Patents

Literature

97results about How to "Reduced chance of wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

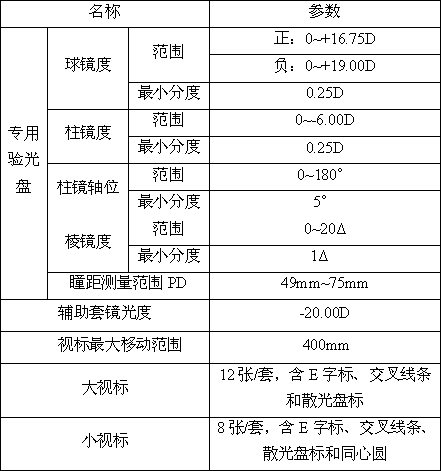

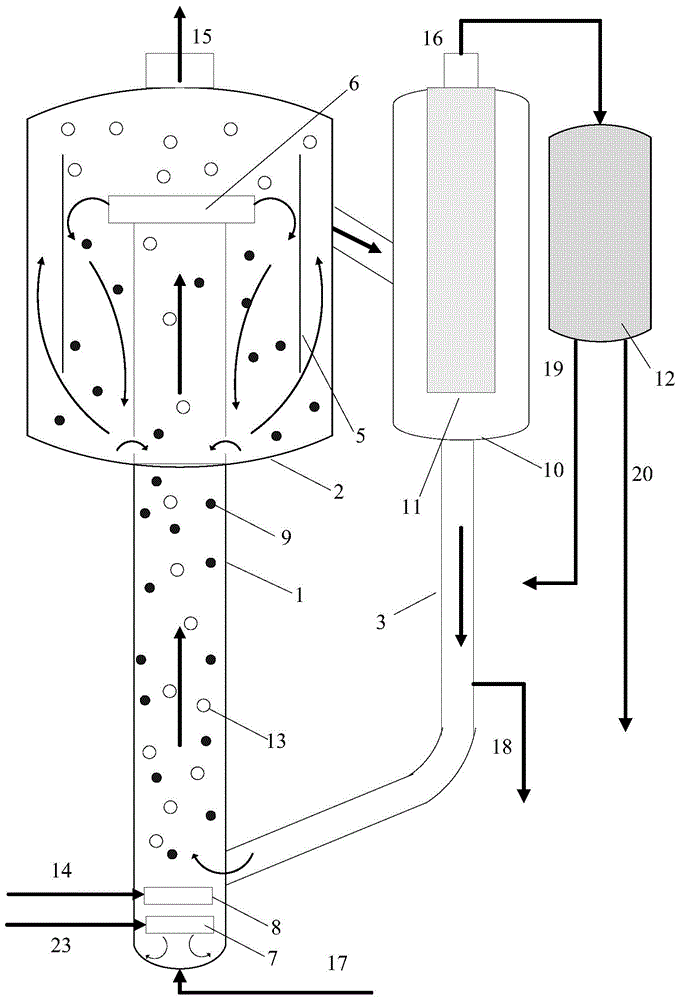

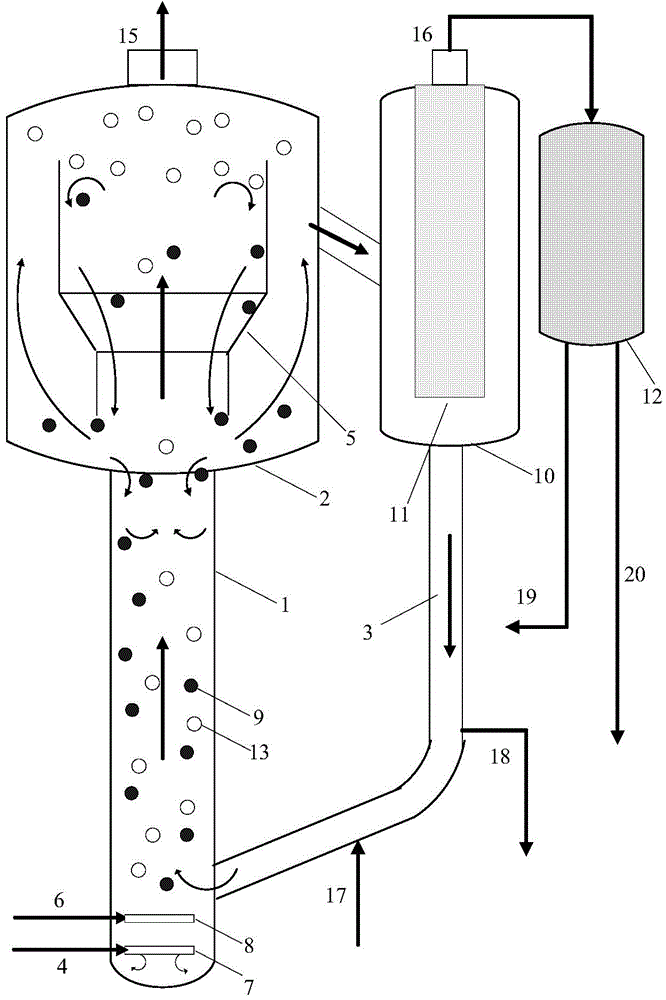

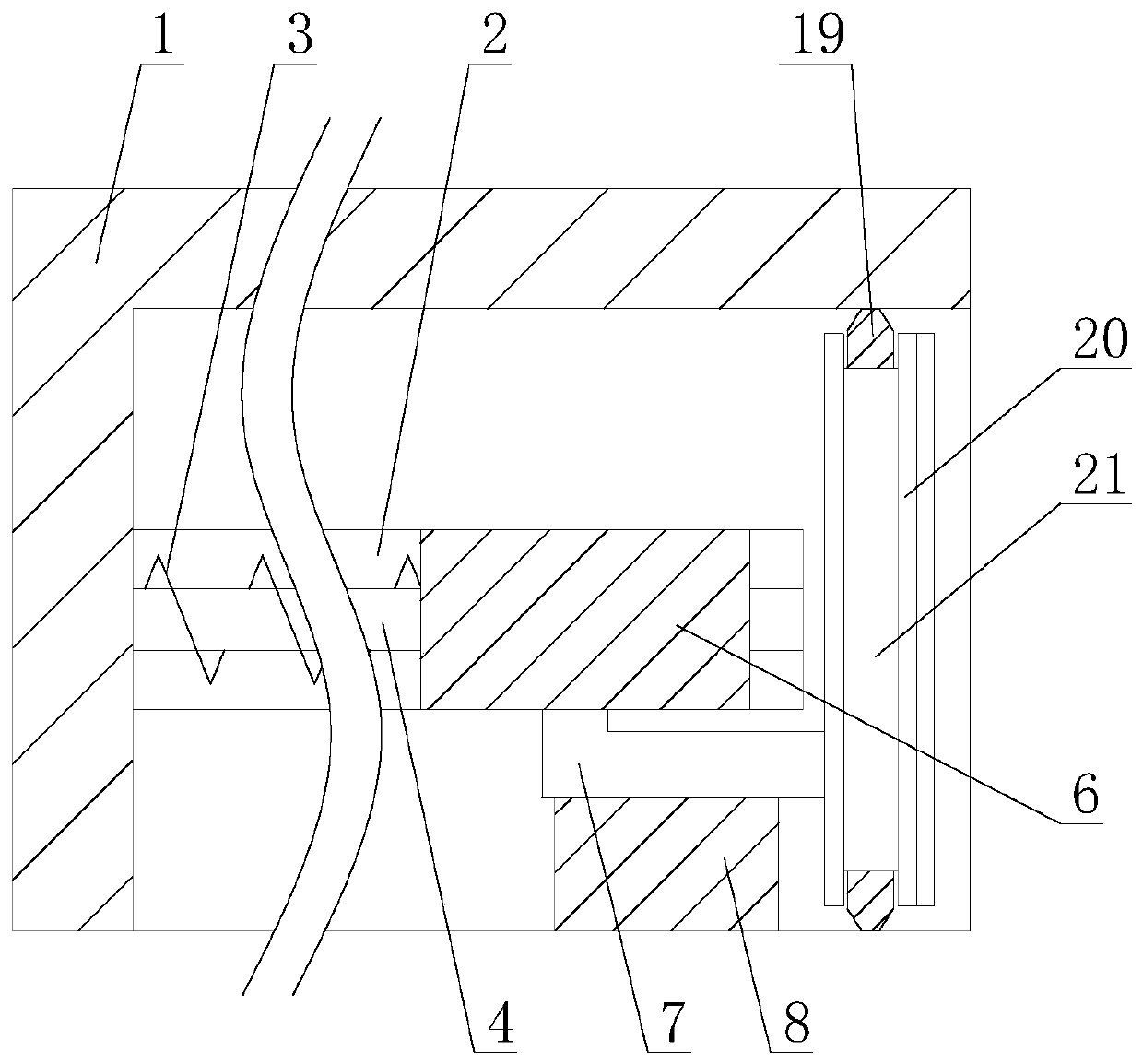

Slurry bed loop reactor, application and method for producing hydrogen peroxide

ActiveCN104549060AExtended operating cycleEasy to separatePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

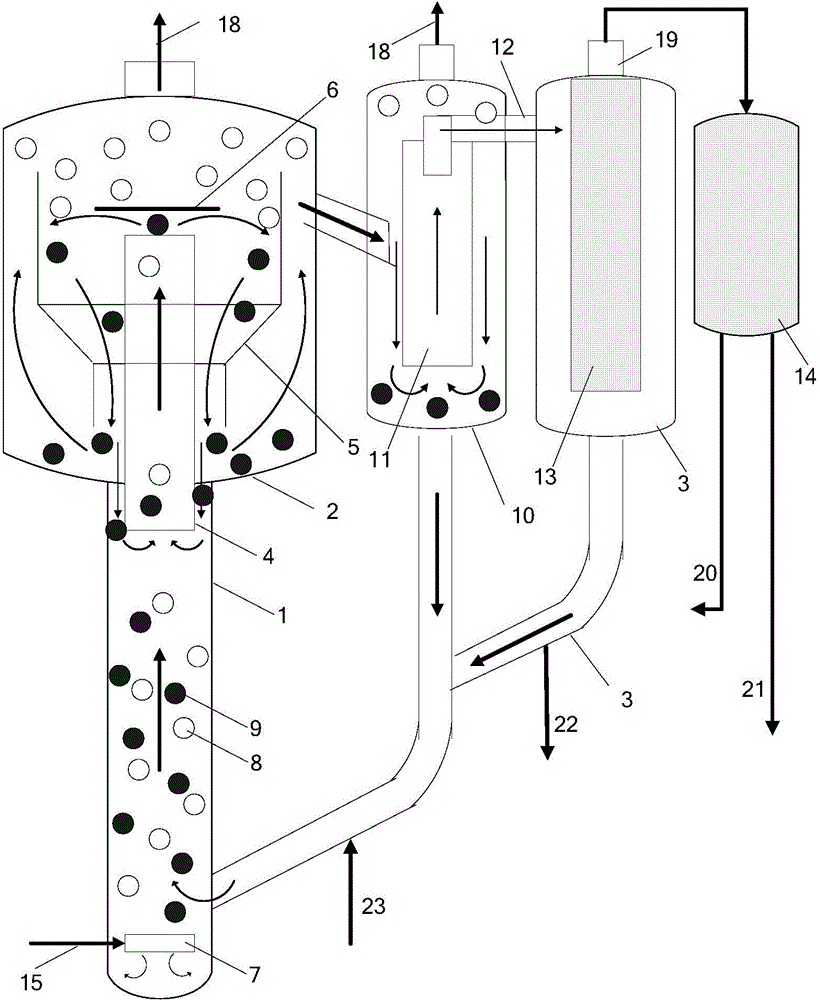

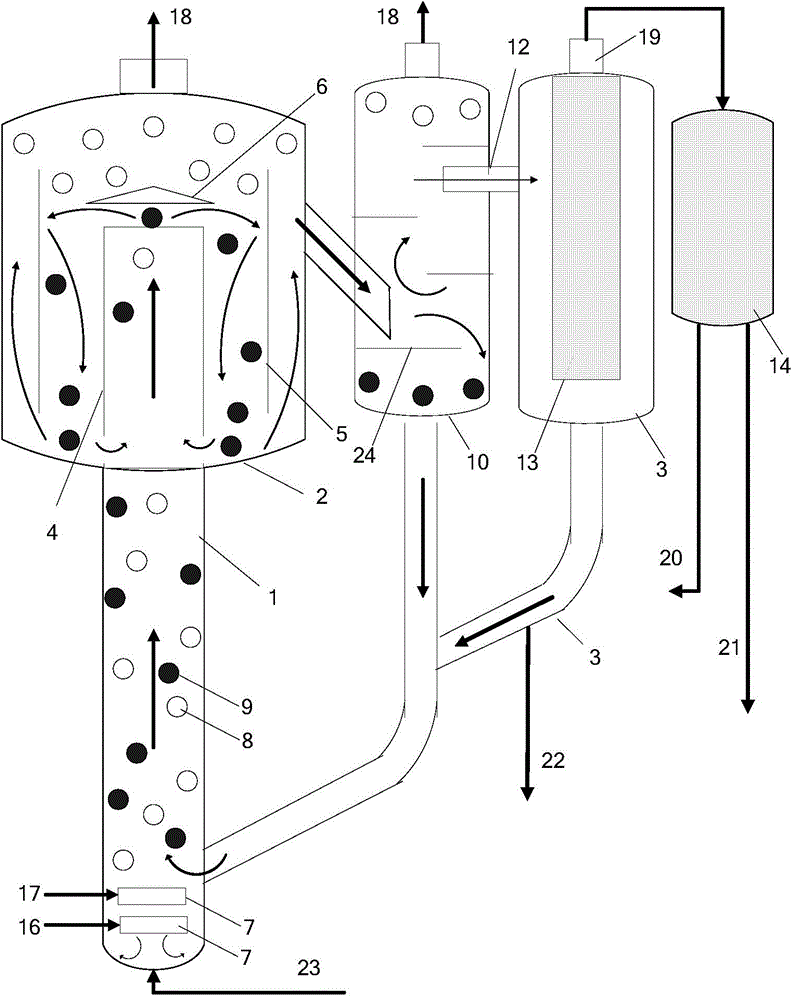

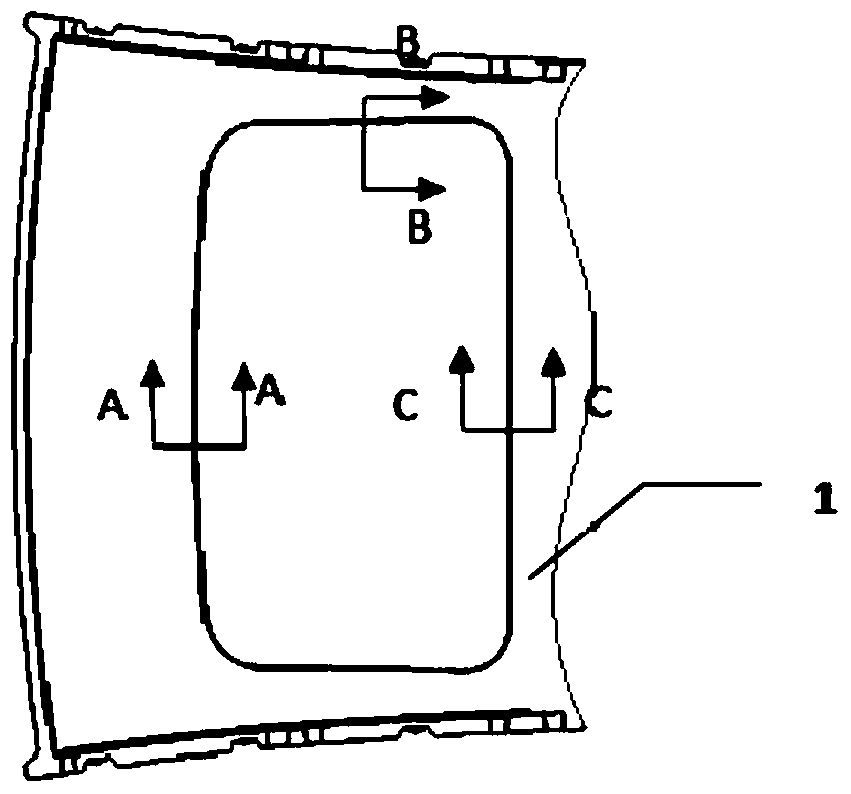

The invention relates to a slurry bed loop reactor, application and a method for producing hydrogen peroxide. The slurry bed loop reactor comprises a riser, a separation tank and a downcomer which are communicated sequentially, wherein an expansion section with expanded pipe diameter is arranged at the upper part of the riser, the upper part of the expansion section is communicated with the separation tank, a liquid phase outlet in the upper part of the separation tank is communicated with the upper part of the downcomer, the bottom of the downcomer is communicated with the bottom of the riser, and the bottom of the separation tank is communicated with the lower part of the downcomer; and a raw material inlet is formed in the bottom of the riser, gas outlets are formed in the top of the expansion section of the riser and in the top of the separation tank, a filtration component is arranged in the downcomer and a clear liquid outlet is formed in the upper part of the downcomer via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

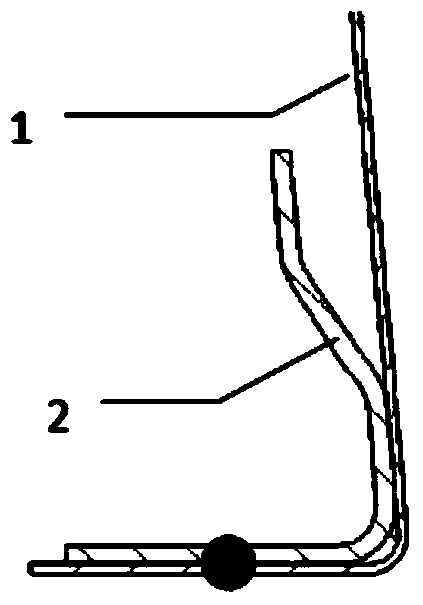

Top-cover outer plate and skylight reinforcing frame structure

InactiveCN103738148AImprove NVH performanceImprove qualityEngine sealsVehicle sealing arrangementsNoise, vibration, and harshnessUltimate tensile strength

The invention relates to a top-cover outer plate and skylight reinforcing frame structure comprising a front reinforcing frame, a rear reinforcing frame, a left reinforcing frame and a right reinforcing frame. In the front reinforcing frame, the rear reinforcing frame, the left reinforcing frame and the right reinforcing frame, gaps are designed above a top-cover outer plate and a skylight reinforcing frame. By the top-cover outer plate and skylight reinforcing frame structure, abnormal sounds at the matching position of the front reinforcing frame due to metal-plate adhesion instead of connection are avoided; through the design of shock-insulating rubber, connection strength of two plates is improved; vehicle NVH (noise vibration and harshness) performance and vehicle quality are improved; through the design of two surfaces, width of the matching surface of a vertical turnup of the front reinforcing frame and a seal rubber strip is shortened, a welding matching surface and a seal rubber strip surface are separated, abrasion of the seal rubber strip surface is reduced, and accordingly, abrasion probability of the rubber strip is greatly reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

