Patents

Literature

161results about How to "Raise modal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

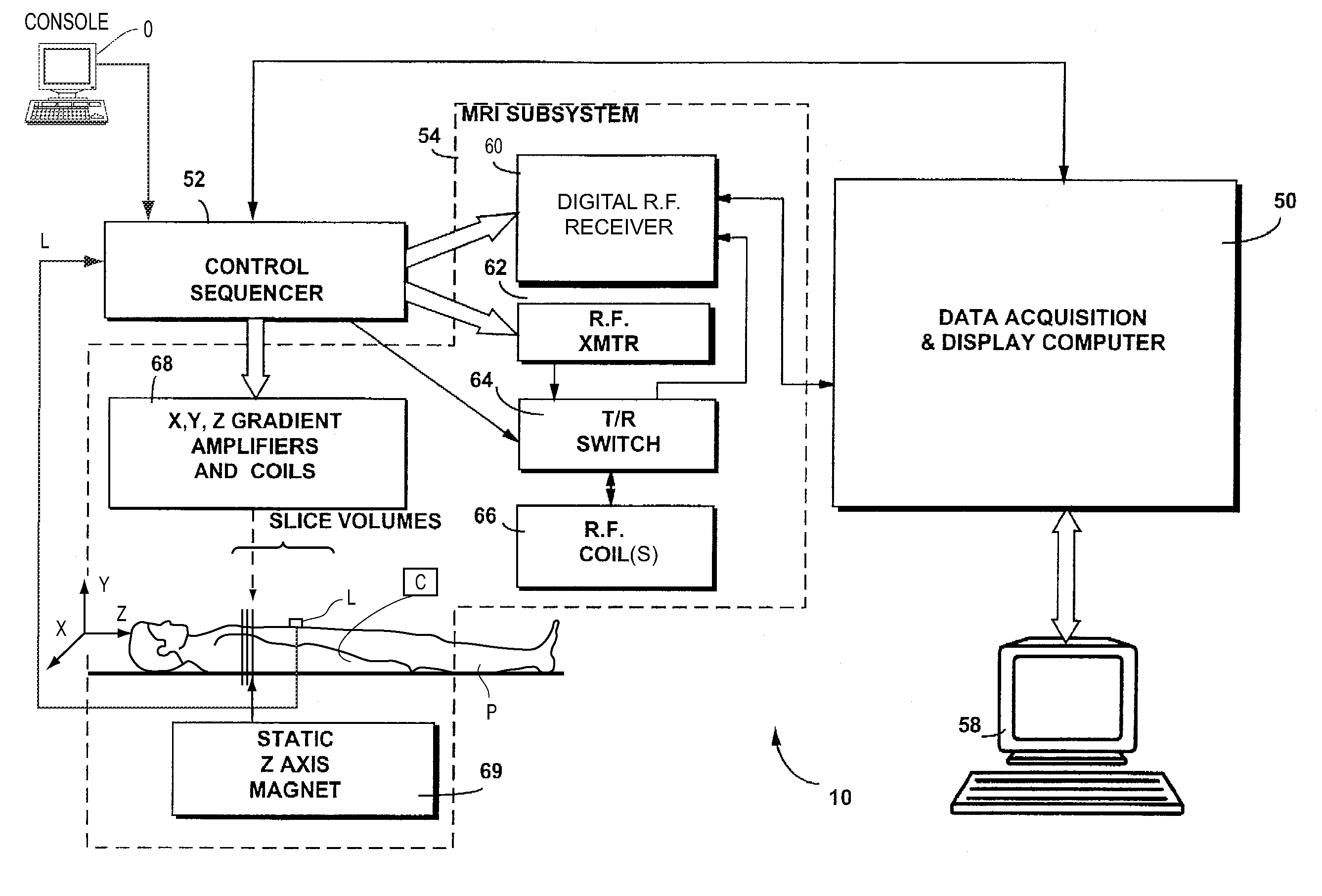

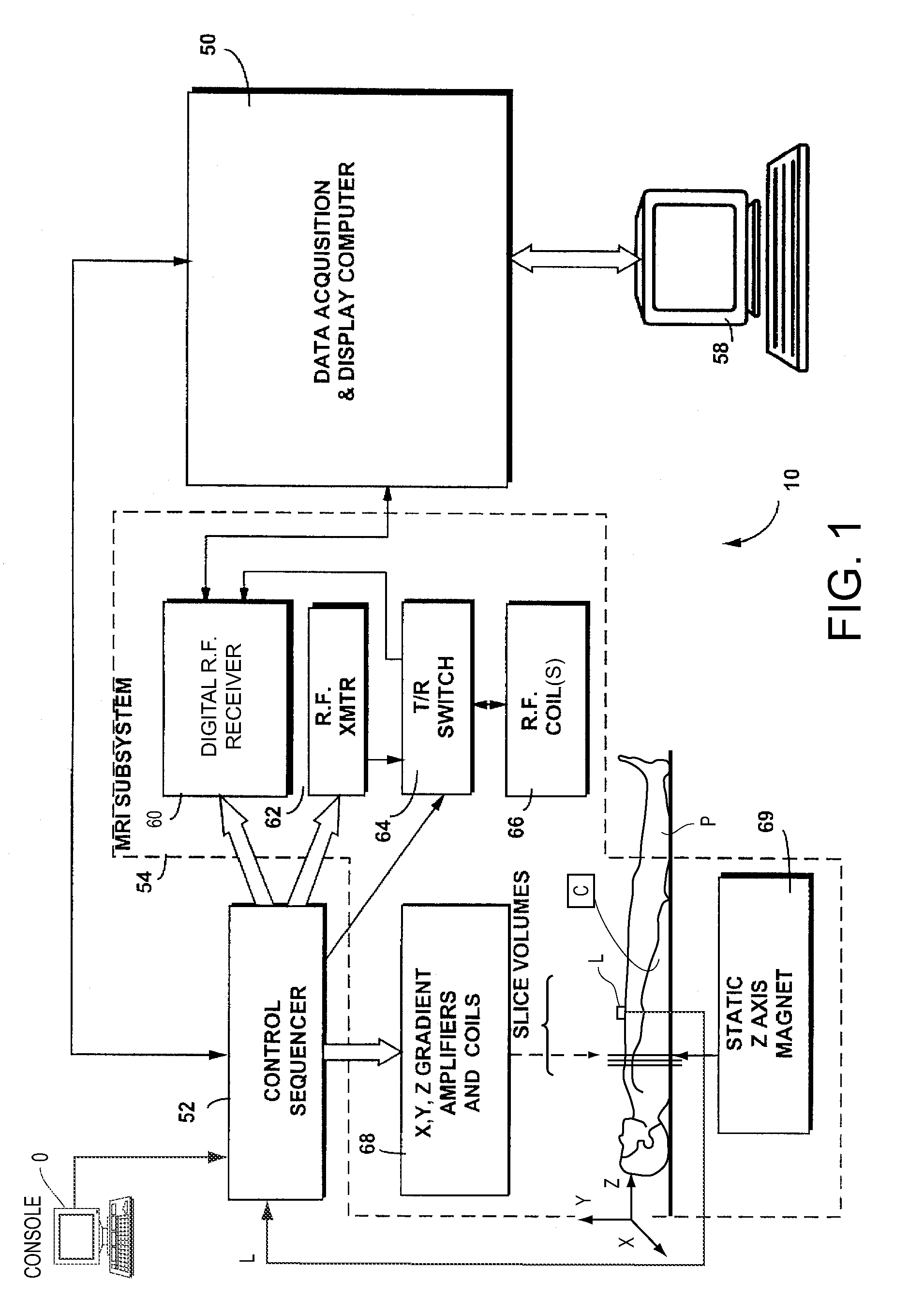

Dark blood delayed enhancement magnetic resonance viability imaging techniques for assessing subendocardial infarcts

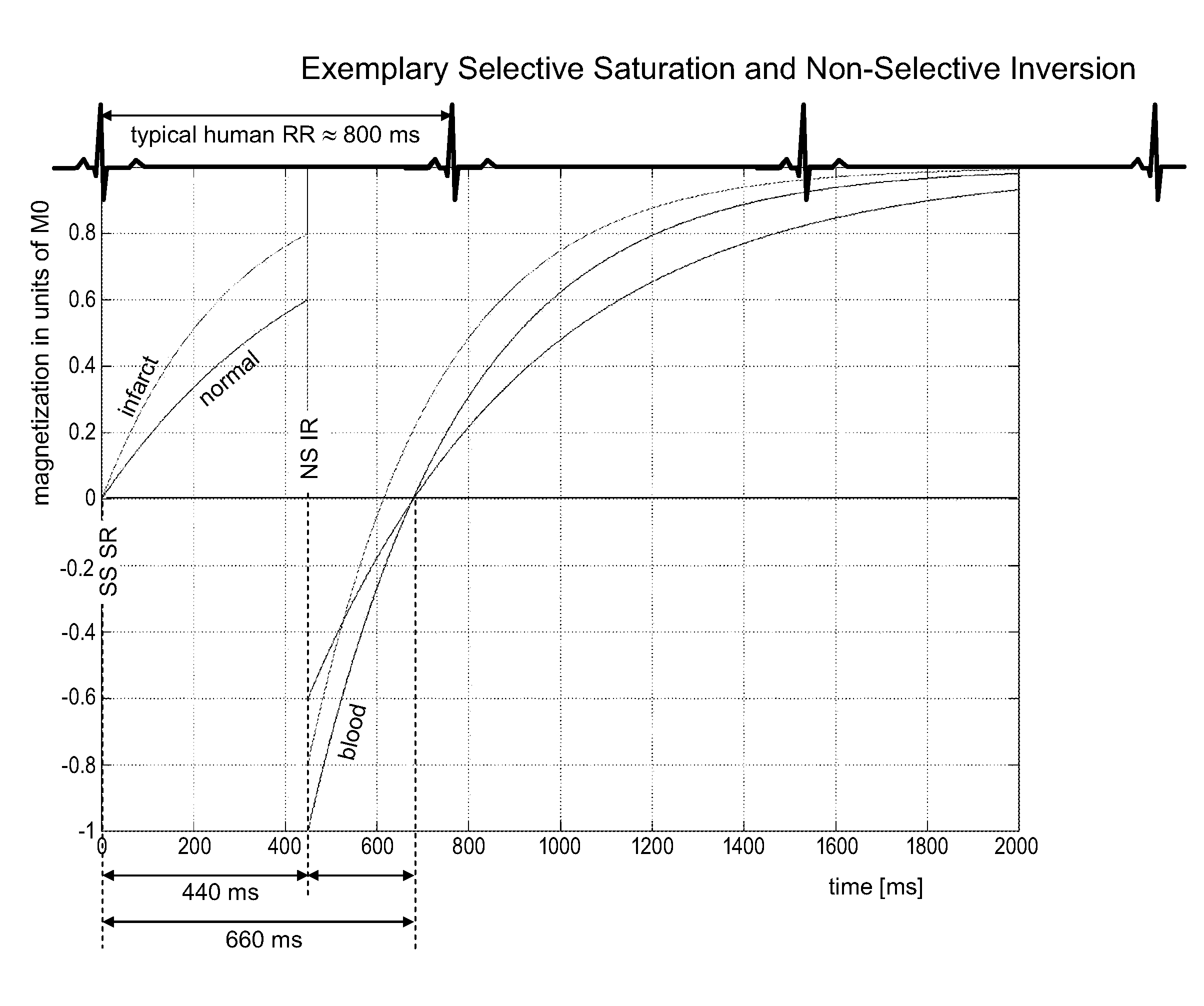

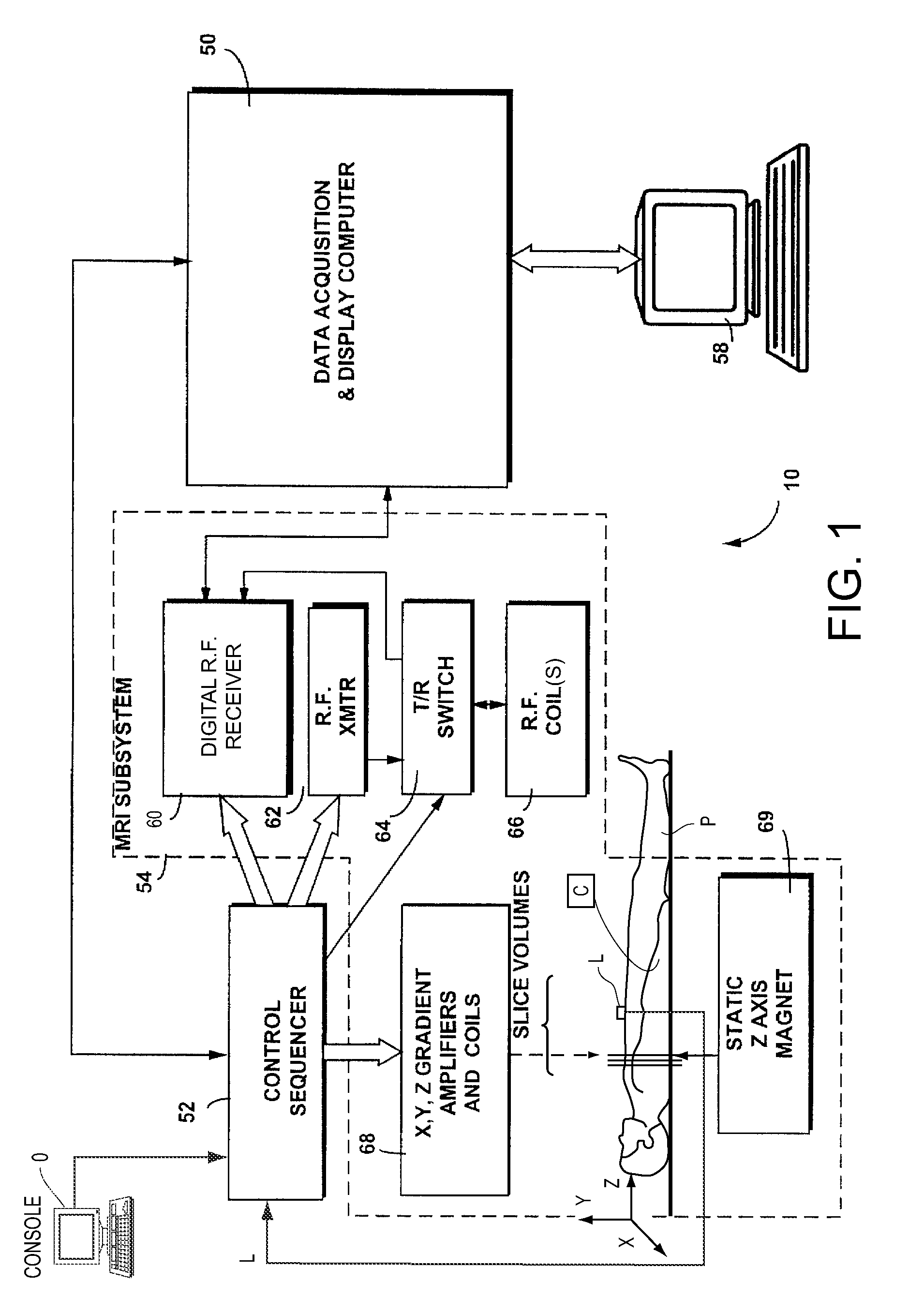

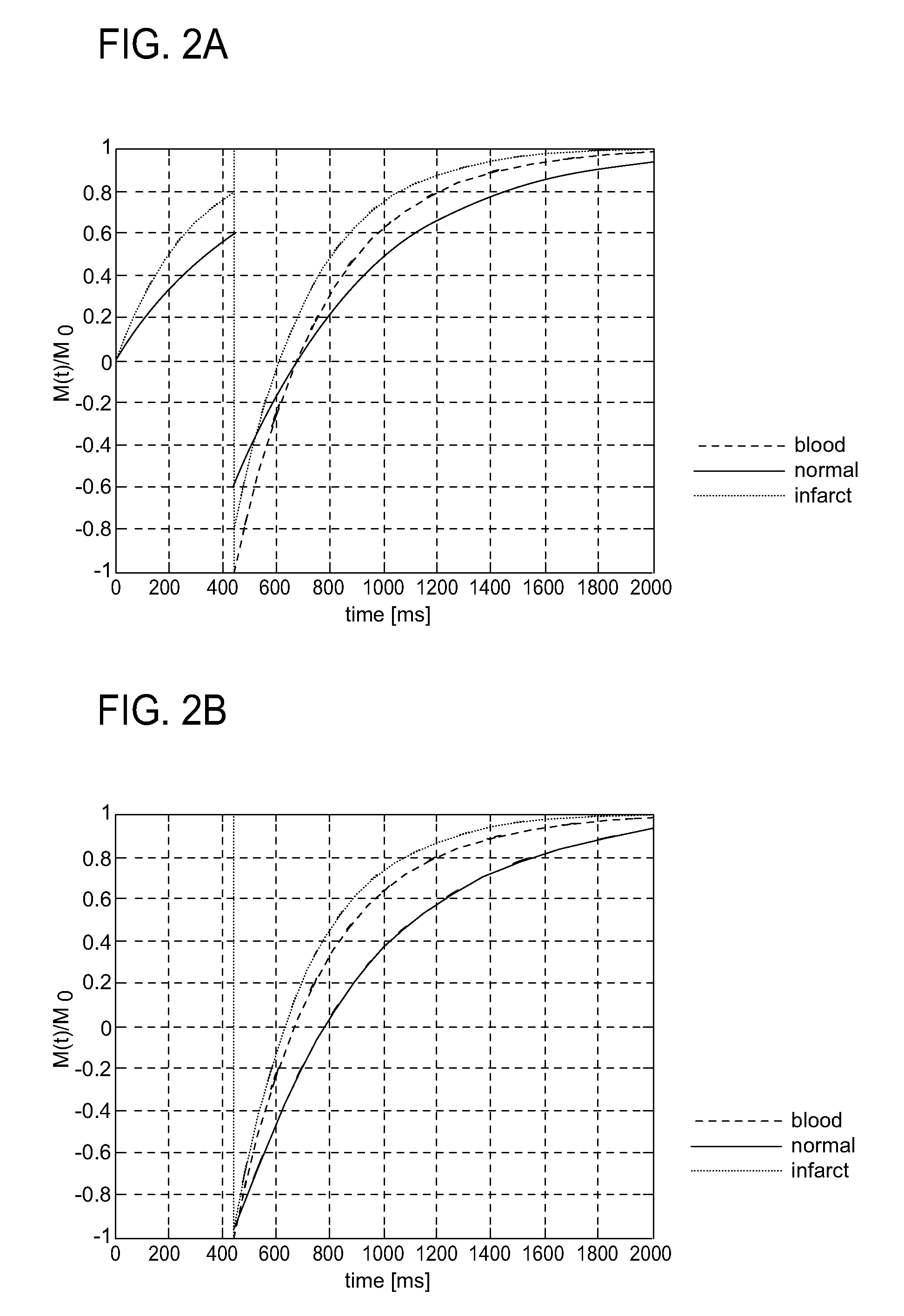

ActiveUS20090005673A1Improve image contrastRaise modalDiagnostic recording/measuringMeasurements using NMR imaging systemsRelaxation curveCardiac cycle

The technology herein provides a dark blood delayed enhancement technique that improves the visualization of subendocardial infarcts that may otherwise be disguised by the bright blood pool. The timed combination of a slice-selective and a non-selective preparation improves the infarct / blood contrast by decoupling their relaxation curves thereby nulling both the blood and the non-infarcted myocardium. This causes the infarct to be imaged bright and the blood and non-infarct to both be imaged dark. The slice-selective preparation occurs early enough in the cardiac cycle so that fresh blood can enter the imaged slice.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC +1

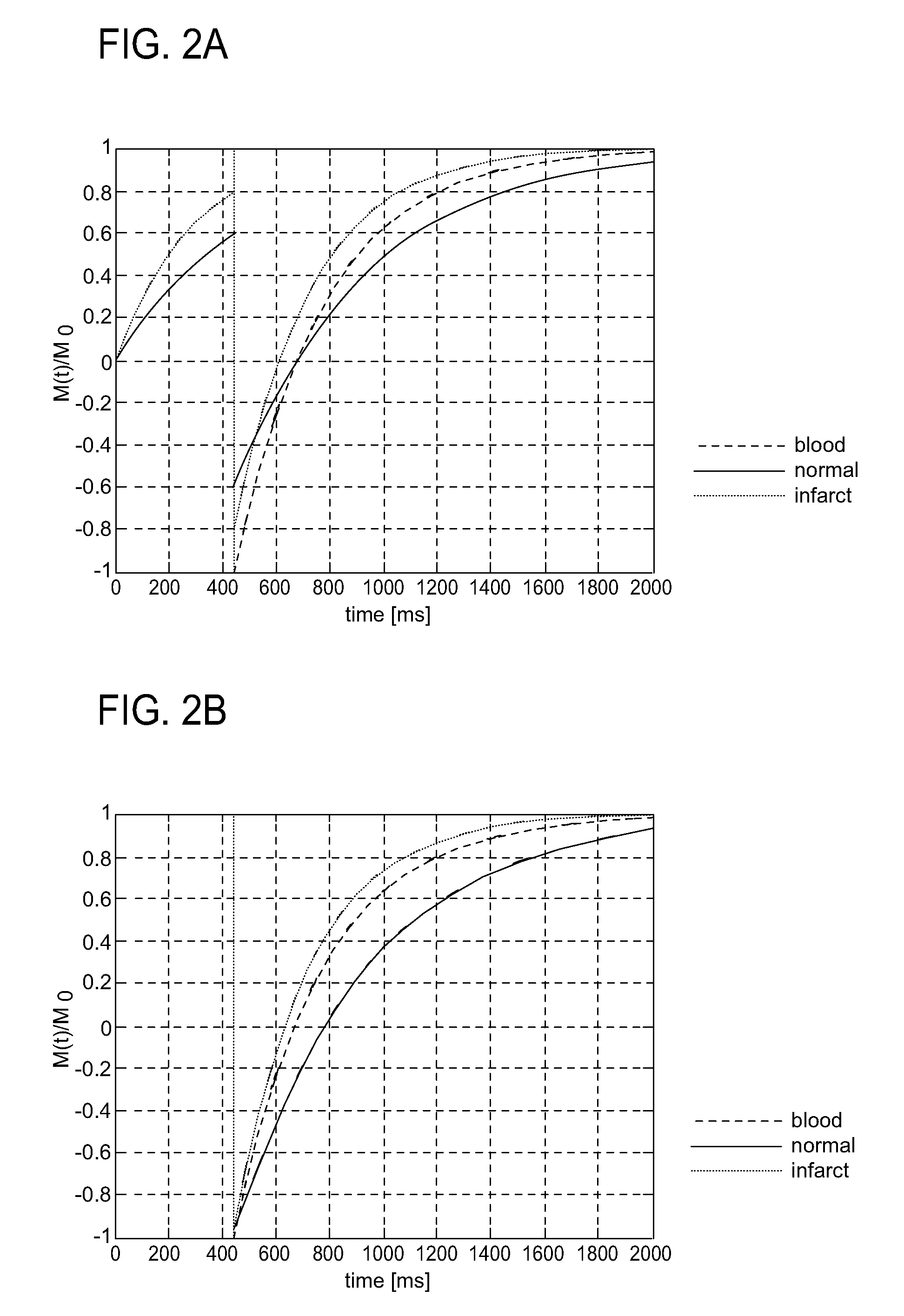

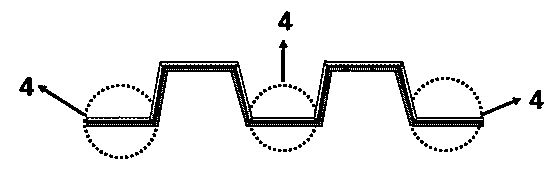

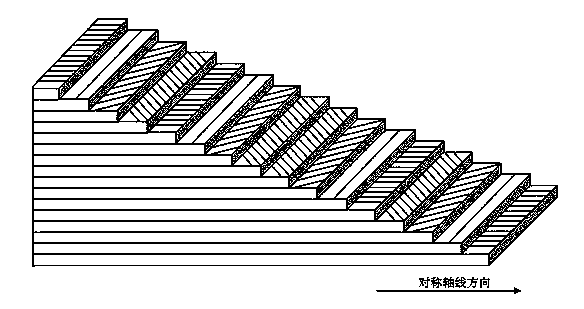

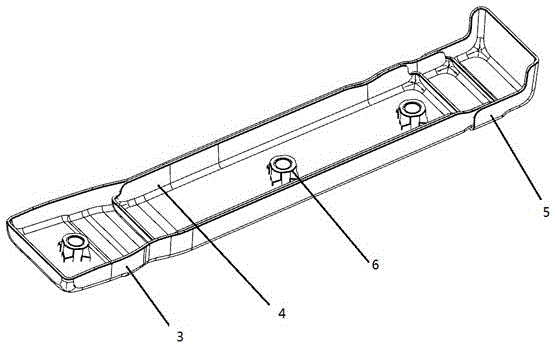

Preparation method of resin fiber composite material vehicle door anti-collision component and method for connecting resin fiber composite material vehicle door anti-collision component with vehicle door

ActiveCN104385559ALow densityHigh strengthLaminationLamination apparatusCarbon fibersAutomobile safety

The invention provides a preparation method of a resin fiber composite material vehicle door anti-collision component and a method for connecting the resin fiber composite material vehicle door anti-collision component with a vehicle door inner plate. The preparation method comprises the followings steps: thermoplastic resin and carbon fiber fabric are pre-impregnated to be processed into unidirectional pre-impregnated sheet materials, the unidirectional pre-impregnated sheet materials are laid and hot-pressed to form thermoplastic resin-carbon fiber fabric composite material laminating sheets according to an optimal laying scheme that anti-collision strength and high temperature resistance are ensured, and finally, hot-pressing is performed through a die so as to form the vehicle door anti-collision component; meanwhile, the vehicle door anti-collision component is connected onto the vehicle door inner plate in a fastening manner through an adhesive and mechanical mixing connecting mode innovatively; the application of resin fiber composite material in the vehicle door anti-collision component is realized firstly, and the prepared vehicle door anti-collision component has higher tensile strength, higher high temperature resistance, and higher connection strength with the vehicle door; meanwhile, on the premise that vehicle safety performance is not sacrificed, the vehicle weight is reduced greatly, NVH performance of the vehicle is improved, and a wide market promotion and application prospect is achieved.

