Patents

Literature

38results about How to "Eliminate flow dead zones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

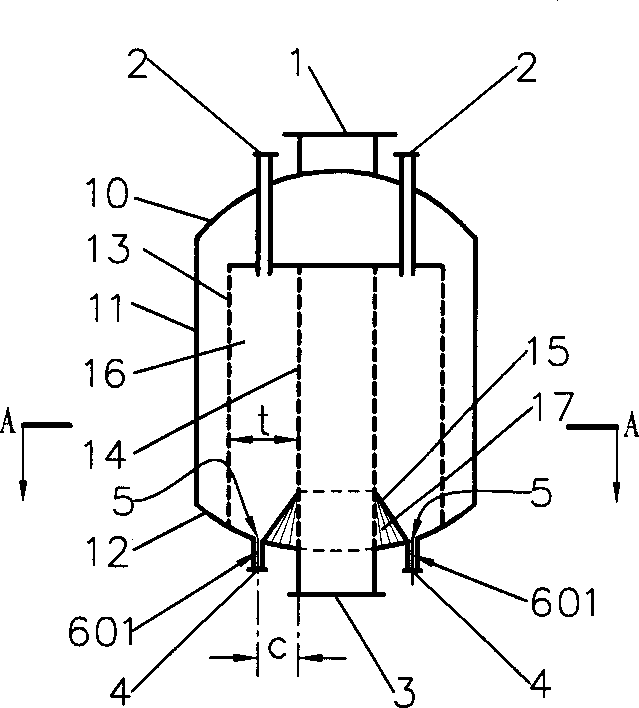

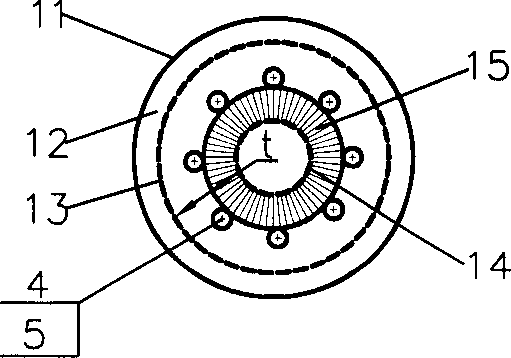

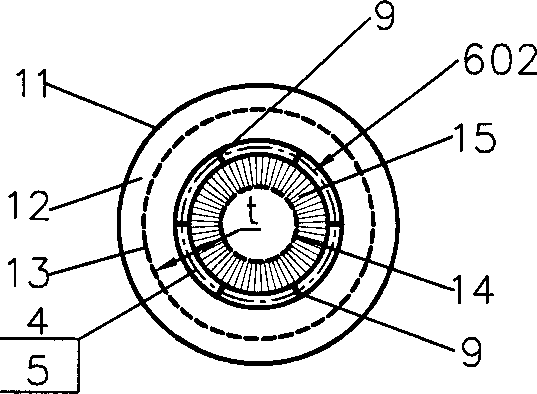

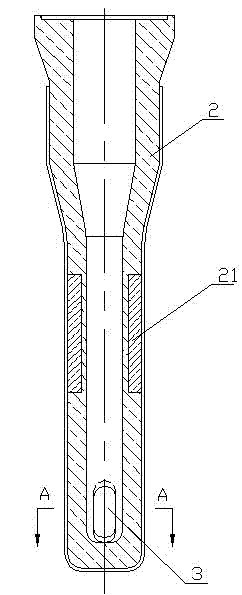

Gas and solid radial reactor for moving-bed

InactiveCN1333084ASimple structureReduce or eliminate flow dead zonesChemical/physical processesChemical industryOil processing

The present invention discloses a gas-solid radial reactor of moving bed for chemical industry and petroleum processing industry, and is characterized by that the lower portion of inner not of said reactor is equipped with a skirt, and the external surface of said skirt is inclined from top to bottom along the direction from inner net toward outer net, its upper edge is connected with inner net, and its lower edge is connected with internal surface of closure head of the bottom, and the radial position of the lower edge is positioned in internal side of radial position of catalyst outlet pipe, and the external surface of said skirt is generally made into circular truncated cone side face or frustum side face. Said invention can effectively reduce or eliminate flow dead zone of catalyst inthe reactor, at the same time the structure of said skirt is simple, and easy to implement. It is specially applicable to hydrocarbon conversion reaction and catforming reaction.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

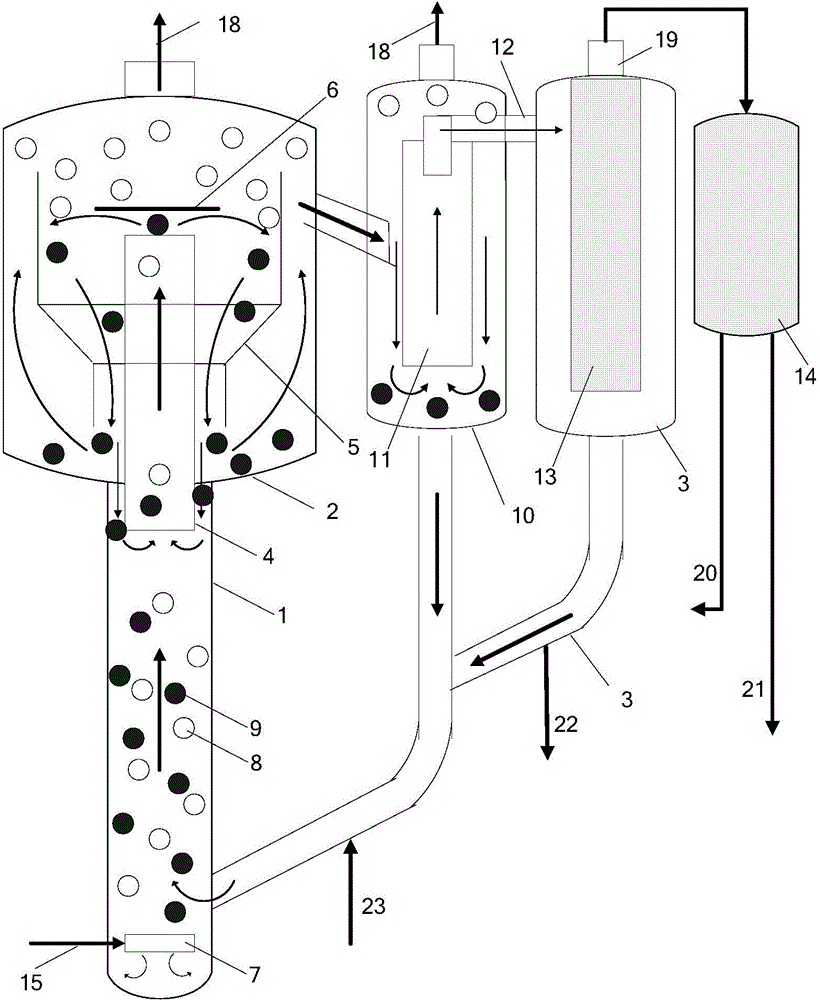

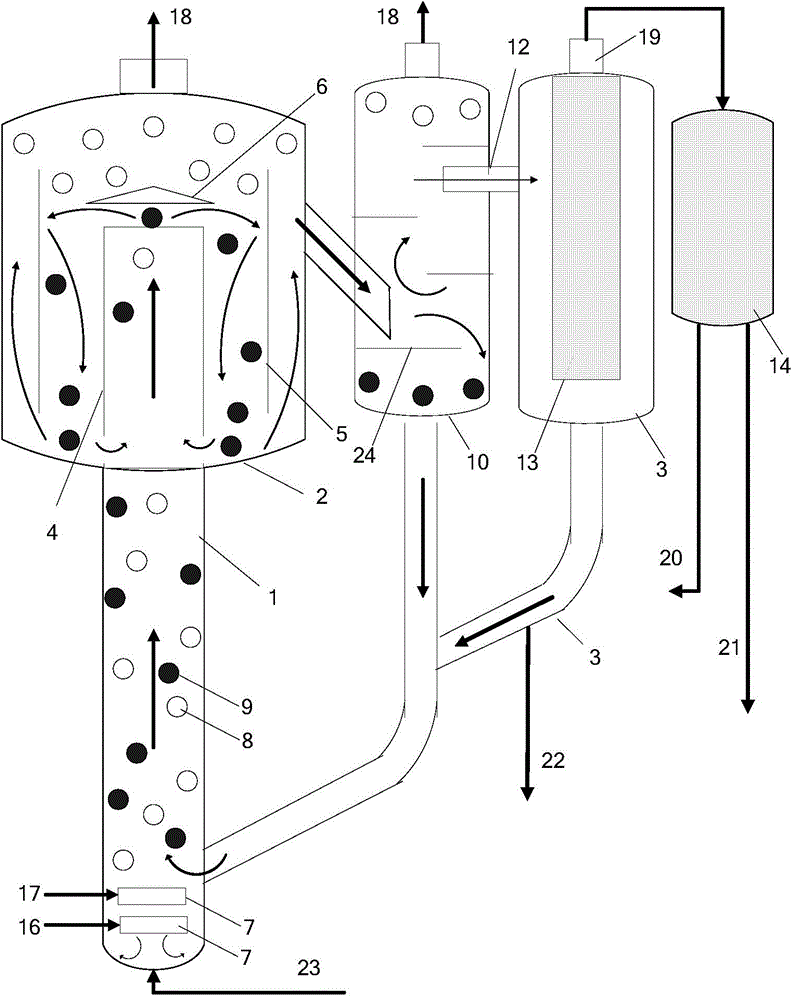

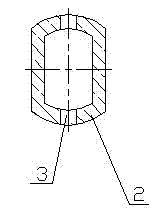

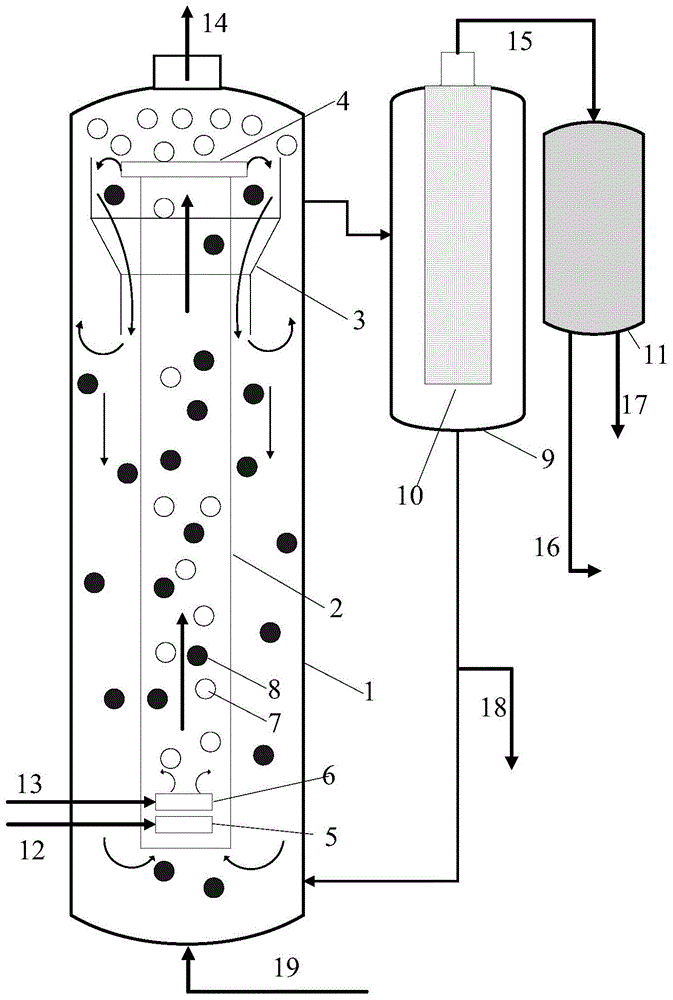

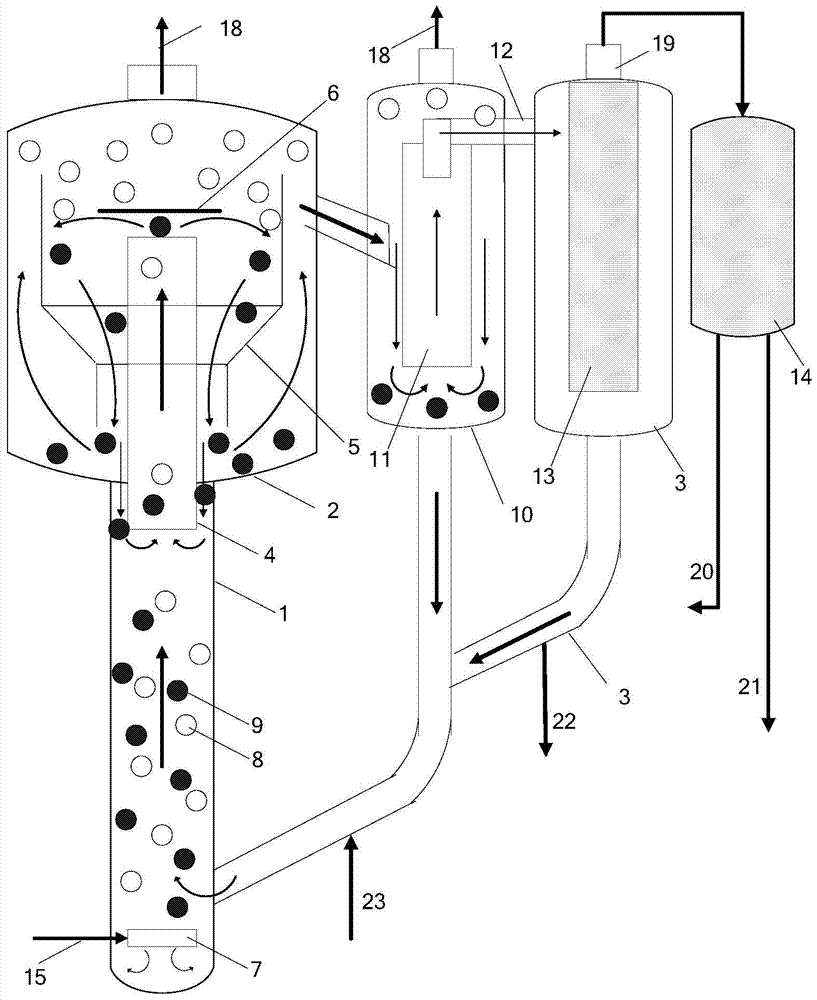

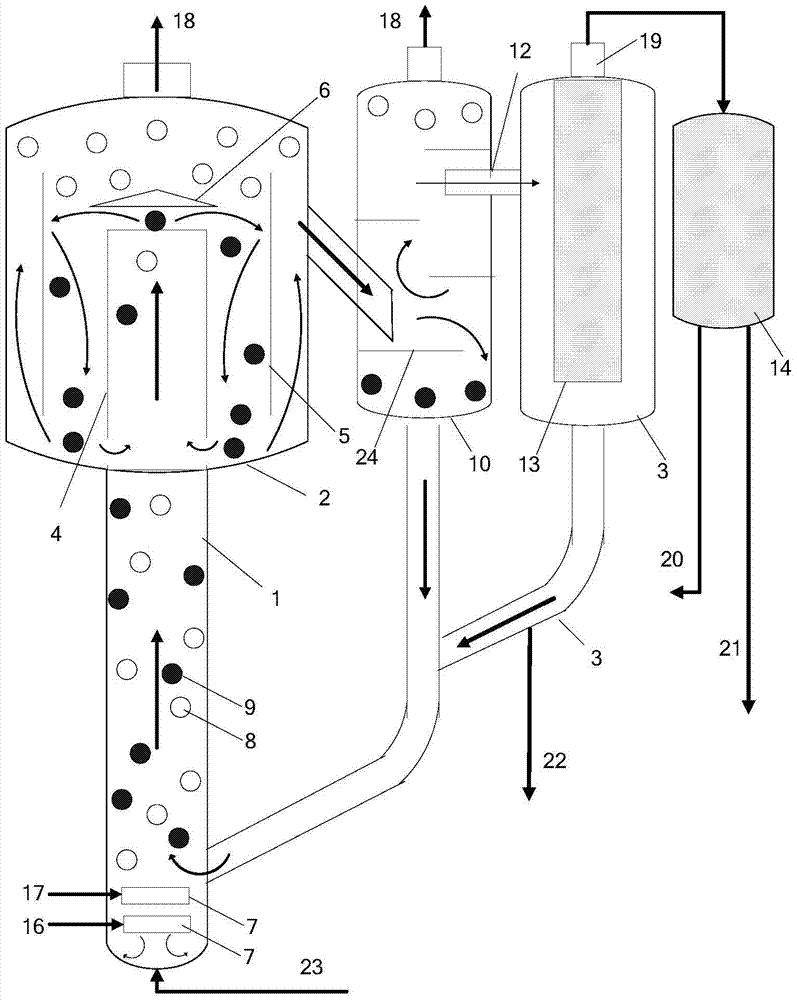

Slurry bed loop reactor, application and method for producing hydrogen peroxide

ActiveCN104549060AExtended operating cycleEasy to separatePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention relates to a slurry bed loop reactor, application and a method for producing hydrogen peroxide. The slurry bed loop reactor comprises a riser, a separation tank and a downcomer which are communicated sequentially, wherein an expansion section with expanded pipe diameter is arranged at the upper part of the riser, the upper part of the expansion section is communicated with the separation tank, a liquid phase outlet in the upper part of the separation tank is communicated with the upper part of the downcomer, the bottom of the downcomer is communicated with the bottom of the riser, and the bottom of the separation tank is communicated with the lower part of the downcomer; and a raw material inlet is formed in the bottom of the riser, gas outlets are formed in the top of the expansion section of the riser and in the top of the separation tank, a filtration component is arranged in the downcomer and a clear liquid outlet is formed in the upper part of the downcomer via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