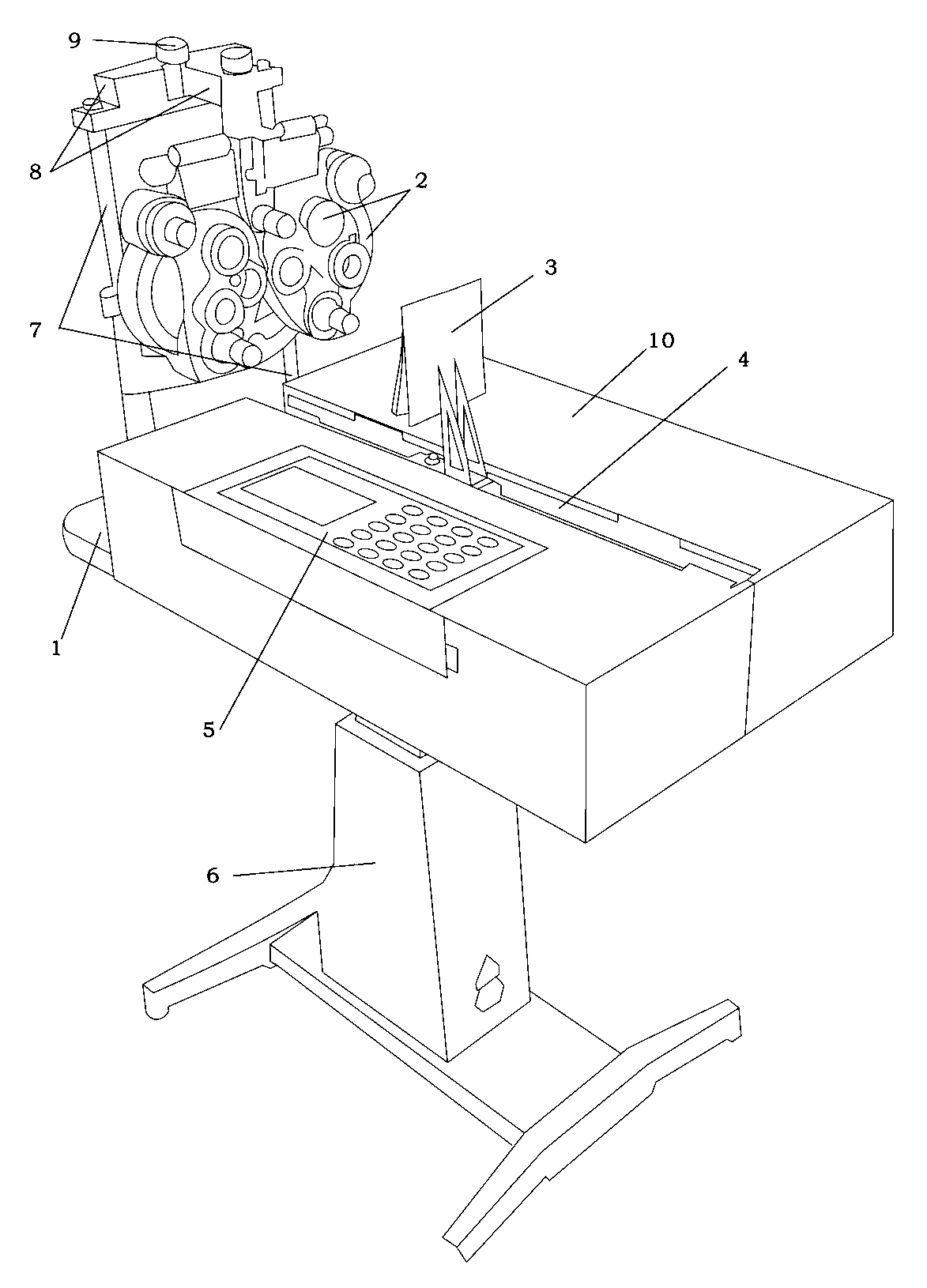

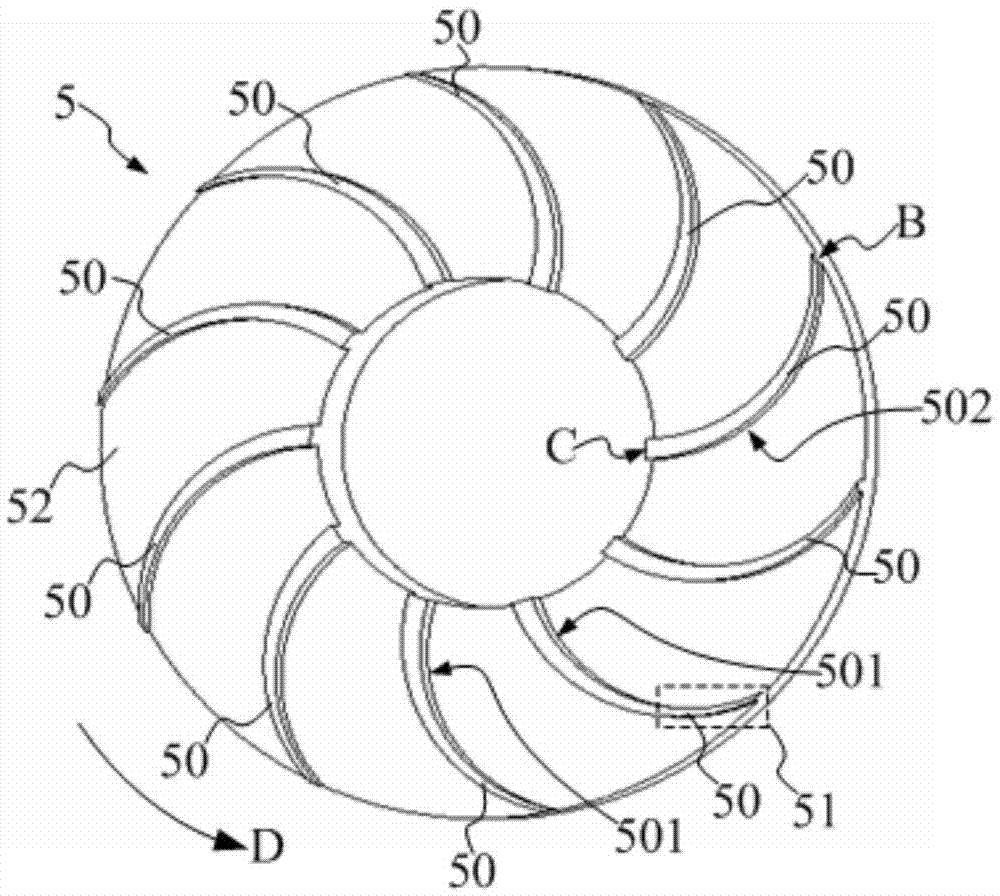

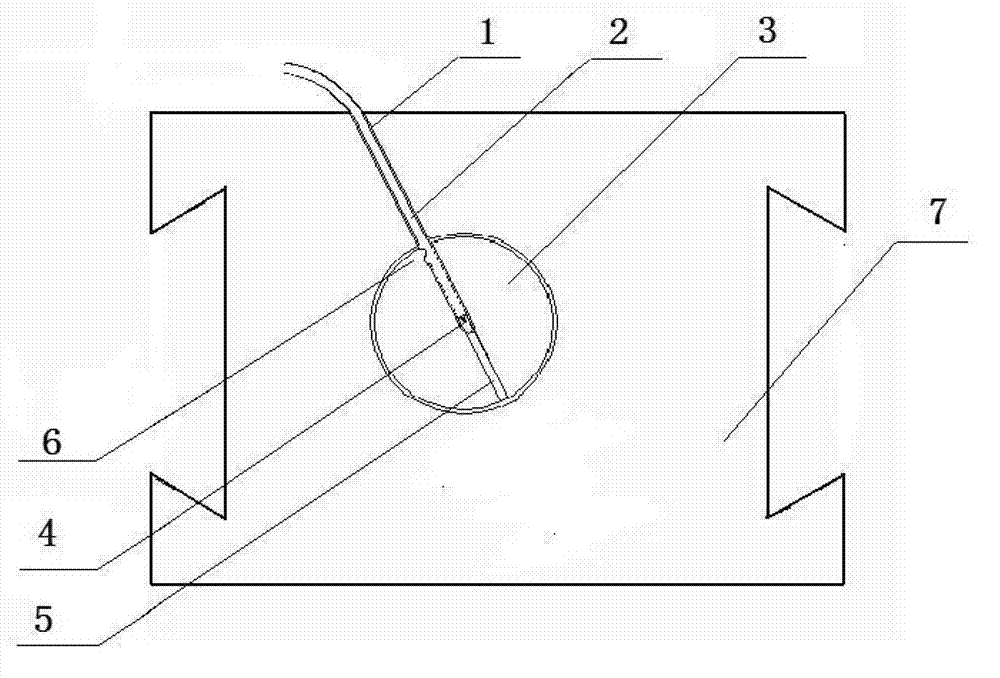

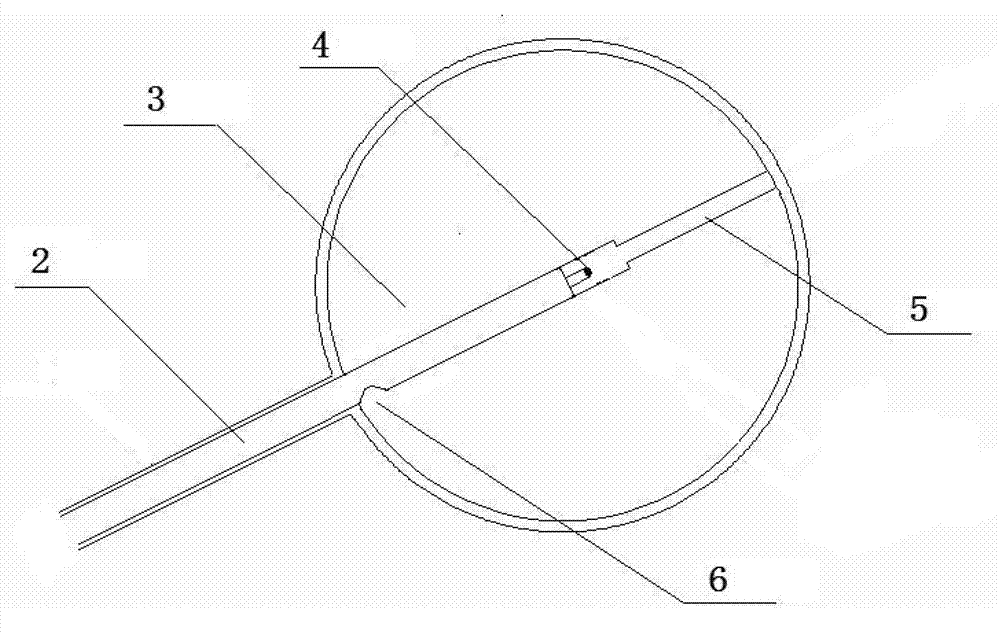

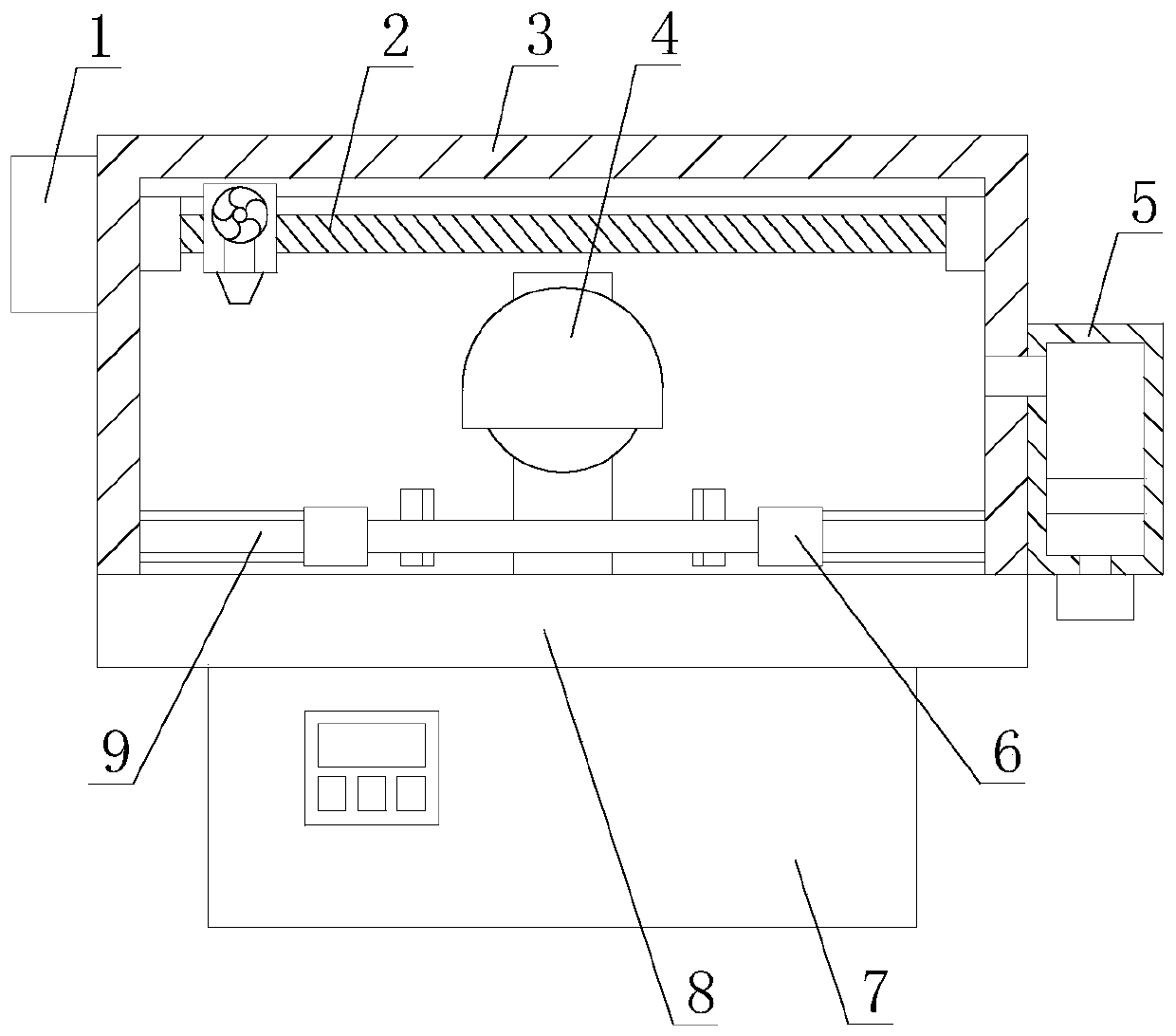

Automatic visual function training device

InactiveCN103156760AFine tune optimization and expansionNegative adjustment ability optimization and expansionEye exercisersVisual functionPhysical medicine and rehabilitation

The invention relates to an automatic visual function training device which comprises a support, a special optometry disk, sighting marks, a sighting mark guide rail, a sighting mark controller and an optometry disk guide column. The automatic visual function training device is safe and reliable and has no side effect. An individuation training scheme can be made according to a specific case of eyes of a person, pertinence is strong, effects are obvious, operation is full-automatic and intelligent, manipulation is easy and practical, and the service life of the automatic visual function training device is long.

Owner:SHANGHAI MINGPU MEDICAL SCI & TECH

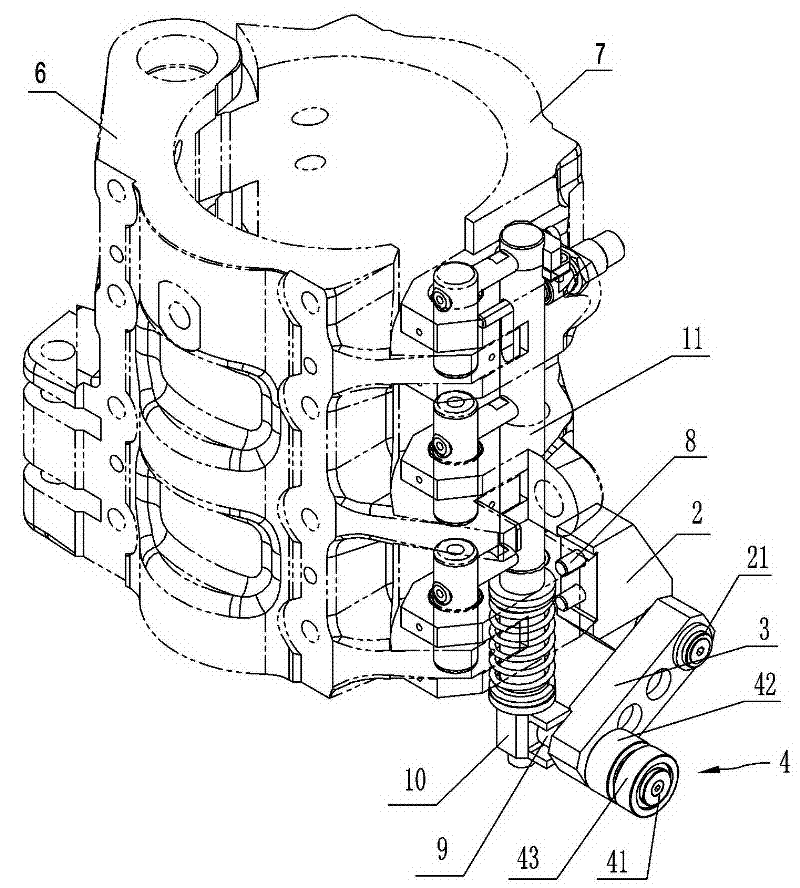

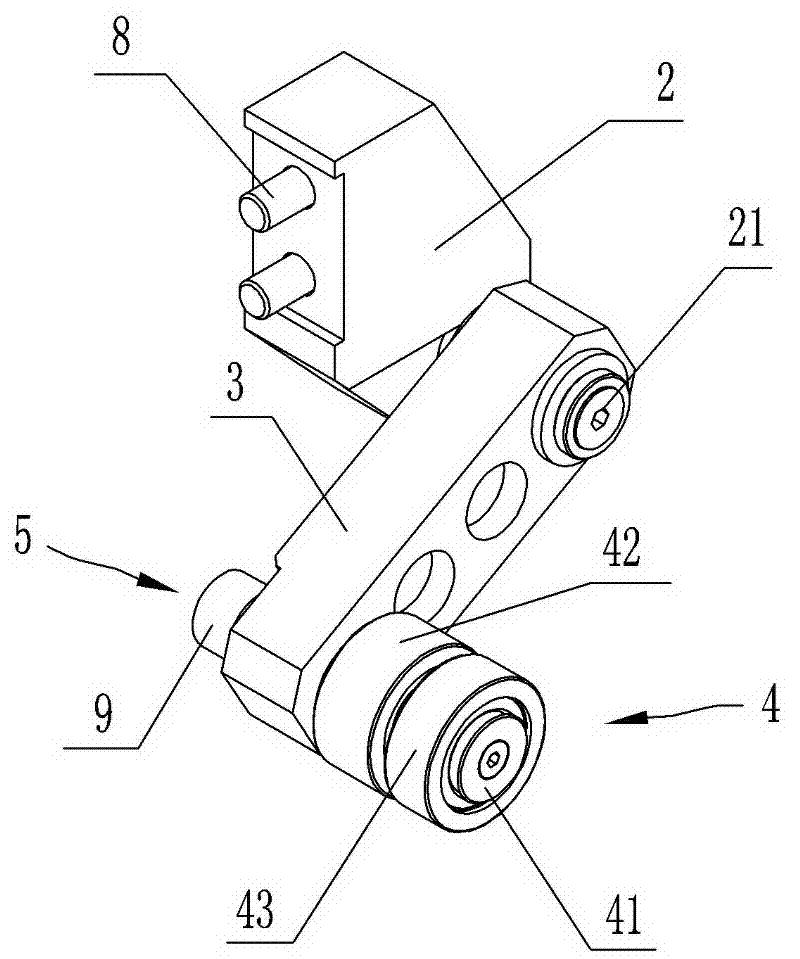

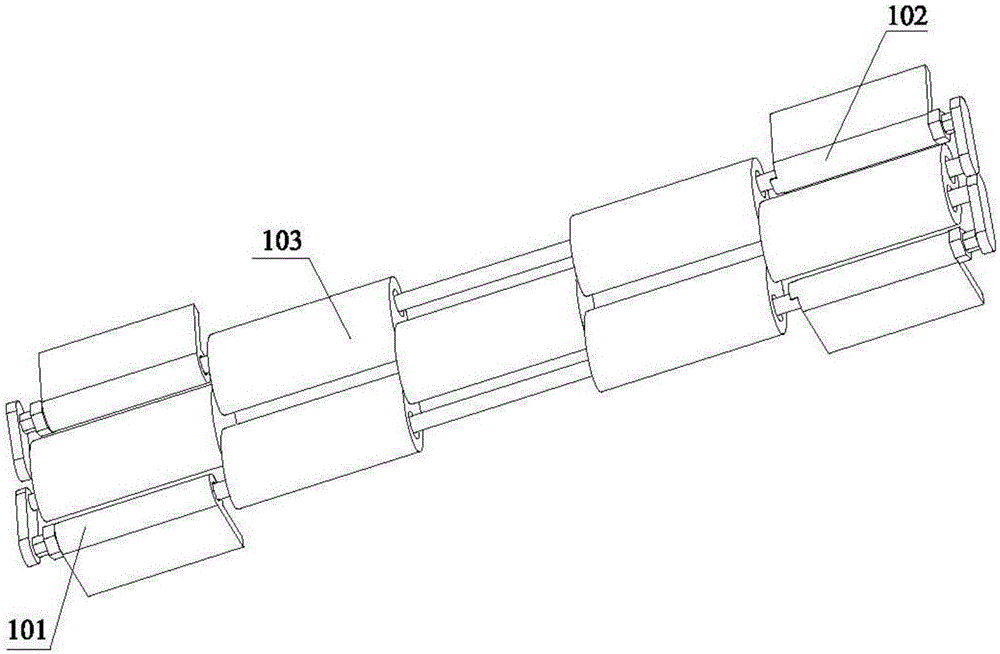

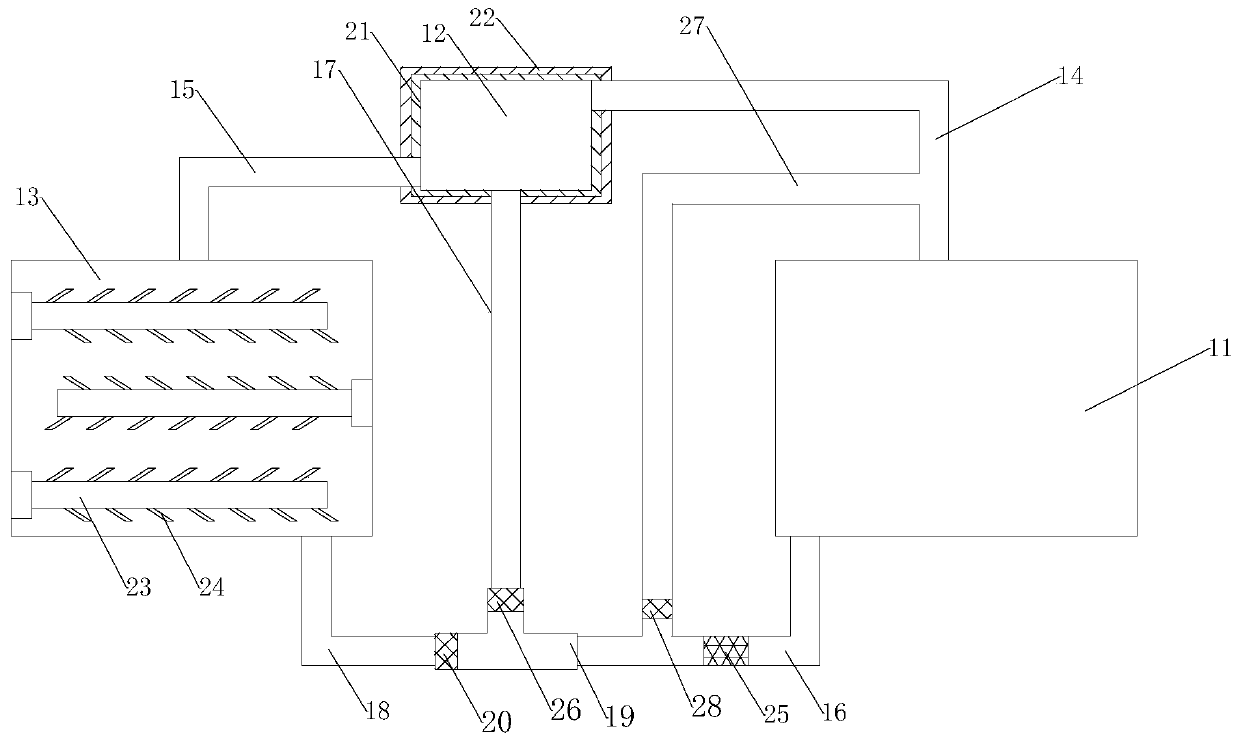

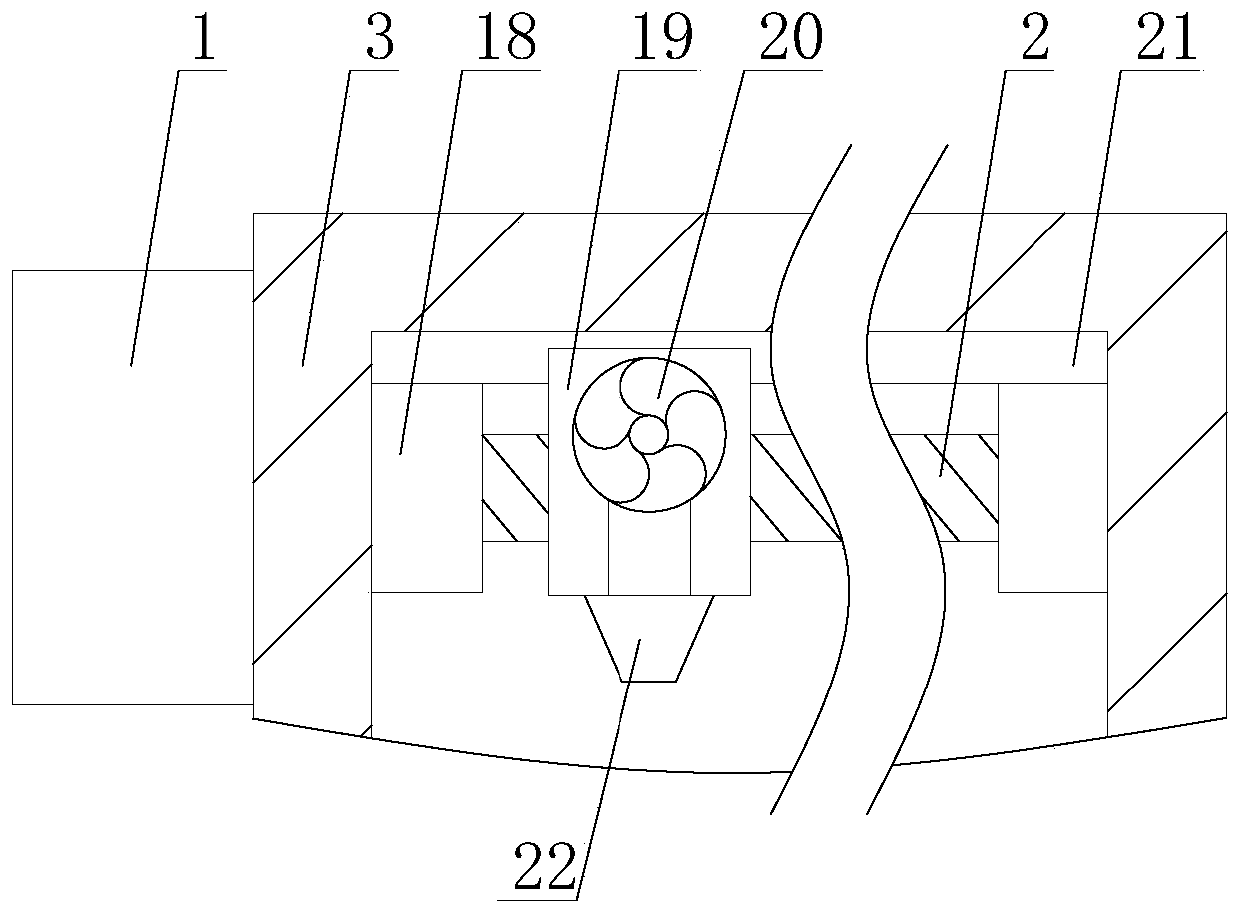

Slurry-bed circulation flow reactor and application and method for producing hydrogen peroxide

ActiveCN104549065AReduced chance of wear and tearIncrease concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

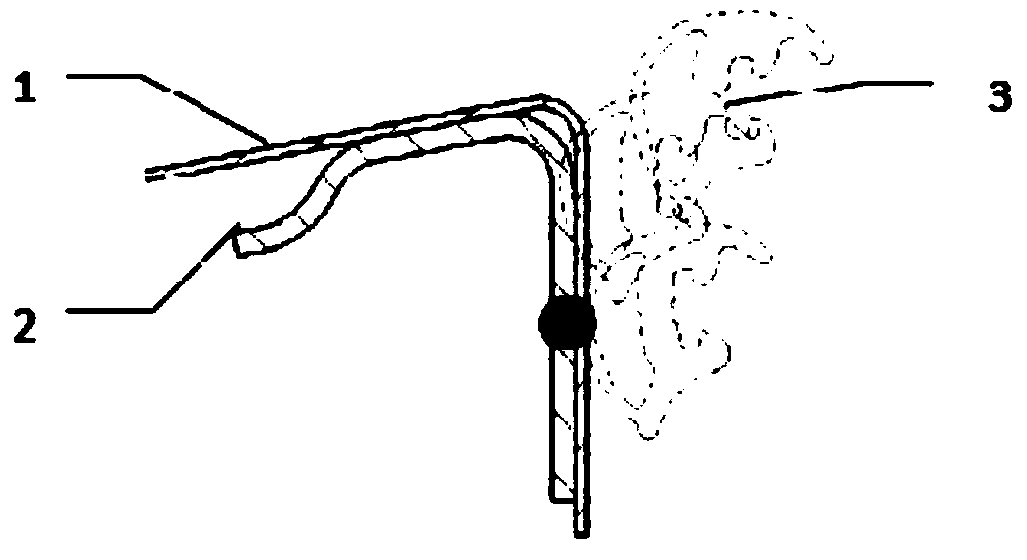

The invention discloses a slurry-bed circulation flow reactor and an application and a method for producing hydrogen peroxide. The slurry-bed circulation flow reactor comprises an ascension pipe, an expanding section used for expanding pipe diameter of the upper part of the ascension pipe and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is communicated with the bottom of the ascension pipe; a three-phase separator of a double sleeve structure is arranged in the expanding section; a raw material inlet is formed in the bottom of the ascension pipe; a gas outlet is formed in the top of the expanding section; a filtration component is arranged in the solid-liquid separator; and a clear liquid outlet is arranged at the upper part of the solid-liquid separator by virtue of the filtration component. According to a method for producing hydrogen peroxide by taking the slurry-bed circulation flow reactor as a hydrogenation reactor, the gas-liquid-solid three-phase separation efficiency is high; the local excessive hydrogenation of the catalyst is avoided; the excessive hydrogenation possibility is reduced; the hydrogenation efficiency is high; and hydrogen peroxide products with high concentration can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