Owner:CHERY AUTOMOBILE CO LTD

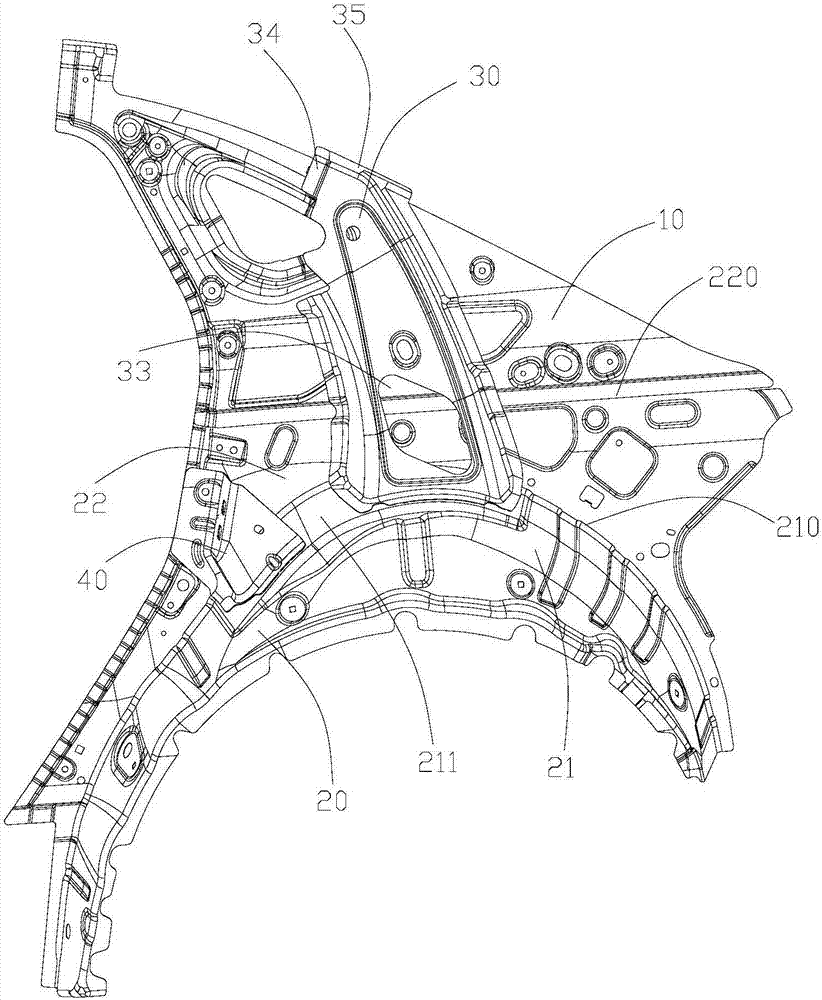

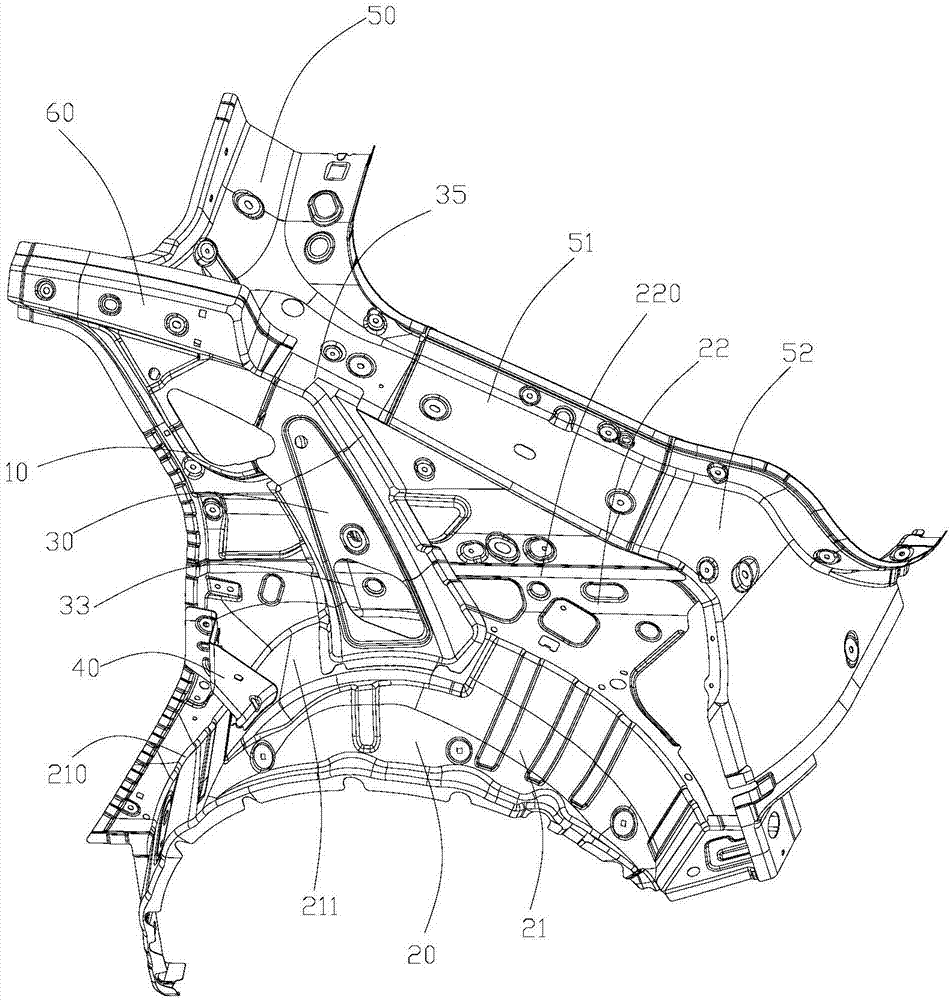

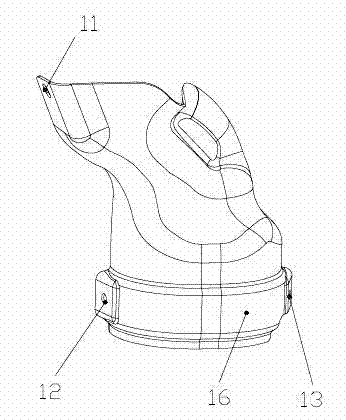

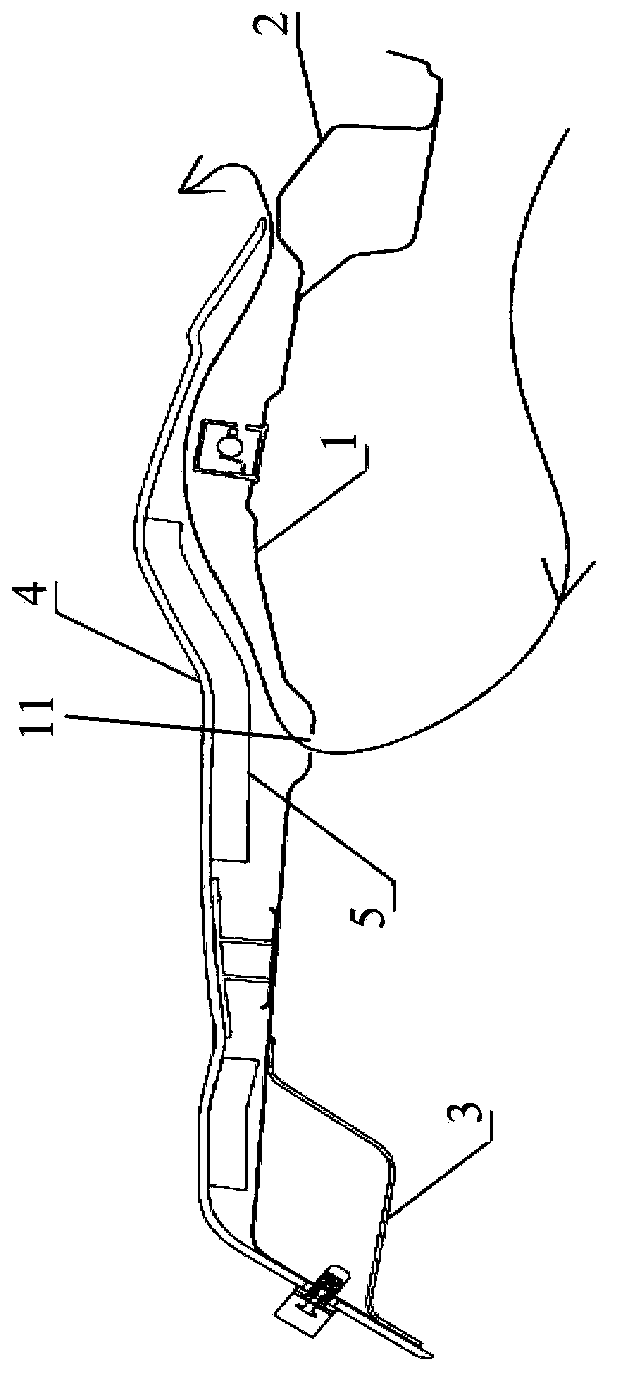

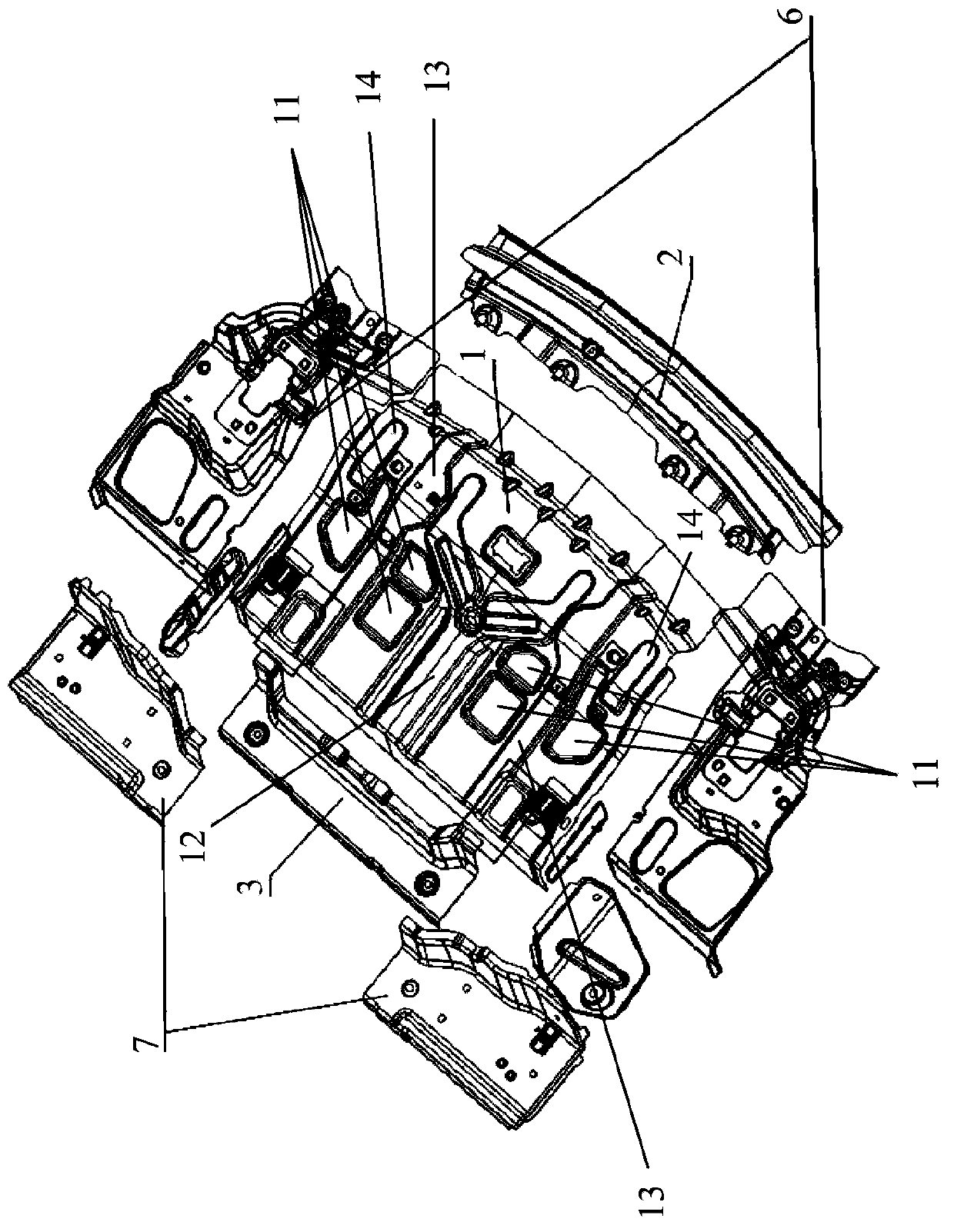

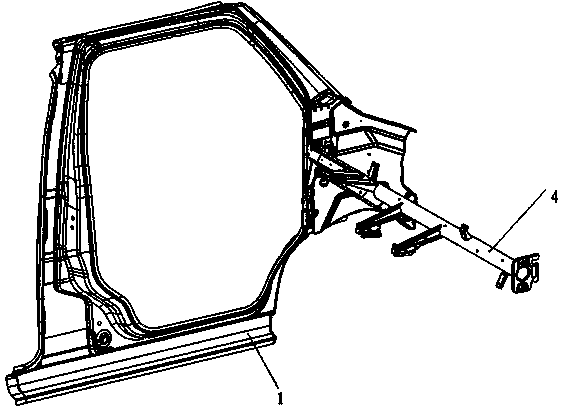

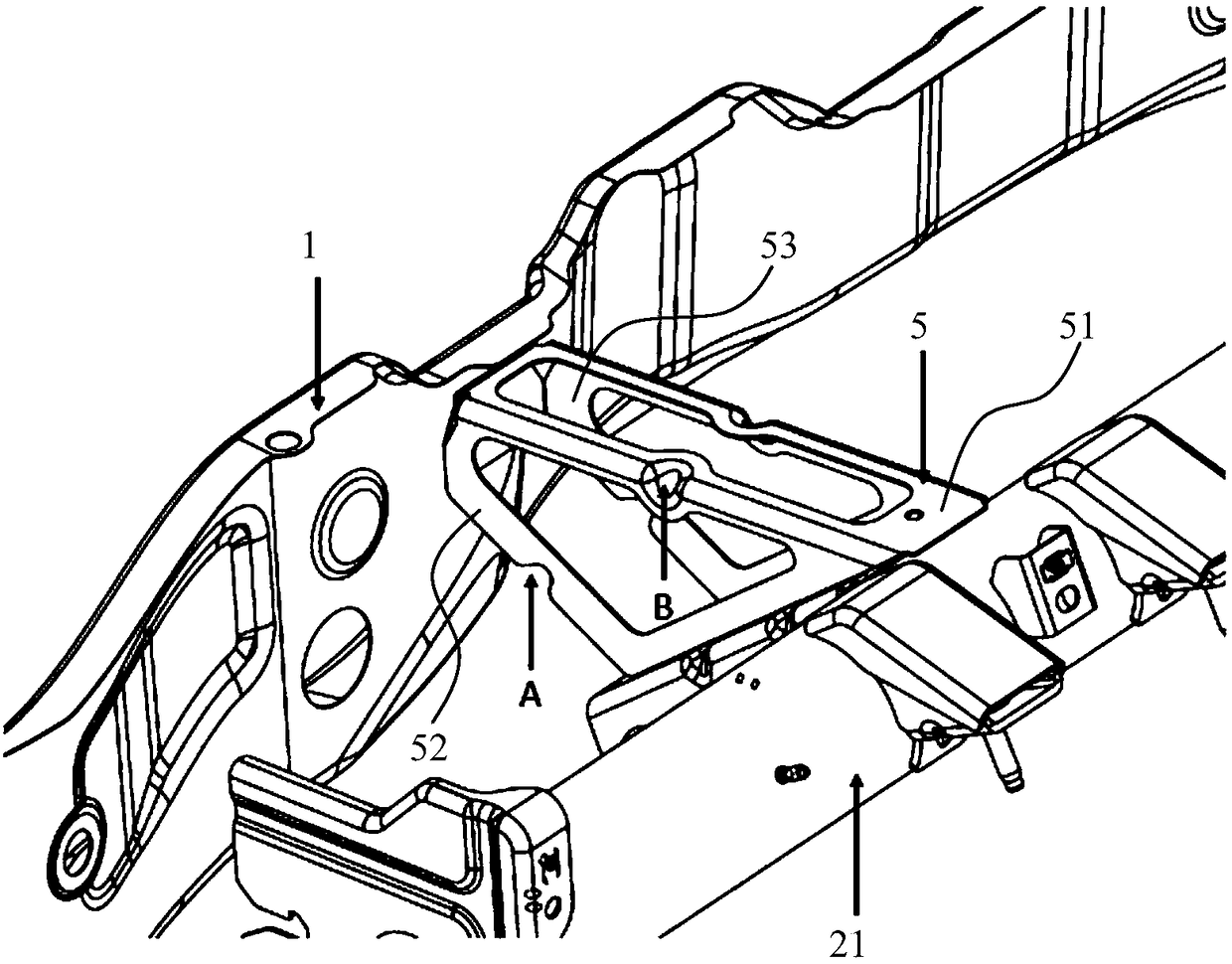

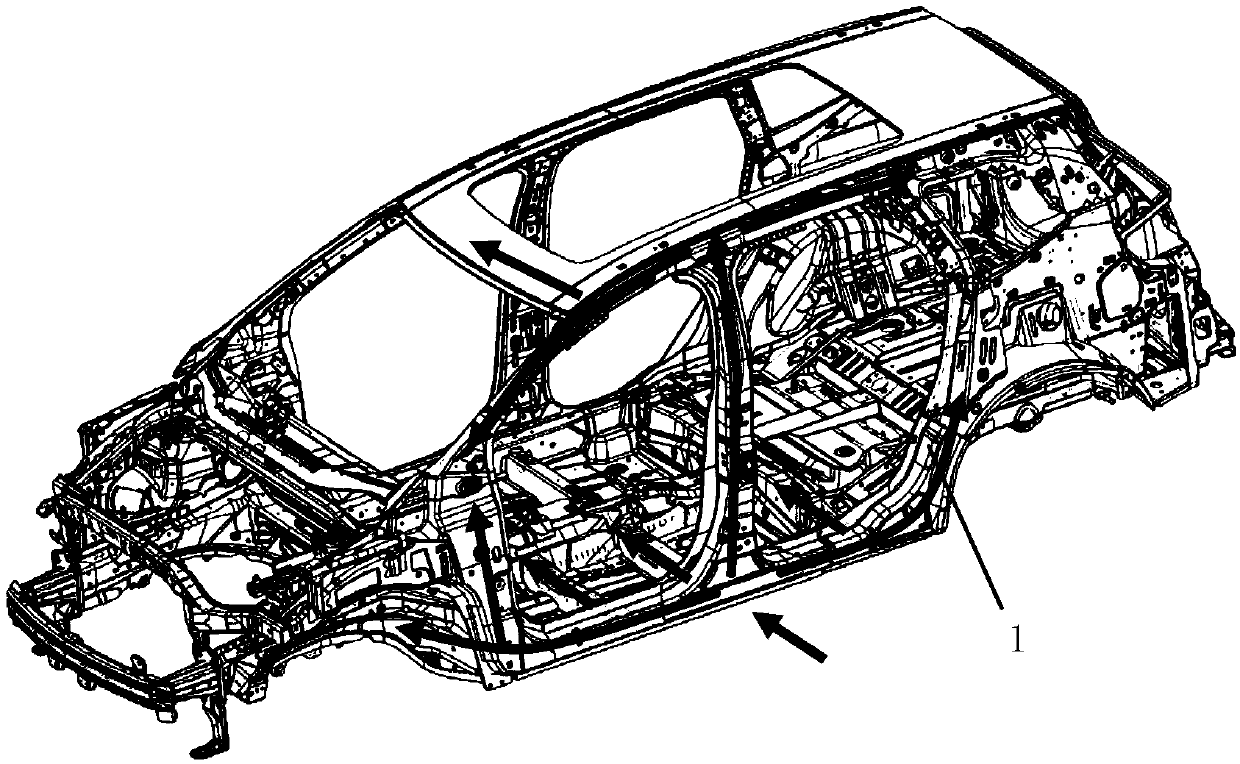

Vehicle body side wall structure, C pillar reinforcing plate and vehicle

ActiveCN107487370AIncrease stiffnessHigh strengthSuperstructure subunitsDiagnostic Radiology ModalityEngineering

The invention relates to a vehicle body side wall structure, a C pillar reinforcing plate and a vehicle. The vehicle body side wall structure comprises a C pillar inner plate, a wheel cover outer plate fixed to the lower edge of the C pillar inner plate and the C pillar reinforcing plate fixed to the C pillar inner plate and the wheel cover outer plate. The upper end of the C pillar reinforcing plate is connected to a connector of the vehicle body side wall structure, the lower end of the C pillar reinforcing plate is connected to the wheel cover outer plate, and the C pillar inner plate, the wheel cover outer plate and the C pillar reinforcing plate jointly define a cavity structure. By fixing the C pillar reinforcing plate between the C pillar inner plate and the wheel cover outer plate, and by arranging the cavity structure extending from the connector to the wheel cover outer plate on the vehicle body side wall structure, the overall rigidity and the strength of the CD pillar are improved greatly, and the modality and the torsional rigidity of the vehicle are improved. In addition, the C pillar reinforcing plate is connected between the connector of the vehicle body side wall structure and the wheel cover outer plate, a force transmission path of a vehicle body framework is increased, the phenomenon that impact force concentration happens on the vehicle body framework is avoided, and prolonging of the service life of the vehicle body framework is facilitated.

Owner:BEIQI FOTON MOTOR CO LTD

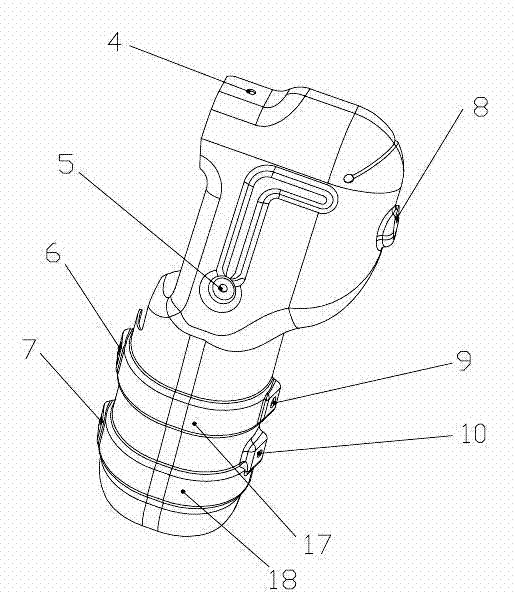

Supercharger engine hot end heat insulating shield assembly

ActiveCN103206289ASimple shape and structureEasy to installExhaust apparatusSilencing apparatusEngineeringMechanical engineering

The invention discloses a supercharger engine hot end heat insulating shield assembly which comprises an exhaust manifold heat insulating shield, a supercharger heat insulating shield and a three-way catalyst heat insulating shield. Both the supercharger heat insulating shield and the three-way catalyst heat insulating shield are in a layered structure, upper layers and lower layers of the two are hot-dipping aluminum plates, and middle layers of the two are ceramic fiber paper plates. The three-way catalyst heat insulating shield is formed by an upper three-way catalyst shield and a lower three-way catalyst shield, wherein the upper portion of the upper three-way catalyst shield is mounted on the left side of a supercharger, the lower portion of the lower three-way catalyst shield is mounted on the left side of a three-way catalyst, and the lower three-way catalyst shield is mounted on the right side of the three-way catalyst. The supercharger heat insulating shield is arranged above the three-way catalyst heat insulating shield, mounted on the right side of the supercharger and connected with the upper portion of the three-way catalyst shield via two mounting points. By the supercharger engine hot end heat insulating shield assembly, the supercharger and the three-way catalyst are integrally subjected to heat insulation, noise reduction and protection, strength can be guaranteed and modal requirements can be met, processing and manufacturing are enabled to be easy, and the mounting is enabled to be convenient.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

