Patents

Literature

725results about How to "Improve NVH performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

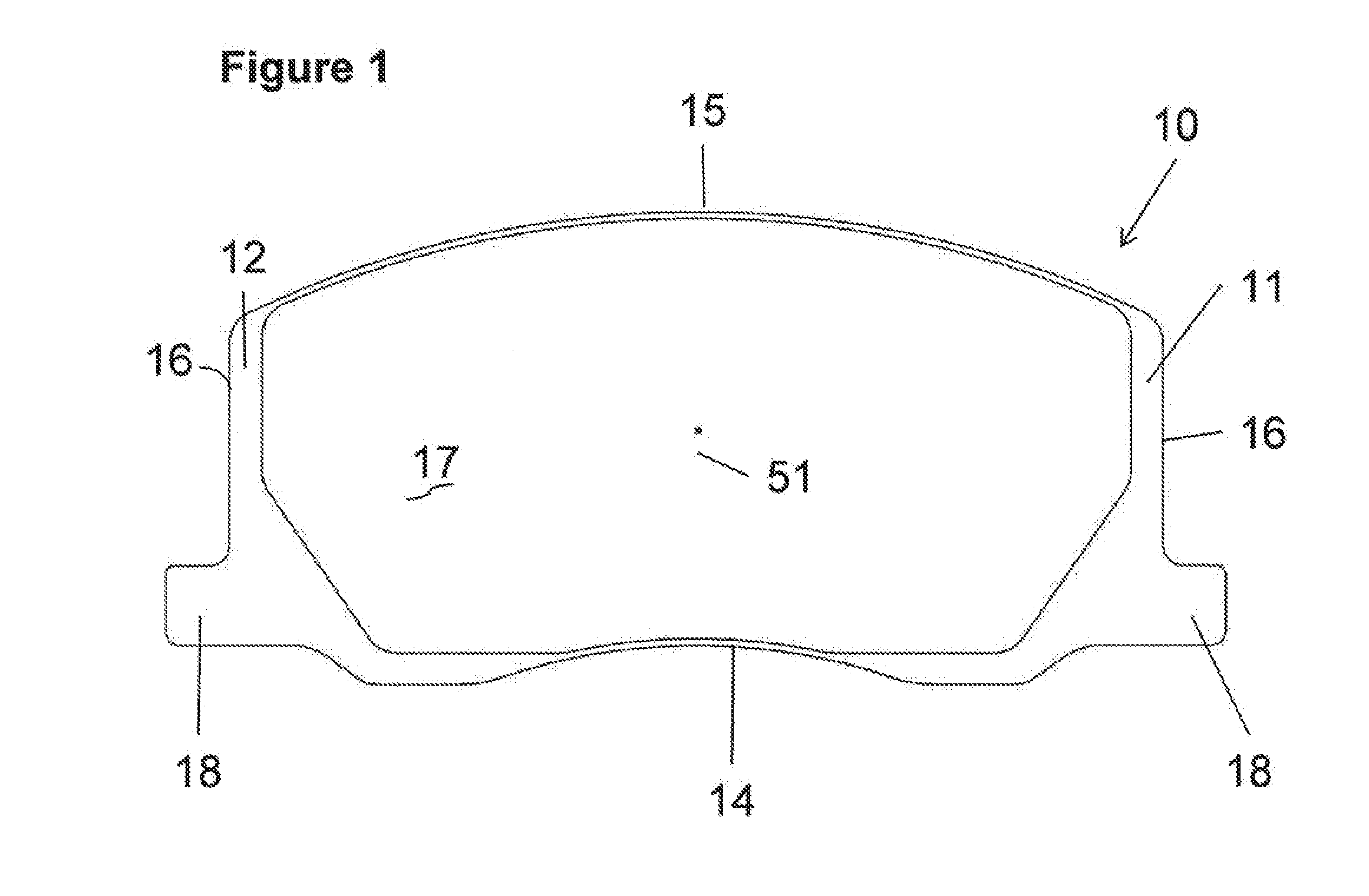

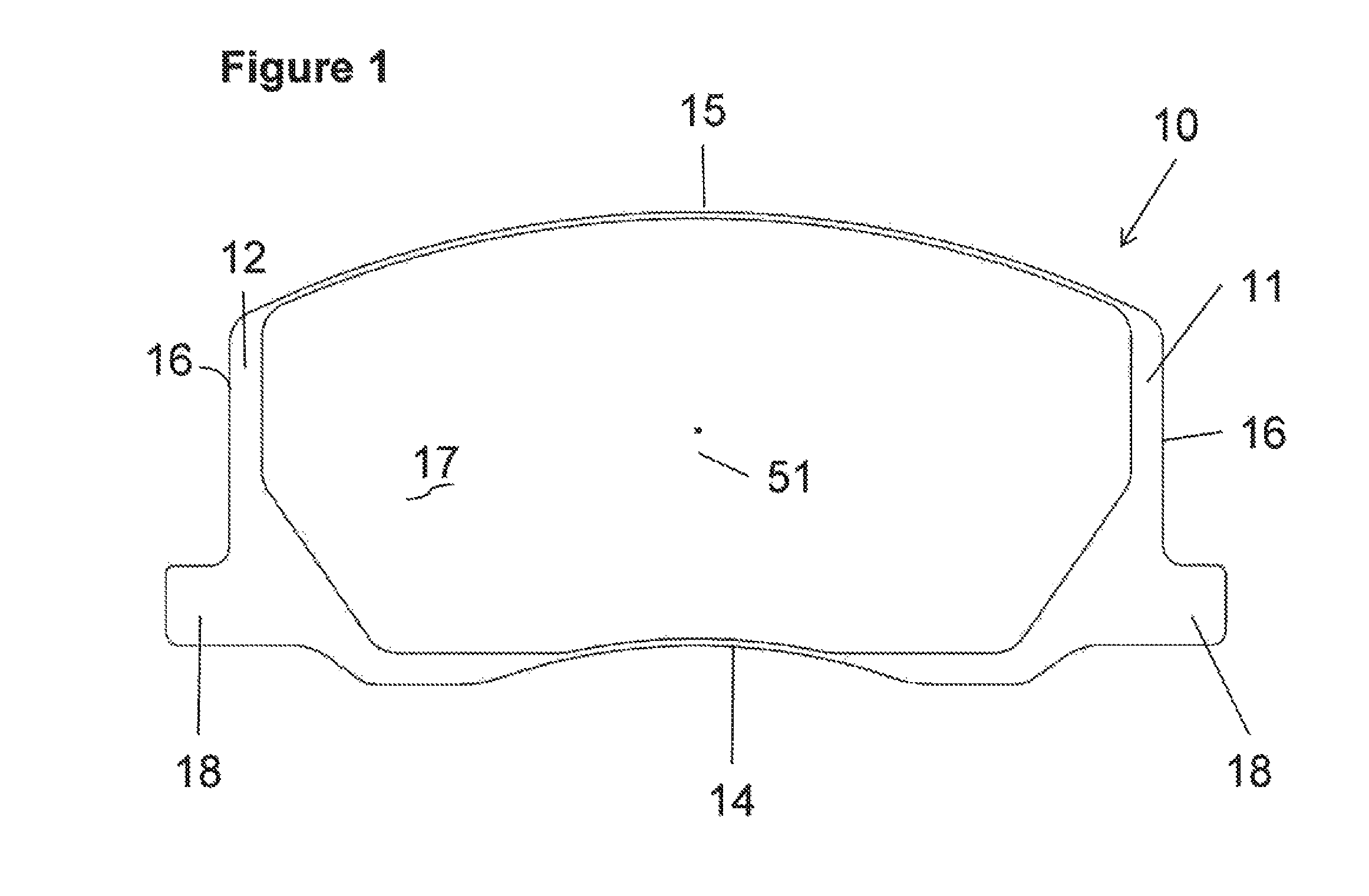

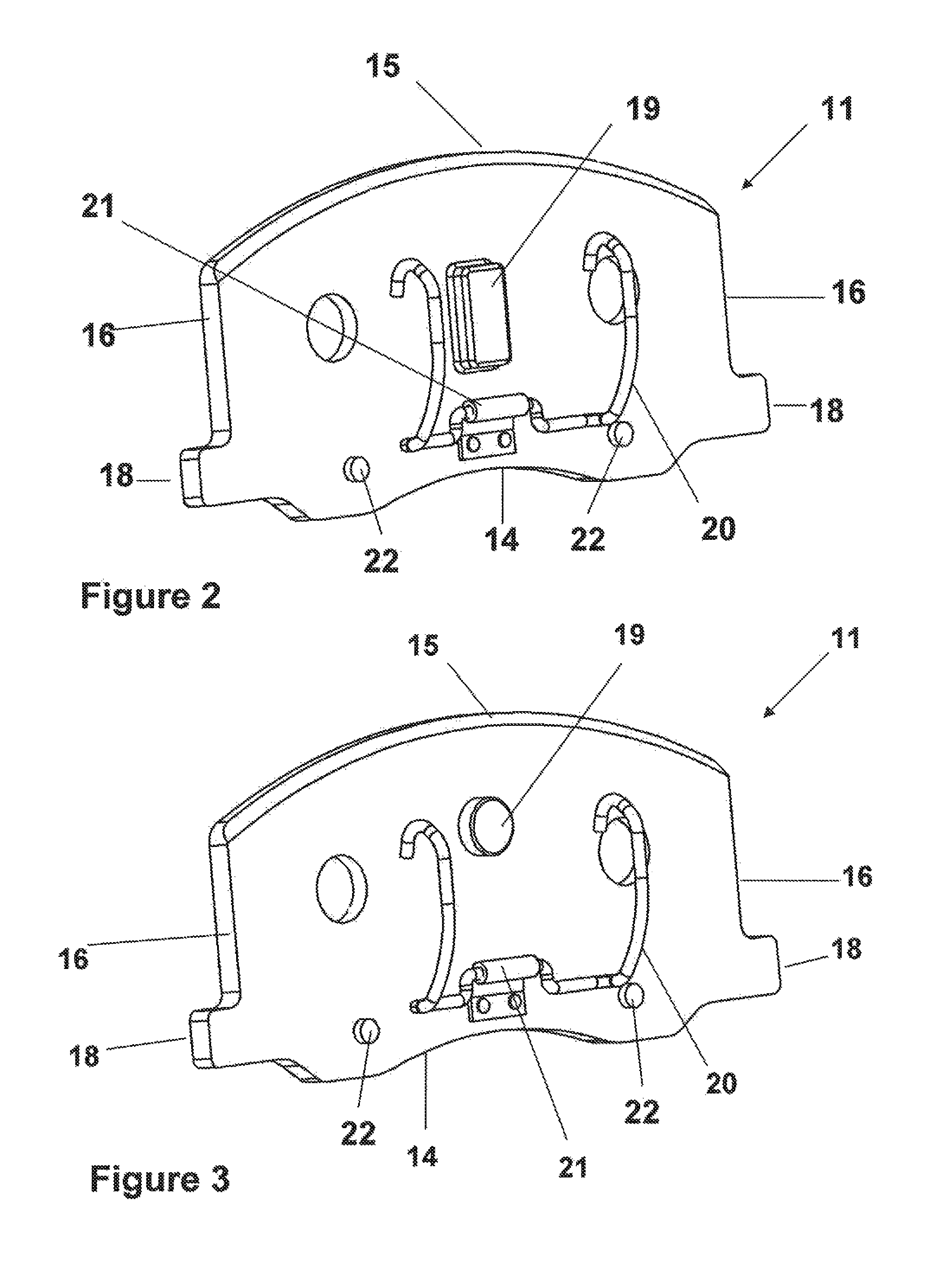

Brake systems, caliper assemblies and pads incorporating differential abutments

InactiveUS20120043168A1Transmission of forceImprove NVH performanceMechanically actuated brakesBraking membersPush pullEngineering

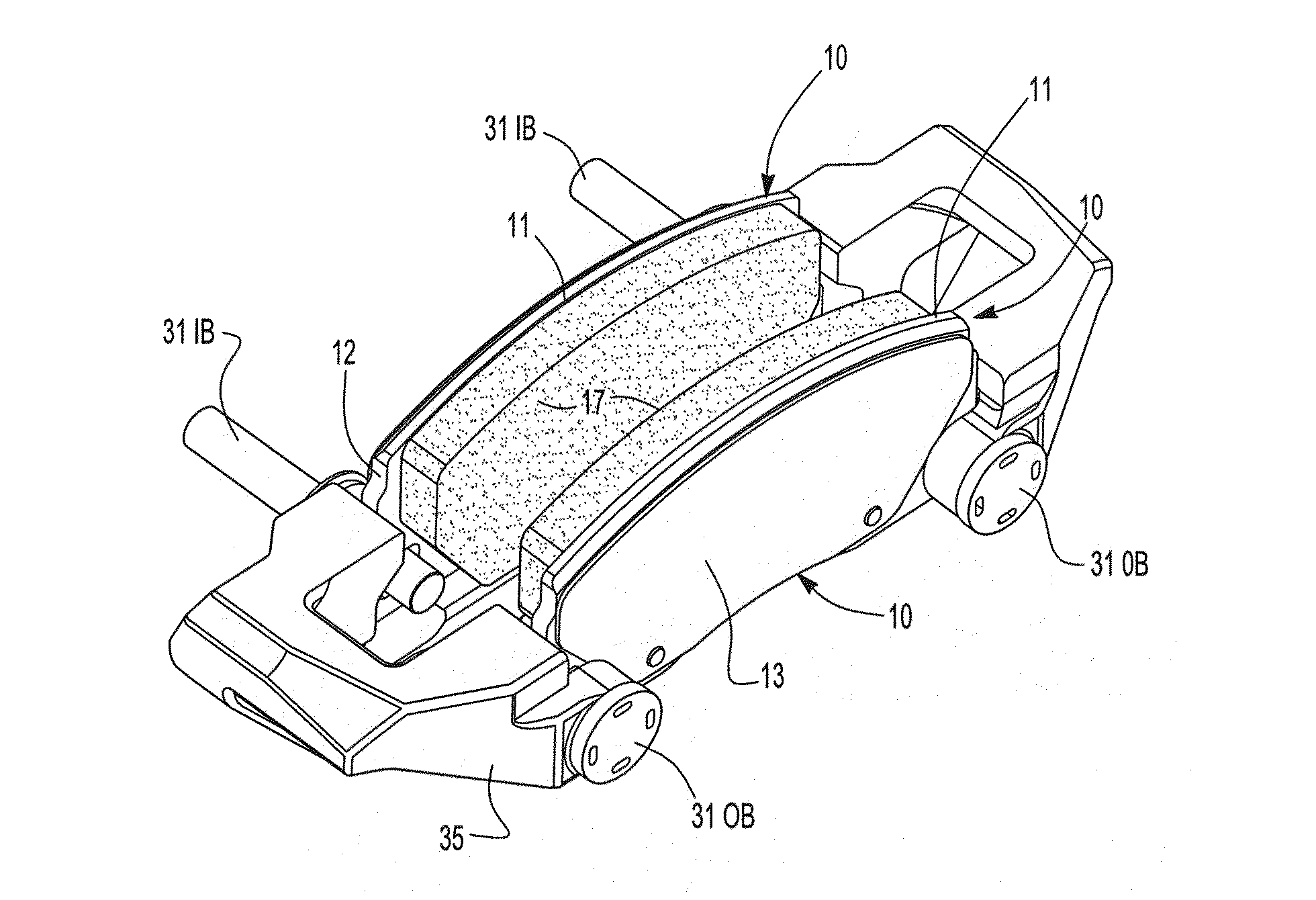

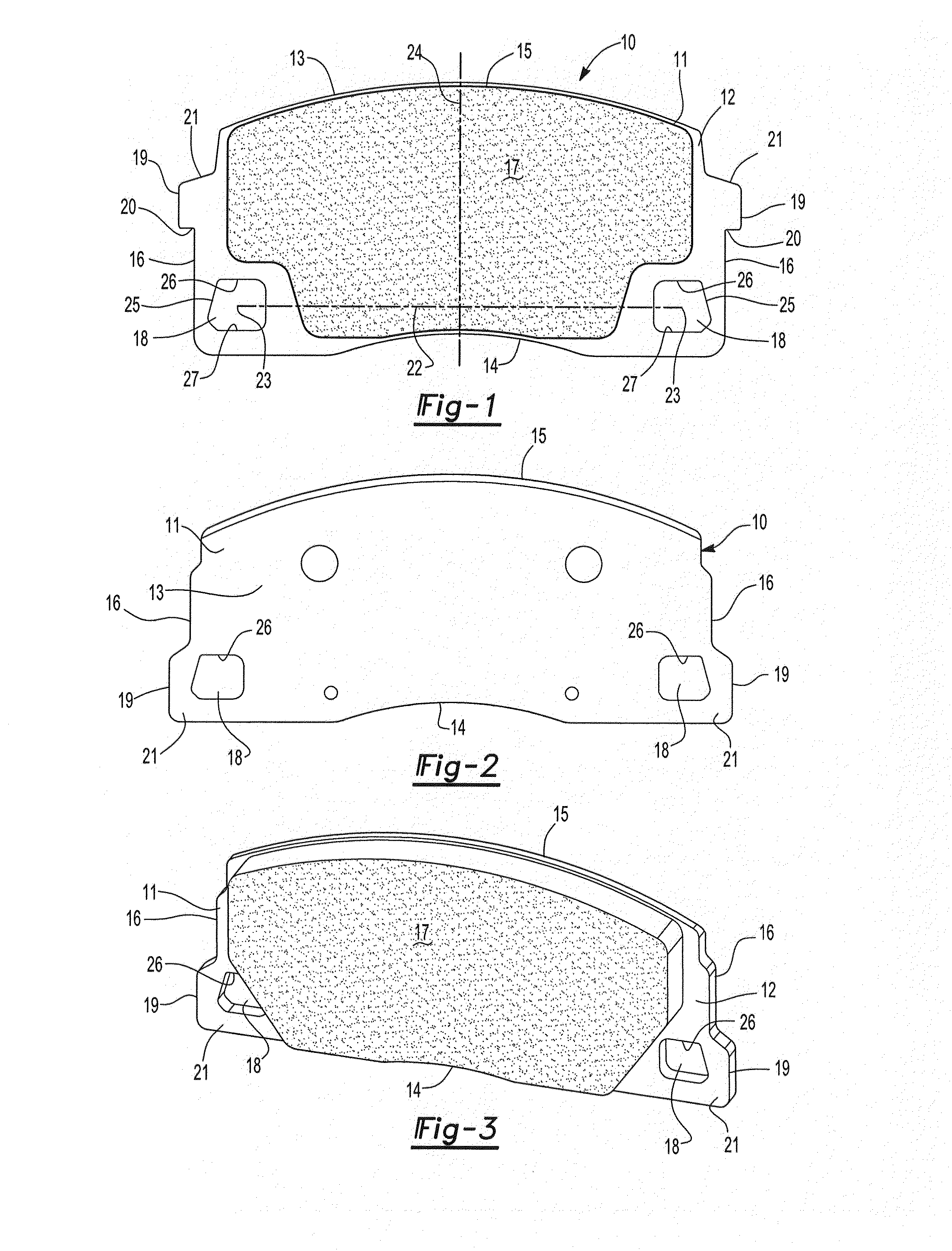

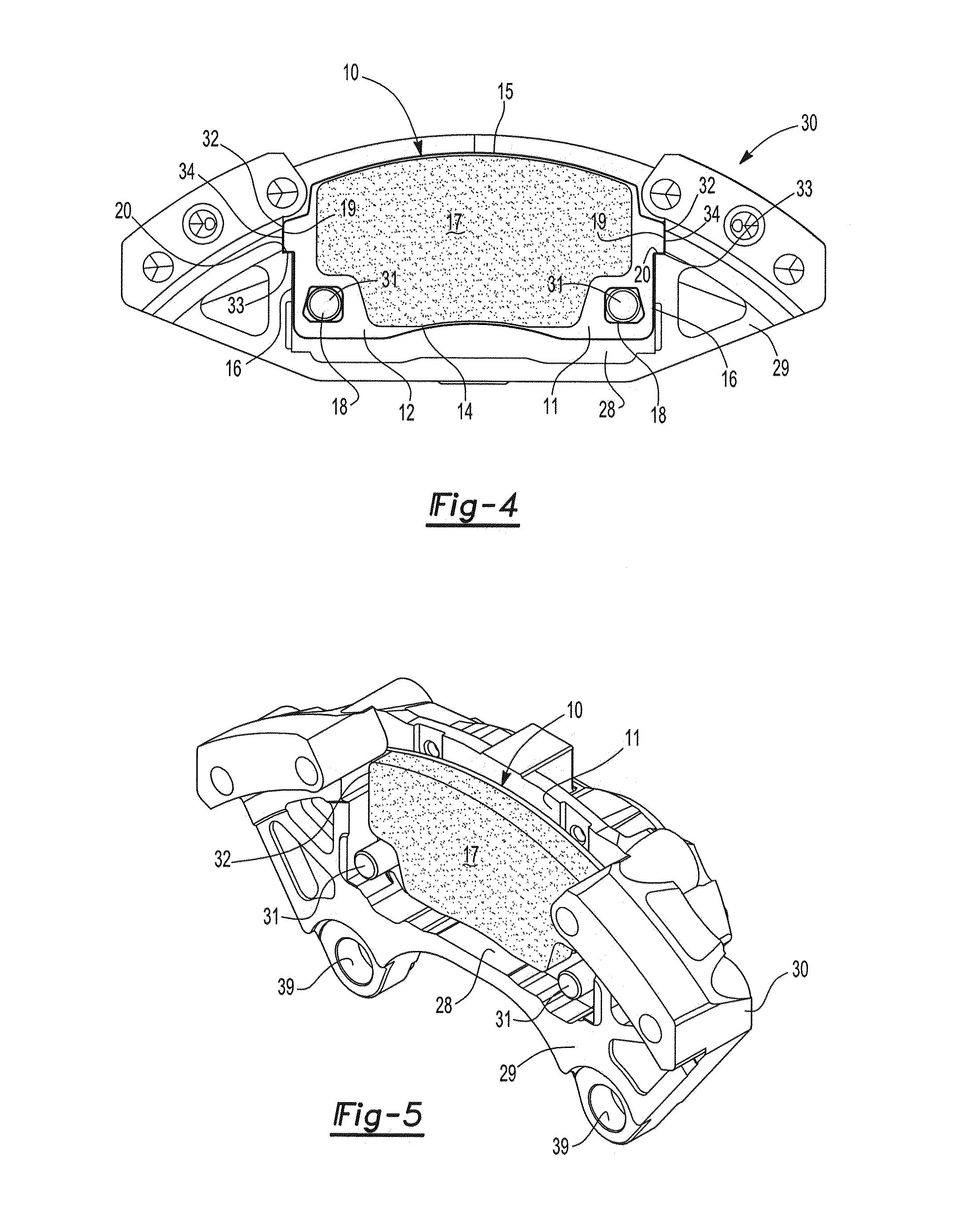

The present invention is directed to a unique solution for caliper assemblies, brake pads utilized in such caliper assemblies, support structures utilized in caliper assemblies and disc brake systems containing such caliper assemblies which utilize push pull or pull push abutment designs.

Owner:AKEBONO CORP (NORTH AMERICA)

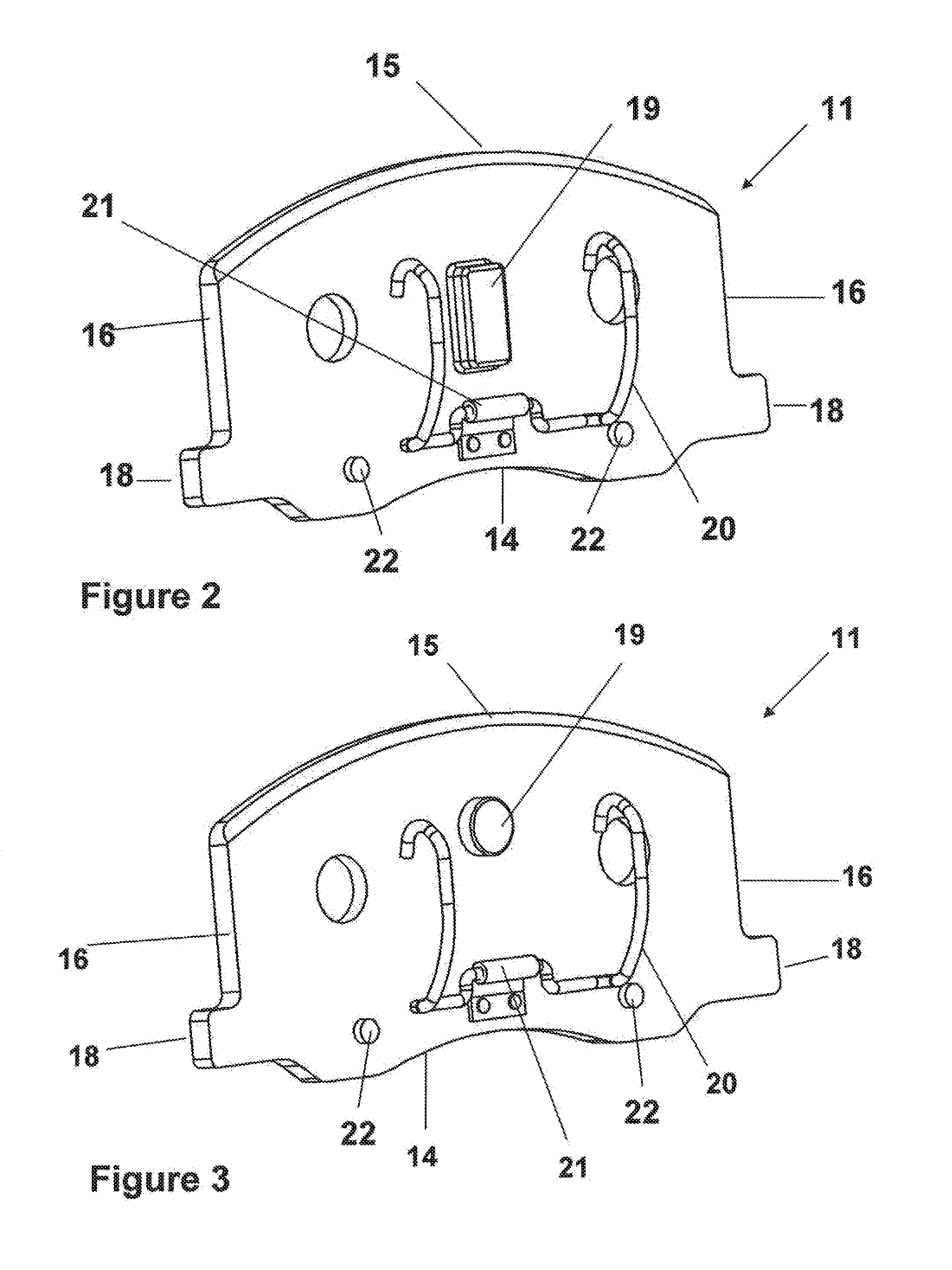

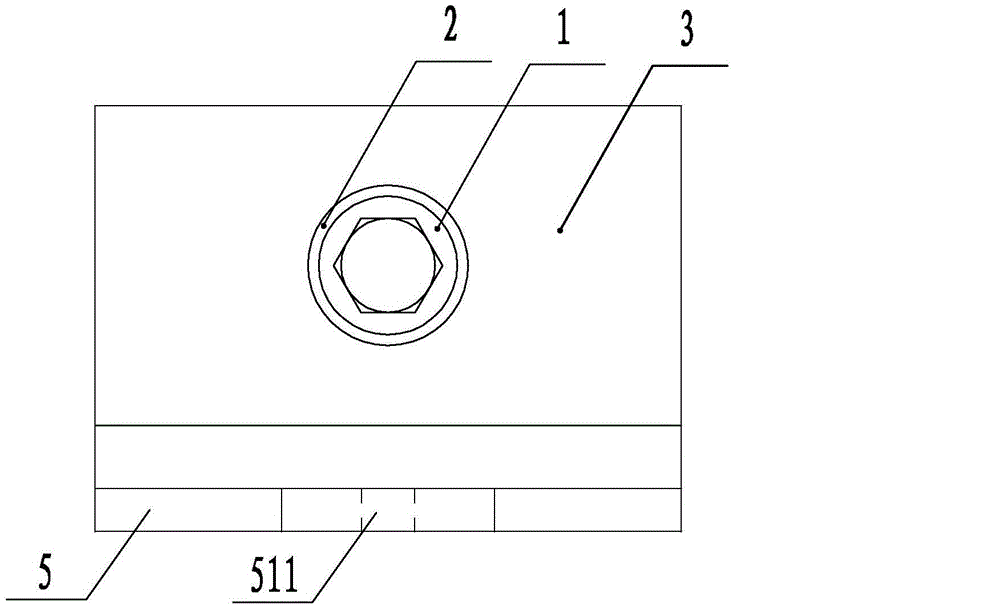

Caliper assembly for disc brake system

InactiveUS20120085597A1Improve NVH performanceImprove component performanceMechanically actuated brakesSlack adjustersEngineeringCalipers

