Experiment table for studying friction mechanism of precision ball screw pair

A technology of ball screw pair and test bench, which is applied in the direction of power measurement, measuring device, instrument, etc., to achieve the effect of precise measurement, running and fixed, and precise friction force of ball screw pair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

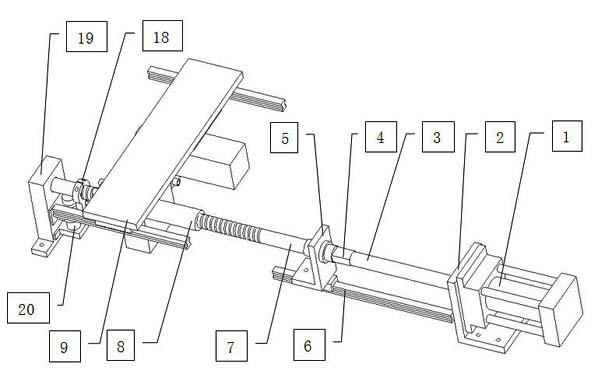

[0018] refer to figure 1 , the precision ball screw pair friction mechanism research experimental bench of the present invention includes a lead screw 7, on the lead screw 7, a connecting sleeve 18 is connected to the friction torque sensor 20 for obtaining the ball screw pair, when the nut is driven and the lead screw rotates , the friction torque sensor 20 directly obtains the friction torque of the ball screw pair through its cantilever constraining the rotational movement of the screw. A screw support 19 and an axial sliding support 5 are respectively provided at both ends of the screw. One end on the same side of the sliding support 5 is connected with an axial force sensor 4 and is connected with one end of the axial force sensor 4, and the other end of the axial force sensor 4 is connected with a hydraulic cylinder 1 and is connected with the hydraulic cylinder 1. Piston rod connection.

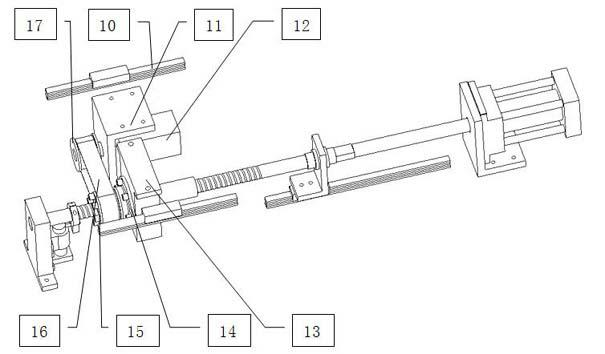

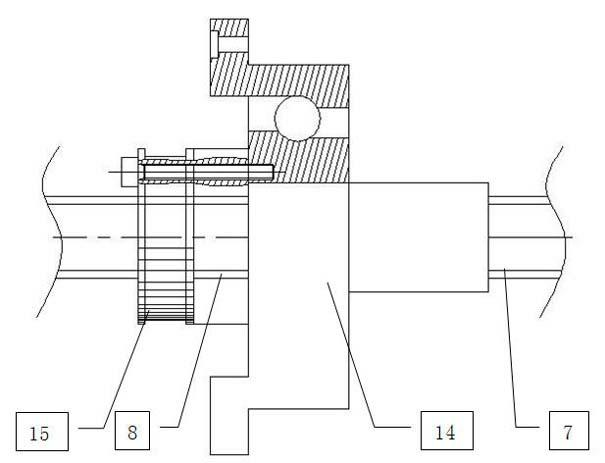

[0019] refer to figure 2 , an angular contact bearing 14 is sleeved on the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com