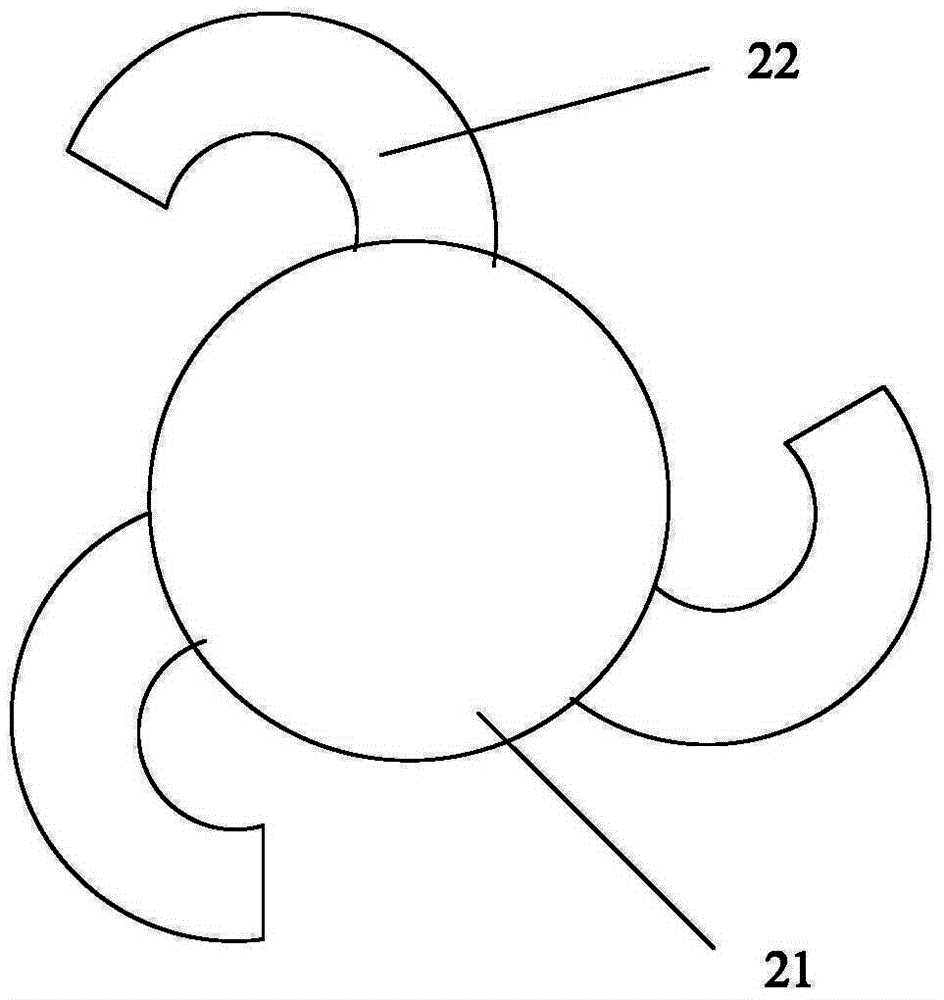

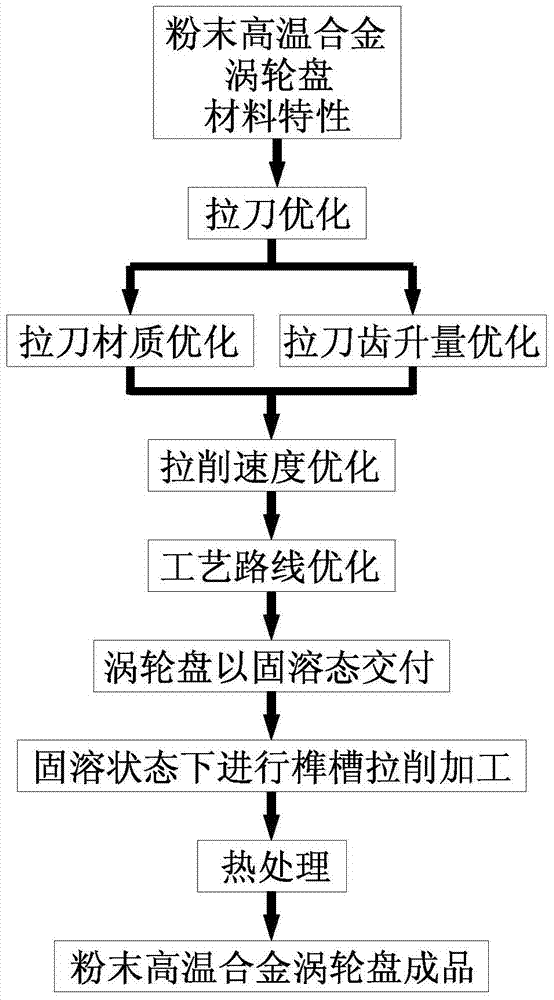

Broaching machining method for mortise of powder metallurgy superalloy turbine disc

ActiveCN103707016AReduce qualityReduces chances of scrappingBroaching toolsBroaching machinesSolid solutionSuperalloy

The invention discloses a broaching machining method for the mortise of a powder metallurgy superalloy turbine disc, wherein a broaching tool is optimized according to the material performances of the powder metallurgy superalloy turbine disc, the toughness and abrasion resistance of the broaching tool are improved by optimizing the material of the broaching tool, and the abrasion resistance, broaching process stability and machining accuracy of the broaching tool are improved by optimizing the rise per tooth of the broaching tool; the machining quality is improved and the loss of the broaching tool is reduced by optimizing a broaching speed; the broaching performance is improved by optimizing a process route; the powder metallurgy superalloy turbine disc is delivered in a solid solution state; broaching machining for the mortise is performed on the powder metallurgy superalloy turbine disc in the solid solution state; the powder metallurgy superalloy turbine disc finished product is obtained through heat treatment. According to the broaching machining method, the broaching performance is improved and the use requirements of the turbine disc are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

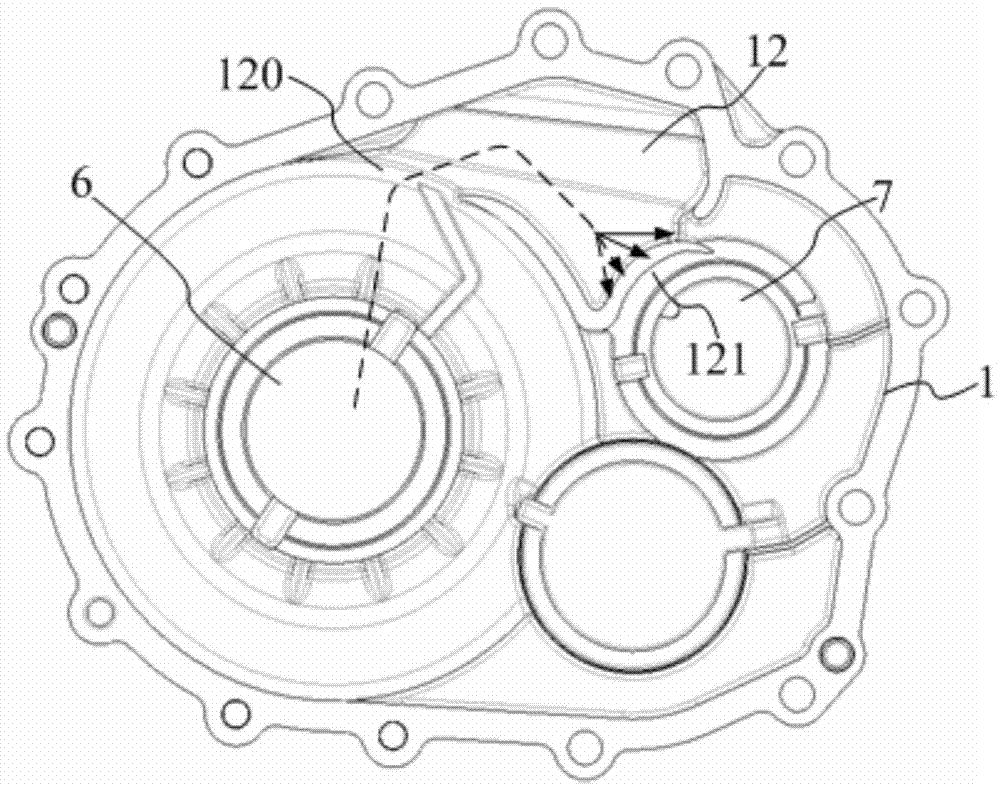

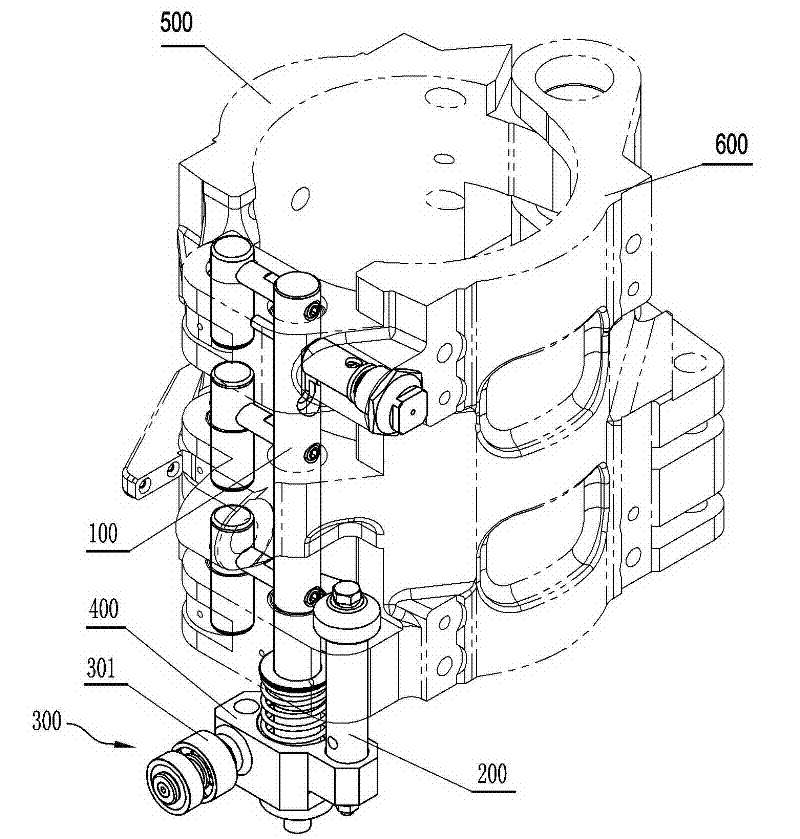

Speed changer and lubricating oil feeding device

InactiveCN107166018AReduced chance of wear and tearGuaranteed continuous supplyGear lubrication/coolingInternal cavityCentripetal force

The invention discloses a speed changer and a lubricating oil feeding device. The lubricating oil feeding device comprises a housing, a hollow pipe and an oil guide piece; the housing is provided with an inner cavity; the hollow pipe is arranged in the inner cavity and can rotate around the central axis of the hollow pipe; an oil storage chamber is formed in the inner wall of the housing; and the oil guide piece is at least partly located in the oil storage chamber and is connected with the hollow pipe, and is used to rotate around the central axis of the hollow pipe under the driving of the hollow pipe, so as to collect and guide lubricating oil in the oil storage chamber to flow into the hollow pipe. According to the lubricating oil feeding device provided by the technical scheme, the oil guide piece is in contact with the lubricating oil in the oil storage chamber in a rotating process and collects the lubricating oil adhered to the oil guide piece. When the lubricating oil rotates from the lowest position to the highest position along with the oil guide piece, the lubricating oil flows into the hollow pipe due to the gravity and the action of the centripetal force. Even if the oil level of the lubricating oil in the oil storage chamber is low, the oil guide piece can be in contact with the lubricating oil along one end, far from the central axis in the radial direction, of the hollow pipe, and can collect and guide the lubricating oil to flow into the hollow pipe. In such technical scheme, no oil level of the lubricating oil in the oil storage chamber is required to reach a pipe opening of the hollow pipe.

Owner:SCHAEFFLER TECH AG & CO KG

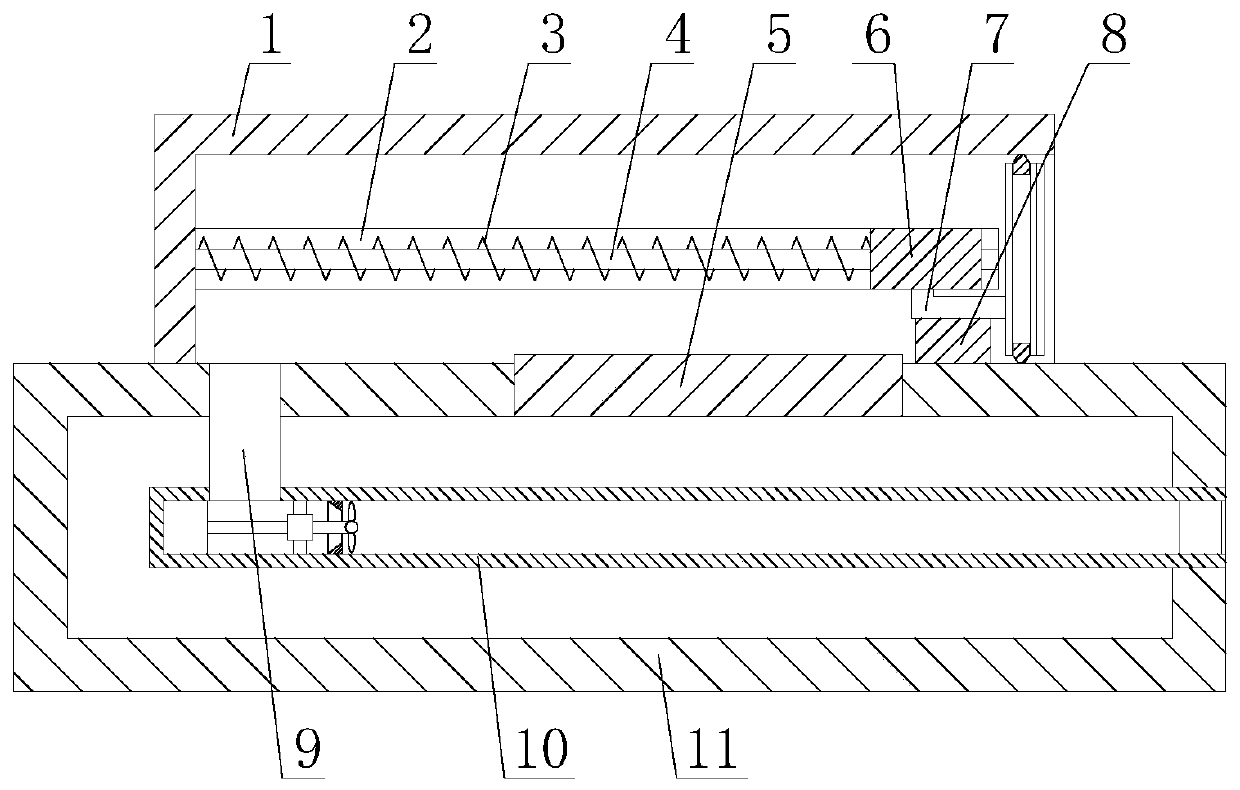

Slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting anthraquinone process and application of slurry bed hydrogenation reactor

ActiveCN104549059AReduce operational burdenReduced chance of wear and tearPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesAnthraquinone processHigh concentration

The invention discloses a slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting an anthraquinone process and application of the slurry bed hydrogenation reactor. The hydrogenation reactor comprises an ascension pipe, an expanding section for expanding the upper pipe diameter of the ascension pipe, and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is connected with the bottom of the ascension pipe; a guide cylinder is arranged in the expanding section; the bottom of the ascension pipe is provided with a raw material inlet; the top of the expanding section is provided with a gas outlet; a filter assembly is arranged in the solid-liquid separator and provided with a purified liquor outlet. The method for preparing the hydrogen peroxide is characterized in that the slurry bed hydrogenation reactor is applied to a hydrogenation unit, the gas-liquid-solid three-phase separation efficiency is high, the catalyst locality cannot be excessively hydrogenated, the excessive hydrogenation possibility is reduced, the hydrogenation efficiency is high, and a hydrogen peroxide product with the relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