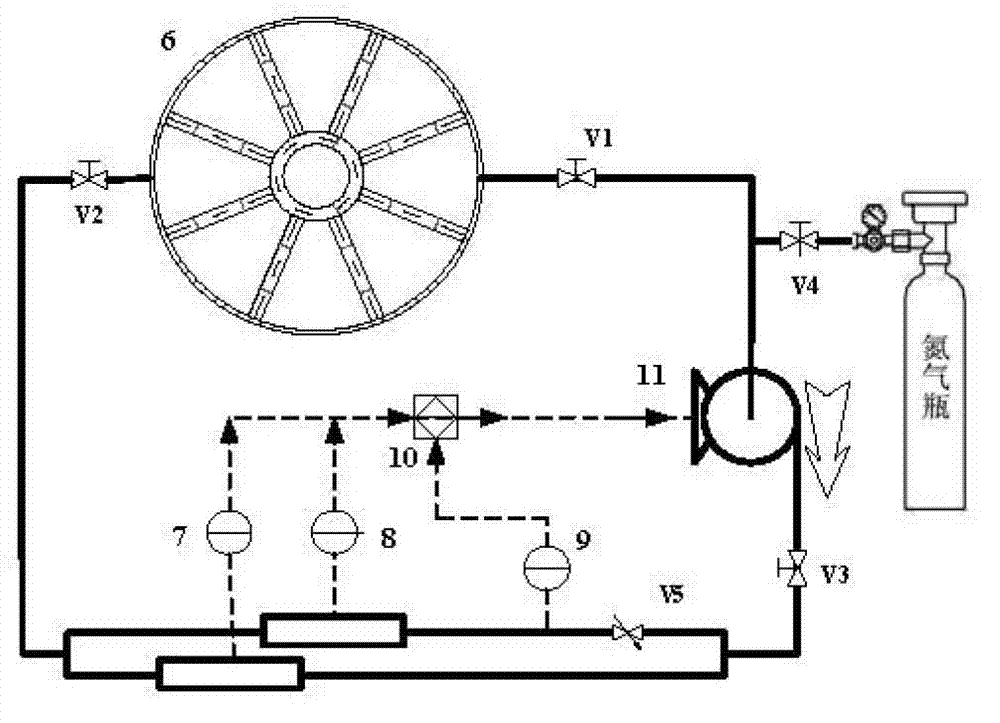

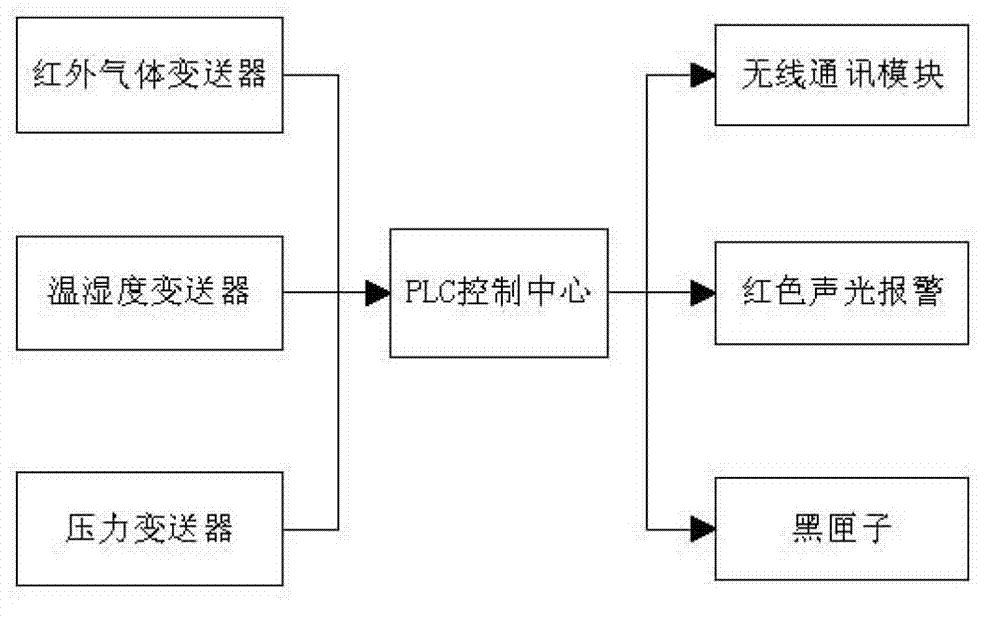

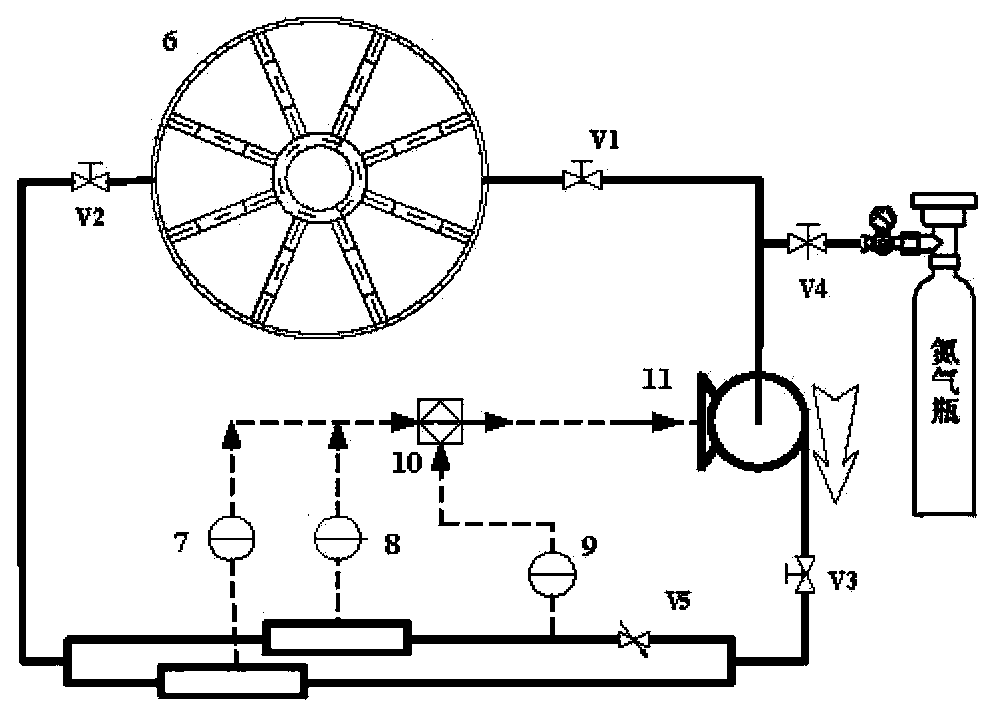

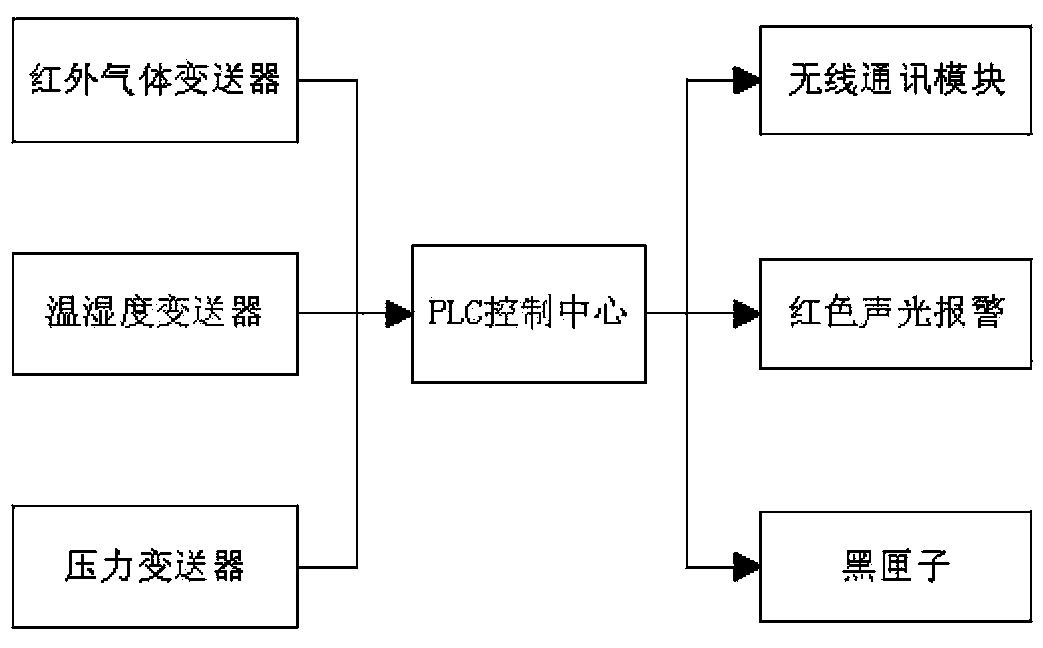

Vertical storage tank leakage monitoring system with dual-layer tank bottom plate structure

ActiveCN102785874AAvoid double-sided corrosionExtend the life cycleLarge containersProgrammable logic controllerMonitoring system

The invention relates to a vertical storage tank leakage monitoring system with a dual-layer tank bottom plate structure. The provided system aims at realizing real-time monitoring of the leakage situation of a tank bottom plate of a vertical storage tank. The technical scheme is that the vertical storage tank leakage monitoring system with the dual-layer tank bottom plate structure comprises the vertical storage tank which consists of a tank body and a tank body, and a leakage monitoring system which is used for monitoring leaked gas. The vertical storage tank leakage monitoring system with the dual-layer tank bottom plate structure is characterized in that the tank bottom comprises an upper layer bottom plate, a lower layer bottom plate and a closed cavity which is arranged between the upper layer bottom plate and the lower layer bottom plate, the leakage monitoring system comprises a circulating pipeline which is provided with a circulating pump and is connected with the cavity, an inert gas source which is communicated with the circulating pipeline, and a PLC (programmable logic controller) control center which is respectively connected with an infrared gas transmitter, a pressure transmitter, a temperature and humidity transmitter and the circulating pump through data lines.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST

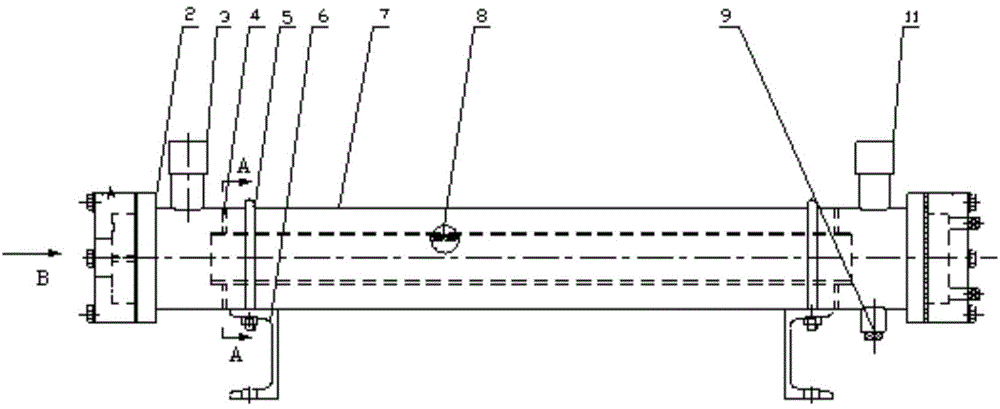

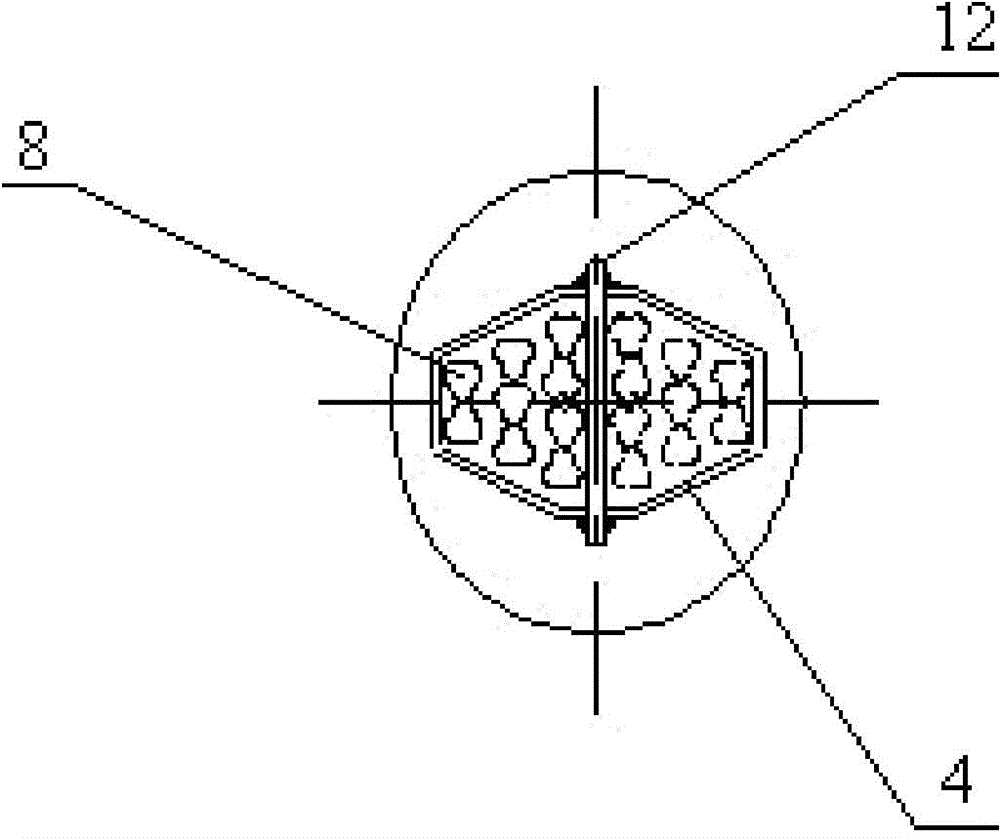

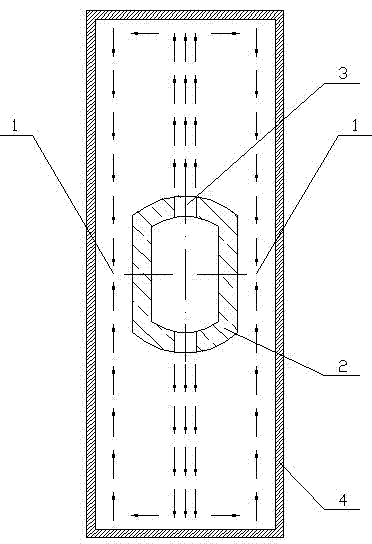

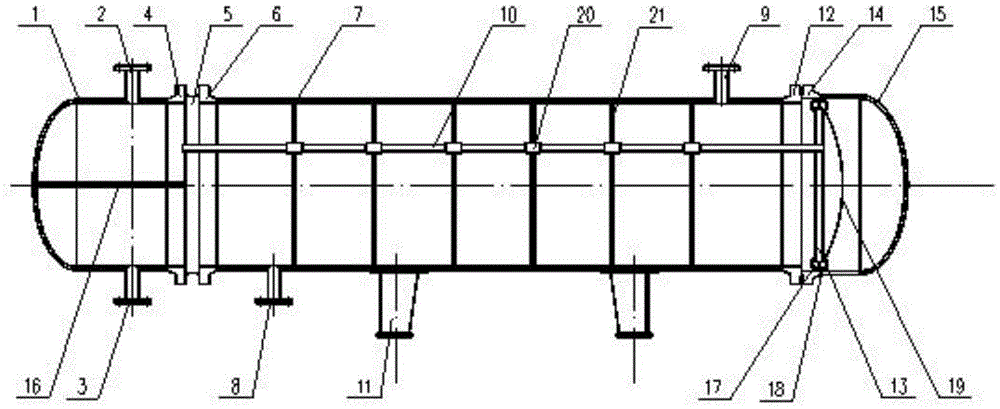

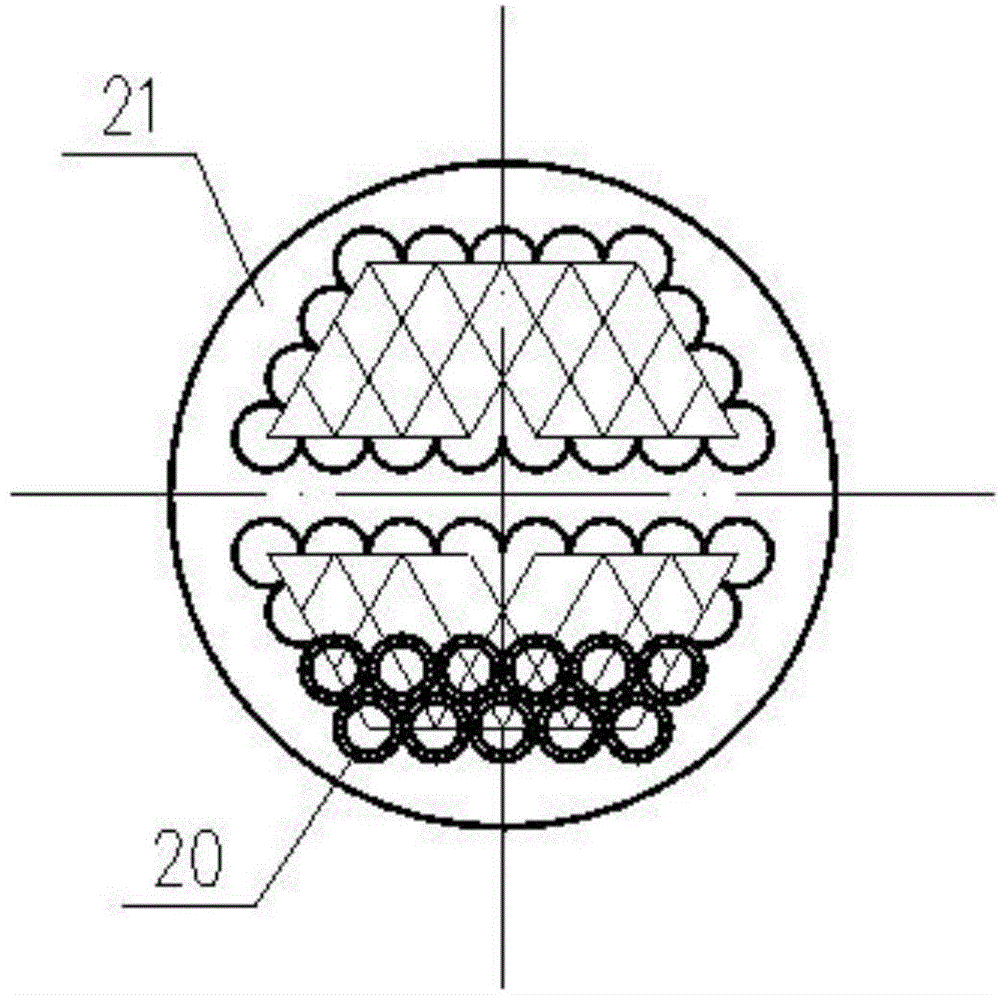

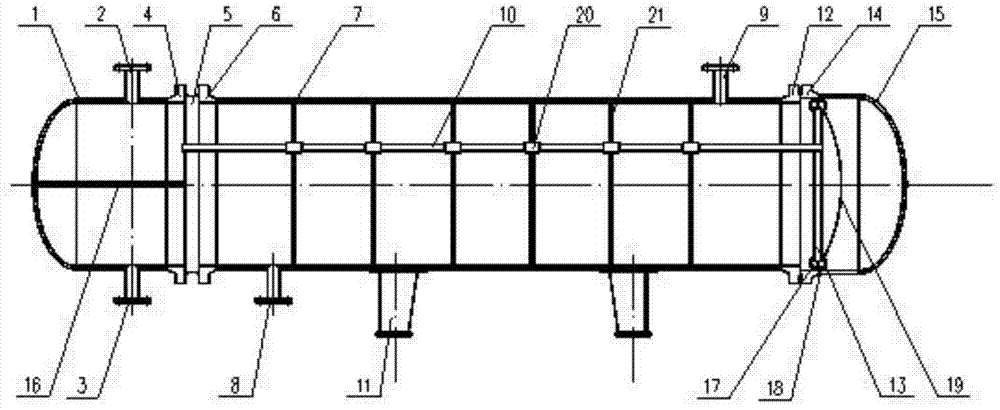

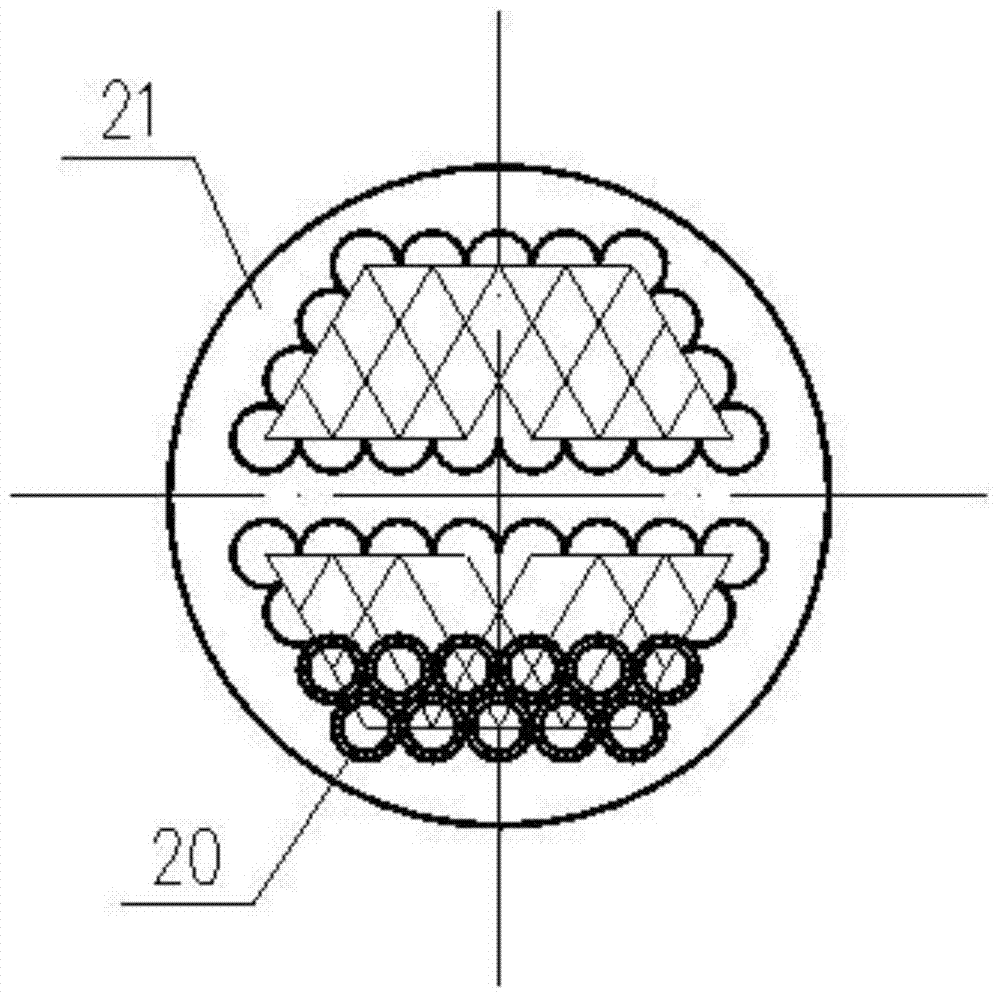

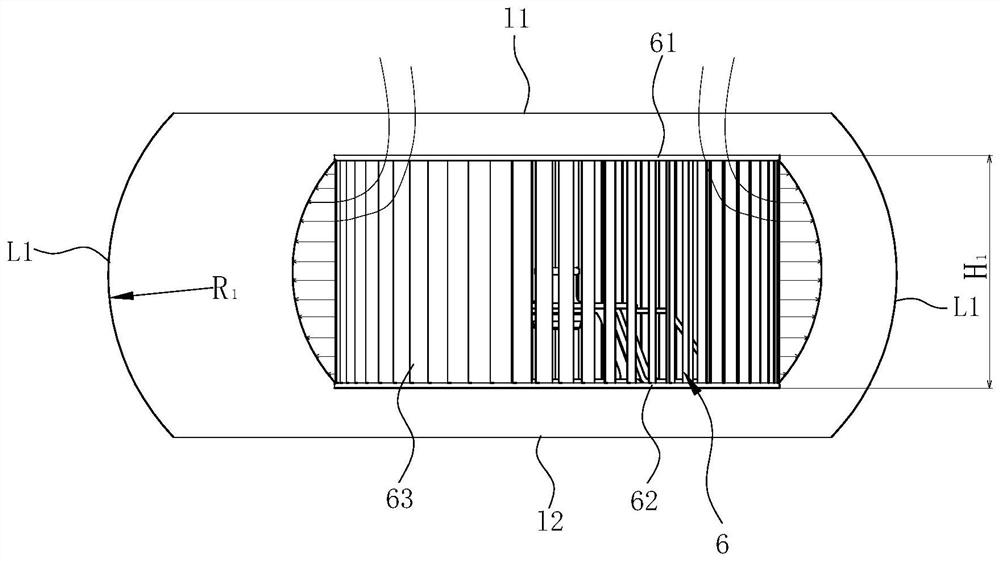

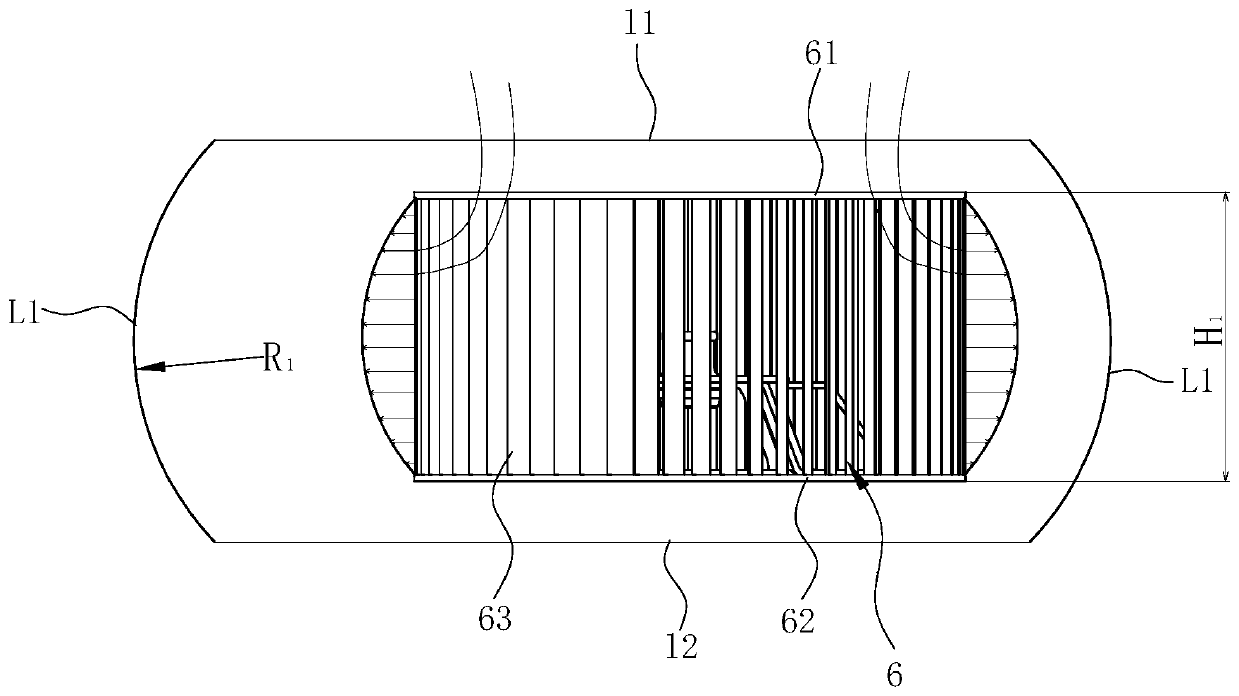

Tube shell pass volume-adjustable longitudinal turbulence oil cooler

InactiveCN104913663AImprove heat transfer coefficientStrong disturbing effectStationary tubular conduit assembliesTubular elementsEngineeringPoint contact

The invention discloses a tube shell pass volume-adjustable longitudinal turbulence oil cooler. The cooler comprises a shell, wherein the two ends of the shell are respectively closed by a first pipe plate and a second pipe plate to form an accommodating space; multiple heat exchange pipes are mounted in the shell, and comprise a deformed heat transfer pipe and first and second round pipes connected to the two ends of the deformed heat transfer pipe, wherein the first round pipe is fixed on the first pipe plate; the second round pipe is fixed on the second pipe plate; the first round pipe, the deformed heat transfer pipe and the second round pipe are the same in perimeters of cross sections; the adjacent heat exchange pipes realize the point contact through projection parts on the deformed heat transfer pipe to form a self-support structure; and gaps correspondingly formed between adjacent two contact points of the adjacent heat exchange pipes are formed to a netty channel in the accommodating space. The cooler realizes the tube / shell pass space control through the deformed heat transfer pipe, and can form a uniform and compact spiral runner in the shell pass to achieve a strong disturbance effect on a shell pass fluid, so that the shell pass heat transfer coefficient can be largely improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Shell-and-tube heat exchanger of fractal structure

ActiveCN105258533AEfficient flowEffectively guide the flowStationary tubular conduit assembliesTubular elementsShell and tube heat exchangerPlate heat exchanger

The invention provides a shell-and-tube heat exchanger of a fractal structure. The shell-and-tube heat exchanger comprises a shell, a shell pass fluid inlet, a shell pass fluid outlet and a heat exchange tube bundle. Both the shell pass fluid inlet and the shell pass fluid outlet are communicated with the interior of the shell. The heat exchange tube bundle is located in the shell and is of a deoxyribose nucleic acid (DNA) type multi-spiral structure. The whole heat exchange tube bundle is of the DNA molecule spiral structure and can effectively guide shell pass fluid to flow along a spiral path. The field synergy of a shell pass is enhanced under the circumstance that pressure drop loss is little, and a flowing dead zone of the shell pass is eliminated.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Shell and tube heat exchanger with novel baffle plates

PendingCN107120995AReduce heat transfer areaUniform heat exchangeHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention discloses a shell and tube heat exchanger with novel baffle plates. The shell and tube heat exchanger comprises a tube pass inlet, a tube pass outlet, a left seal head, a right seal head, a shell pass inlet, a shell pass outlet, a shell, a tube plate, tube holes, the circular baffle plate, the regular hexagon baffle plate, heat exchange tubes, semicircular small holes and a circular ring. The two baffle plates are alternately arranged in the shell. The middle of the circular baffle plate is provided with the circular ring with the diameter being 5-6 times of the outer diameter of the heat exchange tubes for passing of shell pass media. The three semicircular small holes spaced by 120 degrees are formed in an edge tube hole of the circular baffle plate, the three semicircular small holes spaced by 120 degrees are formed in a middle tube hole of the regular hexagon baffle plate, and a small part of shell pass media can flow through the semicircular small holes. According to the heat exchanger, the heat exchange performance can be improved, and meanwhile deposition of dirt on the heat exchange tube walls is effectively reduced.

