Rear luggage rack device for sedan

A technology for luggage racks and cars, which is applied to vehicle parts, transportation and packaging, and can solve the problems of small ribs, insufficient rigidity of the rear bulkhead and local structural modes, and ineffective improvement of the rigidity of the rear bulkhead body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

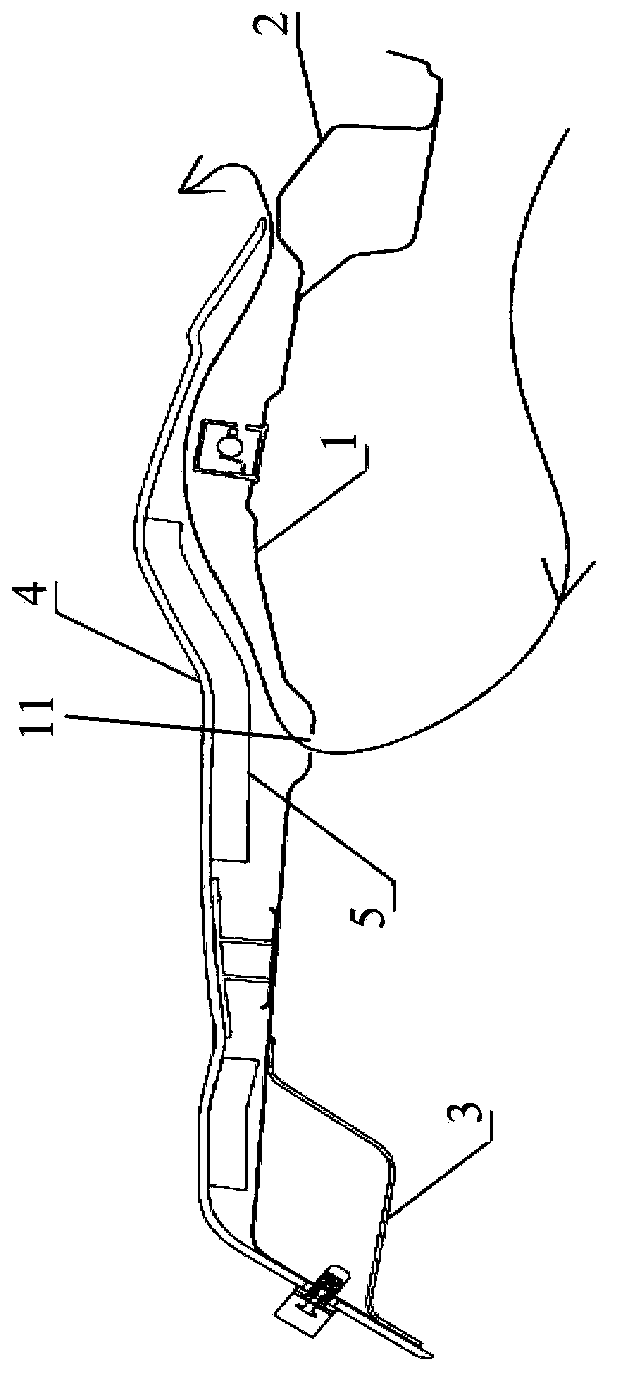

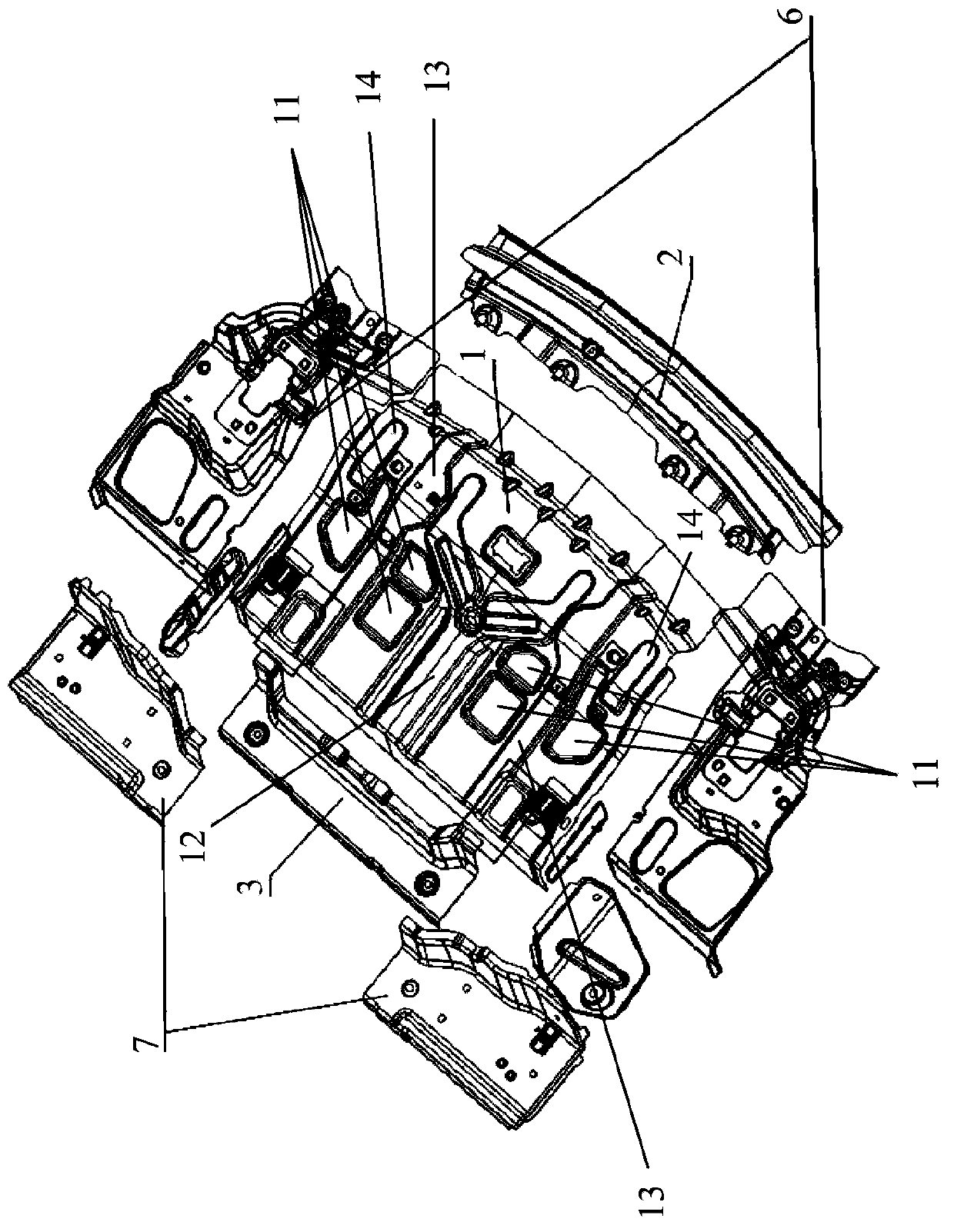

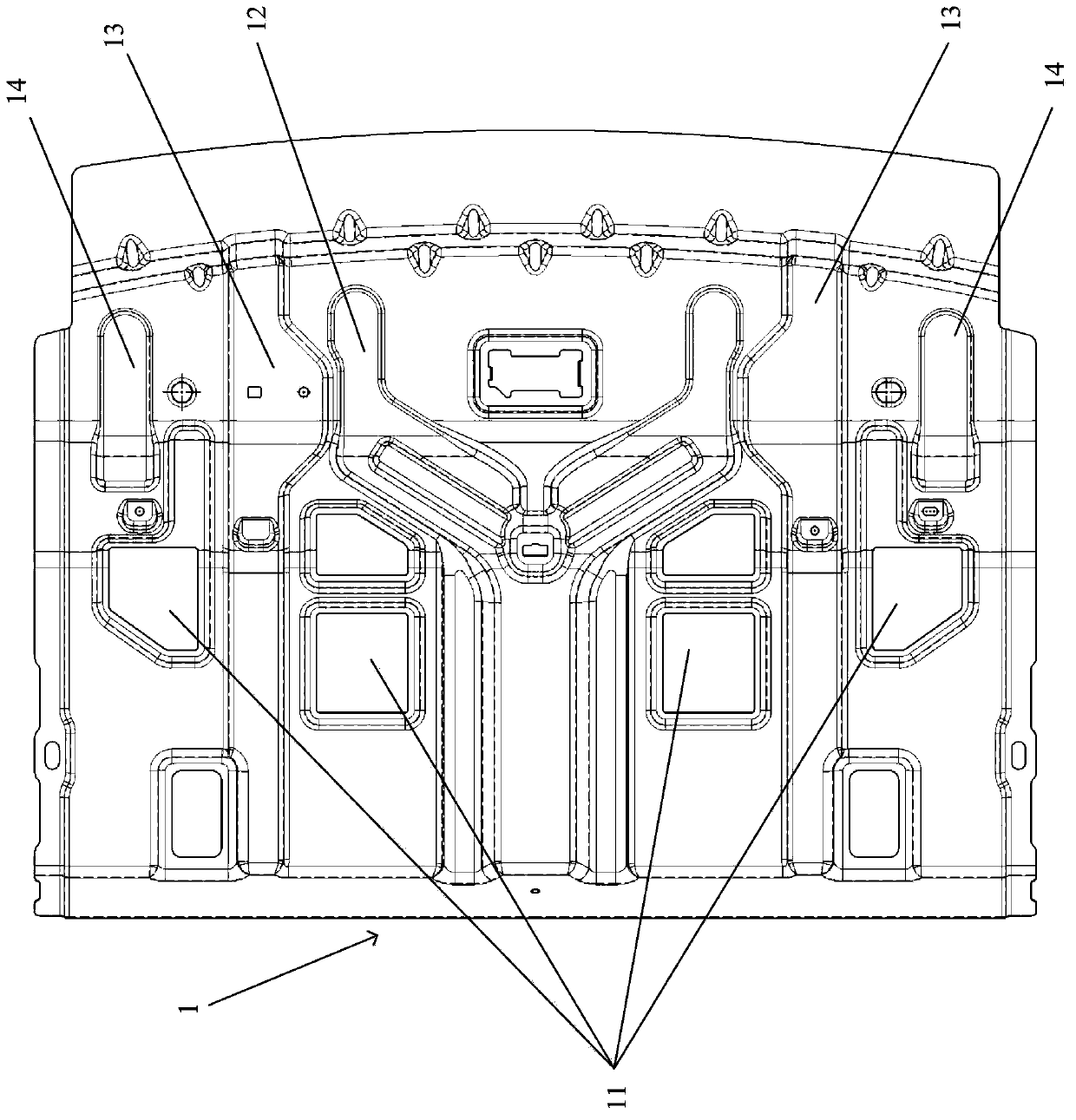

[0018] Such as figure 1 and figure 2 As shown, the rear luggage rack device of a car according to an embodiment of the present invention includes a rear bulkhead body 1 , a rear windshield lower beam 2 installed above the rear portion of the rear bulkhead body 1 , a rear bulkhead body 1 mounted on Rear bulkhead beam 3 under the front part, rear bulkhead trim 4 installed above the rear bulkhead body 1, rear bulkhead sound insulation foam installed between the rear bulkhead body 1 and rear bulkhead trim 4 5. The left and right rear bulkhead assemblies 6 installed on the lateral sides of the rear bulkhead body 1, and the left and right extension plates 7 of the rear bulkhead beam.

[0019] The rear bulkhead cross member 3 according to the invention itself has no opening towards the rear luggage compartment, so that the rear bulkhead cross member 3 is closed relative to the rear luggage compartment. In addition if figure 1 and 2 As shown, a plurality of through holes 11 ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com