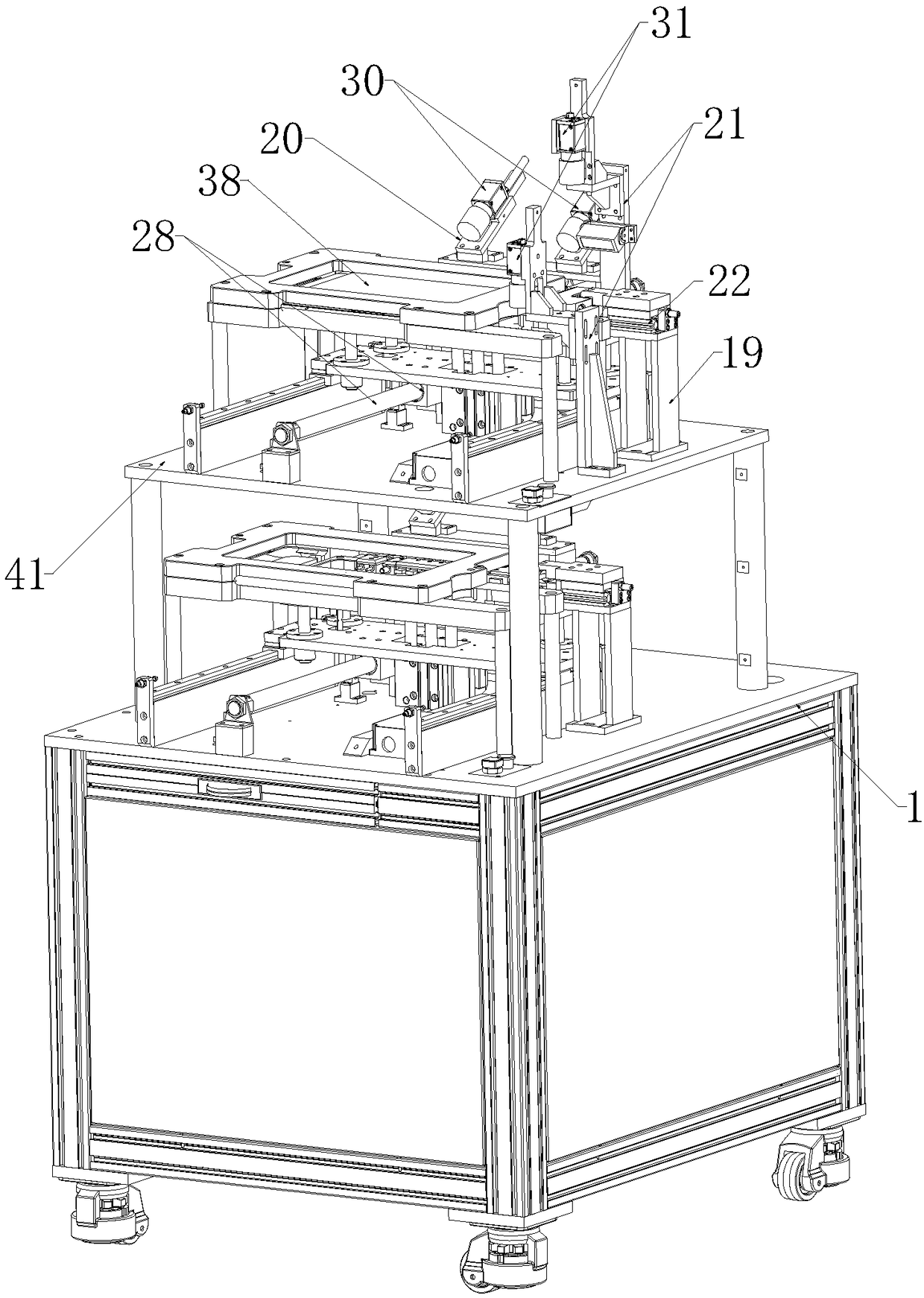

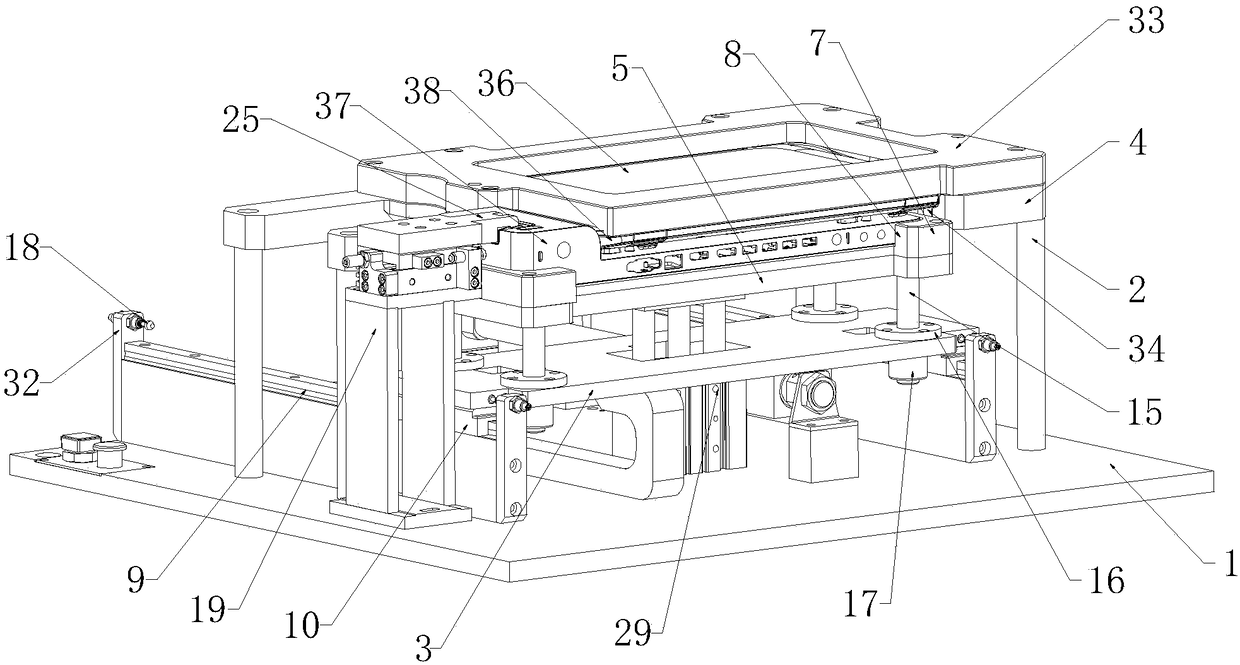

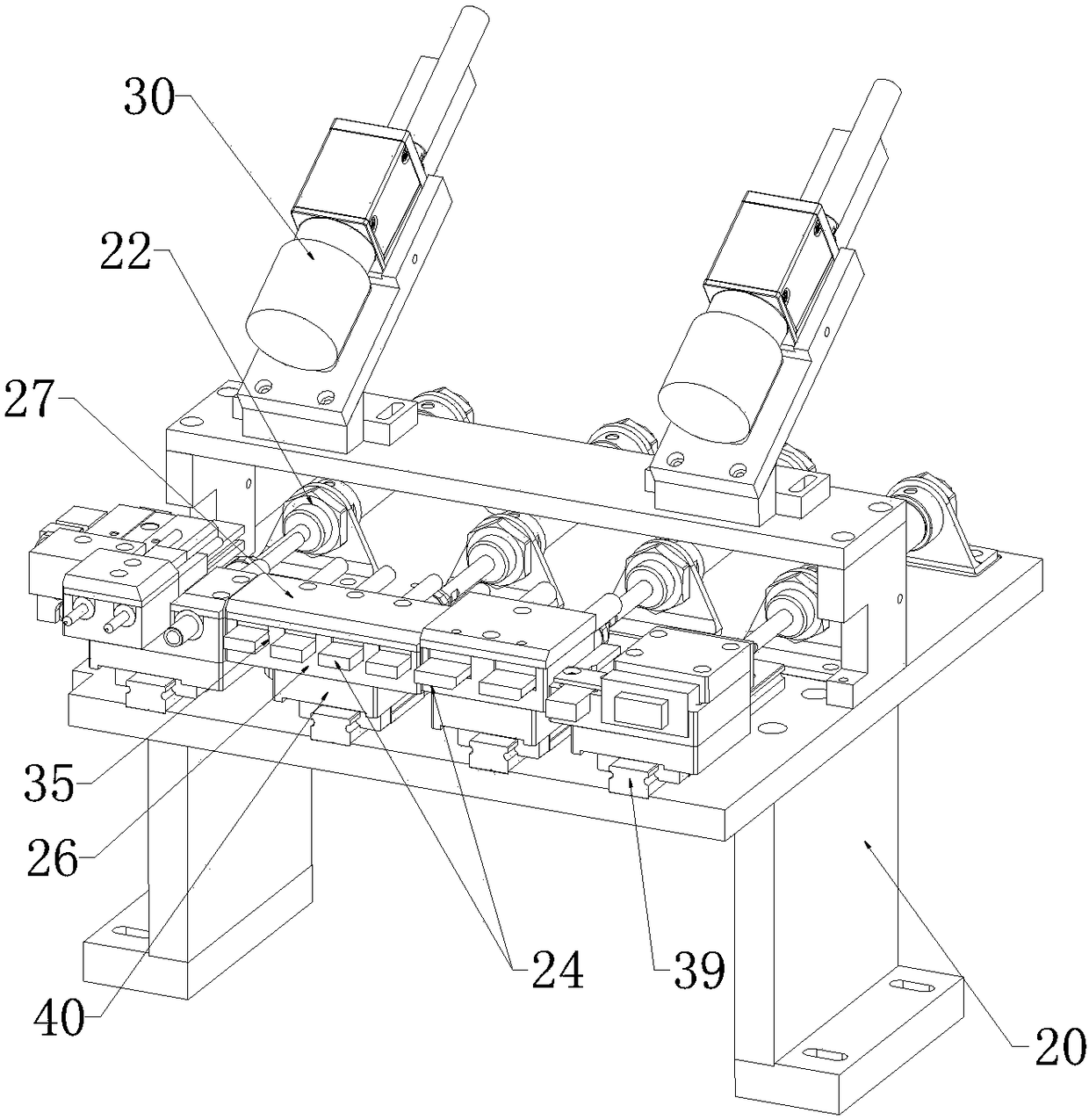

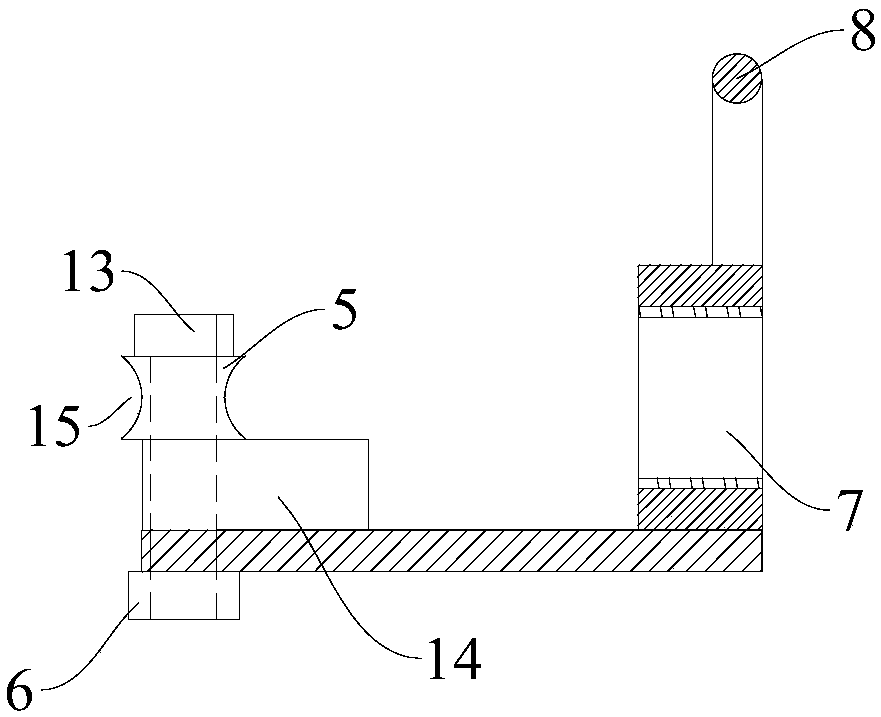

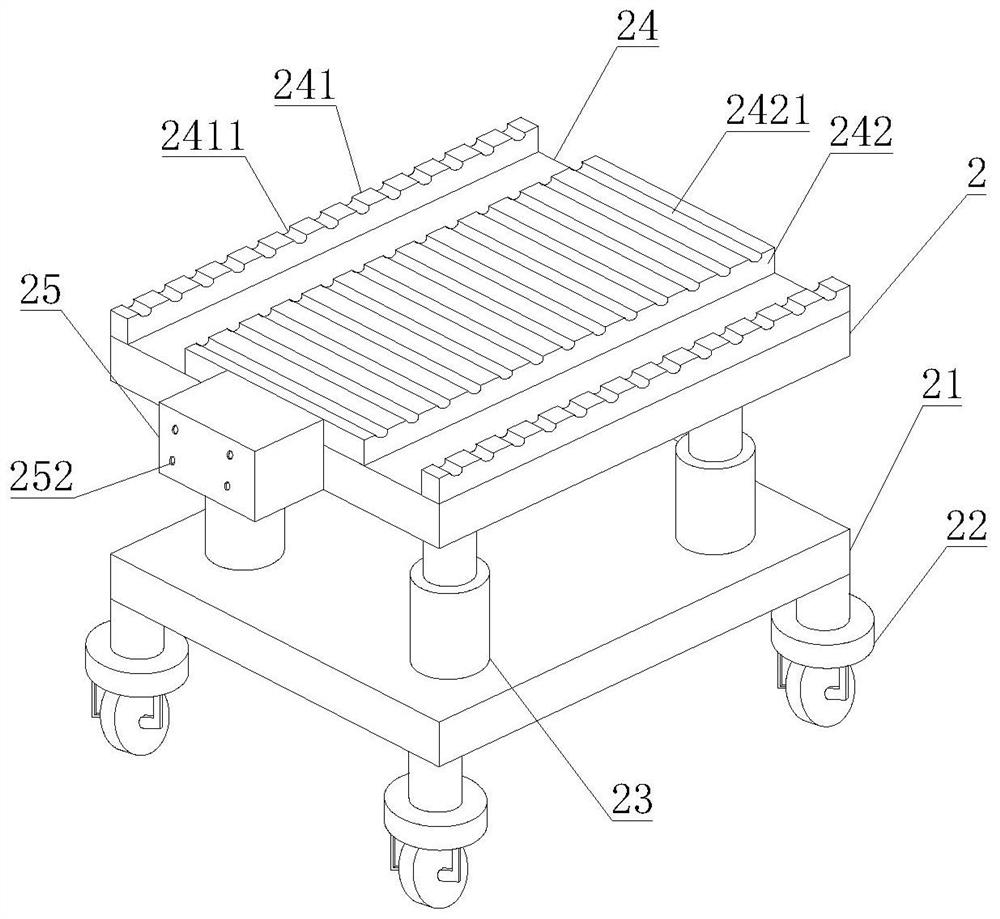

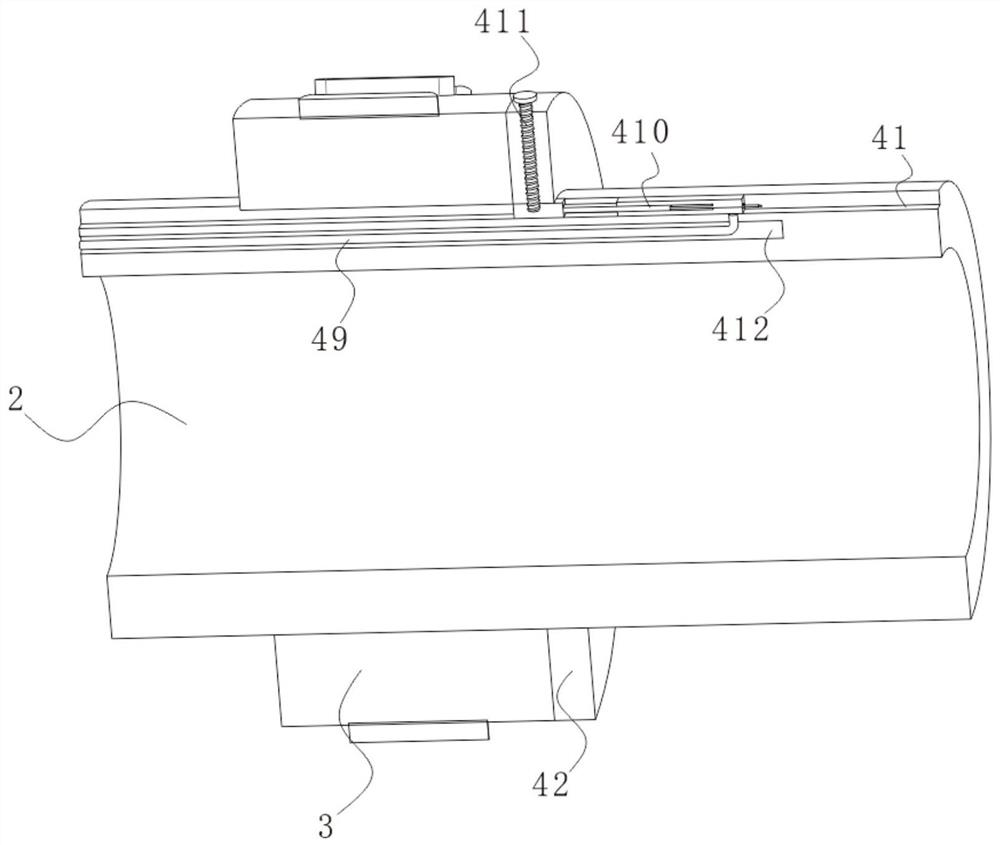

Mold locking shaft assembly lifting and shifting device

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

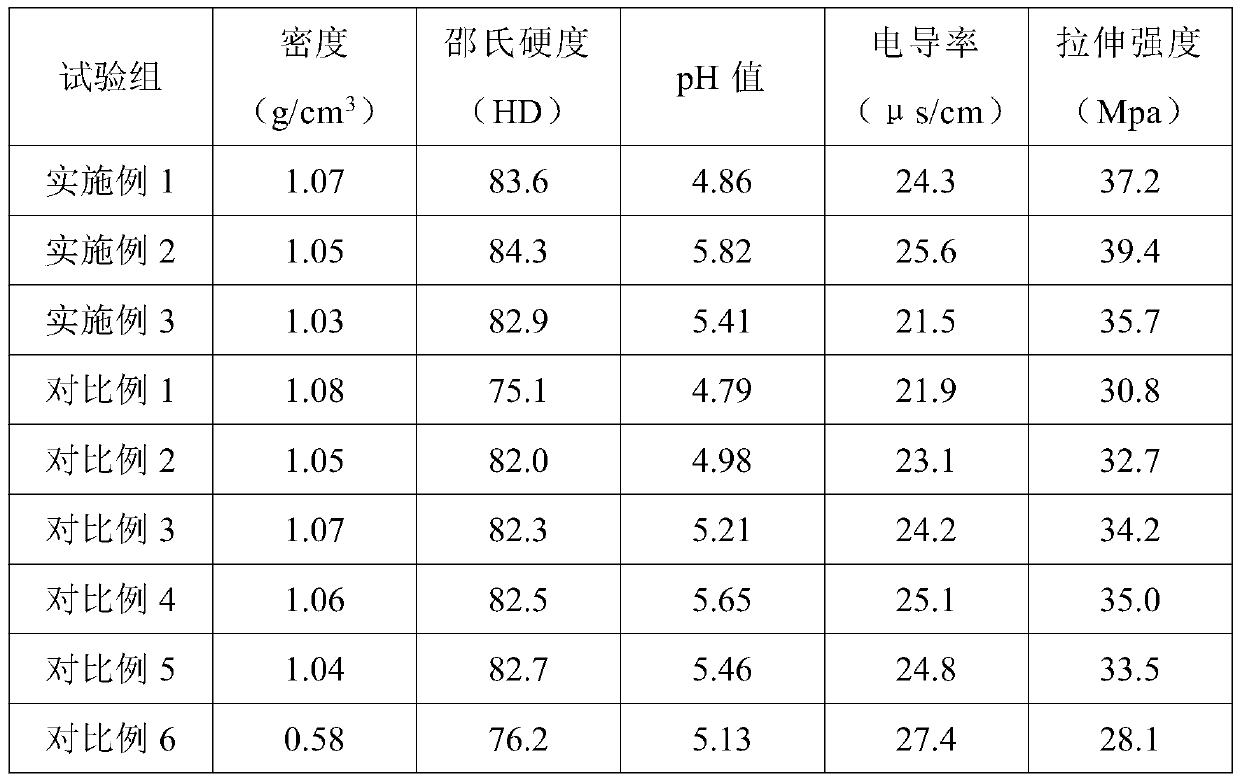

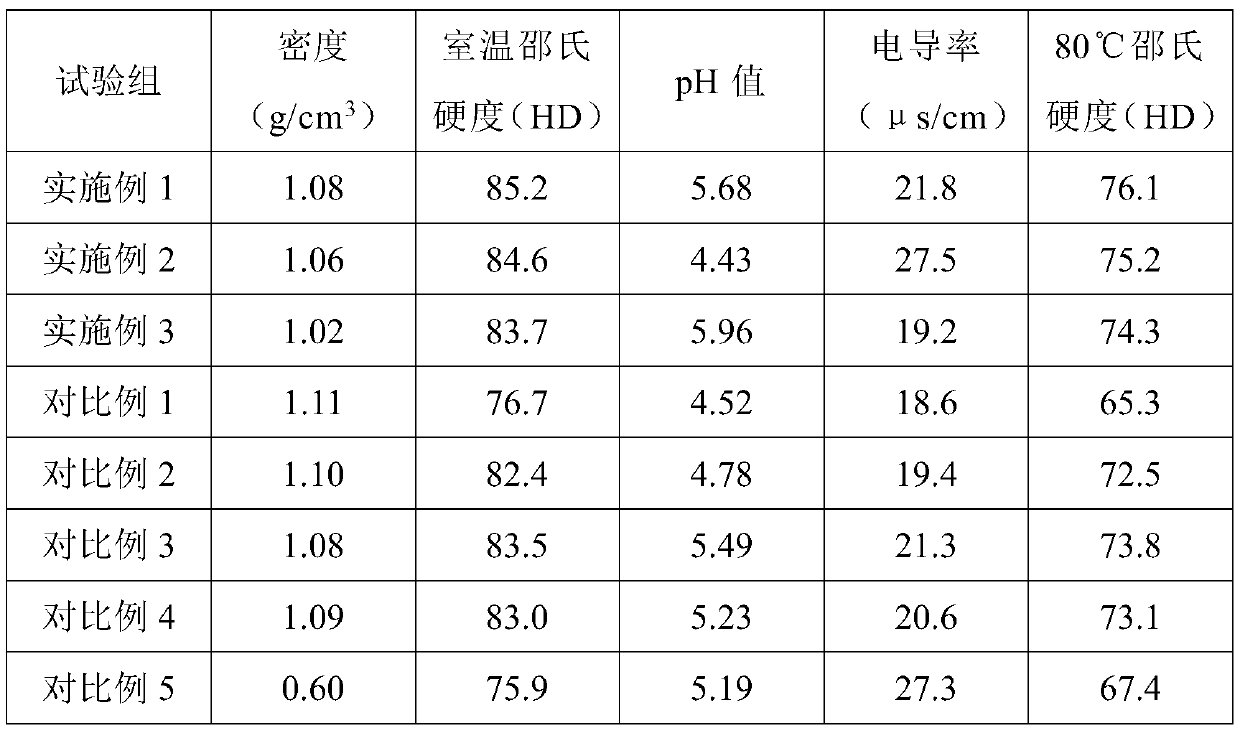

Special plastic plate capable of improving diamond wire cutting large system and preparation method thereof

The invention discloses a special plastic plate capable of improving a diamond wire cutting large system and a preparation method of the special plastic plate. The invention belongs to the technical field of production of plastic plates. The special plastic plate includes, by mass, 65%-90% of ABS resin, 5%-30% of PMMA resin, 1%-10% of a compatilizer, 1%-10% of EAA resin, 0.6%-1.5% of a scale inhibitor, 0.2%-1% of an antioxidant, 0.3%-2% of a lubricant and 0.1%-1% of a surfactant. The special plastic plate is prepared through the steps of raw material mixing, granulation, extrusion molding, polishing, cutting, detection, packaging and the like. The special plastic plate provided by the invention can effectively adjust the pH and conductivity of a large circulation system, has the characteristic of convenience in recycling of silicon materials and ABS / PMMA plastic plates, and can bring obvious benefits of saving energy consumption, reducing cost and improving production efficiency.

Owner:广西拓源新材料有限公司

Hinge

ActiveCN105041843AReduce the number of gapsAvoid missingCasings/cabinets/drawers detailsPivotal connectionsMachiningElectronic equipment

The invention discloses a hinge. The hinge comprises a first rotary piece, a second rotary piece and a protective piece. The first rotary piece comprises a first connecting piece, a first rotary shaft and a first shaft sleeve. The second rotary piece comprises a second connecting piece, a second rotary shaft and a second shaft sleeve. The hinge is formed by splicing the first rotary piece, the second rotary piece and the protective piece. The protective piece of the proper length can be adopted for reducing the number of gaps between the first rotary piece, the second rotary piece and the protective piece, the gaps even can be prevented from being generated, and the technical effect that liquid matter in electronic equipment can be effectively prevented from leaking is achieved. Due to the fact that the hinge special for the electronic equipment can be composed of components which are lower in machining difficulty and simple in splicing manner, the technical effects that the production cost is effectively reduced and production and machining efficiency is improved are achieved.

Owner:LENOVO (BEIJING) CO LTD

Handheld fingerprint acquisition device

InactiveCN110610155AImprove recognition accuracyGood energy saving effectCharacter and pattern recognitionRubber ringProtection mechanism

The invention relates to a handheld fingerprint acquisition device. The device comprises a main body and a collection device, and further comprises a protection mechanism and an electric power auxiliary mechanism. The protection mechanism comprises a protection cover, a moving block, a connecting rod, a baffle, a rubber ring and two return assemblies. The electric power auxiliary mechanism comprises an air conveying pipe, a power pipe, a generator, a transmission shaft, fan blades, a dustproof net, a supporting assembly and an air gathering ring. The return assembly comprises a guide groove, aguide rod, a spring and a mounting hole, and the supporting assembly comprises a supporting rod and a mounting bearing. According to the handheld fingerprint acquisition devicem the collection deviceis covered by the protection mechanism, under the protection effect of the protection mechanism, the probability that the collection device is abraded is reduced, the recognition precision of the fingerprint collector is improved, the electric energy can be generated through the electric power auxiliary mechanism, then the electric energy is supplied to the fingerprint collector for use, so thatthe consumption of the fingerprint collector on the external electric energy is reduced, and the energy-saving performance of the fingerprint collector is improved.

Owner:南京思达捷信息科技有限公司

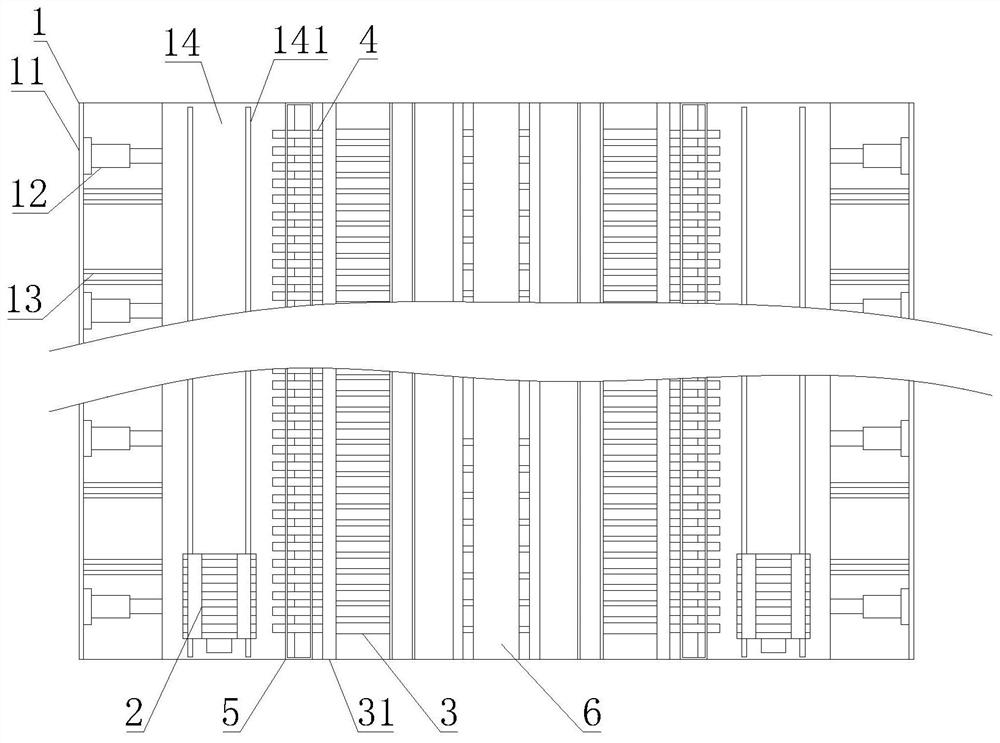

Efficient detector used for docking stations

PendingCN108132411AImprove detection efficiencyAvoid occlusionElectrical testingMeasurement instrument housingDocking stationEngineering

The invention discloses an efficient detector used for docking stations. The efficient detector includes a pedestal and a dividing support dividing a space above the pedestal into an upper area and alower area. A first detection unit is arranged in the upper area and a second detection unit is arranged in the lower area. Each of the first detection and the second detection unit includes a first support rack, a first drive device, a second support rack, a third support rack and a fourth support rack, wherein the first support rack is provided with a first positioning piece, the second is provided with a second drive device and a second positioning piece, the third support rack is provided with a third drive device and the fourth support rack is provided with a detection assembly. The top end of the dividing support is also provided with two fifth support racks arranged in a staggered manner. Each of the fifth support racks is equipped with a second image collector. The detector provided by the invention can perform detection of two docking stations at the same time; the detection efficiency is improved and the detection efficiency can also be ensured.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

Specific acidic plastic plate for photovoltaic diamond wire cutting and preparation method thereof

The invention discloses a specific acidic plastic plate for photovoltaic diamond wire cutting and a preparation method thereof. The plastic plate comprises the following raw materials: matrix resin and an auxiliary agent, and is prepared through the steps of raw material mixing, granulation, extrusion molding, polishing, cutting, detection, packaging and the like. The plastic plate prepared by theinvention meets the requirement of a large circulation system of a diamond wire cutting process, is easy to recycle, can be recycled, and meets the environmental protection requirement of continuousutilization; in a silicon rod cutting process using the diamond wire, impurities adhering to the diamond wire are reduced, the abrasion probability of the diamond wire is reduced, the cost is saved, the superior product rate of silicon wafers is increased, and therefore the production efficiency is effectively improved. Compared with the prior art, the prepared plastic plate is better in shore hardness and equivalent in pH value and conductivity, and has remarkable progress.

Owner:广西拓源新材料有限公司

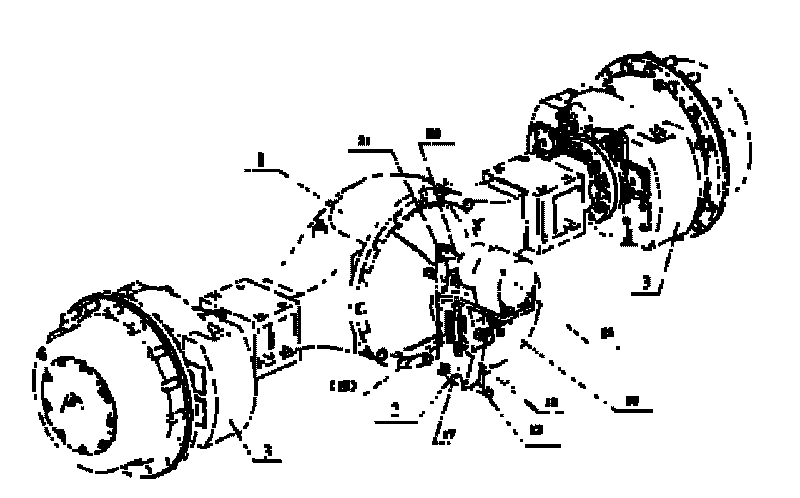

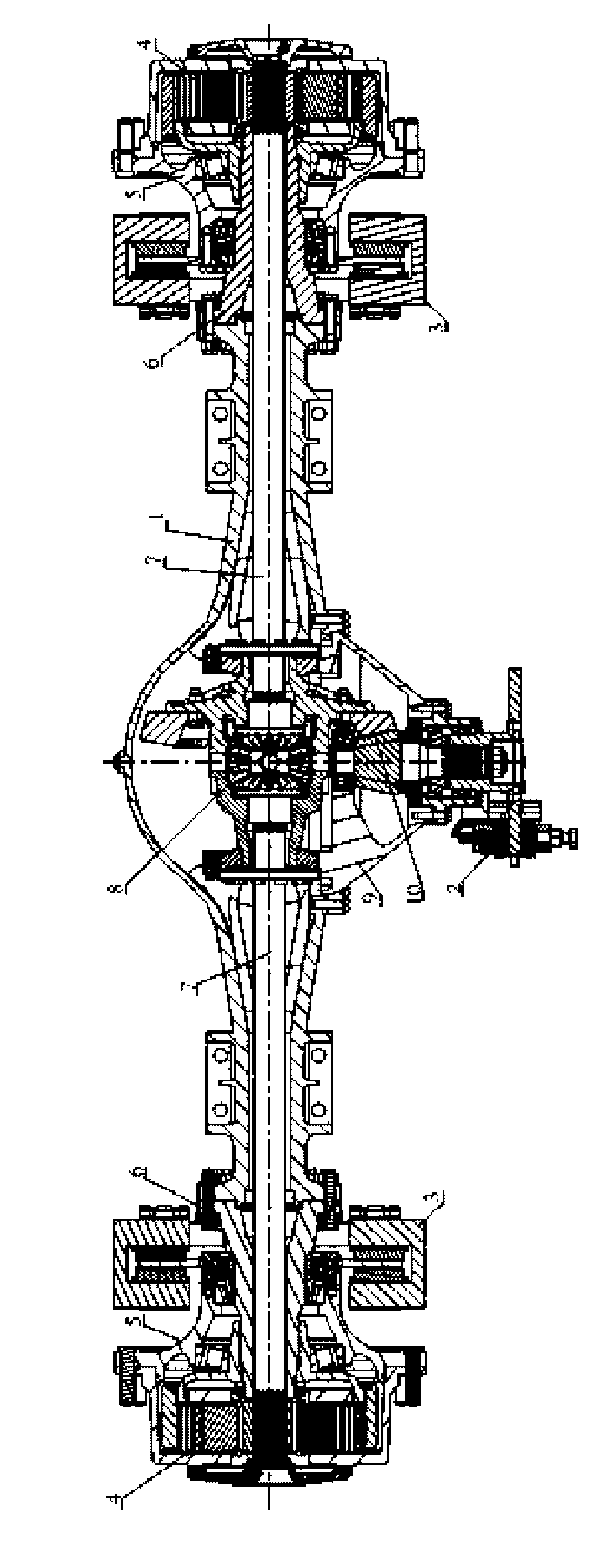

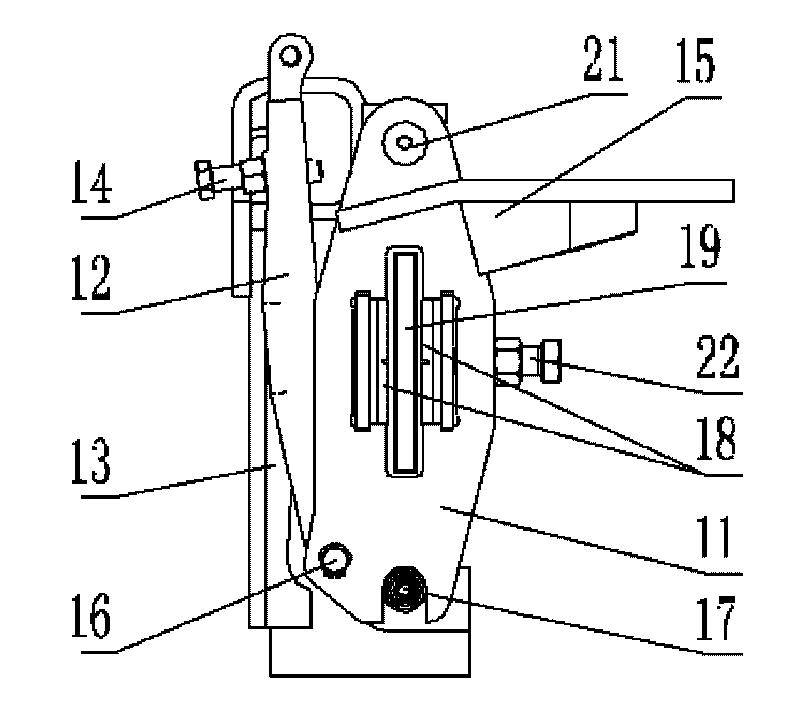

Driving front axle of large-speed ratio mining vehicle

InactiveCN101708712ASimple structureGuaranteed StrengthBraking element arrangementsAxle unitsBrake shoeWear resistance

The invention relates to a driving axle assembly of a large-speed ratio mining vehicle, and provides a driving front axle of a large-speed ratio mining vehicle which comprises an axle case and a central brake. The driving front axle of the large-speed ratio mining vehicle is characterized in that the axle case is an integral-combination axle case; the central brake also comprises a pincers type force self-amplifying mechanism which comprises a vacuum boosting cylinder, a piston rod, a brake rocker and a rocker backing pin, wherein the vacuum boosting cylinder is fixedly connected to a support, the lower end of the brake rocker is installed on a brake pincers body through the rocking backing pin, the upper end of the brake rocker is connected with the piston rod of the vacuum boosting cylinder, and the middle of the brake rocker is provided with a bulge which can be in contact with a brake shoe. The invention has the characteristics of simple structure, large transmission speed ratio, low processing cost and wear resistance.