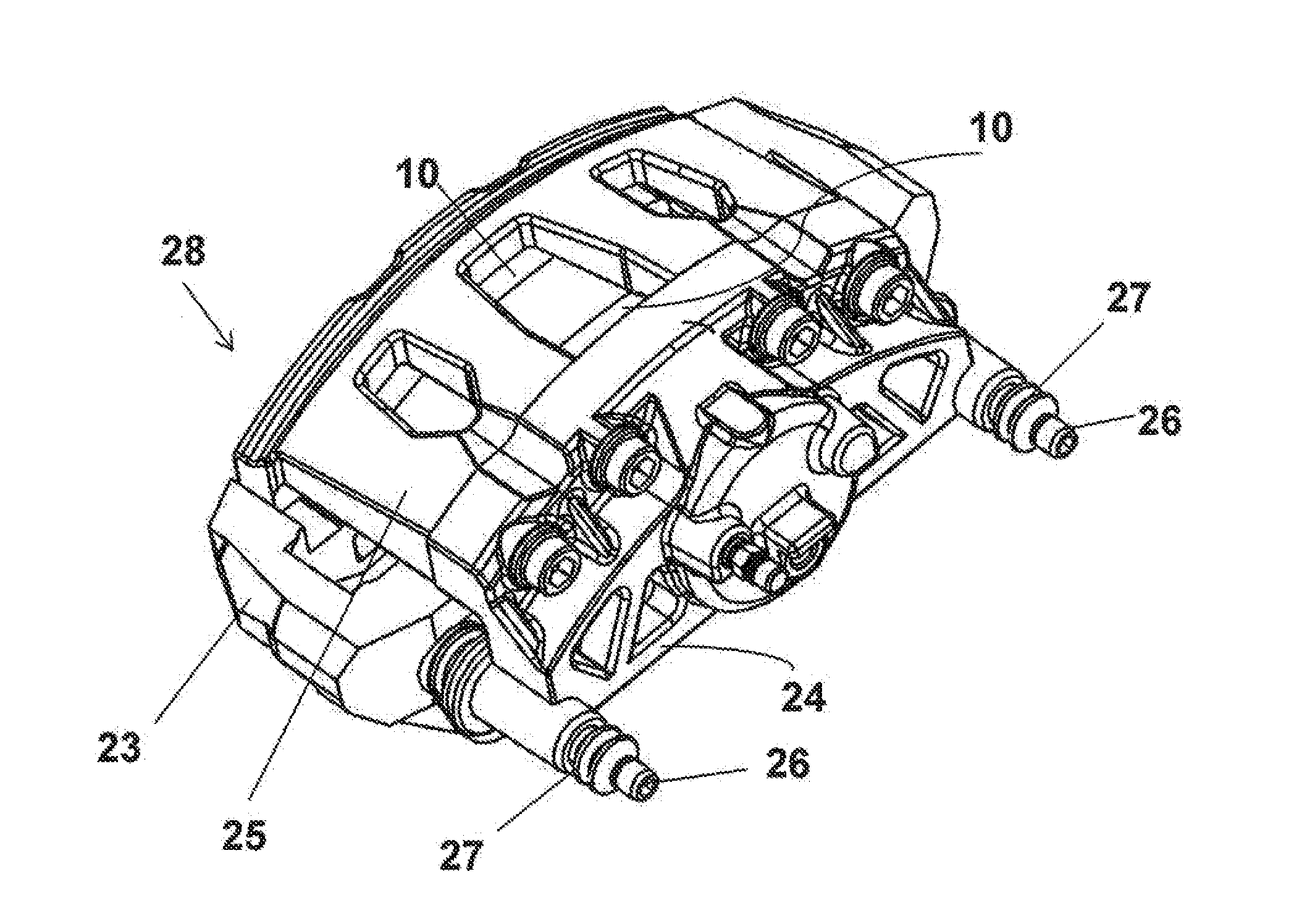

A caliper assembly comprising: a brake pad comprising a carrier plate having two opposing faces and a top edge a bottom edge and two opposing side edges, wherein on one face is friction material and on the opposing face is a projection adapted to seat in a matched hole or recess in a caliper body, the two opposing side edges each having an ear which is adapted to seat in pad locator indentations in a support structure; a support structure comprising a recess for housing at least one brake pad and at least two pad locator indentations adapted for receiving the ears located on the two opposing sides of the brake pad and at least two caliper body locator indentations for seating two ears defined by the caliper body; and a caliper body having a hole or recess adapted for seating the projection on the opposing face of the brake pad and having two ears on each opposing side which are adapted to seat in the caliper body locator indentations of the support structure; wherein the ears of the brake pad are seated in the pad locator indentations of the support structure, the projection on the opposing face of the brake pad is seated in the hole or recess located in the caliper body, and a clip which engages the opposing face of the brake pad and the caliper body and holds the brake pad in position with respect to the caliper body and the ears of the caliper body are seated in the caliper body locator indentations in the support structure.

Owner:AKEBONO BRAKE

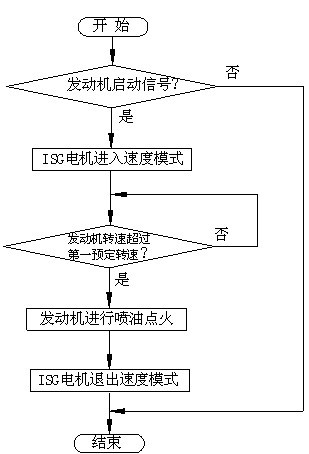

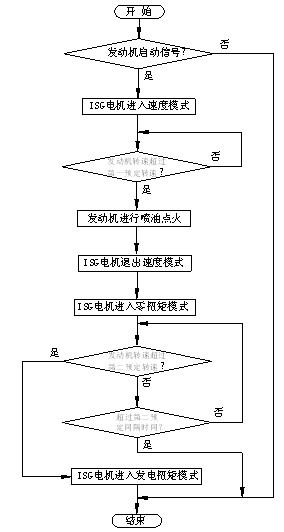

Method for controlling engine revolution speed during starting of hybrid power vehicle

InactiveCN102180167AAvoid problems such as reduced fuel economy and increased emissionsCause mechanical shockHybrid vehiclesInternal combustion piston enginesStarter generatorNoise, vibration, and harshness

The invention aims at providing a method for controlling engine revolution speed during starting of a hybrid power vehicle, in order to improve the fuel economy of the entire vehicle, reduce emission, lighten environmental pollution and improve the NVH (Noise Vibration and Harshness) performances of the entire vehicle. In the method, an ISG (Integrated Starter Generator) motor is used for driving an engine to rotate, the key point is that the engine is controlled to perform oil injection and ignition when the revolution speed of the engine is increased to exceed a first preset revolution speed by the ISG motor, and the ISG motor retreats a speed mode at the same time. In the method for controlling the engine revolution speed during starting of the hybrid power vehicle, by controlling the ignition time of the engine and the working mode variation of the ISG motor in a starting stage, the starting peak revolution speed of the engine is decreased, the fuel economy of the entire vehicle is further improved, and pollutant emission and environment pollution caused by the same are reduced, meanwhile, the NVH performances of the entire vehicle are improved.

Owner:CHERY AUTOMOBILE CO LTD

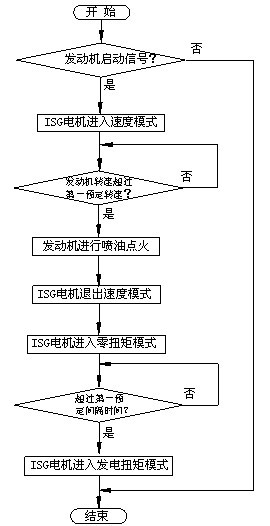

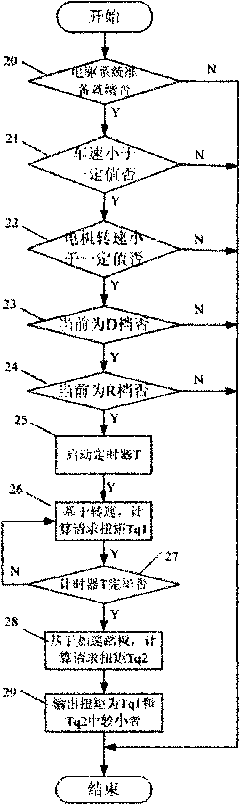

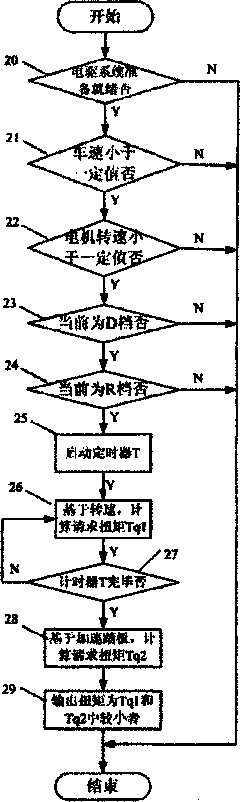

Method for controlling starting torque of electric vehicle

ActiveCN101823444AImprove NVH performanceImprove comfortSpeed controllerElectric energy managementElectricityCurrent electric

The invention relates to a method for controlling a starting torque of an electric vehicle. The method comprises the following steps of: in a step 20, detecting whether a current electric drive system is all set by using a finished vehicle controller; in a step 21, judging whether the current vehicle speed is lower than a fixed value by using the finished vehicle controller; in a step 22, judging whether a motor rotating speed is lower than a fixed value, namely judging whether the current finished vehicle is in a starting stage; in a step 23, judging whether a current gear request is a D gear or an R gear; in a step 25, starting a timer T; in a step 26, calculating a motor rotating speed-based request torque Tq1; in a step 27, judging whether the timer T is finished, if the timer is not finished, returning to the step 26 to continue timing; if the timer is finished, entering a step 28; in the step 28, calculating a driver accelerator pedal-based request torque Tq2; and in the step 29, comparing the Tq2 with the Tq2, wherein the smaller value of the Tq1 and the Tq2 is a final starting torque request value.

Owner:奇瑞新能源汽车股份有限公司

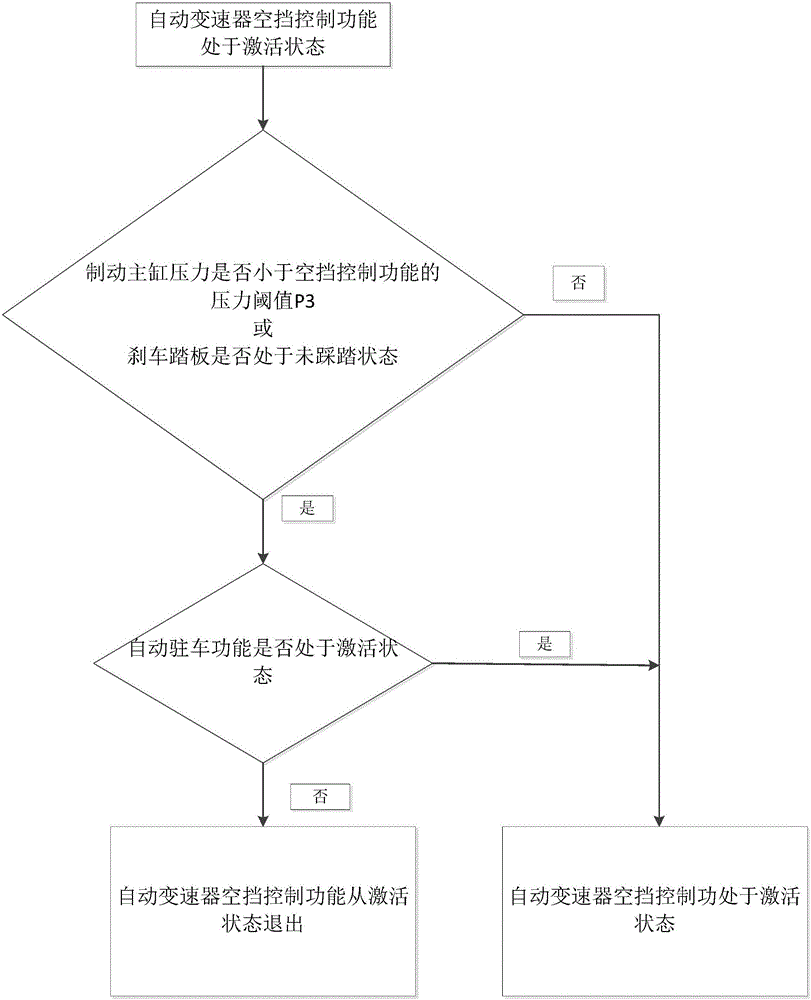

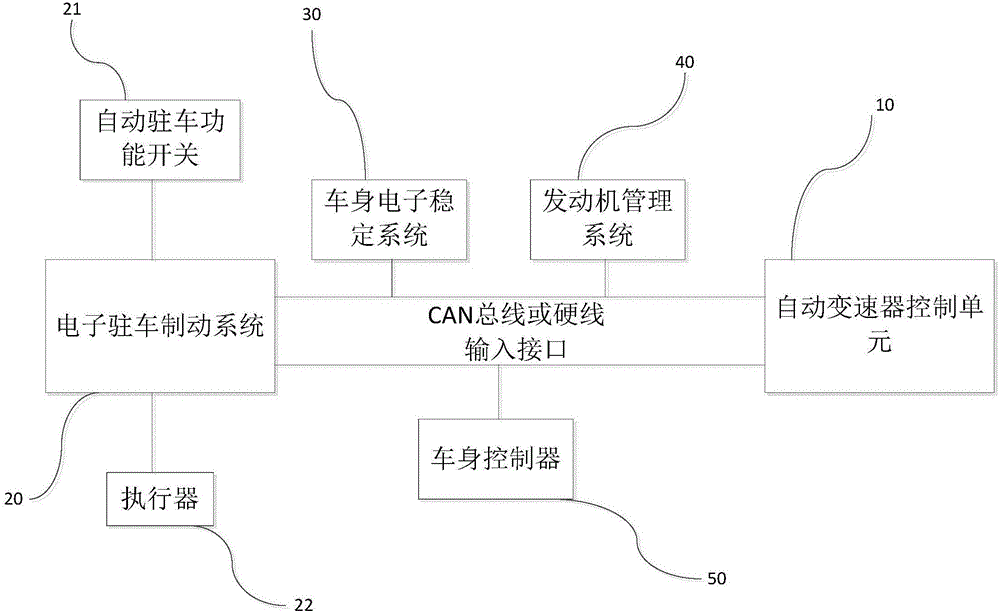

Neutral gear control method for automatic transmission

ActiveCN106195259AReduce fuel consumptionPrevent rolling phenomenonGearing controlDriver input parametersAutomatic transmissionPressure threshold

The invention provides a neutral gear control method for an automatic transmission. The method comprises the following steps that when the neutral gear control function of the automatic transmission is in an activated state, an automatic transmission control unit collects the information including the pressure of a braking main cylinder, the state of a braking pedal and whether the automatic parking function is in the activated state or not. When the pressure of the braking main cylinder is smaller than the pressure threshold value P3 of the neutral gear control function and the automatic parking function is in a non-activated state or when the braking pedal is in a non-stepped state and the automatic parking function is in the non-activated state, the automatic transmission control unit controls the neutral gear control function to retreat from the activated state.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD +1

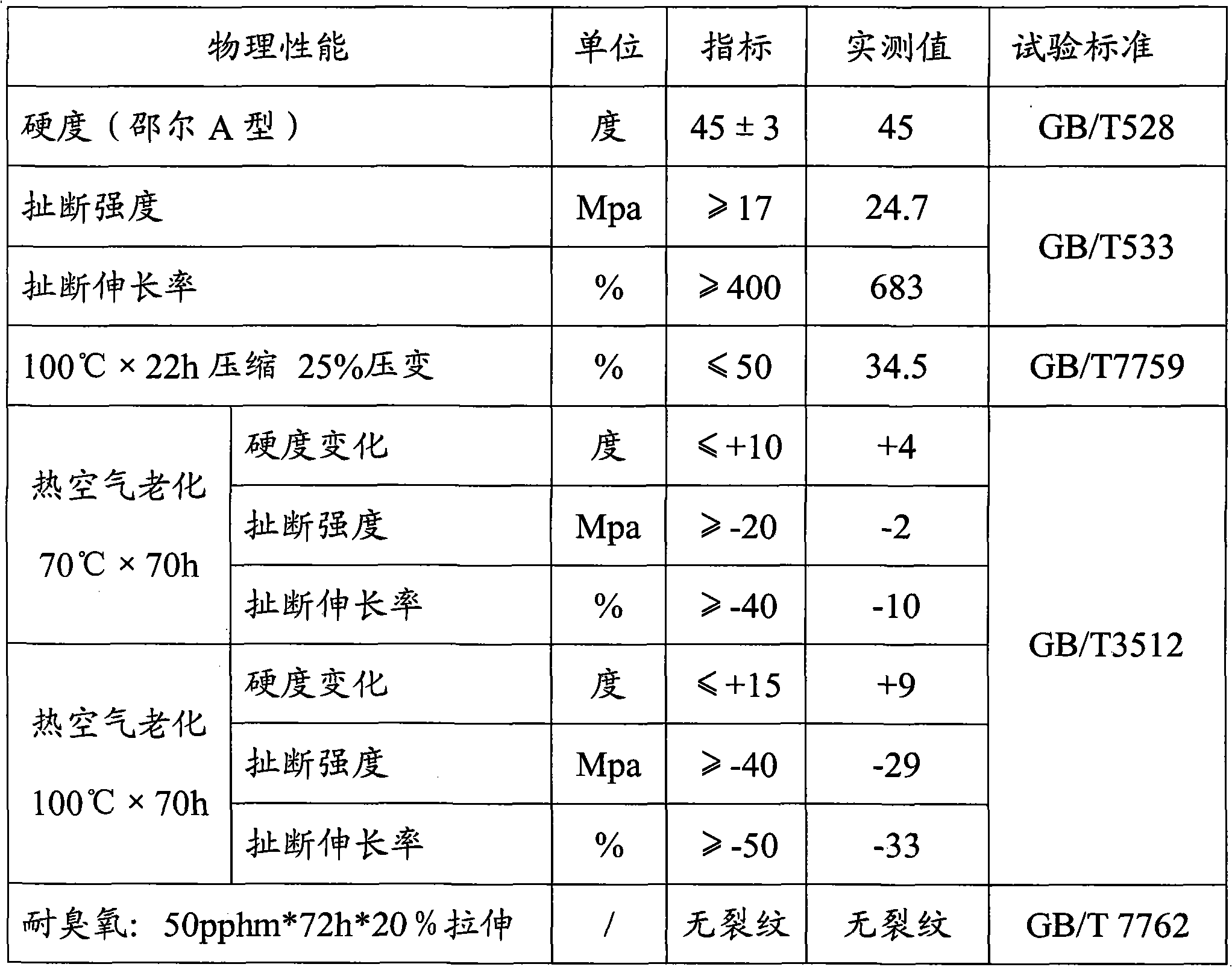

Engine mounting heat-resisting material and preparation method thereof

The invention discloses an engine mounting heat-resisting material and a preparation method thereof. The engine mounting heat-resisting material comprises the following raw materials in parts by weight: 70 to 80 parts of standard natural rubbers, 10 to 20 parts of butadiene rubbers, 5 to 10 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of 2,2,4-trimethyl-1,2-dihydro-chinoline polymers, 1 to 2 parts of N-isopropyl-N-phenylene diamine, 1 to 3 parts of composite paraffin, 25 to 40 parts of carbon black, 3 to 6 parts of complex calcium salt, 5 to 8 parts of white carbon black, 1to 3 parts of silane coupling agent, 1 to 2 parts of sulphur, 1 to 3 parts of zinc diethyl dithiocarbamate, and 1 to 3 parts of N-Cyclohexyl-2-benzothiazole. In the invention, an engine mounting material with good heat-resisting performance is prepared through a special refining process, has long service life and saves the using cost.

Owner:ASIMCO NVH TECH CO LTD ANHUI

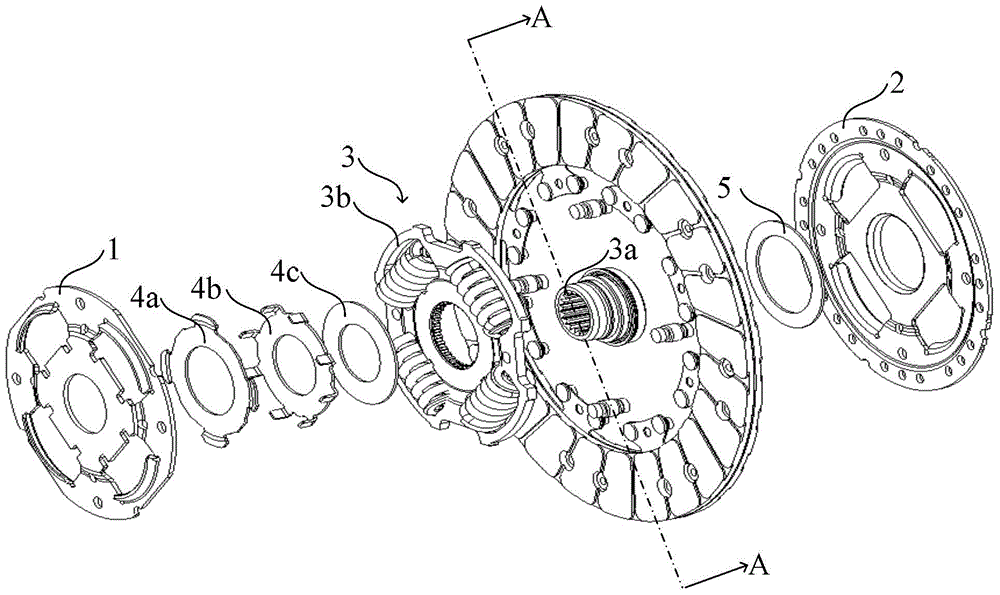

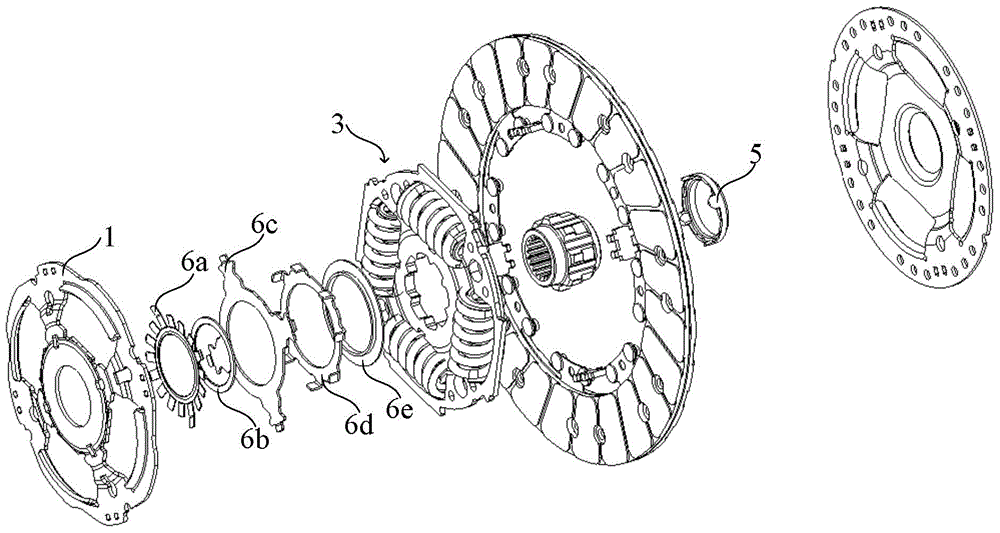

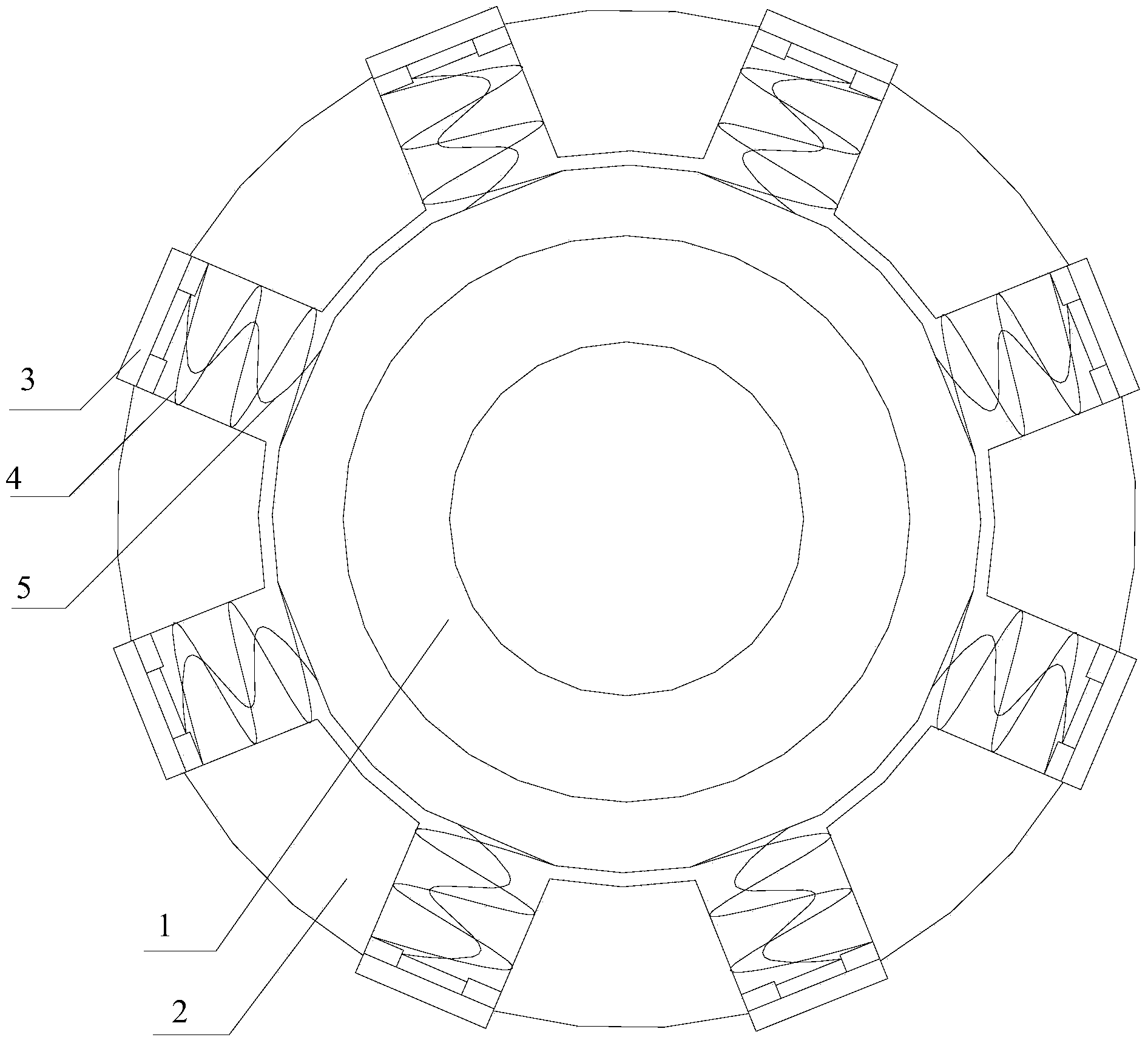

Damping fin applied to clutch driven disc, clutch driven disc and clutch

ActiveCN104791392ASmall moment of inertiaSimple structureFriction clutchesCouplingsEngineeringMoment of inertia

The invention discloses a damping fin applied to a clutch driven disc, the clutch driven disc and a clutch. The clutch driven disc comprises a shock absorbing disc; a driven disc body fixedly connected with the shock absorbing disc in a torsion resisting manner; a driven disc hub rotationally positioned between the shock absorbing disc and the driven disc body and having a disc hub core; two damping fins positioned between the shock absorbing disc and the driven disc hub, extruded with each other and covering the disc hub core, wherein one of the damping discs is fixedly connected with the shock absorbing disc in a torsion resisting manner, the other one of the damping discs is fixedly connected with the driven disc hub in a torsion resisting manner, and the damping fins are annular, and have two opposite annular surfaces; and at least one projection part capable of generating elastic deformation on the surface, wherein the projection part has a slope extending from the top to the bottom in the peripheral direction. The clutch driven disc can solve the problems of complex structure, high cost and large rotating inertia in traditional clutch driven discs.

