Damping fin applied to clutch driven disc, clutch driven disc and clutch

A damping plate and clutch technology, applied in the field of clutches, can solve the problems of large moment of inertia, high cost, limited vibration damping effect of the clutch driven plate, etc., and achieve the effects of reducing moment of inertia, improving vibration damping effect, and good NVH performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

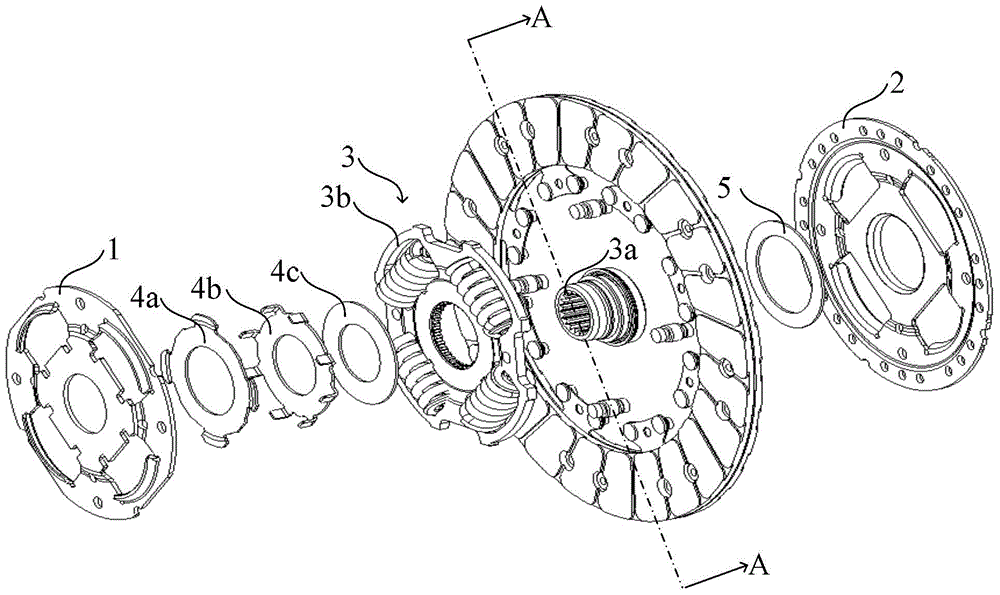

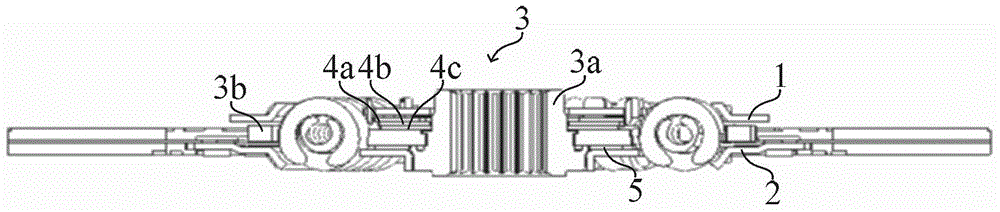

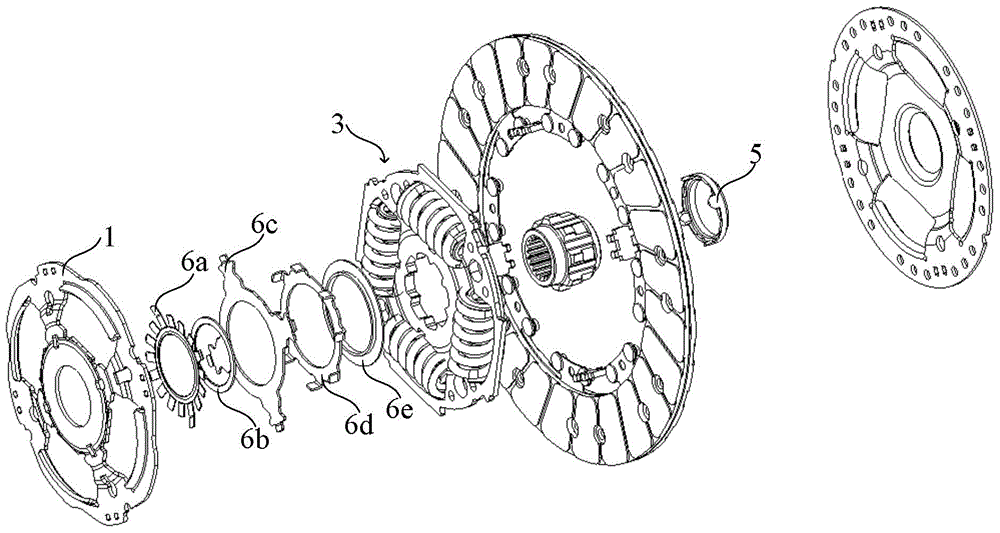

[0055] combine Figure 4 with Figure 5 As shown, the clutch driven disc of this embodiment includes:

[0056] Damping disc 10;

[0057] A driven disc body 20 fixedly connected to the damping disc 10 in a torsion-resistant manner;

[0058] A driven hub 30 rotatably located between the damping disc 10 and the driven disc body 20, the driven hub 30 has a hub core 31 and a flange 32 sleeved on the hub core 31;

[0059] A damping plate 50 located between the driven disc hub 30 and the driven disc body 20;

[0060] Located between the damping disc 10 and the driven hub 30 , there are two annular damping sheets 41 sheathed on the hub core 31 , and the two damping sheets 41 serve as a friction damping assembly. One of the damping plates 41 is fixedly connected to the damping disk 10 in a torsionally fixed manner, and the other damping plate 41 is fixedly connected to the driven hub 30 in a torsionally fixed manner.

[0061] combine Image 6 As shown, the damping plate 41 has: t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com