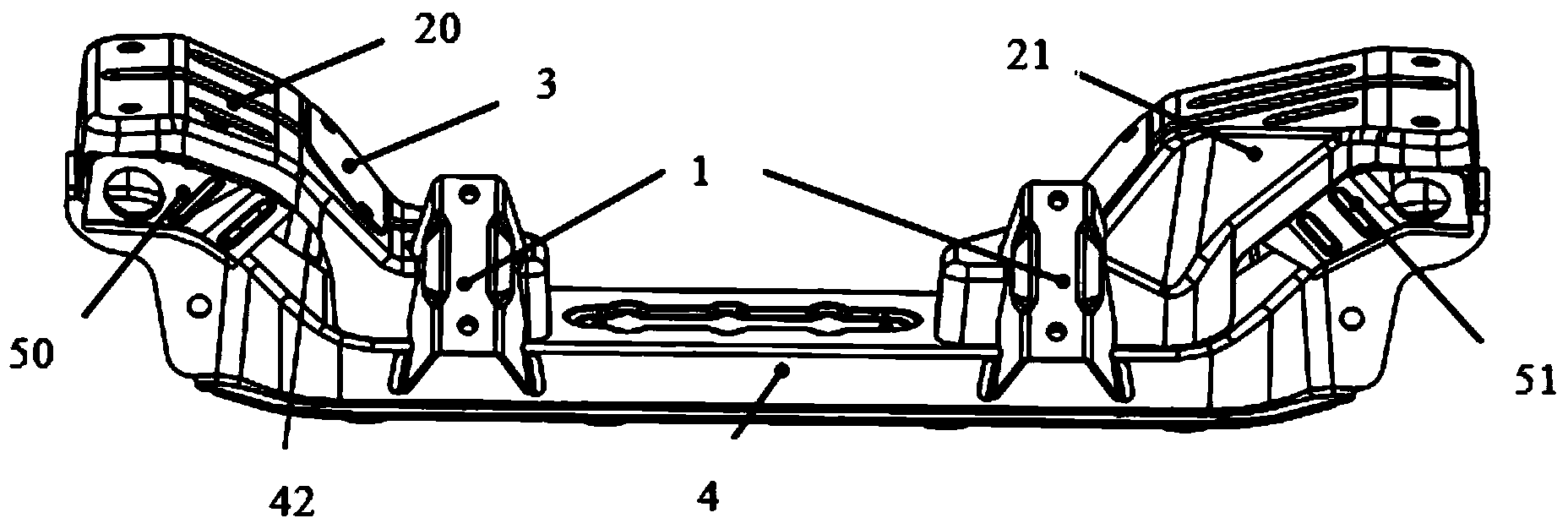

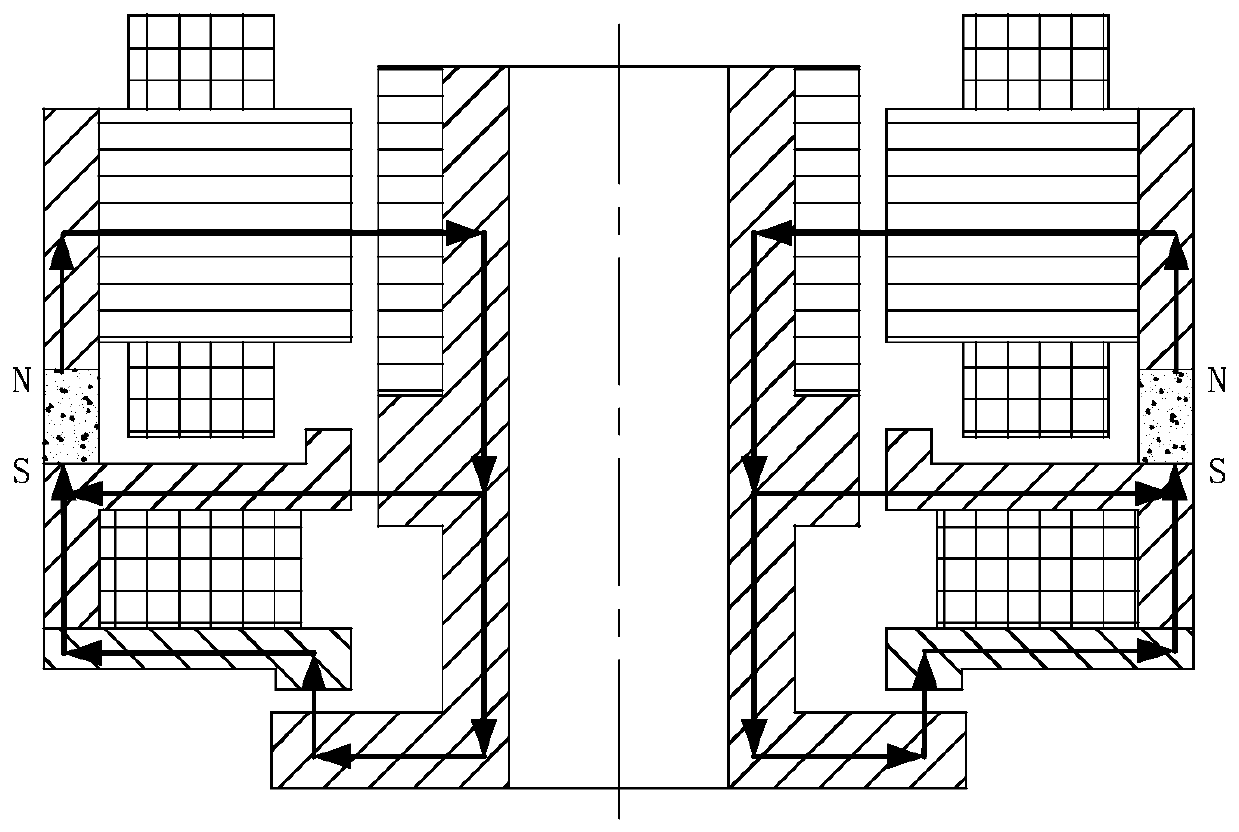

Front axle welding part structure

The invention belongs to an automobile front axle component, and particularly relates to a front axle welding part structure. The front axle welding part structure comprises suspension supports, a steering gear support and a cross beam; the suspension supports and a steering gear are arranged on the cross beam; the suspension supports are provided with a left suspension support and a right suspension support; the suspension supports are located at the two ends of the cross beam; the suspension supports are in fastening connection with the cross beam; no gap exists between the suspension supports and the cross beam; the steering gear support is located on the side faces of the opposite inner ends of the two suspension supports; the steering gear support is connected with the cross beam and the suspension supports. The extra torque negative effects of suspension loads of an engine and loads of a control arm are avoided to the greatest extent; and the component is quite favorable to improving rigidity, the mode and the reliability of the whole front axle welding part structure.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

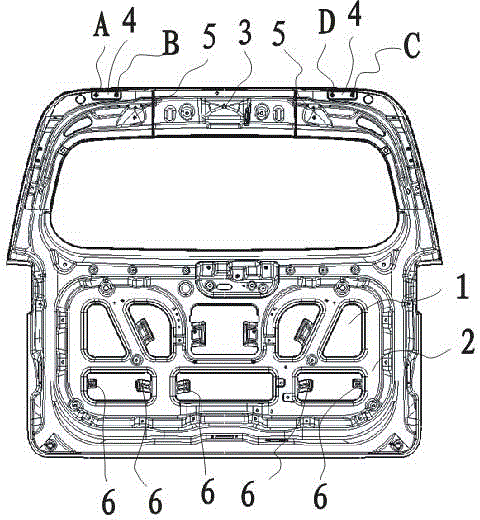

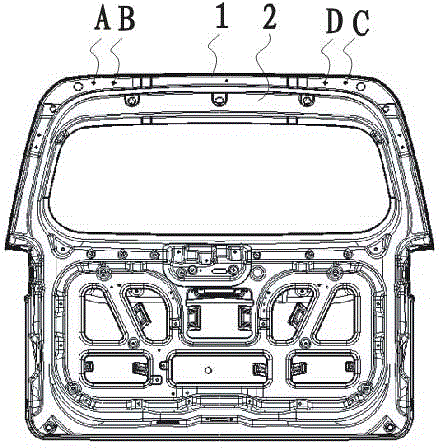

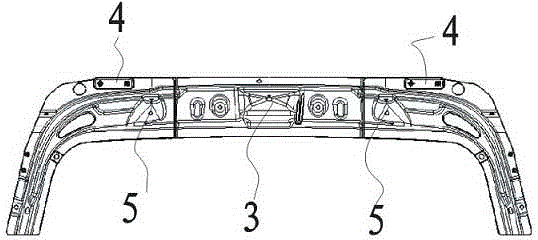

Automobile back door strengthening structure

The invention relates to an automobile back door, in particular to an automobile back door strengthening structure. The automobile back door strengthening structure comprises a back door outer plate and the back door, wherein a back door inner plate and the back door are fixed into a whole. A connecting plate is arranged at the upper portion of an inner cavity formed between the back door outer plate and the back door inner plate, inner plate strengthening plates are fixed to the two ends of the connecting plate, and a strengthening structure is formed by the connecting plate and each inner plate strengthening plate, wherein two face plates of the strengthening structure, the inner plate face of the back door outer plate and the inner plate face of the back door inner plate are welded into a whole. Due to the structure, the modality and lateral rigidity of the back door are improved, and the rigidity performance of a hinge installing point is enhanced.

Owner:北汽瑞翔汽车有限公司

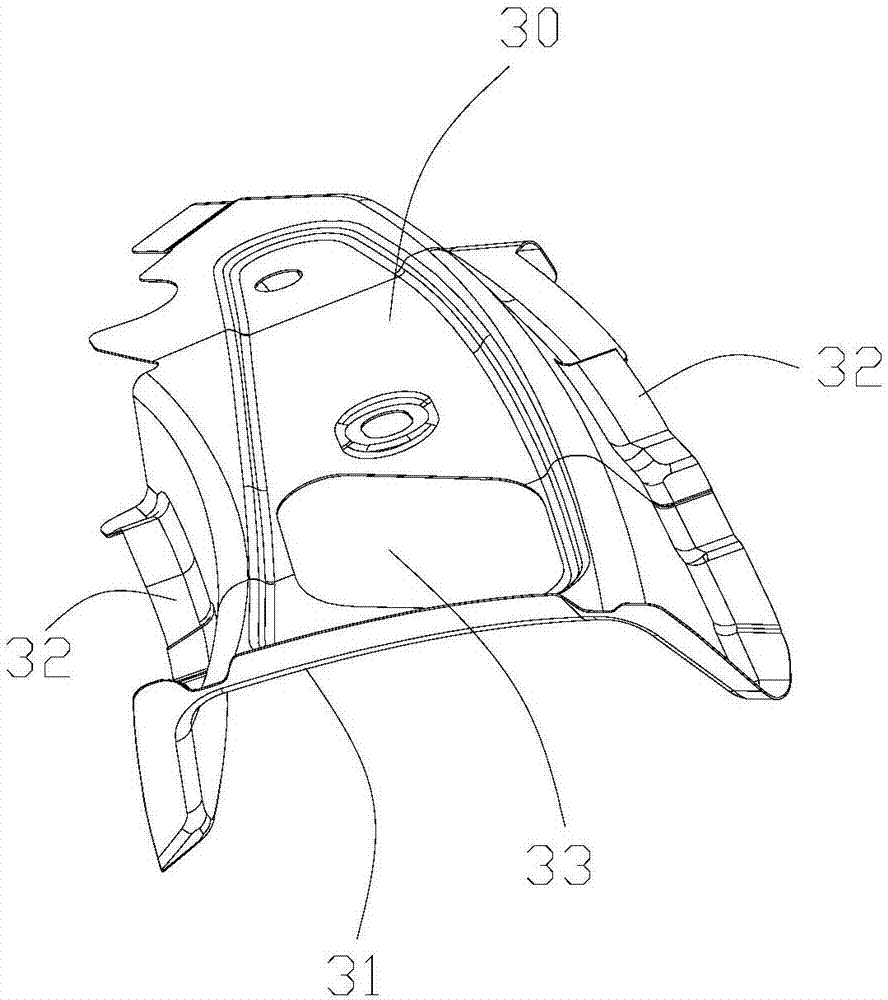

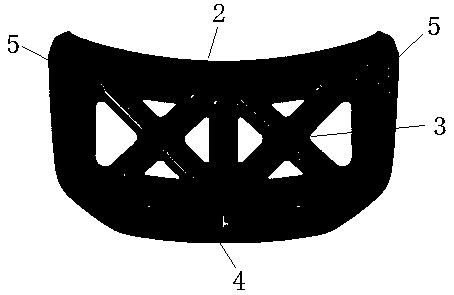

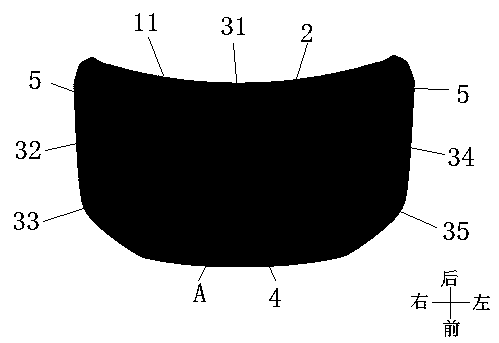

Carbon fiber composite material automobile front cover

InactiveCN109292004AMeet performance requirementsAchieve weight lossSynthetic resin layered productsSuperstructure subunitsMaterials scienceFront cover

The invention discloses a carbon fiber composite material automobile front cover. The carbon fiber composite material automobile front cover comprises an external plate and an internal plate which arebonded with each other; the external plate and the internal plate are made of a carbon fiber composite material of an integral course; a net-shaped reinforcing part is arranged at the middle part ofthe internal plate; a lock catch reinforcing plate and a hinge fixing support are bonded on the internal plate; and a reinforcing course is clamped in the integral course on which the lock catch reinforcing plate and the hinge fixing support are arranged. Light weight is realized on the premise of satisfying performance requirements.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

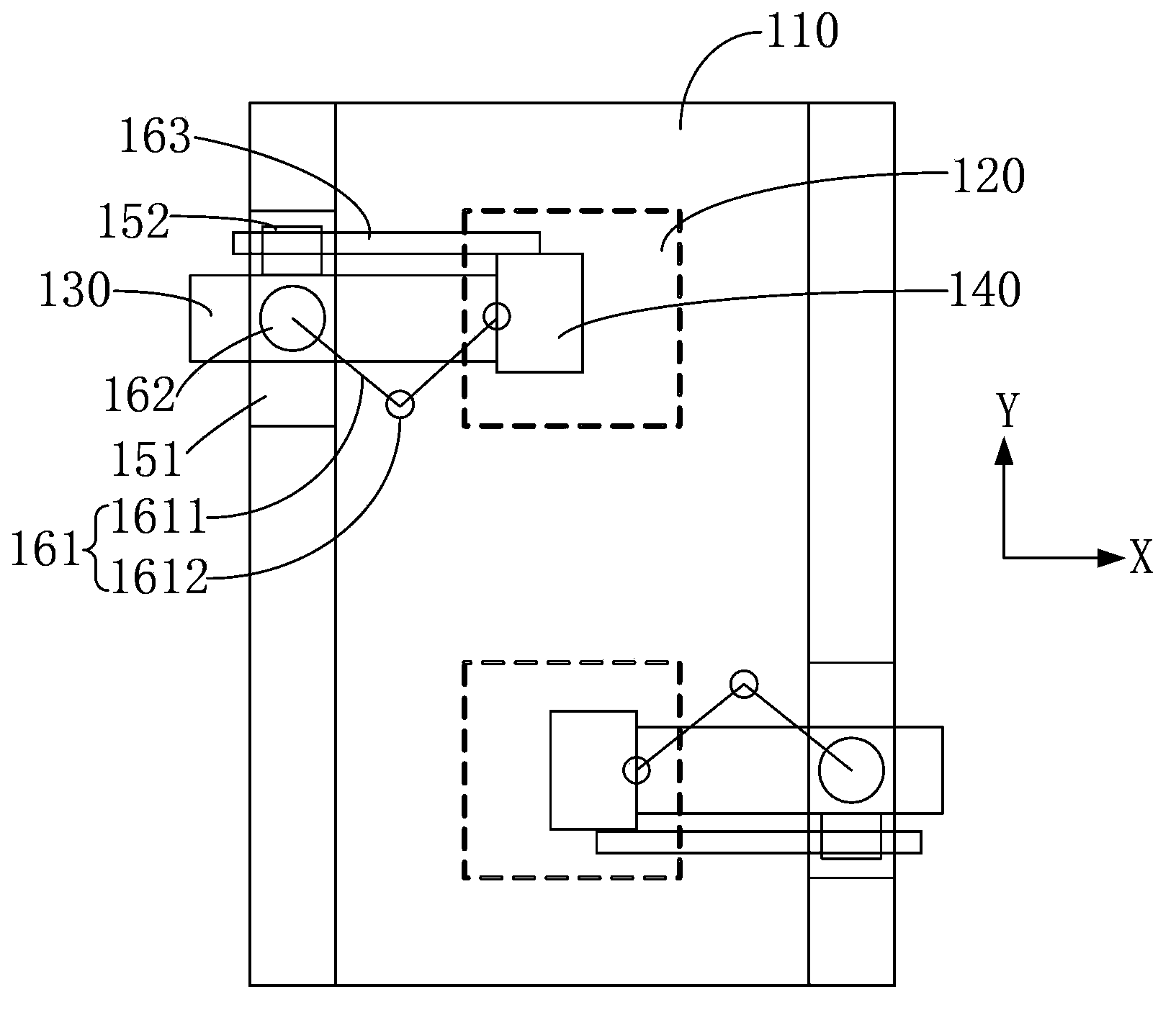

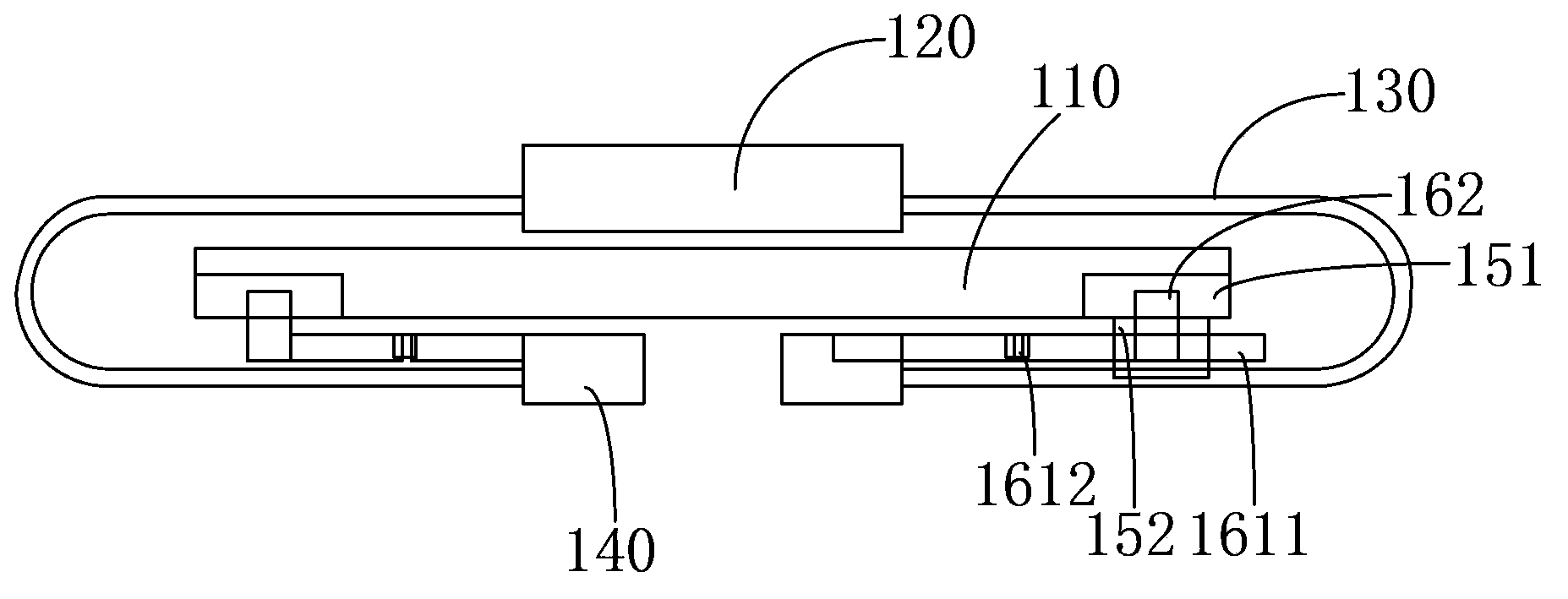

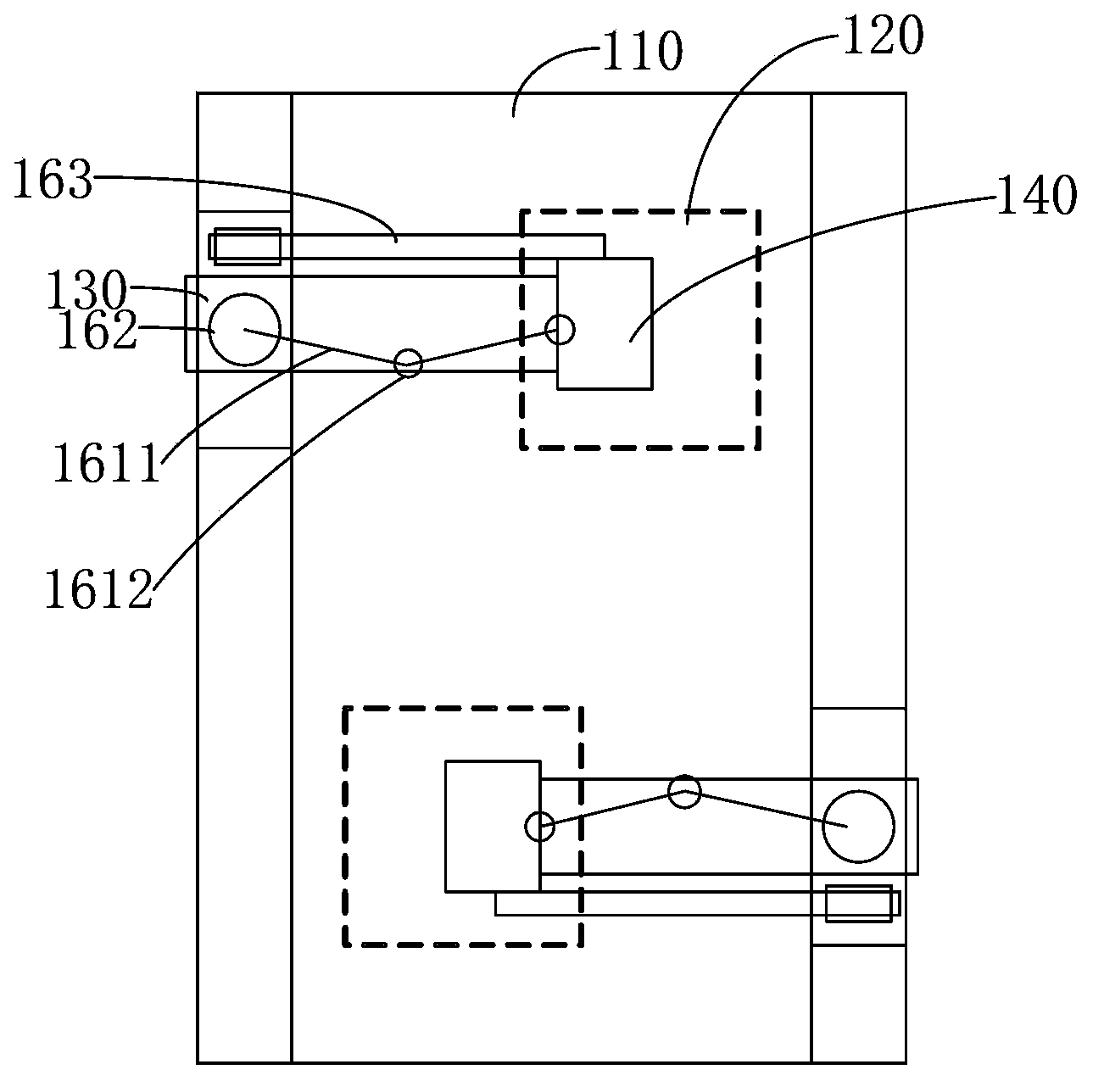

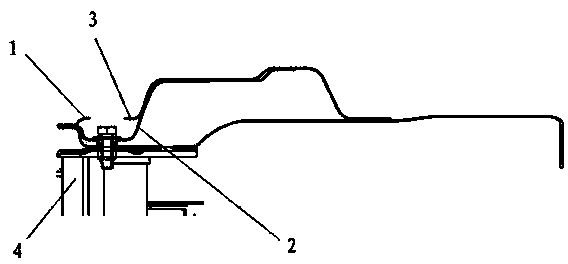

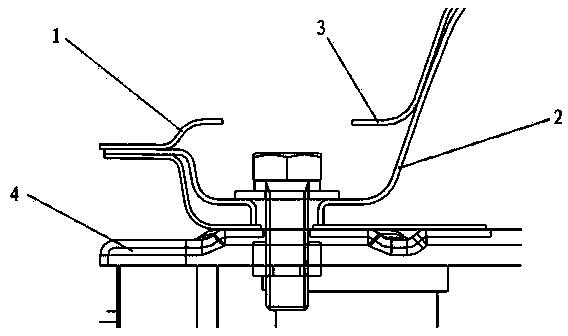

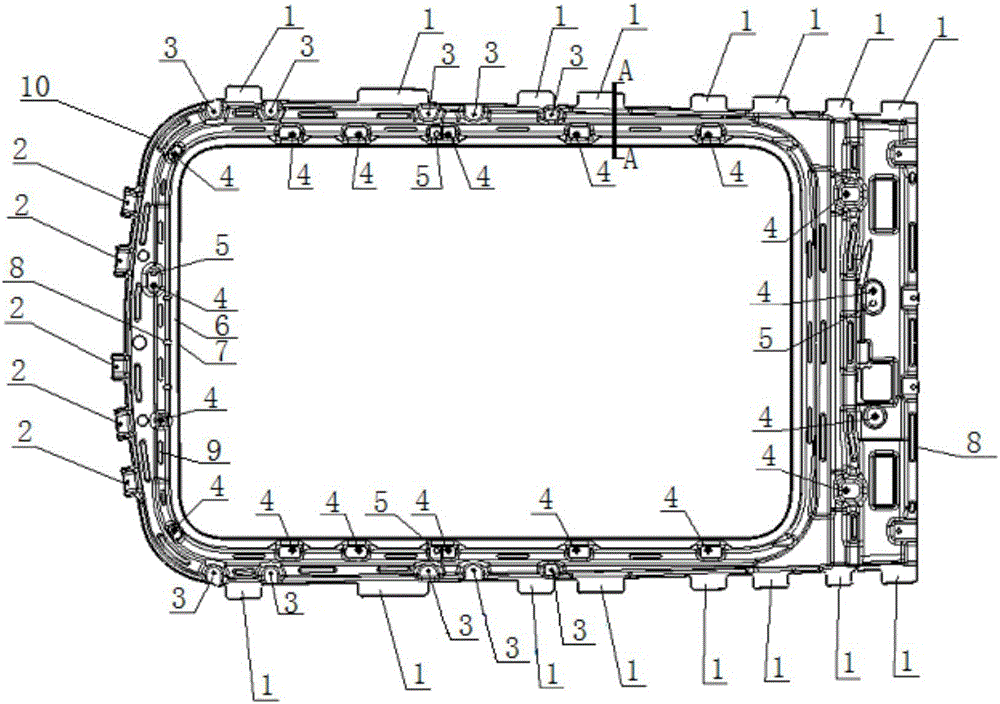

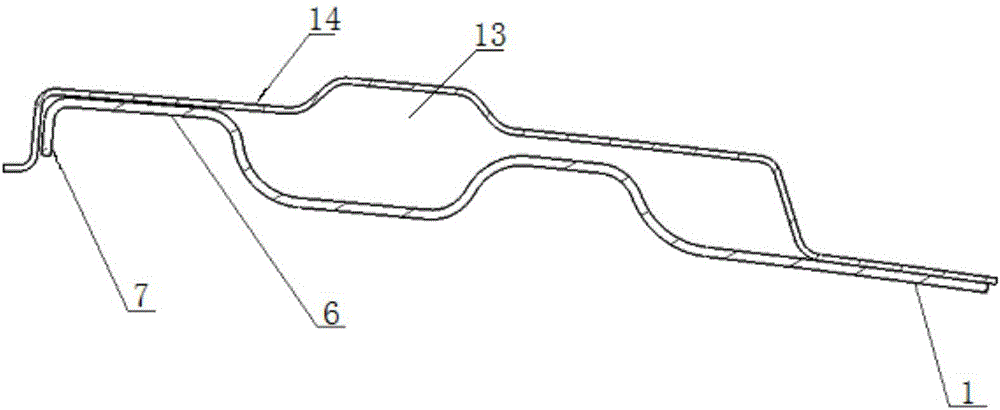

Workbench cable device

ActiveCN103901734AIncrease stiffnessHigh elastic modulusSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPower stationEngineering

A work station cable apparatus comprises a work station (110), a silicon wafer station (120), a cable device (130), a cable connection station (140), an X-direction moving device and a Y-direction moving device. The silicon wafer station (120) and the cable connection station (140) are respectively mounted on the upper side and the lower side of the work station (110). The two ends of the cable device (130) are connected to the silicon wafer station (120) and the cable connection station (140) respectively. The X-direction and Y-direction moving devices are both connected to the cable connection station (140) and respectively drive the cable connection station (140) to move following the silicon wafer station (120) along the X-direction and the Y-direction. The cable connection station (140) drives the cable device (130) to synchronously move following the silicon wafer station (120) along the X-direction and the Y-direction, thus being able to reduce disturbance of the cable device (130) to the motion of the silicon wafer station (120), reduce the bending times of the cable device (130) and prolong the service life of the cable device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

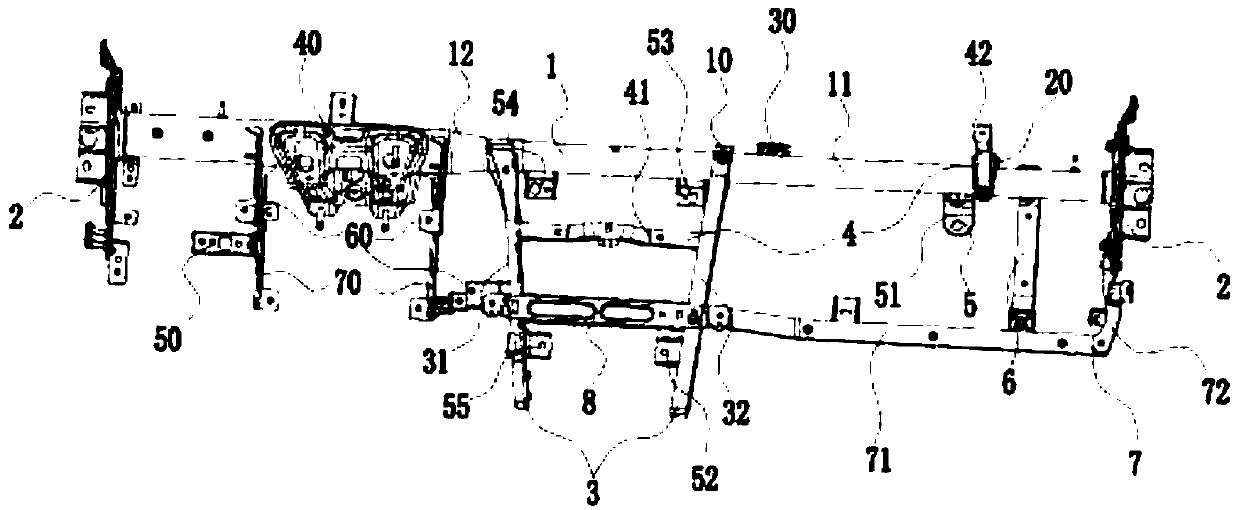

Steel-plastic composite support assembly for automobile instrument panel and automobile

PendingCN107856746AHigh tensile strengthImprove bending strengthSuperstructure subunitsDashboardsDashboardHybrid car

The invention discloses a steel-plastic composite support assembly for an automobile instrument panel (IP) and an automobile. The steel-plastic composite support assembly comprises a cross beam made of steel, wherein vehicle body mounting supports are respectively arranged at two ends of the cross beam. The steel-plastic composite support assembly also at least comprises a connection support for connecting the support assembly with a floor, an IP support for mounting the automobile IP, an air conditioner support for mounting an air conditioner, a PEPS module support for mounting a PEPS moduleand a glove box support for mounting a glove box, wherein all or part of parts of the connection support, the IP support, the air conditioner support, the PEPS module support and the glove box supportare injection molded parts made of plastic obtained by mixing nylon and glass fiber. The steel-plastic composite support assembly for the automobile IP uses the plastic injection molded parts insteadof steel parts to effectively realize the lightweight of the support assembly for the automobile IP. At the same time, by virtue of the selection of plastic material, the steel-plastic composite support assembly improves the rigidity and other performance of each injection molded part, effectively realizes the lightweight, improves the combination of modality, rigidity and strength performance ofthe entire support assembly for the automobile IP, and improves the NVH performance.