Owner:SCHAEFFLER TECH AG & CO KG

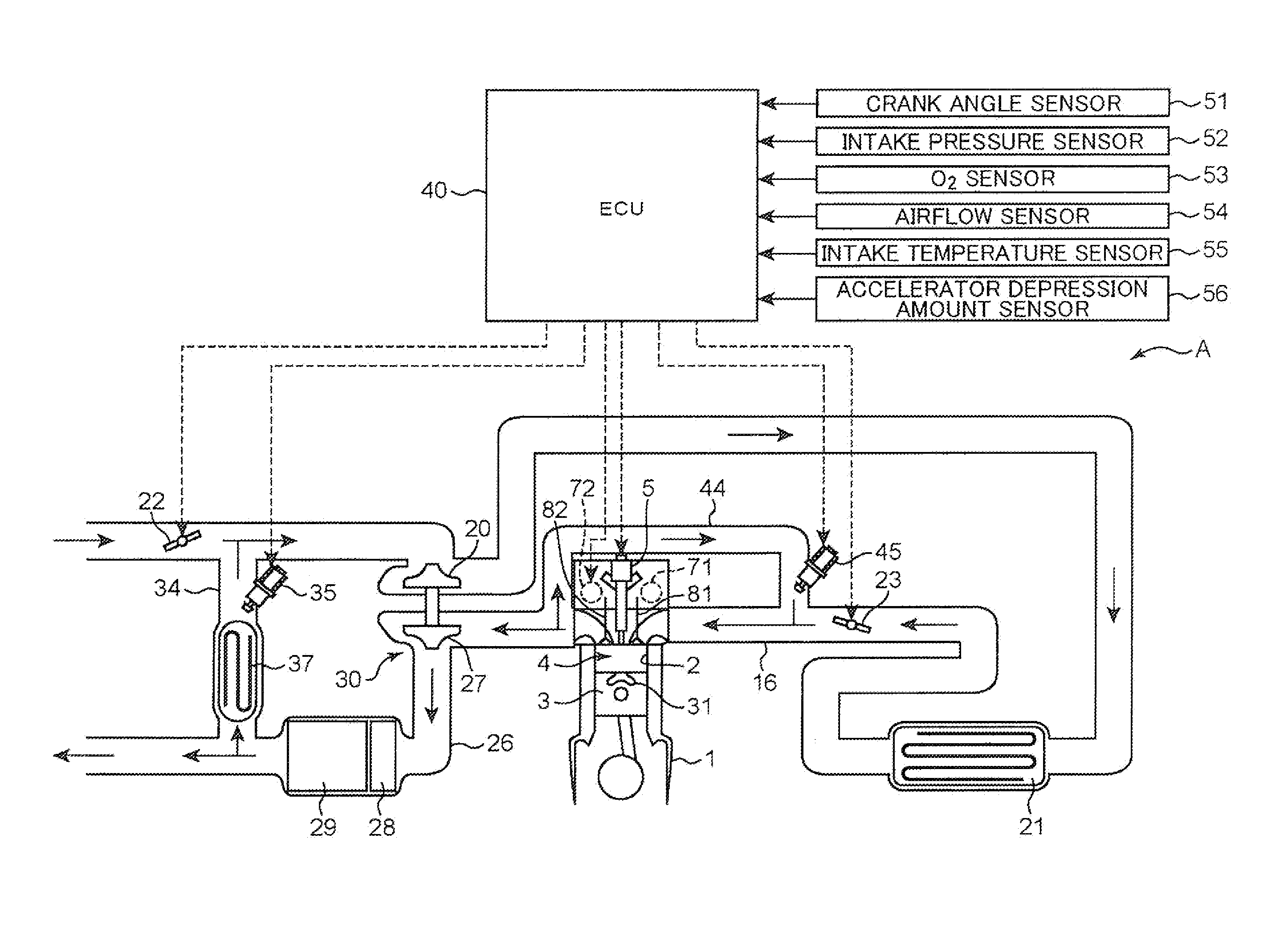

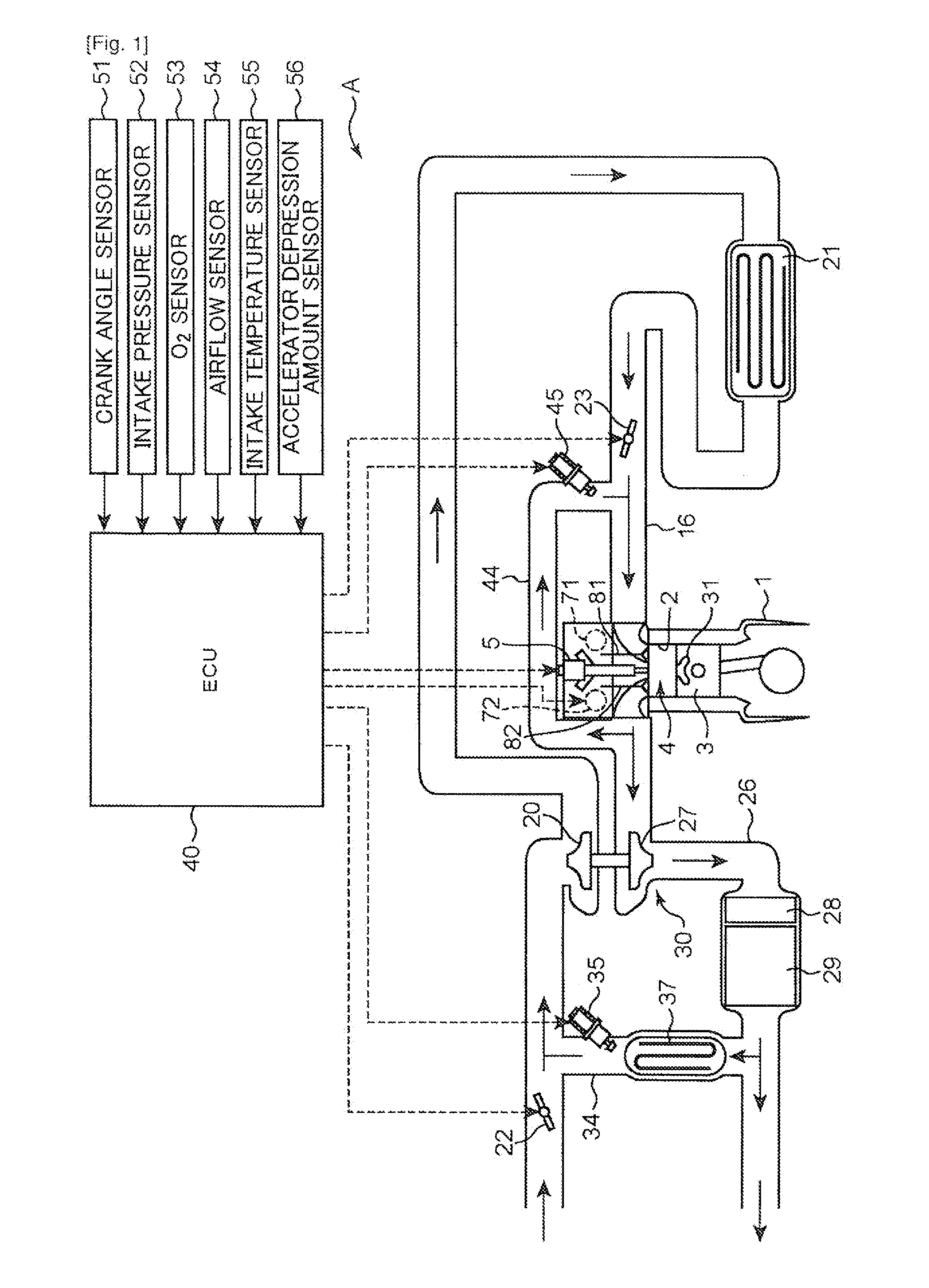

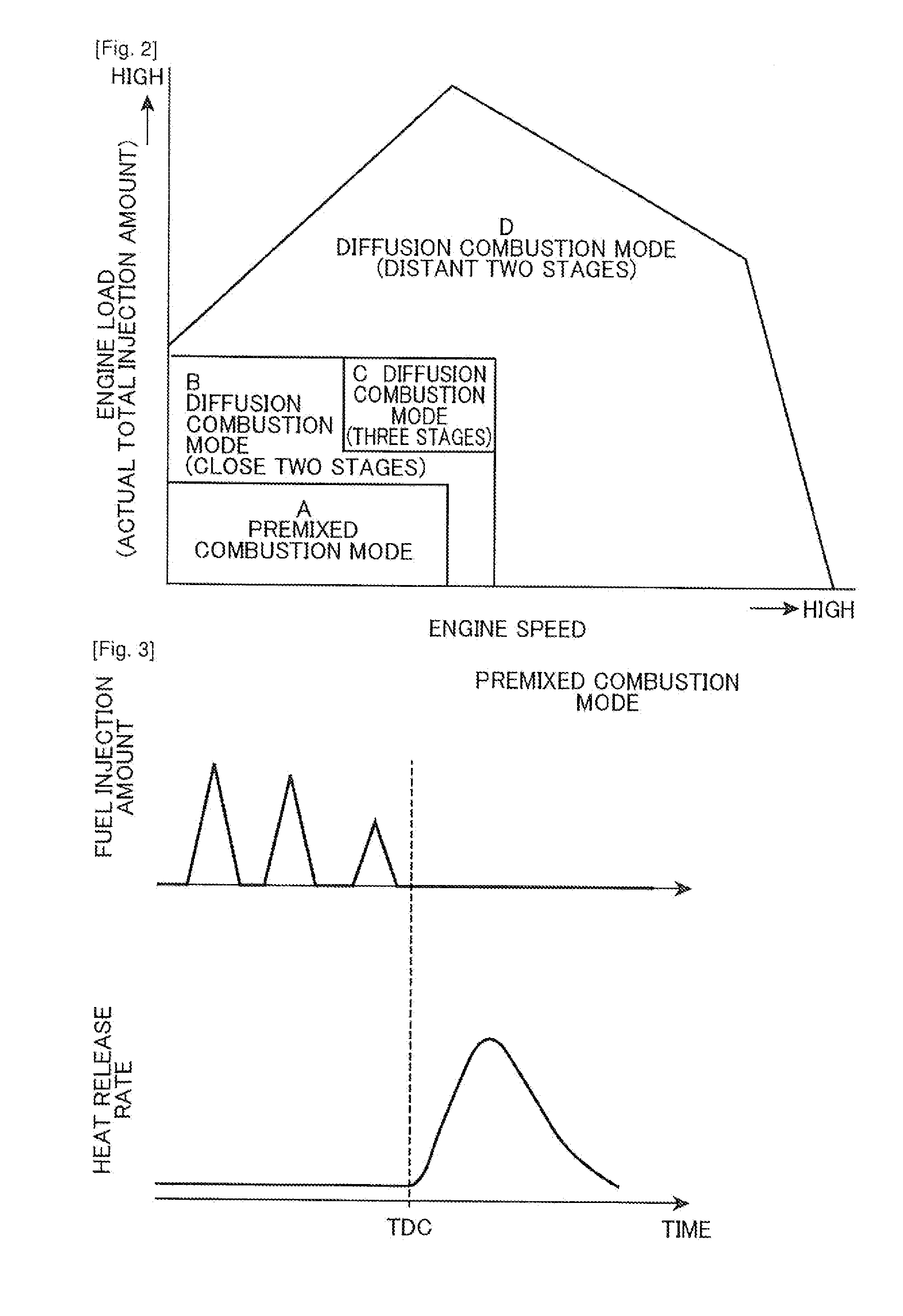

Diesel engine for automobile, control device and control method

ActiveUS20130073186A1Shorten ignition delaySlow down main combustionElectrical controlInternal combustion piston enginesLow speedTop dead center

A geometric compression ratio in an engine main body 1 is set to 15 or less. Injection control means (ECU 40) performs a main injection of injecting fuel near a compression top dead center, and a preceding injection prior to the main injection at a specific region of predetermined load within an operating region on a relatively low-speed side. The injection control means performs, as the preceding injection, a pilot injection of performing injection at a timing such that at least part of a fuel spray reaches outside a cavity 31 on a top face of a piston, and a pre-injection of injecting fuel at a predetermined timing after the pilot injection, to suppress thereby ignition of the fuel injected by the pilot injection and shorten an ignition delay of the fuel injected by the main injection.

Owner:MAZDA MOTOR CORP

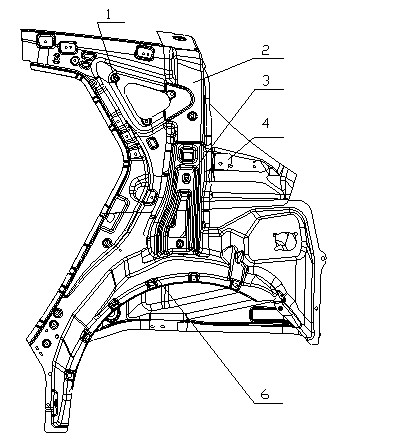

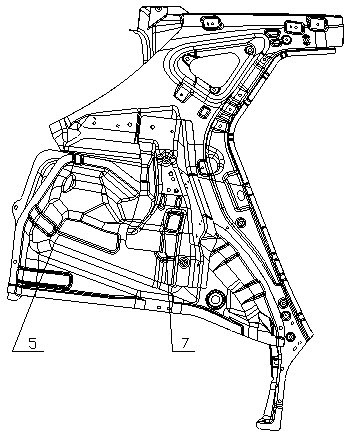

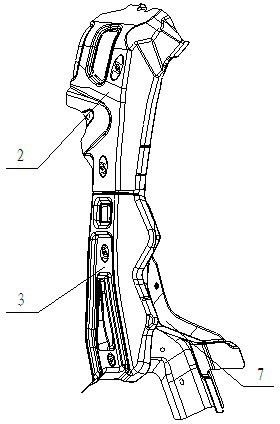

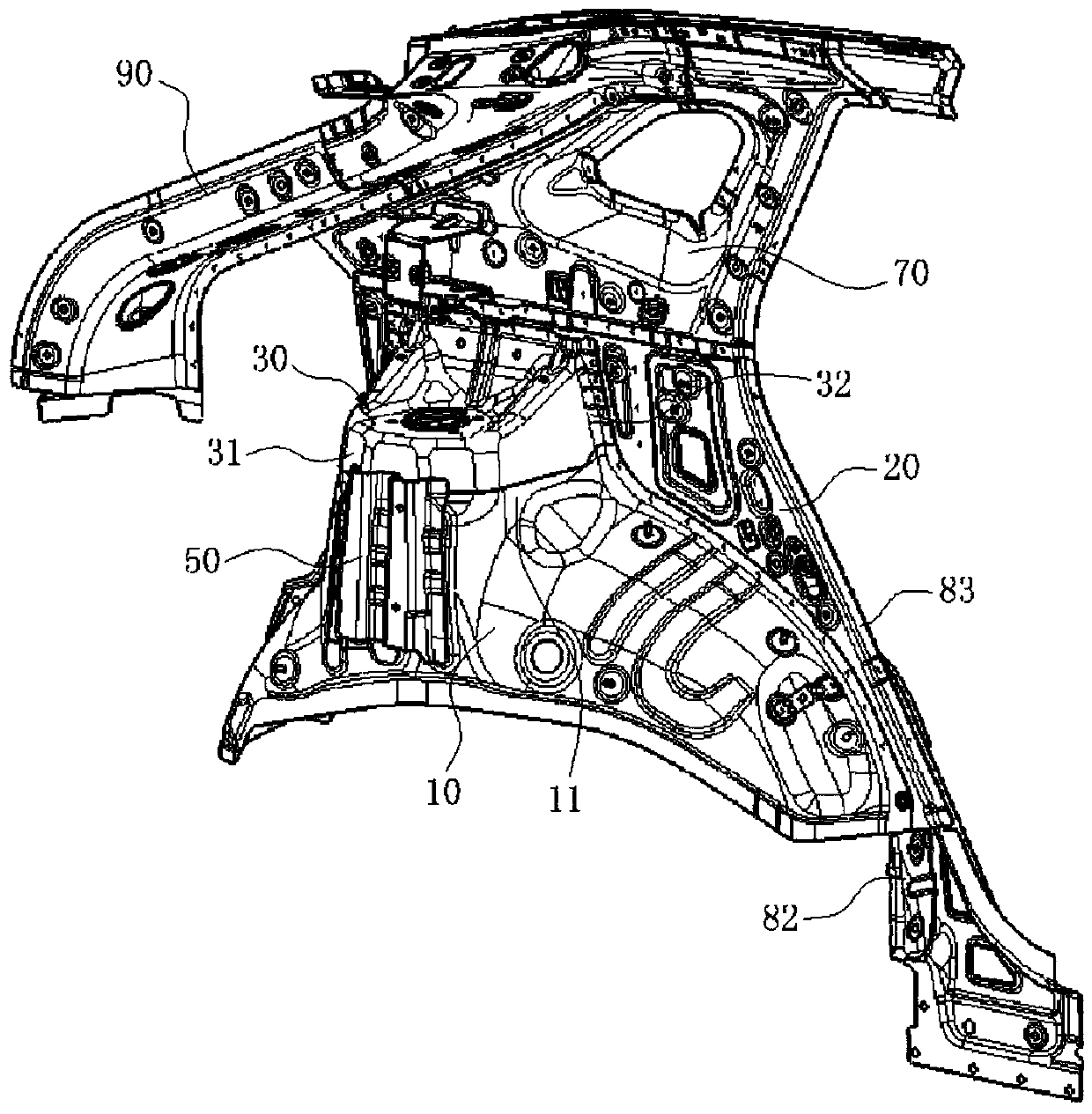

Automotive body rear side wall assembly structure

ActiveCN102424070AIncrease stiffnessAvoid stamping reboundSuperstructure subunitsAssembly structureEngineering

The invention relates to an automotive body rear side wall assembly structure, comprising a rear side wall inner skin, a rear wheel inner bulge, a rear wheel outer bulge and a rear safety belt retractor mounting support reinforcing plate as well as a rear side wall inner skin upper reinforcing plate, a rear side wall inner skin lower reinforcing plate and a rear side wall reinforcement. The automotive body rear side wall assembly structure provided by the invention has the technical effects that the phenomenon that clearance between triangle window glass and the side wall outer skin is excessive after the triangle window glass is mounted can be avoided, local modal stiffness and torsional stiffness of a rear side wall are improved; mounting point stiffness of the safety belt retractor on the side wall inner skin is improved; and riding comfortableness is improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

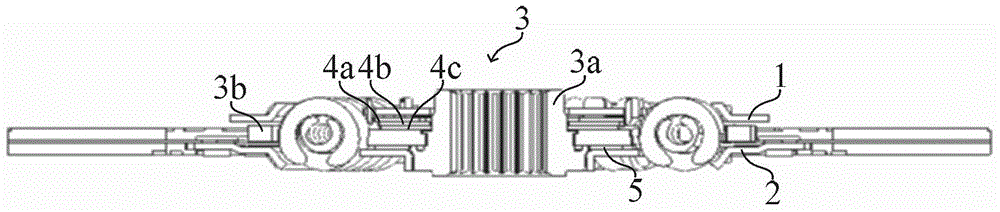

Transmission shaft vibration absorber

ActiveCN103821874AVibration frequency controlFlexible adjustment of screw-in amountRotating vibration suppressionDrive shaftEngineering

Owner:GREAT WALL MOTOR CO LTD

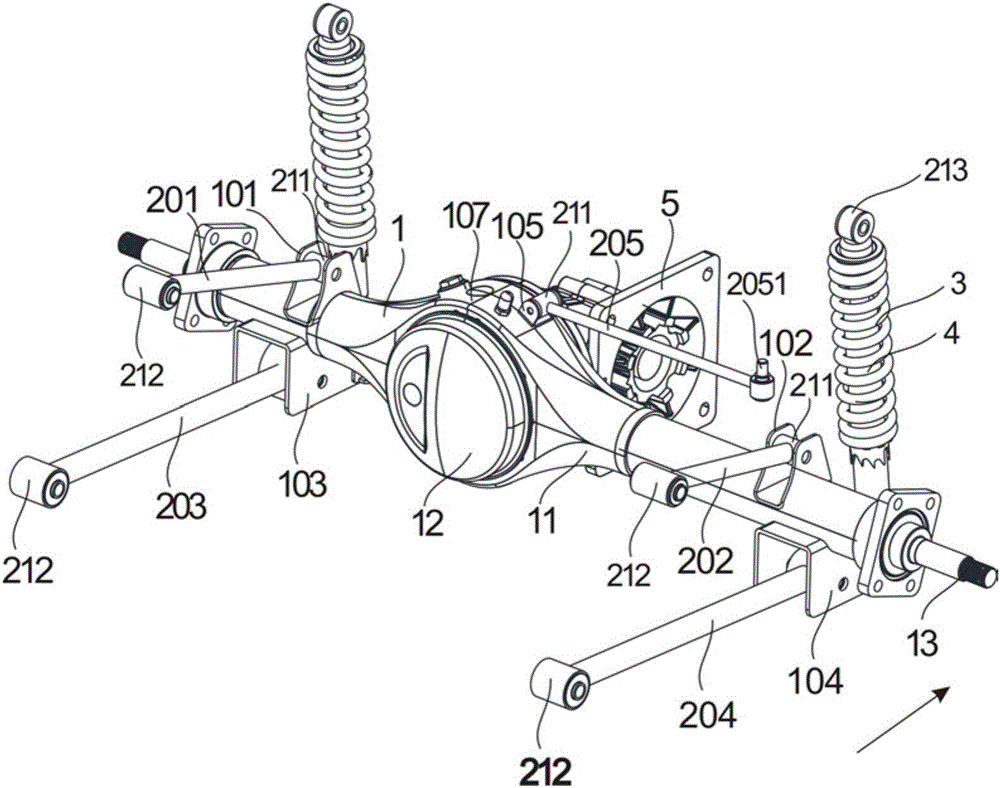

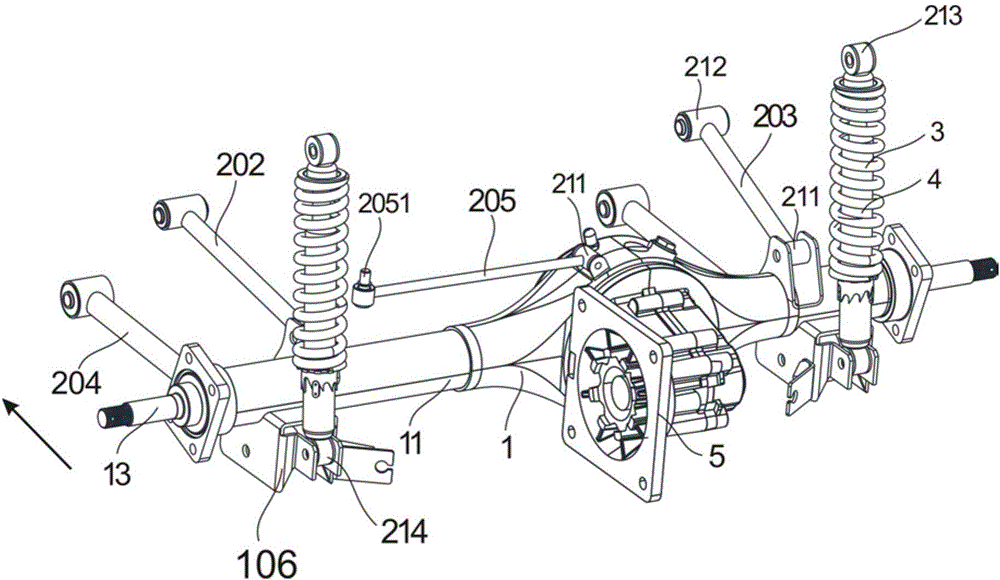

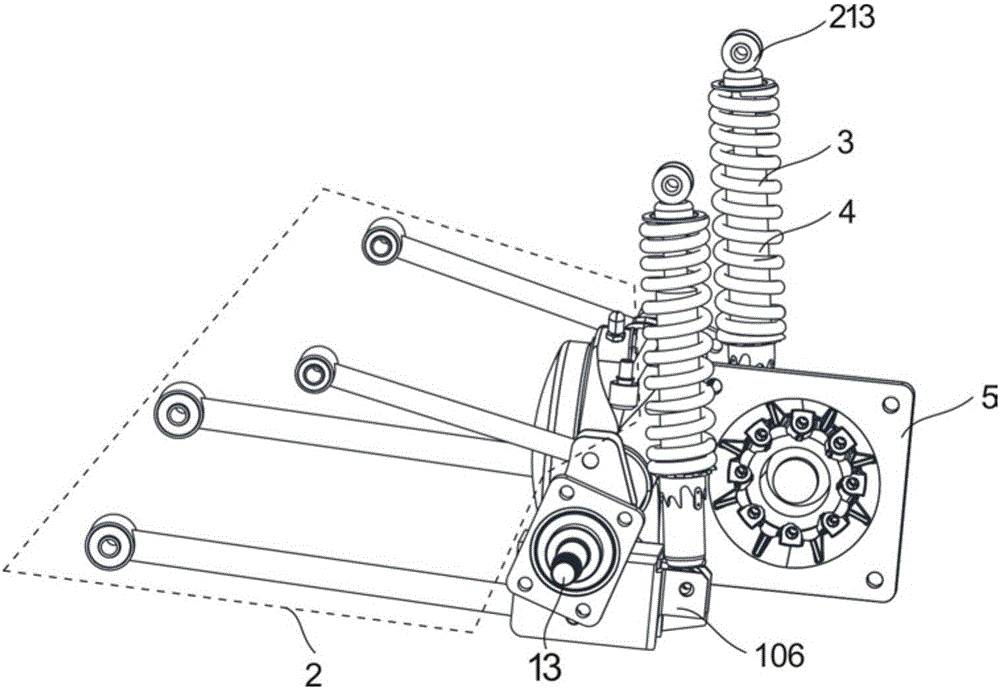

Automobile rear motor type connecting rod integrated rear axle suspension

InactiveCN105128620AImprove riding performanceSmoothness does not affectResilient suspensionsTransverse forceSprung mass

The invention provides an automobile rear motor type connecting rod integrated rear axle suspension comprising an integrated rear axle shell body. A guide mechanism is arranged on the integrated rear axle shell body. The integrated rear axle shell body includes an axle shell, a cover body, and axle shaft sleeves arranged at the two ends of the axle shell and connected with wheels. The guide mechanism includes a longitudinal connecting rod mechanism arranged on the side walls of the two ends of the axle shell and a transverse connecting rod mechanism arranged on the upper end of the axle shell. The automobile rear motor type connecting rod integrated rear axle suspension further comprises shock absorbers which are longitudinally arranged at the two sides of the axle shell, and elastic elements which sleeve the shock absorbers respectively. The shock absorbers are disposed at the back of the guide mechanism. According to the invention, the longitudinal and transverse connecting rods of the guide mechanism bear the longitudinal force and transverse force in the running process of an automobile body, and the elastic elements and the shock absorbers jointly bear vertical load. Therefore, the dynamic unsprung mass is reduced, the dynamic sprung mass is increased, kinetic energy is released effectively, and the smoothness and comfort of a whole automobile are improved.