Owner:SHANDONG UNIV OF SCI & TECH

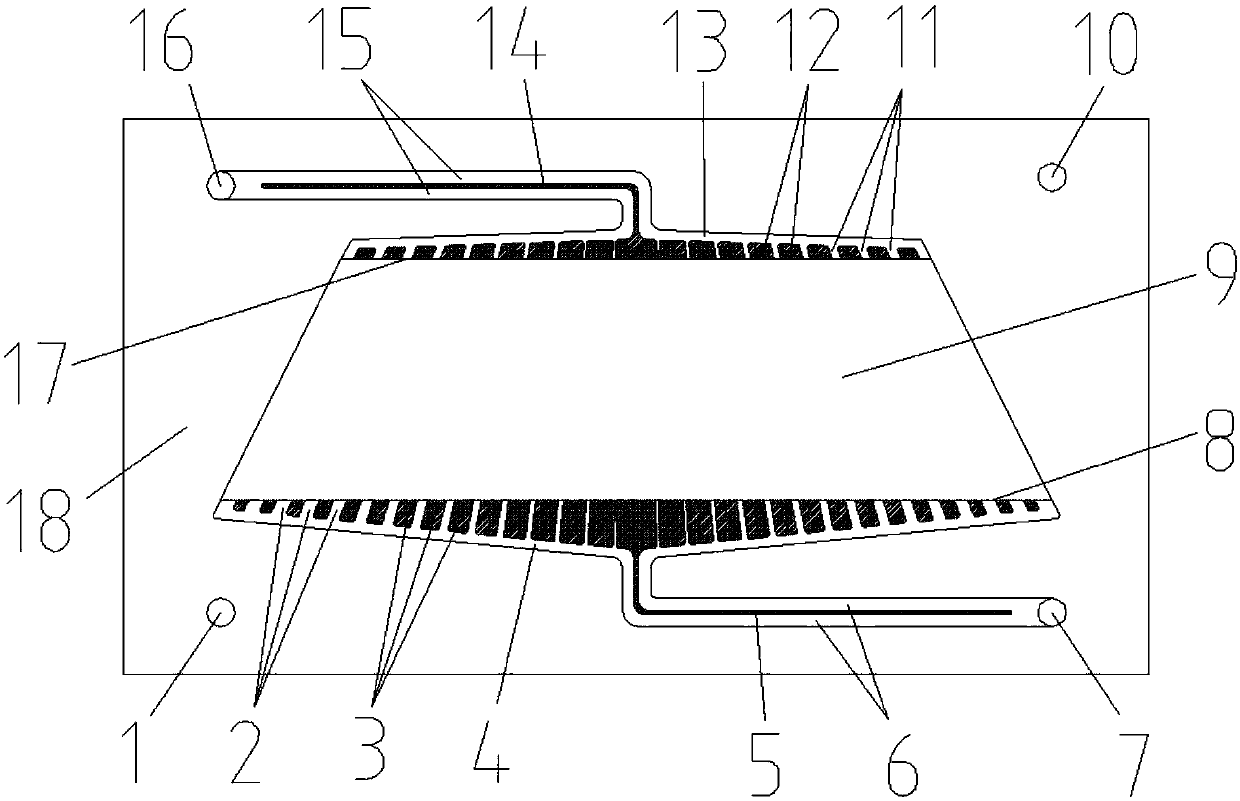

Wound tube heat exchanger with baffle plates

PendingCN110455098AEffective installationEasy to installHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerStraight tube

The invention discloses a wound tube heat exchanger with baffle plates. The wound tube heat exchanger comprises a shell, wherein a multi-section spiral wound heat exchange tube is arranged in the shell, and the multi-section spiral wound heat exchange tube is formed by winding a plurality of spiral wound tube sections and a plurality of straight tube sections alternately; a plurality of combined baffle plates are respectively arranged between the straight tube sections and the shell and are vertically arranged along the axis of the shell; and the two ends of the shell are further respectivelyprovided with tube sheets, and the shell is divided into a tube-side heat exchange area and a shell-side heat exchange area. By means of the wound tube heat exchanger with the baffle plates, through the improvement of the structure, the baffle plates can be effectively and conveniently installed on the multi-section spiral wound heat exchange tube, so that a dead zone of shell-side flow is effectively eliminated, the disturbance of shell-side fluid is enhanced, the fluid heat exchange process is prolonged, the shell-side heat transfer is finally enhanced, consumables and energy sources are saved, the integral heat exchange uniformity of the heat exchanger is improved, and the practicability is high.

Owner:ZHONGKAI UNIV OF AGRI & ENG

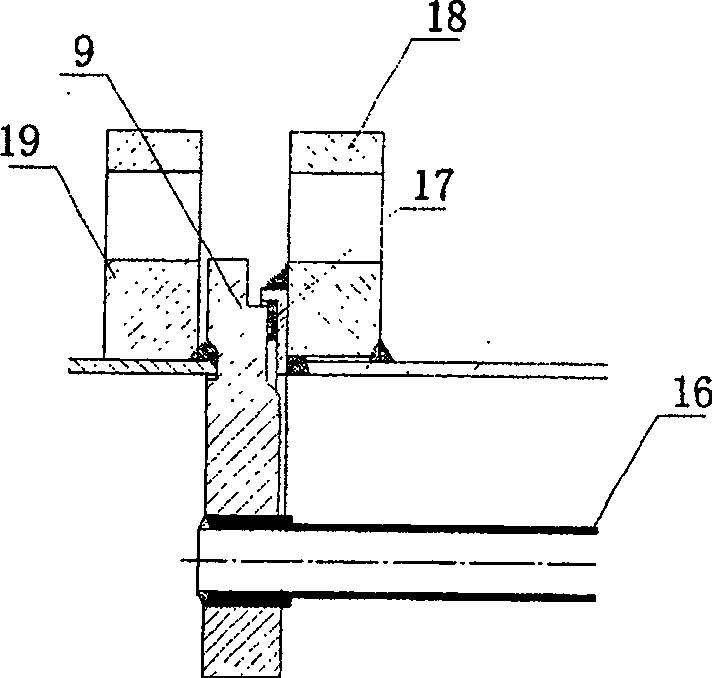

Submersed nozzle for slab continuous casting

InactiveCN103192041AUniform temperaturePromote meltingMelt-holding vesselsConventional castingMolten steel

The invention relates to the field of molten steel continuous casting, in particular to a submersed nozzle for slab continuous casting. A pair of discharge holes (3) are eccentrically formed in the two sides of a central line at the bottom of a nozzle body respectively; one discharge hole is close to the inner wall on one side at the bottom of the nozzle body; and the other discharge hole is close to the inner wall on the other side of a diagonal line at the bottom of the nozzle body. According to the submersed nozzle, the pair of eccentric discharge holes can form a mixing flow field in a crystallizer in the casting process, so that a good effect of reducing subsurface inclusions and air bubbles can be obtained, a flowing dead zone is removed at the same time, the molten steel temperature is uniform, and casting powder is conveniently molten and uniformly flows into the crystallizer, thereby improving the slab surface quality; and compared with electromagnetic mixing equipment, the investment cost can be greatly reduced, the slab continuous casting operation is also easily carried out on the conventional casting machine at the same time, the crystallizer of the continuous casting machine does not need to be complicatedly improved, the improvement and usage costs are very low, the energy is saved, the environment is protected, and the value in popularization and application is wide.

Owner:BAOSHAN IRON & STEEL CO LTD

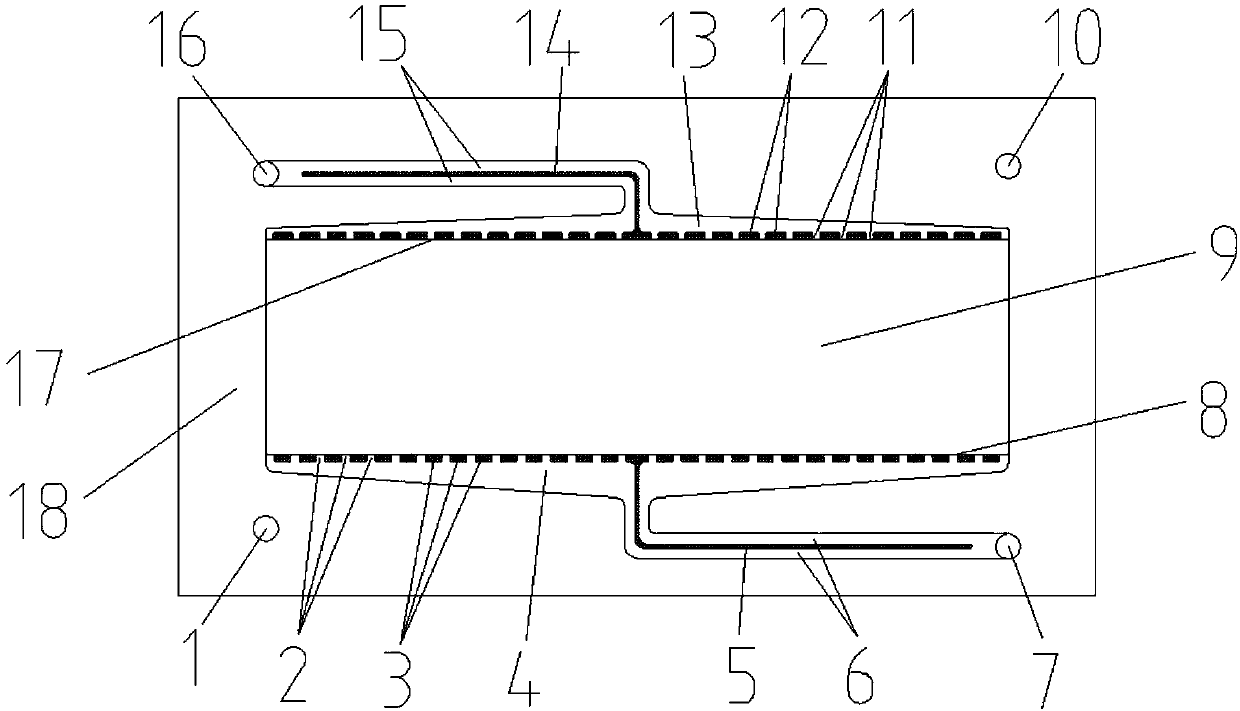

Liquid flow frame suitable for flow battery stack

PendingCN109841873AIncrease profitUniform responseElectrolyte stream managementRegenerative fuel cellsIsosceles trapezoidEngineering

The invention relates to a liquid flow frame suitable for a flow battery stack or a flow battery. The liquid flow frame is a plate-shaped structure with through holes in the middle, the through holesare electrode regions, the cross sections of the through holes parallel to a plate body plane are rectangles or isosceles trapezoids, one side surface or two side surfaces of a plate are provided withgrooves for free flow areas of electrolyte close to edges of upper and lower bottom sides of the through holes, a groove at an edge of one side of the rectangle or a lower bottom side of the trapezoid is an inlet free flow area, an opposite side of the side of the rectangle or an upper bottom side of the trapezoid is an outlet free flow area, and more than two grooves for secondary flow guiding channels are set between each free flow area and the through holes. The liquid flow frame has the advantages of simple structure and convenient processing, the uniformity of electrolyte distribution can be effectively improved, the local overheating inside a reactor is suppressed, the polarization is reduced, and the electrolyte utilization is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

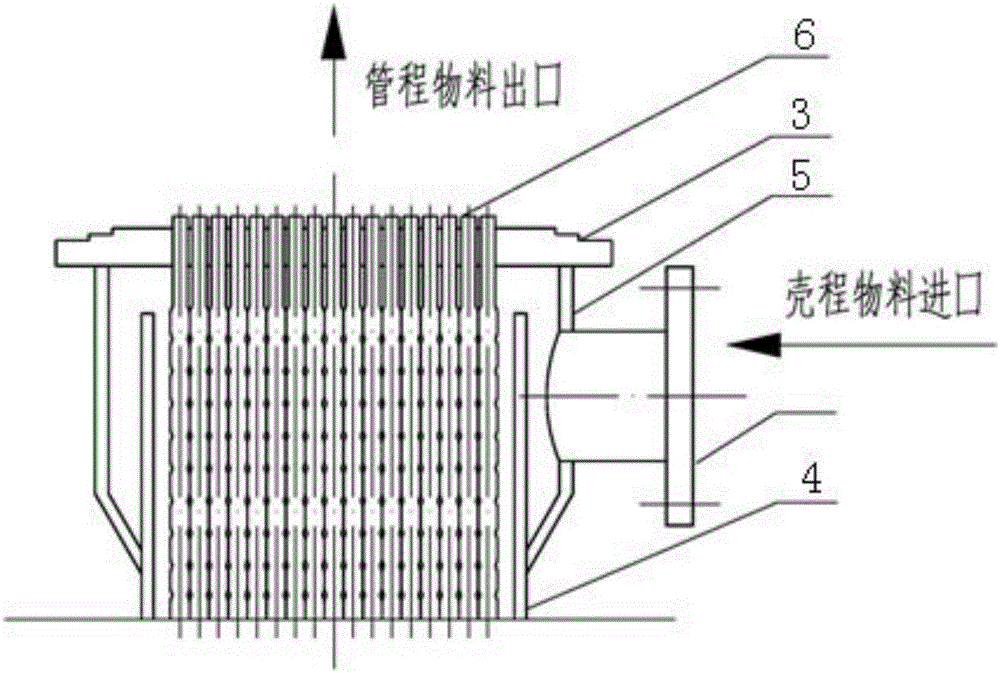

Self-support double spiral finned tube heat exchanger

PendingCN108519007ALow flow resistanceReduce consumptionStationary tubular conduit assembliesTubular elementsStraight tubeMaterial consumption

The invention relates to a self-support double spiral finned tube heat exchanger. The self-support double spiral finned tube heat exchanger comprises a heat exchanger main body composed of an upper tube box, an upper tube plate, a shell, a lower tube plate and a lower tube box. A heat exchange tube bundle is arranged in the shell and is a self-support double spiral finned tube bundle composed of aplurality of vertically arranged double spiral finned tubes. Each double spiral finned tube is composed of a smooth straight tube and two spiral fins wound on the periphery of the smooth straight tube. The adjacent double spiral finned tubes make multipoint contact, support each other and form a spoiler structure. Each double spiral finned tube forms a spiral channel in the longitudinal direction. The self-support double spiral finned tube bundle composed of the multiple double spiral finned tubes forms a netty spiral channel. The double spiral finned tubes are adopted for mutual supporting and combination to form the self-support heat exchange bundle, every two spiral fins are simultaneously used as shell pass spoiler elements, thus, the heat transfer area is greatly enlarged, a shell pass flow path is optimized, and the heat transfer effect is improved; and in addition, the shell pass flow resistance is lowered, flow dead zones and leakage flow paths are avoided, and material consumption is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

