Top-cover outer plate and skylight reinforcing frame structure

A technology for strengthening frames and sunroofs, which is applied in the fields of car bodies and car sunroofs. It can solve the problems of affecting the NVH effect of the whole vehicle, the wear of the sealant strip, and the friction failure of the sheet metal, so as to improve the NVH performance, reduce the probability of wear and tear, and increase the connection. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

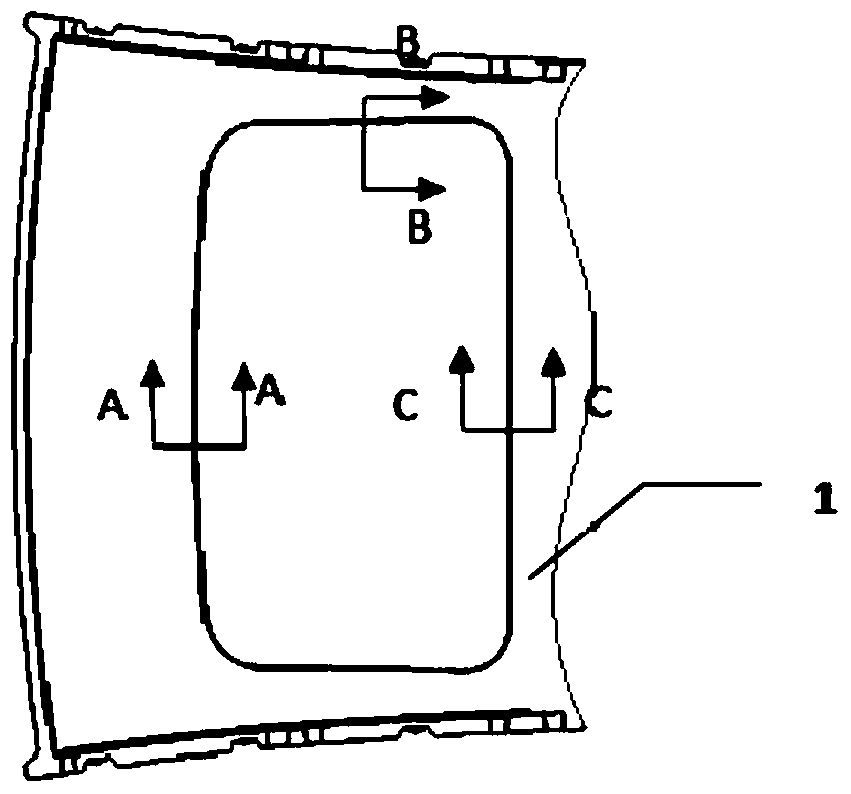

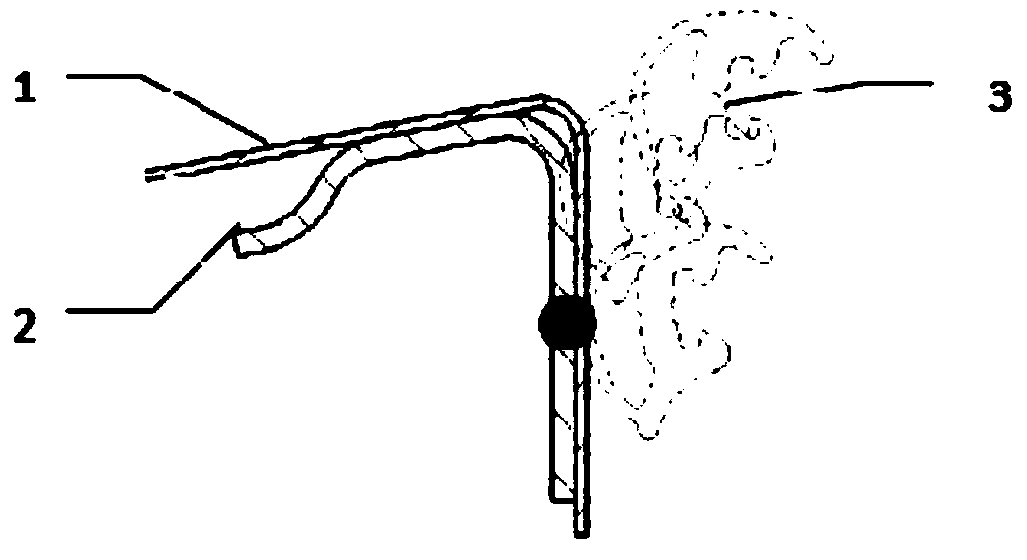

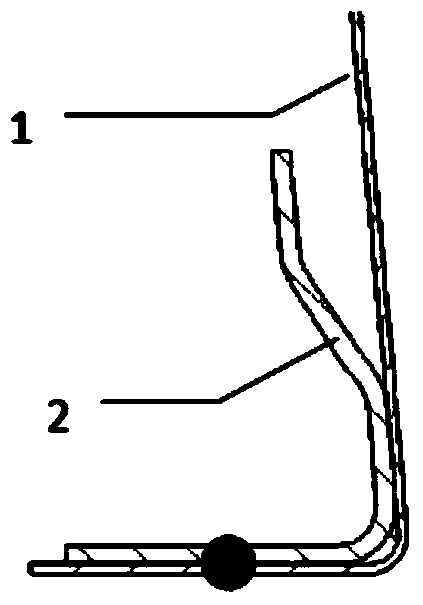

[0032] Such as Figure 5 to Figure 8 As shown, a top cover outer panel 1 and a sunroof reinforcement frame structure 2 include a front reinforcement frame, a rear reinforcement frame and a left and right reinforcement frame;

[0033] In the front reinforcement frame, a gap of 3mm is designed between the outer plate of the top cover and the reinforcement frame of the skylight, and a 2mm glue groove is designed on the reinforcement frame of the skylight, and a shock-isolating glue 4 is arranged between the skylight and the glue groove. At the vertical flanges of the two panels, the skylight is provided with two surfaces in the shape of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com