Owner:SHANGHAI FUEL CELL VEHICLE POWERTRAIN

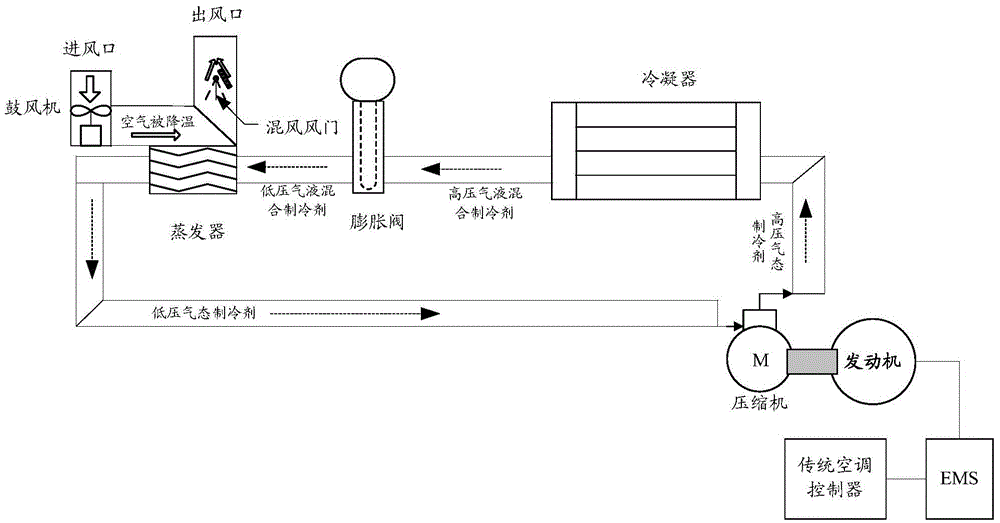

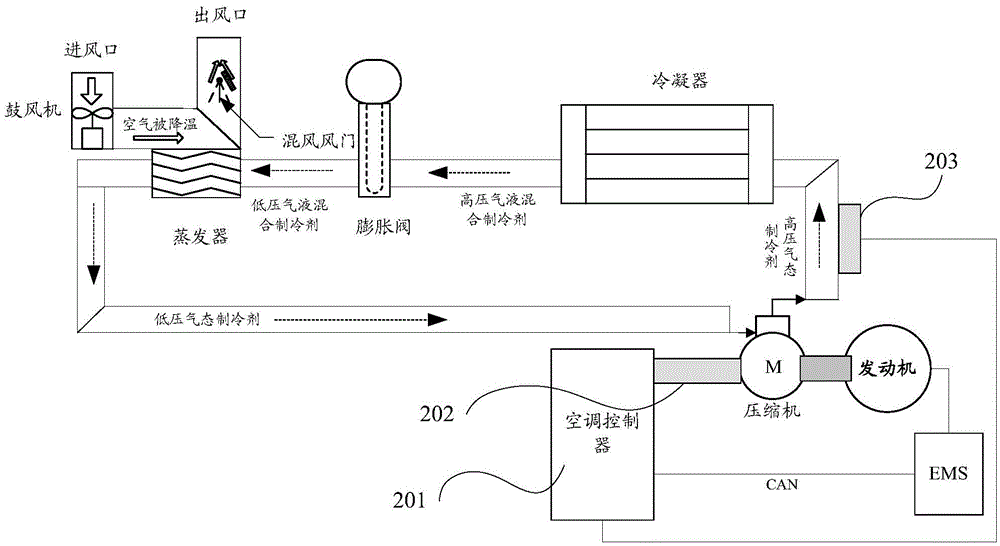

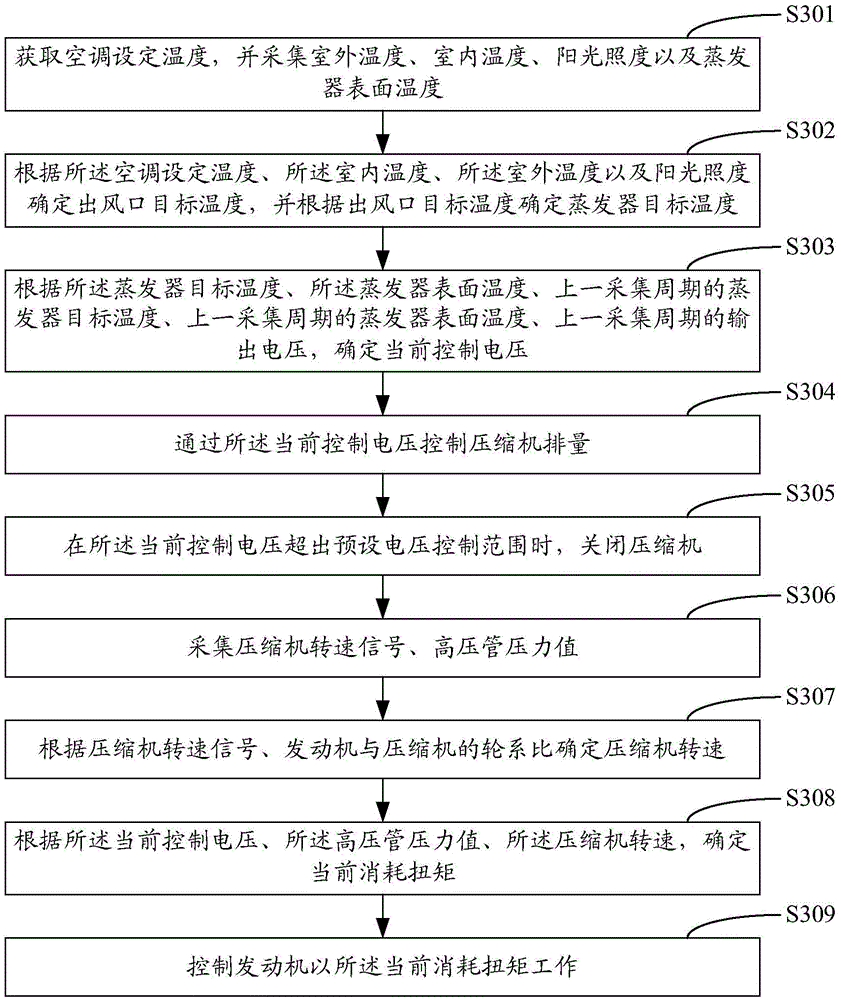

Air conditioner control method, device and system and air conditioner controller

ActiveCN105627521APrecise temperature controlRealize automatic controlMechanical apparatusSpace heating and ventilation safety systemsIlluminanceAutomatic control

The invention discloses an air conditioner control method, device and system and a controller. The air conditioner control method comprises the steps that the set temperature of an air conditioner is obtained, and the outdoor temperature, the indoor temperature, the sunlight illuminance and the surface temperature of an evaporator are acquired; the target temperature of an air outlet is determined according to the set temperature of the air conditioner, the indoor temperature, the outdoor temperature and the sunlight illuminance, and the target temperature of the evaporator is determined according to the target temperature of the air outlet; the current control voltage is determined according to the target temperature of the evaporator, the surface temperature of the evaporator, the target temperature, obtained in the previous acquisition cycle, of the evaporator, the surface temperature, obtained in the previous acquisition cycle, of the evaporator, and the output voltage obtained in the previous acquisition cycle; and the discharge rate of a compressor is controlled according to the current control voltage. According to the air conditioner control method, device and system and the controller, automatic control over the displacement of the compressor is achieved, the control accuracy of the surface temperature of the evaporator is improved, the opening and closing frequency of a clutch is reduced, and the energy utilization rate is increased.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

CAE simulated prediction method of road vibration and noise of vehicle

InactiveCN106066921AAnalysis time aheadImprove NVH performanceDesign optimisation/simulationSpecial data processing applicationsKnucklePrediction methods

The invention aims at providing a CAE simulated prediction method of road vibration and noise of a vehicle, and the method can be used to analyze vibration and noise, caused by that the vehicle loads spindle load, excited by the road, provide convenience for rectification later and improve the NVH performance of the vehicle. The CAE simulated prediction method comprises the following steps that A) the acceleration of a knuckle of a sample vehicle is tested, and an acceleration signal matrix Ga of the knuckle is obtained; B) a finite element method or an experimental test method is used to obtain a transfer function Hs from the wheel center to the knuckle; C) according to the transfer function Hs from the wheel center to the knuckle and the acceleration signal matrix Ga of the knuckle, the spindle load Gf is calculated on the basis of a spindle load theoretical formula Gf=Hs+GaHs+H, wherein + represents pseudo-inverse, and H represents conjugate transposition; and D) an NVH finite element simulation model of the vehicle is established, the spindle load Gf is loaded in the wheel center of the finite element simulation model, and a vibration-noise curve in the vehicle is calculated.