Owner:奇昊汽车系统(苏州)有限公司

Rear luggage rack device for sedan

InactiveCN104175963AImprove NVH performanceIncrease stiffnessVehicle componentsClosest relativesMechanical engineering

Owner:PEUGEOT CITROEN CHINA AUTOMOTIVE TRADE +1

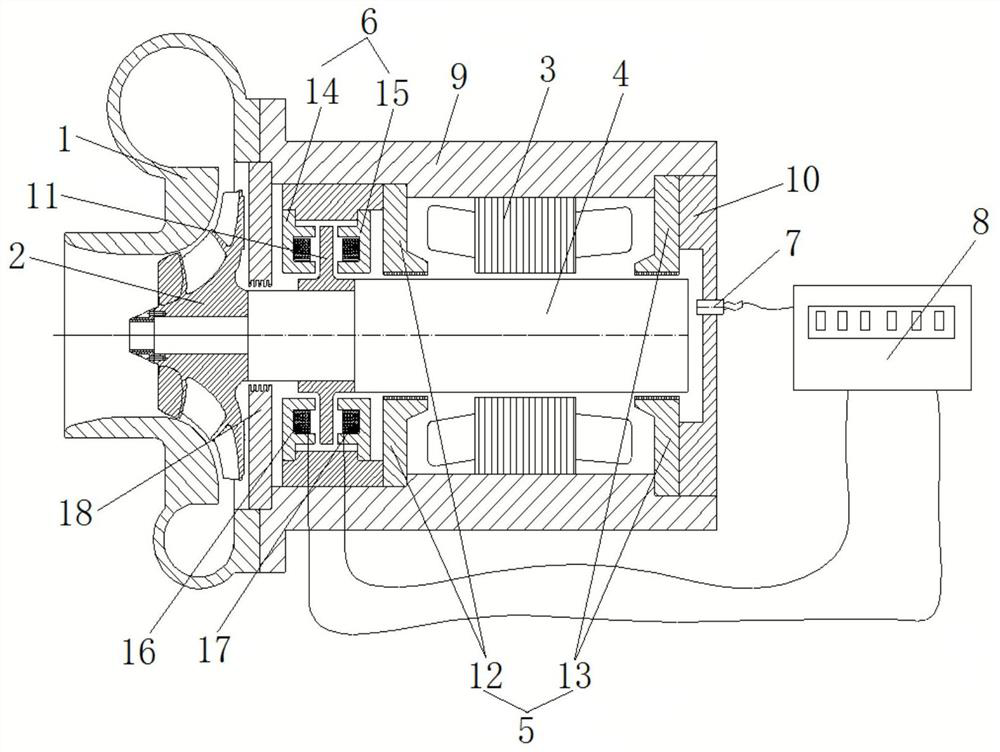

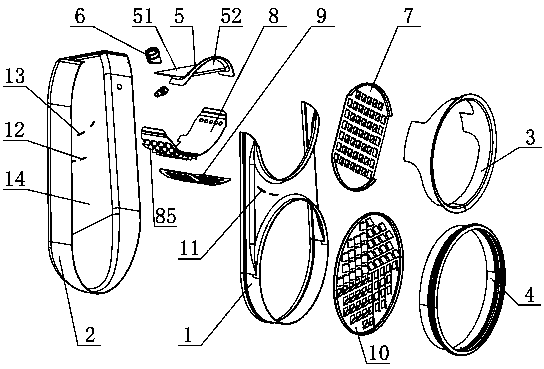

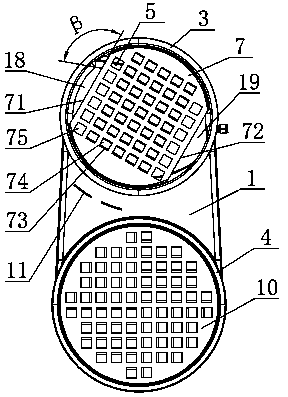

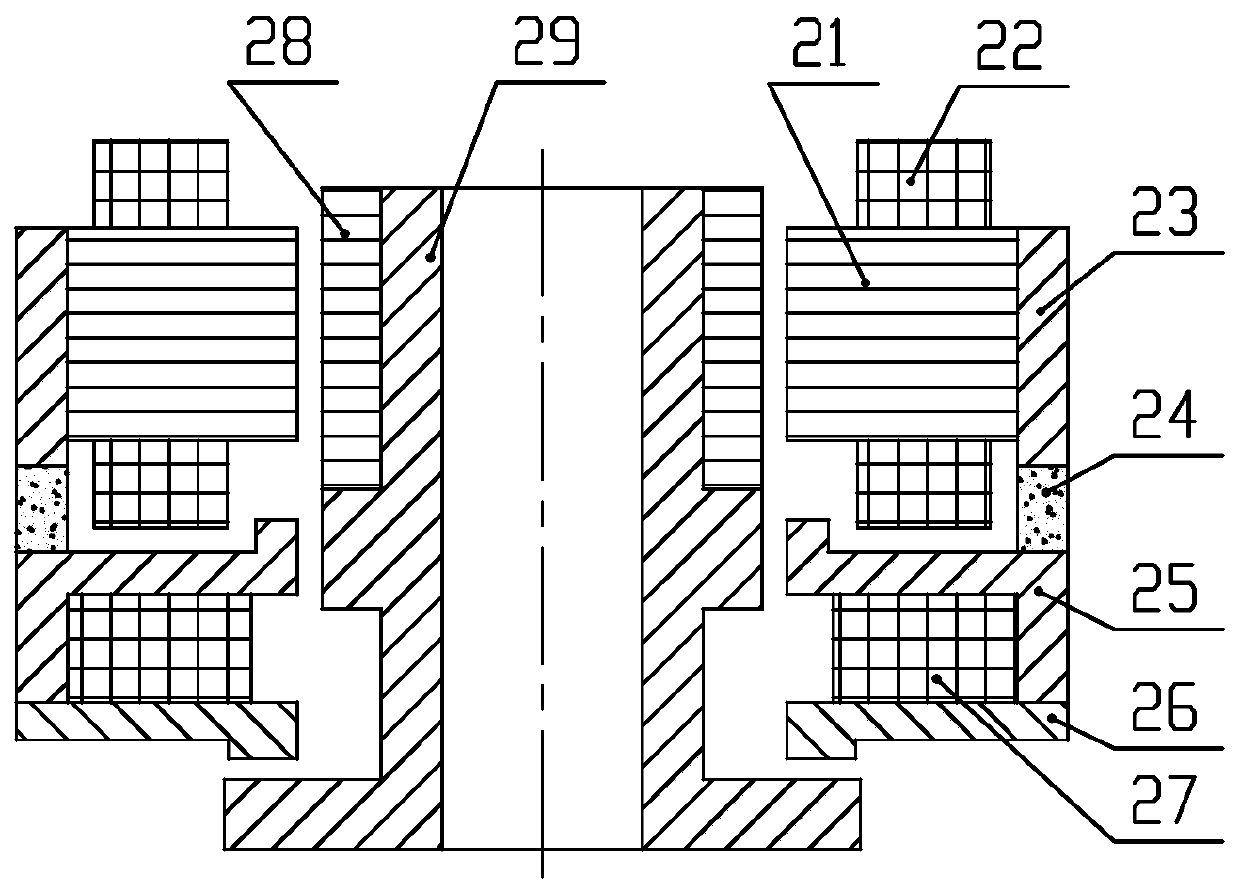

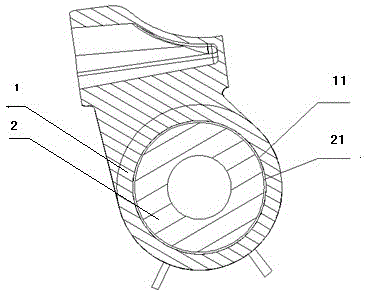

High-speed fan supported by air bearing and magnetic bearing in mixed mode

InactiveCN112467932AImprove securityImprove reliabilityPump componentsStructural associationMagnetic bearingAir bearing

The invention discloses a high-speed fan supported by an air bearing and a magnetic bearing in a mixed mode. The high-speed fan comprises a volute, a main shell, and a high-speed motor stator, a high-speed motor rotor, a radial air suspension bearing, an axial magnetic bearing, a displacement sensor and an axial magnetic bearing controller which are arranged in the main shell; the volute is connected to the main shell; the high-speed motor rotor is rotationally arranged in the main shell, and one end of the high-speed motor rotor extends into the volute; the impeller is connected to the high-speed motor rotor and located in the volute, and the high-speed motor stator is connected into the main shell; the radial air suspension bearing is used for radially supporting the high-speed motor rotor; the axial magnetic bearing is used for axially positioning the high-speed motor rotor and preventing the high-speed motor rotor from axially moving; and the displacement sensor is used for detecting a movement signal of the high-speed motor rotor in the axial direction and transmitting the signal to the axial magnetic bearing controller to control the axial magnetic bearing to reset the high-speed motor rotor. The high-speed fan is compact in structure, high in reliability and easy to control.

Owner:CHANGZHOU INST OF TECH

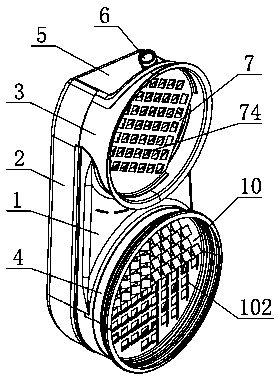

Aqueous urea solution decomposing mixing device

PendingCN110821615AReduce hindranceReduce lossesInternal combustion piston enginesExhaust apparatusVertical planeEngineering

The invention discloses an aqueous urea solution decomposing mixing device. A spoiler and a pore plate are arranged between a front shell and a rear shell. The spoiler and the pore plate divide an inner cavity into an upper spraying cavity, a middle flow guide cavity and a lower rotational flow cavity. A top cover is arranged at the top of the rear shell. An inclined plane is arranged in the spraying cavity, and an included angle is formed between the vertical plane and the inclined plane. A flow guide plate is provided with a flow guide vane. The spoiler is provided with a turbulent flow vane. A rotational flow plate is provided with a rotational flow vane outwards through a third vane hole. The inner cavity of the aqueous urea solution decomposing mixing device is divided into the spraying cavity, the flow guide cavity and the rotational flow cavity only through the spoiler and the pore plate. Little blocking occurs in an airflow channel, the airflow channel is smoother, mixed airflow passes through few turning points in the airflow channel, energy loss is small, and the airflow pressure drop is low. The top cover is provided with an inclined lower plane, and the spraying cavityforms a cavity which is asymmetric along the vertical plane. A nozzle seat is located in a low position of the lower plane, and thus the urea spraying line is toward the direction directly facing thedirection of the turbulent flow vane of the spoiler.

Owner:无锡亿利环保科技有限公司

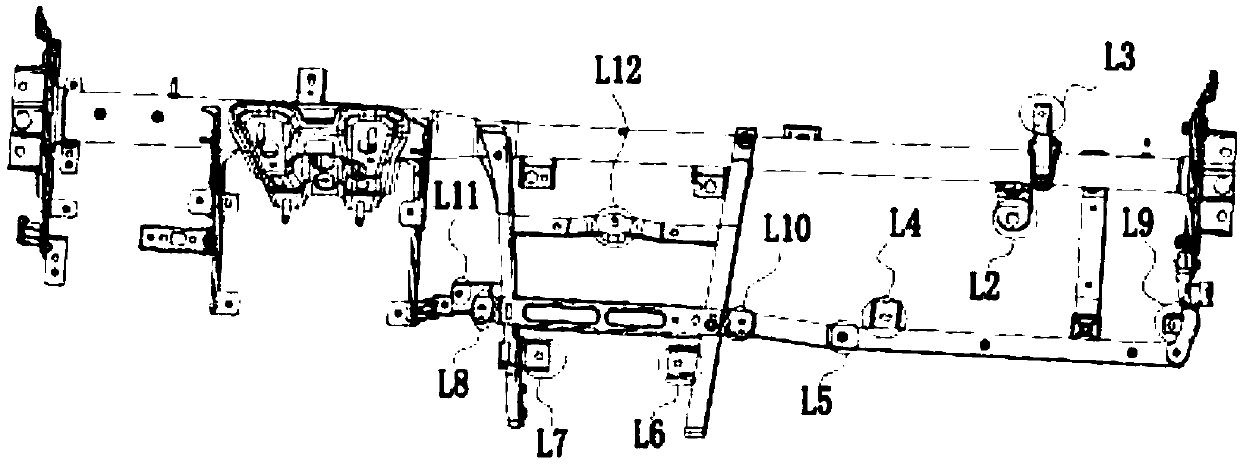

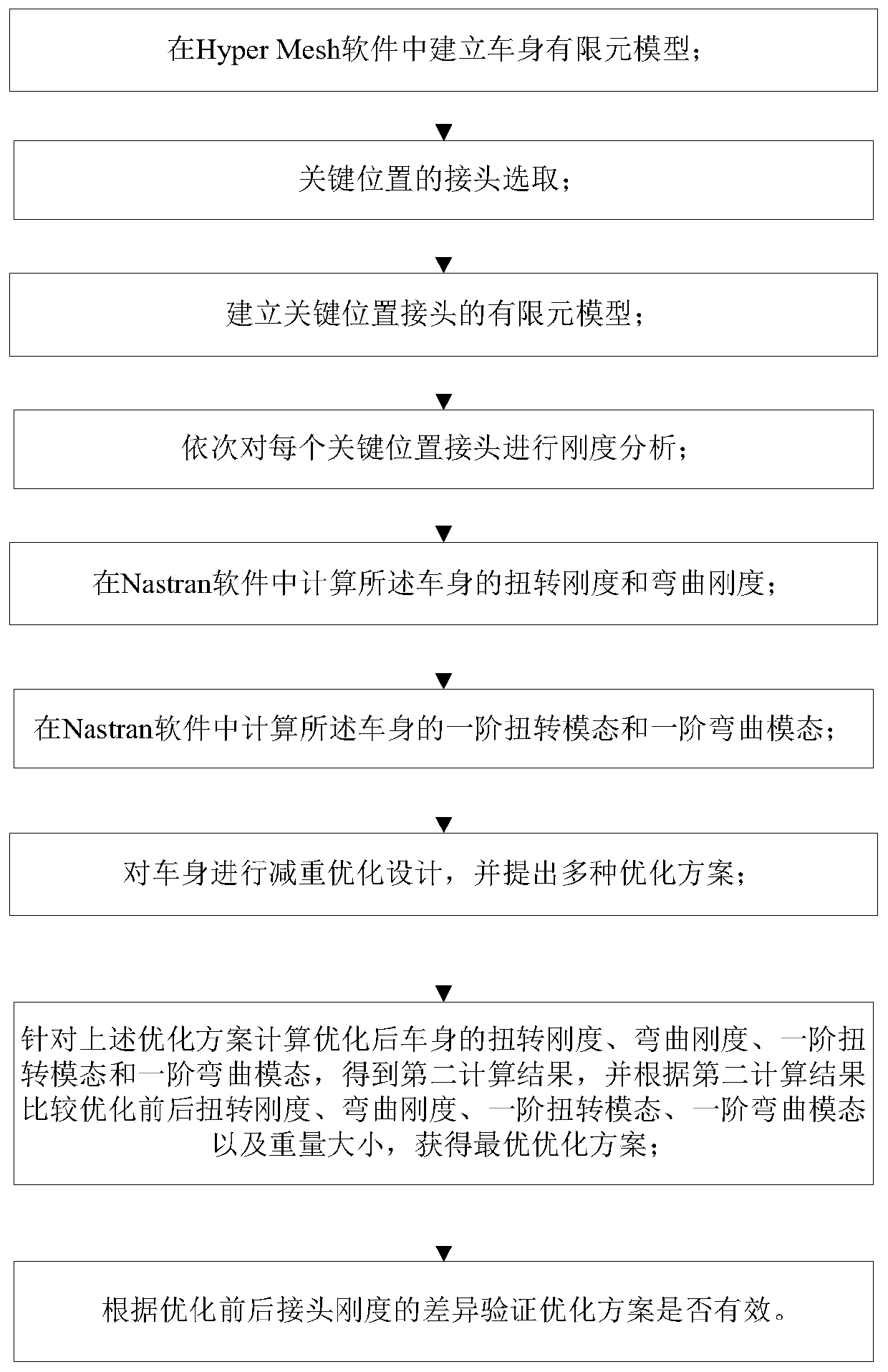

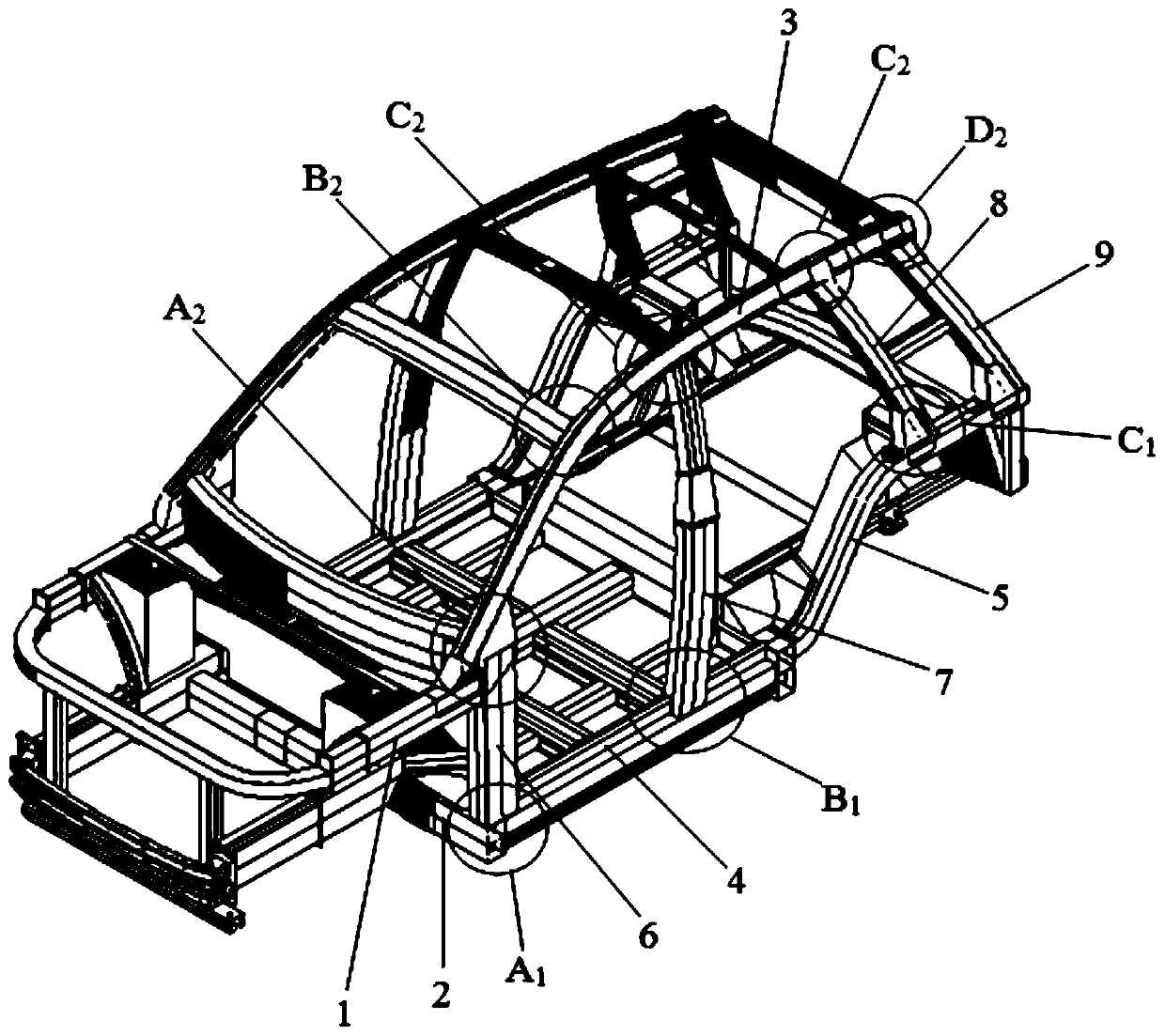

Analysis method for improving modality and rigidity performance of an aluminum vehicle body based on a vehicle body joint

ActiveCN109800460AReduce weightAchieve weight lossInternal combustion piston enginesSustainable transportationElement modelNew energy

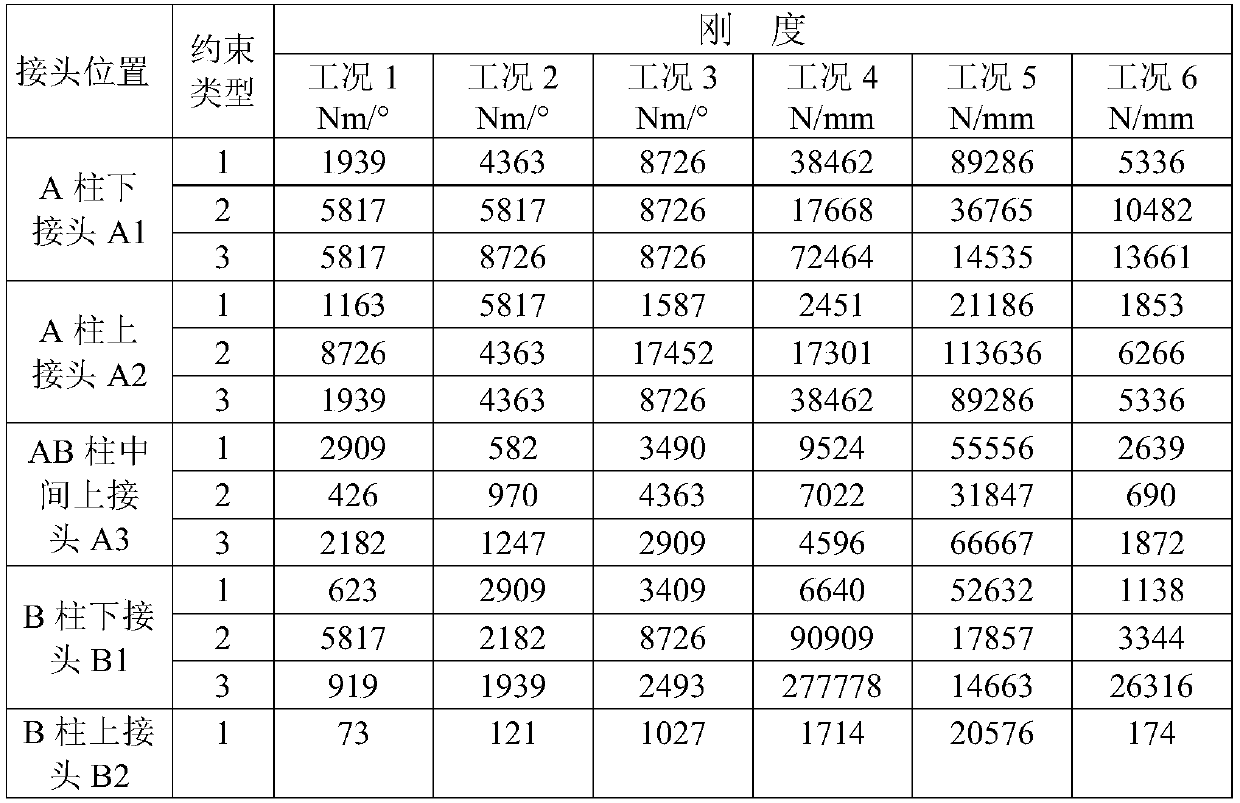

The invention discloses an analysis method for improving modality and rigidity performance of an aluminum vehicle body based on a vehicle body joint. The method comprises the steps of using HyperMeshsoftware for carrying out finite element modeling, then grabbing key position joints in a vehicle body, establishing a joint structure finite element model, carrying out rigidity analysis under six working condition loads on a connecting element of each joint, and calculating the rigidity and the mode of the vehicle body are calculated through Nastran software; extracting a connecting piece in thekey joint for structure optimization; carrying out rigidity and modal calculation on the vehicle body for each optimization scheme to obtain an optimal optimization scheme; and conducting rigidity analysis on the key joint in the optimal optimization scheme, verifying the effectiveness of the optimization scheme through rigidity changes of the key joint before and after optimization, and therefore achieving the purposes of improving the vehicle sound rigidity and mode and reducing the overall weight of a vehicle body. According to the method, the scientificity, reliability and effectiveness of an optimization result are greatly improved, and a new idea is provided for a light-weight solution of the overall weight of the new energy automobile body in the field.

