Anti-ultraviolet coating

An anti-ultraviolet and coating technology, applied in the field of coatings, can solve the problems of decreased anti-ultraviolet ability, difficult to maintain anti-ultraviolet for a long time, poor stability, etc., to achieve the effect of reducing surface tension, good compatibility, and reducing the probability of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

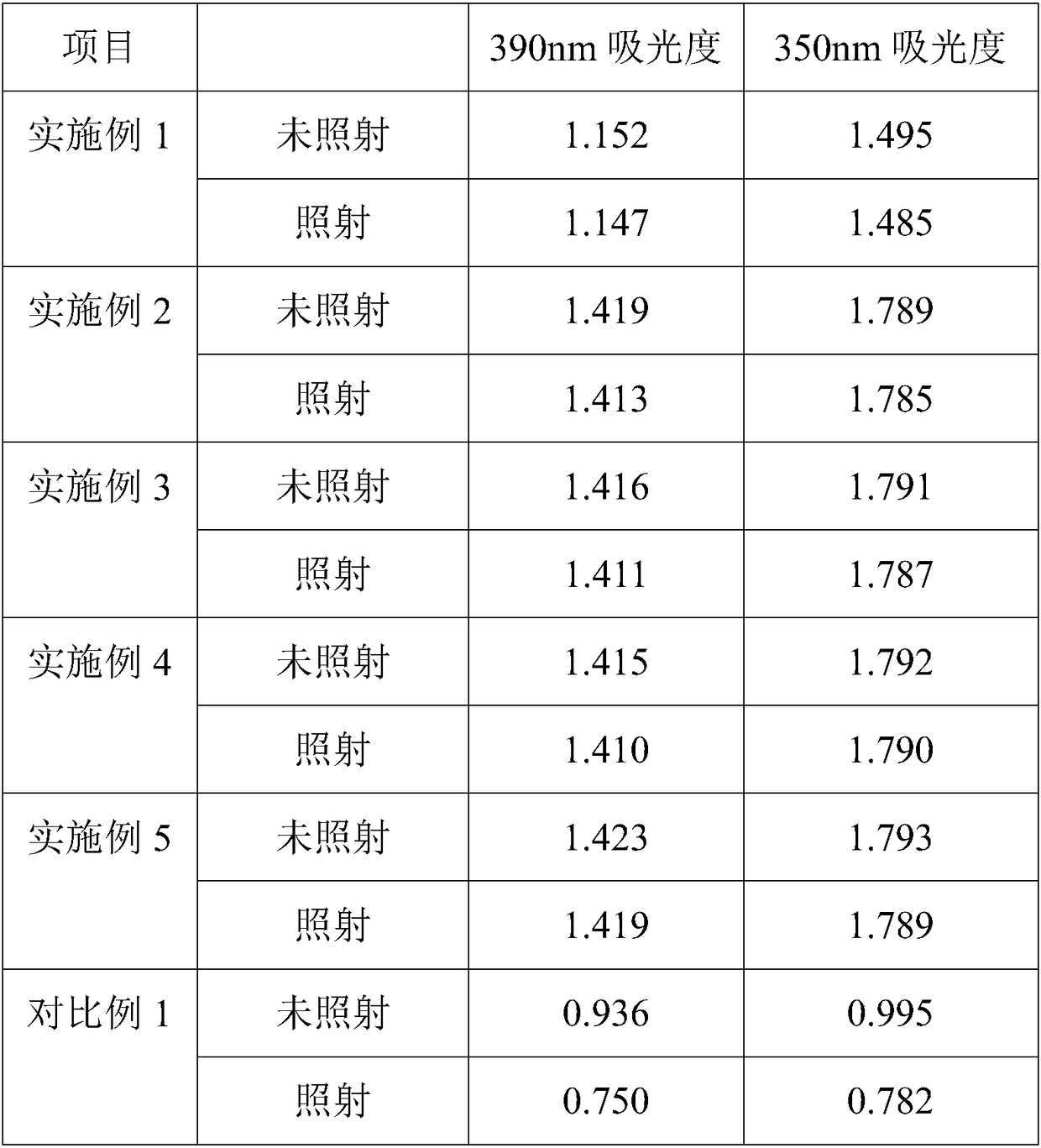

Examples

Embodiment 1

[0017] An anti-ultraviolet coating, its raw materials include by weight: 40 parts of epoxy acrylic resin, 23 parts of water glass, 7 parts of modified nano-titanium dioxide, 9 parts of nano-ceramic powder, 4 parts of polyoxyethylene laurate, propylene glycol methyl ether 16 parts of acetate, 1.5 parts of perchlorethylene resin, 4.5 parts of film forming agent, 3 parts of calcium carbonate, 1.8 parts of flame retardant, and 1 part of dispersant.

Embodiment 2

[0019] An anti-ultraviolet coating, its raw materials include by weight: 55 parts of epoxy acrylic resin, 12 parts of water glass, 13 parts of modified nano-titanium dioxide, 3 parts of nano-ceramic powder, 7 parts of polyoxyethylene laurate, propylene glycol methyl ether 9 parts of acetate, 3.5 parts of perchlorethylene resin, 2 parts of film forming agent, 5 parts of calcium carbonate, 0.5 part of flame retardant, 2 parts of dispersant;

[0020] Wherein, the preparation method of the modified nano-titanium dioxide is as follows: take vinyl neodecanoate, add sodium hydroxide solution, stir, add tetrabutyl titanate, and reflux reaction to obtain modified nano-titanium dioxide.

Embodiment 3

[0022] An anti-ultraviolet coating, its raw materials include by weight: 50 parts of epoxy acrylic resin, 18 parts of water glass, 10 parts of modified nano-titanium dioxide, 6 parts of nano-ceramic powder, 5.5 parts of polyoxyethylene laurate, propylene glycol methyl ether 12 parts of acetate, 2.5 parts of perchlorethylene resin, 3.5 parts of film forming agent, 4 parts of calcium carbonate, 1 part of flame retardant, 1.5 parts of dispersant;

[0023] Wherein, the preparation method of the modified nano-titanium dioxide is: take vinyl neodecanoate, add sodium hydroxide solution, stir, add tetrabutyl titanate, and reflux reaction to obtain modified nano-titanium dioxide;

[0024] The volume ratio of the vinyl neodecanoate to the sodium hydroxide solution is 1:0.2;

[0025] The volume ratio of vinyl neodecanoate to tetrabutyl titanate is 1:0.7;

[0026] The massfraction of described sodium hydroxide solution is 30wt%;

[0027] The time of stirring is 30min;

[0028] The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com