Owner:CHERY AUTOMOBILE CO LTD

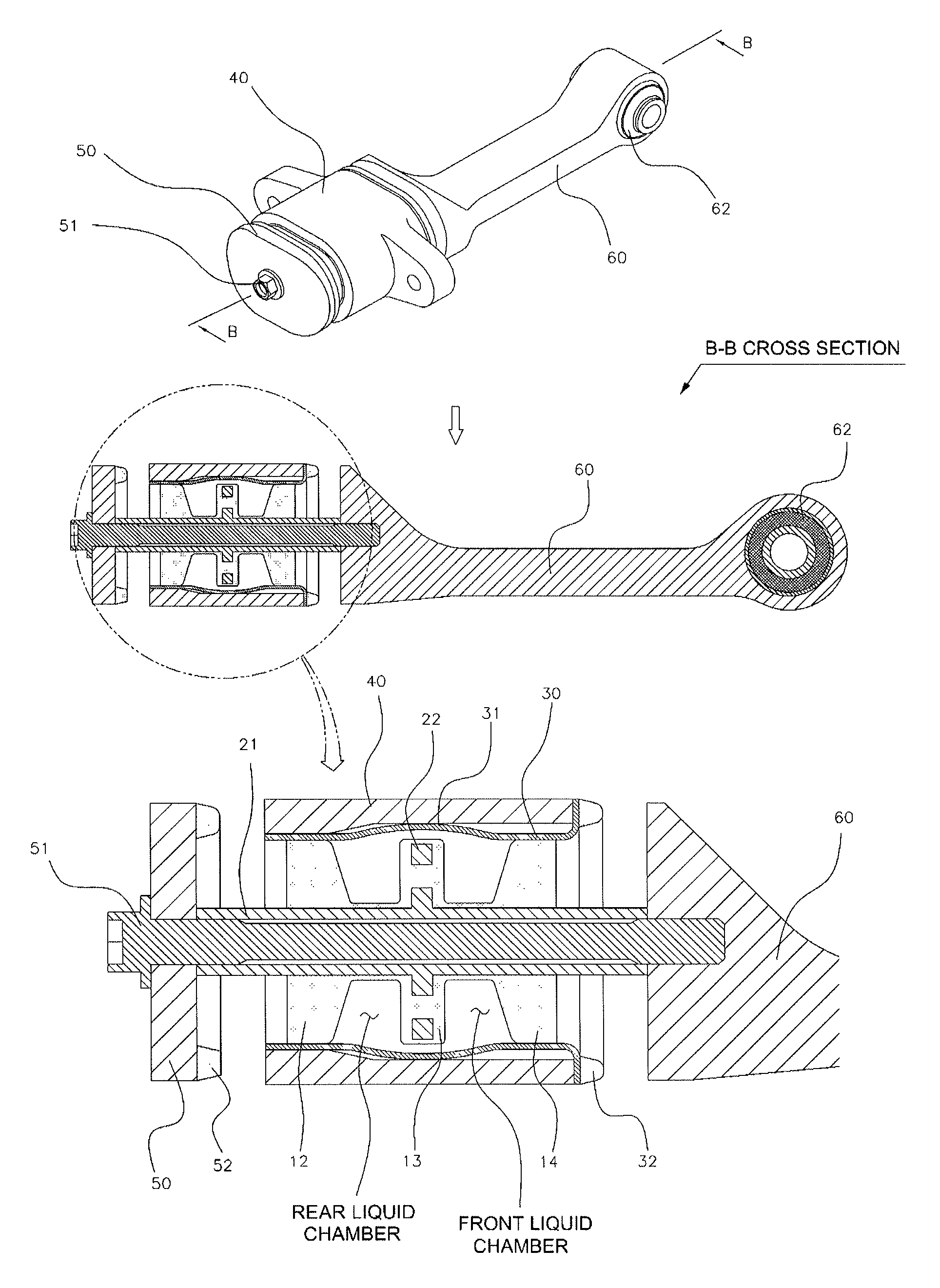

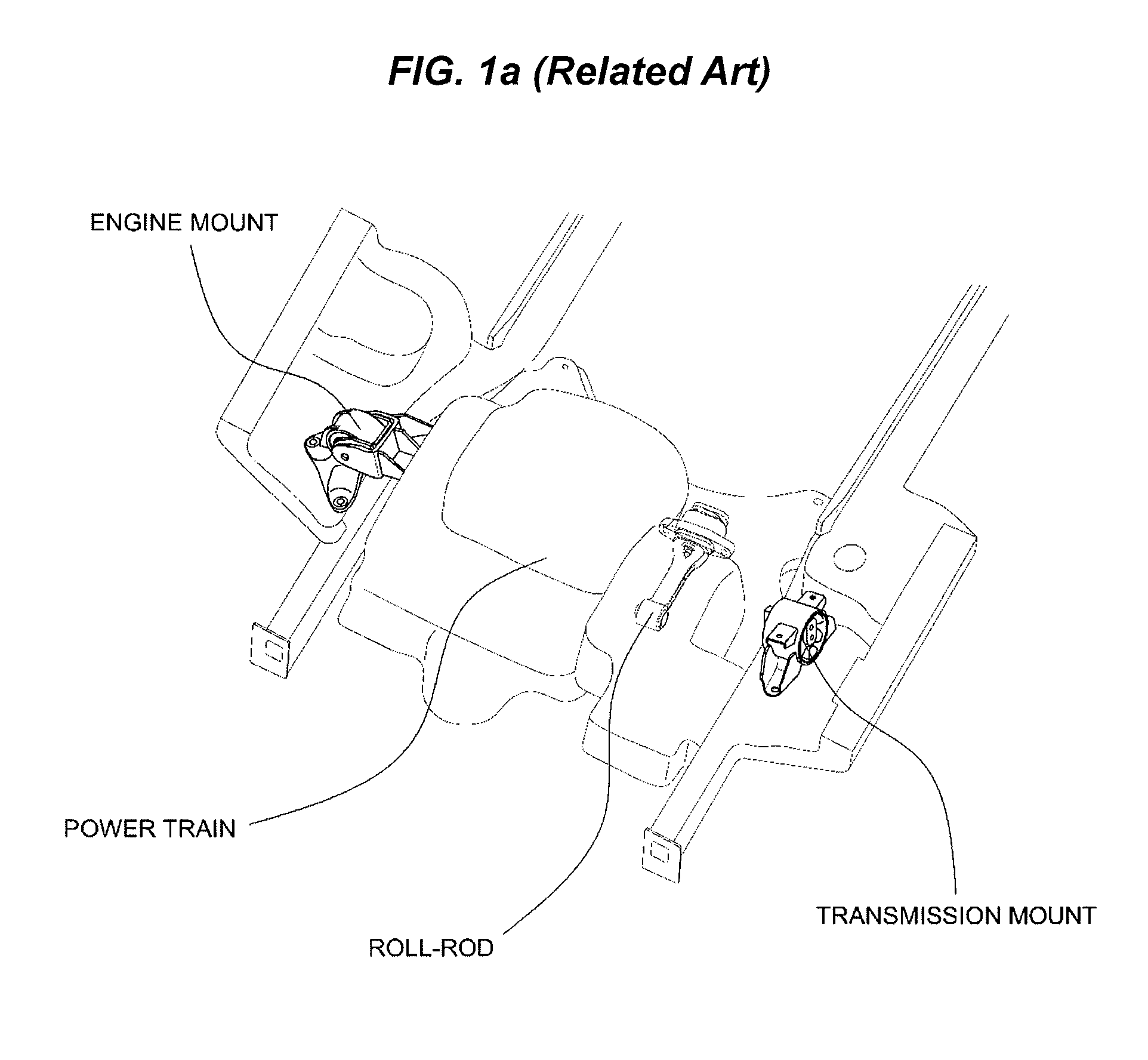

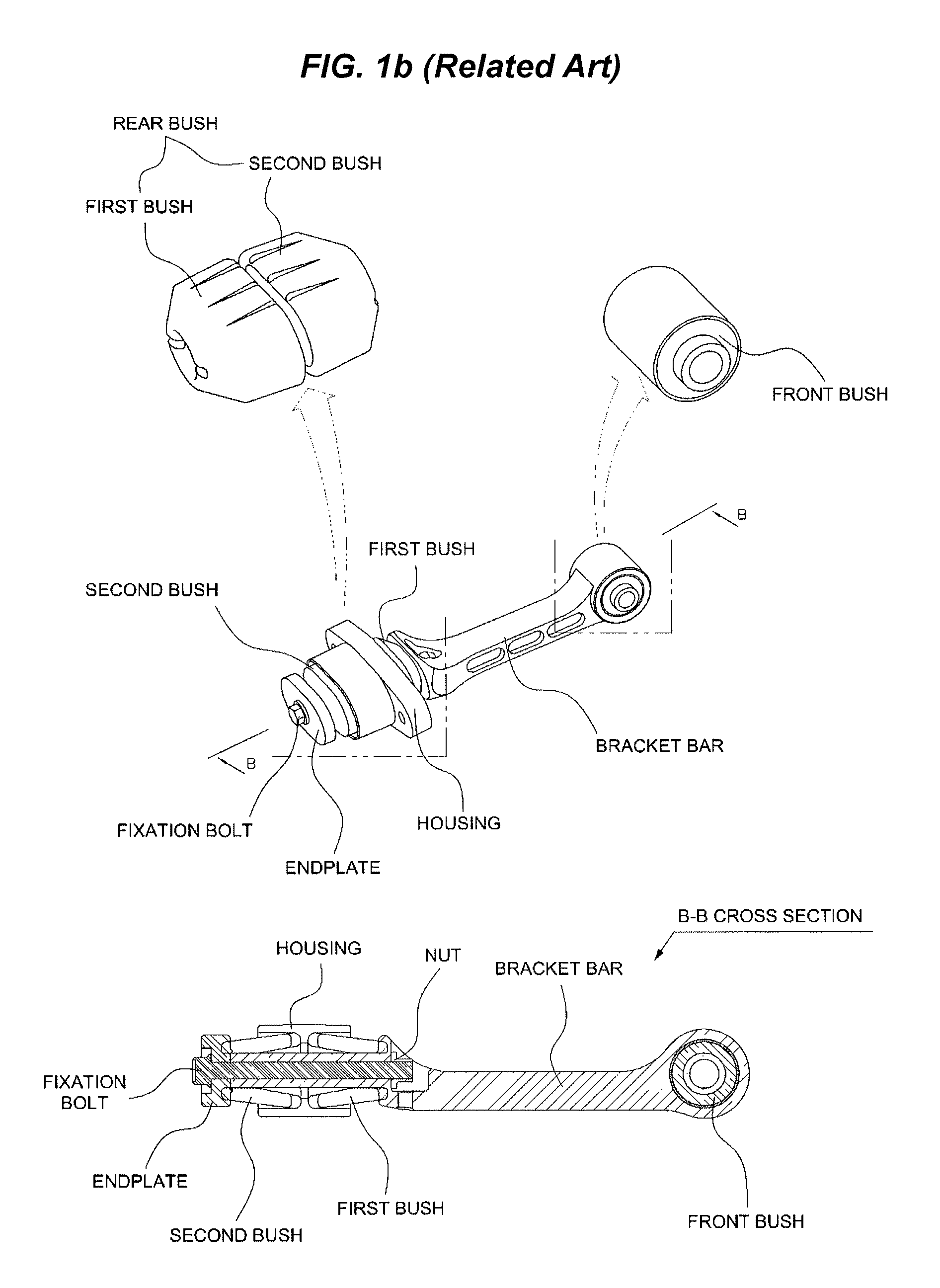

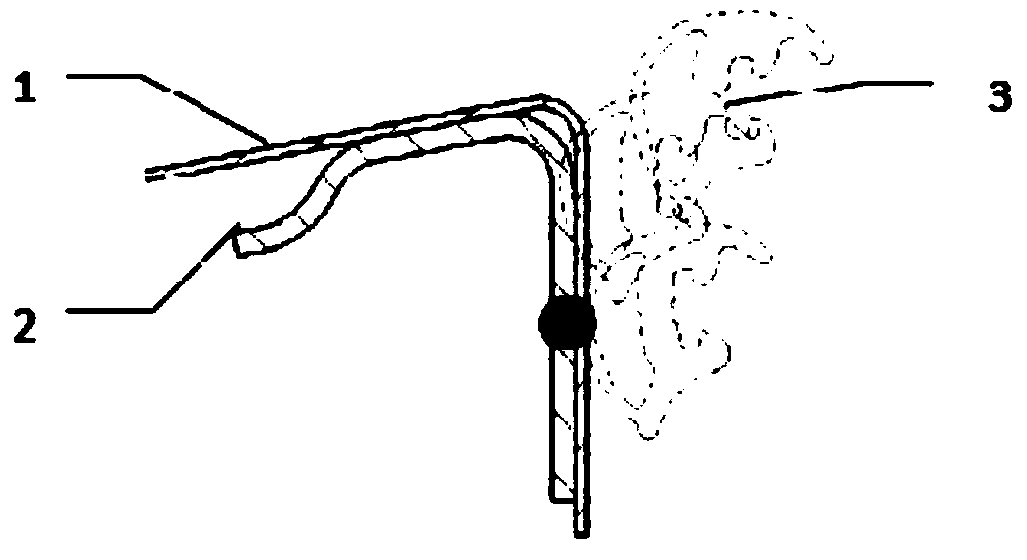

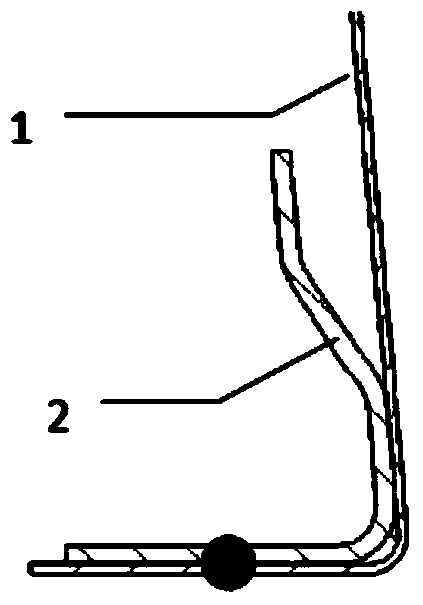

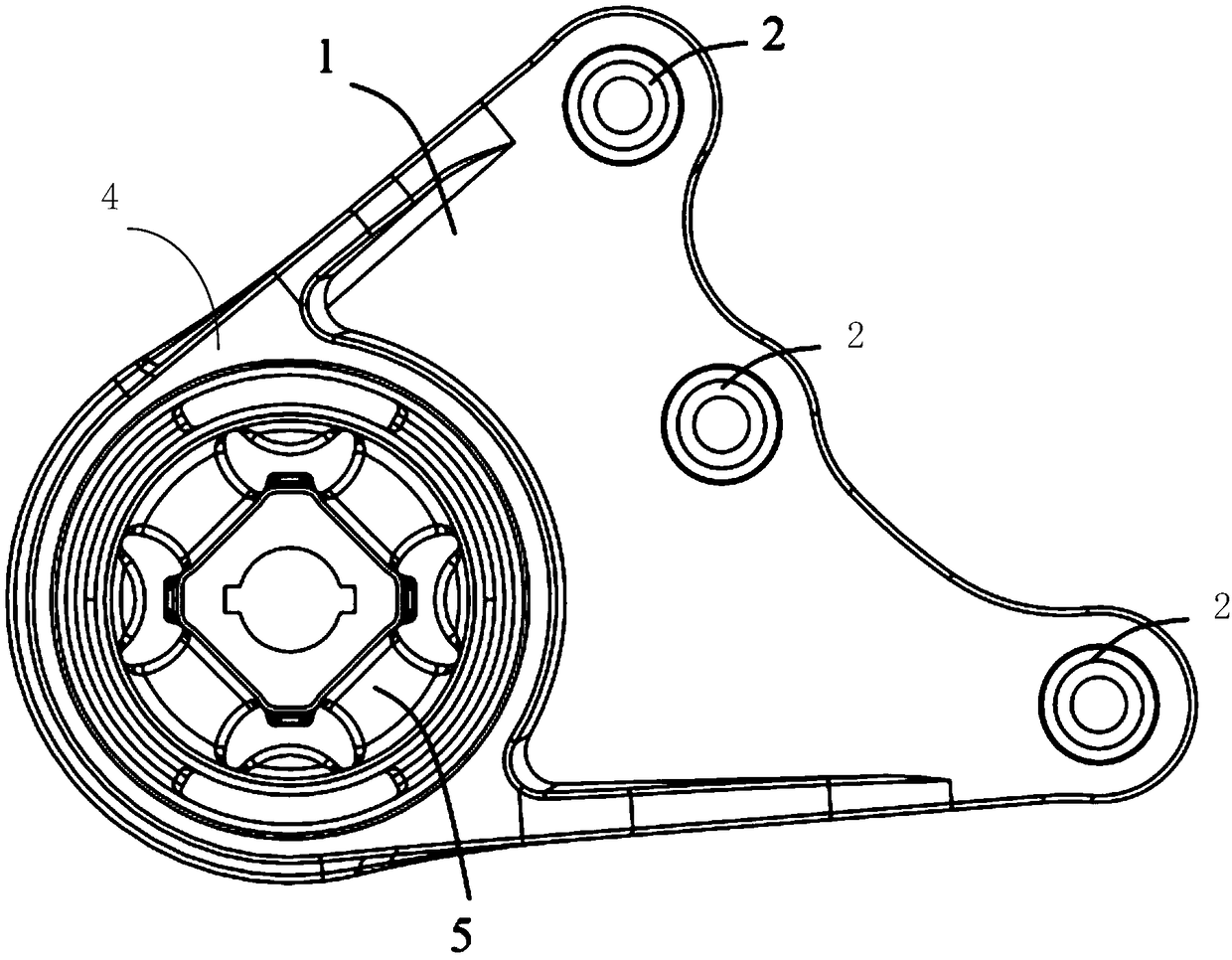

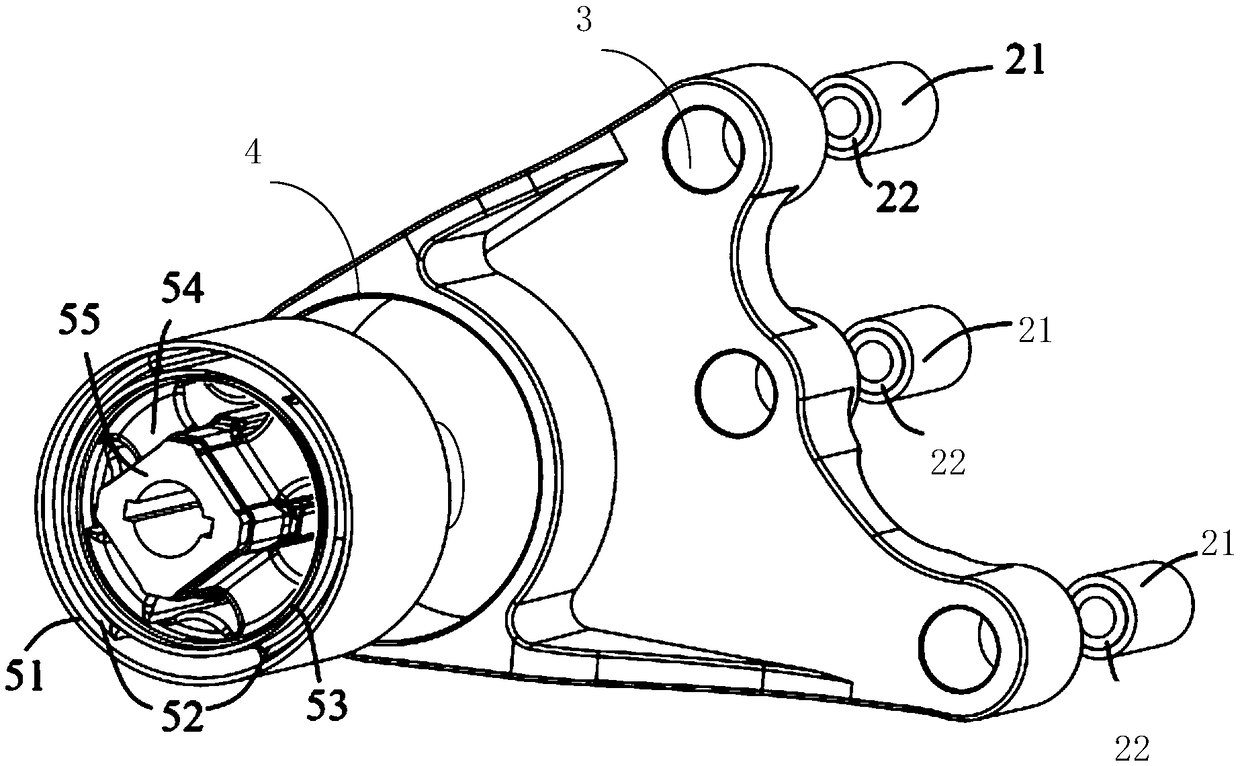

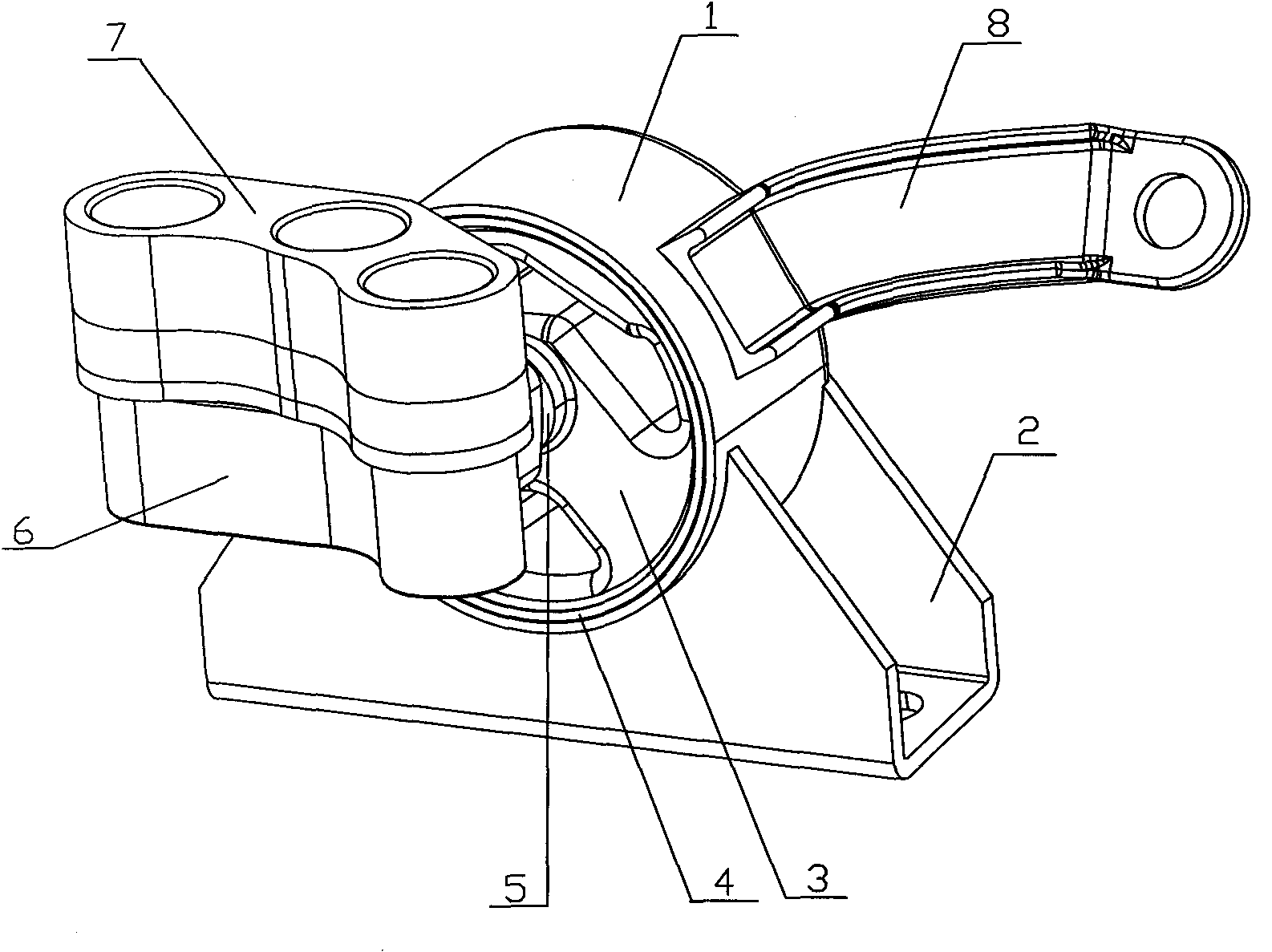

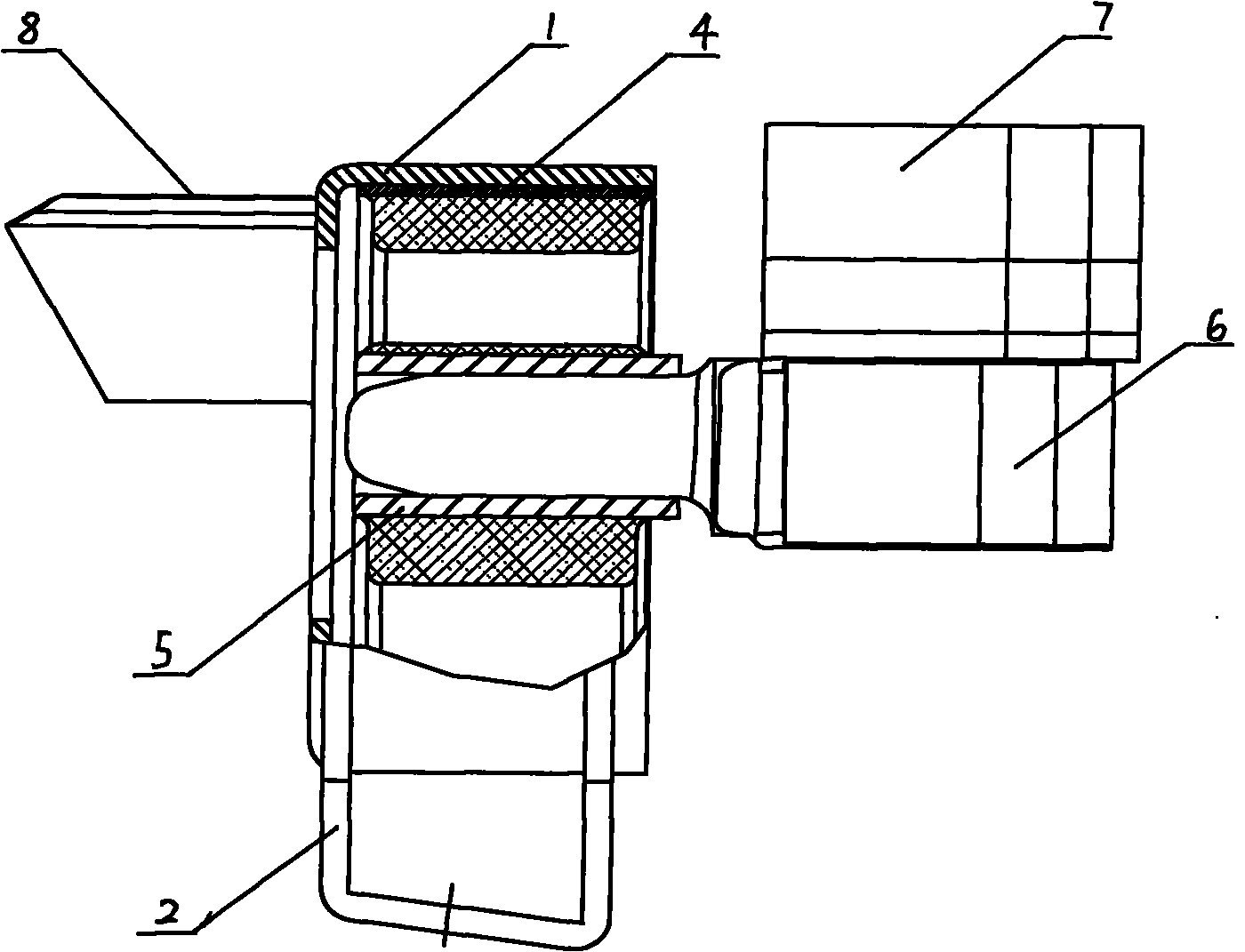

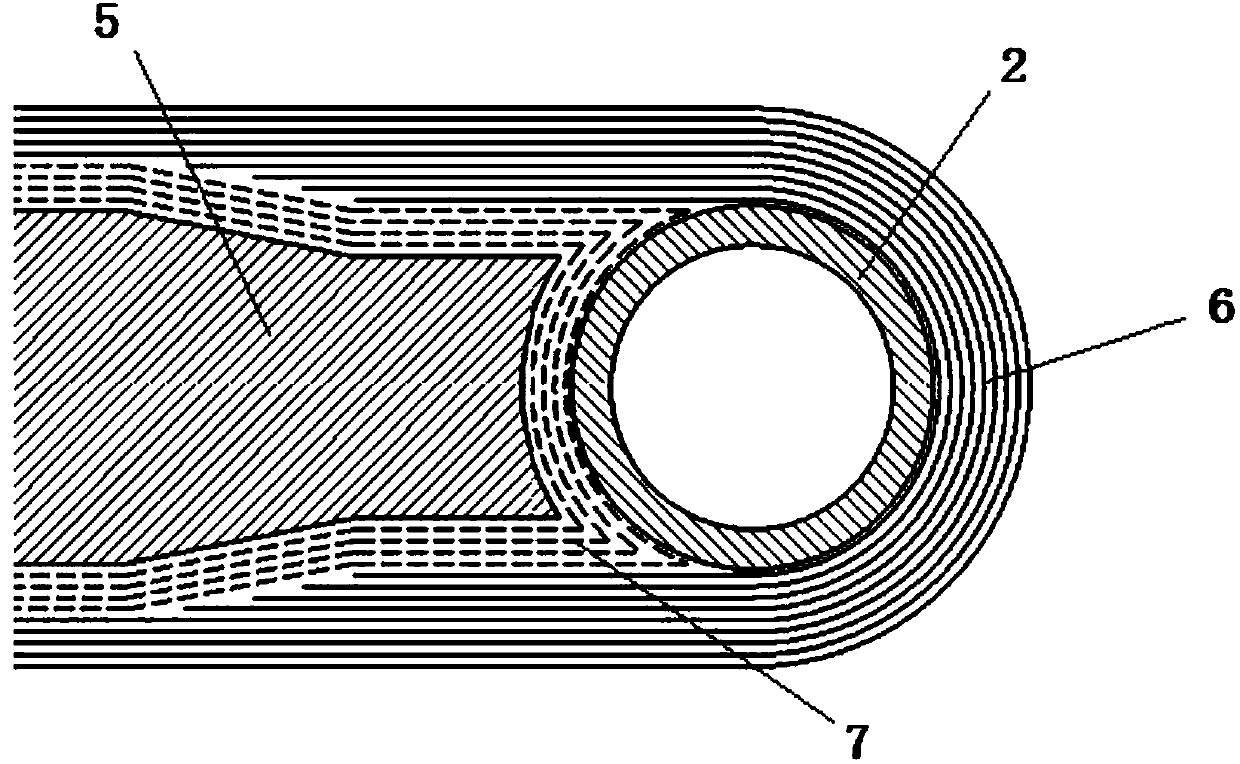

Structure of roll-rod for subframe

ActiveUS8839900B2Improve NVH performanceReduce ratePortable framesUnderstructuresVehicle frameCurve shape

A structure of a roll-rod for a subframe filled with a hydro liquid therein, may include a bracket bar, an inner pipe including a cylindrical pipe and a supporting plate joined with the cylindrical pipe, an endplate joined to the cylindrical pipe, an outer pipe enclosing the inner pipe between the bracket bar and the endplate and including an extension part, where the supporting plate may be disposed with a gap in the extension part having a curved shape, an insulator forming a front liquid chamber and a rear liquid chamber with the supporting plate to receive the hydro-liquid therein, and a housing, wherein the supporting plate may move relative to the outer pipe such that the gap varies while the insulator is elastically transformed according to movement of the bracket bar and the endplate.

Owner:HYUNDAI MOTOR CO LTD

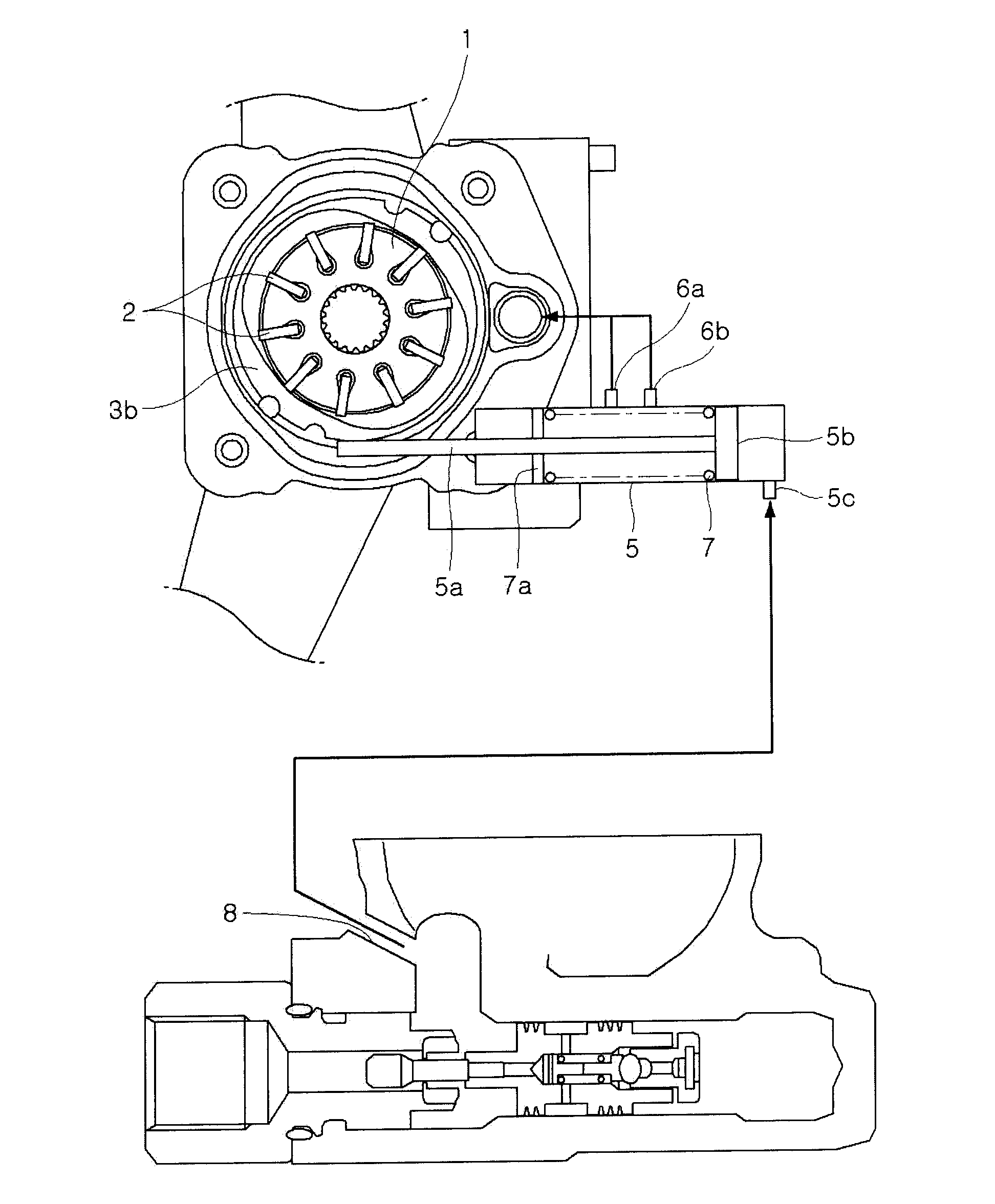

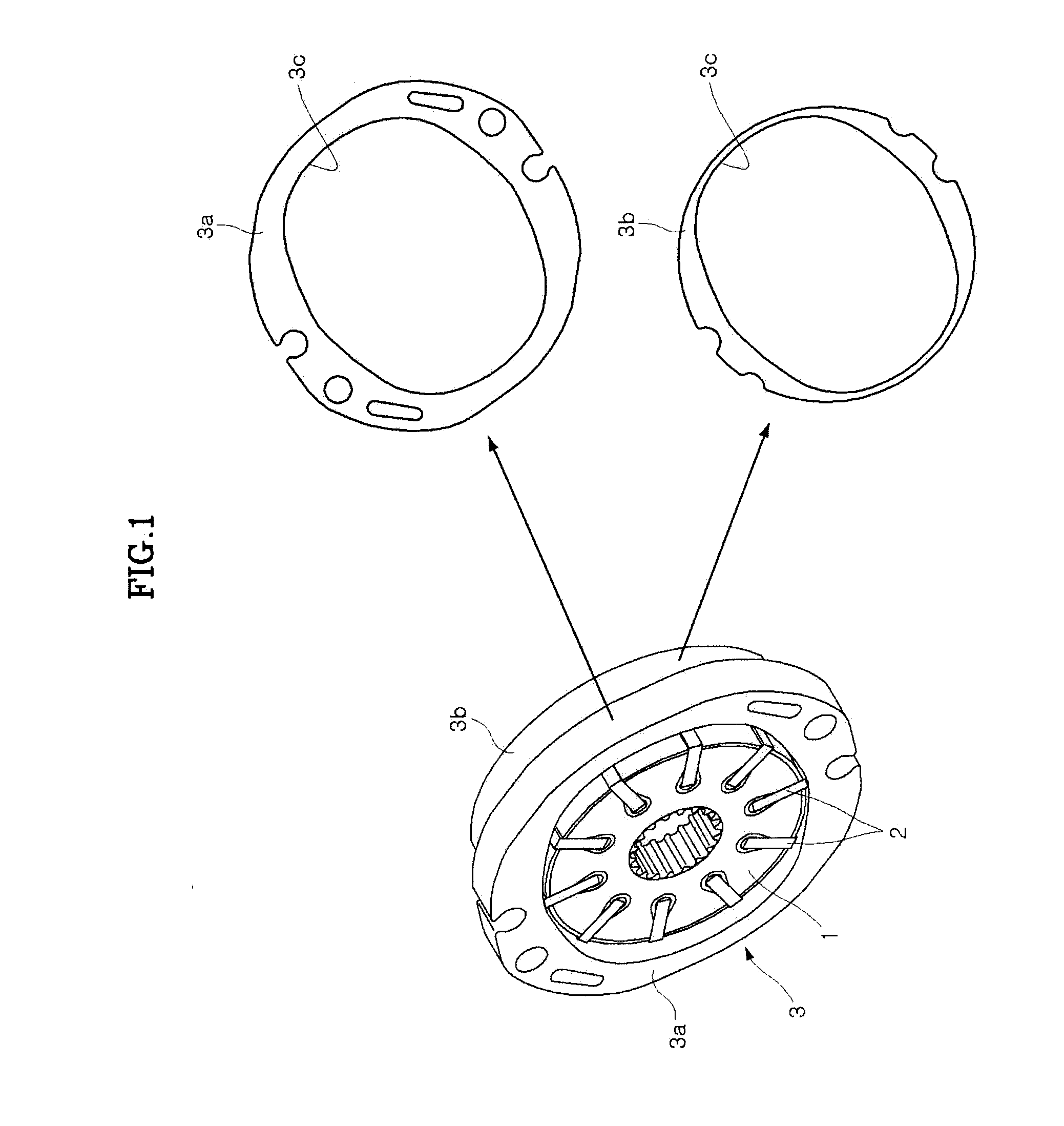

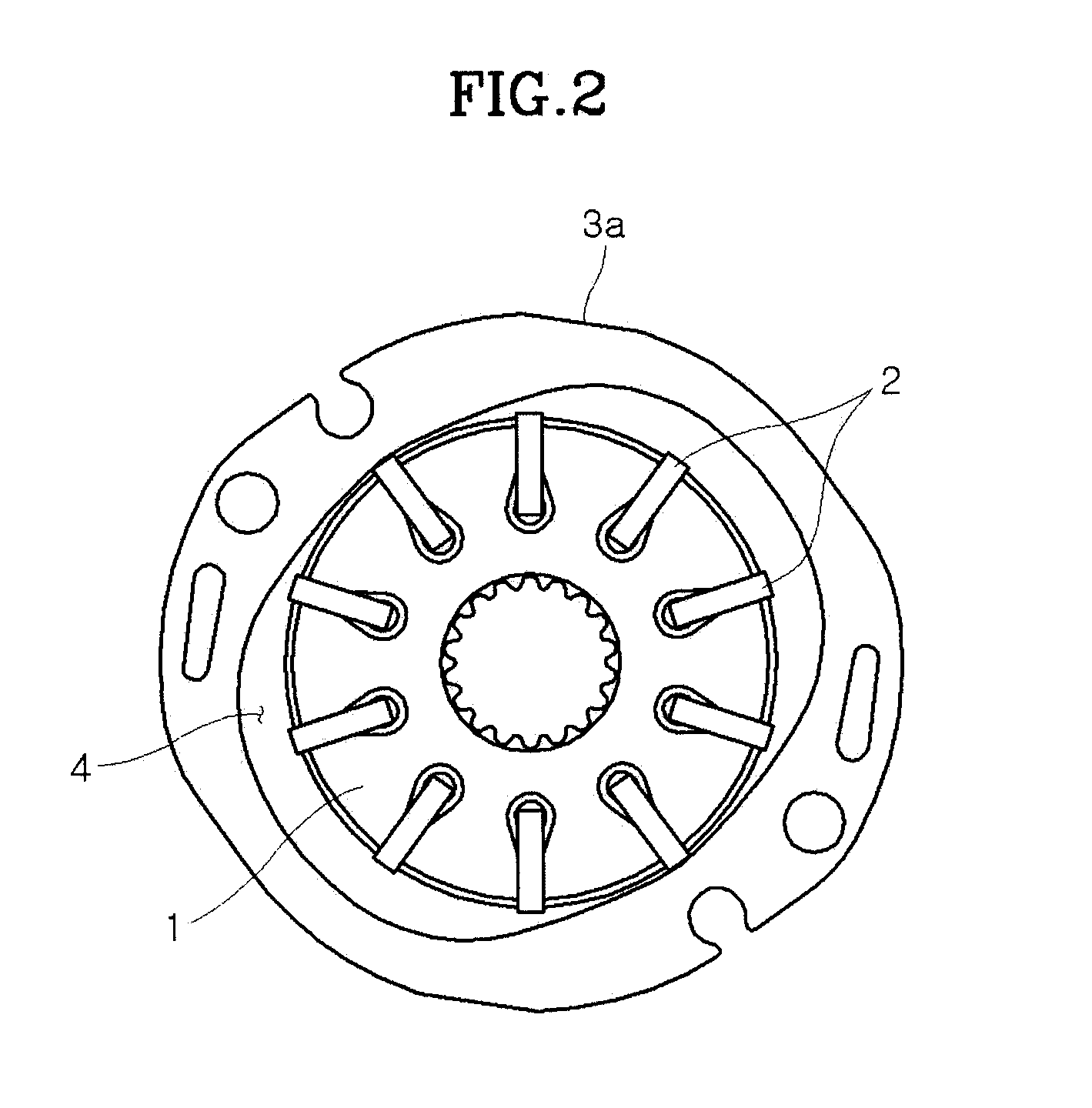

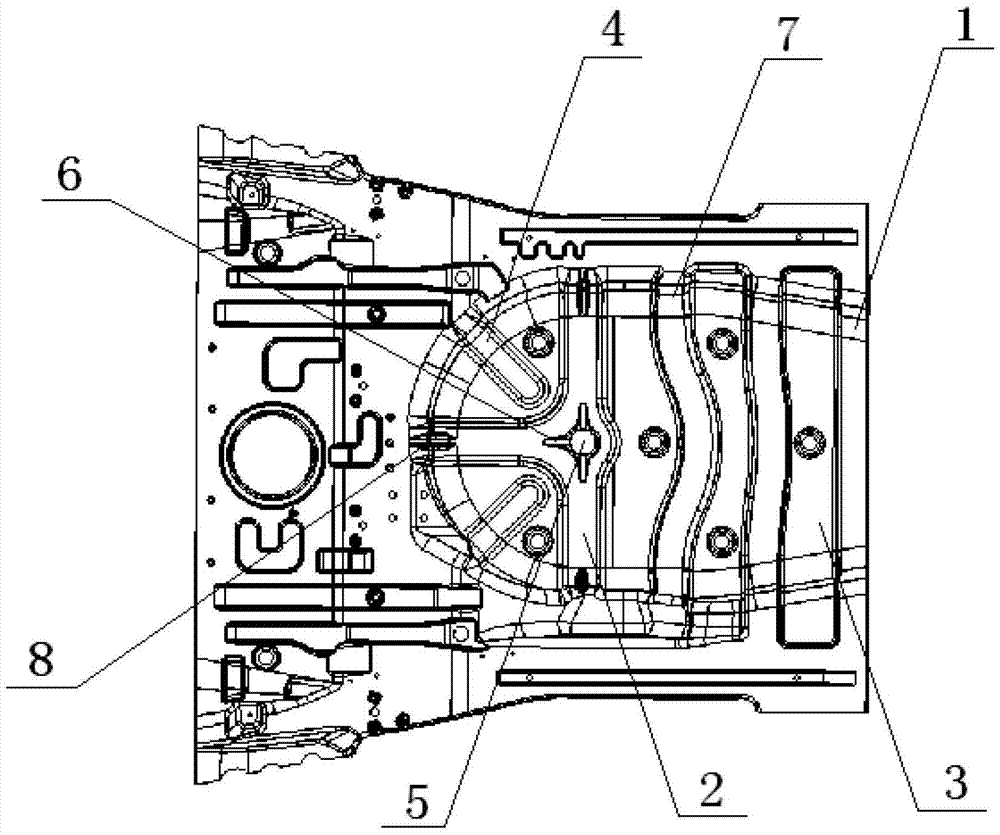

Flow Rate Control Device of Hydraulic Pump in Power Steering System

InactiveUS20100154402A1Reduce manufacturing costOptimize layoutFluid couplingsPump componentsHydraulic pumpEngineering

A flow rate control device of a hydraulic pump in a power steering system, may include an upper cam ring having a cam profile, which is fixedly installed, a lower cam ring having a cam profile, which is engaged with the upper cam ring to be relatively rotatable about the upper cam ring, and a rotor including a plurality of veins and engaged with the upper and lower cam rings to form an inner space therebetween to pressurize oil by protruding the veins in the inner space by centrifugal force while rotating.

Owner:HYUNDAI MOTOR CO LTD

Reinforcing structure of saloon car rear floor spare wheel groove

ActiveCN102785714AAvoid resonance phenomenonImprove NVH performanceSuperstructure subunitsSpare wheel arrangementsPunchingResonance

The invention discloses a reinforcing structure of a saloon car rear floor spare wheel groove, and is characterized in that the reinforcing structure is that the spare wheel groove tends to be closed up from front to rear; T-shaped ribs are arranged by taking a spare wheel installation point as a center, and line ribs are distributed at the rear end of the spare wheel installation point at equal width intervals; and straight ribs are arranged at the periphery of the spare wheel installation point. Due to the adoption of the structure, the reinforcing structure has the following advantages that 1. The spare wheel groove resonance phenomenon in the car running process is avoided with a lower cost, and the NVH (noise, vibration and hardness) performances of the entire car are enhanced; and 2. The reinforcing structure is easy to realize by a punching process, and is worthy of industrially popularizing and applying.

