Reinforcing structure of saloon car rear floor spare wheel groove

A technology for strengthening structure and rear floor, applied in the directions of superstructure, spare tire arrangement, superstructure sub-assembly, etc., can solve the problem of increasing the investment cost of stamping dies and welding fixtures, failing to achieve floor stiffness and modal, increasing stamping Process difficulty and other issues to avoid the resonance of the spare tire groove, improve performance, and improve NVH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

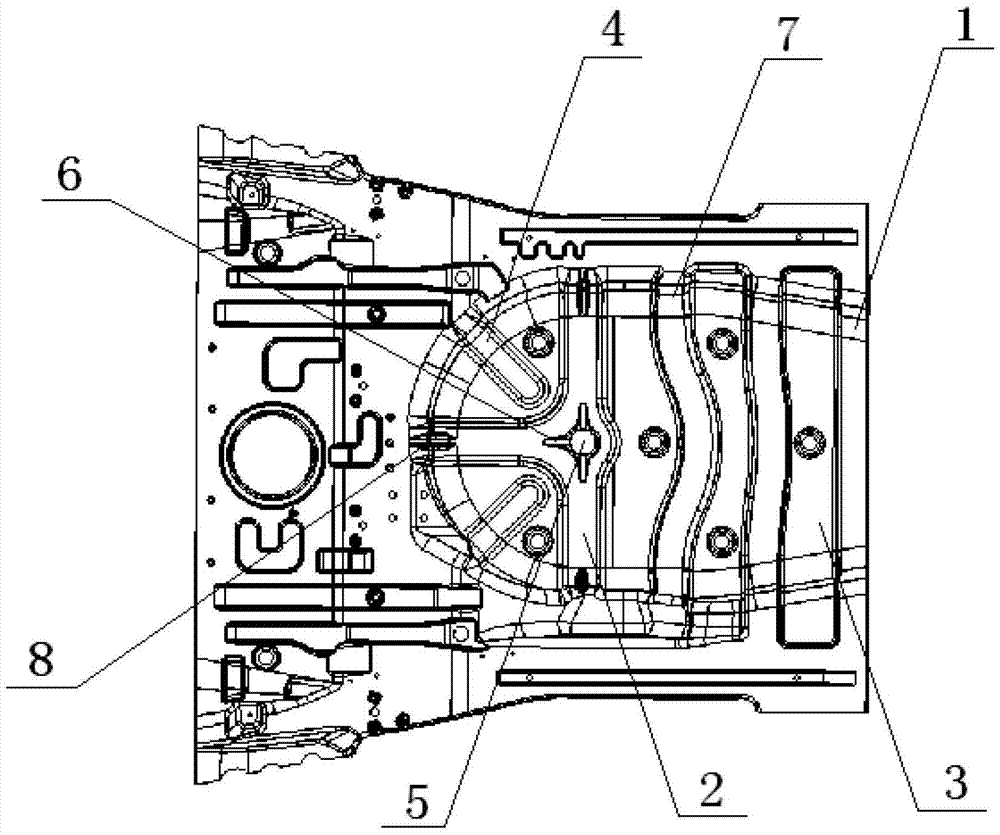

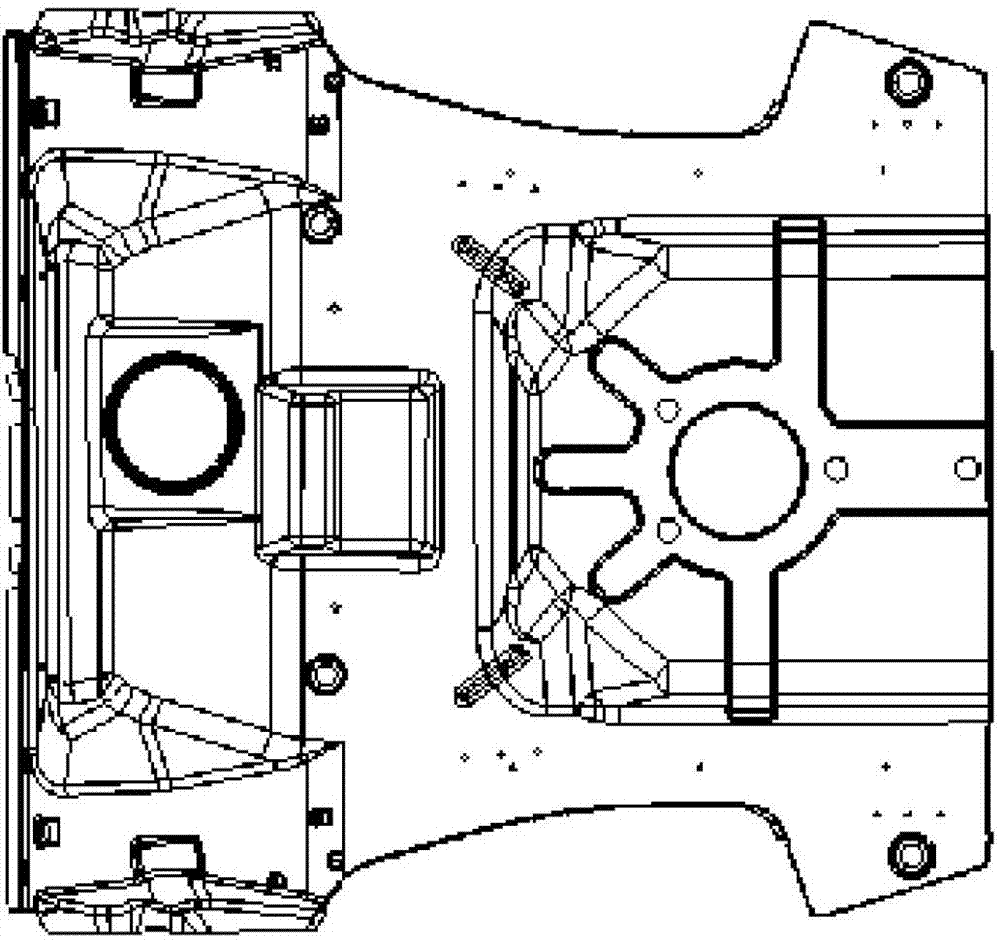

[0020] Take the direction of the front of the car as the front end, and the direction of the rear of the car as the rear end. In the present invention, the spare tire groove 1 tends to be closed from the front to the rear; a T-shaped rib 2 is arranged around the spare tire mounting point 5, and line ribs 3 of equal width are evenly distributed at the rear end of the spare tire mounting point 5; A linear rib 4 is arranged around the spare tire installation point 5, so as to avoid the resonance phenomenon in the spare tire groove by ingeniously adding reinforcing ribs.

[0021] The purpose of the present invention is to improve the spare tire groove on the rear floor of the car, significantly increase the rigidity and mode of the spare tire groove, avoid the occurrence of resonance phenomenon, and facilitate the full deformation and energy absorption of the car after a collision, so as to protect the fuel tank and passengers .

[0022] The present invention includes a spare tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com