Power divider and power assembly

A transfer case and power output terminal technology, applied to control devices, transportation and packaging, vehicle components, etc., can solve the problems of performance degradation and large energy loss of transfer case, and achieve the effect of reducing energy loss and improving NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

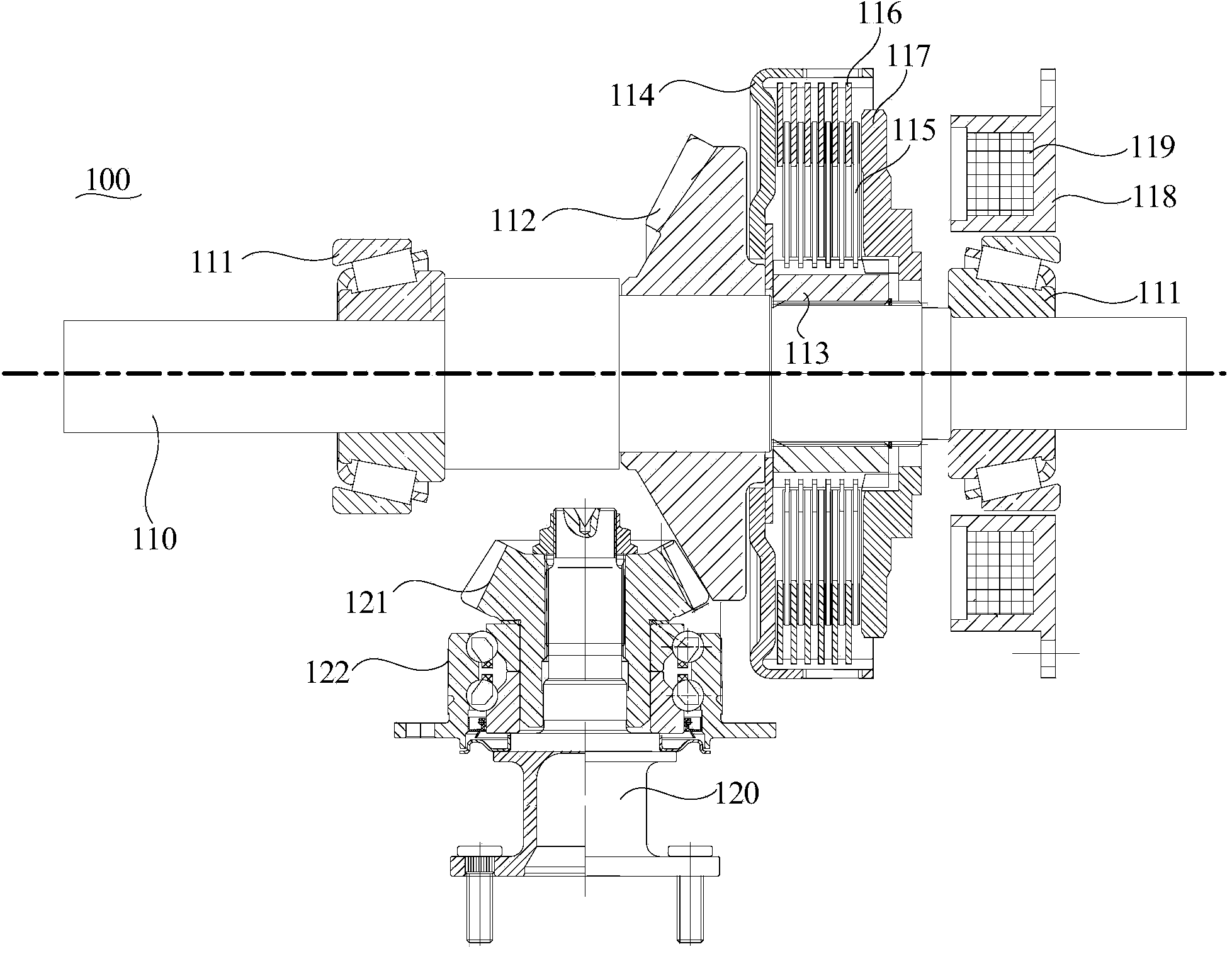

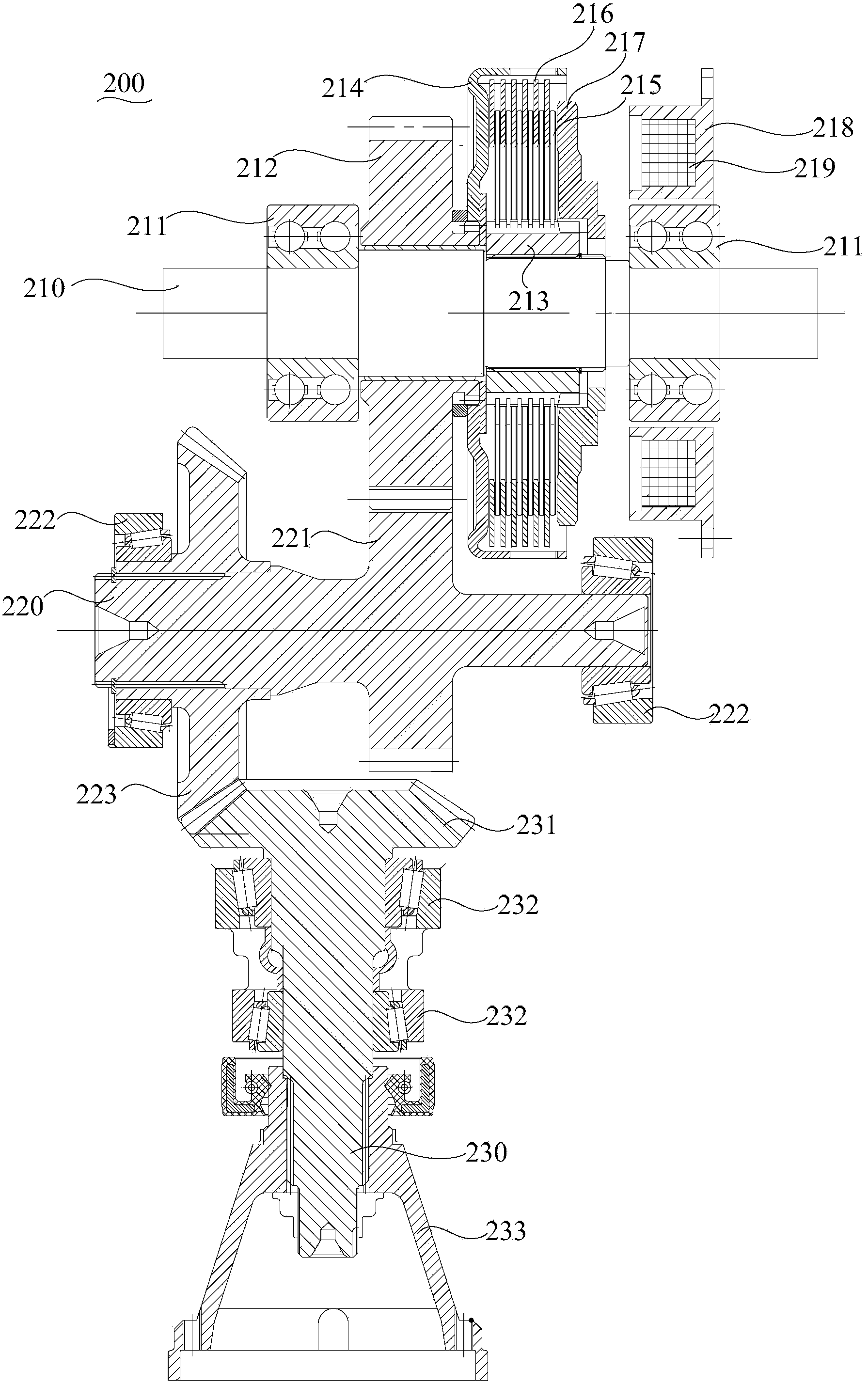

[0030] Such as figure 1 As shown, the unipolar transfer case 100 includes a first shaft 110 and a second shaft 120 perpendicular to the first shaft 110. The left and right ends of the first shaft 110 are respectively provided with first bearings 111 (as shown in the figure Shown cone bearing), the first shaft 110 between the left and right first bearings 111 is rotatably provided with a first gear 112 (bevel gear) through a needle bearing, the first gear 112 and the first bearing at the right end A clutch is fixedly connected between 111, the input end of the clutch is connected to the first shaft 110, and the output end is connected to the first gear 112, and the clutch is used to engage or disconnect the power transmission between the first shaft 110 and the first gear 112; The second shaft 120 is provided with a second gear 121 (bevel gear), a second bearing 122 (a ball bearing as shown in the figure), the first gear 112 meshes with the second gear 121, and the first shaft ...

Embodiment 3

[0049] The present invention also provides a power assembly, including an engine, a transmission, a transfer case, and a drive axle. The output end of the engine is connected to the input end of the transmission, and the output end of the transmission is connected to the input end of the transfer case. The output end is connected to the drive bridge, wherein, since the transfer device has been described in detail in the above embodiments, it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com