Owner:CHERY COMML VEHICLE ANHUI

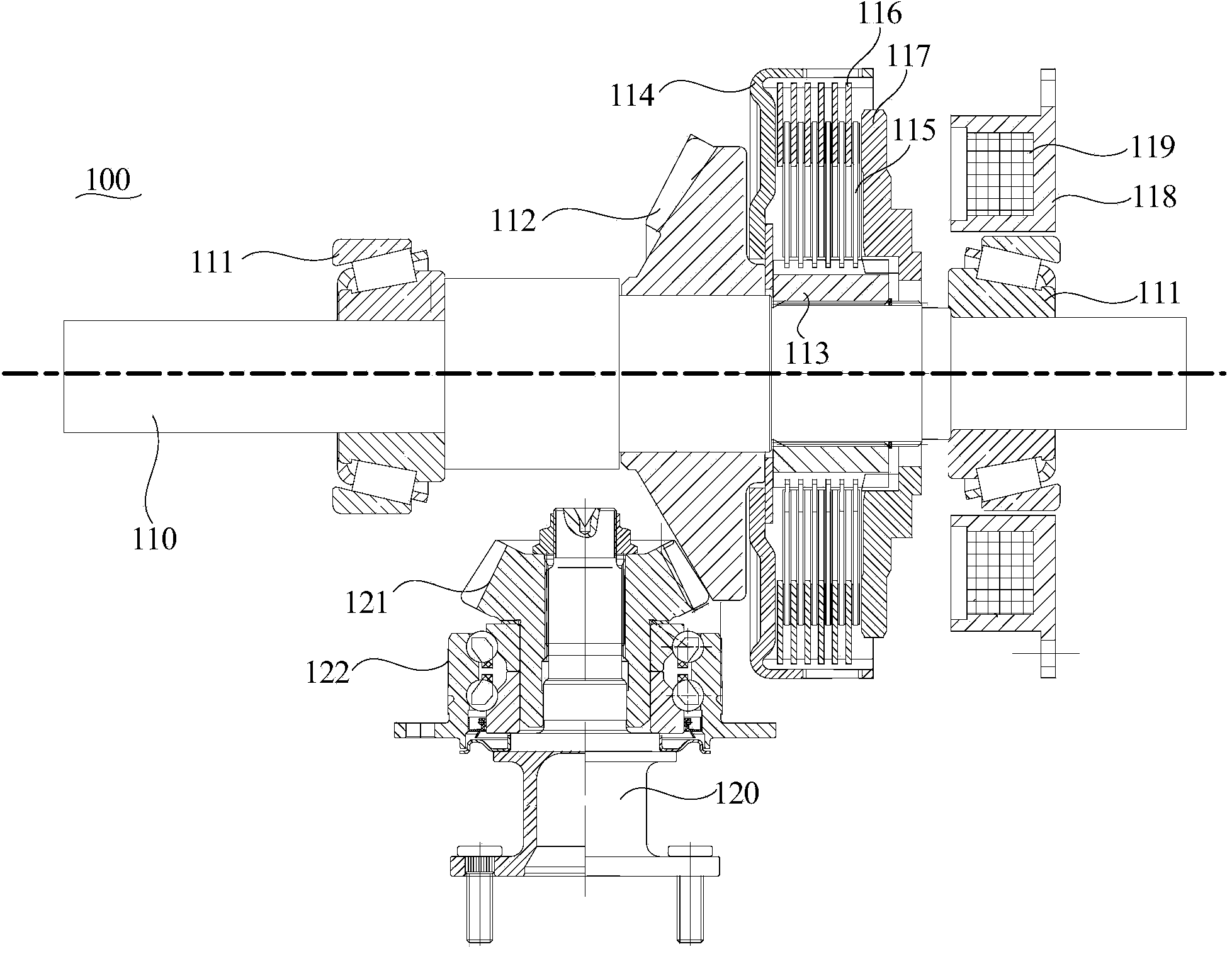

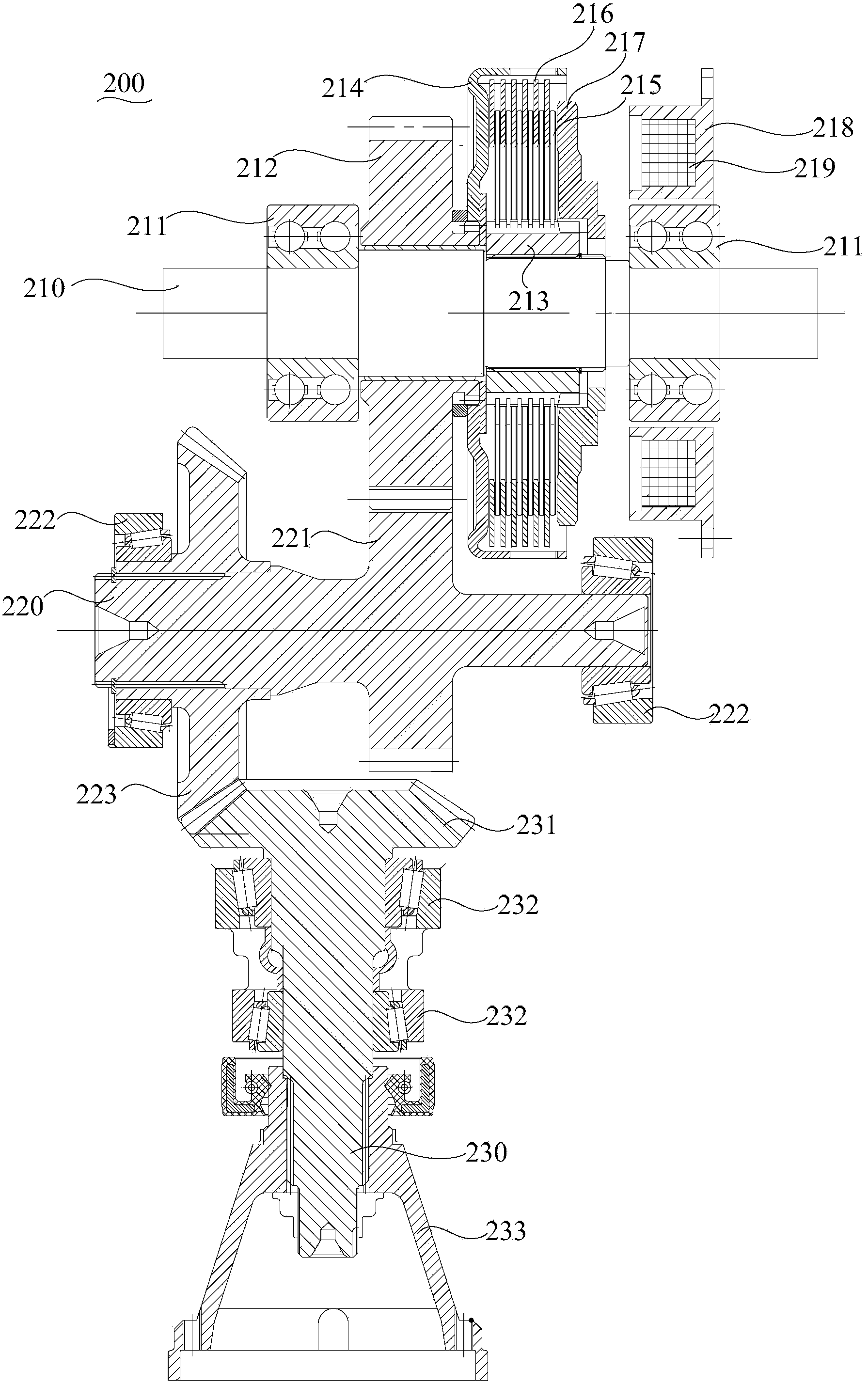

Power divider and power assembly

The invention discloses a power divider and a power assembly, relates to the technical field of automobile power assemblies and is used for reducing energy loss of the power divider and improving integral noise, vibration and harshness (NVH) performance. The power divider comprises a first shaft and a second shaft, wherein the first shaft or the second shaft is used for being connected with a power output end of a transmission, a first gear is sleeved on the first shaft rotatably, a second gear is fixed on the second shaft, the first gear is meshed with the second gear, a clutch is arranged on the first shaft, an input end of the clutch is connected with the first shaft, an output end of the clutch is connected with the first gear, and the clutch is used for connecting or disconnecting power transfer between the first shaft and the first gear.

Owner:GREAT WALL MOTOR CO LTD

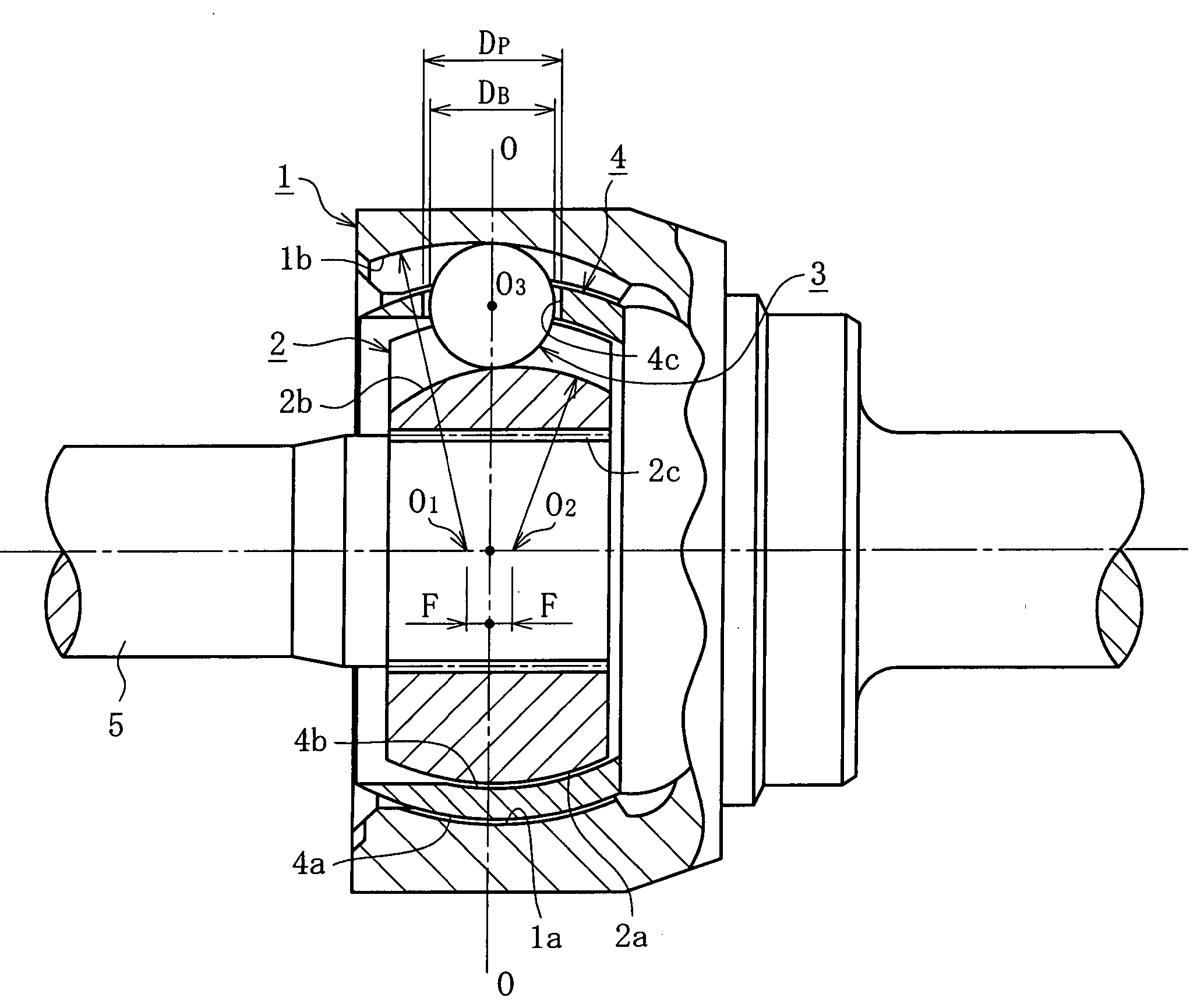

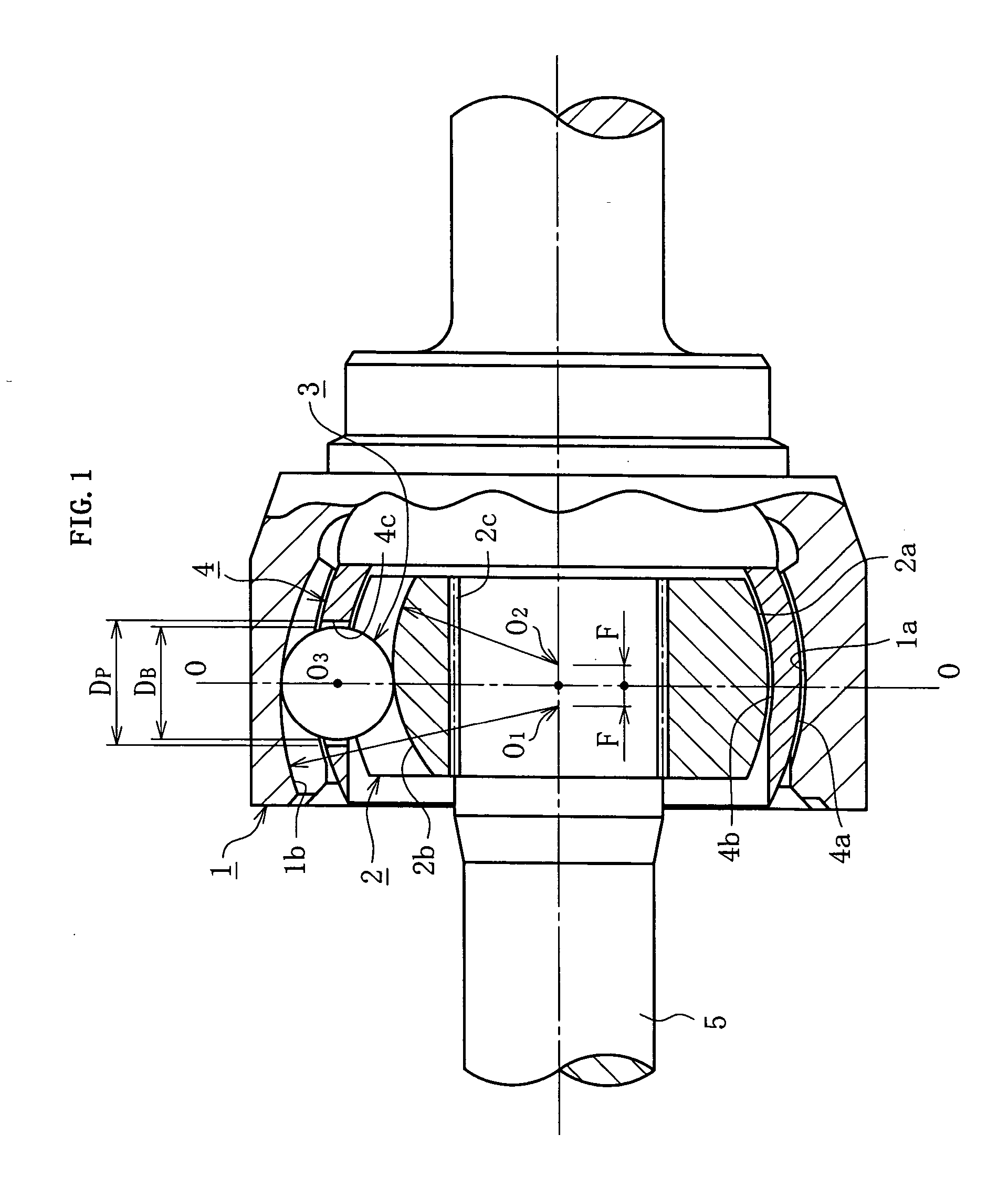

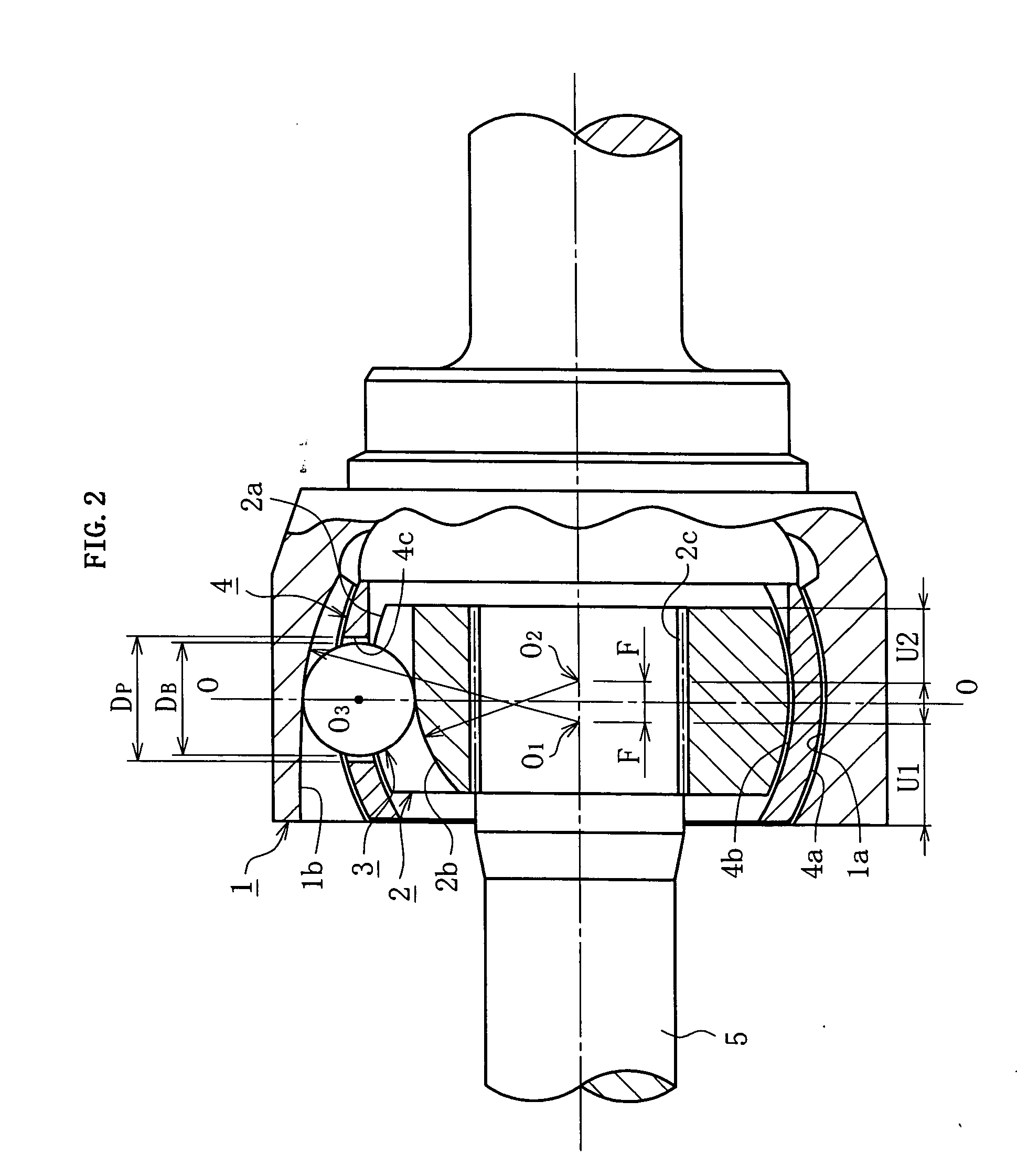

Fixed constant velocity universal joint

ActiveUS20050148397A1Improve NVH performanceYielding couplingRotary machine partsUniversal jointDiameter ratio

A fixed constant velocity universal joint includes: an outer ring having a plurality of track grooves extending axially in its inner spherical surface; an inner ring having a plurality of track grooves extending axially in its outer spherical surface; torque transmission balls arranged in ball tracks formed by cooperation of the track grooves of the outer ring and the track grooves of the inner ring; and a cage having pockets for retaining the torque transmission balls. The center of the track grooves of the outer ring and the center of the track grooves of the inner ring are offset from the spherical center of the inner spherical surface and the spherical center of the outer spherical surface, respectively, by the same distance axially in opposite directions. An axial clearance between the pockets and the torque transmission balls is set within the range of −0.006 and −0.035 mm. A spherical portion clearance between the cage and the inner ring is set so that a clearance-to-diameter ratio falls within the range of 0.9 and 2.3.

Owner:NTN CORP

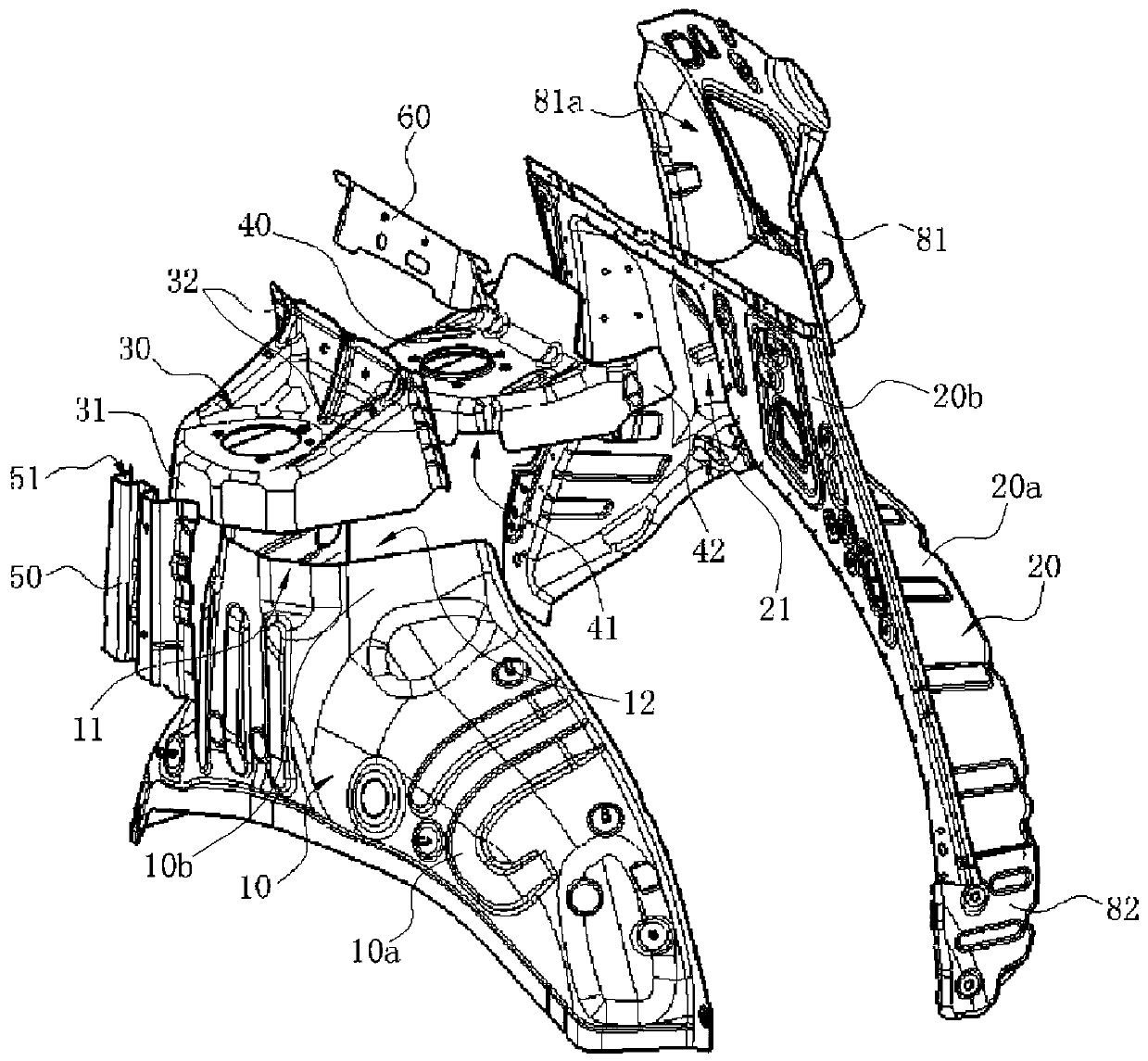

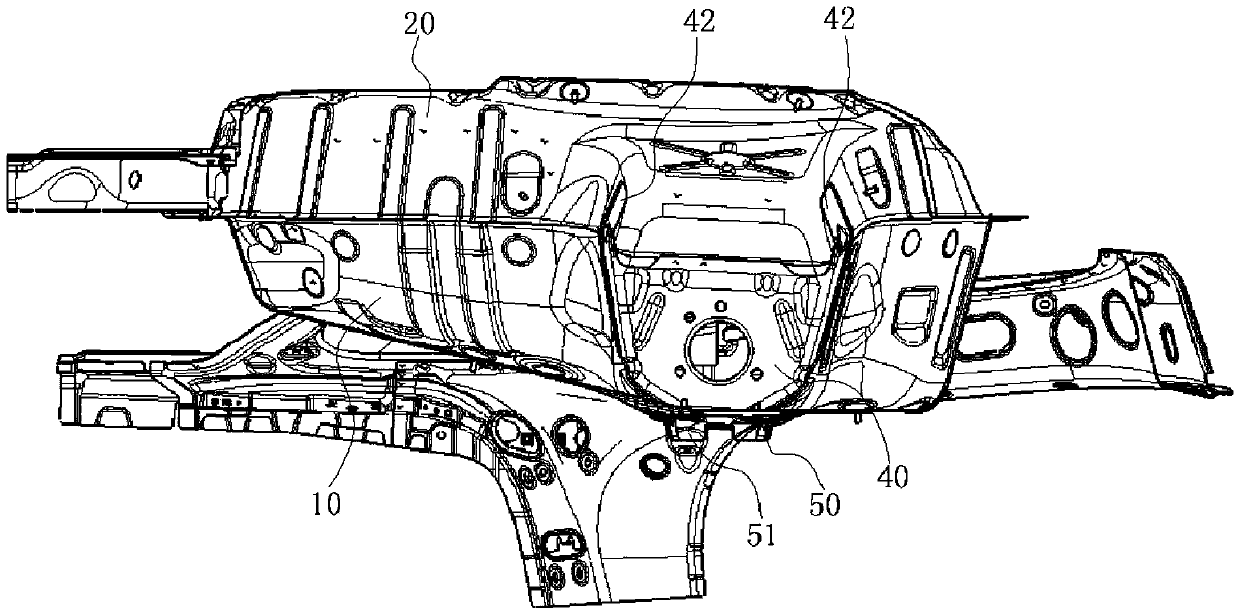

Vehicle body rear structure and automobile

PendingCN111332368AHigh strengthIncrease stiffnessSuperstructure subunitsStructural engineeringSuspension (vehicle)

The invention provides a vehicle body rear structure. The vehicle body rear structure comprises a rear wheel cover outer plate; the rear wheel cover inner plate is arranged opposite to the rear wheelcover outer plate and connected with the rear wheel cover outer plate in a matched mode; the lower edge part of the rear suspension mounting plate is connected with the upper edge part of the rear wheel cover inner plate, and the side edge part of the rear suspension mounting plate is connected with the inner wall of the rear wheel cover outer plate; and the rear suspension reinforcing plate is arranged in the rear suspension mounting plate, the lower edge part of the rear suspension reinforcing plate is connected with the upper edge part of the rear wheel cover inner plate, and the rear suspension reinforcing plate forms a first columnar cavity between the rear wheel cover inner plate and the rear wheel cover outer plate. According to the rear structure of the vehicle body, through reasonable structural design, the problems of poor rigidity, strength and NVH (Noise Vibration and Harshness) performance of back-sliding type vehicles, steel-aluminum hybrid vehicles, vehicles without cross beams on rear floors and other types of vehicles are well solved while structural light weight is considered. The invention further provides a vehicle comprising the vehicle body rear structure.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

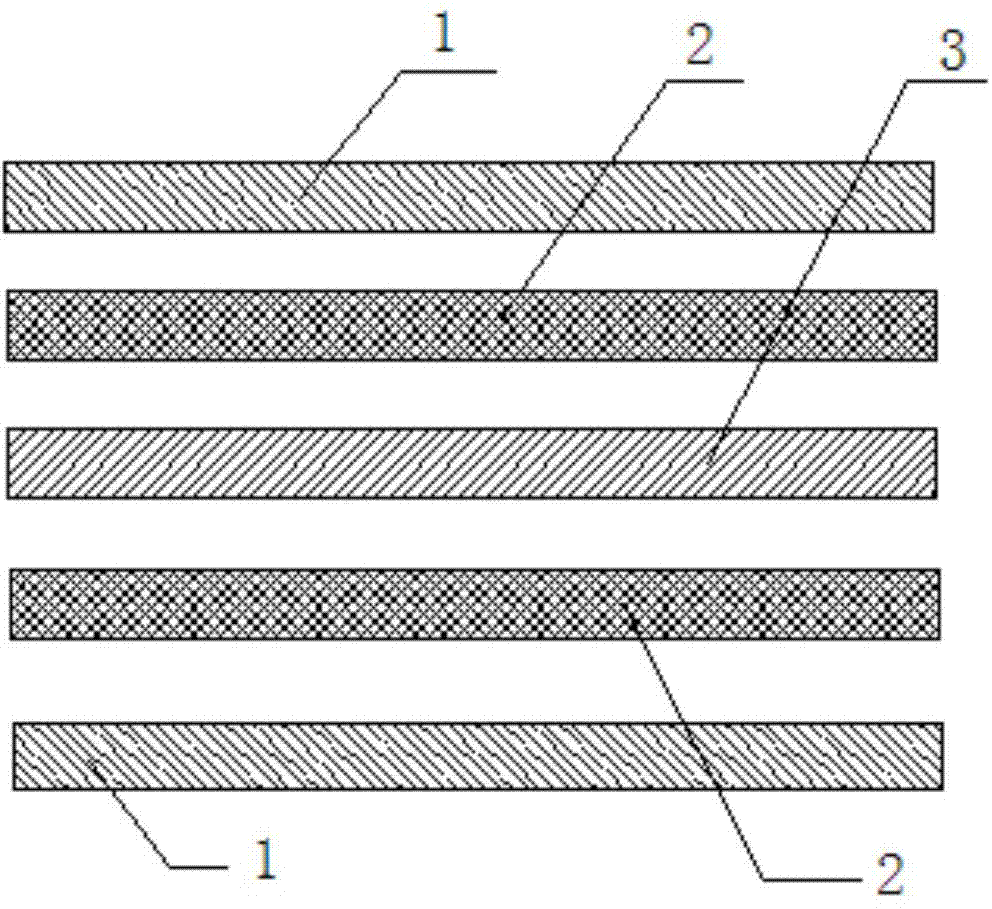

Automobile interior trim part and forming process for same

ActiveCN103753891ALow costGood technical effectSynthetic resin layered productsLaminationGlass fiberPolyethylene terephthalate

The invention provides an automobile interior trim part and a forming process for the same. The automobile interior trim part sequentially consists of a composite knitted fabric layer, a fiberglass mat, a PU (polyurethane) foam sheet, the fiberglass mat and a PET (polyethylene terephthalate) material layer from top to bottom. The automobile interior trim part and the forming process for the same have the advantages and positive effects that the cost is lowered, the production efficiency is improved, and the occurrence rate of quality problems is lowered; sound insulation and noise reduction effects can be achieved, and the NVH (noise vibration and harshness) performance of a product assembly can be improved; energy is saved, and the consumption is reduced.