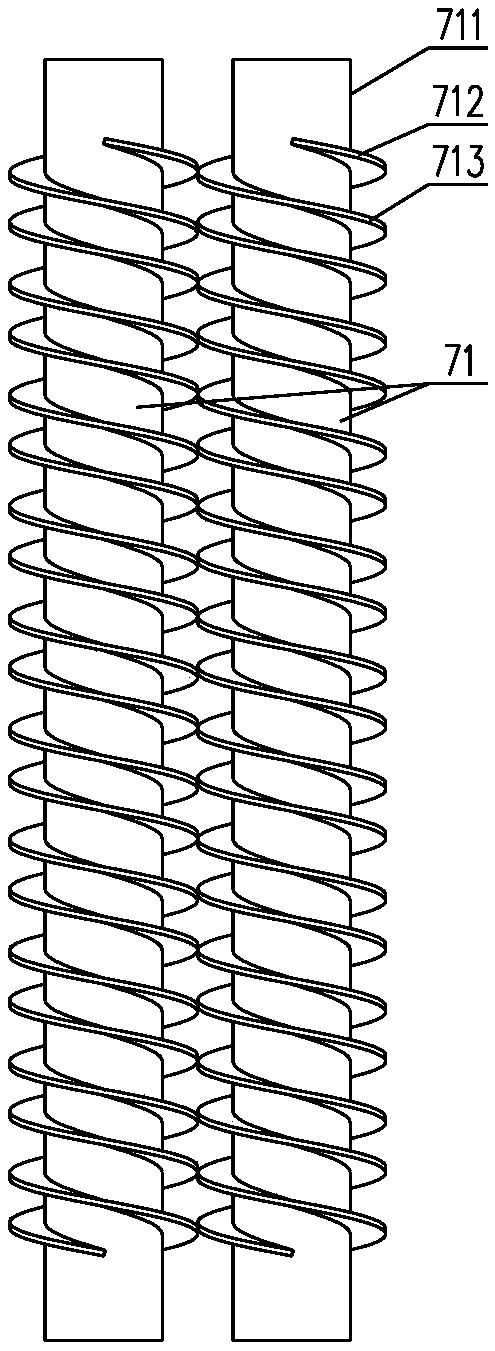

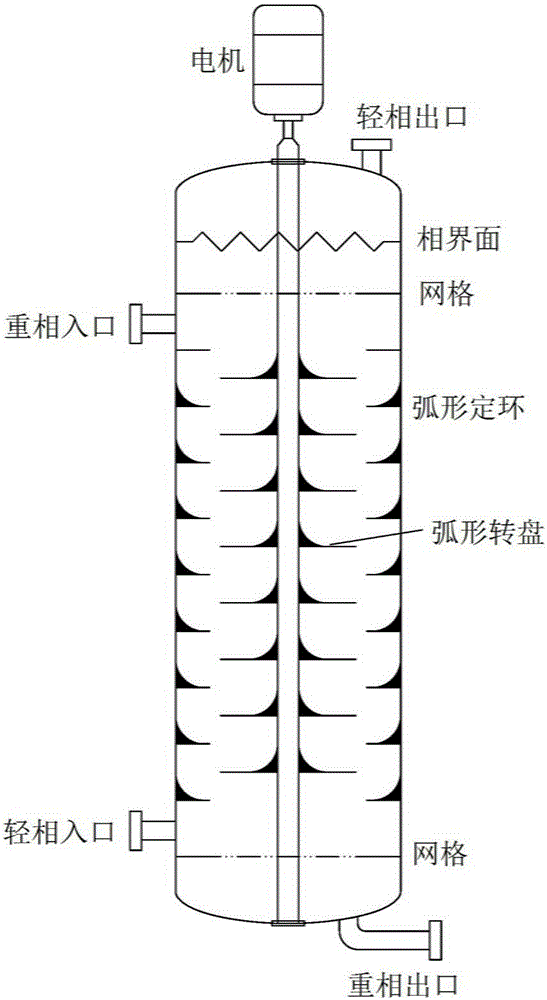

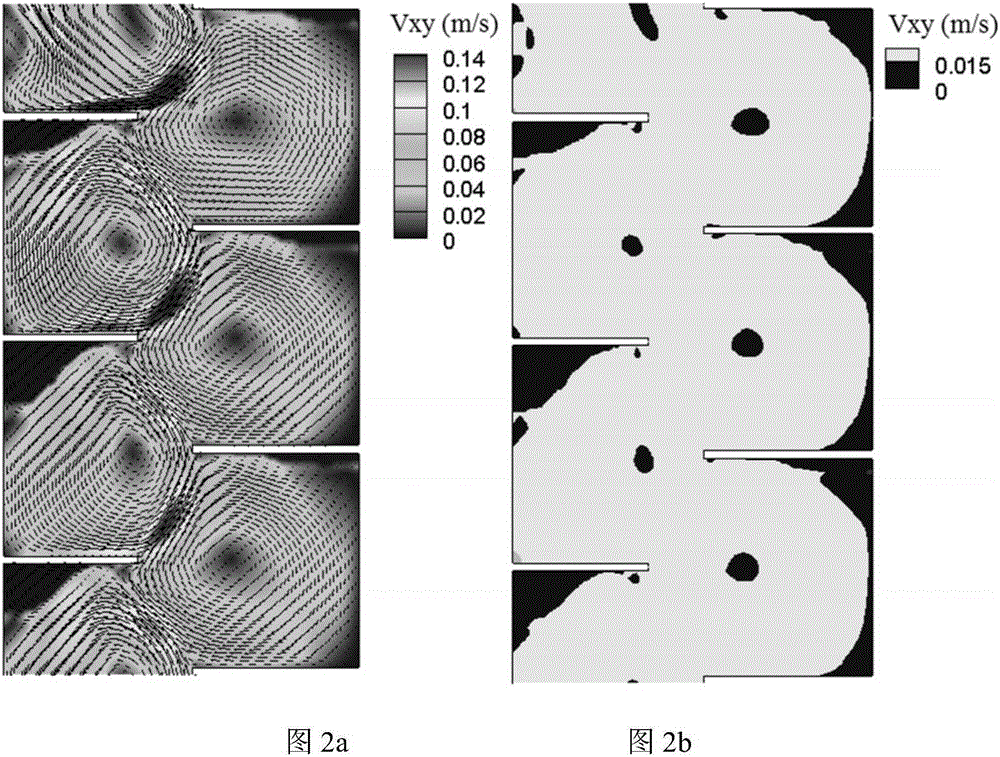

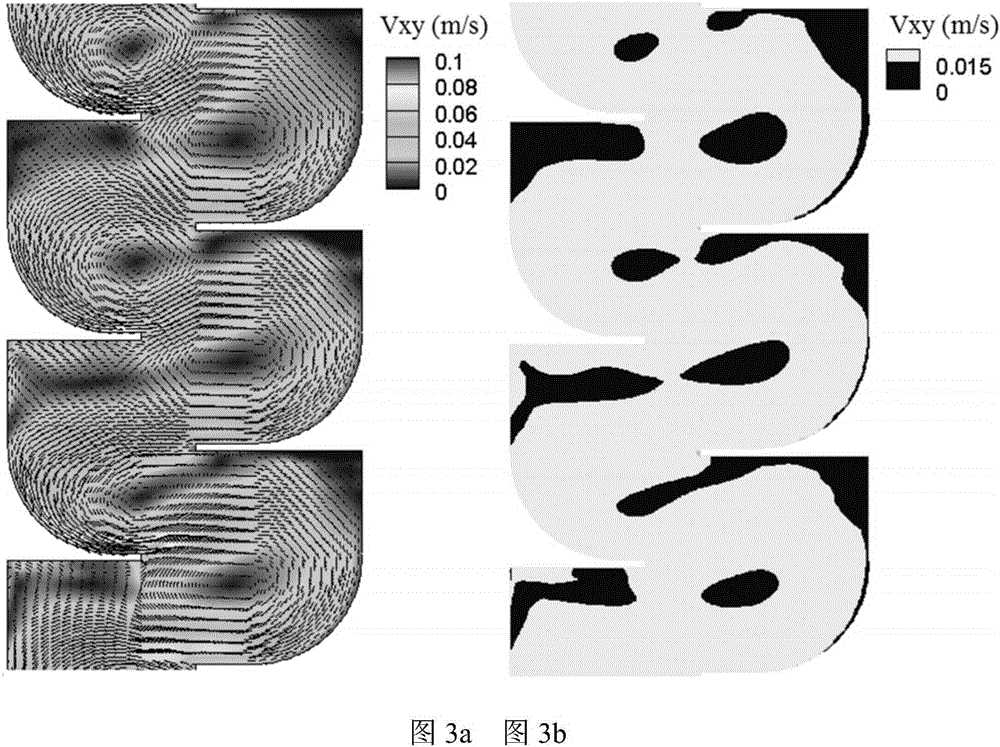

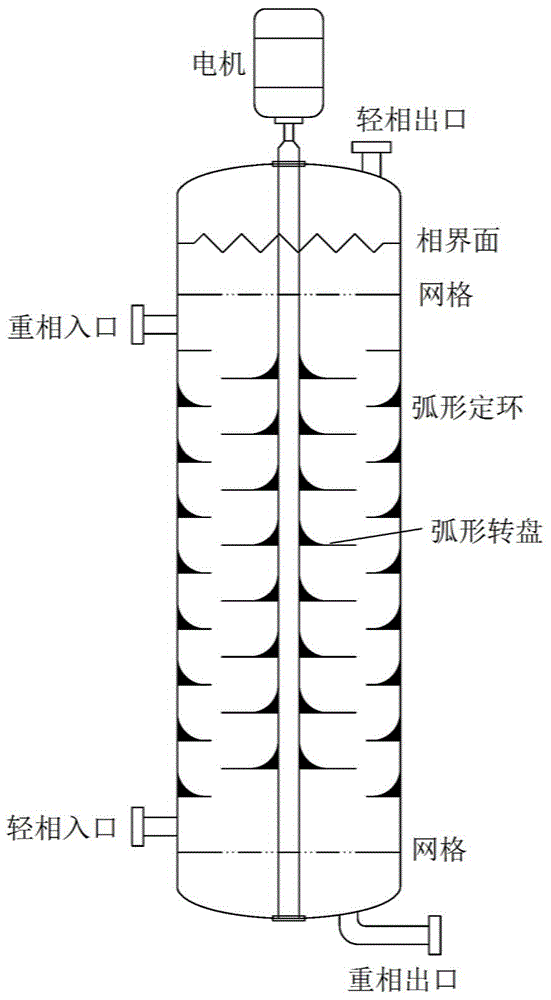

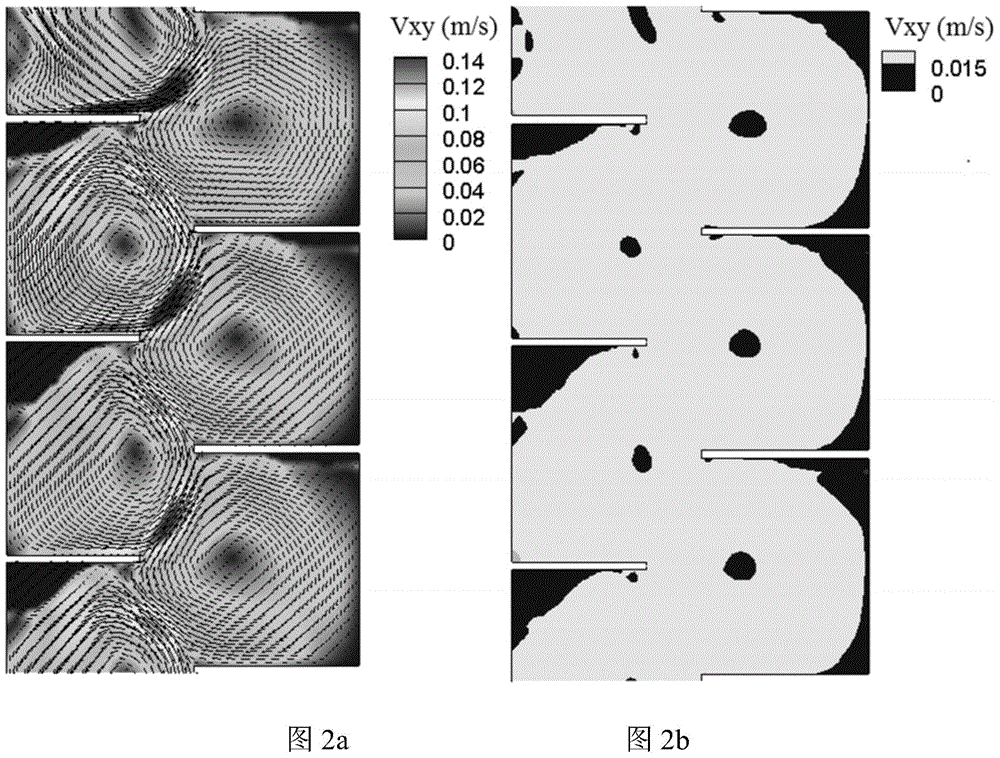

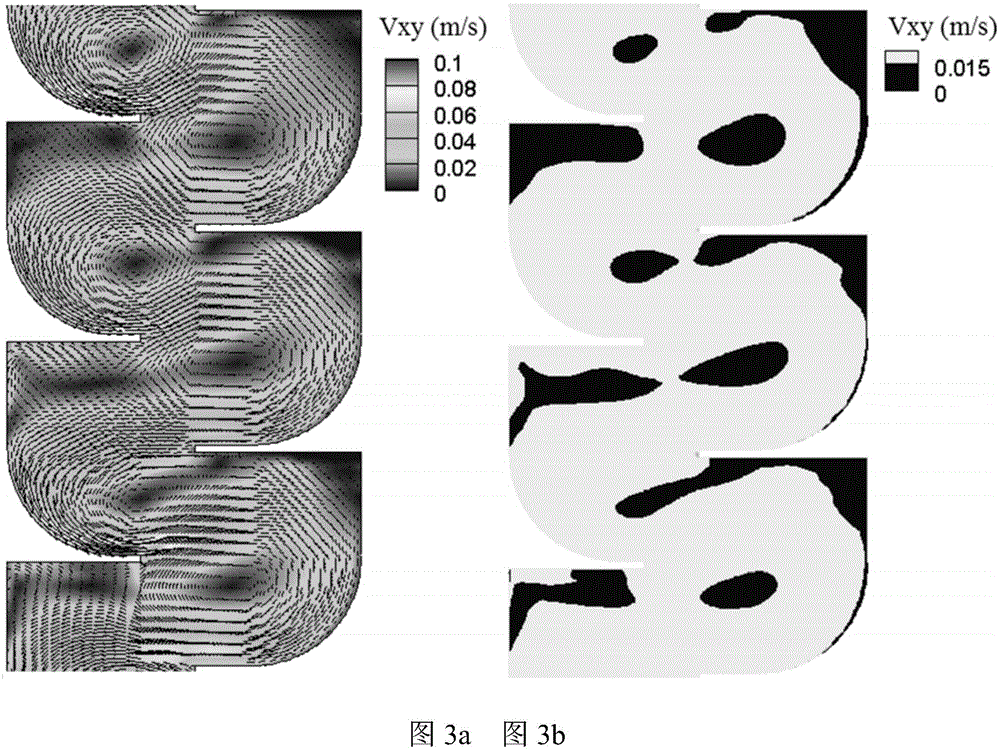

Improved Rotating Disk Column Internals for Solids-Containing Extraction Operations

