Front auxiliary frame cross reinforcement structure

A technology of front subframe and strengthening structure, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of weak resistance to lateral impact, poor anti-brake nodding effect, insufficient rigidity of the subframe, etc. The effect of low cost, reduced damage, and improved vehicle ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

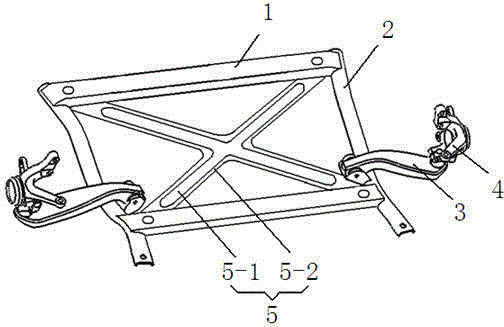

[0017] See attached picture:

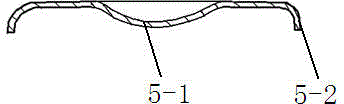

[0018] Front sub-frame cross reinforcement structure, including two front sub-frame longitudinal beams 2 welded and fixed at both ends of two front sub-frame beams 1, two front sub-frame beams 1 and two front sub-frame longitudinal beams 2 Constitute a square frame, two front sub-frame longitudinal beams 2 opposite inner walls are symmetrically hinged and installed with a swing arm 3, and the swing arm 3 is close to the junction of the rear side sub-frame beam 1 and the two front sub-frame longitudinal beams 2 , the upper end surface of the swing arm 3 is fixed with a steering knuckle 4, and an "X"-shaped reinforcement plate 5 is provided under the two front sub-frame beams 1, and the four ends of the reinforcement plate 5 are connected with each corresponding front sub-frame The two ends of the beam are fixed.

[0019] The two front sub-frame beams 1 are hollow rectangular beams, and the two front sub-frame longitudinal beams 2 are hollow cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com