Owner:GREAT WALL MOTOR CO LTD

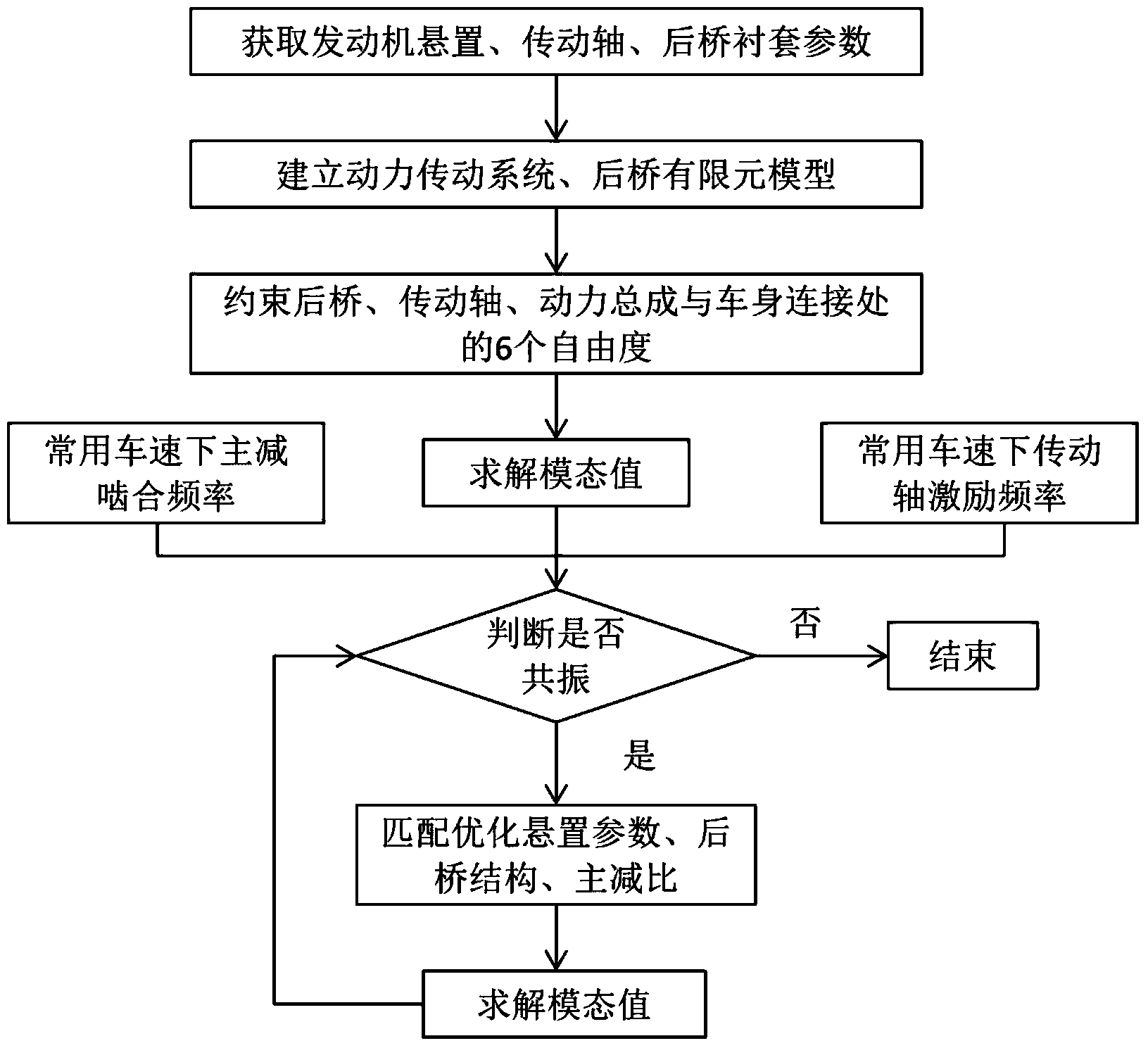

Method for matching power system and drive system based on vibration performance

ActiveCN104063549AReduce development costsImprove NVH performanceSpecial data processing applicationsForce frequencyResonance

The invention relates to a method for matching a power system and a drive system based on vibration performance. The method includes the steps that the rigid body mode of the power system, the drive system, the main speed reducing ratio and the mode of a rear axle system are matched reasonably, the rigid body mode of the power system cannot stimulate the drive system mode, and the exciting force frequency below the main speed reducing ratio cannot stimulate the mode of the rear axle system. The method is mainly and specifically used for automobile model development at the earlier stage. Due to the fact that a practical entire automobile does not exist in entire automobile development, checking can only be achieved through simulation, CAE simulated analysis is conducted on the power system and the drive system, a mode distribution table is planned, the power system and the drive system are matched reasonably, and the phenomena that the rigid body mode of the power system stimulates the drive system mode, and the exciting force frequency below the main speed reducing ratio stimulates the mode of the rear axle system so that resonance can happen are avoided. The entire automobile NVH performance is improved, the development cycle is shortened, and the development cost of an automobile is lowered.

Owner:HUNAN UNIV

Top-cover outer plate and skylight reinforcing frame structure

InactiveCN103738148AImprove NVH performanceImprove qualityEngine sealsVehicle sealing arrangementsNoise, vibration, and harshnessUltimate tensile strength

The invention relates to a top-cover outer plate and skylight reinforcing frame structure comprising a front reinforcing frame, a rear reinforcing frame, a left reinforcing frame and a right reinforcing frame. In the front reinforcing frame, the rear reinforcing frame, the left reinforcing frame and the right reinforcing frame, gaps are designed above a top-cover outer plate and a skylight reinforcing frame. By the top-cover outer plate and skylight reinforcing frame structure, abnormal sounds at the matching position of the front reinforcing frame due to metal-plate adhesion instead of connection are avoided; through the design of shock-insulating rubber, connection strength of two plates is improved; vehicle NVH (noise vibration and harshness) performance and vehicle quality are improved; through the design of two surfaces, width of the matching surface of a vertical turnup of the front reinforcing frame and a seal rubber strip is shortened, a welding matching surface and a seal rubber strip surface are separated, abrasion of the seal rubber strip surface is reduced, and accordingly, abrasion probability of the rubber strip is greatly reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

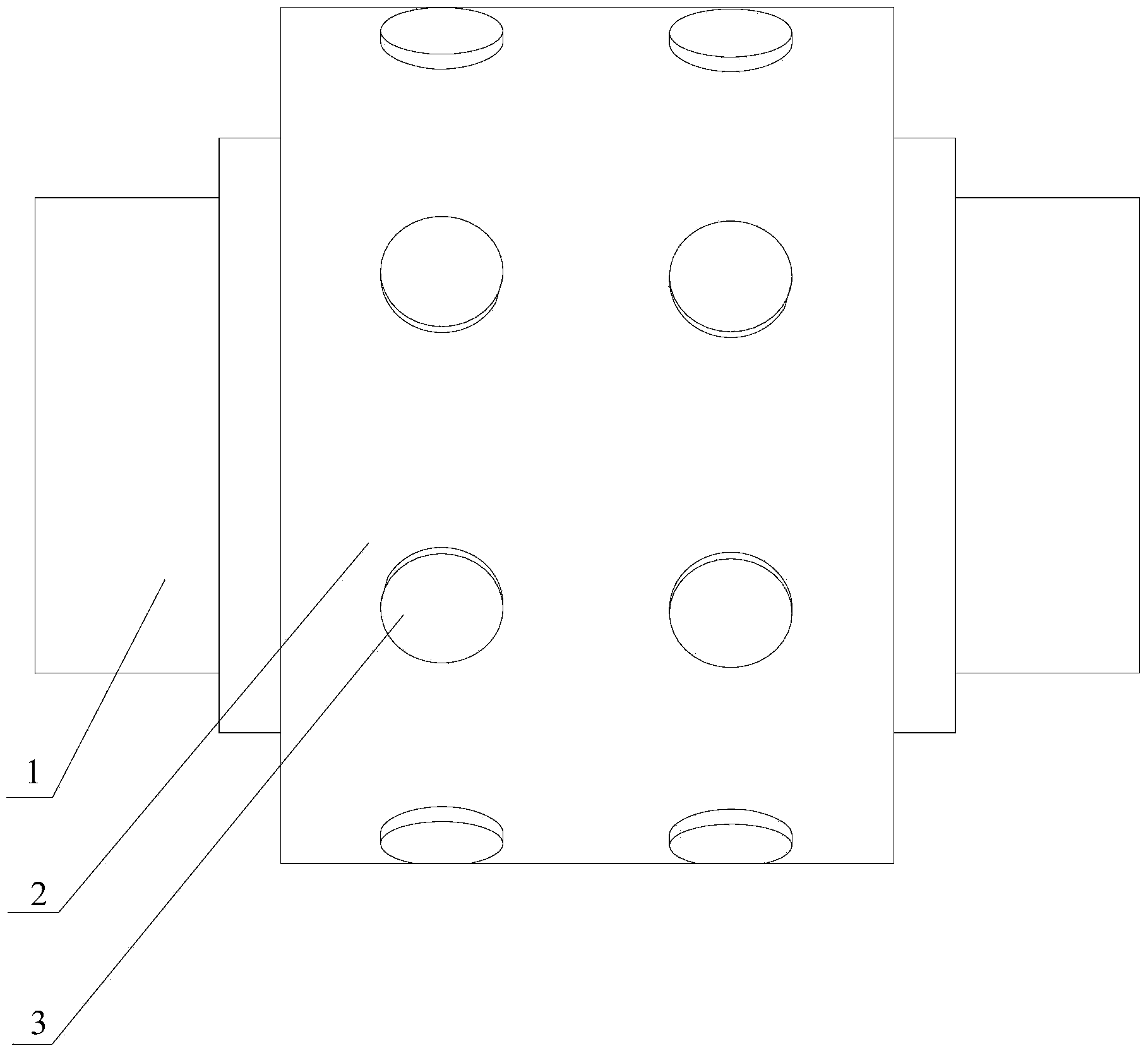

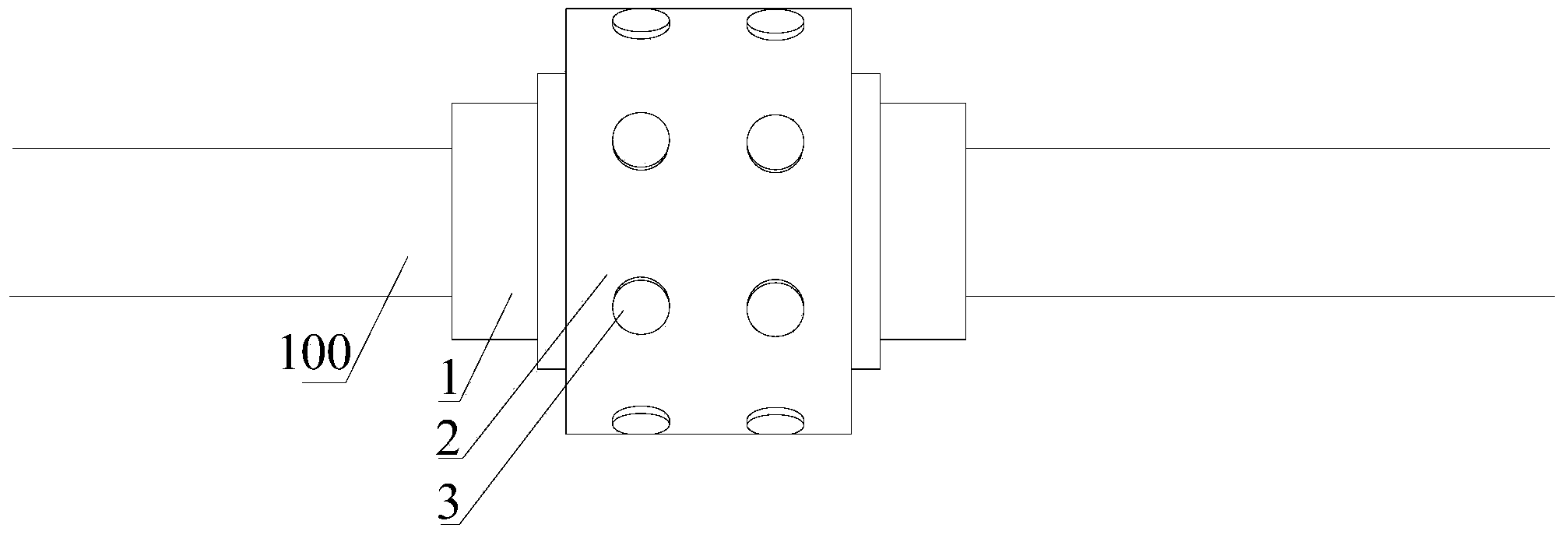

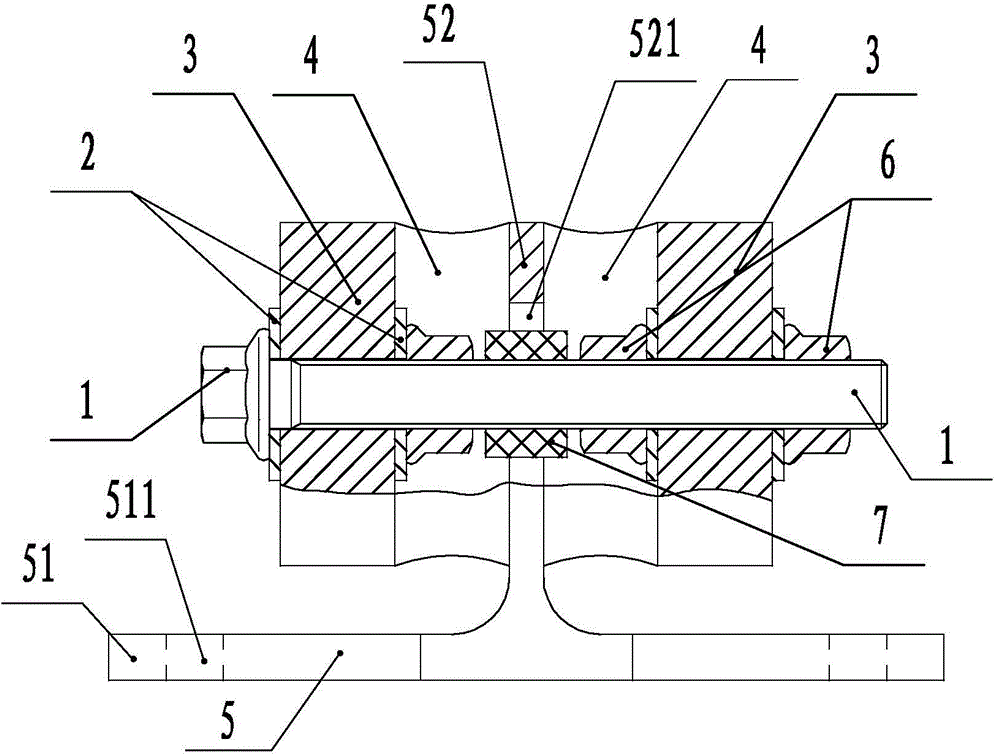

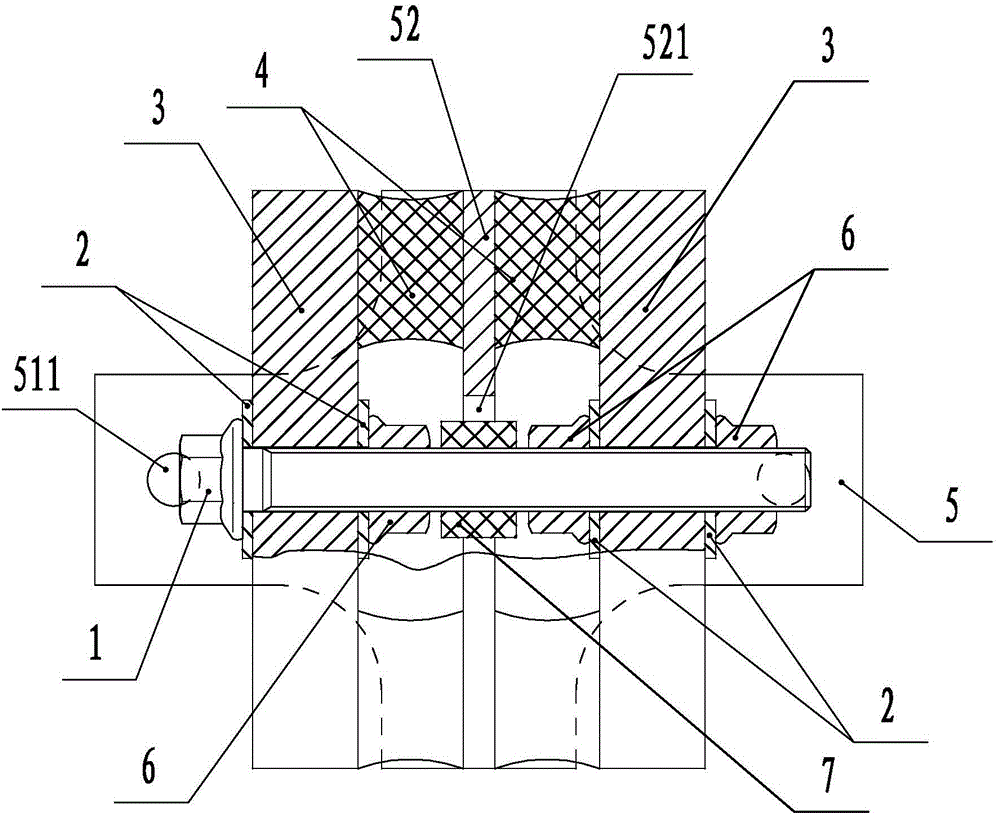

Rear axle mass shock absorber

InactiveCN104696407AReduce vibration and noiseDissipate vibrational energyShock absorbersInertia effect dampersVulcanizationVibration absorption

The invention discloses a rear axle mass shock absorber and relates to a shock absorber. The rear axle mass shock absorber comprises a screw, mass inertia blocks, vibration absorption rubber and a mounting bracket. The mounting bracket is formed by a bottom plate and a vertical plate; the vertical plate is provided with a limiting hole; the mass inertia blocks are respectively arranged on both sides of the vertical plate; each mass inertia block is provided with a center round hole; the mass inertia blocks are connected with the vertical plate by the vibration absorption rubber in a vulcanizing manner; the screw is sleeved by a gasket, a nut and a buffer rubber sleeve; the screw passes through the center round holes of the mass inertia blocks, the vibration absorption rubber and the limiting hole of the vertical plate and enables the buffer rubber sleeve to be positioned in the limiting hole of the vertical plate; the two mass inertia blocks, the two pieces of vibration absorption rubber and the vertical plate are locked together by the gasket and the nut, so that lateral compression or stretching deformation of the vibration absorption rubber can be regulated. According to the rear axle mass shock absorber, vibration noise can be reduced; after the rubber is vulcanized and formed, rigidity can be freely regulated; safety performance is good; NVH (Noise Vibration and Harshness) performance of a vehicle can be improved; the development period of the vehicle or the shock absorber product is shortened; the rear axle mass shock absorber is easy to popularize and apply.

Owner:柳州金鸿橡塑有限公司

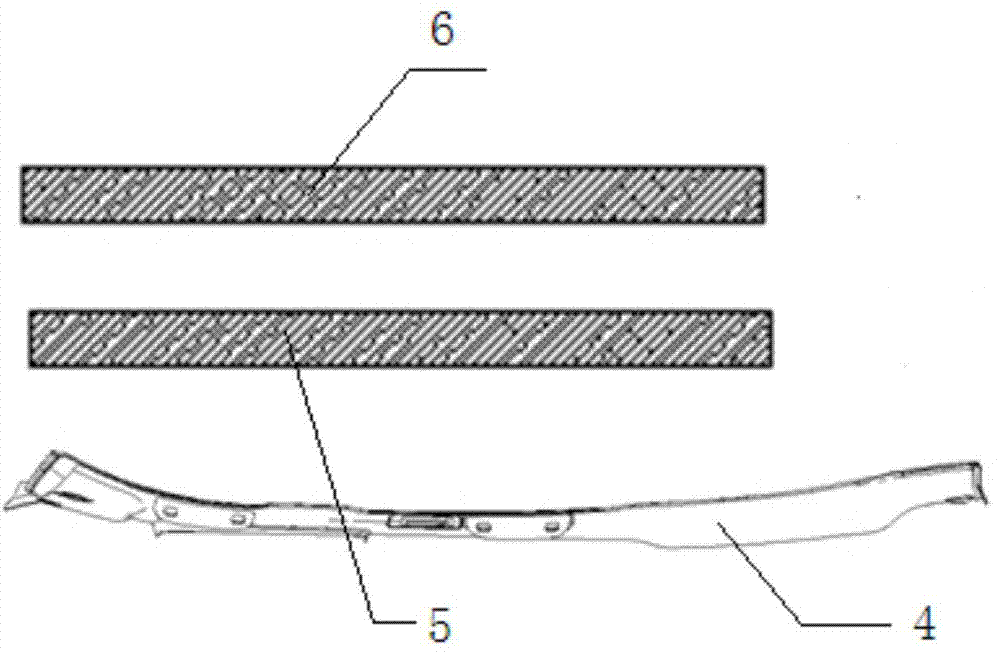

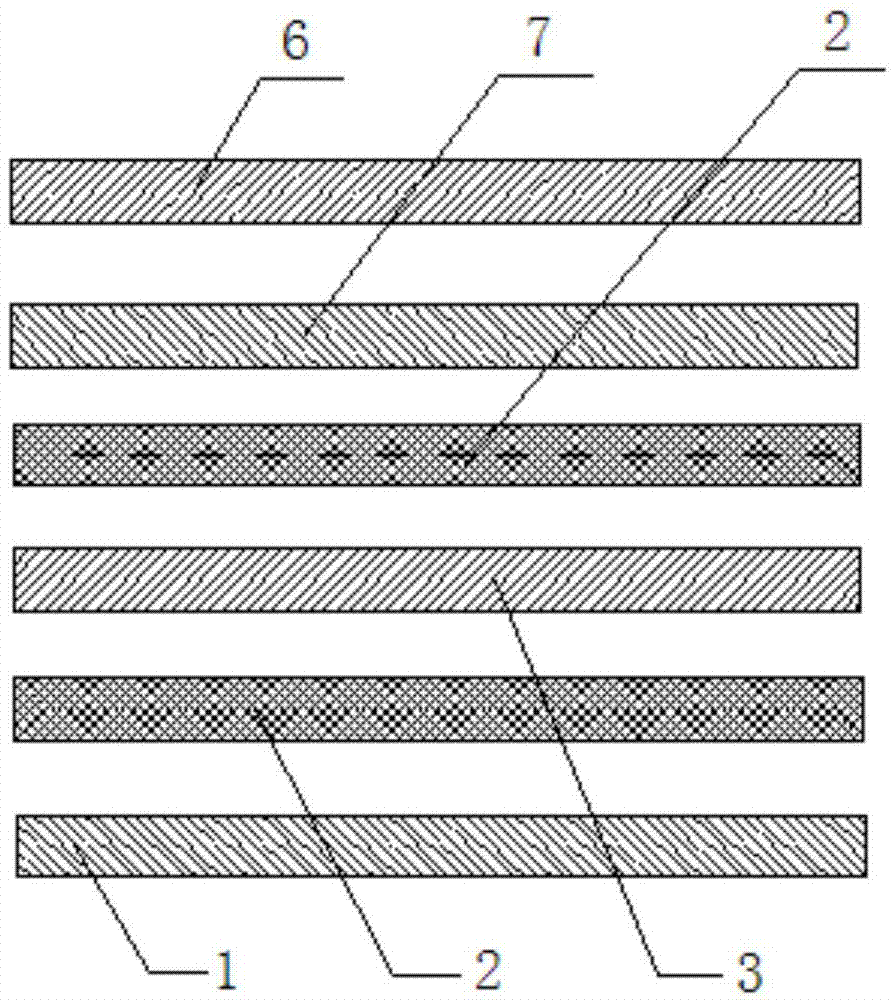

Stiffener film substrate composition, stiffener film substrate as well as stiffener film and steel plate composite material

ActiveCN103509506AReduce vibration and noiseImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesButadiene-styrene rubberNitrile rubber

The invention provides a stiffener film substrate composition, a stiffener film substrate, a stiffener film and a steel plate composite material comprising the stiffener film. The stiffener film substrate composition comprises epoxy resin, nitrile rubber, butadiene styrene rubber, a curing agent and a tackifier. The prepared stiffener film substrate has strong bonding force with a vehicle body steel plate, the strength of the cured stiffener film substrate is further improved, meanwhile, the vibration noise of a vehicle body can be reduced, and the NVH (Noise Vibration and Harshness) property of a vehicle can be enhanced.

Owner:BYD CO LTD

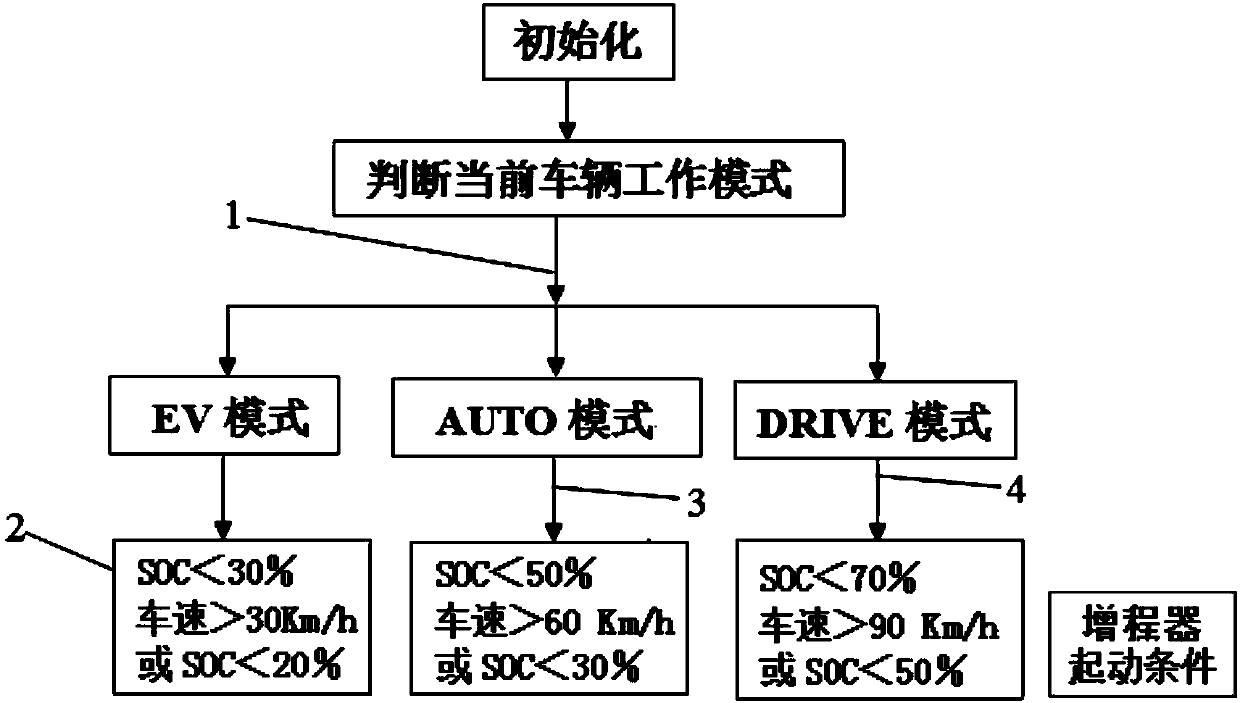

Control method for improving noise, vibration and harshness (NVH) performance of extended-range electric vehicle

InactiveCN107650694AMeeting driving comfort requirementsImprove NVH performanceHybrid vehiclesPropulsion using engine-driven generatorsLow speedElectric vehicle

The invention discloses a control method for improving noise, vibration and harshness (NVH) performance of an extended-range electric vehicle. The control method comprises the processes that initialization is conducted; the current vehicle working mode is judged; under the different working modes, a range extender is started according to the set starting condition; or according to the set startingcondition, the range extender is automatically started. By adopting the technical scheme, a vehicle control unit (VCU) controls starting and stopping of the extended-range electric vehicle accordingto vehicle speeds and SOC values; under the condition that the vehicle requirements are met, the situation that the range extender is not started at the low speed and the high SOC value is met to thegreatest extent; and by optimizing and sacrificing part of economical efficiency, working points of a range extender system all work at the point with the good NVH performance, finally, the situationsthat the range extender system is not operated when the vehicle operates at the low speed, an engine used for the range extender operates at the economical working point when the vehicle operates atthe medium speed, and the range extender system operates at the medium-high speed working point when the vehicle operates at the high speed are achieved, the requirement of the driving comfort of a driver is met, and the NVH performance of the vehicle is improved.