Owner:中国航天三江集团公司特种车辆技术中心

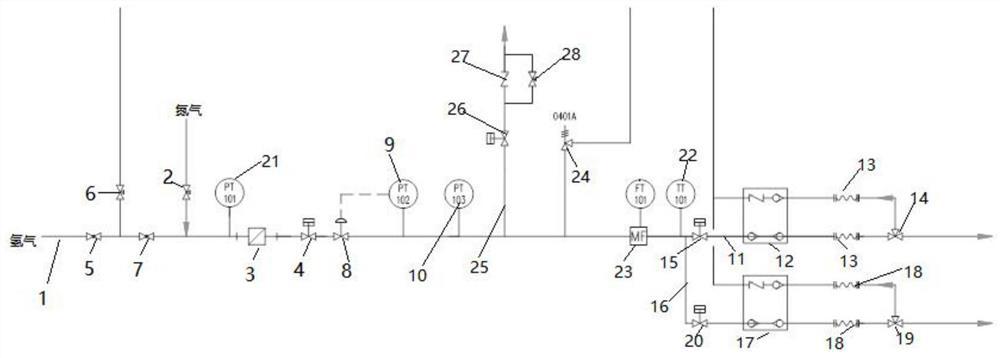

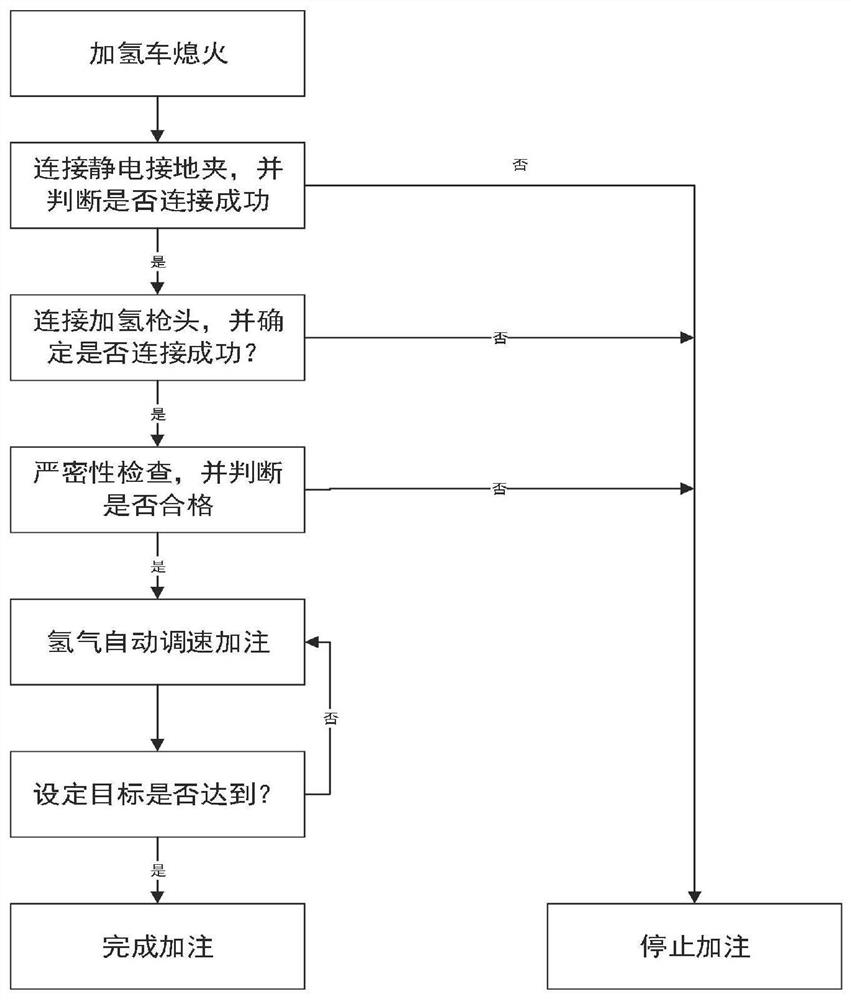

Hydrogen conveying system for hydrogenation vehicle

PendingCN113390017ARefill time shortenedBoost slowlyContainer filling methodsSecondary cellsThermodynamicsPressure curve

The invention provides a hydrogen conveying system for a hydrogenation vehicle. The hydrogen conveying system comprises a hydrogen conveying pipeline, a hydrogen conveying pressure adjusting assembly and a control unit, wherein the hydrogen conveying pressure adjusting assembly is arranged on the hydrogen conveying pipeline; the hydrogen conveying pressure adjusting assembly is connected with the control unit; and the hydrogen conveying pressure adjusting assembly adjusts the hydrogen conveying pressure in the hydrogen conveying pipeline behind the hydrogen conveying pressure adjusting assembly according to a pressure curve set in the control unit. The problem that in the existing hydrogenation process, due to the fact that the pressure difference value between a hydrogen storage tank in a hydrogenation machine and a vehicle-mounted hydrogen storage bottle is large, the hydrogen flow in the hydrogen conveying pipeline is large and then small, the possibility that the temperature exceeds the standard after hydrogen is injected into the vehicle-mounted hydrogen storage bottle in the hydrogenation vehicle is likely to occur, and the hydrogen flow in the hydrogen conveying pipeline is reduced along with the reduction of the pressure difference between the hydrogen storage tank in the hydrogenation machine and the vehicle-mounted hydrogen storage bottle, so that the hydrogenation time in the hydrogen storage bottle in the hydrogenation vehicle is long is solved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Fixing device of optical fiber temperature sensor

ActiveCN102954844AAvoid collision damageAvoid damageThermometer detailsThermometers using physical/chemical changesFiberBiochemical engineering

The invention relates to a fixing device of an optical fiber temperature sensor. The fixing device of the optical fiber temperature sensor comprises an insulating sheet, the optical fiber temperature sensor and pigtail. A groove is arranged in the insulating sheet. A connector of the pigtail is connected with a connecting end of the optical fiber temperature sensor. The optical fiber temperature sensor is fixedly arranged in the groove. A packaging boy made of a polytetrafluoroethylene material is wrapped on the surface of the pigtail. A protruding outer edge is arranged at the edge of the insulating sheet. The tail fiber is fixed with the insulating sheet provided with the protruding outer edge through the groove. A groove matched with the protruding outer edge is arranged in the surface of the packaging body. The fixing device of the optical fiber temperature sensor provided by the invention has the effect of protecting, installing and fixing the optical fiber temperature sensor. The fixing device of the optical fiber temperature sensor is very convenient to install, and can be fixed and protected by the special insulating sheet in the device in the common storage and conveying process of the optical fiber temperature sensor.

Owner:江苏国电南自海吉科技有限公司

Steel bar bending machine

The invention provides a steel bar bending machine, and belongs to the technical field of power transmission line construction equipment. The steel bar bending machine comprises a base and a pressurehead arranged above the base; the pressure head is connected with the movable end of a hydraulic device arranged on the base, and two rotating rollers rotationally connected with the base and used forabutting against steel bars are further arranged on the base, and arranged on the two sides of the pressure head correspondingly; vertical columns are arranged on the base, and the rotating rollers rotationally sleeve the vertical columns; cushion blocks sleeving the vertical columns and used for supporting the rotating rollers are arranged below the rotating rollers; and bolts are adopted as thevertical columns and penetrate through the base to be in threaded connection with nuts arranged at the bottom of the base. According to the steel bar bending machine provided by the invention, the technical problems that a steel bar wrench is adopted to bend, abrasion of a zinc coating of the surface of a grounding down lead is prone to being caused, and the labor intensity is large are solved.

Owner:STATE GRID CORP OF CHINA +2

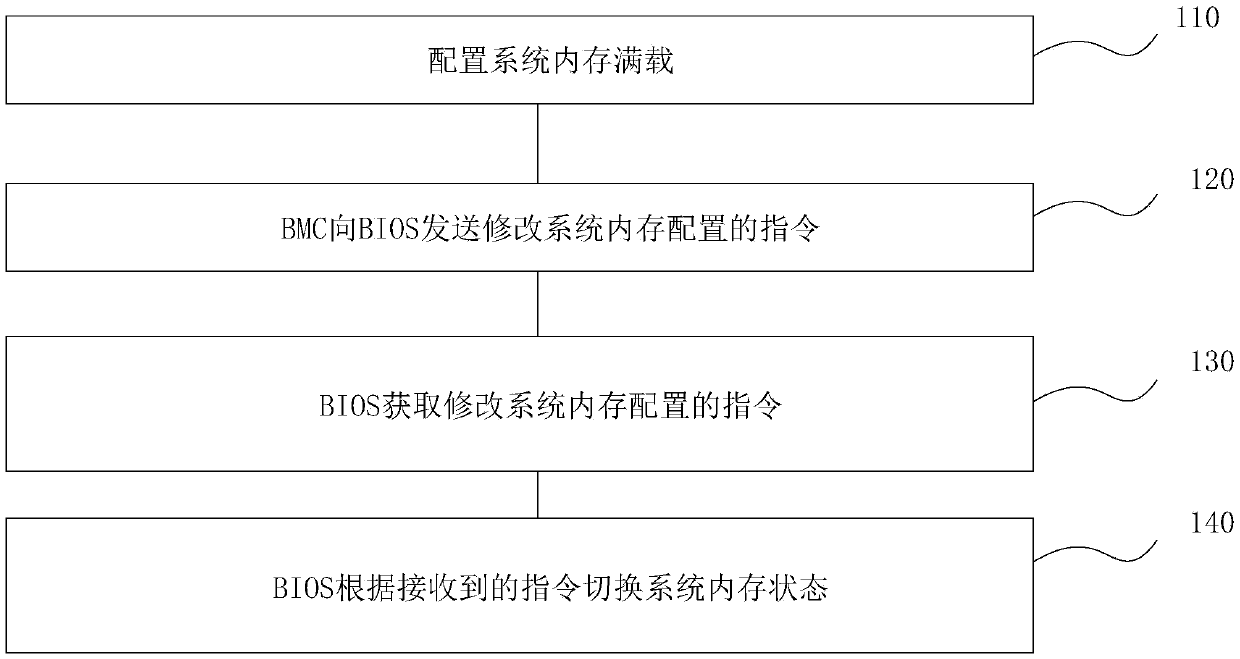

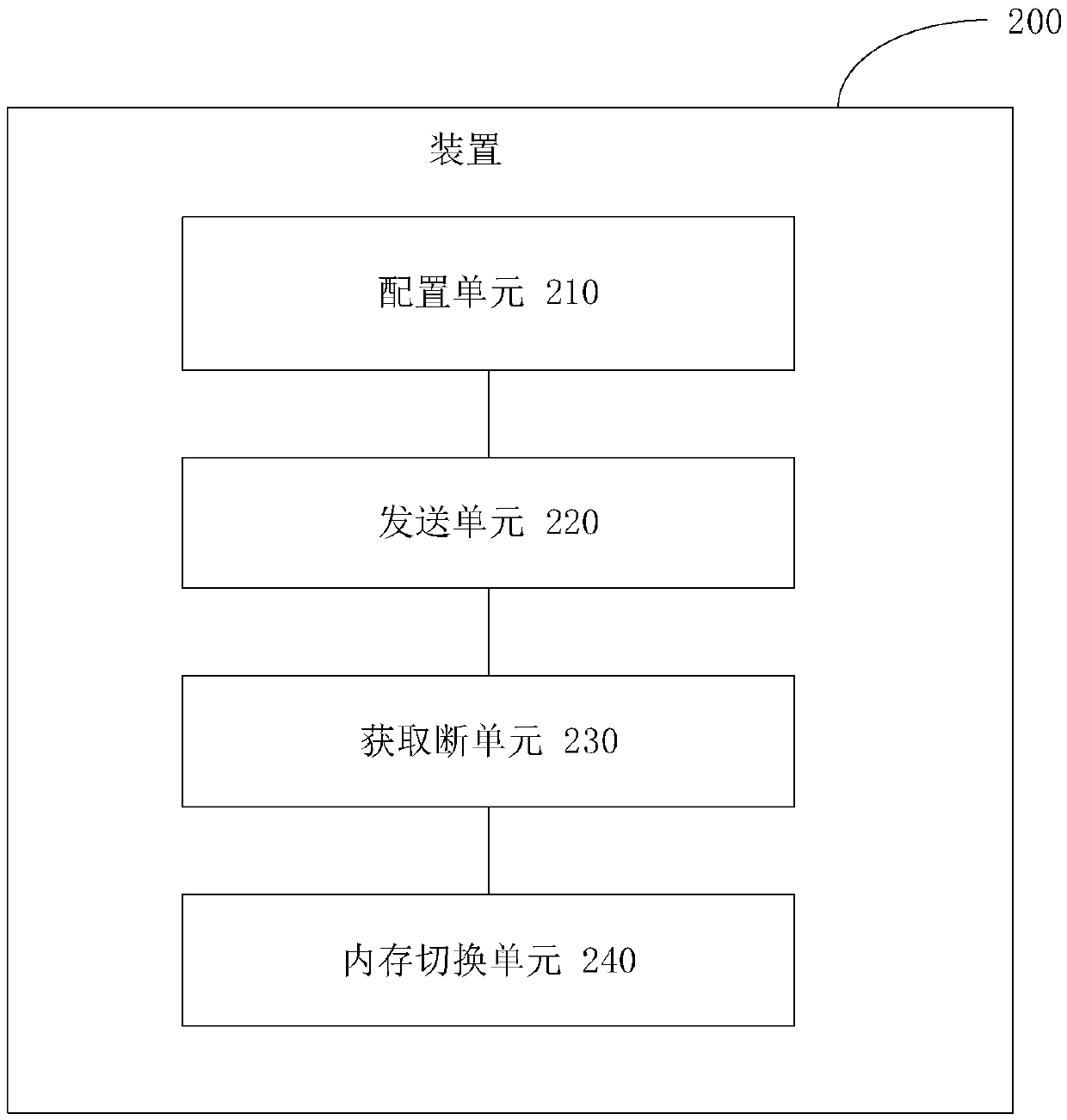

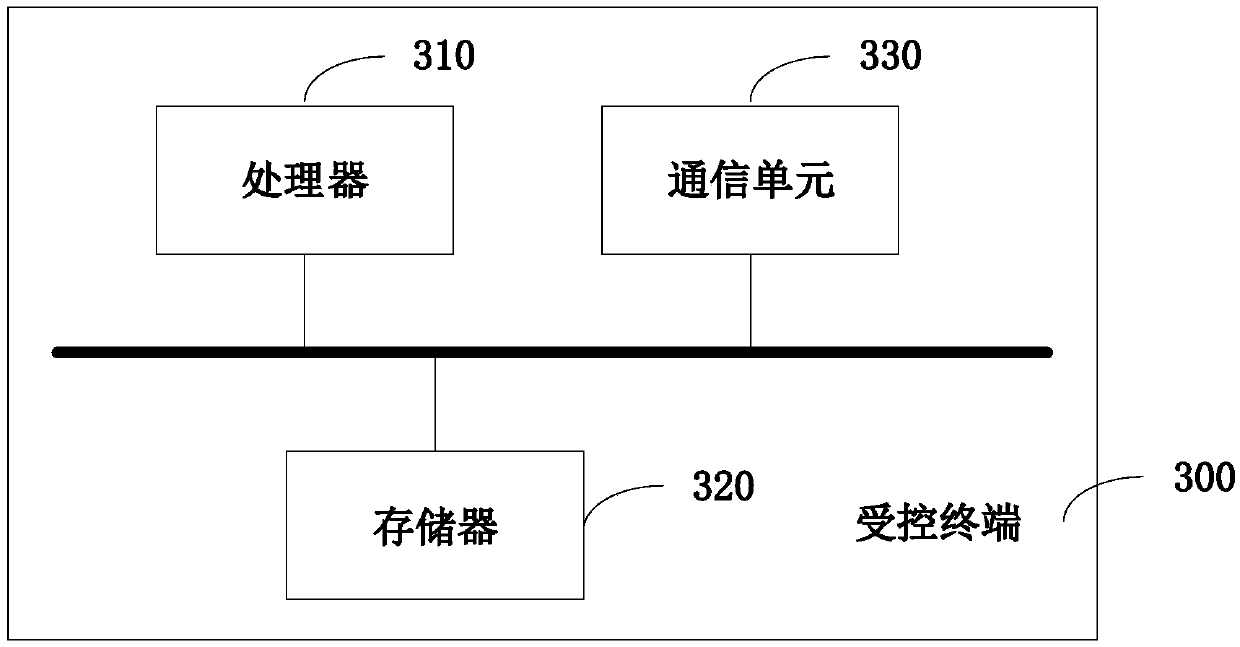

Method, device, terminal and storage medium for switching system memory configuration through BMC

InactiveCN109542525AReduced chance of wear and tearShorten the timeBootstrappingComputer architectureComputer terminal

The invention provides a method, a device, a terminal and a storage medium for switching system memory configuration through a BMC. The method includes: a system memory is configured with a full load;BMC sends instructions to BIOS to modify system memory configuration; The BIOS obtains instructions for modifying the system memory configuration; The BIOS switches the system memory state accordingto the received instruction; The invention realizes the quick replacement of the memory state through the BMC distribution, the user may not need to manually manipulate the machine hardware, only theinstructions to modify the system memory configuration need to be issued by the BMC, BIOS configure that system memory state according to us instructions, The memory configuration state of the systemcan be changed, the time is saved, the wear probability of the machine and the memory strip is reduced, and the defects of the memory strip damage and the server slot damage caused by the artificial insertion and removal of the memory strip and the poor contact caused by the non-standard insertion and removal of the memory strip and the system can not start normally are avoided.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Cotton carding equipment for spinning

The invention relates to the technical field of spinning, and discloses cotton carding equipment for spinning. The cotton carding equipment comprises a rolling mechanism and a pneumatic element located on one side of the rolling mechanism; the rolling mechanism comprises a fixed disc and a rotating disc, and multiple rolls are arranged between the rotating disc and the fixed disc; one end of eachroll is rotatably connected with the rotating disc, and the other end of each roll is slidingly connected with the fixed disc; a first driving part used for driving the rotating disc to rotate and a second driving part used for driving the rolls to rotate are arranged on the rotating disc; a sliding groove is formed in the position, below one roll, of the fixed disc, a sliding plate is slidingly connected inside the sliding groove, a button switch and multiple elastic parts abutting against the fixed disc are arranged below the sliding plate, a slide way is further formed in the fixed disc, the depth of the slide way is gradually decreased in the rotating direction of the rotating disc, and the button switch controls the first driving part to be started or shut down. The cotton carding equipment provides convenience when strip-shaped threads are collected, and the operation difficulty of an operator is lowered.

