Driving shaft assembly with support structure

A technology for driving shafts and bearing retaining rings, which is applied in the directions of axles, wheels, transportation and packaging, etc. It can solve the problems that the vibration and modal frequency of the driving shaft cannot be optimized, cannot be adjusted, and the fit is loose, etc., and the structure is simple , Strong practicability, the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

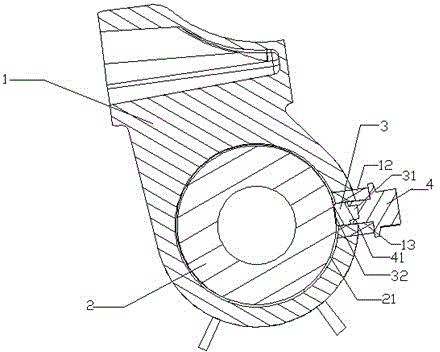

[0012] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

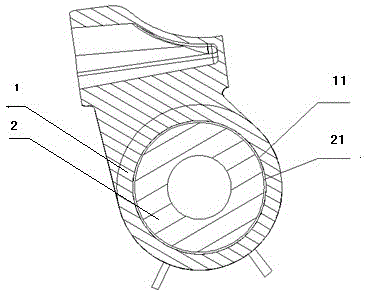

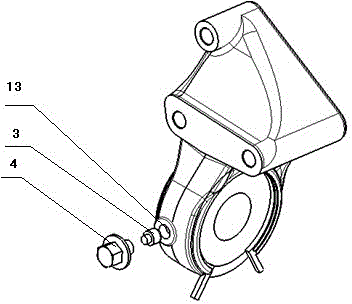

[0013] see figure 2 with image 3 , The drive shaft assembly with a bracket structure includes a bracket body 1, a bearing retaining ring and a spring assembly 2, a rubber plug 3 and a hollow bolt 4. When casting the drive shaft bracket body 1, cast a machinable boss 12 as required, tap the threaded through hole 13 of the corresponding specification along the radial direction of the bracket body on the boss, make the hollow bolt 4 that matches the threaded through hole, and Install the glue plug 3 in the groove 41 of the hollow bolt 4, after the tail part 31 of the glue plug and the groove 41 of the hollow bolt 4 are assembled through interference fit, screw the hollow bolt 4 into the threaded through hole 13 on the boss 12 , the rubber plug 3 and the threaded hole 13 of the boss are an interference fit. At this time, the end 32 of the rubber plug presses the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com