Automobile interior trim part and forming process for same

A technology for automotive interior parts and processes, applied in synthetic resin layered products, lamination, and layered products, etc., can solve problems such as poor products, low mold temperature and fabric performance requirements, and reduce the incidence of quality problems. , The effect of improving NVH performance and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

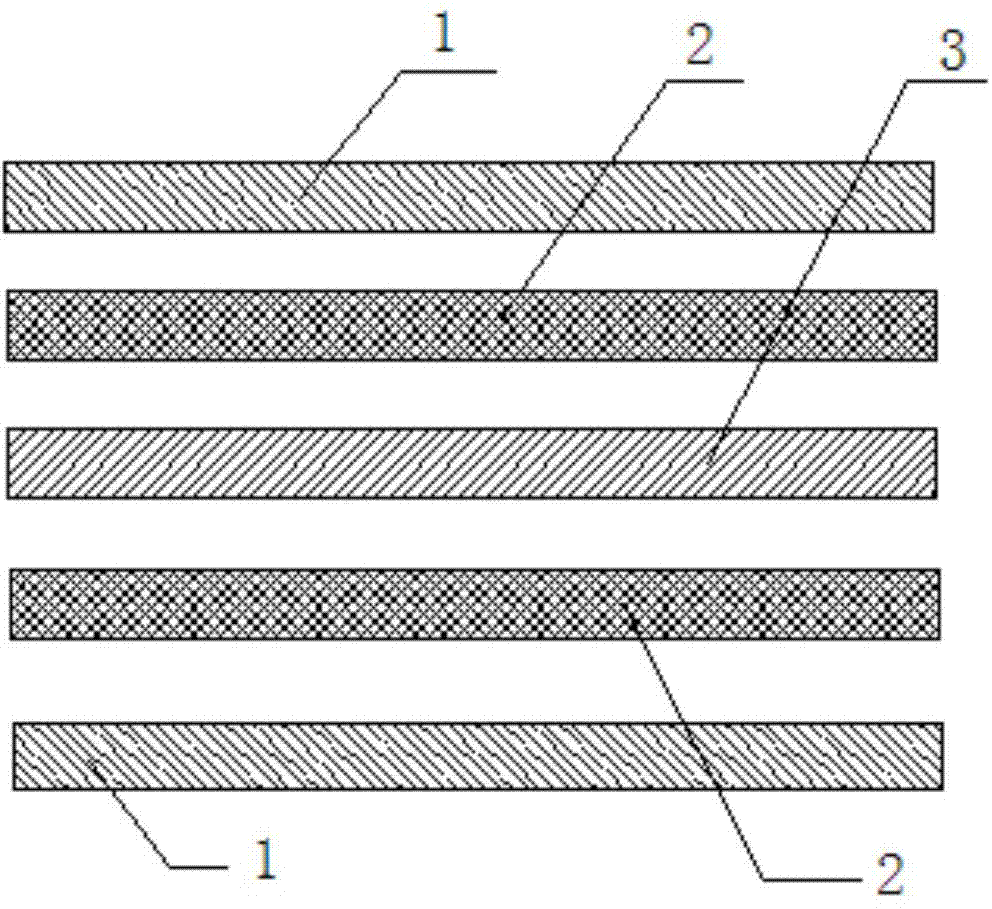

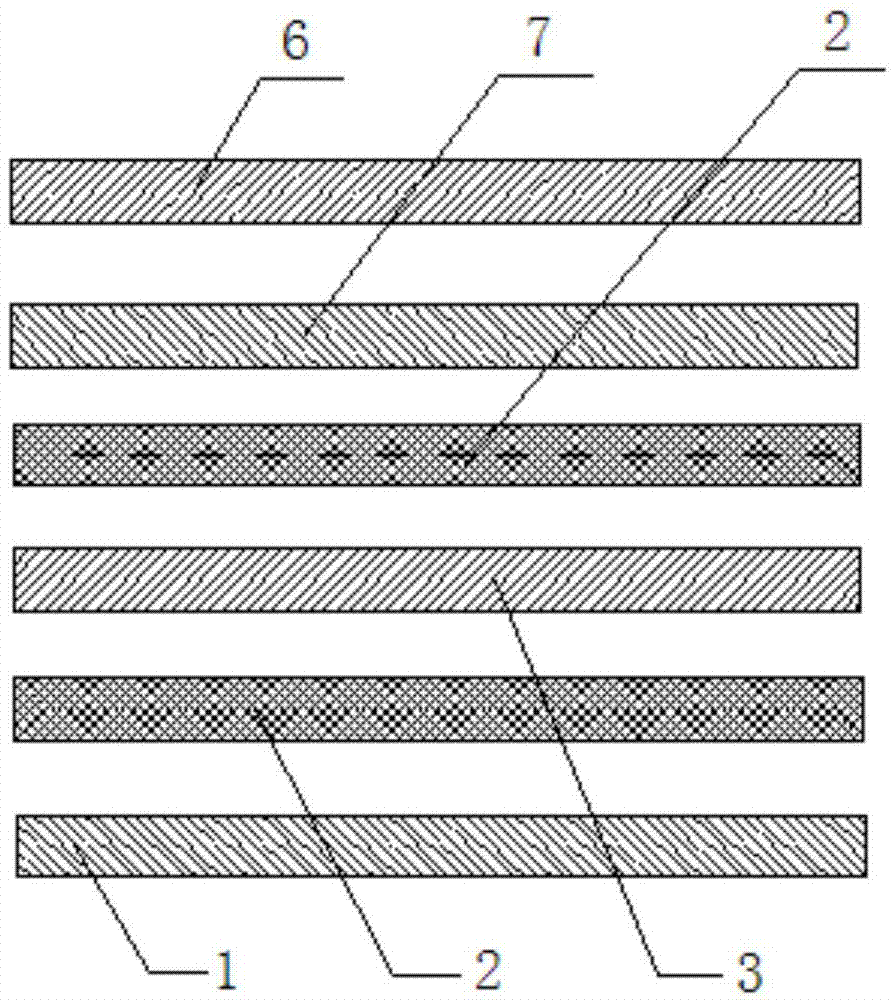

[0034] An automobile interior part is composed of a composite knitted fabric layer, a glass fiber felt, a PU foam board, a glass fiber felt, and a PET material layer from top to bottom.

[0035] A process for producing the above-mentioned automotive interior parts, comprising the following processing steps:

[0036] (1) Put the PU foam board through the roller glue machine to apply glue on the upper and lower sides, and then spray the PU foam board with water, wherein the ratio of glue to water is 2:1;

[0037] (2) Stack the PET material layer, glass fiber felt, double-sided glued PU foam board, glass fiber felt and composite knitted fabric layer from bottom to top in order, and send them to the mold cavity after the stacking is completed;

[0038] (3) Cold material hot mold compression molding, in which the temperature of the mold is 140oC, and the pressure is kept at 10MPa-15MPa. During the pressure keeping process, the exhaust is exhausted at intervals. After the pressure ...

Embodiment 2

[0042] An automobile interior part is composed of a composite knitted fabric layer, a glass fiber felt, a PU foam board, a glass fiber felt, and a PET material layer from top to bottom.

[0043] A process for producing the above-mentioned automotive interior parts, comprising the following processing steps:

