Seven-degree-of-freedom series-parallel hybrid mechanical arm and robot

A degree of freedom, robotic arm technology, applied in the field of robotics, can solve the problems of large rotational inertia, insufficient flexibility and degrees of freedom of the robotic arm, and achieve the effect of flexible movement, simplified kinematics calculation model, and convenient kinematics solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

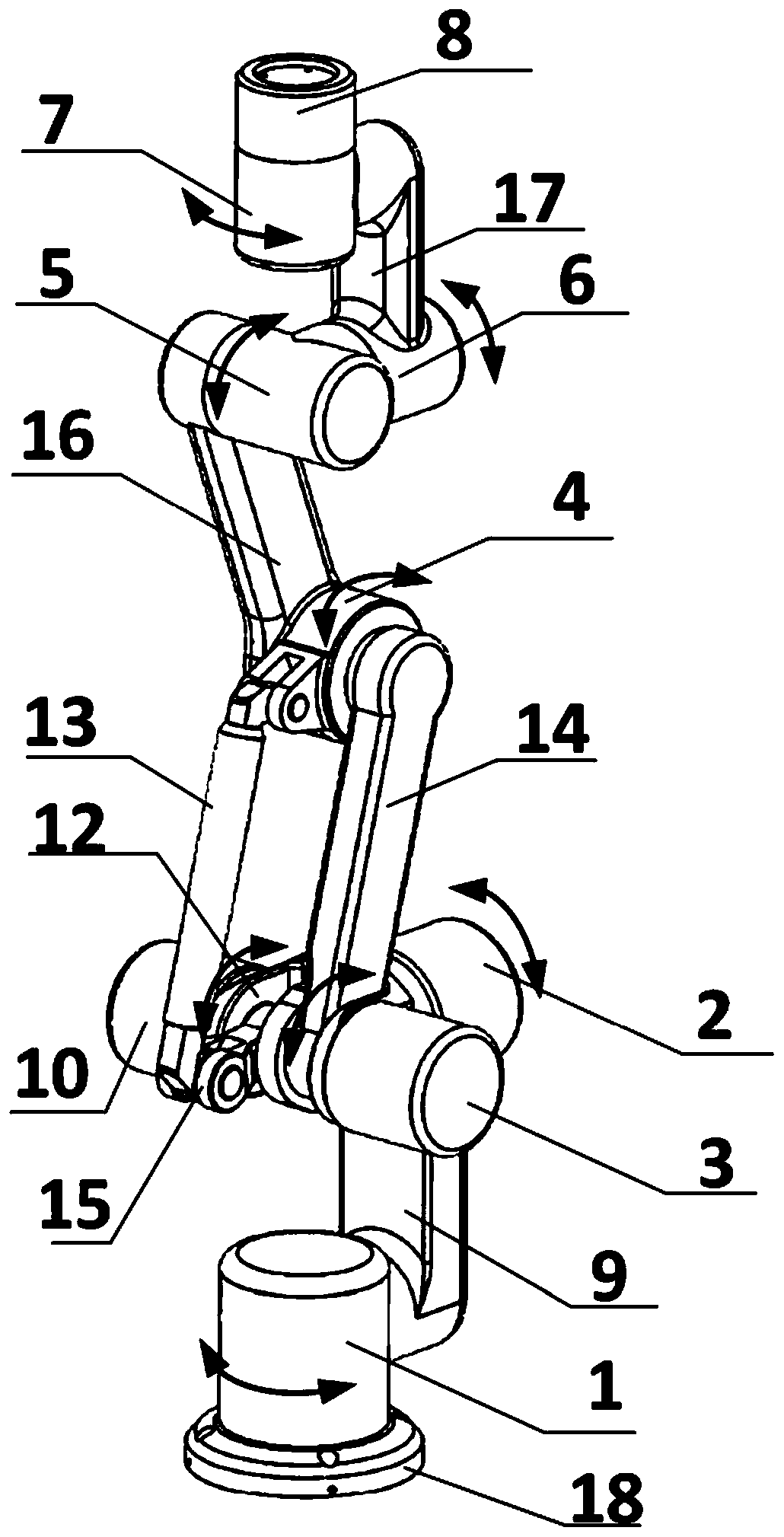

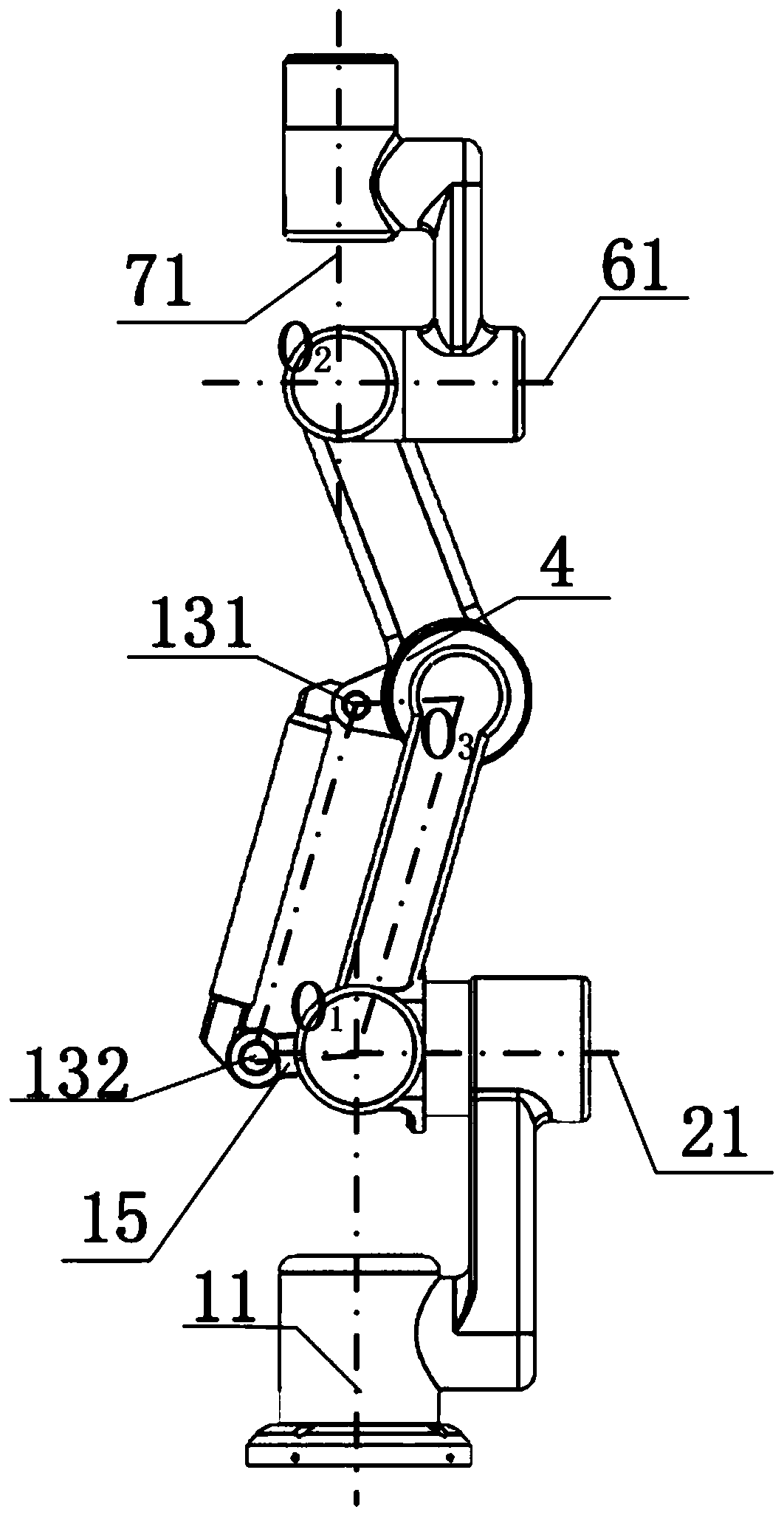