Owner:苏州奥杰汽车工业有限公司

Dark blood delayed enhancement magnetic resonance viability imaging techniques for assessing subendocardial infarcts

ActiveUS8086297B2Raise modalIncreases length and complexityDiagnostic recording/measuringSensorsContrast levelRelaxation curve

The technology herein provides a dark blood delayed enhancement technique that improves the visualization of subendocardial infarcts that may otherwise be disguised by the bright blood pool. The timed combination of a slice-selective and a non-selective preparation improves the infarct / blood contrast by decoupling their relaxation curves thereby nulling both the blood and the non-infarcted myocardium. This causes the infarct to be imaged bright and the blood and non-infarct to both be imaged dark. The slice-selective preparation occurs early enough in the cardiac cycle so that fresh blood can enter the imaged slice.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC +1

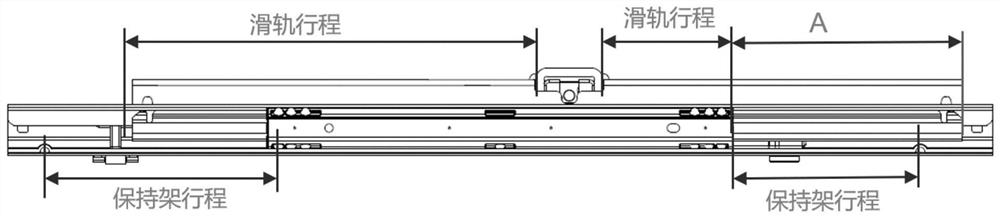

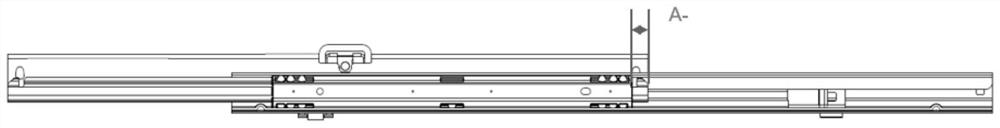

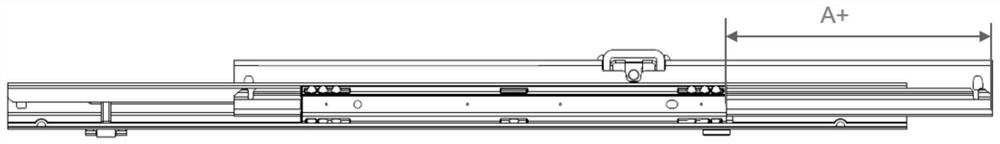

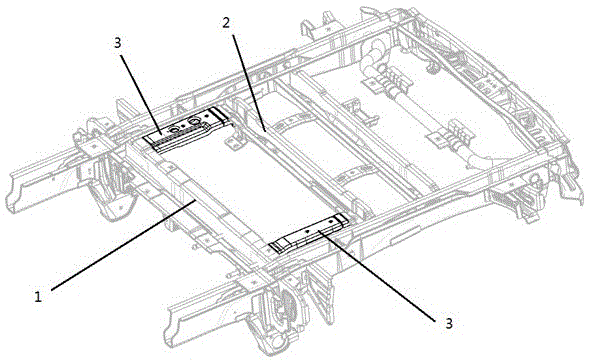

Slide rail capable of enhancing rigidity modulus

The invention relates to an automobile seat sliding rail, in particular to a sliding rail capable of enhancing rigidity modulus. The sliding rail is composed of an upper rail assembly, a lower rail assembly and retainers; the upper rail assembly is slidably arranged in a sliding groove of the lower rail assembly through a pair of retainers, and first protruding ribs and / or steel ball clamping grooves are arranged on the surfaces, in contact with the upper rail assembly and the lower rail assembly, of the retainers at intervals. Steel balls are installed in the steel ball clamping grooves, supporting structures extending backwards in the field length direction of the retainers are arranged at the rear ends of the retainers; and when the upper rail assembly slides backwards to the farthest stroke, the supporting structure provides longitudinal auxiliary supporting for the middle rear section of the upper rail assembly, and the supporting structure makes contact with the lower rail assembly, and a gap is reserved between the supporting structure and the upper rail assembly. The whole upper rail can be supported through the supporting structures, and the mode of the sliding rail can beeffectively improved especially under the working condition of jolting and vibrating, so that the overall rigidity of the sliding rail is improved, and noise generated by the sliding rail in an automobile can be reduced.

Owner:KEIPER (CHANGSHU) SEATING MECHANISMS CO LTD

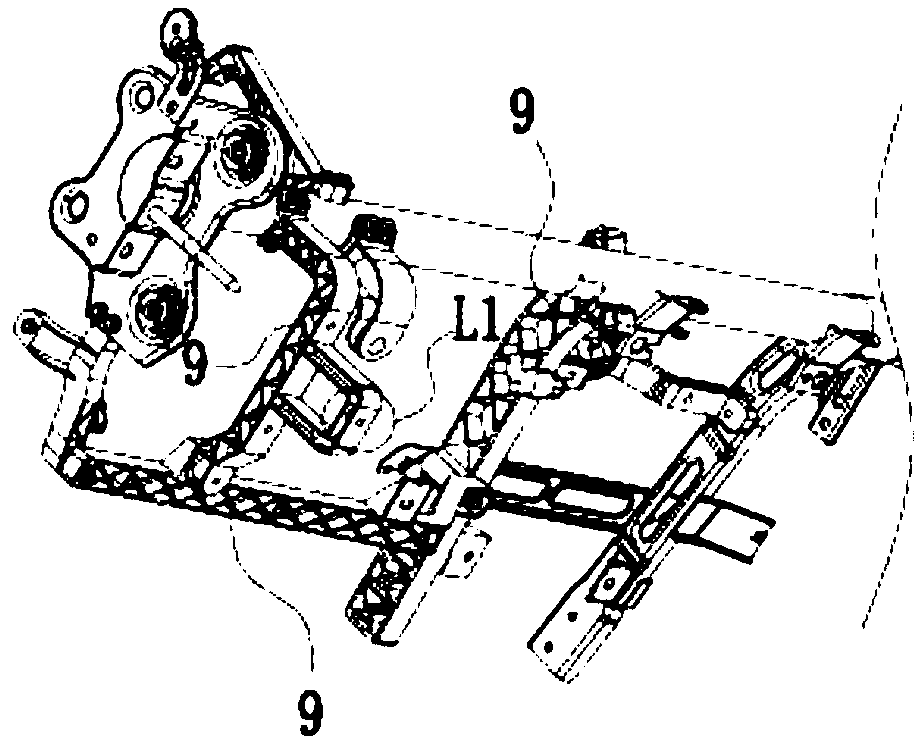

Reinforcing structure for rear-row seat mounting

The invention provides a reinforcing structure for rear-row seat mounting. The reinforcing structure comprises a first transverse beam and a second transverse beam which are parallel, wherein at least two side-edge longitudinal beams are connected between the first transverse beam and the second transverse beam; the side-edge longitudinal beams are arranged in parallel; first seat mounting holes are formed in each side-edge longitudinal beam. The reinforcing structure disclosed by the invention has the benefits that the strength of seat mounting points is reinforced through the additional arrangement of the side-edge longitudinal beams, the modality is improved, and the NVH performance is good.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

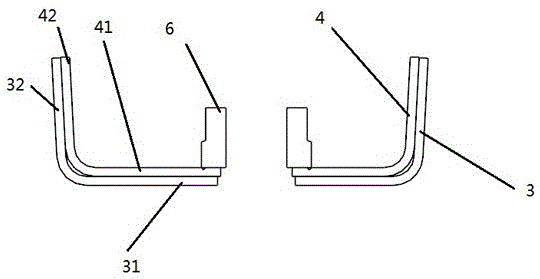

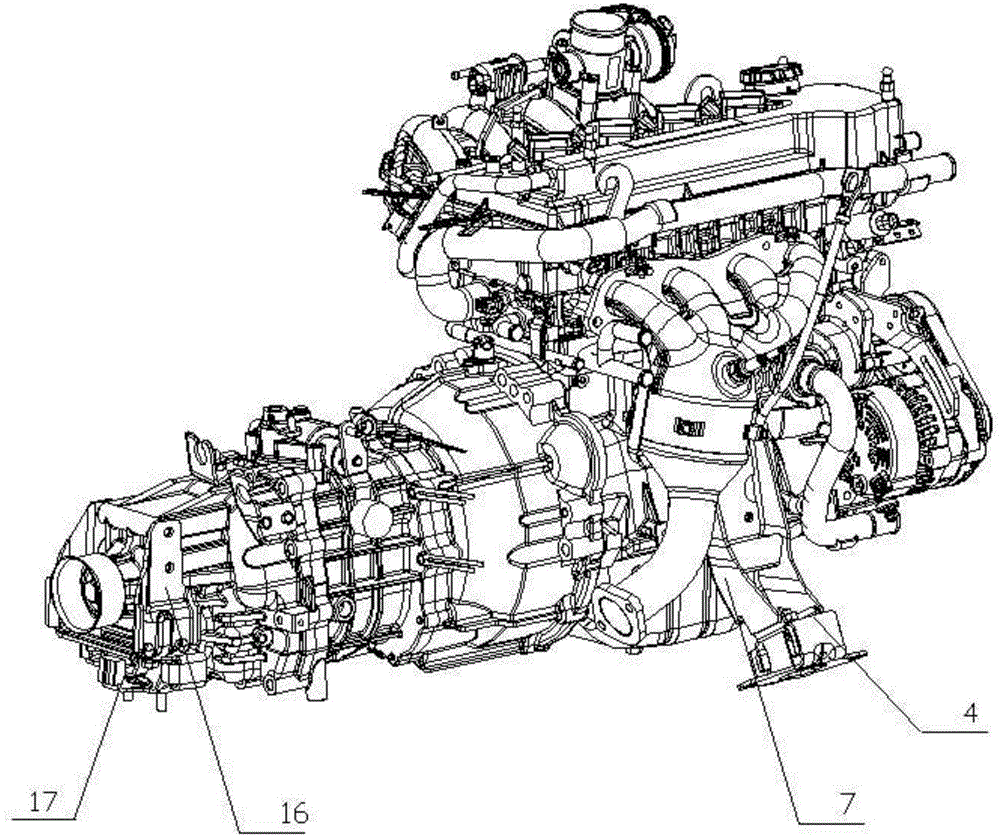

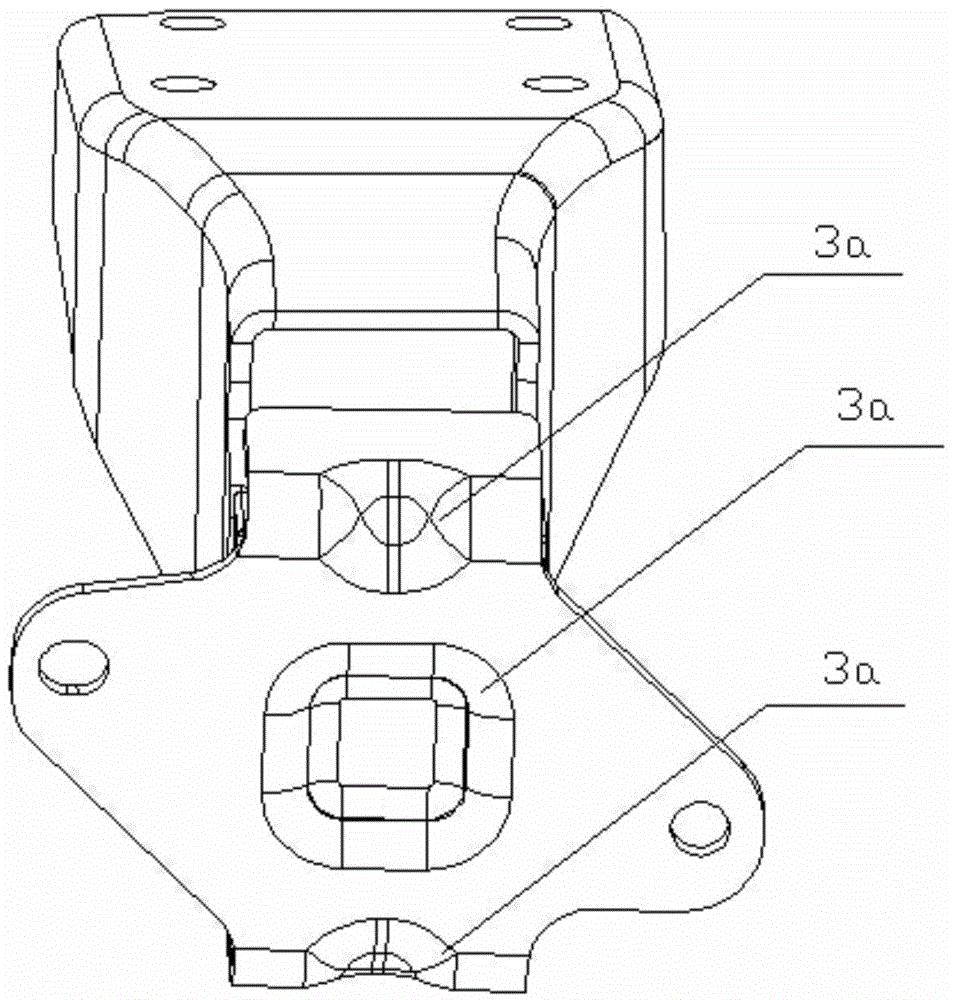

Automobile engine suspension mounting structure

InactiveCN104553725AHigh strengthPrevent overshootingNon-rotating vibration suppressionJet propulsion mountingElastomerEngineering

The invention discloses an automobile engine suspension mounting structure. A left suspension and a right suspension are mounted on the left side and the right side of a cylinder body respectively, a rear suspension is mounted on a tail housing of a transmission, each of the left suspension and the right suspension comprises an elastomer, an upper limiter, a lower limiter and a suspension support, the rear suspension comprises a rear suspension support and a rear suspension cushion assembly, the side plates of the lower limiters extend upwards, the upper portions of the extending parts of the lower limiters are folded inwards to form limit portions, the rear suspension support is a 'U'-shaped frame, the left end and the right end of an upper suspension plate extend downwards and extend horizontally towards the inner side after overpassing the ends of a lower suspension plate, and the middle of the front end of the lower suspension plate first extends forwards and then extends vertically upwards to form a forward-rush preventing limit plate. A forward-rush preventing rubber cushion block is sleeved with the forward-rush preventing limit plate, the middle of the rear end of the lower suspension plate extends backwards and then extends vertically upwards to form a backward-rush preventing limit plate, and a backward-rush preventing rubber cushion block is sleeved with the backward-rush preventing limit plate. The automobile engine suspension mounting structure is not easy to fail.

Owner:CHONGQING KAITE POWER SCI & TECH

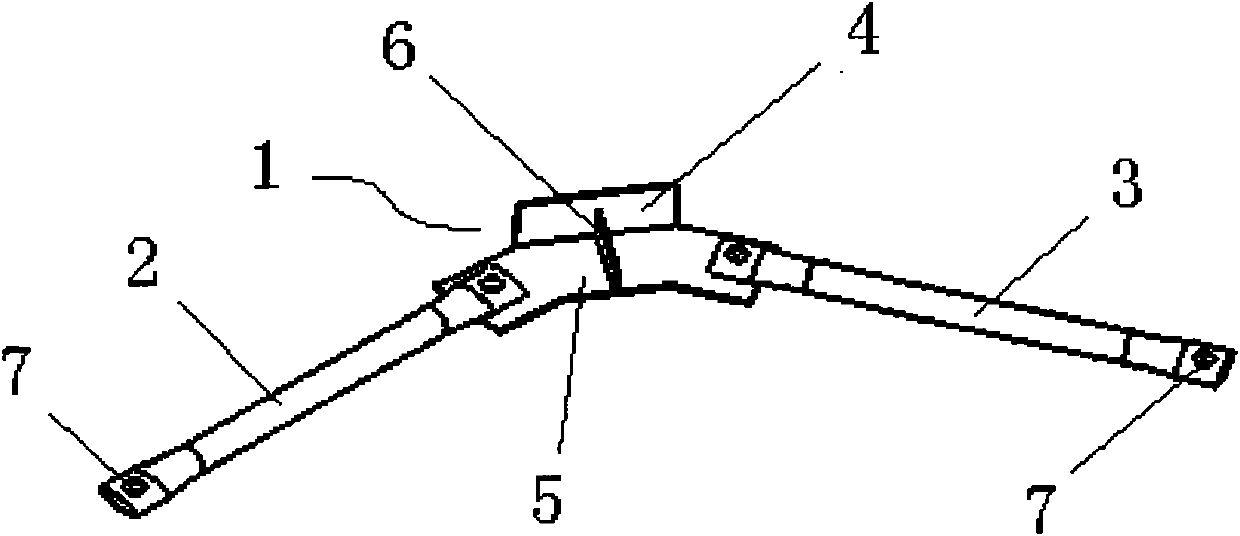

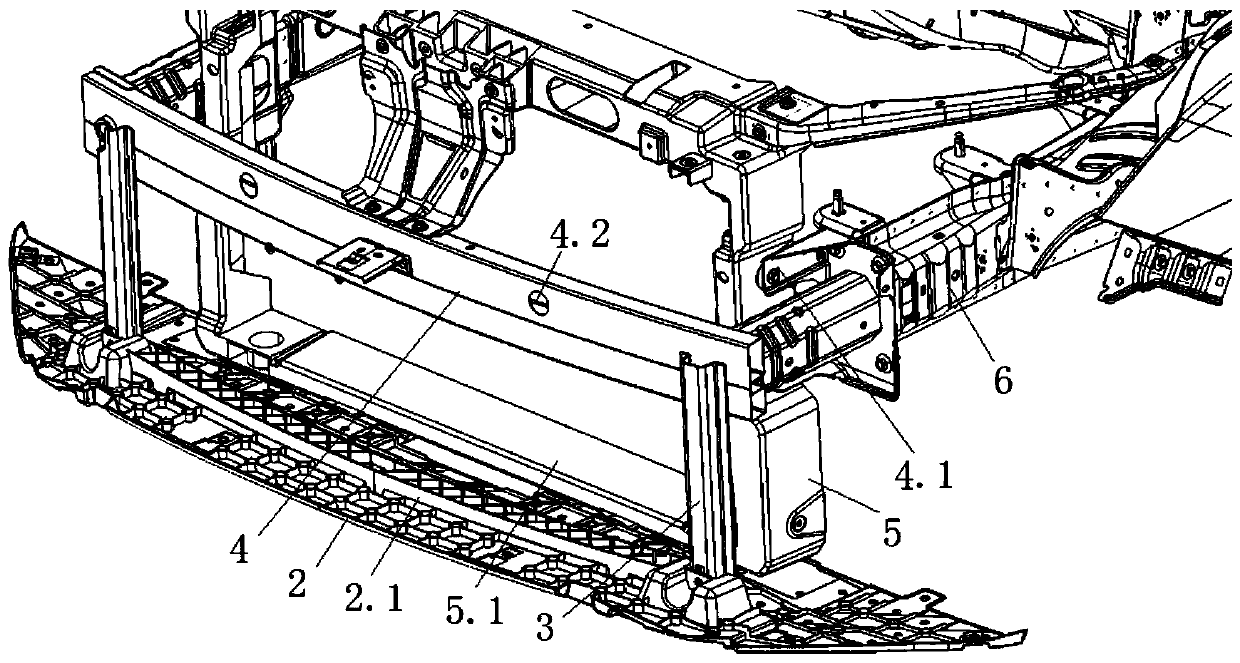

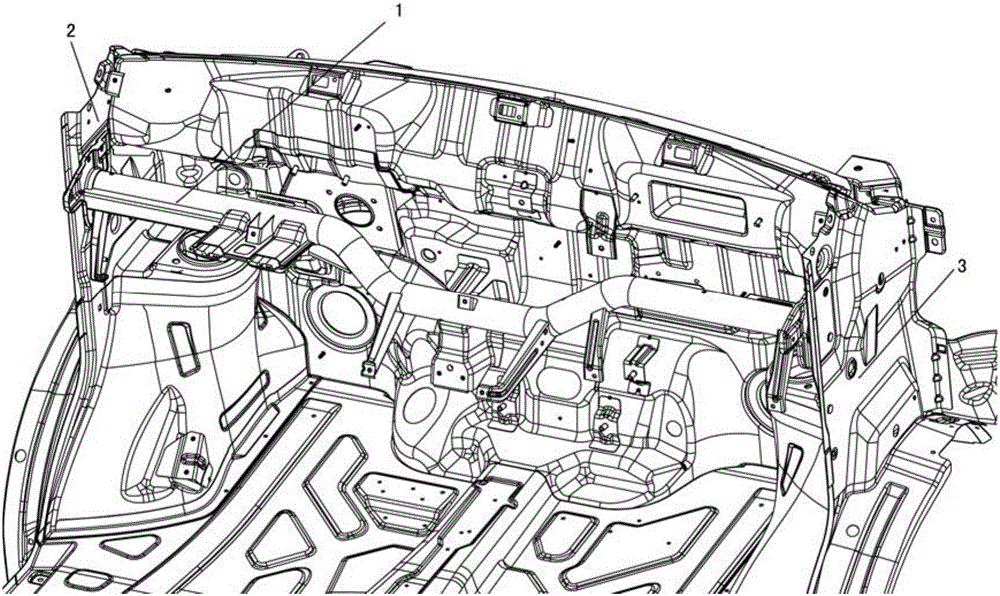

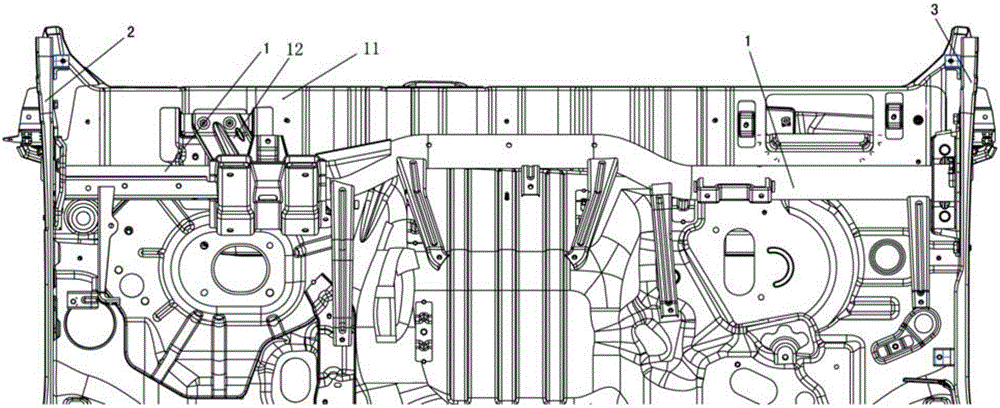

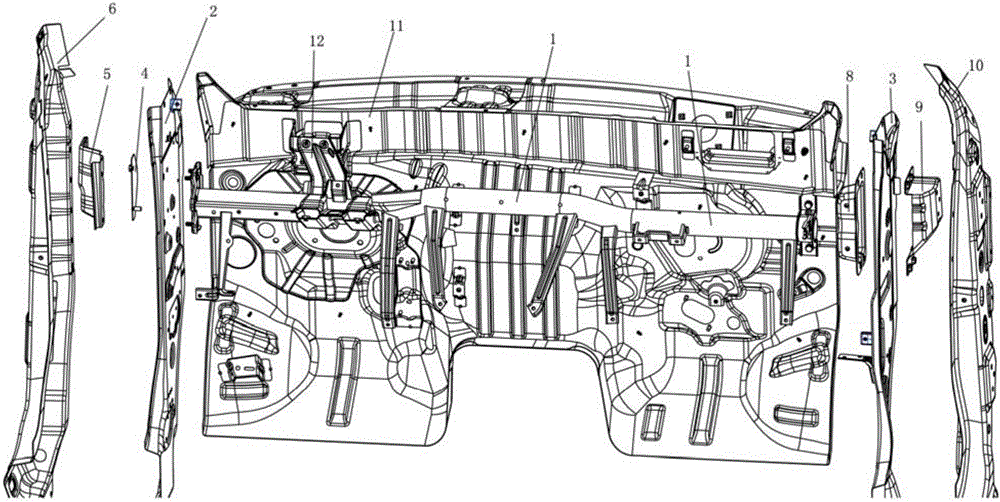

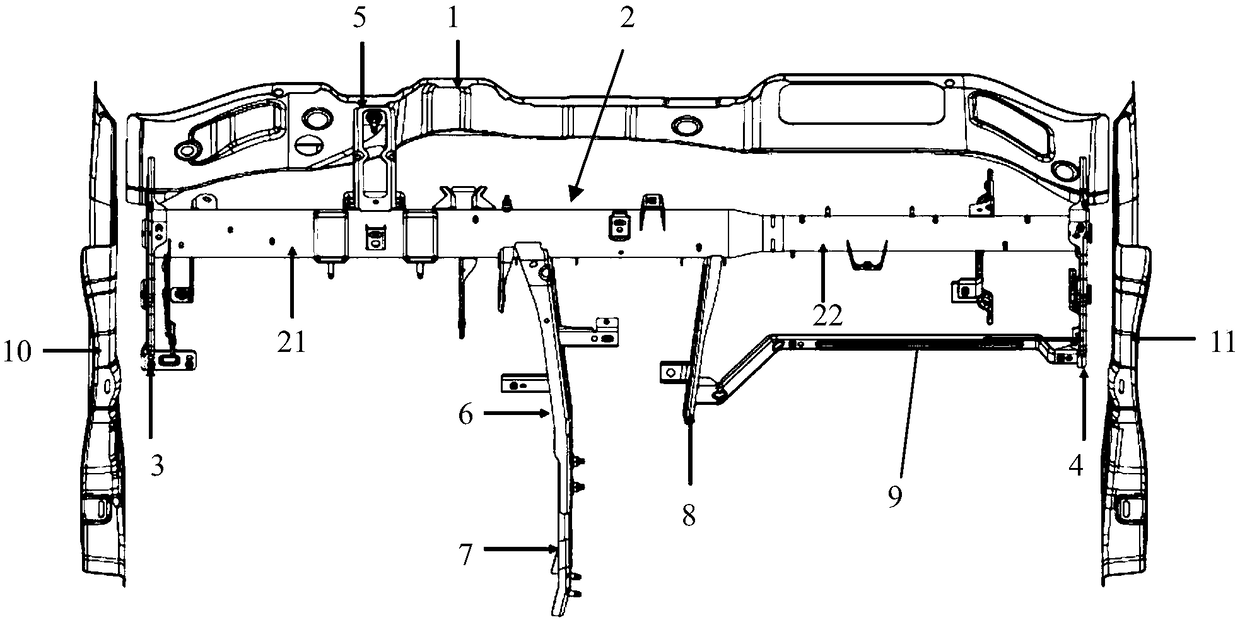

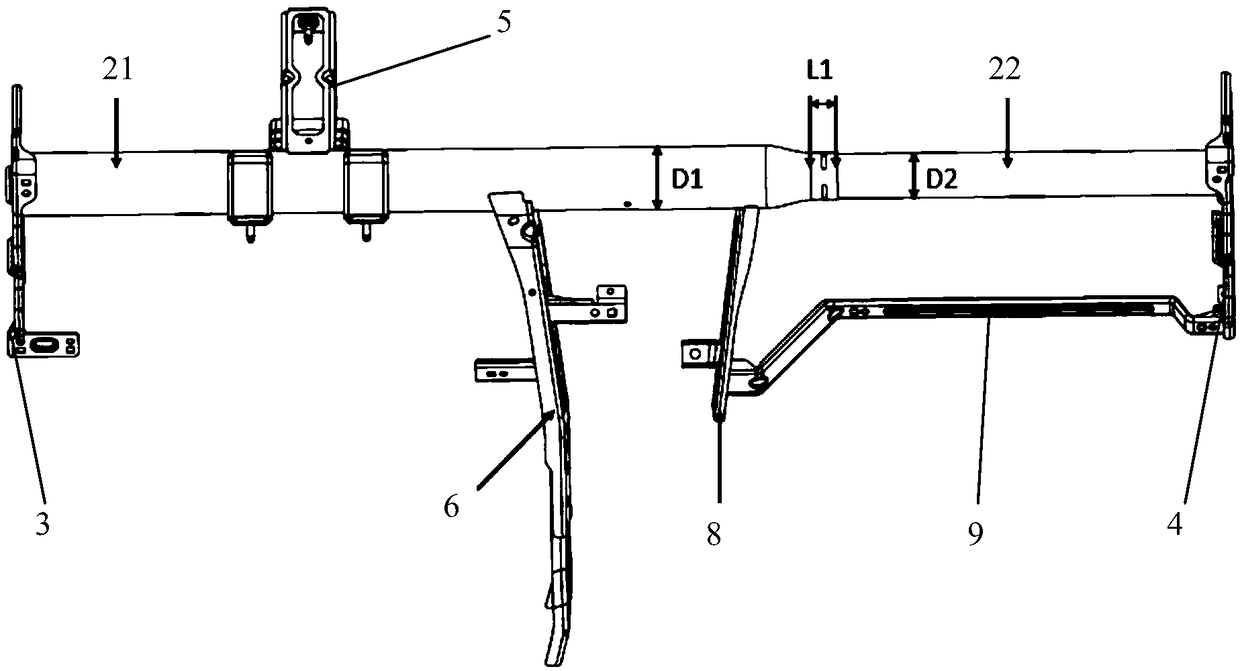

Support frame of automobile forecabin and automobile forecabin applying same

InactiveCN101992807ASimple structureLow costUnderstructuresMonocoque constructionsAutomotive engineeringNoise, vibration, and harshness