[0044] (1) Pass the PU foam board through the roller glue machine to apply glue on the upper and lower sides, and then spray the PU foam board with water, wherein the ratio of glue to water is 1.5:1;

[0045](2) Stack the PET material layer, glass fiber felt, double-sided glued PU foam board, glass fiber felt and composite knitted fabric layer from bottom to top in order, and send them to the mold cavity after the stacking is completed;

[0046] (3) Cold material hot mold compression molding, in which the temperature of the mold is 130oC, and the pressure is maintained, and the pressure is 10MPa-15MPa. During the pressure maintenance process, the exhaust is exhausted at i...

Embodiment 3

[0050] An automobile interior part is composed of a composite knitted fabric layer, a glass fiber felt, a PU foam board, a glass fiber felt, and a PET material layer from top to bottom.

[0051] A process for producing the above-mentioned automotive interior parts, comprising the following processing steps:

[0052] (1) Put the PU foam board through the roller glue machine to apply glue on the upper and lower sides, and then spray the PU foam board with water, wherein the ratio of glue to water is 1:1;

[0053] (2) Stack the PET material layer, glass fiber felt, double-sided glued PU foam board, glass fiber felt and composite knitted fabric layer from bottom to top in order, and send them to the mold cavity after the stacking is completed;

[0054] (3) Cold material hot mold compression molding, in which the temperature of the mold is 120oC, and the pressure is kept at 10MPa-15MPa. During the pressure keeping process, the exhaust is exhausted at intervals, and the pressure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com