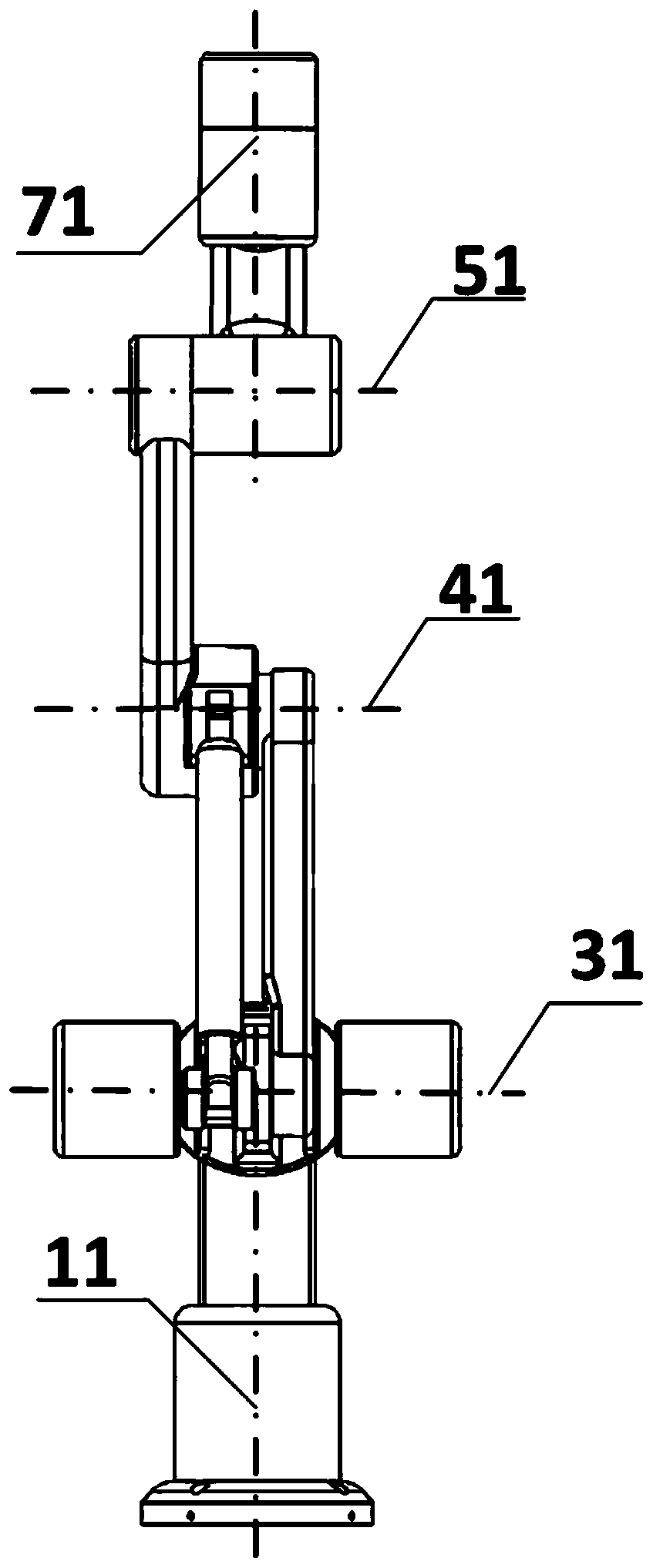

[0031] Such as Figure 1 to Figure 8 As shown, a seven-degree-of-freedom serial-parallel hybrid robot arm includes a base 18, a first joint 1, a first connecting rod 9, a second joint 2, a connecting bracket 12, a third joint 3, a second The connecting rod 14, the fourth joint 4, the fifth connecting rod 16, the fifth joint 5, the sixth joint 6, the sixth connecting rod 17, the seventh joint 7 and the connecting flange 8 of the end effector, the connecting bracket 12 is connected with The fourth joint motor housing 10; the fourth joint motor housing 10 and the third joint 3 are located on both sides of the second connecting rod 14 and are coaxial at the same height;

[0032] A third connecting rod 15 and a fourth connecting rod 13 are also arranged between the third joint 3 and the fourth joint 4. One end of the fourth connecting rod 13 is connected to the fourth joint 4 through a hinge 131, and the other end is connected to the third connecting rod through a hinge 132. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com