The invention relates to an improved rotating disc tower internal component suitable for solid-containing extraction operation. The component comprises rotating discs and fixed rings, and the rotating discs and the fixed rings are in an arc-shaped design. The radian on the fixed rings and the radian on the rotating discs are matched with eddies formed by multiphase fluid of materials in a tower. According to the improved rotating disc tower internal component suitable for solid-containing extraction operation, fixed rings and rotating discs of a traditional rotating disc tower are improved, the arc-shaped interface design structure is adopted, the multiphase flow field structure in the rotating disc tower can be well matched with the geometrical interface of the tower, flowing dead areas in the tower are eliminated, hence, the turbulence characteristic in the tower can be fully utilized, solid phase deposition is prevented, and the processing capacity of the rotating disc tower to a solid-containing extraction system is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Self-supporting type tube bundle heat exchanger

ActiveCN104457385AIncreased turbulenceImprove heat transfer efficiencyHeat exchanger casingsBlind zoneEngineering

The invention relates to a self-supporting type tube bundle heat exchanger. The self-supporting type tube bundle heat exchanger includes a tubular heat exchanger. Heat exchange tube bundles in the tubular heat exchanger are mutually supported through fixing sleeves installed outside single heat exchange tubes in a sleeving mode, and the heat exchange tube bundles are supported and fixed through supporting plates in the circumferential direction. The fixing sleeves press grooves to be closely connected with the heat exchange tubes. Compared with the prior art, the self-supporting type tube bundle heat exchanger has the advantages that media in a shell side form complex, continuous and uniform flow passages between the heat exchange tubes, the turbulence degree of the media is increased, a flowing boundary layer is thinned, heat transfer resistance is reduced, and therefore heat exchange efficiency is improved; the equipment is small in size, and the manufacturing cost is low; no baffle plate is arranged in the shell side, so that flowing dead zones in the shell side are eliminated, and the pressure drop of the media in the shell side is lowered; as no blind zone exists in the shell side, scaling is not prone to occur; the flow velocity is high in the shell side, so accumulation of impurities in the media is lowered; because large-area through holes are formed in a hole plate, compared with a traditional baffle plate, the heat exchange tubes are quite convenient to assemble and disassemble.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

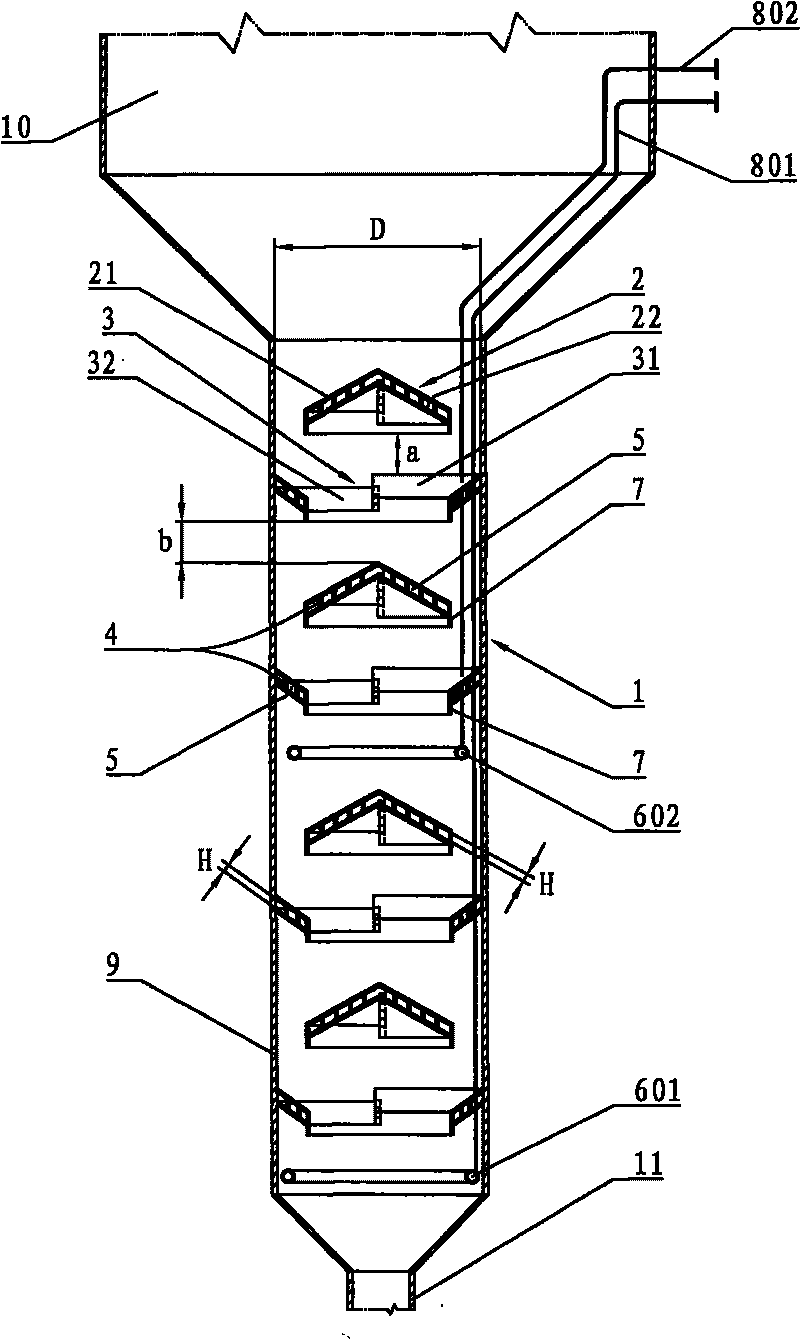

A catalytic conversion stripper

ActiveCN101711962BImprove stripping efficiencyEasy to handleCatalytic crackingChemical/physical processesPetrochemicalPetroleum

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

Flow cell stack

PendingCN110970648AImprove performanceEasy to processRegenerative fuel cellsElectrolytic agentFlow cell

The invention relates to the field of flow cells, particularly relates to a flow cell stack assembly structure. The flow cell stack assembly structure comprises a sheet porous electrode and a liquid flow frame provided with a through hole with the shape and the size corresponding to those of the liquid flow frame; the porous electrode is arranged in the middle through hole of the liquid flow frame; the peripheral edges of the porous electrode are attached to the inner wall surface of the middle through hole of the liquid flow frame; a through hole serving as an electrolyte inflow channel and athrough hole serving as an electrolyte outflow channel are formed in the liquid flow frame; the through hole of the electrolyte inflow channel communicates with the middle through hole through a groove or a through hole serving as an inlet flow guide area, and the through hole of the electrolyte outflow channel communicates with the middle through hole through a groove or a through hole serving as an outlet flow guide area. The flow cell stack assembly structure is characterized in that a cavity for buffering and redistributing the electrolyte is formed near the inner wall surface of the liquid flow frame at the middle through hole where the inlet flow guide area and the outlet flow guide area are located; and the inlet or outlet flow guide area communicates with the middle through hole through the cavity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

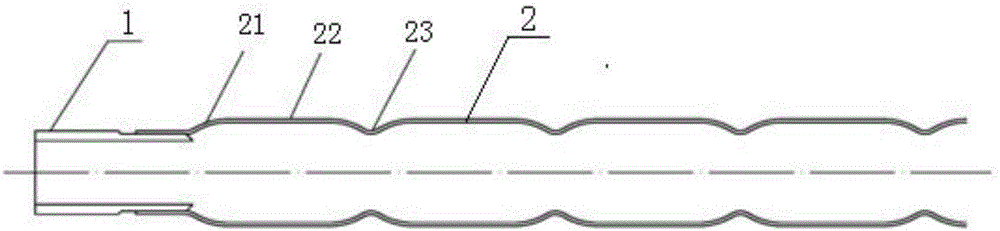

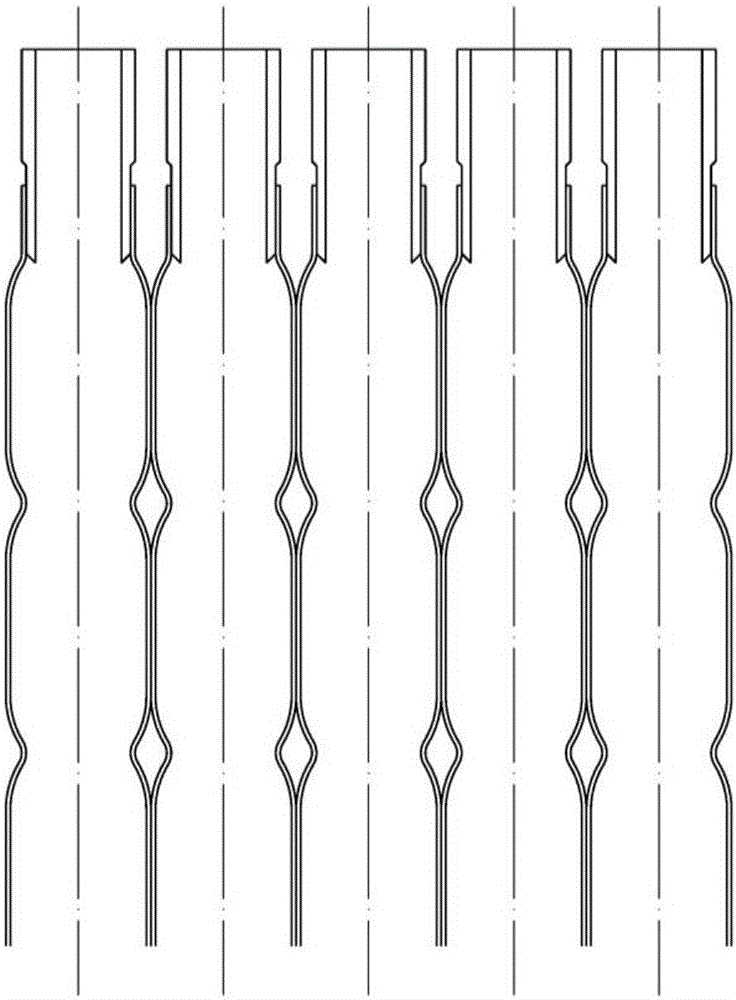

Self-supported type corrugated straight heat exchange tube bundle

InactiveCN105865246AIncreased turbulenceImprove heat transfer efficiencyHeat exchanger casingsTubular elementsStraight tubeEngineering

The invention relates to a self-supported type corrugated straight heat exchange tube bundle which comprises a plurality of heat exchange tubes, wherein the heat exchange tubes are arranged in parallel; each heat exchange tube consists of a corrugated straight tube and a smooth straight tube; the main body of the corrugated straight tube is of a structure of a corrugated straight tube section and a straight tube section, that is, one waveform of a period comprises a wave peak, a straight tube, a wave peak and a wave trough; the smooth straight tubes are arranged at two ends of the corrugated straight tubes and are fixedly connected with a tube plate in a heat exchanger; the heat exchange tubes are self-supported through linear contact of the straight tube sections. By adopting the self-supported type corrugated straight heat exchange tube bundle, the heat exchange efficiency of the heat exchanger can be effectively improved, generation of dirt can be inhibited, abrasion of baffle plates can be avoided, and in addition, the self-supported type corrugated straight heat exchange tube bundle has the advantages of convenience in disassembling, equipment size reduction, low manufacturing cost and the like.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Improved rotating disc tower internal component suitable for solid-containing extraction operation

The invention relates to an improved rotating disc tower internal component suitable for solid-containing extraction operation. The component comprises rotating discs and fixed rings, and the rotating discs and the fixed rings are in an arc-shaped design. The radian on the fixed rings and the radian on the rotating discs are matched with eddies formed by multiphase fluid of materials in a tower. According to the improved rotating disc tower internal component suitable for solid-containing extraction operation, fixed rings and rotating discs of a traditional rotating disc tower are improved, the arc-shaped interface design structure is adopted, the multiphase flow field structure in the rotating disc tower can be well matched with the geometrical interface of the tower, flowing dead areas in the tower are eliminated, hence, the turbulence characteristic in the tower can be fully utilized, solid phase deposition is prevented, and the processing capacity of the rotating disc tower to a solid-containing extraction system is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

