the large-span steel beams on the cantilevered floor, and realizes the transition from the vertically cantilevered l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com