Oil-immersed type transformer

A technology of oil-immersed transformers and transformer oil, which is applied in the field of transformers, and can solve problems such as lack of heat dissipation, temperature rise of transformer coil windings, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

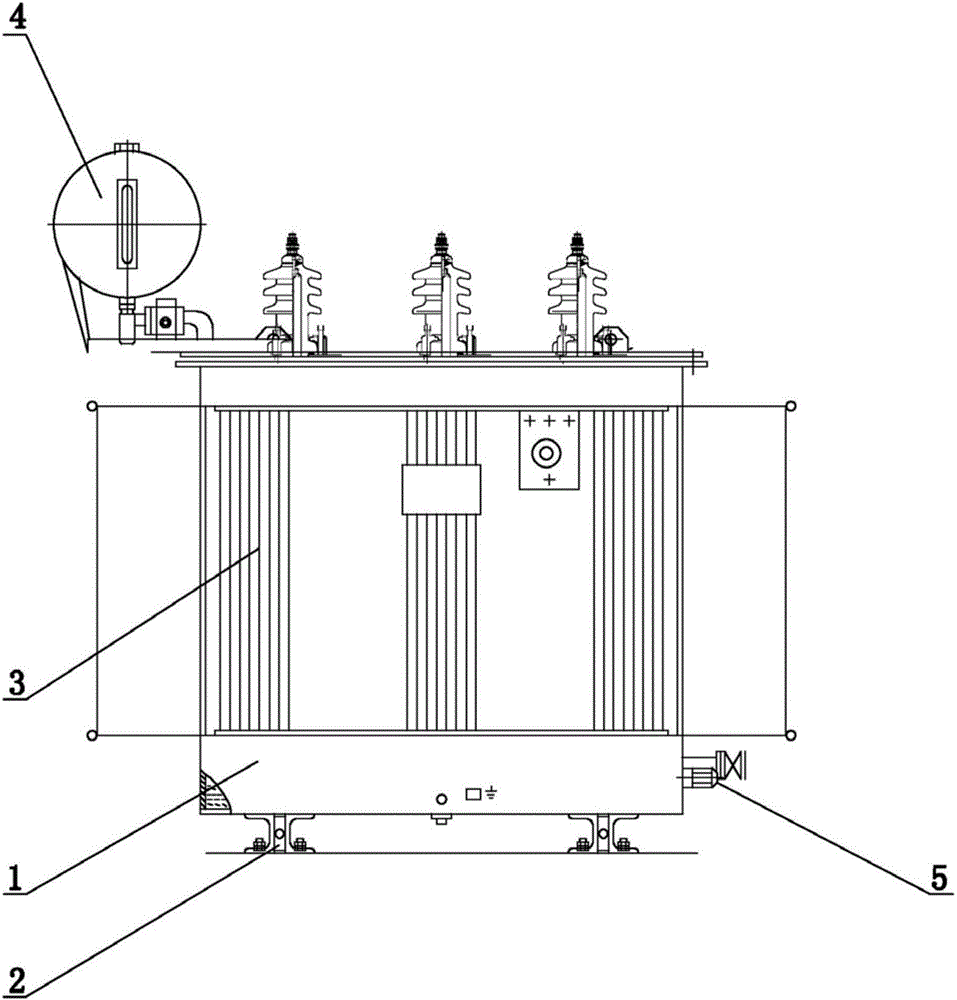

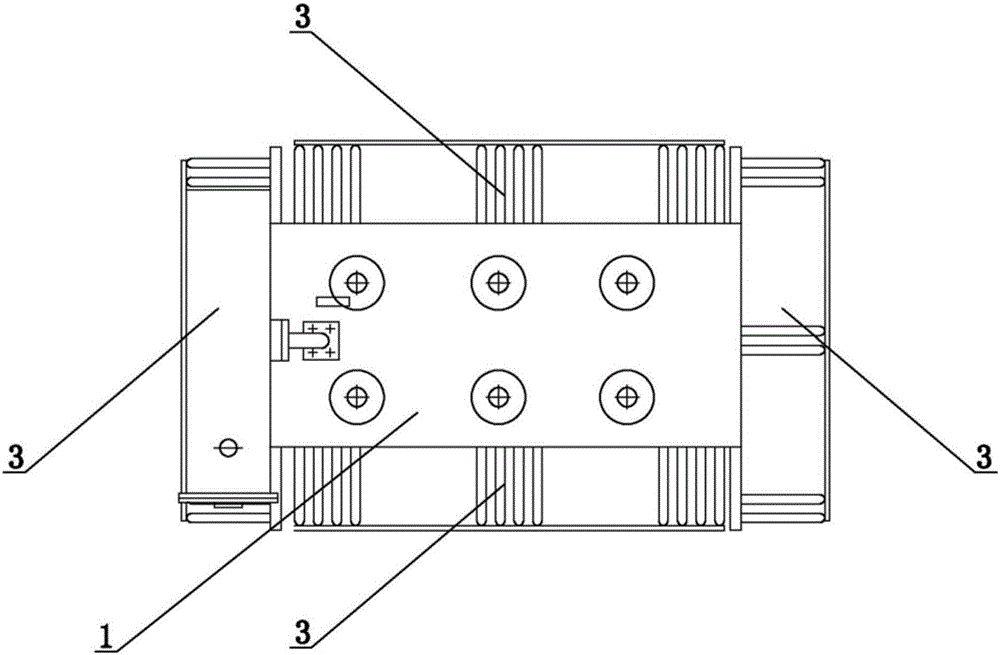

[0017] refer to Figure 1 to Figure 2 The embodiment of the oil-immersed transformer of the present invention will be further described.

[0018] An oil-immersed transformer, comprising an oil tank 1 filled with transformer oil, an iron core and a coil winding arranged in the oil tank 1, and a pad 2 arranged below the oil tank 1, and a radiator 3 is arranged on the side wall of the oil tank 1, The radiator 3 includes several cooling fins that can cover the side wall of the oil tank 1, and the cooling fins include cooling chambers that can accommodate transformer oil.

[0019] By adopting the above technical scheme, radiators 3 are provided on the side walls of the fuel tank 1, and the radiators 3 include a plurality of cooling fins that can cover the side walls of the fuel tank 1. The fins include a heat dissipation chamber that can accommodate transformer oil. The transformer oil in the oil tank 1 can enter the heat dissipation chamber, and the heat dissipation effect is ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com