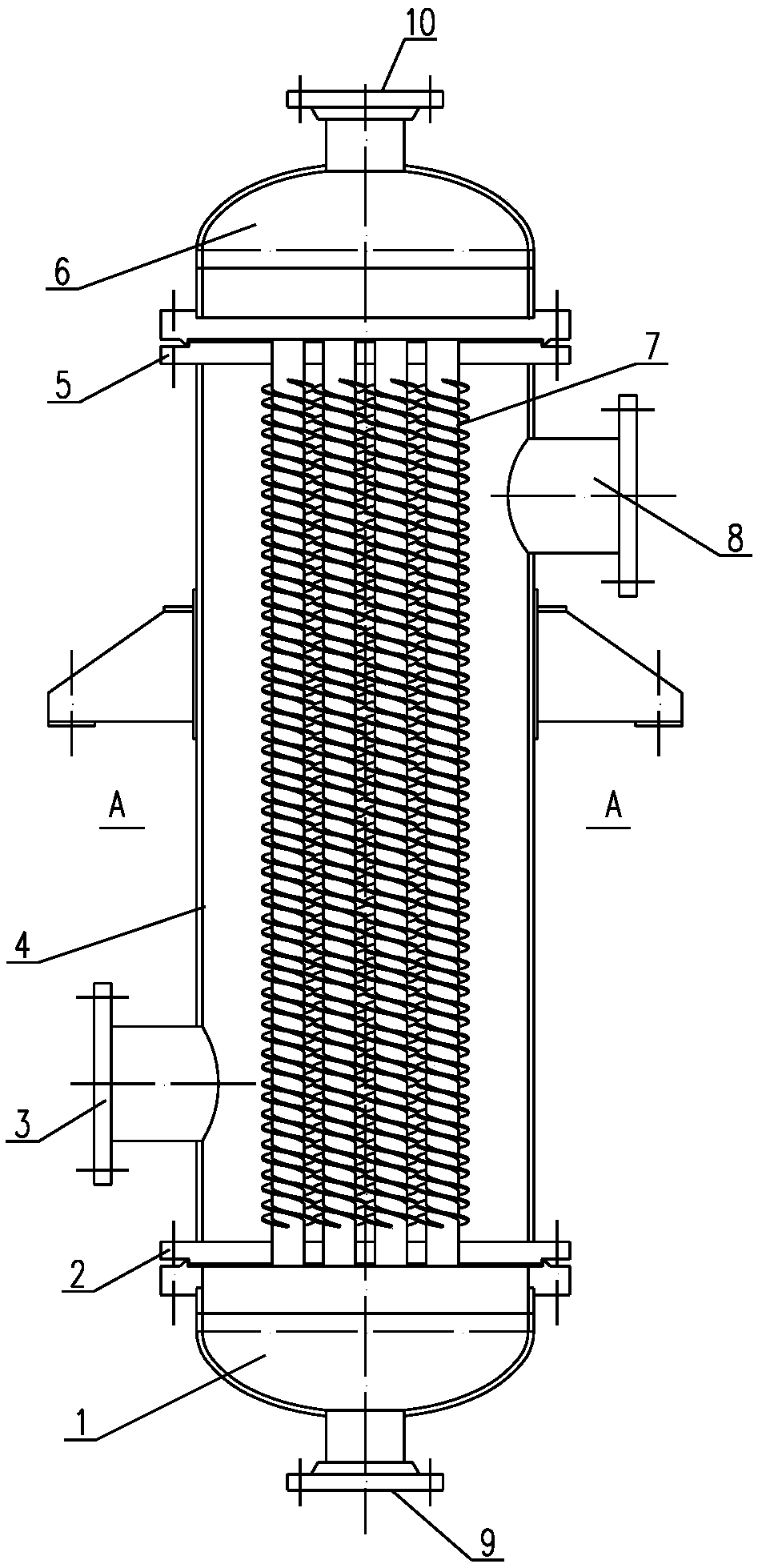

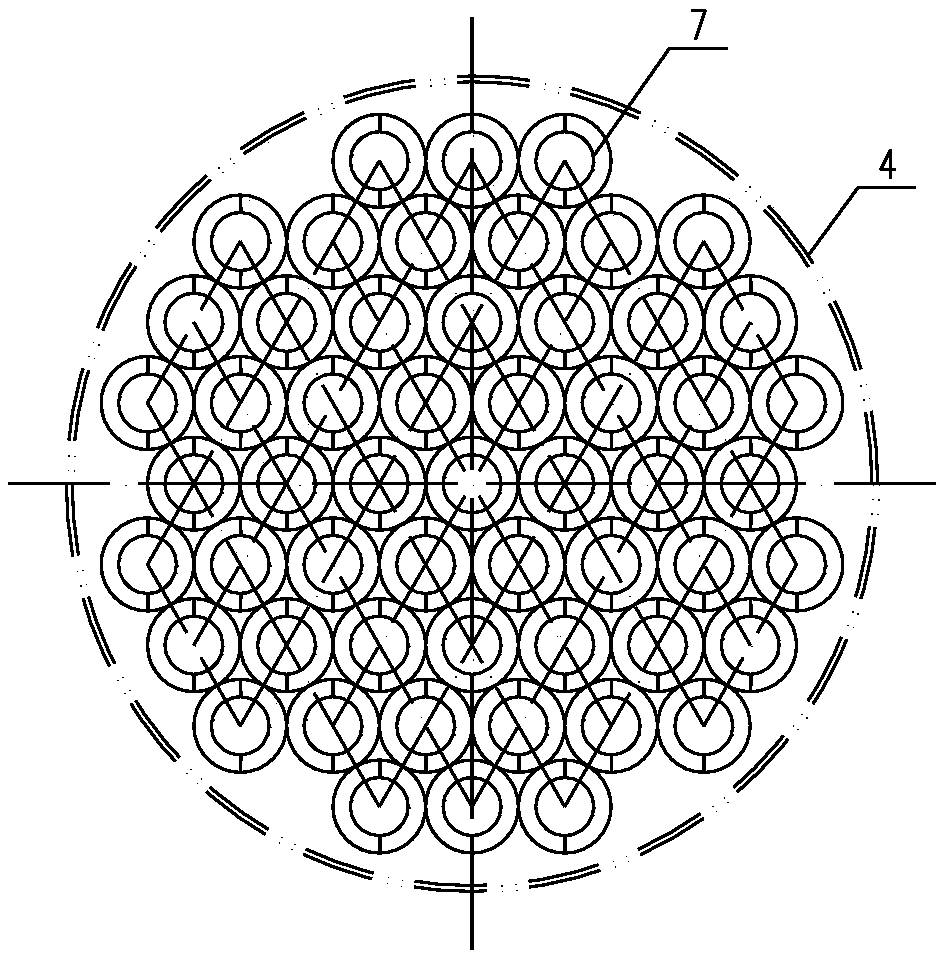

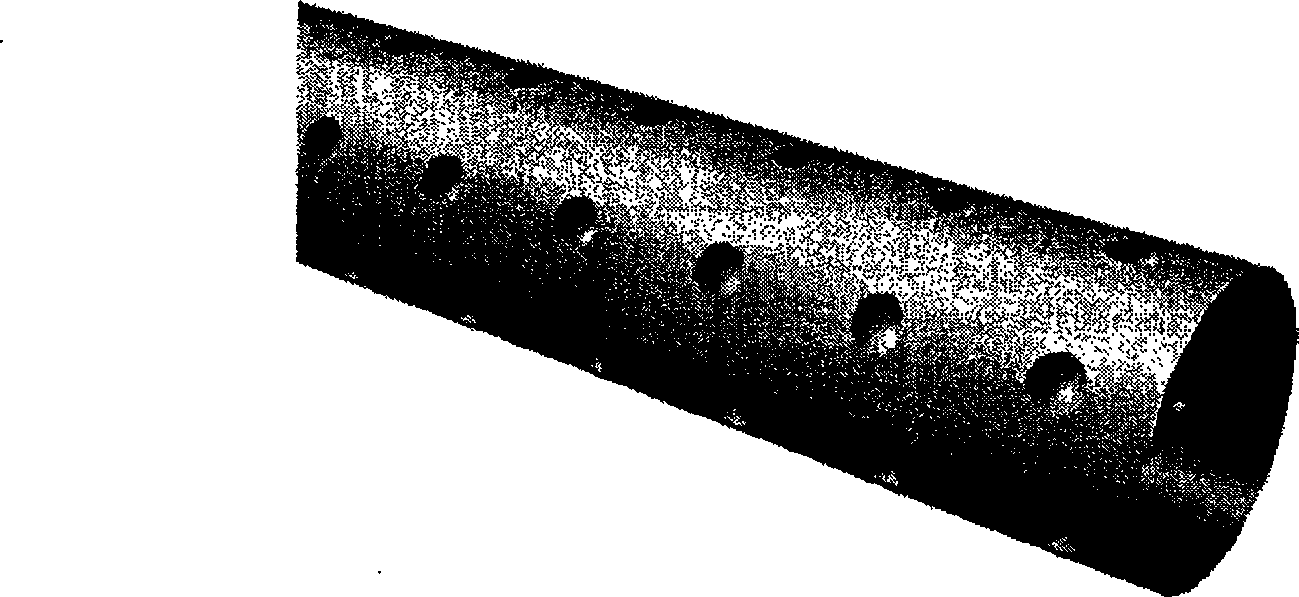

Helical baffles support dimpled pipe bundle heat exchanger

InactiveCN100467993CIncrease disturbanceImprove performanceHeat exchanger casingsStationary tubular conduit assembliesFriction lossEngineering

The invention discloses a spiral traverse baffle supporting dimple tube bundle heat exchanger which comprises: a front tube case and a back tube case which are arranged at two sides of a shell, a tube case clapboard which is arranged in the front tube case, a tube side inlet and a tube side outlet which are respectively arranged at the upper side and the lower side of the tube case clapboard, a shell side inlet and a shell side outlet which are respectively arrange at the upper side and the lower side of the shell, a dimpled surface enhancing heat exchange tube bundle which is arranged in the shell, has two ends respectively fixed on a front tube plate and a back tube plate and communicated with a tube side inlet and a tube side outlet which are arranged on the front tube case, and is also provided with a plurality groups of spiral traverse baffles. The heat exchanger shell sides adopts the dimpled surface enhancing heat exchange tube, the turbulivity of the shell sides fluid is enhanced effectively and the shell sides heat exchange is further enhanced; the shell sides adopts the spiral traverse baffles as supporting structure, resistance loss of the shell sides is greatly reduced. The invention is characterized by high efficiency of heat exchange, small resistance loss of the shell sides flowing, compact structure, small occupied area, long service life and uneasy deposition.

Owner:XI AN JIAOTONG UNIV

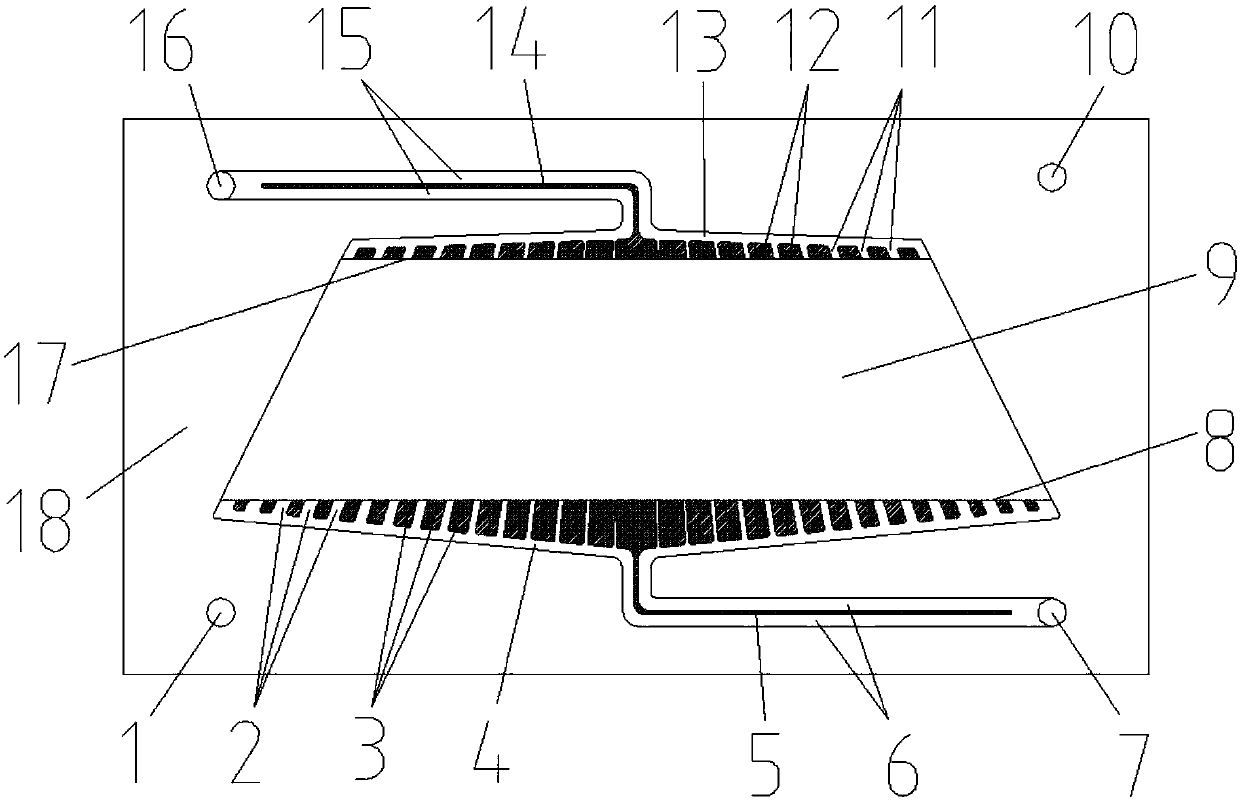

Herringbone corrugated plate for welding plate type heat exchanger

InactiveCN101839667AEvenly distributedSimple structureLaminated elementsPlate heat exchangerEngineering

The invention discloses a herringbone corrugated plate structure for a welding plate type heat exchanger, which comprises distributing diversion areas and a heat transfer area, wherein the triangle distributing diversion areas are arranged at the upper end and the lower end of a plate, and the rectangular heat transfer area is arranged in the middle; when the plates are assembled, supporting pieces are not needed to be additionally arranged between the plates, and the hypotenuses of the triangle distribution areas far away from the rectangular heat transfer area are connected with each other by a welding method after the plates are assembled; and the two sides of the plate are respectively used as runners of different media, and the flow directions of the media at the two sides of the plate are opposite. The invention has simple structure, even fluid distribution and no dead zone.

Owner:GANSU LANPEC TECH +3

High-temperature fire tube type waste heat boiler tube plate cooling room

ActiveCN104791747AEvenly distributedFully distributedFire-tube steam boilersHeat transmissionEngineering

The invention relates to a high-temperature fire tube type waste heat boiler tube plate cooling room. The high-temperature fire tube type waste heat boiler tube plate cooling room comprises four parts including a cooling room tube plate, a synthetic air tube flexible tube plate, a synthetic air tube and a cooling water tube. The cooling room is enclosed space formed by the cooling room tube plate and the synthetic air tube flexible tube plate, the synthetic air tube penetrates through the whole cooling room through the flexible tube plate and the cooling room tube plate, and the cooling water tube is connected into the cooling room through the cooling room tube plate. The cooling room is in a certain height, therefore, the uniform distribution of the cooling water nearby the flexible tube plate is guaranteed, and the situation that the flexible tube plate is overheated caused by the less local cooling water distribution is avoided. The cooling water enters the cooling room from the cooling water tube to flow out through the end outlet of the cooling water tube, and functions of the intensification of flowing nearby the synthetic air tube and the elimination of flowing dead zones are achieved. An insulation casting tube is arranged in the synthetic air tube close to the inlet of the flexible tube plate, therefore, the local thermal resistance can be increased, the local heat transmission capacity can be reduced, and the thermal stress and the temperature nearby tube walls are reduced.

