Rear axle mass shock absorber

A mass shock absorber and rear axle technology, applied in shock absorbers, inertia effect shock absorbers, shock absorbers, etc., can solve the problems of rework, complex structure, and many manufacturing processes, so as to reduce vibration noise, reduce noise and improve safety. Good performance and the effect of reducing the loss of non-conforming products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

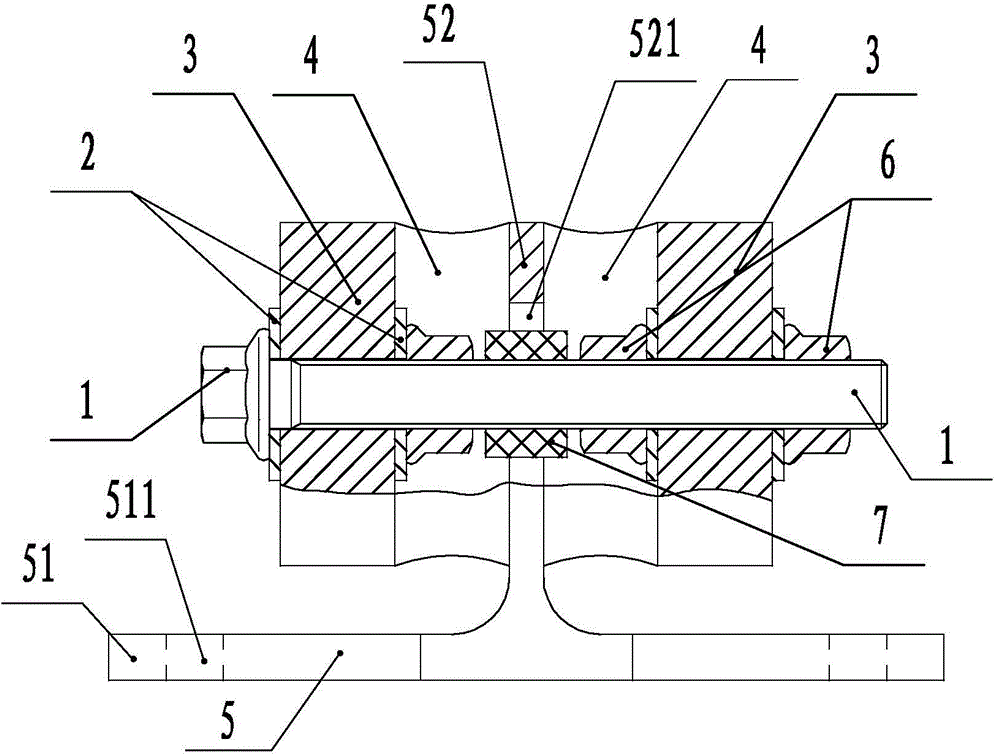

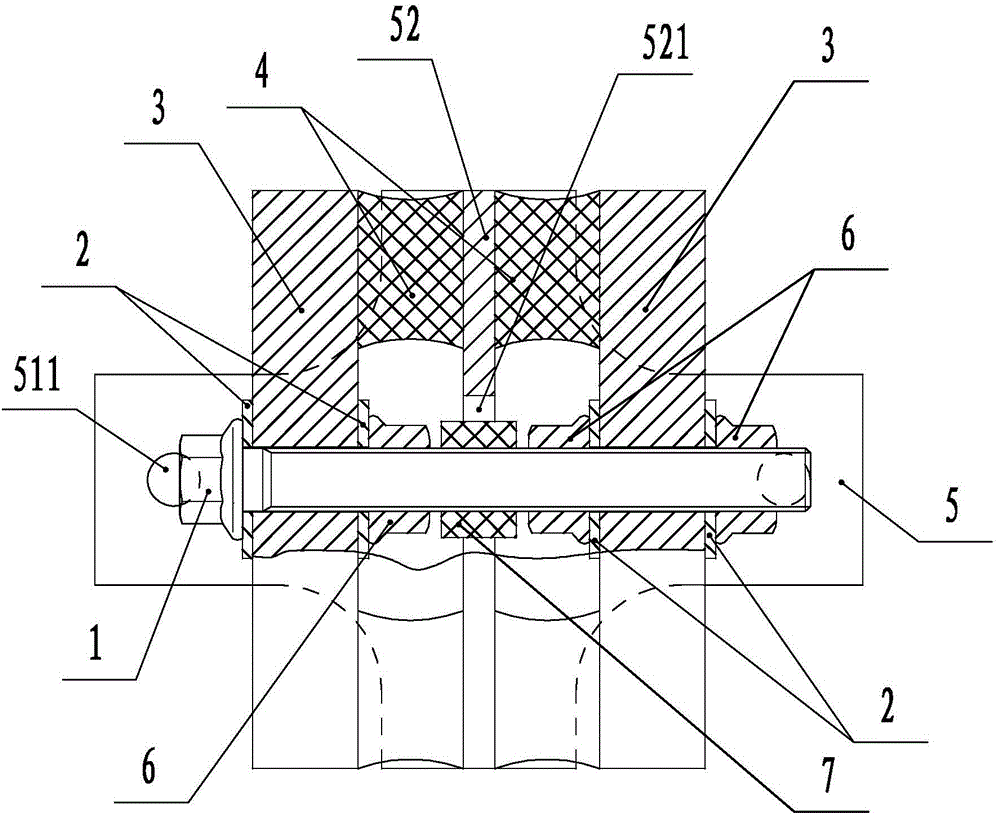

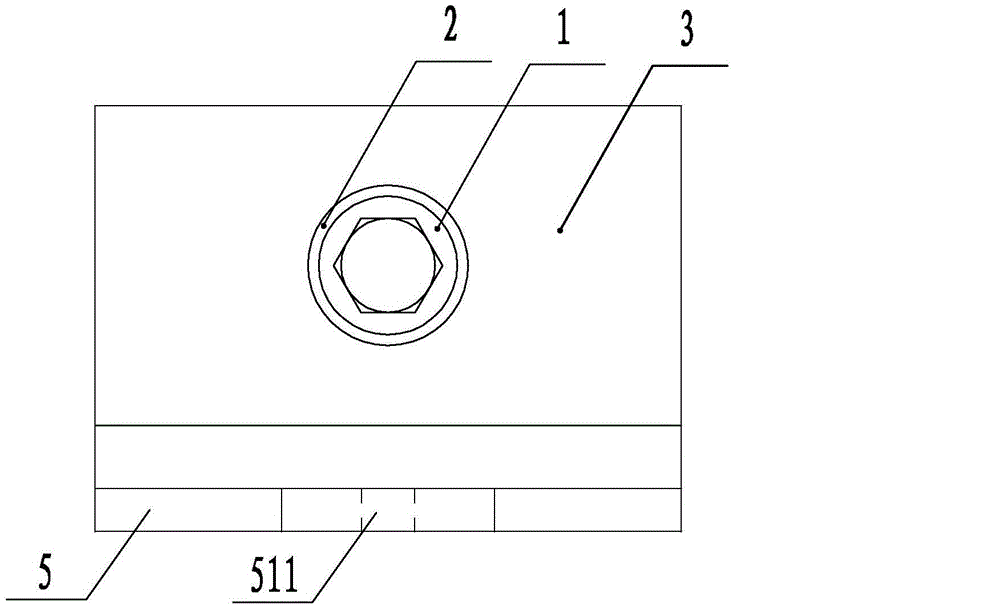

[0040] A rear axle mass shock absorber, see Figure 1 ~ Figure 3 As shown, it includes a screw rod 1, a mass inertia block 3 capable of generating inertial displacement with sufficient weight, a vibration-absorbing rubber 4, a mounting bracket 5 for supporting the vibration-absorbing rubber 4 and being assembled and connected with the rear axle of the automobile,

[0041] The mounting bracket 5 is composed of a base plate 51 and a vertical plate 52, and the vertical plate 52 is provided with a limiting hole 521;

[0042] Described mass inertial block 3 has two, is respectively symmetrically arranged on the vertical plate 52 both sides of mounting bracket 5, and this mass inertial block 3 is cuboid, and each mass inertial block 3 is provided with central circular hole, and the central circular hole The inner diameter matches the screw rod 1, and the mass inertia block 3 and the vertical plate 52 of the mounting bracket 5 are vulcanized and connected through the vibration-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com