Owner:JIANGSU SUMEITE MACHINERY

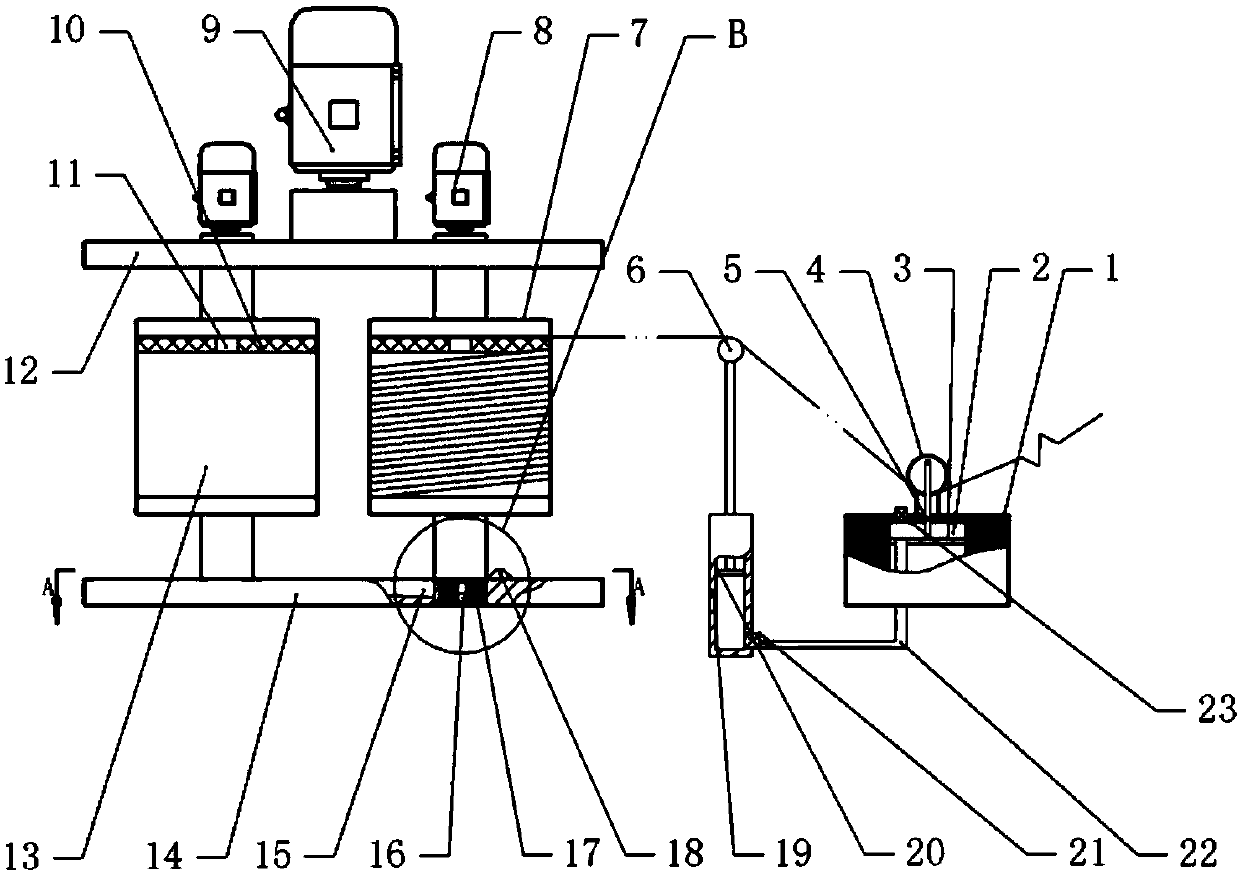

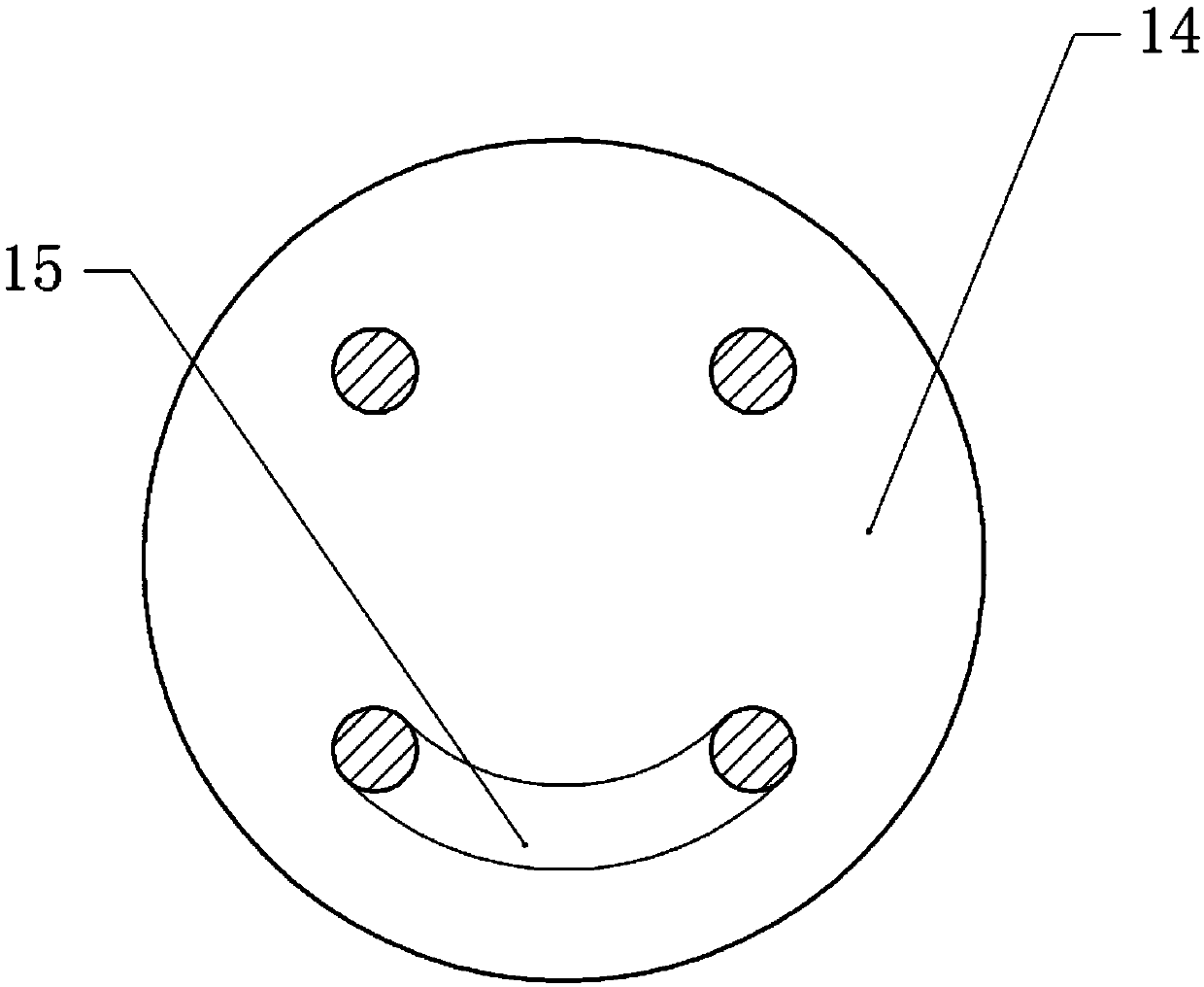

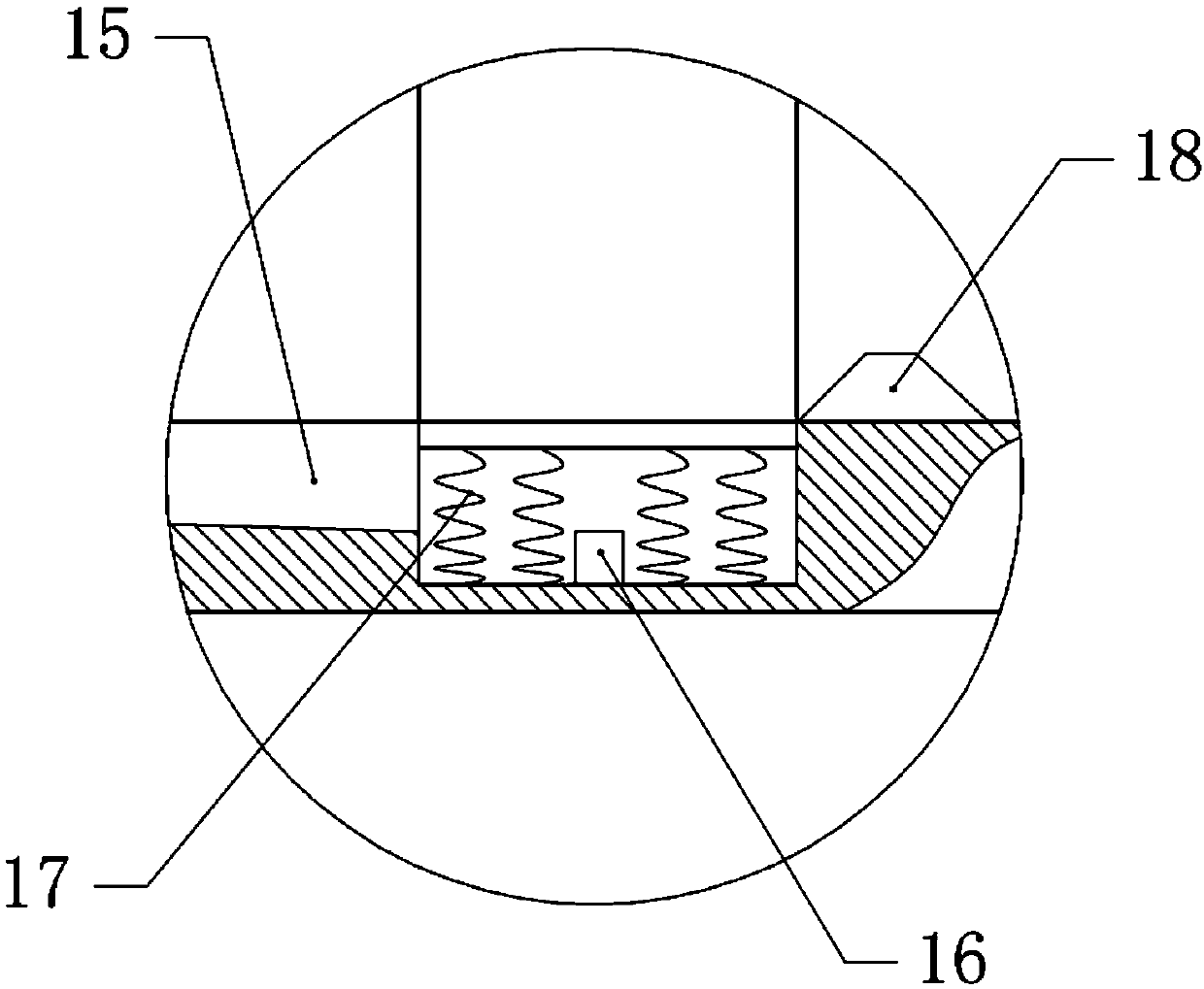

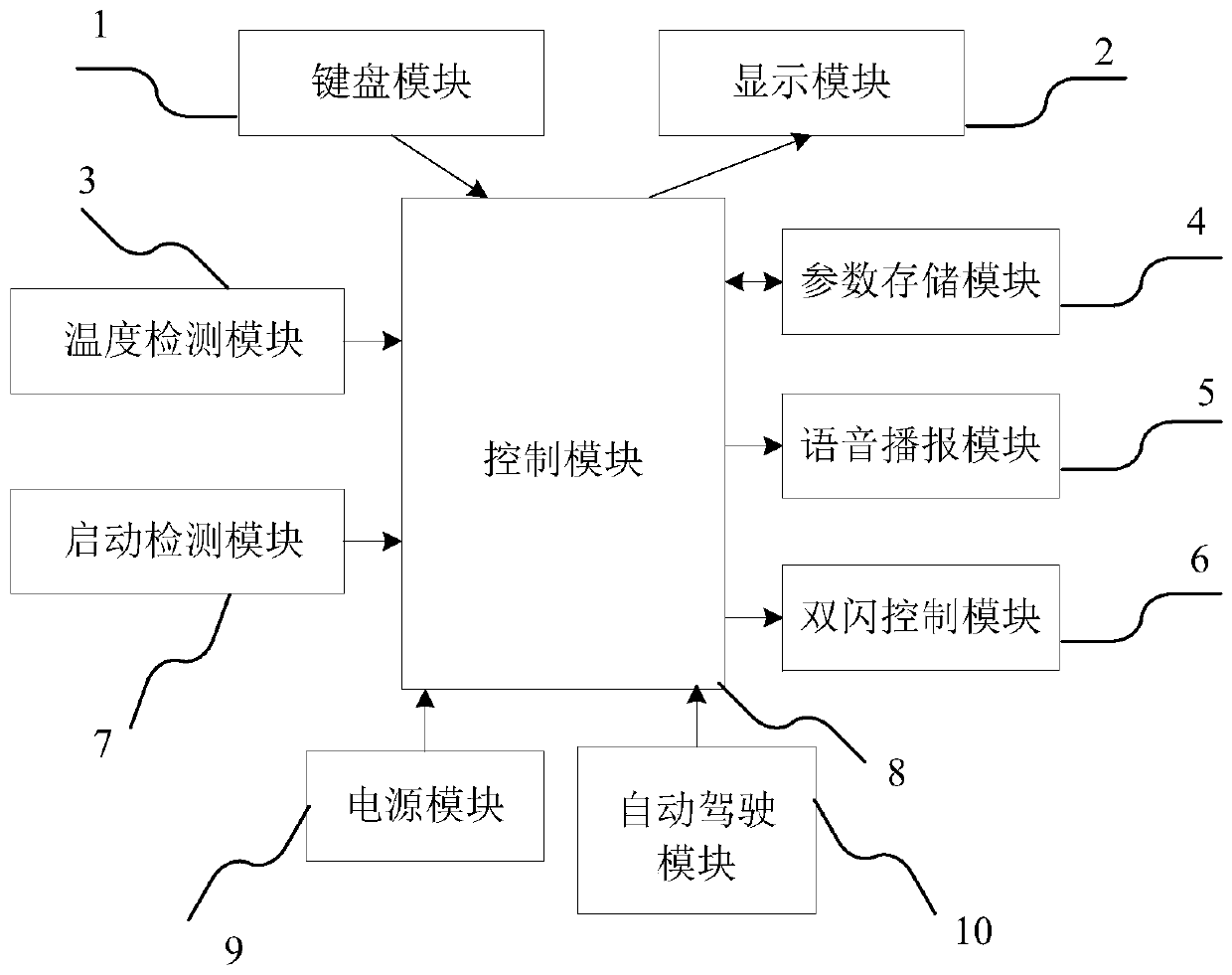

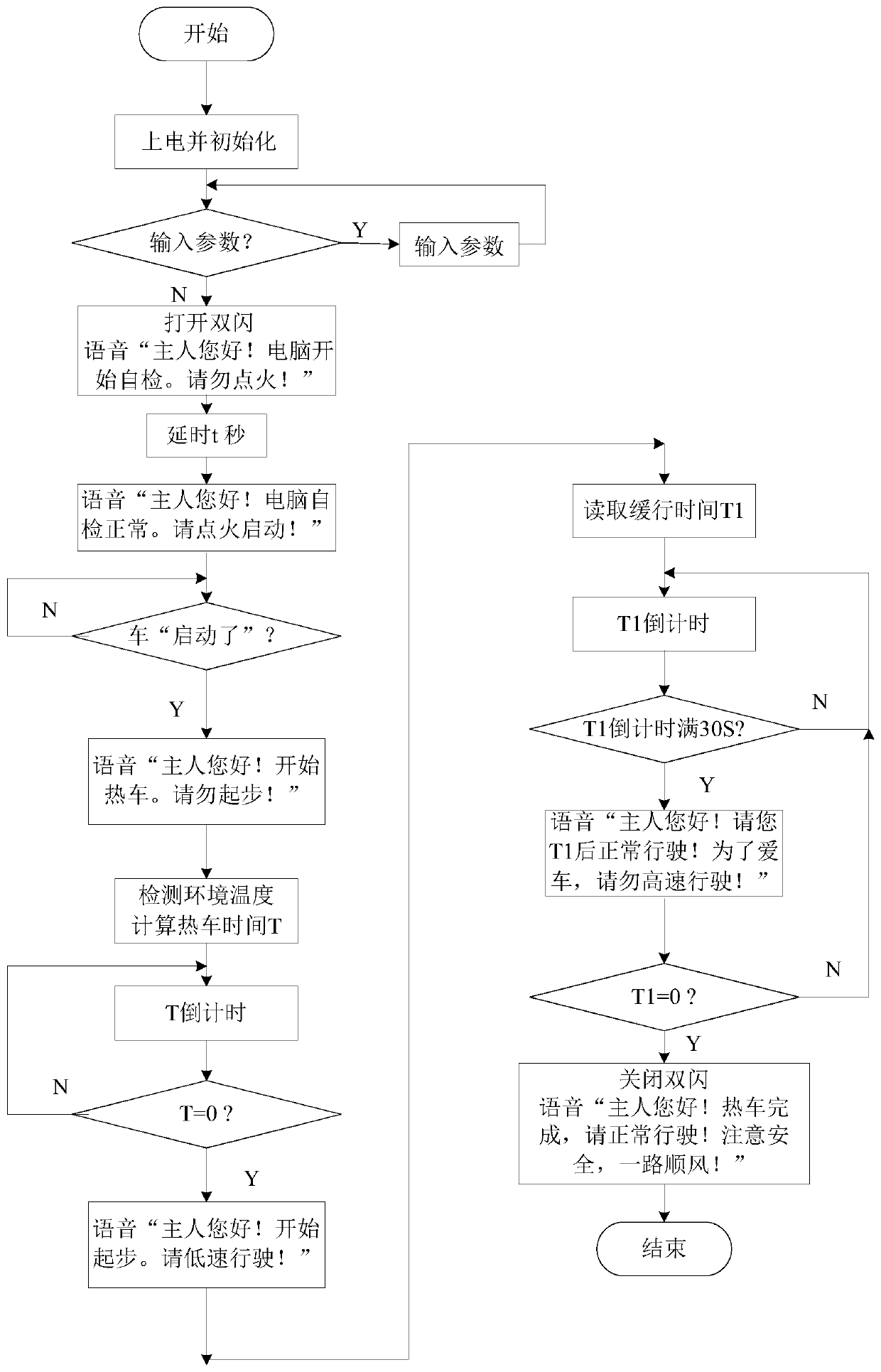

Voice prompting device and method for motor vehicle warming and starting

InactiveCN109808616AReduced chance of wearEnergy savingMachines/enginesSignalling/lighting devicesElectricityAutopilot

The invention belongs to the field of automobile driving, in particular to a voice prompting device and a voice prompting method for motor vehicle warming and starting. The voice prompting device comprises a start detection module, a temperature detection module, a parameter storage module, a voice broadcasting module, a power module and a control module, and further comprises a keyboard module, adisplay module, a double flash control module and an automatic driving module, wherein the keyboard module comprises a manual mode and an automatic mode. The voice prompting method comprises the following five steps: electrifying and initializing, turning on a double-flash lamp and performing self-inspection on a computer, judging whether the motor vehicle is started, warming the motor vehicle, and slowing down and closing the double-flash lamp after completion of slowing down. By adopting the voice prompting device and the voice prompting method, the wear probability of an automobile enginecan be reduced, and the effects of saving energy and reducing haze are achieved.

Owner:XIAN PEIHUA UNIV

Surface grinding machine with dust removing function and high machining precision

InactiveCN110497269AImprove firmnessReduced chance of wear and tearCleaning using gasesGrinding work supportsSurface grindingEnvironmental resistance

The invention relates to a surface grinding machine with a dust removing function and high machining precision. The surface grinding machine comprises a base, a platform and a polishing device, and further comprises a clamping mechanism and a dust removing mechanism; the dust removing mechanism comprises a dustproof cover, a driving module, a driving block, a fan, a nozzle, a dust collecting box,a pipe, a filter screen and an exhaust pump; the clamping mechanism comprises two guide rails and two fixing modules; the fixing modules comprise support plates, cylinders, clamping plates, two slidesleeves, two slide rods, two springs and two limiting blocks; and the driving module comprises a motor, a lead screw and two mounting bearings. In the surface grinding machine with the dust removing function and high machining precision, the workpiece clamping firmness is improved through the clamping mechanism; meanwhile, the workpiece wear probability is reduced; the machining effect of the surface grinding machine is improved; and the dust removing mechanism can absorb dust generated in the machining process of the surface grinding machine, so that the environmental protection performance of the dust removing mechanism is improved.

Owner:李志聪

Quick disassembling actuator cylinder

The invention relates to a quick disassembling actuator cylinder. The quick disassembling actuator cylinder comprises an outer cylinder and a piston rod, wherein a stop clamping sleeve is detachably fixed at one end of the outer cylinder; a section of the piston rod penetrates through the stop clamping sleeve to extend into the outer cylinder, and a boss matched with the outer cylinder is arrangedat one end, extending into the outer cylinder, of the piston rod; a guide sleeve which sleeves the piston rod is arranged on the inner side of the stop clamping sleeve; and one side, far away from the stop clamping sleeve, of the guide sleeve is provided with a buffering mechanism which is in clearance fit with the piston rod and is integrally connected to the outer cylinder. According to the quick disassembling actuator cylinder, the impact load and the stress borne by the main bearing part of the actuating cylinder are reduced, and the structural life is prolonged.

Owner:LANDING GEAR ADVANCED MFG

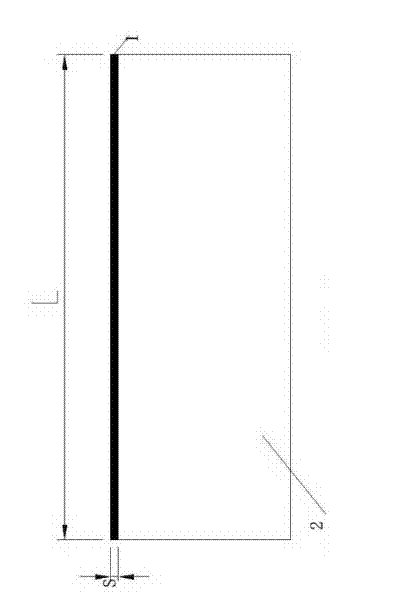

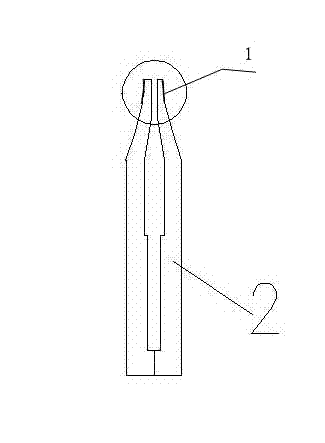

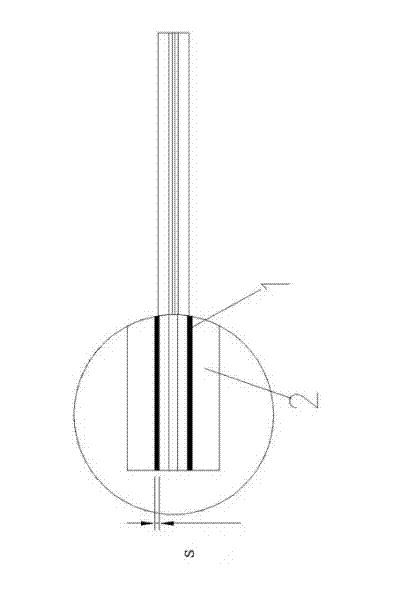

Method for eliminating longitudinal stripes on surface of cast rolling stock for ultra-thin aluminium foil

InactiveCN102240786ASimple and fast operationReduced chance of wear and tearMetal rolling arrangementsSlagAlclad

The invention discloses a method for eliminating longitudinal stripes on the surface of a cast rolling stock for an ultra-thin aluminium foil, which belongs to the technical field of aluminium foil production. The method comprises the following steps of: 1, pre-treating a cast spout: in the event of manufacturing the cast spout, graphite paper which is L (the length of the cast spout) in length, 15 mm in width and 0.5 mm in thickness is bonded at a lip of the cast spout so as to increase flexible contact between the lip of the cast spout and a casting and rolling roller and reduce abrasion possibility of the lip in the production process and in the event of processing strips online, thereby reducing the possibility of forming the longitudinal stripes on the surface of the cast rolling stock because of the damage of the lip; and 2, processing the longitudinal stripes online: copper foils or aluminium foils are bonded on the corresponding casting and rolling rollers when the surface of the cast rolling stock has the longitudinal stripes in the production process; friction is generated between the foils and slag at the lip of the cast spout; and the slag at the lip of the cast spout is taken out so as to eliminate the longitudinal stripes on the surface of the cast rolling stock. The method disclosed by the invention has the advantages of being simple and convenient in operation, good economical efficiency and the like. The method is especially applicable for producing the cast rolling stock for the ultra-thin aluminium foil.

Owner:YUNNAN HAOXIN ALUMINUM FOIL

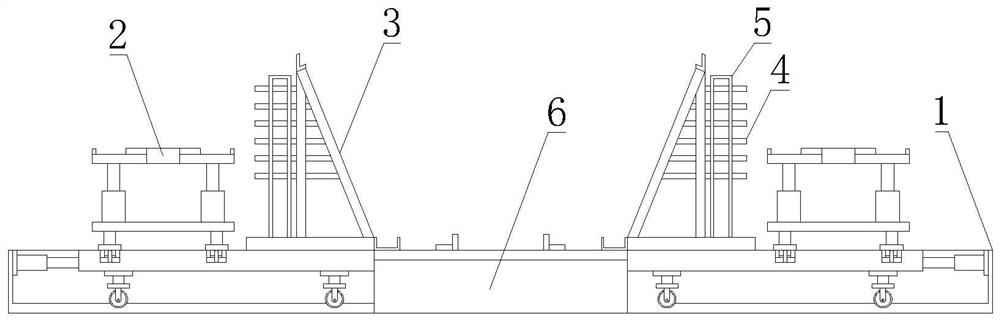

Shaping formwork for box girder reinforcement cage

The invention discloses a shaping formwork for a box girder steel reinforcement framework, and relates to the technical field of shaping formworks. The shaping formwork comprises a formwork pedestal, a steel reinforcement positioning frame and a base, the formwork pedestal comprises a pedestal body, the side face of the pedestal body is fixedly connected with the side face of the base, and a movable plate is movably installed in the pedestal body; and the upper surface of the movable plate is fixedly connected with the bottom surface of the steel reinforcement positioning frame. An output shaft of a motor rotates to drive a driving gear to rotate, a rotating shaft rotates through meshing connection of the driving gear and a driven gear, then a drive wheel and a first rolling wheel are matched to drive reinforcing steel bars in a reinforcing steel bar conveying groove to move, reinforcing steel bar conveying is completed, and the problems that a box girder is larger in size, the mass of needed reinforcing steel bars is extremely large, manual feeding wastes manpower and material resources, meanwhile, great inconvenience exists, time of workers is wasted, and the production efficiency is reduced are solved, so that the effects of saving the time of the workers and improving the production efficiency are achieved.

Owner:蒋友富

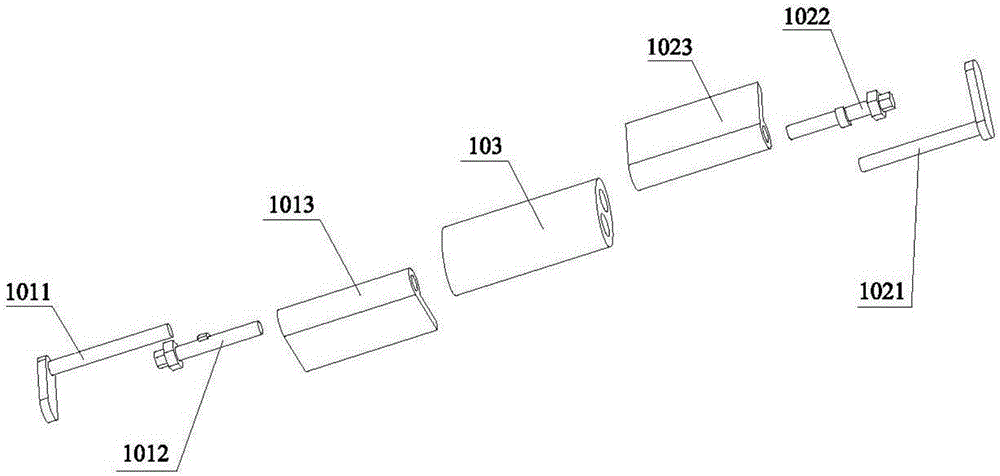

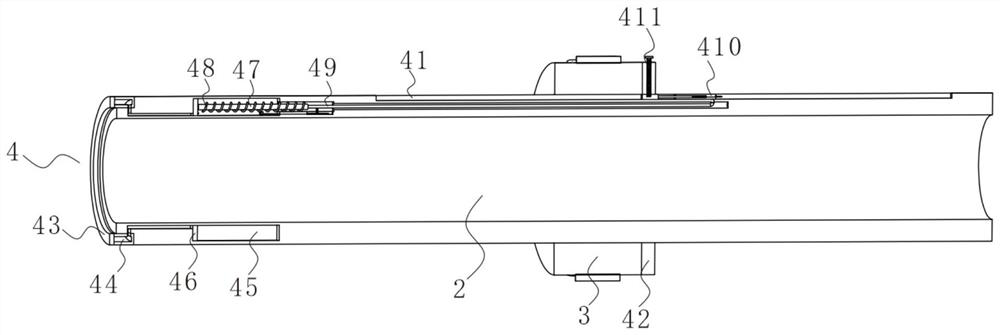

Down filling machine down filling pipe mechanism with down filling depth adjusting function

ActiveCN113615917AReduce air pressureRelieve pressureToysClothes making applicancesContact pressureEngineering

The invention discloses a down filling machine down filling pipe mechanism with a down filling depth adjusting function, and belongs to the technical field of down filling equipment. The down filling machine down filling pipe mechanism comprises a down filling outer pipe and a down filling inner pipe, the down filling inner pipe is slidably inserted into an inner cavity of the down filling outer pipe, and a threaded sleeve is rotatably mounted on the outer wall of the right side of the down filling outer pipe; the threaded sleeve is arranged on the outer wall of the down filling inner pipe in a sleeving mode, a placing groove is formed in the left end of the down filling inner pipe, an adjusting device is arranged in an inner cavity of the placing groove, in the device, a guide block is pulled rightwards, a pull rod pulls two sets of piston plates rightwards to move rightwards, air in an annular groove is drawn into an air storage groove, and the air pressure in the annular groove is reduced; a sealing ring is shrunk, the contact pressure between the sealing ring and the inner wall of the down filling outer pipe is reduced or the sealing ring does not make contact with the inner wall of the down filling outer pipe, the probability of friction between the down filling outer pipe and the sealing ring is reduced in the moving and adjusting process of the down filling outer pipe, the probability of abrasion of the sealing ring is reduced, and the probability of bending deformation of the sealing ring due to contact friction is also reduced.