The invention relates to a support frame of an automobile forecabin and the automobile forecabin applying the same, aiming at enhancing the lateral rigidity of the automobile forecabin so as to improve the transversely swinging mode of the automobile forecabin and enhancing the NVH (Noise Vibration and Harshness) property of an automobile. The support frame of the automobile forecabin comprises a base, a left connecting rod and a right connecting rod, wherein the left connecting rod and the right connecting rod are respectively connected at both sides of the base; the end parts of the left connecting rod and the right connecting rod are provided with bolt holes; the base of the support frame of the automobile forecabin is fixed on a front baffle plate of the automobile forecabin; the left connecting rod is connected with a shock absorber bearing positioned at the left side of the automobile, and the right connecting rod is connected with a shock absorber bearing positioned at the right side of the automobile. The support frame of the automobile forecabin and the automobile forecabin applying the same have simple structure and lower cost, and is easy for manufacture and realization; in addition, the connecting rods combine the front baffle plate with a stiffening beam into a shape similar to a tripod so as to convert the bending rigidity of the stiffening beam into the compressive rigidity of the connecting rods, therefore the lateral rigidity of the forecabin is effectively enhanced, the mode of the forecabin is improved, and the NVH property of the integral automobile is enhanced.

Owner:CHERY AUTOMOBILE CO LTD

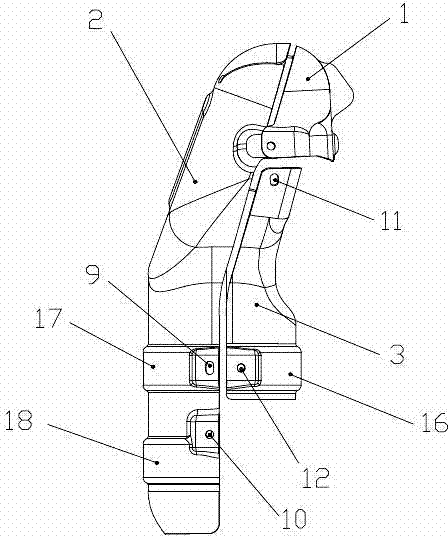

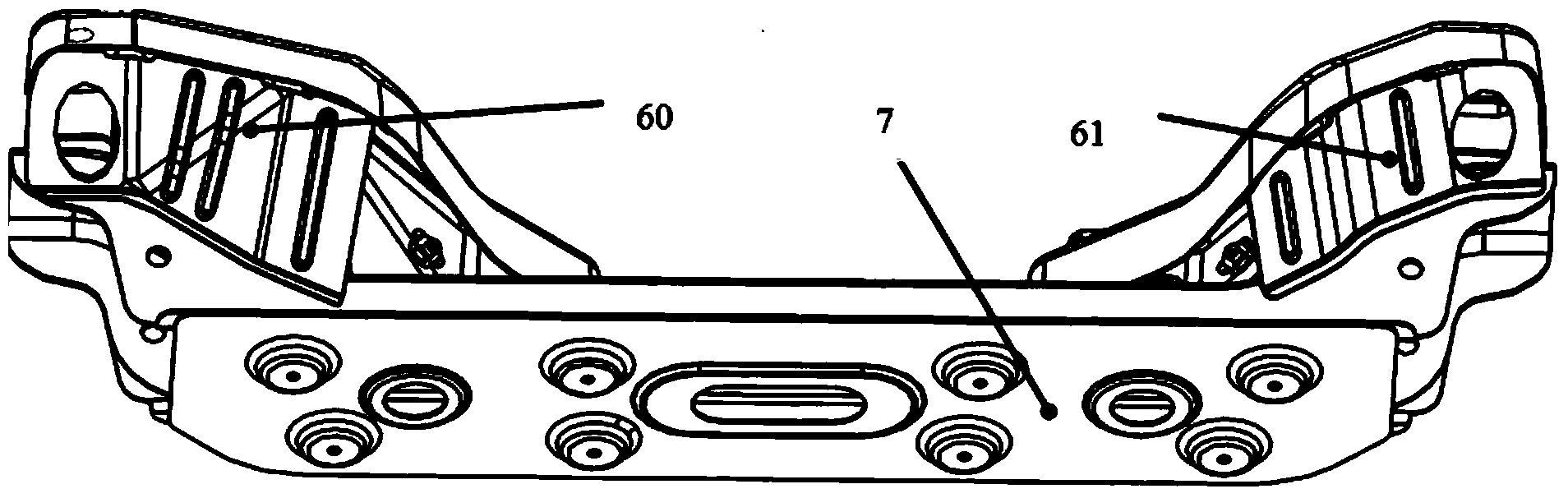

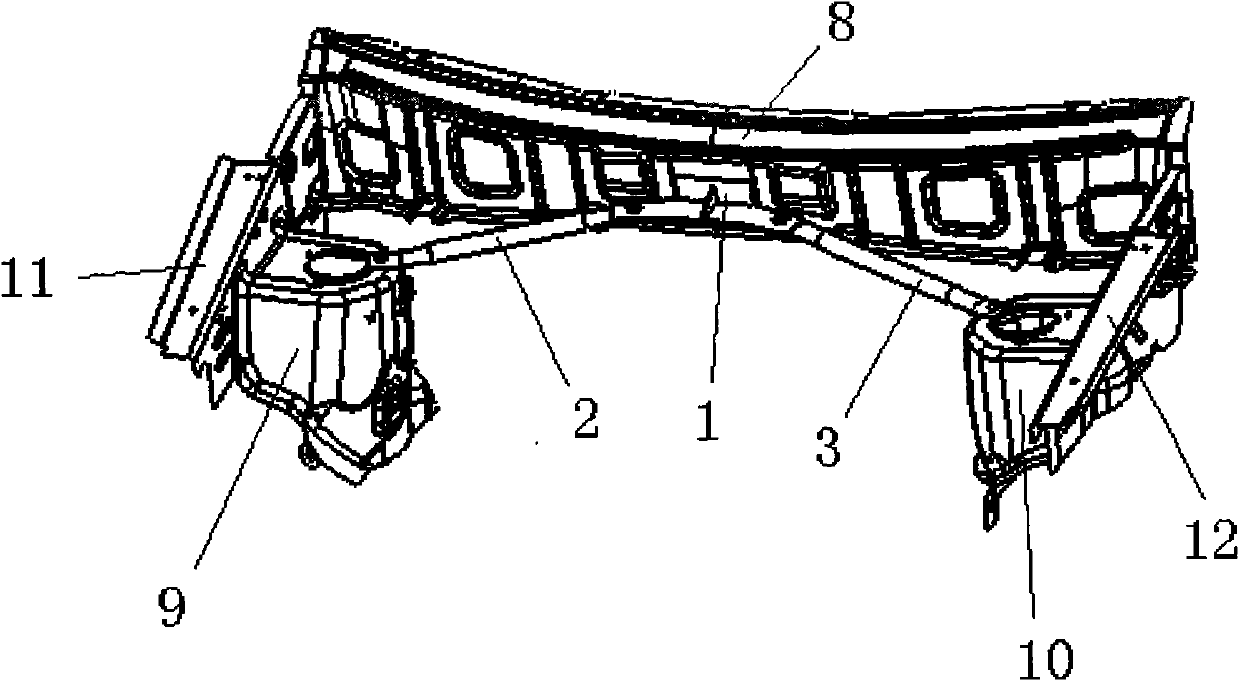

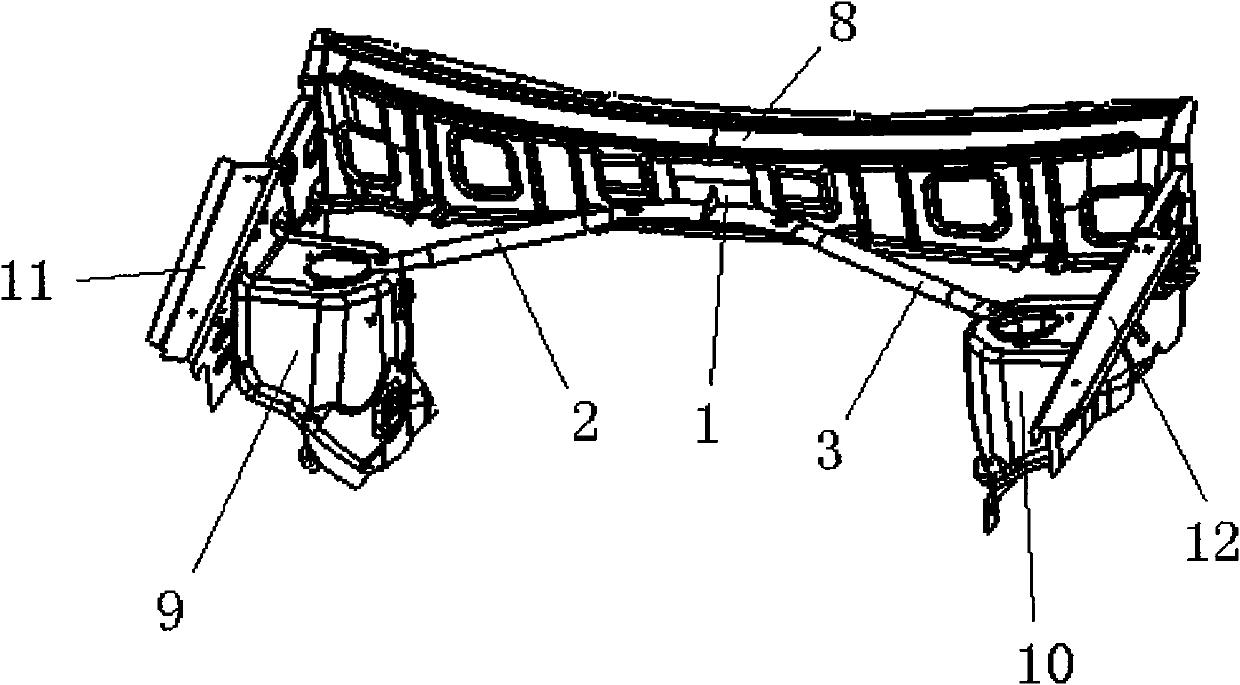

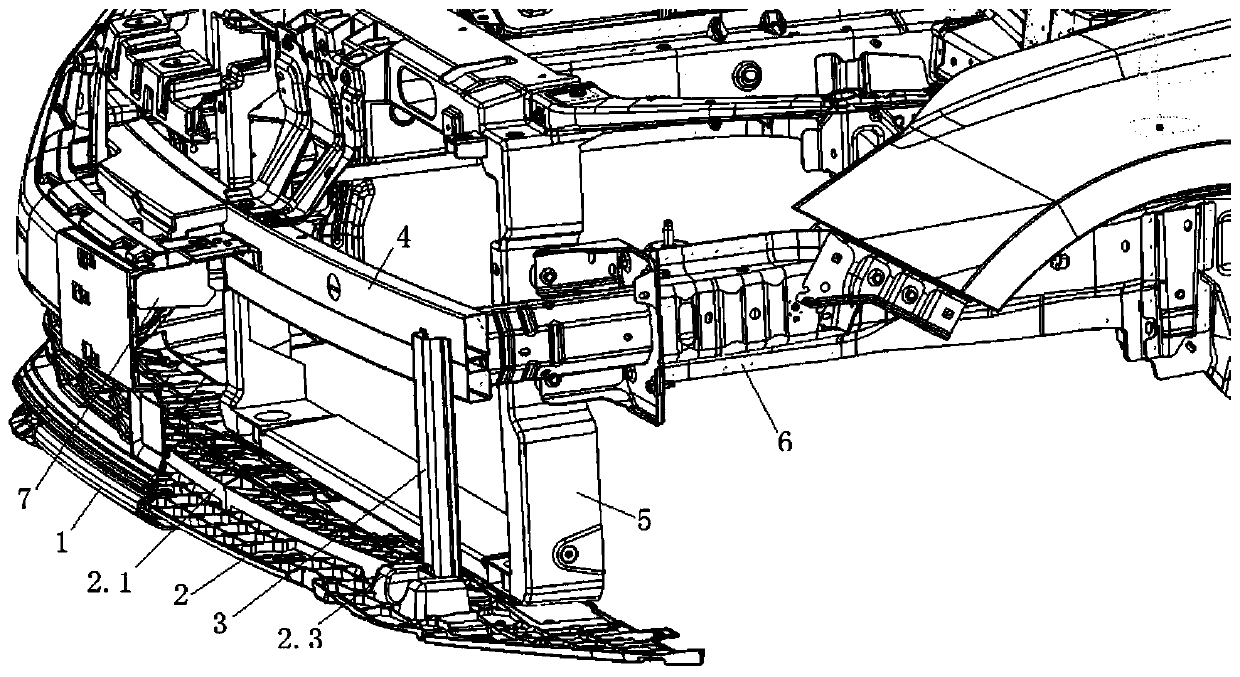

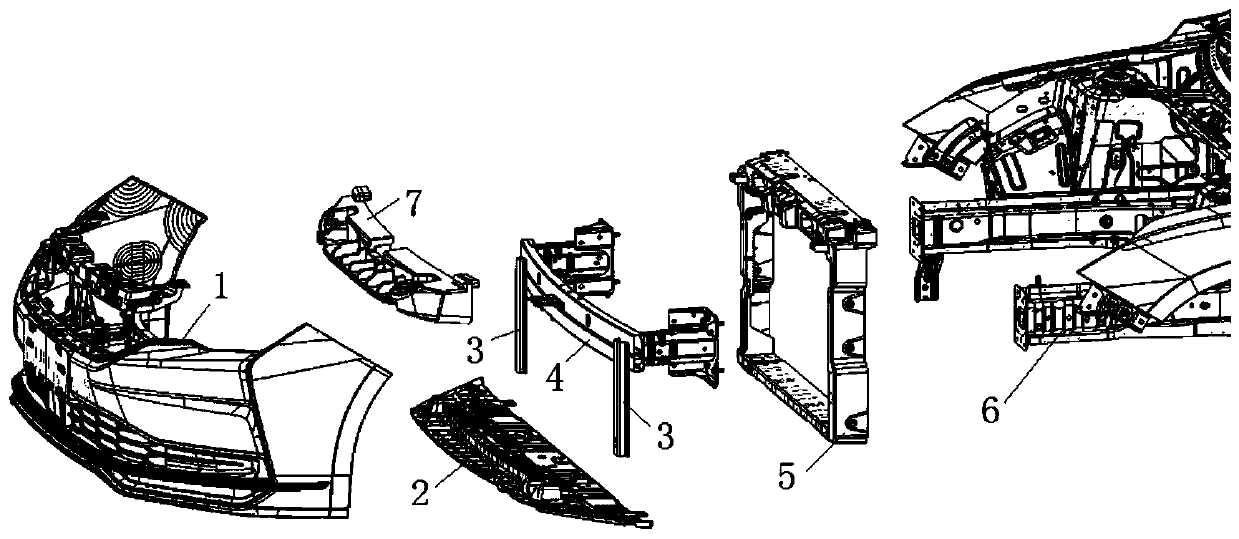

Pedestrian protection leg type protection integrated structure

InactiveCN111516634AEffectively absorb impact energyReduce in quantityPedestrian/occupant safety arrangementEnergy absorptionMechanical engineering

The invention relates to a pedestrian protection leg type protection integrated structure. The protection integrated structure comprises a lower protection plate, an energy absorption block and an anti-collision beam, the lower protection plate is installed between a front end frame and a front bumper skin, the two ends of the lower protection plate are connected with the anti-collision beam through side supporting supports, the anti-collision beam is connected with a longitudinal beam, and the energy absorption block is fixed to the anti-collision beam. A shank supporting cross beam is integrated on the lower protection plate, and part of collision energy on the lower portion of the shank is transmitted to the side supporting supports through the shank supporting cross beam and then transmitted to a vehicle body through the front anti-collision beam; and part of collision energy is transmitted to the front end frame through the lower protection plate and then transmitted to the longitudinal beam. The lower protection plate is connected with a lower cross beam of the front end frame, and a gap between a front bumper and the bottom of the front end frame is sealed. Light weight is achieved, impact energy on the lower portions of shanks of pedestrians can be effectively absorbed, the number of parts is reduced, cost is reduced, the modality of the whole front end is improved, andimprovement of NVH is facilitated.

Owner:DONGFENG MOTOR CORP HUBEI

A-column reinforcing plate connection structure

The invention relates to automobile bodies, in particular to an A-column reinforcing plate connection structure in the automobile bodies. The A-column reinforcing plate connection structure comprises a front peripheral plate, an A-column reinforcing plate, a front lateral plate and a dashboard crossbeam support. The A-column reinforcing plate is connected with the front peripheral plate and provided with a flanging, and the front lateral plate and the dashboard crossbeam support are respectively connected with the flanging. The A-column reinforcing plate connection structure has the advantages that without increasing parts, the flanging is additionally arranged on the A-column reinforcing plate which is connected with the front lateral plate and the dashboard crossbeam support through the flanging, and consequently strength of the front lateral plate and the dashboard crossbeam support can be improved to enable the front lateral plate and the dashboard crossbeam support to be firmer, modality of the automobile body is improved, and cost increase is avoided.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

