Automobile back door strengthening structure

A technology for strengthening the structure and the back door, which is applied to doors, vehicle parts, transportation and packaging, etc., and can solve problems such as unreasonable design, cracking of the door lock position, and performance that cannot meet certain requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

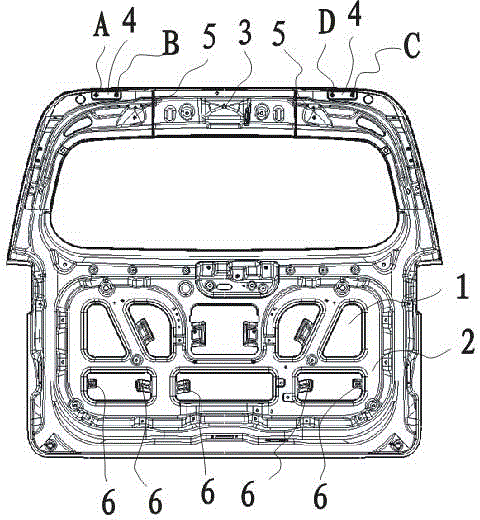

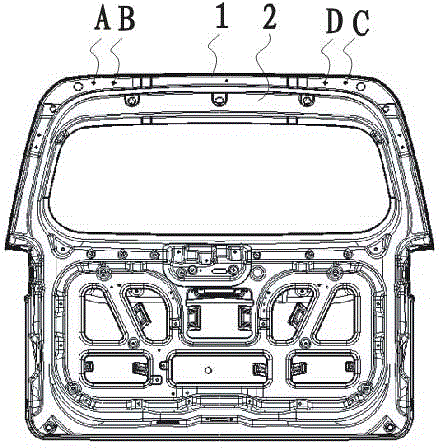

[0016] See attached Figures 1 to 4 , the automobile back door reinforcement structure in the figure, comprises the back door outer panel 1 and the back door inner panel 2 fixed positions integral; Wherein:

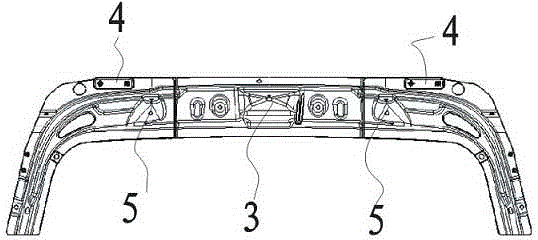

[0017] The upper part of the inner cavity formed between the back door outer panel 1 and the back door inner panel 2 is provided with a connecting plate 3, and the two ends of the connecting plate 3 are fixed with inner panel reinforcing plates 5, and the connecting plate 3 and the inner panel The reinforcement plate 5 forms a reinforcement structure, and the two panels of the reinforcement structure are respectively welded together with the inner surface of the back door outer panel 1 and the inner surface of the back door inner panel 2 . In this embodiment, the tailgate modal, lateral stiffness is increased. Under the same experimental conditions, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com