Owner:广东鸿图实业有限公司

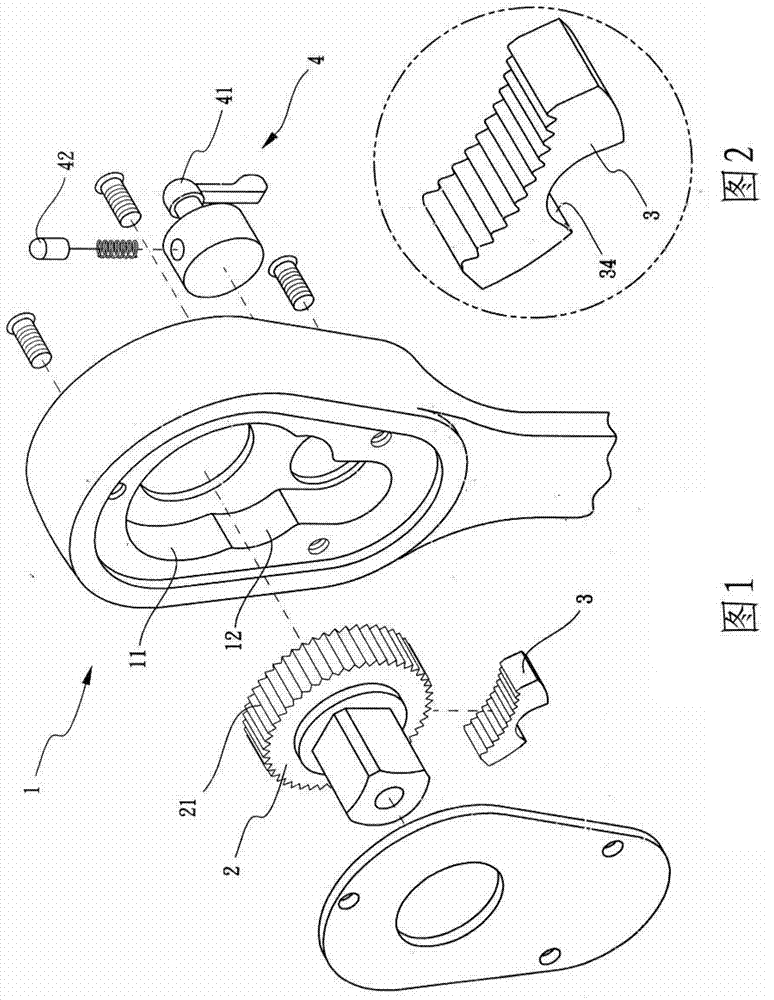

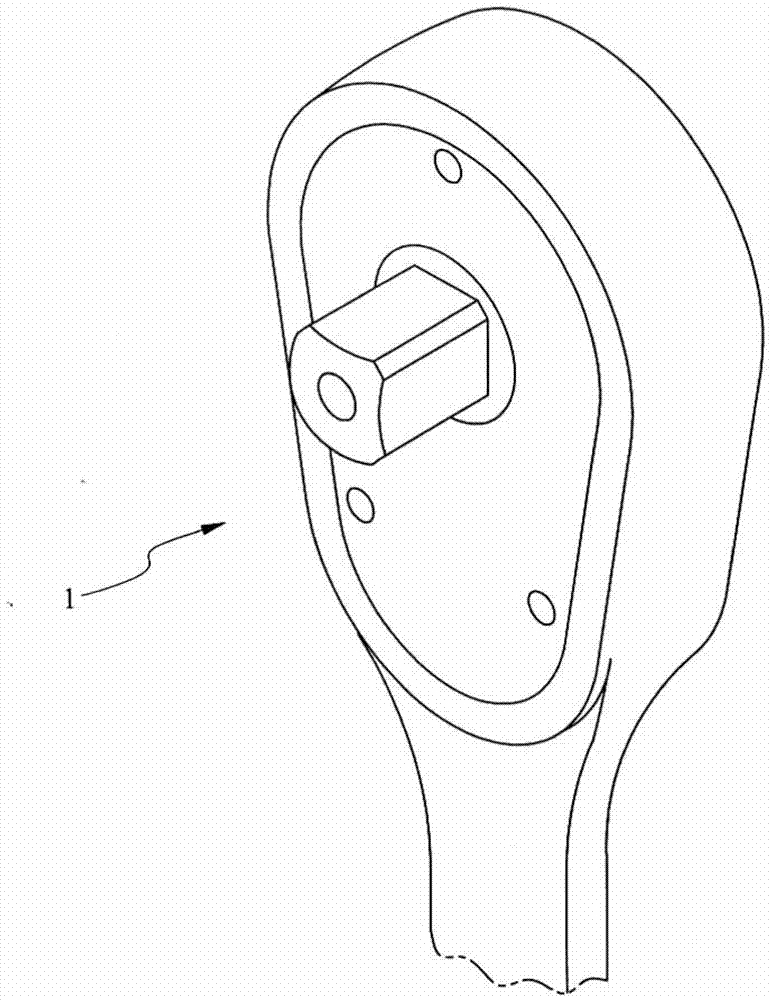

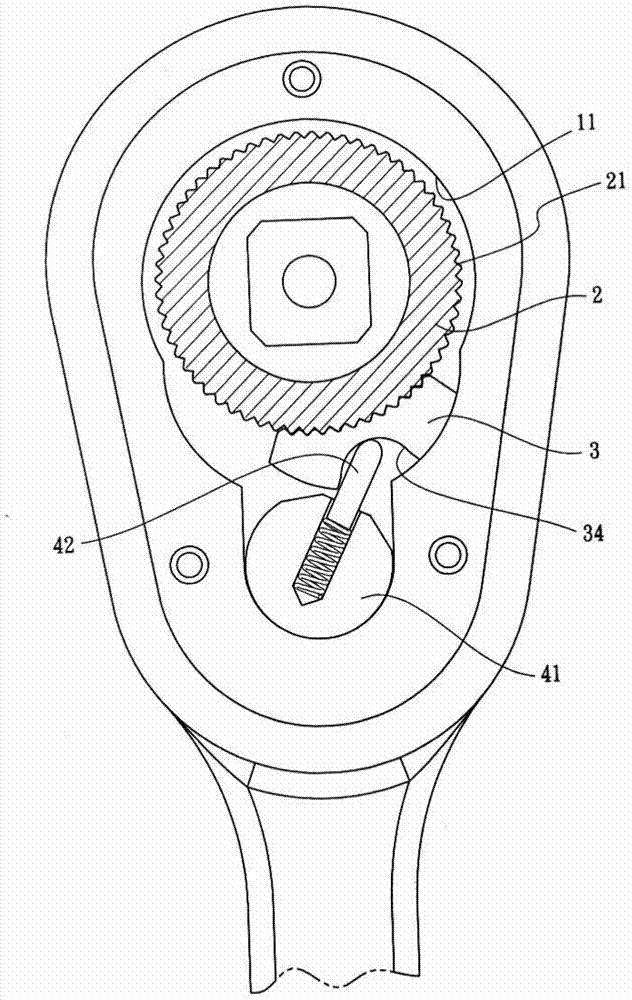

Improved wrench tool structure

ActiveCN104742057ASolve the problem of insufficient torqueIncreased processing complexitySpannersWrenchesEngineeringWrench

The invention relates to an improved wrench tool structure which comprises a wrench body. A ratchet wheel is provide with a plurality of ratchets; each first auxiliary tooth and a corresponding second auxiliary tooth of a ratchet block are respectively positioned on two sides of a corresponding main tooth; when the ratchet block is meshed towards a first direction and a second direction, each main tooth is meshed with the optional ratchet, two sides of each main tooth cling to tooth surfaces of the corresponding ratchet, opposite tooth surfaces of the multiple first auxiliary teeth and the multiple second auxiliary teeth are meshed with the multiple ratchets, and gaps are reserved between reverse tooth surfaces of the various first auxiliary teeth and the various second auxiliary teeth and the tooth surfaces of the various ratchets. The improved wrench tool structure has the advantages that when the ratchet block is meshed with the ratchet wheel towards the first direction or the second direction, contact areas of the opposite tooth surfaces of the first auxiliary teeth and the second auxiliary teeth of the ratchet block and the tooth surfaces of the ratchets are small, accordingly, tooth jumping can be smoothly carried out by the ratchet block, and abrasion loss of the main teeth, the first auxiliary teeth and the second auxiliary teeth can be reduced.

Owner:陈怡富

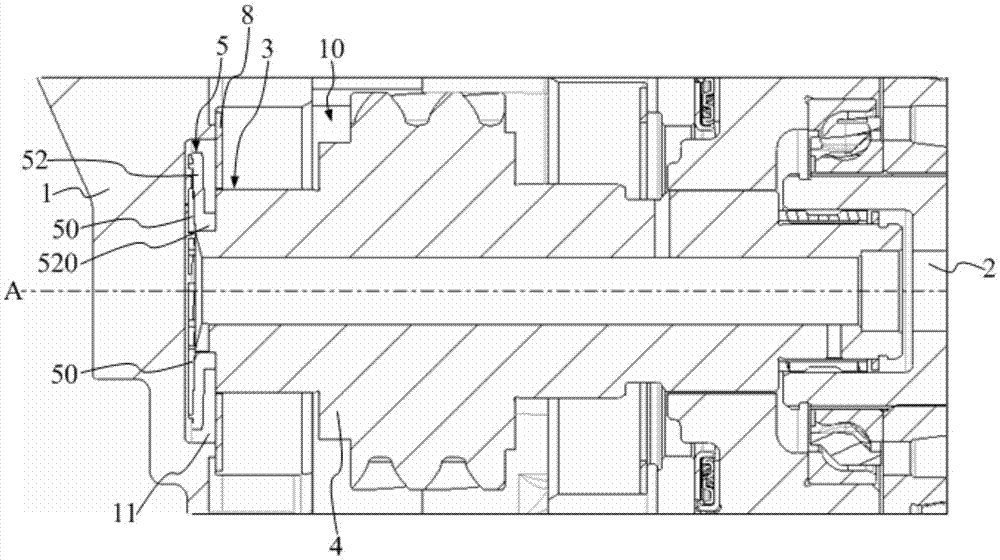

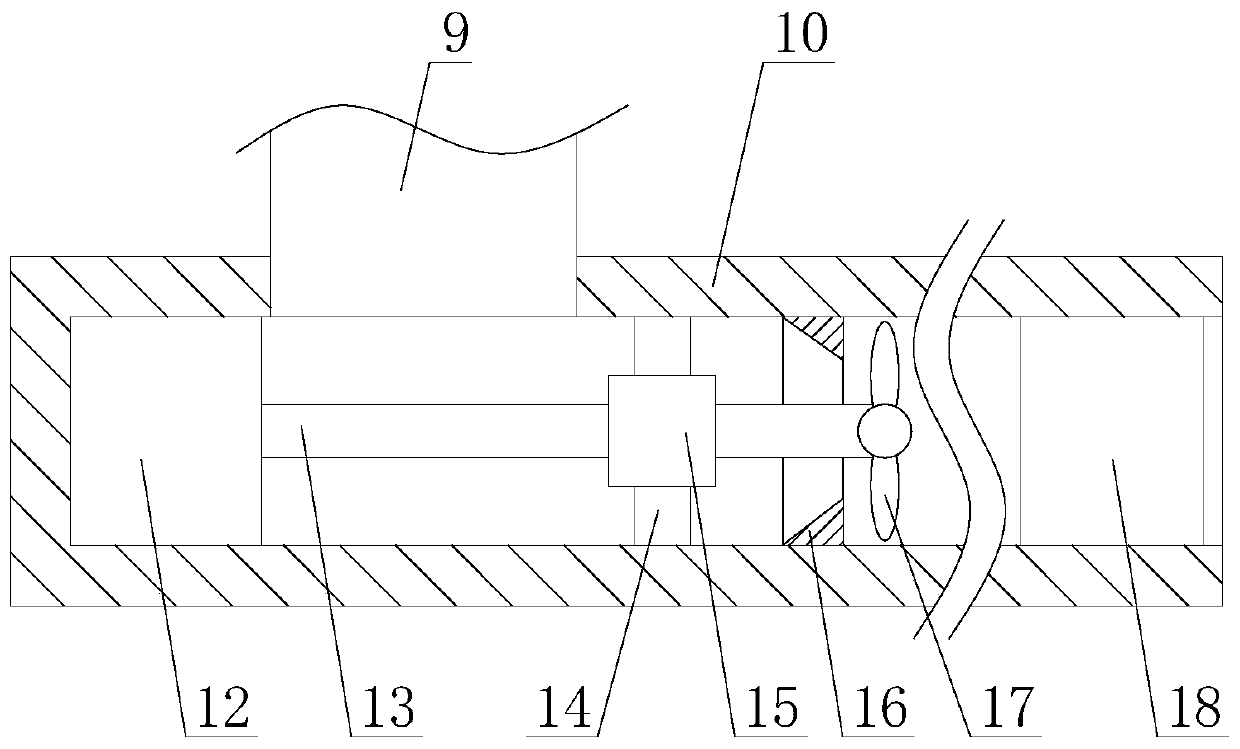

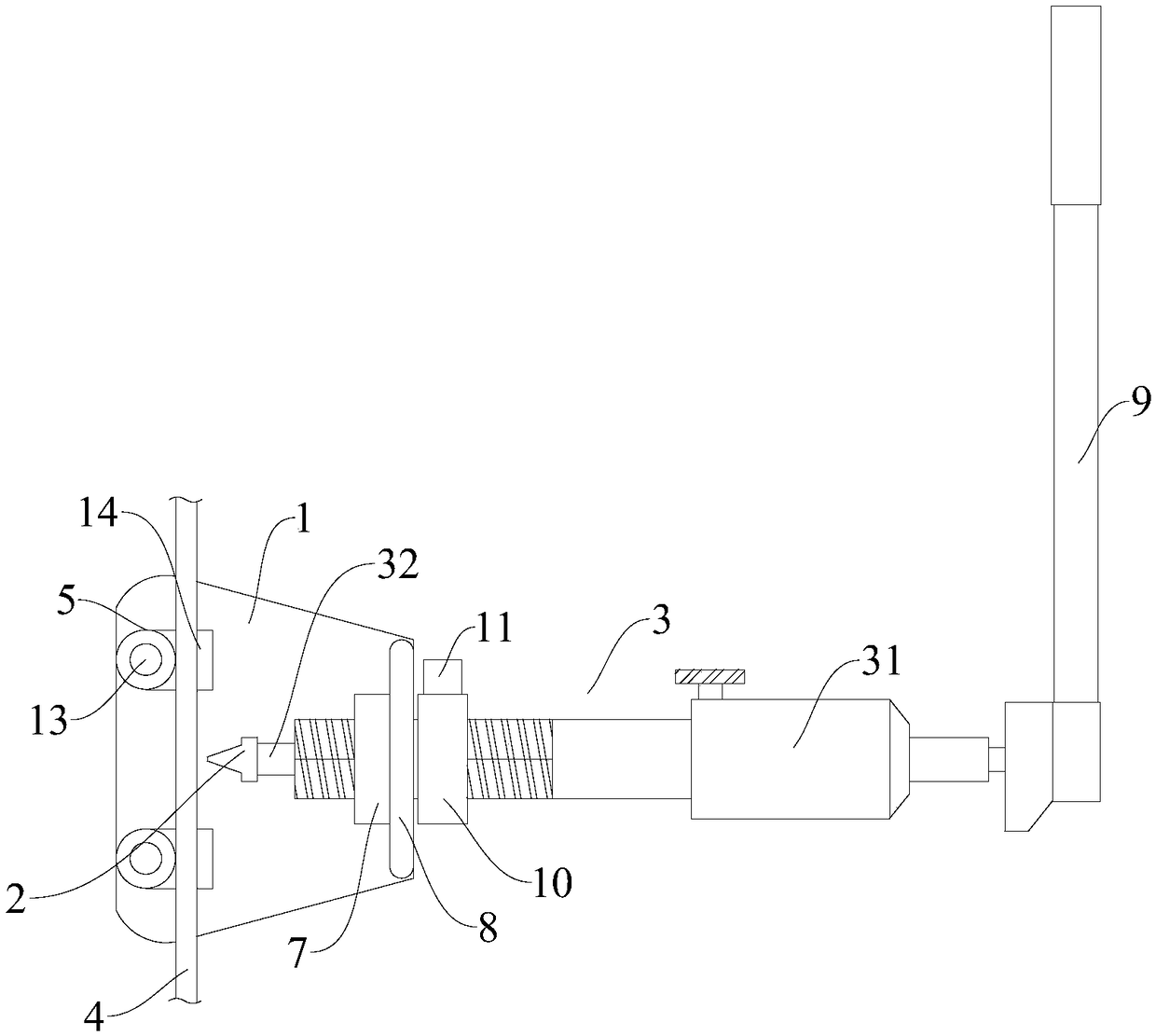

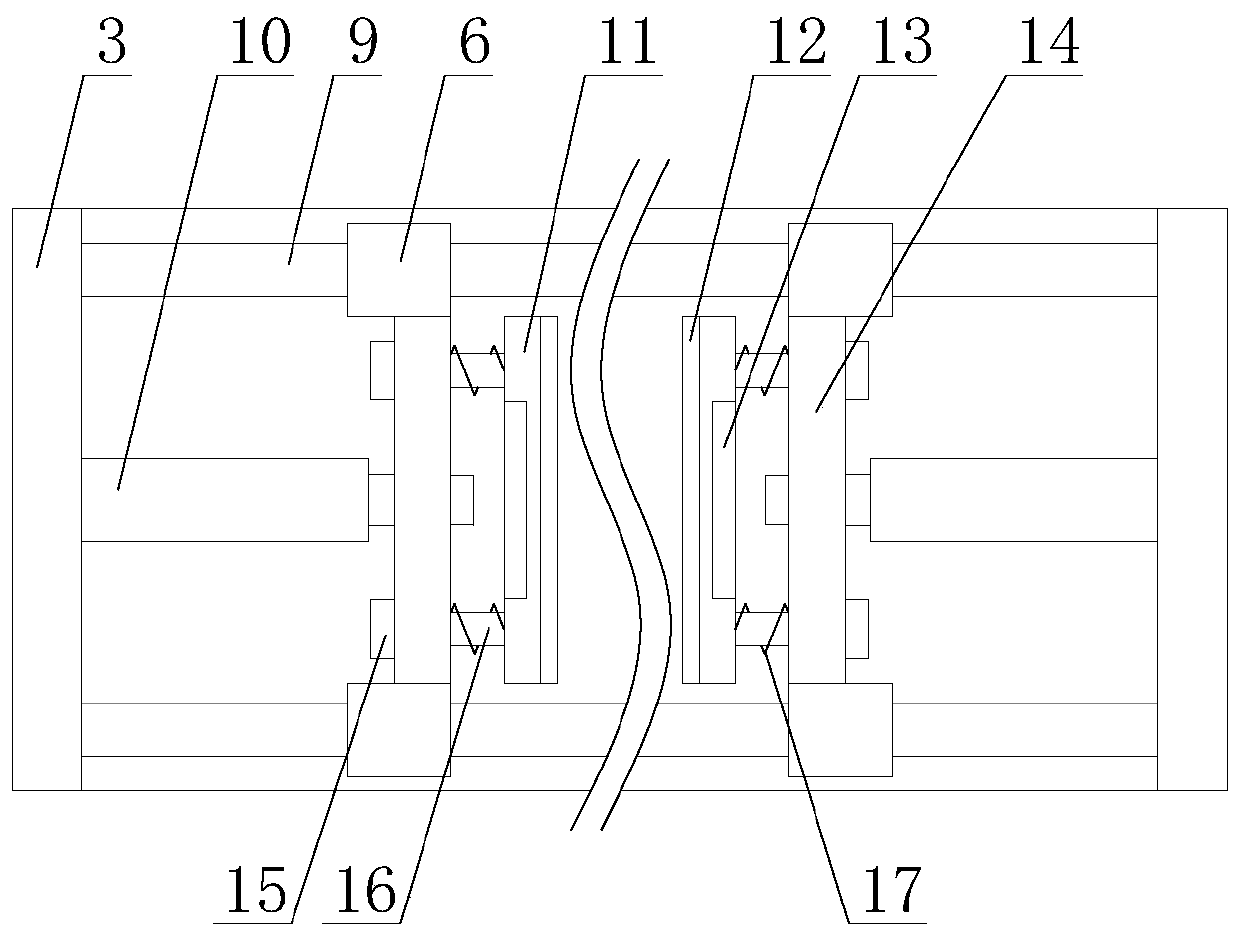

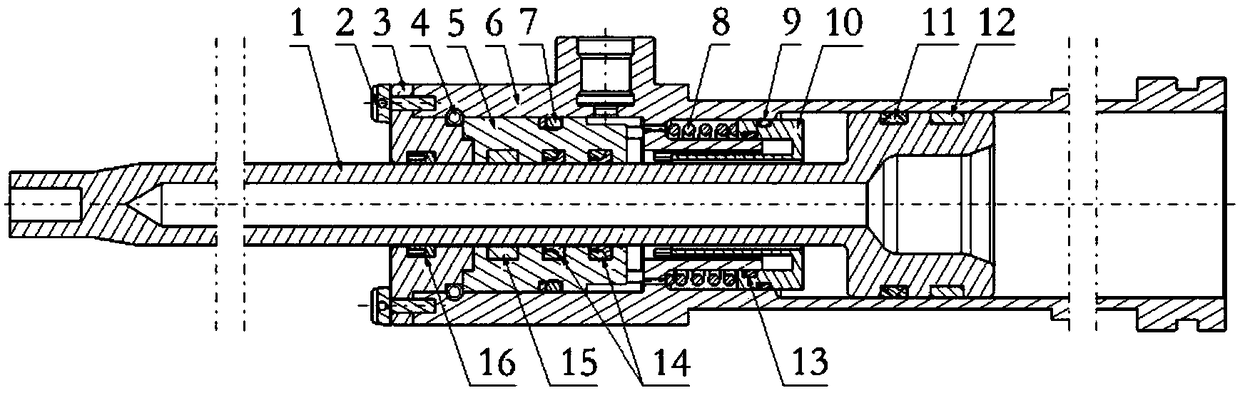

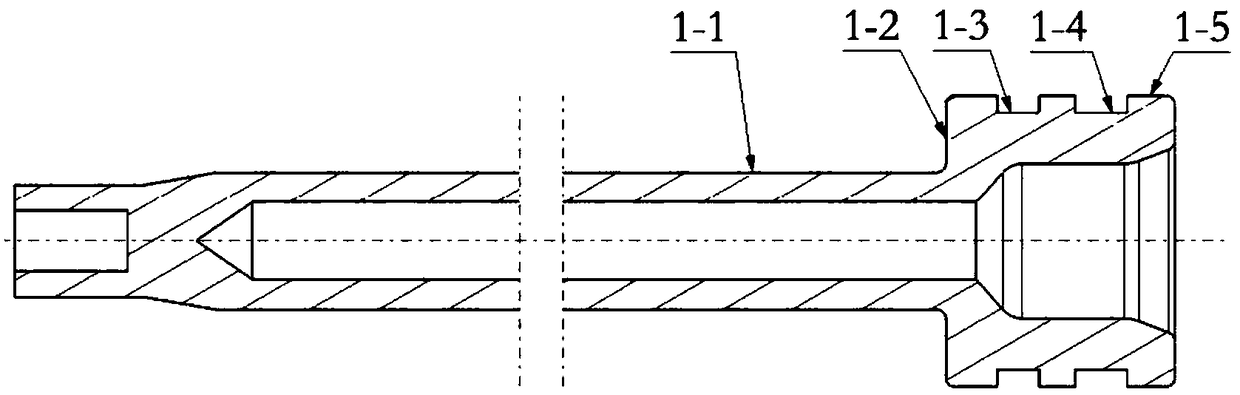

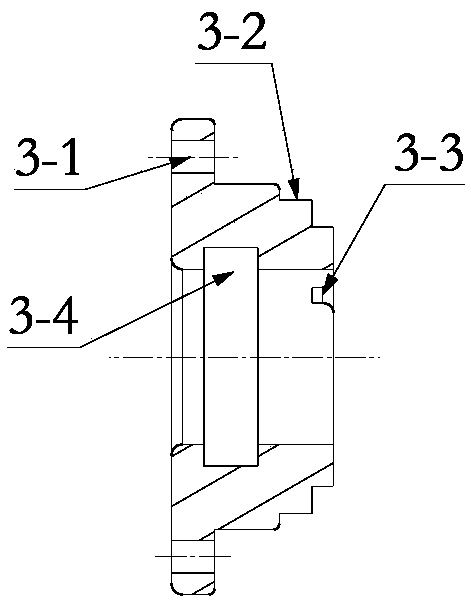

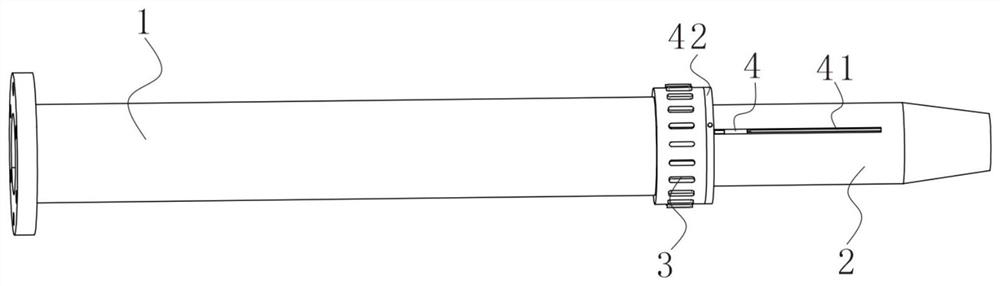

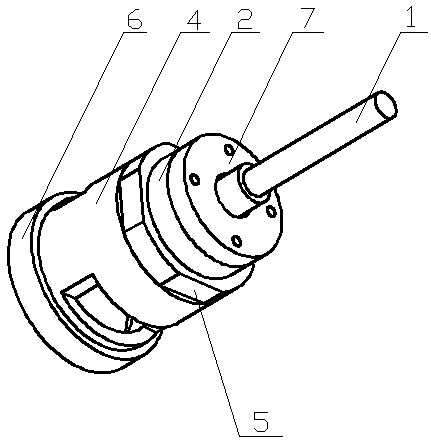

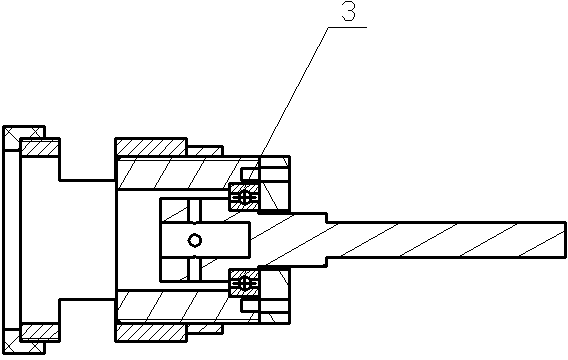

Simple countersinking depth limiting device

InactiveCN107717016ASimple structureEasy to operateDrilling/boring measurement devicesTransportation and packagingStatorEngineering