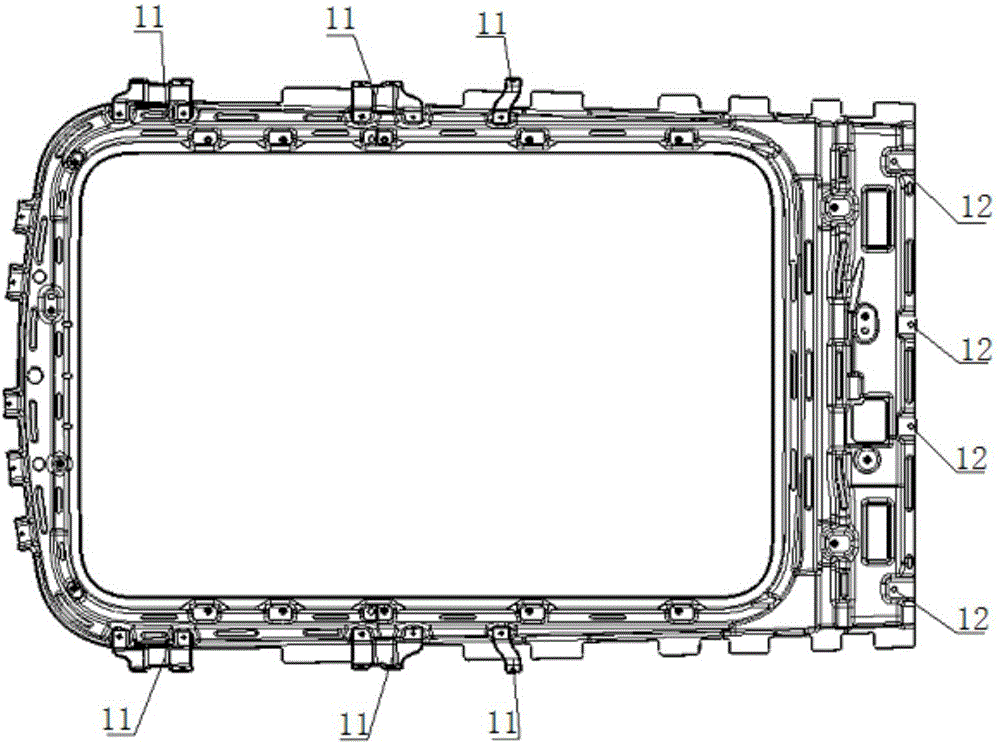

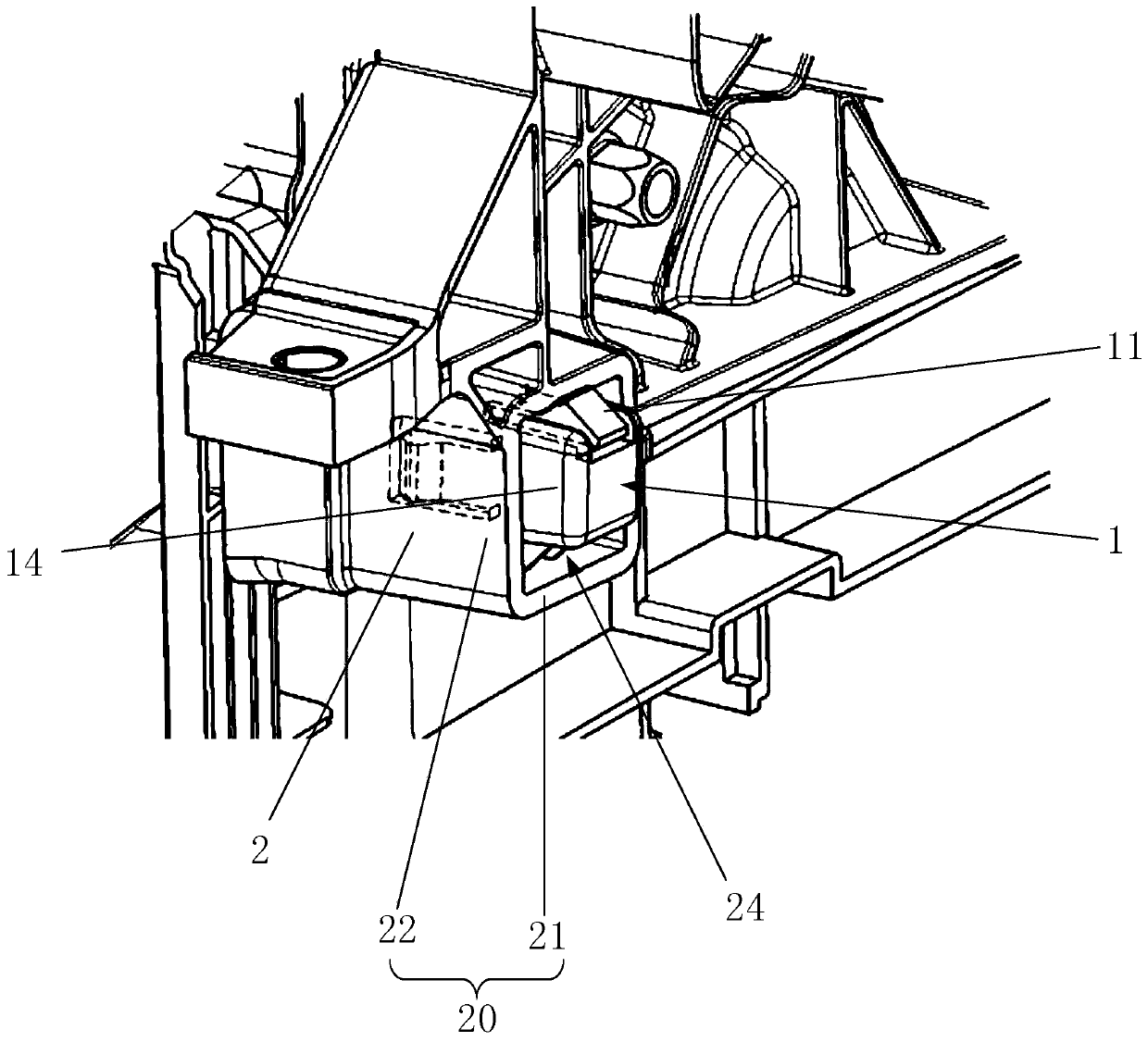

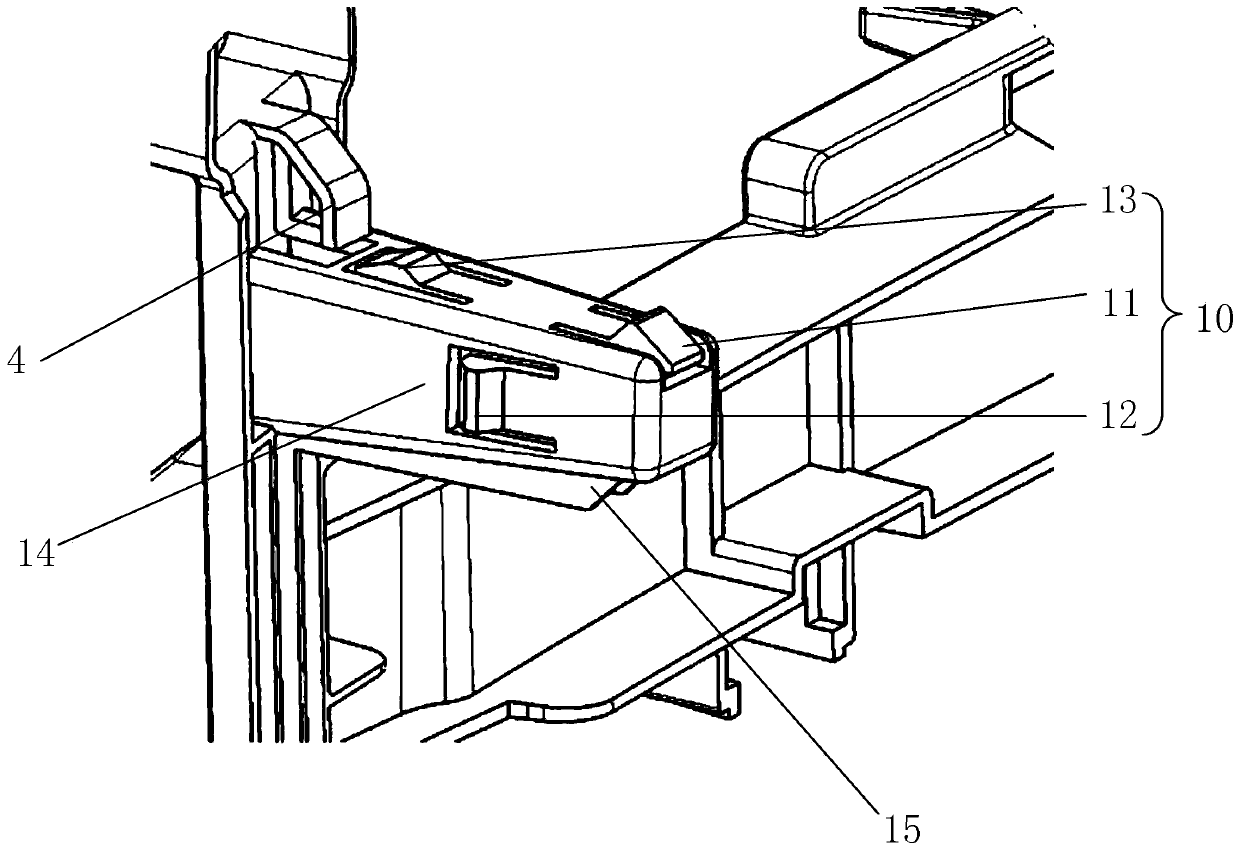

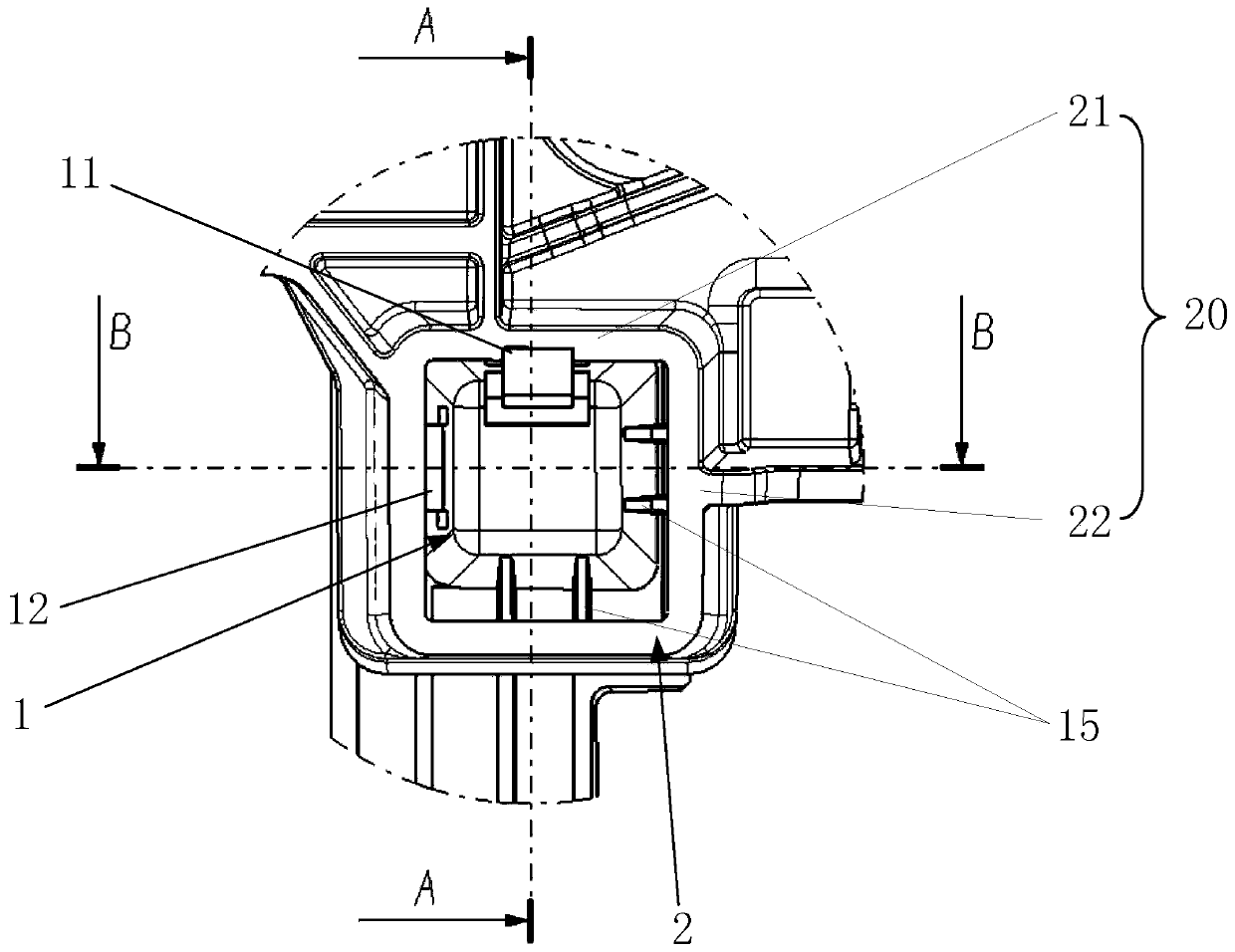

Skylight reinforcing ring structure and vehicle

The invention discloses a skylight reinforcing ring structure. The skylight reinforcing ring structure comprises a main body, an overlapping edge, an overlapping platform, a lug boss, a mounting point, a positioning hole, a gluing structure, a flanging structure and a gluing groove; a cavity structure can be defined by a skylight reinforcing ring and a roof outer plate. In a mounting process, firstly, a structural adhesive and an expansion adhesive are used for coating the gluing structure and the gluing groove respectively to fix the overlapping edge and the flanging structure with the roof outer plate; meanwhile, the overlapping edge is fixedly connected with a side wall and the overlapping platform is matched and connected with a front transverse beam; finally, the whole vehicle assembling of the skylight reinforcing ring structure is finished with the help of the positioning hole. The mounting process is simple to operate and the rigidity and the modals of a whole vehicle are effectively improved; the positioning hole and the mounting point are designed so that a skylight can be accurately assembled and one-step in-place mounting is realized. The skylight reinforcing ring structure disclosed by the invention can guarantee the rigidity and the modals and effectively improve the assembling precision of the skylight; difficulties in the prior art are solved.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

Front bumper assembly supporting structure

A front bumper assembly supporting structure comprises a supporting frame and a supporting platform. The supporting frame is installed on a front bumper, the supporting platform is connected with a vehicle body, a cavity is arranged in the supporting platform, a plurality of supporting surfaces arranged in different directions are arranged around the cavity, buckles are arranged on the supportingframe, and the supporting frame is supported and limited in the cavity through the supporting surfaces and the buckles in the X direction, the Y direction and the Z direction.

Owner:NINGBO GEELY AUTOMOBILE RES & DEV CO LTD +1

Automobile storage battery holder assembly

ActiveCN104029589AAvoid stress concentrationImprove structural strengthElectric propulsion mountingLap jointEngineering

The invention discloses an automobile storage battery holder assembly which comprises a lower support, an upper support and an upper support reinforcing piece. The cross section of the lower support is of an M shape. A first lap joint turned edge and a second lap joint turned edge are arranged on the two sides of the lower support respectively. The lower support is provided with a downward-concave face. The top face of the lower support is an inclined face, wherein the included angle between the top face of the lower support and the downward-concave face ranges from 20 degrees to 45 degrees. The top face of the upper support is of a T shape. Two concave portions are formed in the two sides of the upper support respectively. The bottom faces of the two concave portions are located in the same plane and incline relative to the top face of the upper support. Upper support installation holes are formed in the bottom faces of the two concave portions. The top face of the T-shaped upper support is provided with a downward-concave first U-shaped reinforcing rib and provided with a first storage battery installation hole. The upper support reinforcing piece is of a T shape, the two ends of the upper support reinforcing piece are provided with second storage battery installation holes and provided with downward-concave second U-shaped reinforcing ribs overlapping with the first U-shaped reinforcing rib. The automobile storage battery holder assembly has high structural strength and modal, occupies small space in a cabin and is convenient to install.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

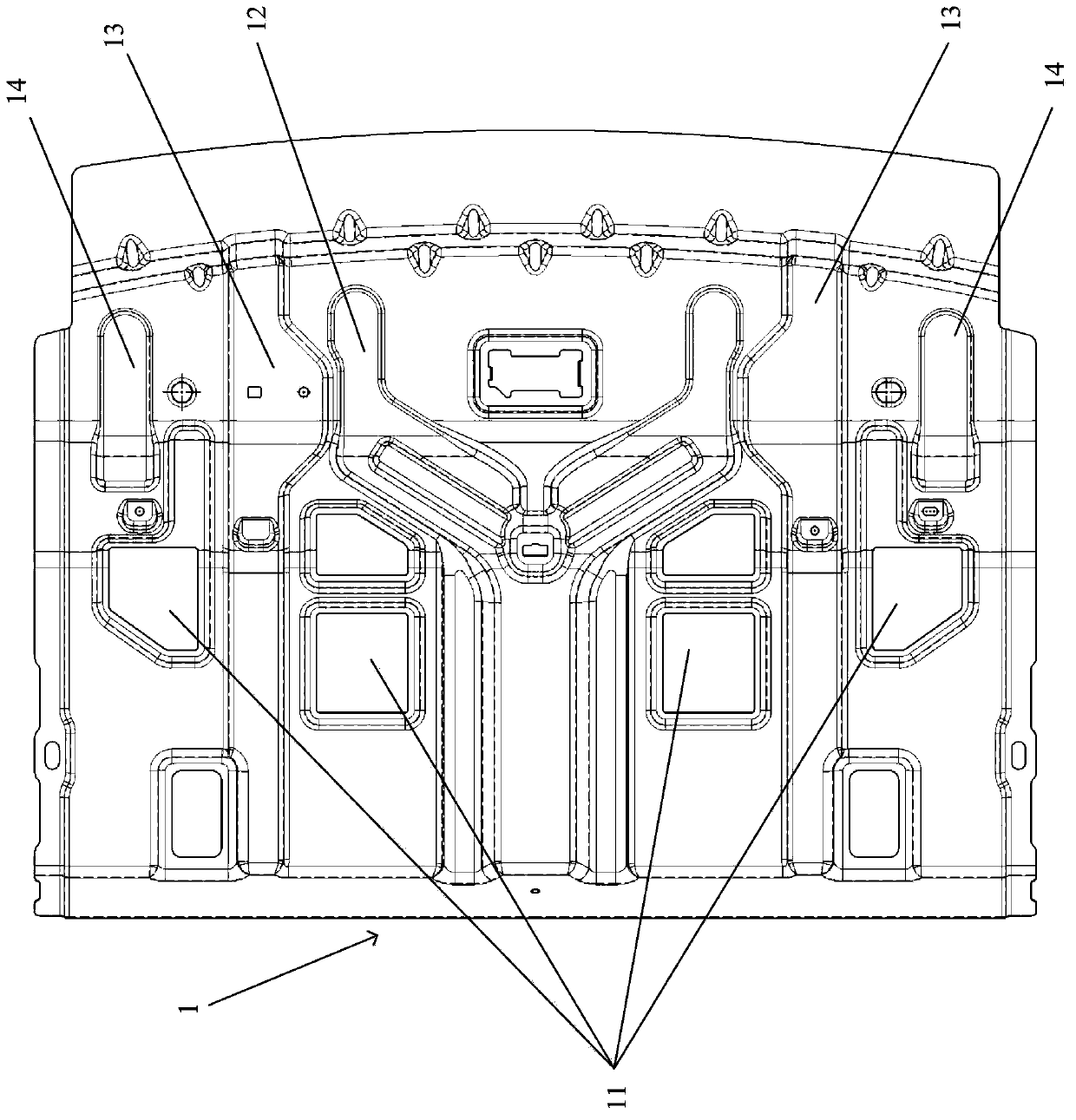

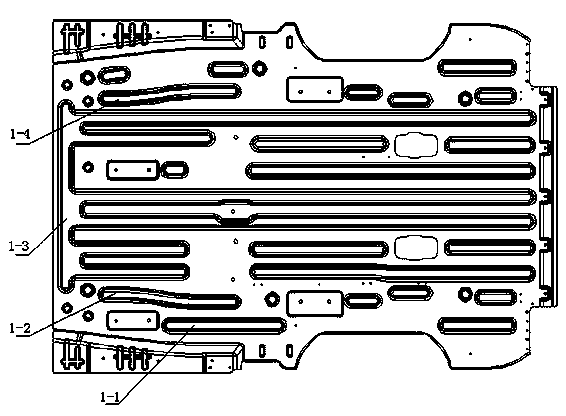

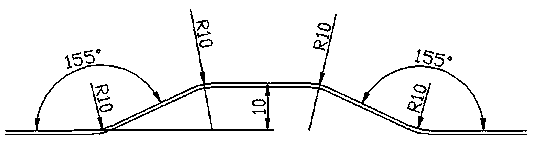

Arrangement structure for rear floor ribs of car

ActiveCN103507865AImproved Noise Transfer FunctionImprove NVH performanceSuperstructure subunitsAutomotive engineeringEngineering

The invention relates to an arrangement structure for rear floor ribs of a car. The arrangement structure for the rear floor ribs of the car comprises a first transverse rib arranged at the lower left portion of a rear floor of the car, a second transverse rib arranged above the first transverse rib, a third transverse rib arranged at the upper left portion of the rear floor of the car, a plurality of rows of transverse ribs arranged in the middle of the rear floor of the car from top to bottom, and a vertical rib which is arranged at the left side of the rear floor of the car and communicated with the rows of transverse ribs. The arrangement structure for the rear floor ribs of the car is characterized in that a plurality of columns of vertical ribs are arranged in the middle of the rear floor of the car from left to right and are vertically communicated with the rows of transverse ribs. The arrangement structure for the rear floor ribs of the car has the advantages of only changing the arrangement method of the rear floor ribs but not increasing the mass, enabling the rigidity of the rear floor to be better than that adopting an existing arrangement structure of the rear floor ribs of the car, largely improving the result of the noise transfer function, improving NVH performance, being suitable for arrangement of all flat floor ribs, and being suitable for arrangement of ribs of a high-floor micro bus on a large plane.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

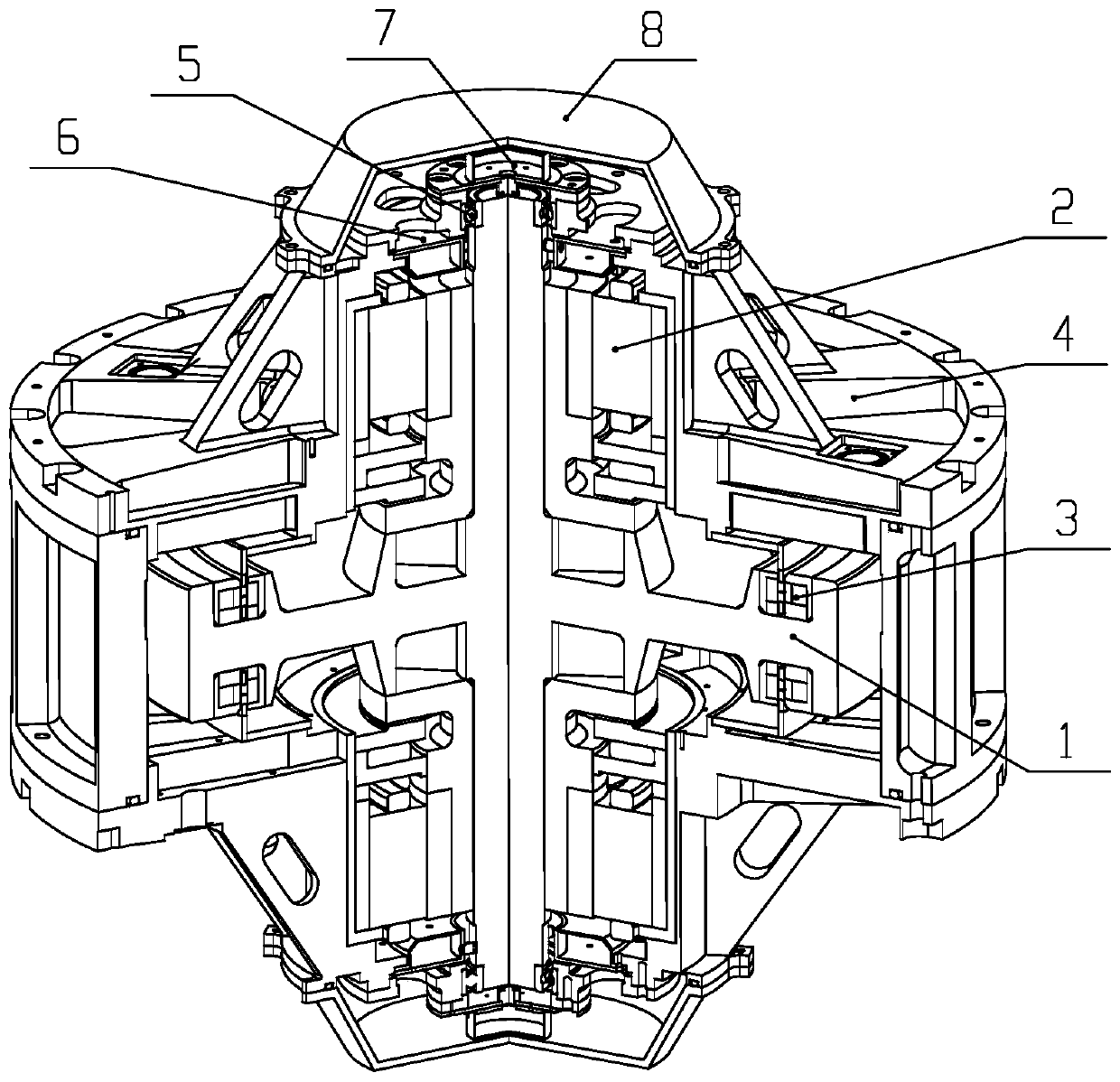

Magnetic suspension control moment gyroscope high-speed rotor device

ActiveCN110435931AShorten the axial lengthIncrease working speedCosmonautic vehiclesSpacecraft guiding apparatusAxial displacementGyroscope

The invention discloses a magnetic suspension control moment gyroscope high-speed rotor device. The device comprises a flywheel, three-degree-of-freedom integrated magnetic bearings, a high-speed motor, a gyroscope case, a protective bearing, a radial displacement sensor, an axial displacement sensor and an end cover, wherein a rotor component of the device is composed of the flywheel, a rotor part of the high-speed motor and rotor parts of the three-degree-of-freedom integrated magnetic bearings, a stator component is composed of the gyroscope case, a stator part of the high-speed motor, stator parts of the three-degree-of-freedom integrated magnetic bearings and the end cover, and high-speed rotation of a rotor is achieved between the rotor component and the stator component through thehigh-speed motor to provide angular momentum for output torque of a gyroscope. According to the device, through supporting by the two three-degree-of-freedom integrated magnetic bearings which are symmetrically arranged, radial and axial non-contact stable suspension of the rotor can be achieved, so that a magnetic bearing supporting system is compact in layout, the size and weight of the device are reduced, the axial length of the rotor can be shortened so that higher rotor inherent frequency and higher rotating speed can be obtained.

Owner:BEIHANG UNIV

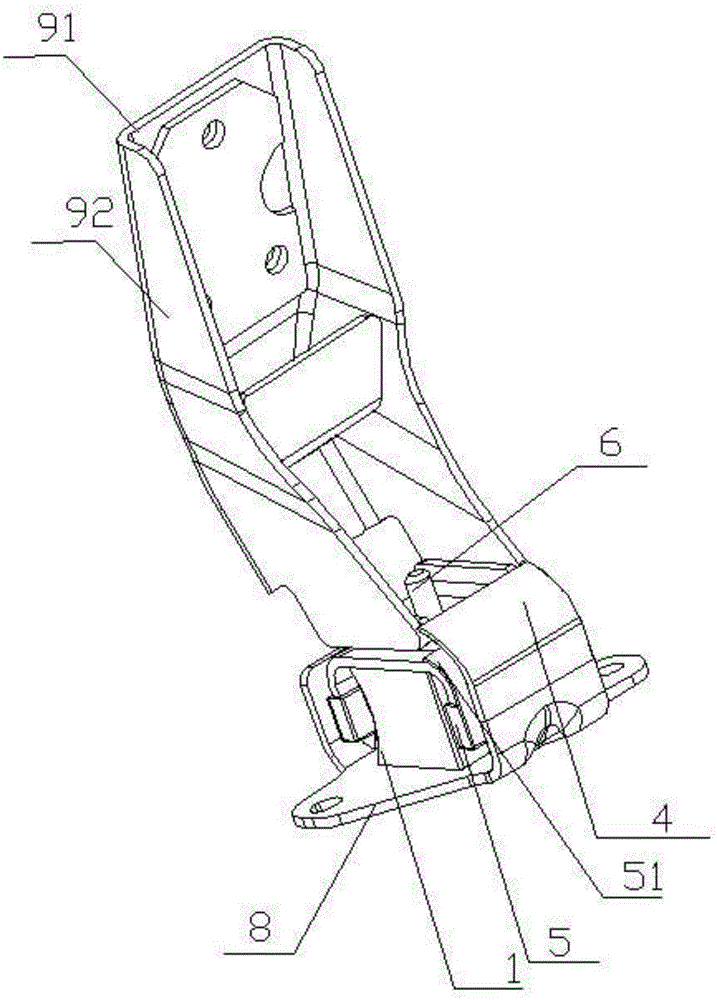

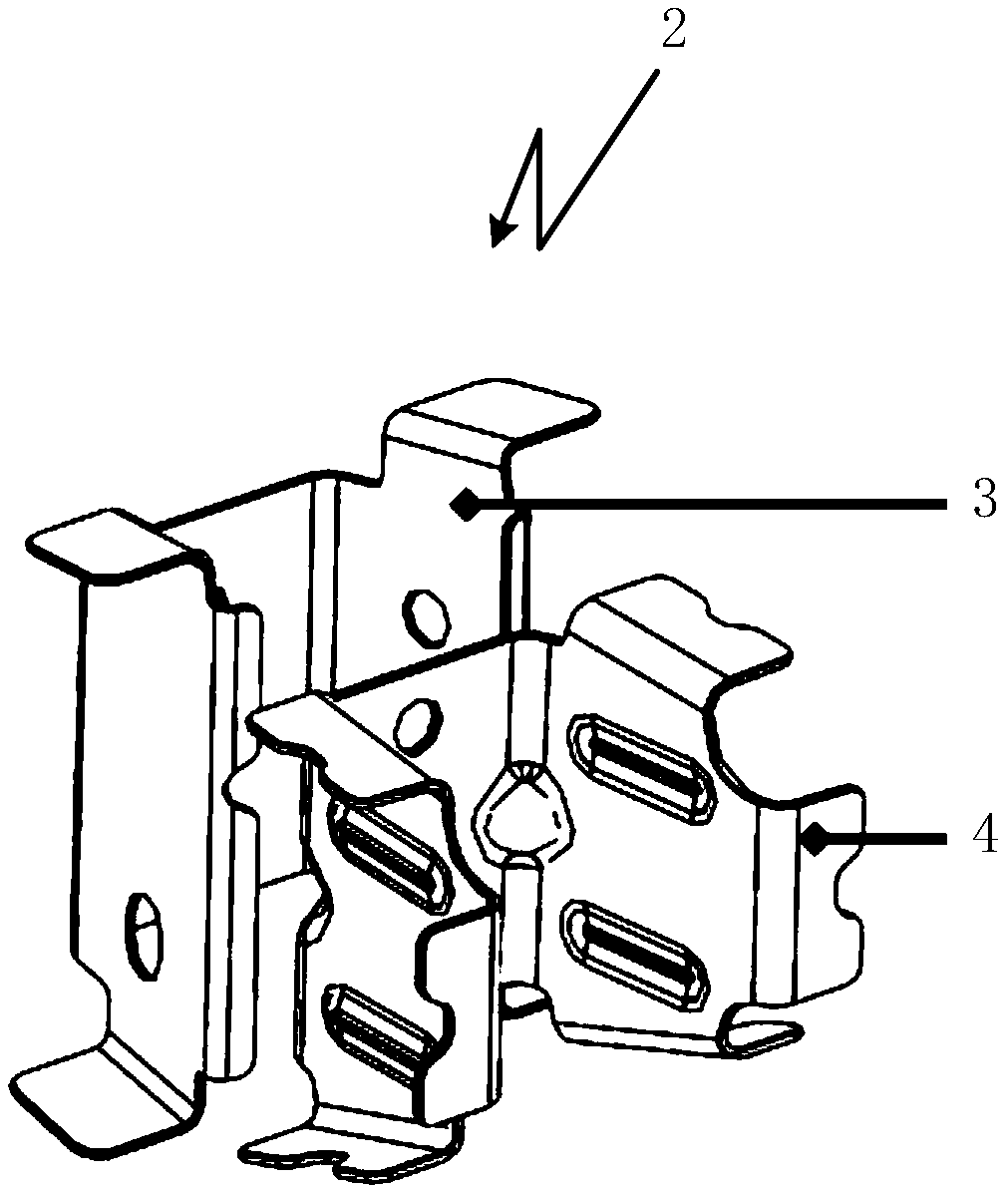

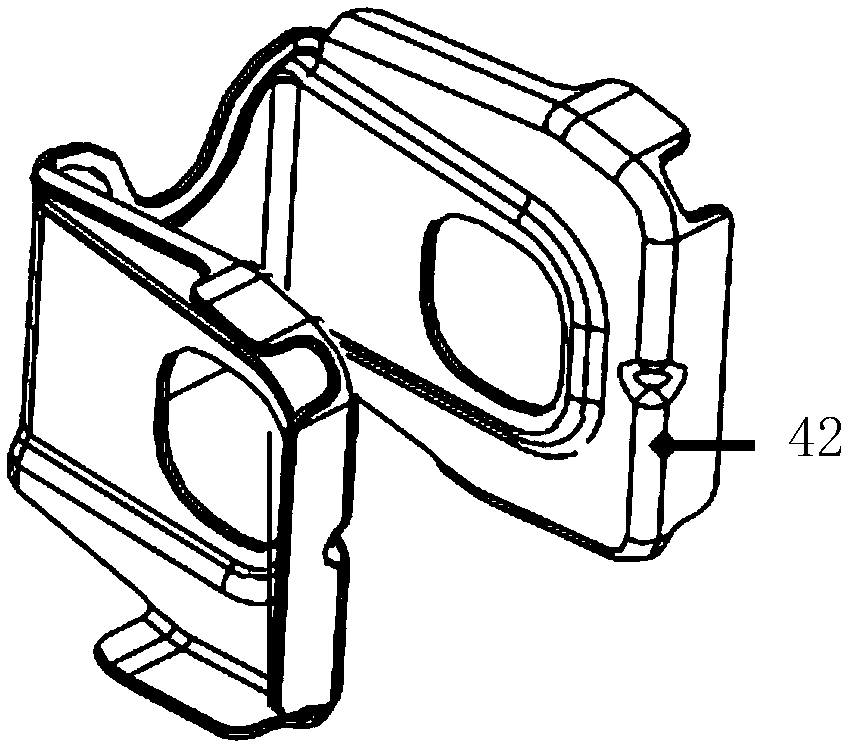

Gauge board beam installation component

ActiveCN106347495AEasy to installRealize three-point installationSuperstructure subunitsSteering wheelArchitectural engineering

