Method for controlling engine revolution speed during starting of hybrid power vehicle

A hybrid vehicle, engine speed technology, applied in hybrid vehicles, combustion engines, internal combustion piston engines, etc., can solve problems such as poor engine and electrode coordination, engine combustion pollution, affecting vehicle NVH performance, etc., to improve NVH performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

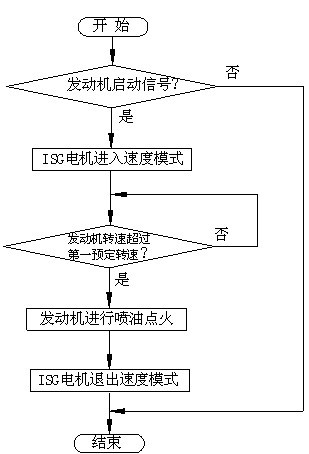

[0019] Such as figure 1 As shown, in the method for controlling the engine speed when the hybrid electric vehicle is started in this embodiment, the ISG motor is connected in parallel with the engine. After the electric motor increases the rotational speed of the engine to 500 revolutions per minute exceeding the first predetermined rotational speed, the engine is controlled to perform fuel injection and ignition, and the ISG electric motor exits the speed mode at the same time.

Embodiment 2

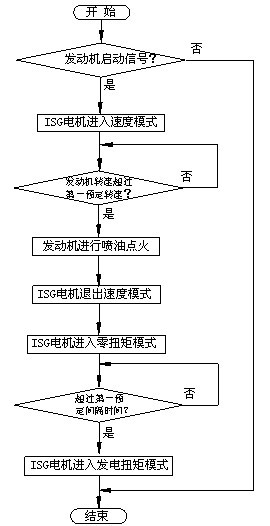

[0021] Such as figure 2 As shown, the difference from Embodiment 1 is that in the method for controlling the engine speed when the hybrid electric vehicle starts in this embodiment, when the ISG motor exits the speed mode, it first enters the zero torque mode, and at the first predetermined interval of 100 milliseconds Then enter the power generation torque mode to apply power generation torque to the engine until the start process ends.

[0022] When the ISG motor is used to apply generating torque to the engine, the higher the rotation speed of the engine, the greater the applied generating torque.

Embodiment 3

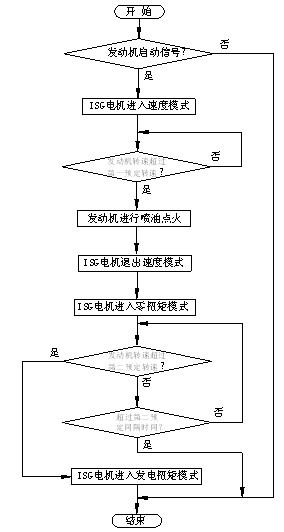

[0024] Such as image 3 As shown, the difference from Embodiments 1 and 2 is that in the method for controlling the engine speed when the hybrid electric vehicle starts in this embodiment, after the ISG motor exits the speed mode, the ISG motor first enters the zero torque mode. If the engine speed is at the second If the speed is higher than the second predetermined speed of 600 r / min within a predetermined interval (150 milliseconds), it will enter the power generation torque mode, otherwise it will remain in the zero torque mode until the start-up process ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com