The invention discloses a countersinking limiting device, and relates to a simple countersinking depth limiting device mainly used for controlling the countersinking depth of an onboard radome. The problems that an existing device is complex in structure, high in operation difficulty, short in service life cycle, high in production and manufacturing cost, low in operation efficiency and product precision, and the like are solved. The simple countersinking depth limiting device is characterized by comprising a spindle (1), a stator (2), a bearing (3), an adjusting sleeve (4), a limiting nut (5), a protective casing (6) and a cover plate (7); the bearing (3) sleeves the spindle (1) in an interference fit mode at first and then is installed in the stator (2) in an interference fit mode to befixed by the cover plate (7) through screws; the outer cylindrical face of the stator (2) is provided with an external thread; the adjusting sleeve (4) and the protective casing (6) are provided withinternal threads; and the limiting nut (5), the adjusting sleeve (4) and the protective casing (6) are sequentially assembled with the stator (2) in a thread connection mode.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

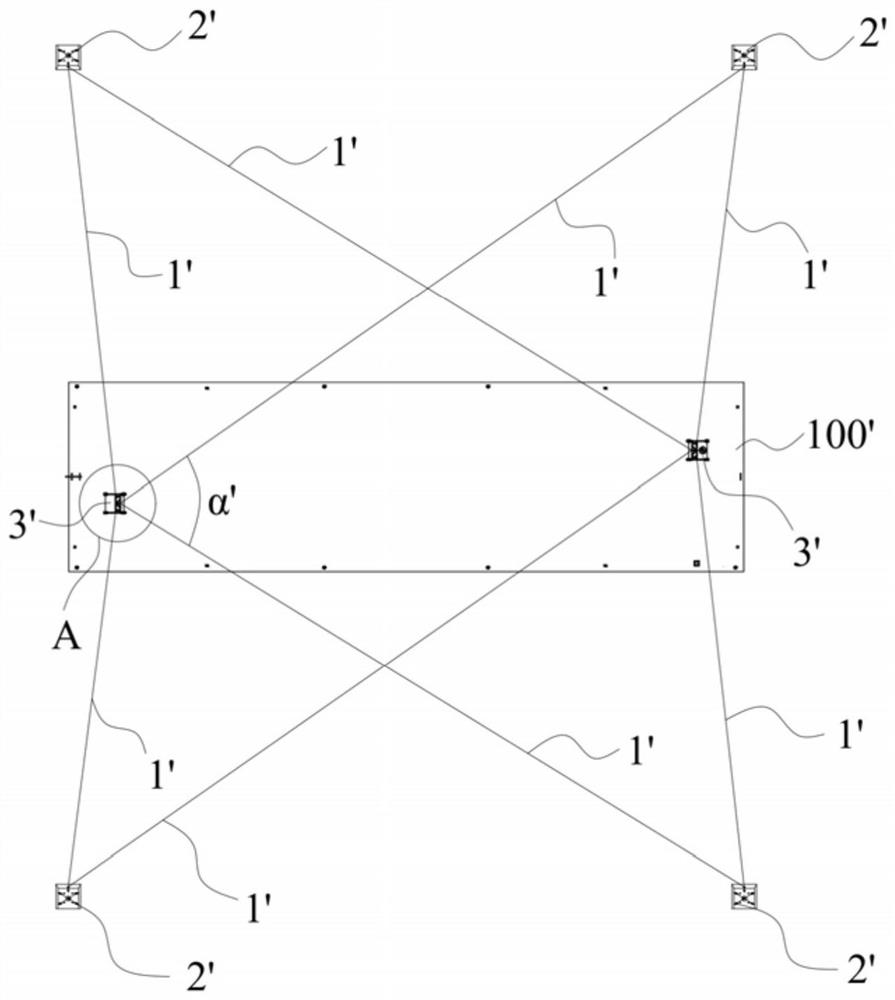

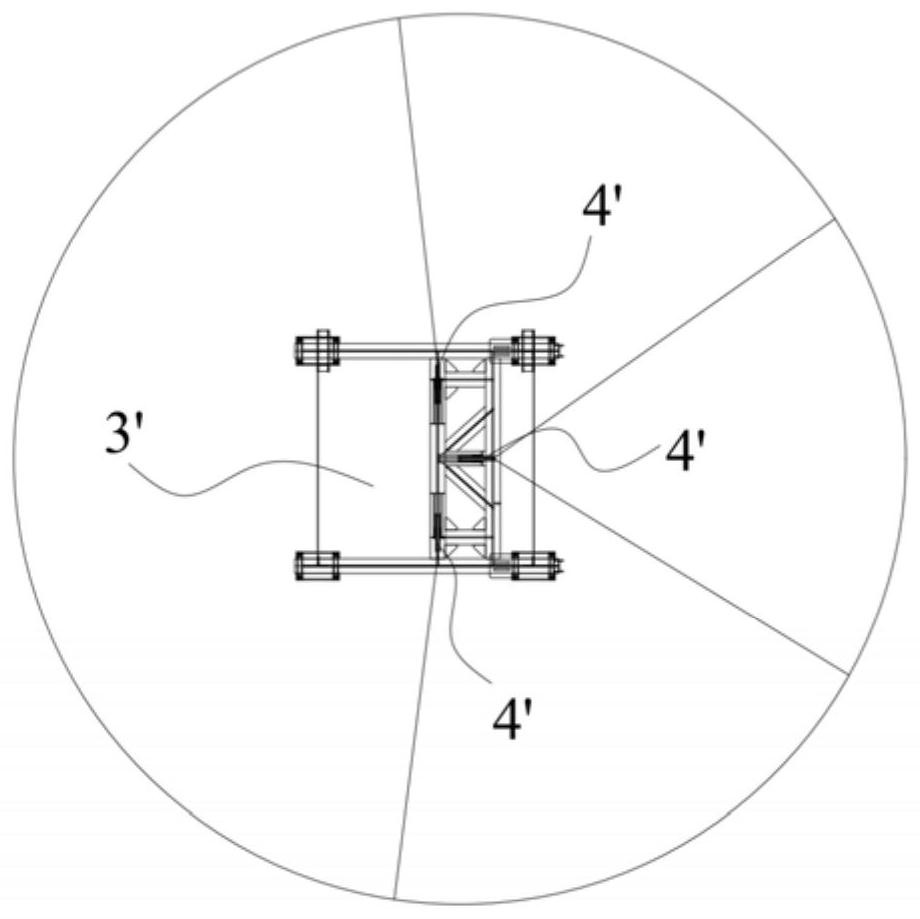

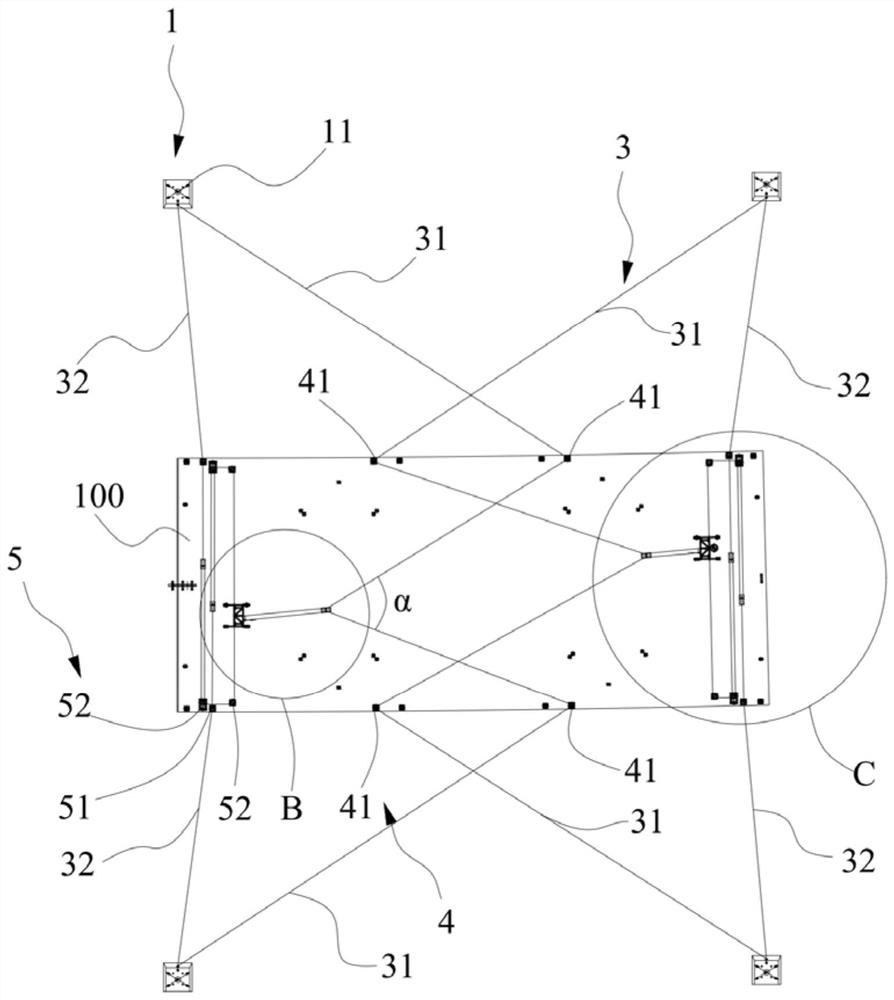

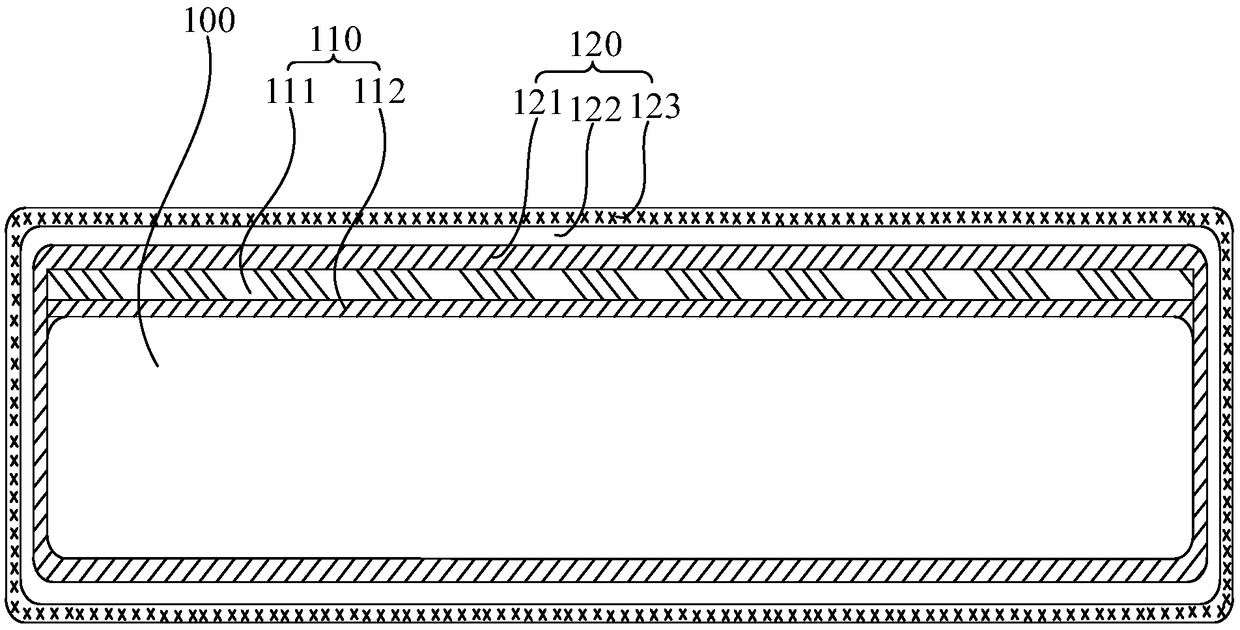

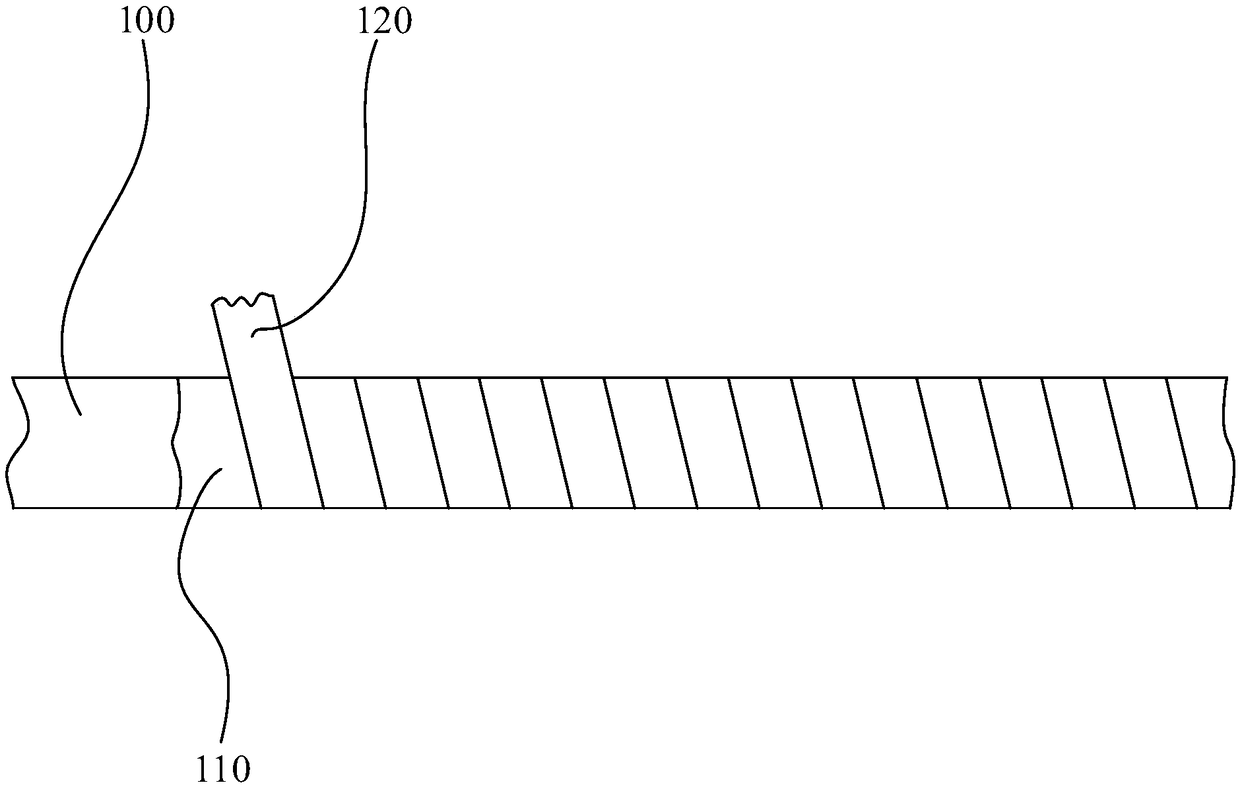

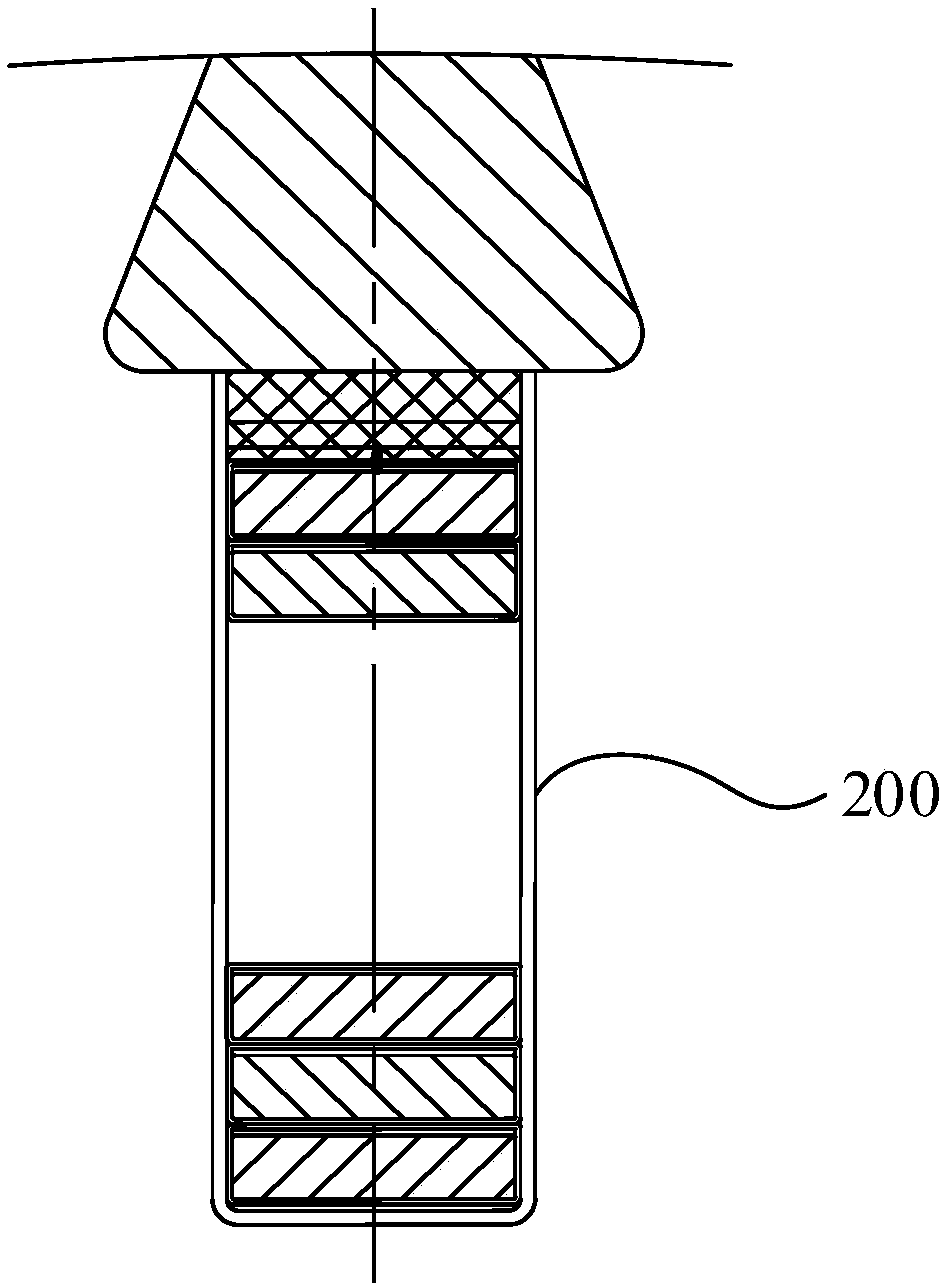

Mooring system for pipe joint sinking

PendingCN112158730AReduce wearReduced chance of wear and tearArtificial islandsUnderwater structuresTunnel engineeringWinch

The invention discloses a mooring system for pipe joint sinking, and belongs to the technical field of tunnel engineering. The mooring system for pipe joint sinking comprises an anchor head set, a winch set, a mooring rope set, a longitudinal transfer supporting assembly and a transverse transfer supporting assembly. The anchor head set is arranged on the periphery of a pipe joint. The winch set is arranged on the pipe joint. The mooring rope set comprises a longitudinal cable adjusting set and a transverse cable adjusting set, one ends of the longitudinal cable adjusting set and the transverse cable adjusting set are wound on the winch set to be connected, the other ends of the longitudinal cable adjusting set and the transverse cable adjusting set are connected with the anchor head set,the longitudinal cable adjusting set is used for adjusting the longitudinal distance of the pipe joint, and the transverse cable adjusting set is used for adjusting the transverse distance of the pipejoint. The longitudinal transfer supporting assembly is arranged on the pipe joint and can adjust the distance between the longitudinal cable adjusting set and the top of the pipe joint in the vertical direction and adjust the ratio of component force of the longitudinal cable adjusting set in the longitudinal direction to component force of the longitudinal cable adjusting set in the transversedirection. The transverse transfer supporting assembly is arranged on the pipe joint and can adjust the distance between the transverse cable adjusting set and the top of the pipe joint in the vertical direction.

Owner:交通运输部广州打捞局

Turn-to-turn insulation single-turn coil and rotor winding

PendingCN108832746AReduce short circuitImprove insulation performanceWindings insulation shape/form/constructionEngineeringCopper

The invention provides a turn-to-turn insulation single-turn coil and a rotor winding, and belongs to the technical field of motor manufacturing. The turn-to-turn insulation single-turn coil includesa copper bus, an insulating plate and an adhesive tape. The insulating plate is laminated on the wide surface of the copper bus, the adhesive tape is wrapped around the outer periphery of the laminated structure composed of the insulating plate and the copper bus, and the insulating plate is provided with a first sliding layer, wherein the first sliding layer is coated on the insulating plate forreducing the friction between the insulating plate and the copper bus. The objective of the invention to provide the turn-to-turn insulation single-turn coil and the rotor winding, which are capable of generating an insulating effect through the insulating plate. Meanwhile, the first sliding layer on the surface of the insulating plate is used for reducing the friction between the insulating plateand the copper bus. Meanwhile, the adhesive tape is used for fixing the insulating plate and the copper bus, so as to reduce the damage of the insulation structure caused by the friction caused by the friction between the insulating plate and the copper bus during normal use, thereby reducing the coil short circuit phenomena of the rotor winding due to damage of the insulation structure.

Owner:CHINA CHANGJIANG ENERGY CORP GROUP

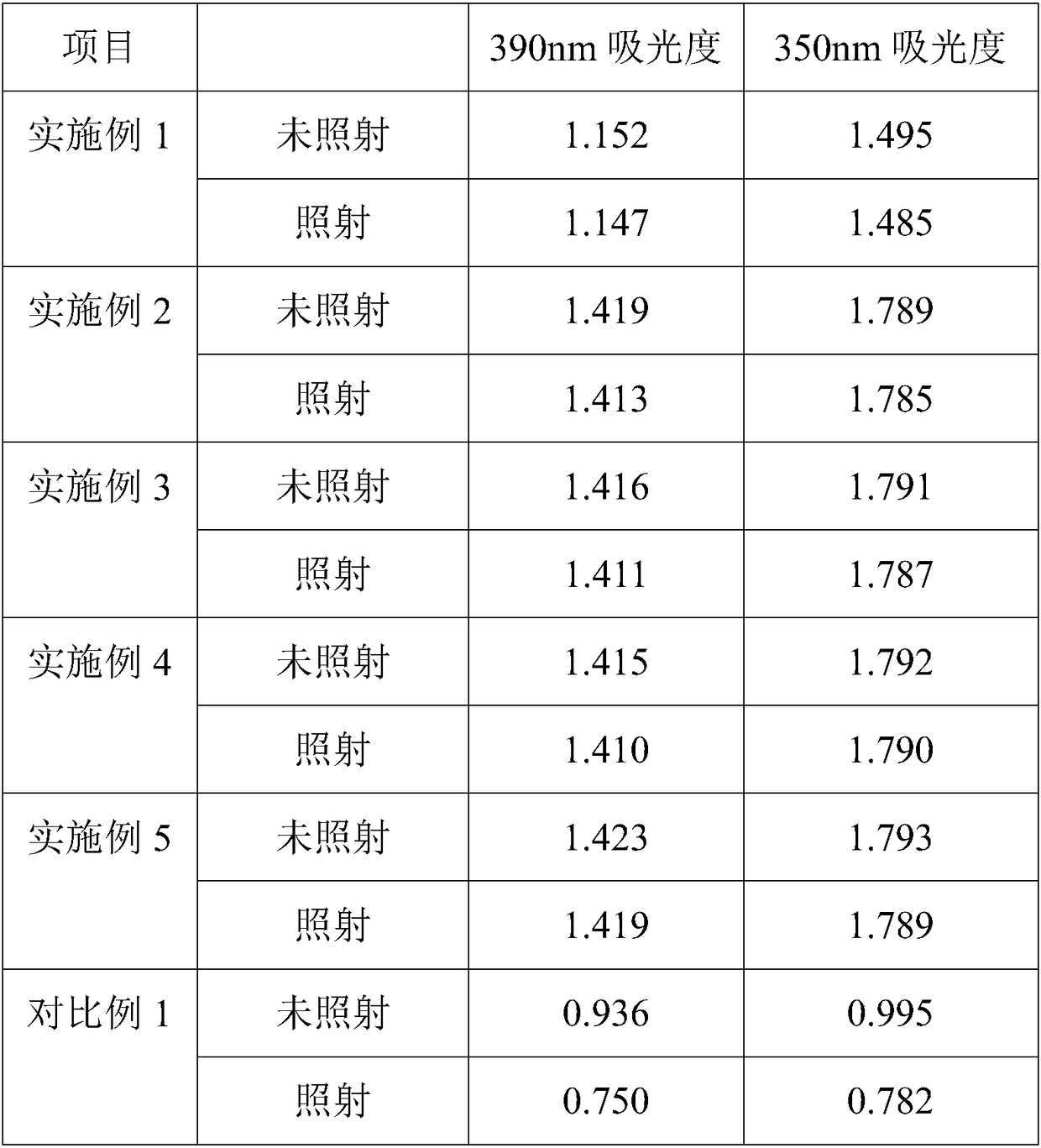

Anti-ultraviolet coating

InactiveCN109401561AGood compatibilityImprove dispersion stabilityRadiation-absorbing paintsEpoxy resin coatingsAcrylic resinUltraviolet

The invention relates to the technical field of coating, in particular to anti-ultraviolet coating. The anti-ultraviolet coating is prepared from the following raw materials in part by weight: 40-55 parts of epoxy acrylic resin, 12-23 parts of water glass, 7-13 parts of modified nanometer titanium dioxide, 3-9 parts of nano-ceramic powder, 4-7 parts of polyoxyethylene laurate, 9-16 parts of propylene glycol methyl ether acetate, 1.5-3.5 parts of perchlorovinyl resin, 2-4.5 parts of a film-forming agent, 3-5 parts of calcium carbonate, 0.5-1.8 parts of a fire retardant, and 1-2 parts of a dispersant. The anti-ultraviolet coating has the excellent anti-ultraviolet performance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com