The invention discloses a gauge board beam installation component which consists of a left installation component used to install the gauge board beam to the weld assembly of the left front side plate, and a right installation component used to install the gauge board beam to the weld assembly of the right front side plate. The right installation component comprises a U-shape right mounting bracket of the beam with flanged edges on both sides and a U-shape reinforcing plate with flanged edges on both sides set between the weld assembly of the right front side plate and the right internal plate. The right mounting bracket of the beam is fixed with the gauge board beam along X direction. Both sides of the weld assembly of the right front side plate are respectively fixed with the right mounting bracket of the beam and the U-shape reinforcing plate. The other side of the U-shape reinforcing plate is fixed with the right internal plate. The gauge board beam installation component has a simple structure and can be installed conveniently. Besides, the installation component also has enough rigidity and a high mode, and can prevent the steering wheel and gauge board from shaking at a low speed.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

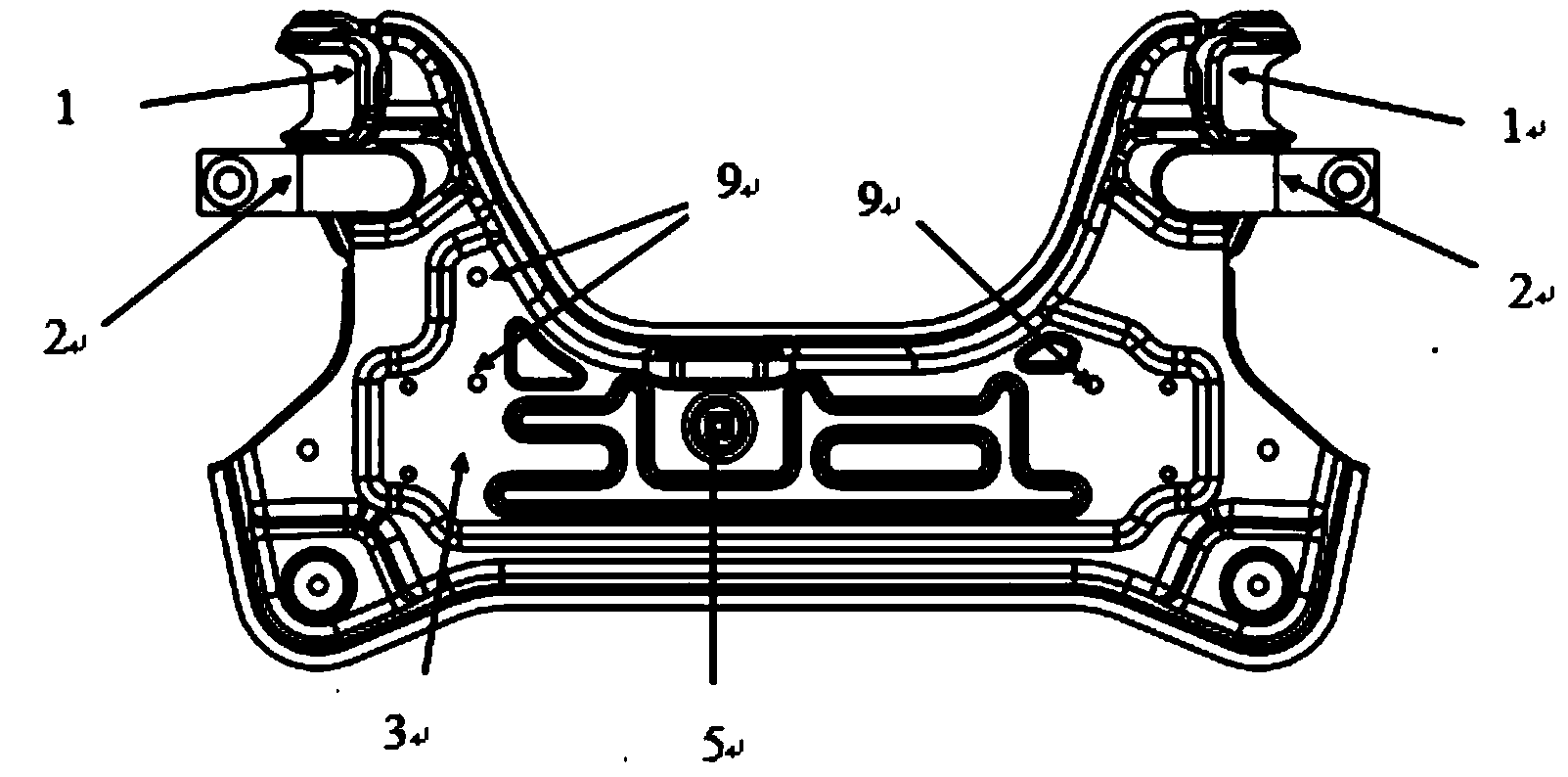

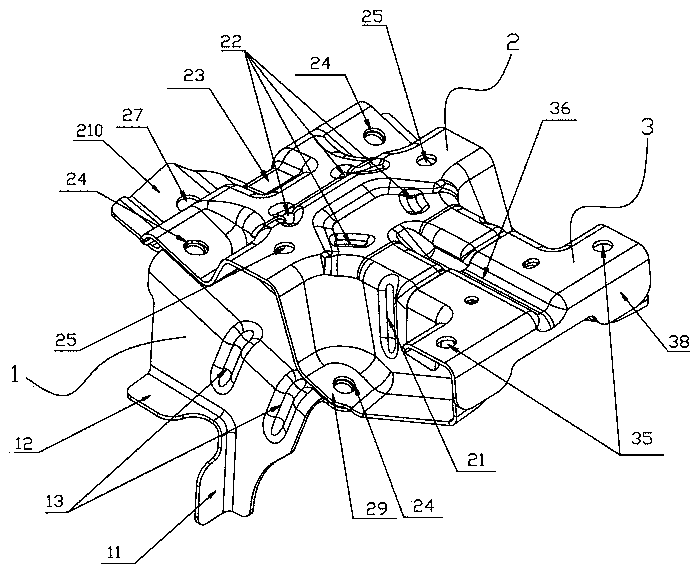

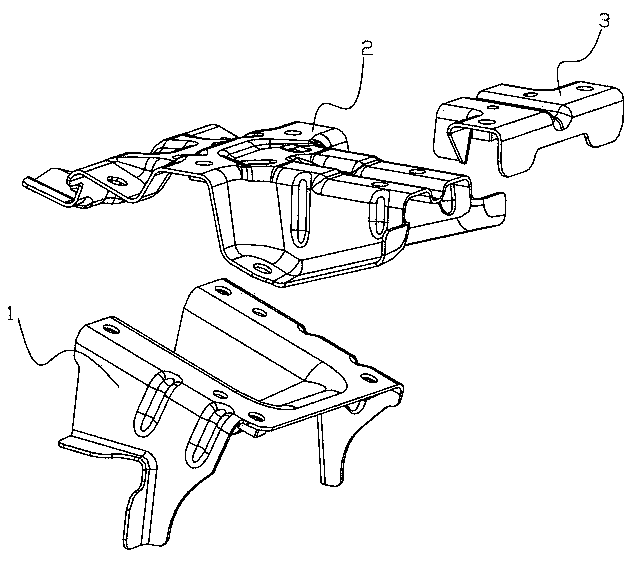

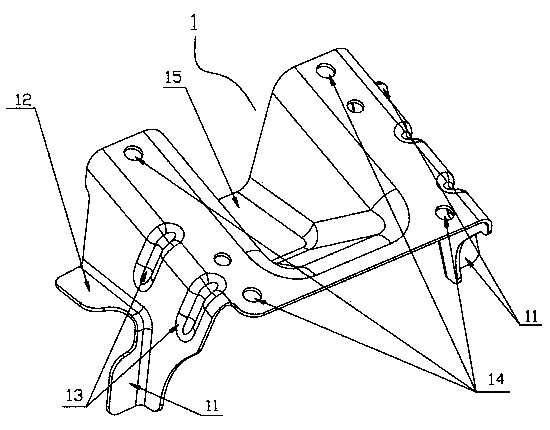

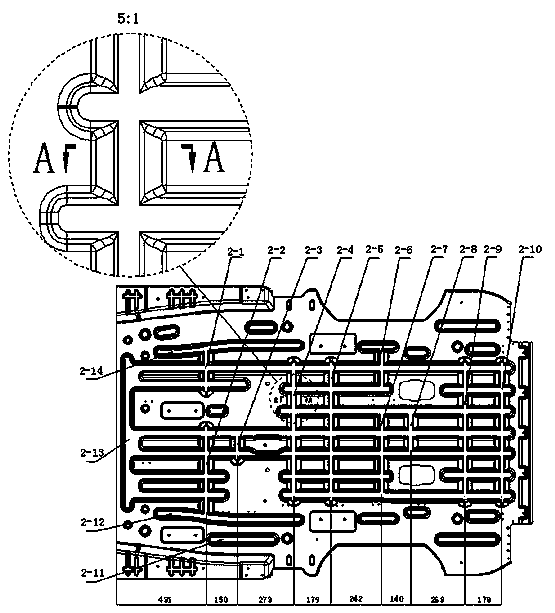

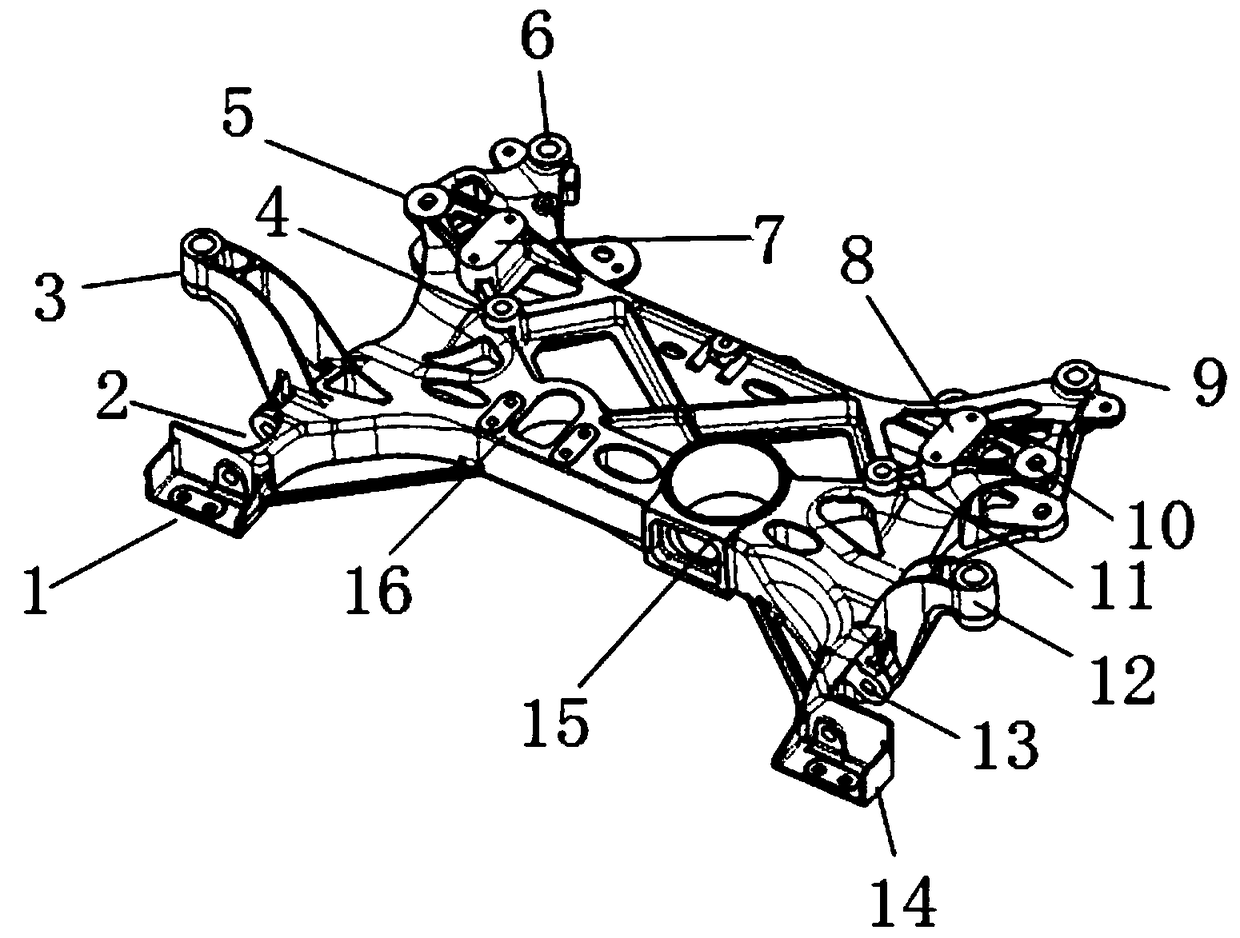

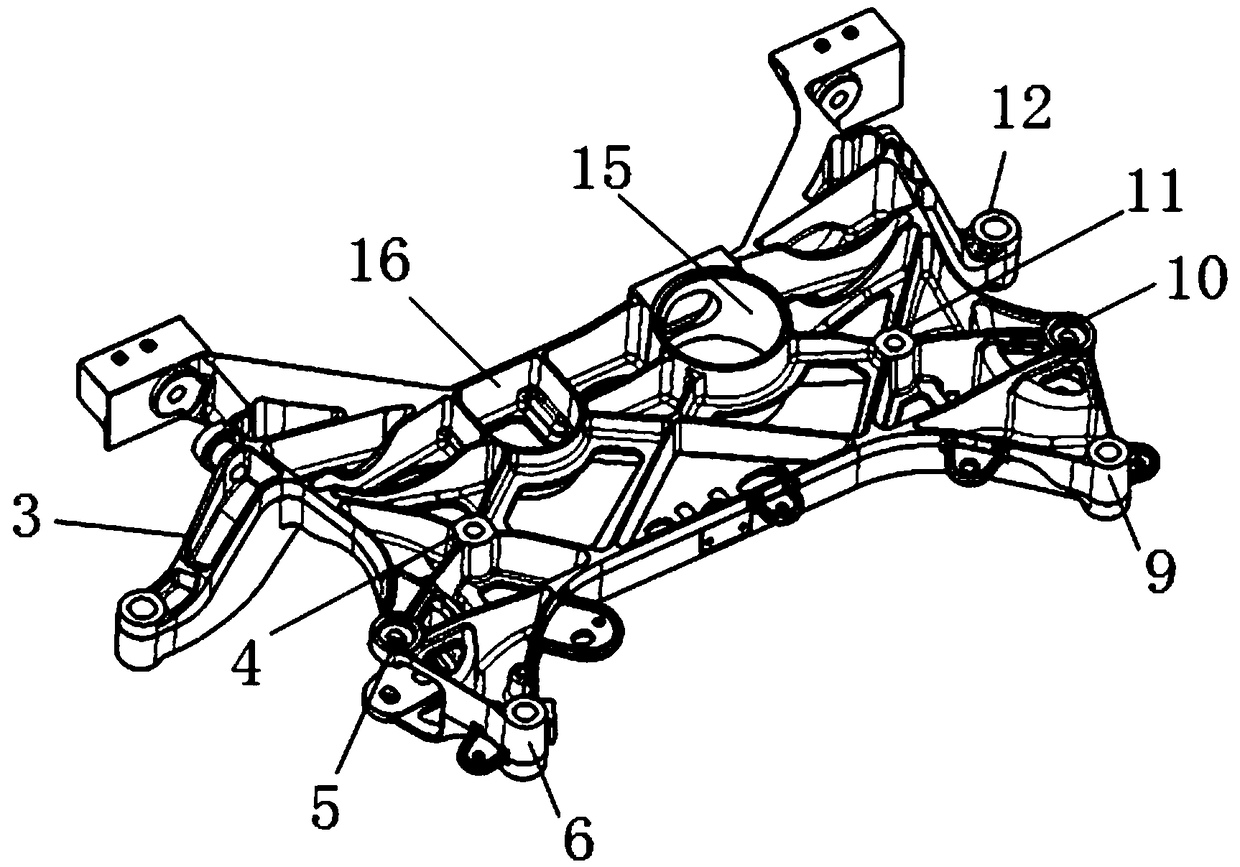

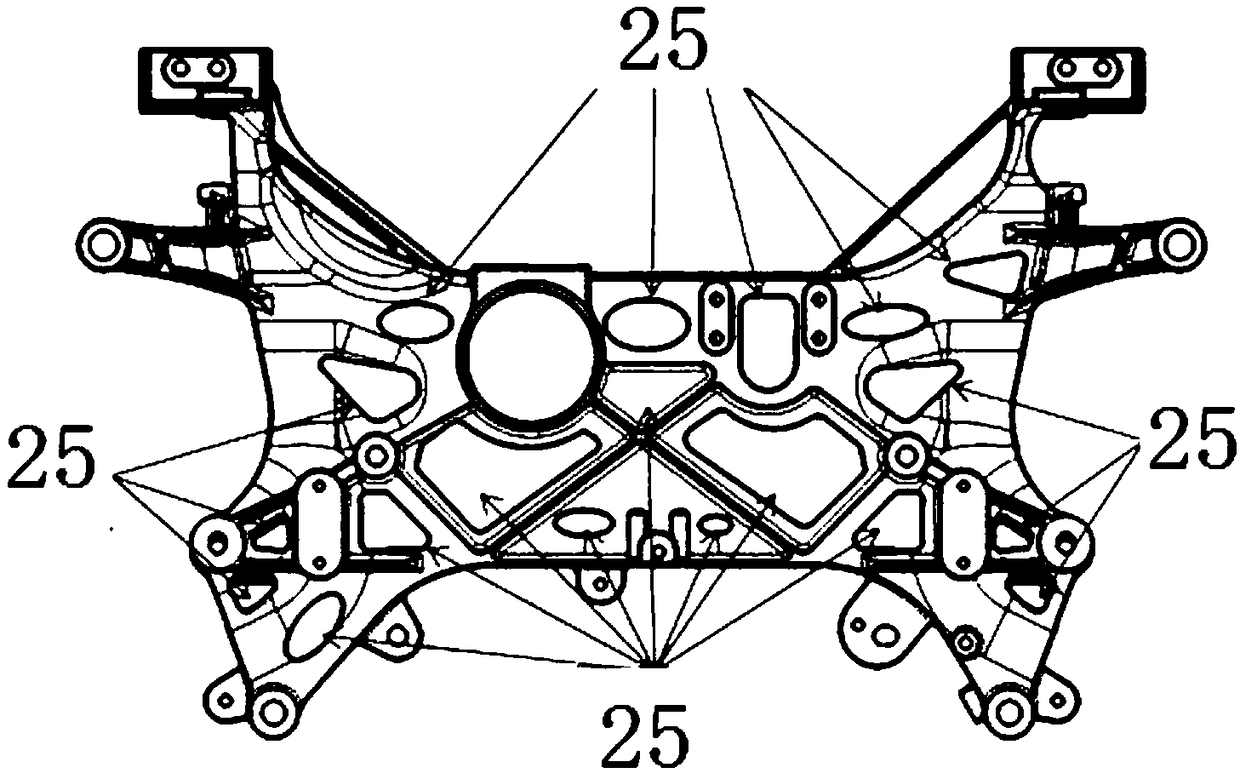

A subframe lightweight structure

InactiveCN108945106AIncrease stiffnessRaise modalUnderstructuresSuperstructuresVehicle frameEngineering

The invention discloses a lightweight structure of a subframe, which comprises a subframe body, wherein the subframe body is provided with a weight reducing hole; the lightweight structure further comprises a cross reinforcing rib structure for connecting mounting points on the subframe body to form an integral structure; and the cross reinforcing rib structure is arranged on the subframe body. The whole subframe of the invention is butterfly-shaped, and the main body is designed in the form of box-shaped cross-grid reinforcing ribs, so that the rigidity and strength of the subframe are increased and the mode of the subframe is lifted at the same time. Multiple irregular hollowed-out weight loss design to minimize weight loss.

Owner:CHERY AUTOMOBILE CO LTD

Dashboard cross beam assembly

The invention discloses a dashboard cross beam assembly. The dashboard cross beam assembly comprises a vehicle body front wall metal plate, a cross beam main body, a left cross beam metal plate and aright cross beam metal plate; the vehicle body front wall metal plate is located at the front end of a vehicle body, the left cross beam metal plate is mounted on the left side of the vehicle body front wall metal plate, the right cross beam metal plate is mounted on the right side of the vehicle body front wall metal plate, the cross beam main body is located between the left cross beam metal plate and the right cross beam metal plate, and the dashboard cross beam assembly is made of steel; the dashboard cross beam assembly further comprises an intermediate connection bracket which is mountedbetween the vehicle body front wall metal plate and the cross beam main body. On the basis of meeting the high performance requirements for a steering tubular column mode and a collision intrusion amount, the requirements for a lightweight effect and a cockpit layout space are met conveniently, and meanwhile the cost can be reduced to the maximum extent.

Owner:SAIC GENERAL MOTORS +1

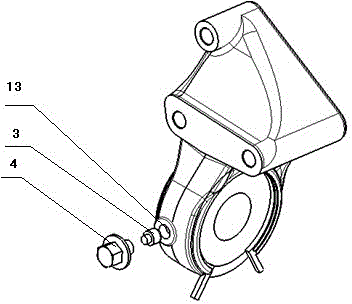

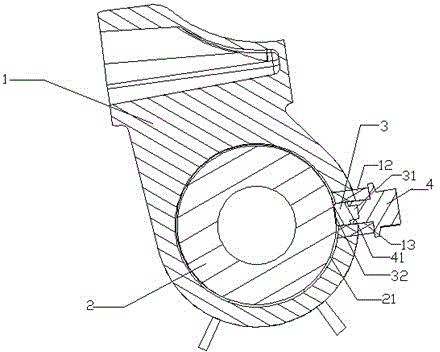

Driving shaft assembly with support structure

The invention discloses a driving shaft assembly with a support structure. The driving shaft assembly comprises a support body 1 and a bearing retainer ring clamp spring assembly 2, a bearing outer ring 21 of the bearing retainer ring clamp spring assembly 2 is installed in a support inner ring 11 of the support body 1, and the bearing outer ring 21 is in clearance fit with the support inner ring 11. The driving shaft assembly is characterized in that a threaded through hole is formed in the radial direction of the support body 1, a rubber plug 3 is installed in the threaded through hole, an end portion 32 of the rubber plug presses the bearing outer ring 21 tightly, a bolt 4 is screwed into the threaded through hole, the rubber plug 3 is pressed tightly, the pressing force to the bearing outer ring is generated through compression of the rubber plug 3, and therefore the matched tightness degree between the bearing outer ring 21 and the support inner ring 11 is adjusted so as to achieve the purposes of vibration reducing and mode optimization. The driving shaft assembly has the advantages of being simple in structure, convenient to operate, high in practicability and the like.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

Automobile side wall frame reinforcing assembly

PendingCN110962938AHigh energy absorptionReduce intrusionSuperstructure subunitsEnergy absorptionEngineering

The invention discloses an automobile side wall frame reinforcing assembly, which comprises an A-pillar reinforcing assembly, a B-pillar reinforcing assembly, a threshold reinforcing assembly, a C-pillar reinforcing assembly, a D-pillar reinforcing assembly, a side wall roof side rail reinforcing assembly and a rear side wall connecting assembly. The rear end of the upper part of the A-pillar reinforcing assembly is fixed at the front end of the side wall roof side rail reinforcing assembly. The rear end of the lower part of the A-pillar reinforcing assembly is fixed to the front end of the threshold reinforcing assembly. The upper end part of the B-pillar reinforcing assembly is fixed on the A-pillar reinforcing assembly. The lower end of the B-pillar reinforcing assembly is fixed to thethreshold reinforcing assembly. The rear end of the threshold reinforcing assembly is fixed to the front end of the rear side wall connecting assembly. The upper end of the C-pillar reinforcing assembly is fixed to the side wall roof side rail reinforcing assembly. The upper end of the D-pillar reinforcing assembly is fixed to the rear end of the side wall roof side rail reinforcing assembly. According to the automobile side wall frame reinforcing assembly, the energy absorption capacity of an automobile body structure in the side collision process can be increased, the invasion amount and theinvasion speed are reduced, and threshold overturning is reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com