Owner:奇瑞新能源汽车股份有限公司

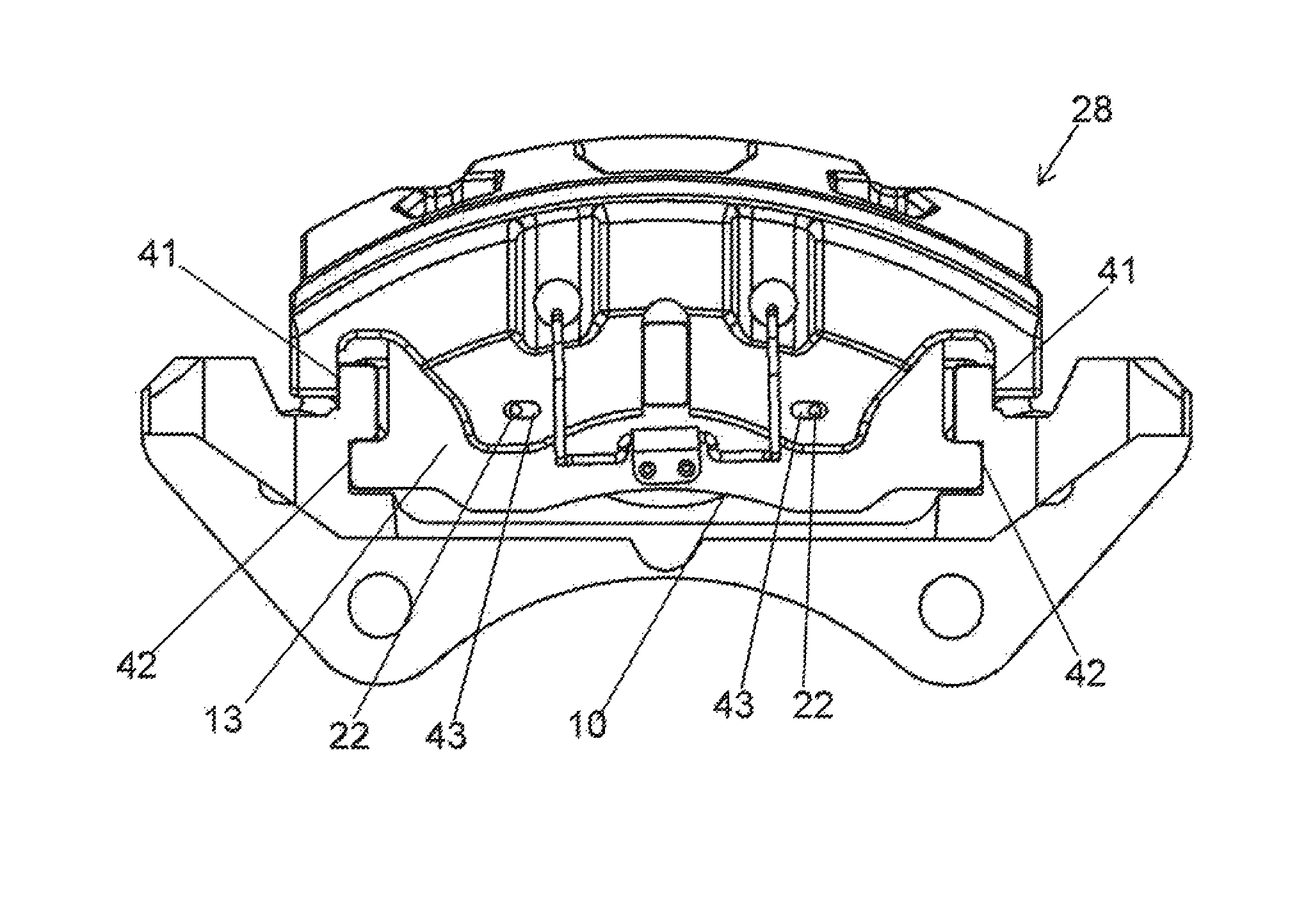

Caliper assembly for disc brake system

InactiveUS8485323B2Promote achievementGood flexibilityMechanically actuated brakesFriction liningEngineeringCalipers

A caliper assembly comprising: a brake pad comprising a carrier plate having two opposing faces and two opposing side edges each having an ear which is adapted to seat in pad locator indentations in a support structure, wherein on one face is friction material and on the opposing face is a projection adapted to seat in a matched recess in a caliper body; a support structure having at least two pad locator indentations for receiving the ears located on the brake pad and at least two caliper body locator indentations for seating two ears defined by the caliper body; and a caliper body having a recess for seating the projection on the opposing face of the brake pad and having two ears adapted to seat in the caliper body locator indentations of the support structure; and a clip which holds the brake pad in position.

Owner:AKEBONO BRAKE

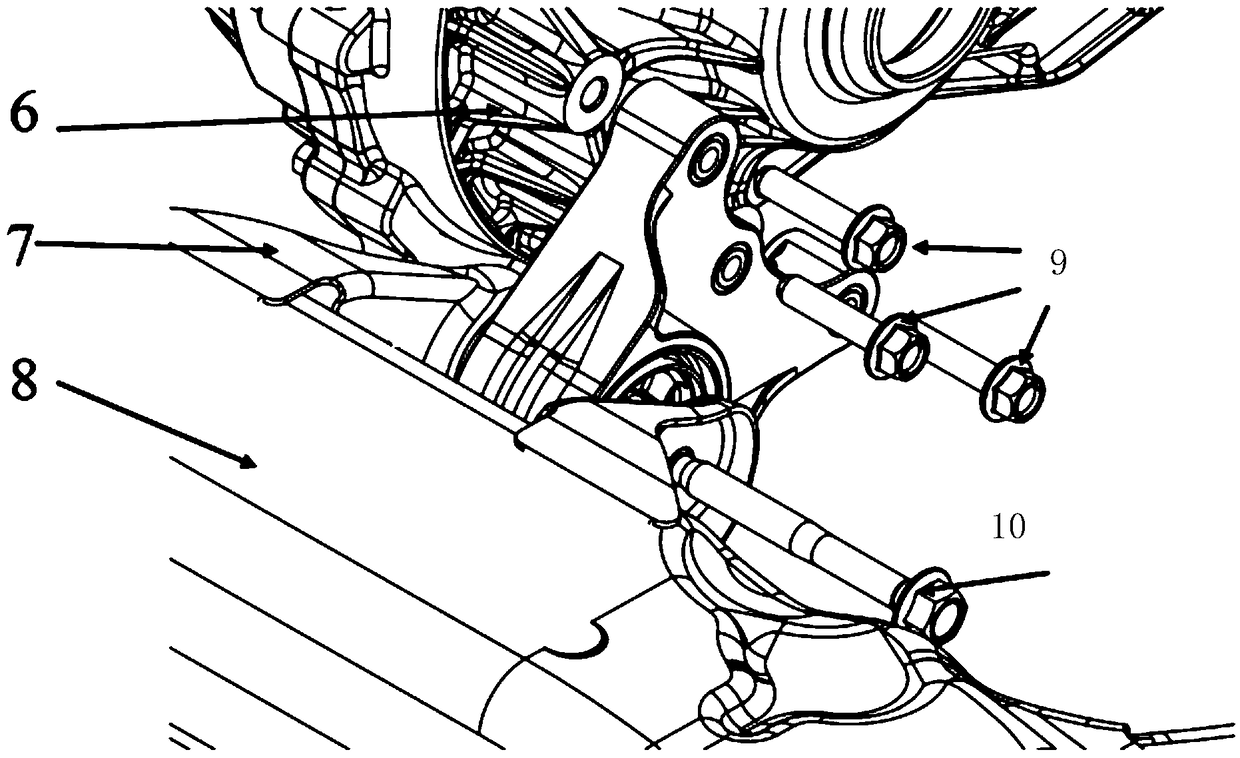

Suspension device for driving motor and electric vehicle with suspension device

ActiveCN109501565AReduce shockControl vibration transmissionElectric propulsion mountingVehicle frameEngineering

The invention discloses a suspension device for a driving motor and an electric vehicle with the suspension device. The suspension device comprises a suspension body, the suspension body comprises a first end and a second end which are opposite to each other, the first end is provided with multiple through holes at intervals in the width direction, the through holes are internally provided with vibration isolation rubber bushings, and first bolts penetrate through the vibration isolation rubber bushings to fix the first end to a motor shell; the second end is provided with limiting supportingbases and screw holes, the limiting supporting bases are internally provided with vibration isolation rubber bushing assemblies, and second bolts penetrate through the vibration isolation rubber bushing assemblies and the screw holes in sequence to fix the second end to an auxiliary vehicle frame. According to the suspension device for the driving motor and the electric vehicle with the suspensiondevice, the degree of freedom is increased, the vibration isolation frequency band range is expanded, the capability of absorbing vibration is improved, the durability is improved while the overall dimension is not increased, and the requirement for NVH rigidity debugging is met.

Owner:SAIC GENERAL MOTORS +1

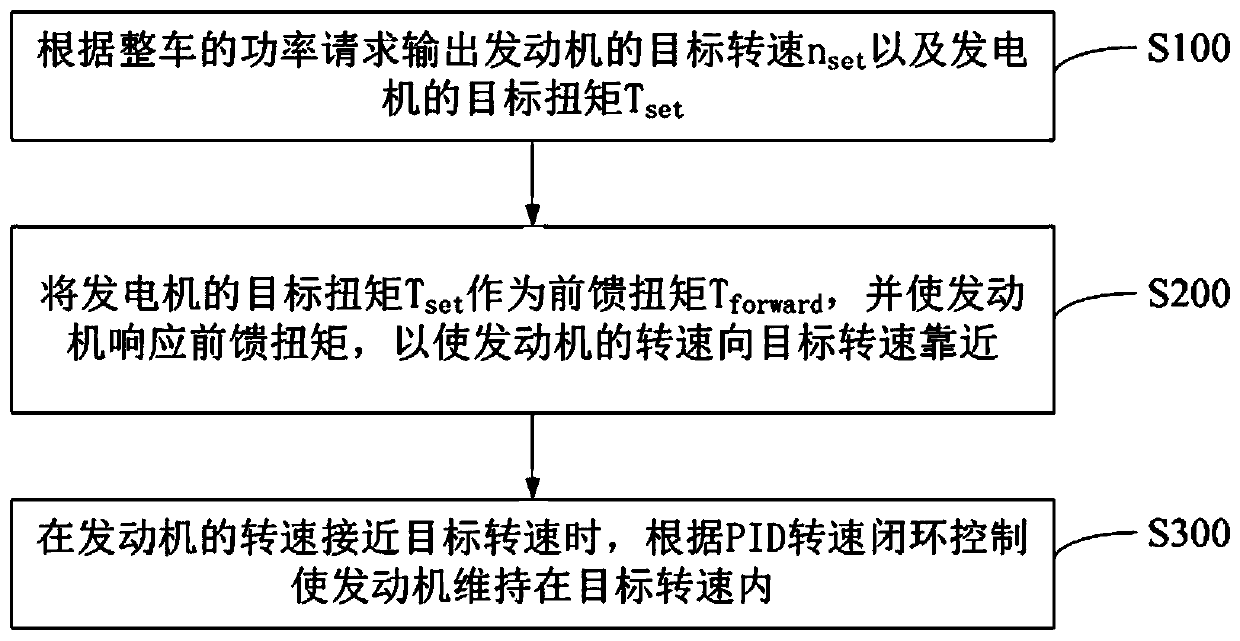

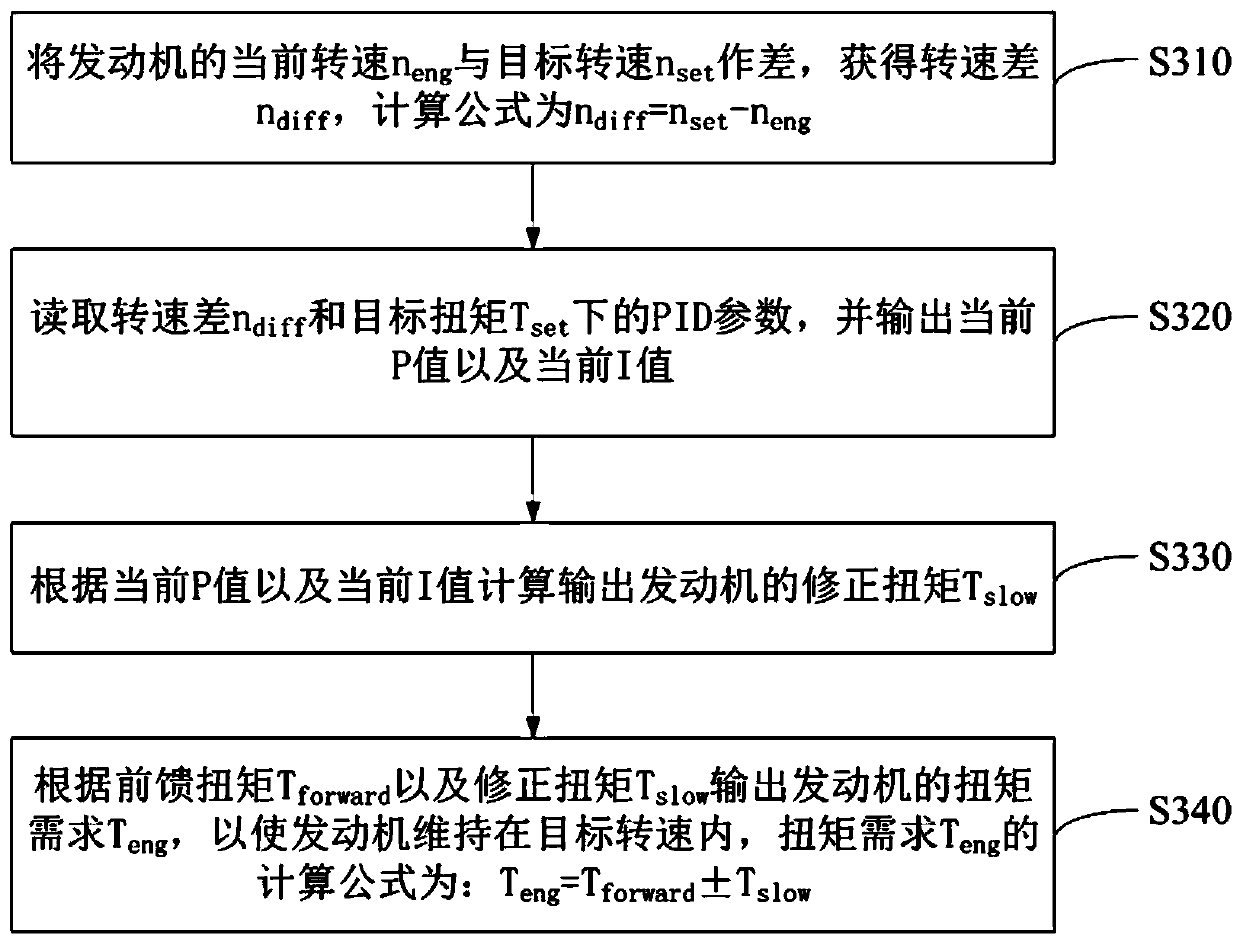

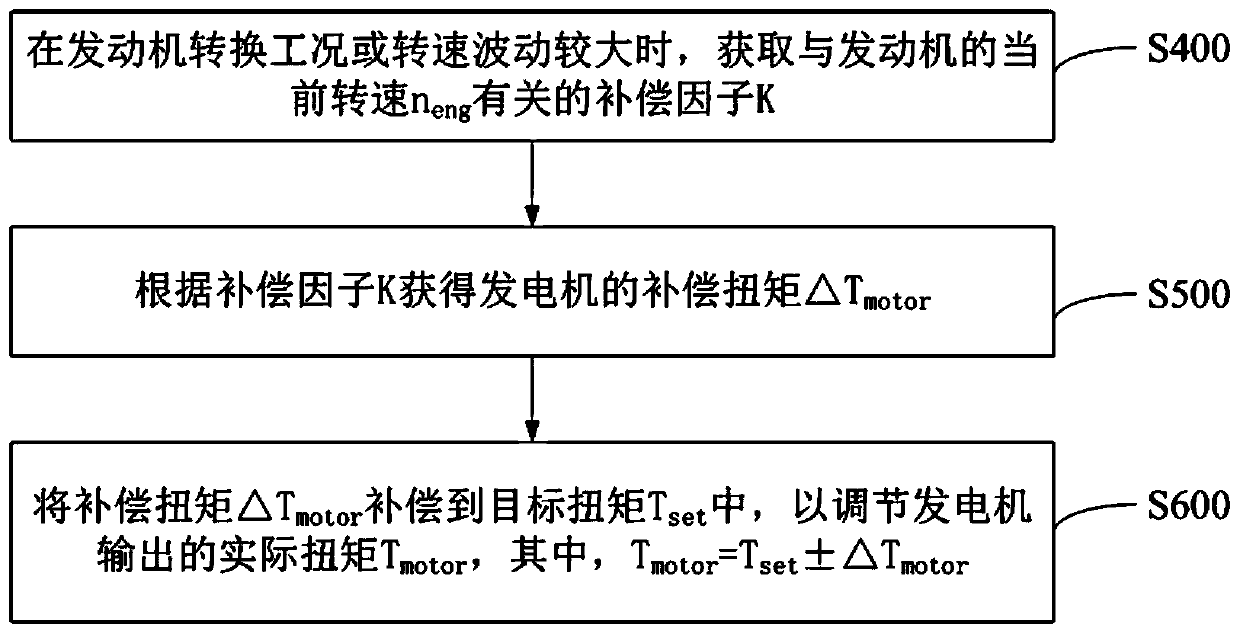

Control method and system for adjusting rotating speed stability of range extender

ActiveCN111267643AFast response to speed requirementsReduce rateHybrid vehiclesSpeed controllerLoop controlElectric generator

The invention provides a control method and system for adjusting rotating speed stability of a range extender. The control method comprises the following steps that: the target rotating speed nset ofthe engine and the target torque Tset of the generator are output according to a power request of a whole vehicle; the target torque Tset of the generator is taken as a feed-forward torque Tforward, and the engine responds to the feed-forward torque so as to enable the rotating speed of the engine to be close to the target rotating speed; and when the rotating speed of the engine is close to the target rotating speed, the engine is maintained within the target rotating speed according to PID rotating speed closed-loop control. Through the generator real-time torque compensation control methodand PID rotating speed closed-loop accurate control, the rotating speed of the range extender can be continuously and stably output under the target power, the fluctuation of the rotating speed of theengine is reduced, and then the purposes of reducing vibration of a range extender system and improving the overall NVH performance of the range extender are achieved.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +3

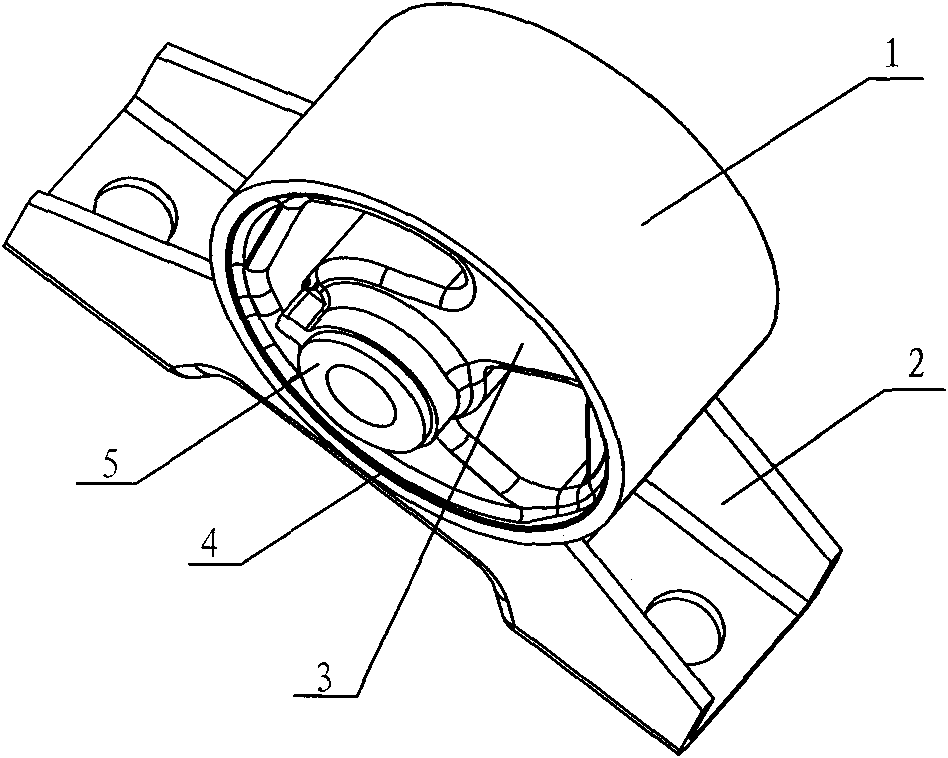

Automobile power assembly suspending cushion with vibration absorbing function

InactiveCN101850712AIsolated deliveryImprove NVH performanceNon-rotating vibration suppressionJet propulsion mountingCushionPowertrain

The invention discloses an automobile power assembly suspending cushion with a vibration absorbing function, which comprises a metal frame, a rubber bushing, a core shaft and a dynamic vibration absorber. The dynamic vibration absorber is arranged on the core shaft, the dynamic vibration absorber is of a shape identical to the shape of the part of the core shaft except the extension shaft and is provided with at least two bolt holes corresponding to the core shaft for connection with a power assembly bracket, and the dynamic vibration absorber and the core shaft are connected to a bracket on the driving side of an engine through bolt assembly. Due to the dynamic vibration absorber additionally arranged on the core shaft, the invention can better isolate the vibration of the engine from being transmitted to the automobile body. Moreover, since the shapes of the dynamic vibration absorber and the core shaft are designed to be identical, the invention can be arranged conveniently and is more applicable to forecabins with small space.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

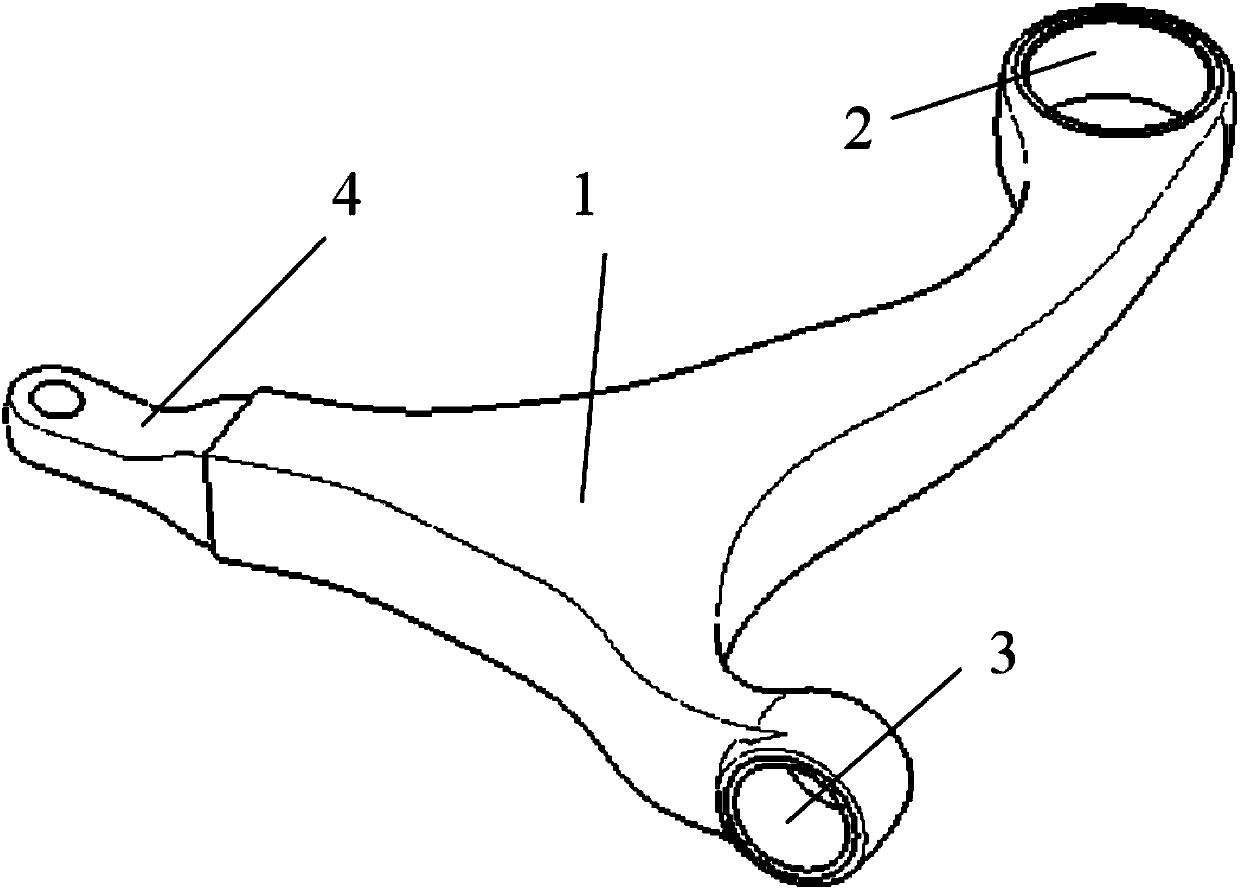

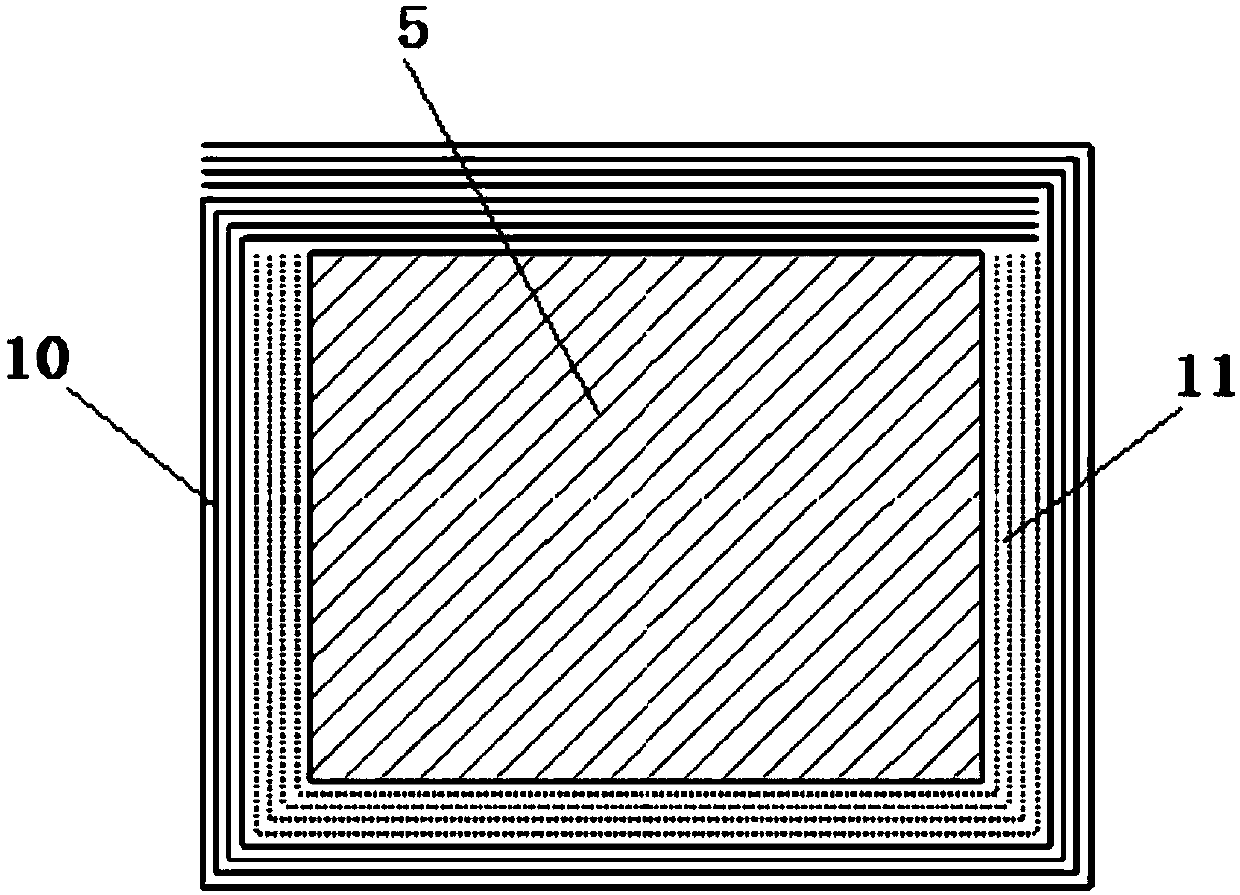

Composite material control arm of passenger vehicle

PendingCN108032696AHigh strengthImprove fatigue performanceLayered productsPivoted suspension armsFiberControl engineering

The invention discloses a composite material control arm of a passenger vehicle. The composite material control arm of the passenger vehicle comprises a control arm body, a front bushing, a rear bushing and a connection joint. The control arm body comprises a carbon fiber fabric laminate and a PMI foam core material. The carbon fiber fabric laminate comprises a control arm body integral overlay and a control arm body local overlay. A bushing insulation overlay is arranged at the contacts between the front bushing and the PMI foam core material and between the rear bushing and the PMI foam corematerial. The bushing insulation overlay covers the PMI foam core material, with the exterior being wrapped by a bushing wrapping overlay. A joint isolation overlay is arranged between the connectionjoint and the PMI foam core material, with the exterior being wrapped by the joint wrapping overlay. The control arm body, the front bushing, the rear bushing and the connection joint are cured together through the HP-RTM process. The composite material control arm of the passenger vehicle adopts insert molding, so that the structural strength is high, the composite material control arm replacesthe existing steel structure control arms and cast aluminum structure control arms, the weight loss efficiency is high, and the fatigue performance is superior.

Owner:康得复合材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com