Owner:EAST CHINA UNIV OF SCI & TECH +1

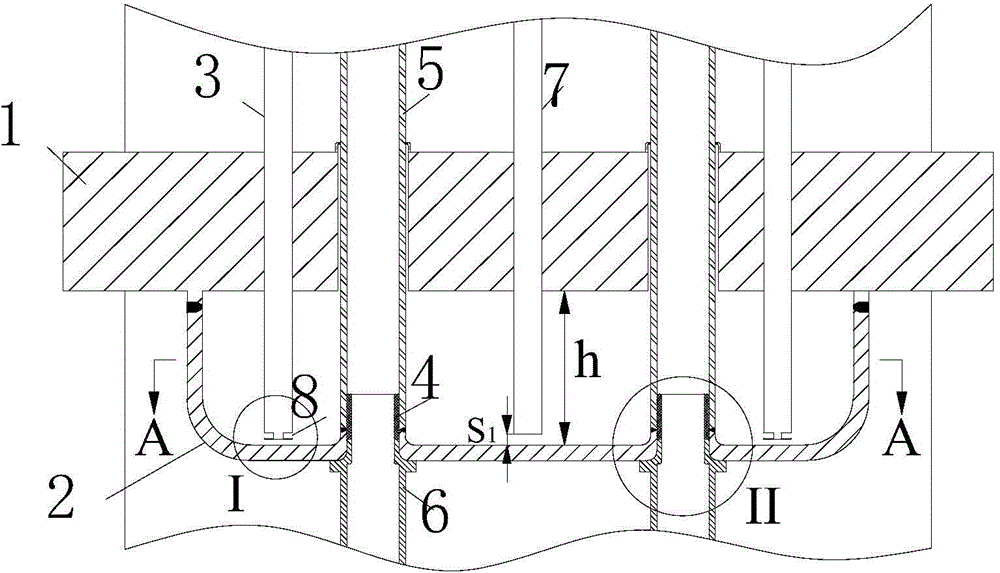

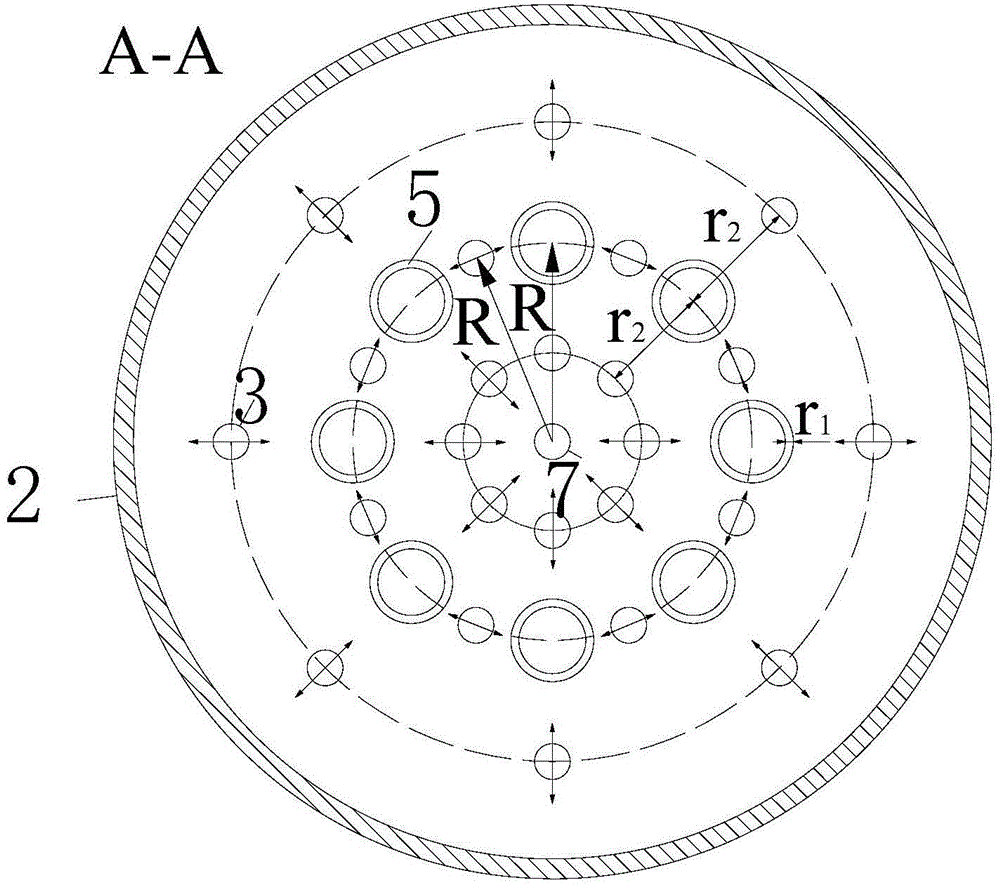

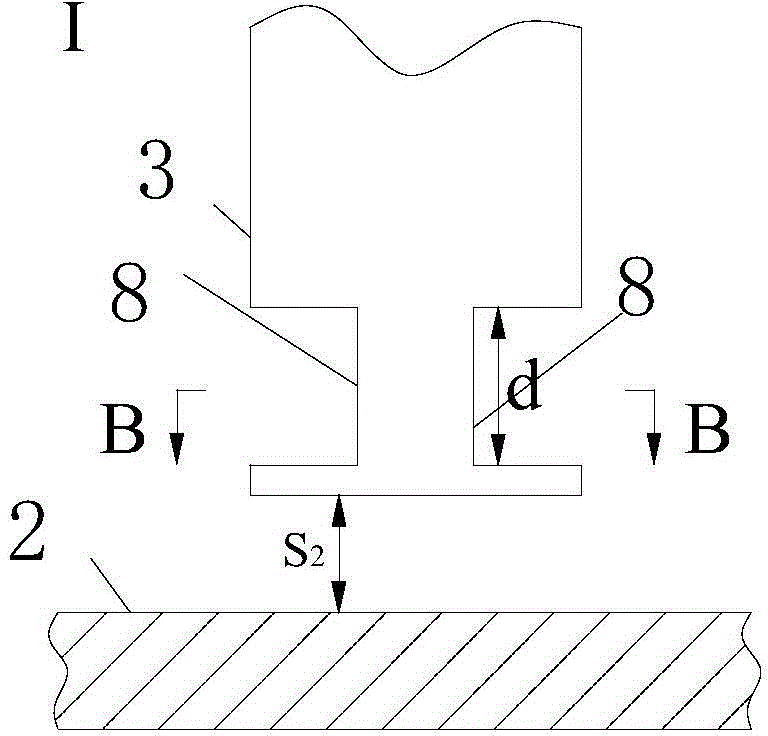

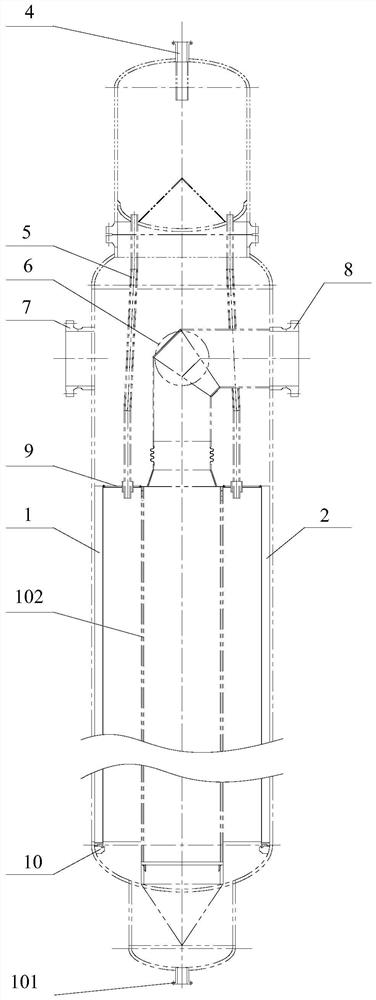

A slurry bed internal circulation reaction device and its application and method for producing hydrogen peroxide

ActiveCN104549066BExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention relates to a loop reaction device in a slurry bed, application and a method for producing hydrogen peroxide. The loop reaction device comprises a slurry bed reactor and a solid-liquid separator, wherein the upper part of the slurry bed reactor is communicated with the upper part of the solid-liquid separator, and the bottom of the slurry bed reactor is communicated with the bottom of the solid-liquid separator; and a coaxial inner sleeve is arranged in the slurry bed reactor, an outer sleeve is arranged between the inner sleeve and the outer wall of the slurry bed reactor at the upper part of the slurry bed reactor, a raw material inlet and a fluid distributor are arranged in the inner sleeve and at the bottom, a gas outlet is formed in the top of the slurry bed reactor, a filtration component is arranged in the solid-liquid separator, and a clear liquid outlet is formed in the wall of the solid-liquid separator via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

A tube bundle self-supporting heat exchanger

ActiveCN104457385BIncreased turbulenceImprove heat transfer efficiencyHeat exchanger casingsVena contracta diameterEngineering

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

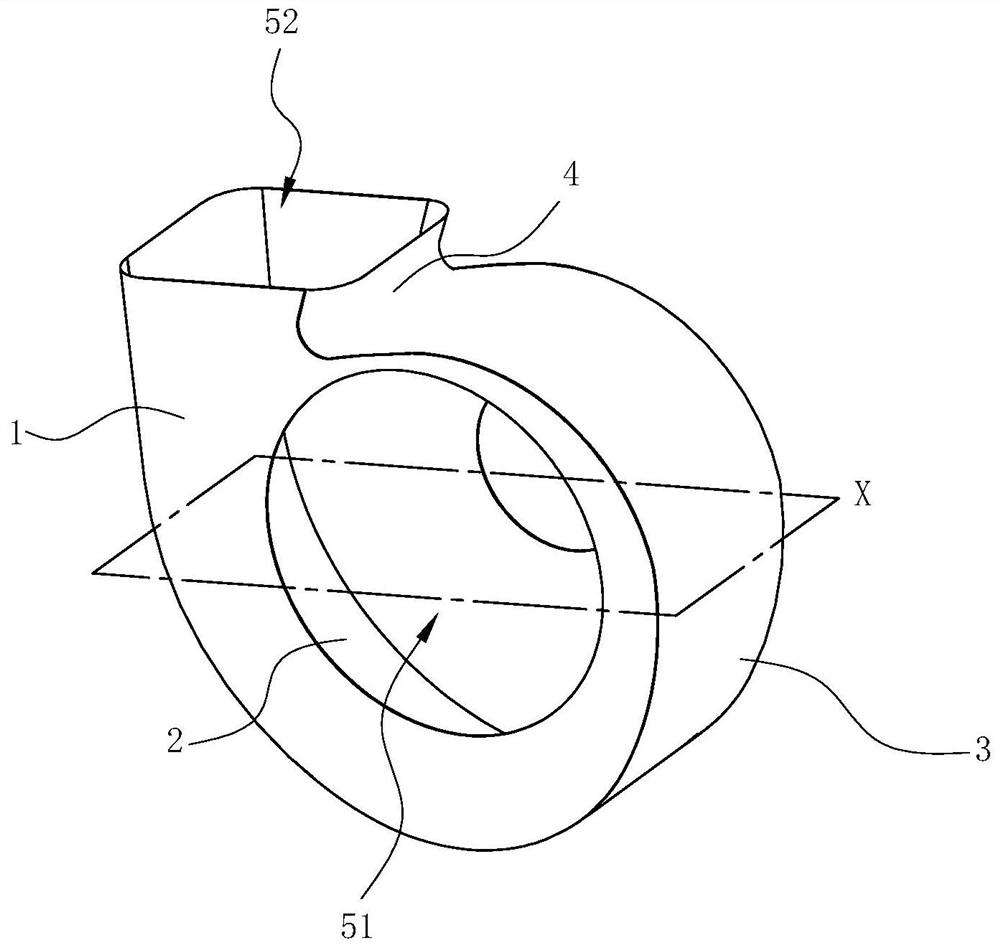

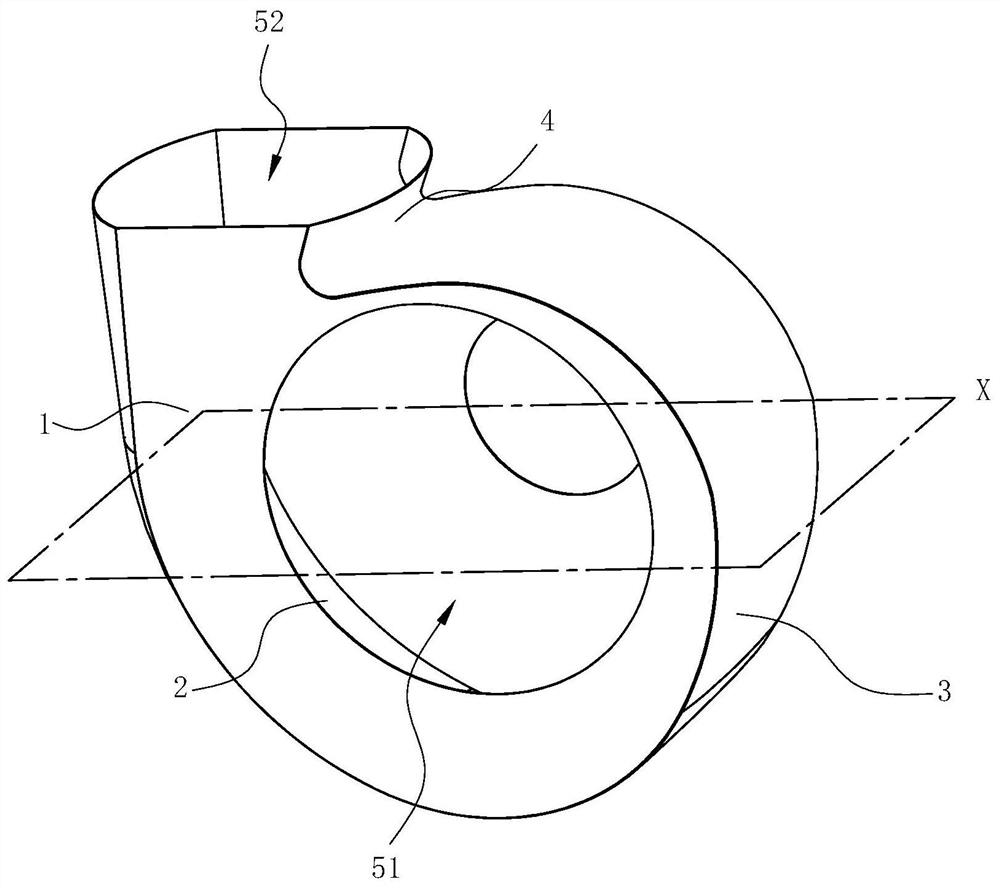

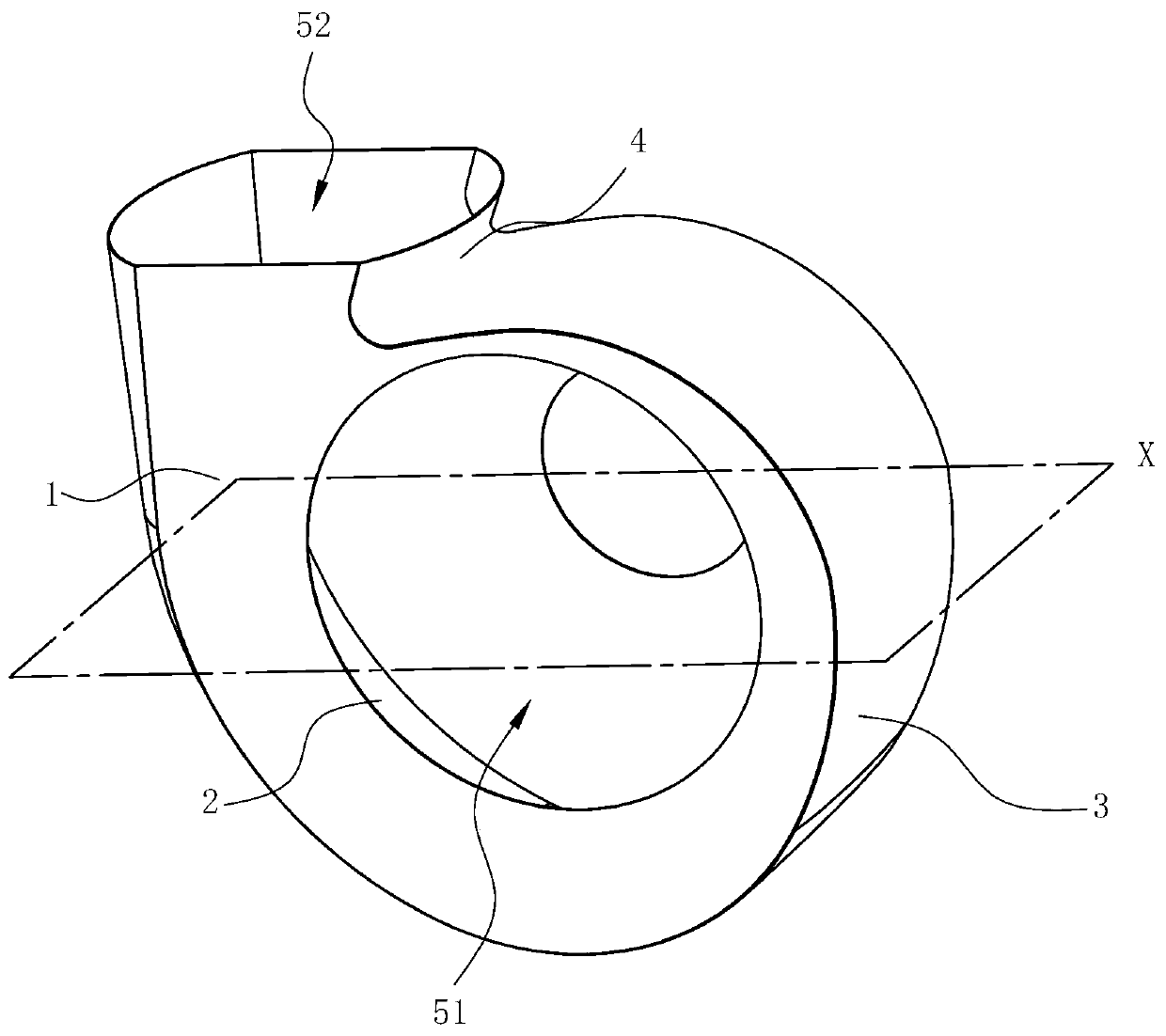

a centrifugal fan

ActiveCN110259724BReduce flow dead zoneEliminate flow dead zonesPump componentsPumpsCentrifugal fanPhysics

The invention discloses a volute for a centrifugal fan. The volute comprises a front cover and a rear cover which are parallel to each other, and a ring wall connected between the front cover and the rear cover, wherein an air outlet is formed among the front cover, the rear cover and an annular wall, a plane which is perpendicular to the front cover and the rear cover, penetrates through the annular wall, and is parallel to the air outlet is used as a section, on the section, a molded line of the annular wall comprises two line segments connecting the corresponding end portions of a front cover type line and a rear cover type line, and the middles of the line segments are more protruded out of the volute relative to the two ends. The invention further discloses a centrifugal fan using the volute. Compared with the prior art, the volute has the advantages that the annular wall can meet the characteristics that the flow speed of an outlet of an impeller is large in the middle, and small on the two sides, the non-uniform impact of the outlet air flow to the annular wall is weakened, airflow turbulence caused by mutual interference among air flow is reduced, circulation flowing caused by mutual interference among the air flow is eliminated, vortexes are eliminated, the performance of the fan can be effectively improved, and pneumatic noise is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

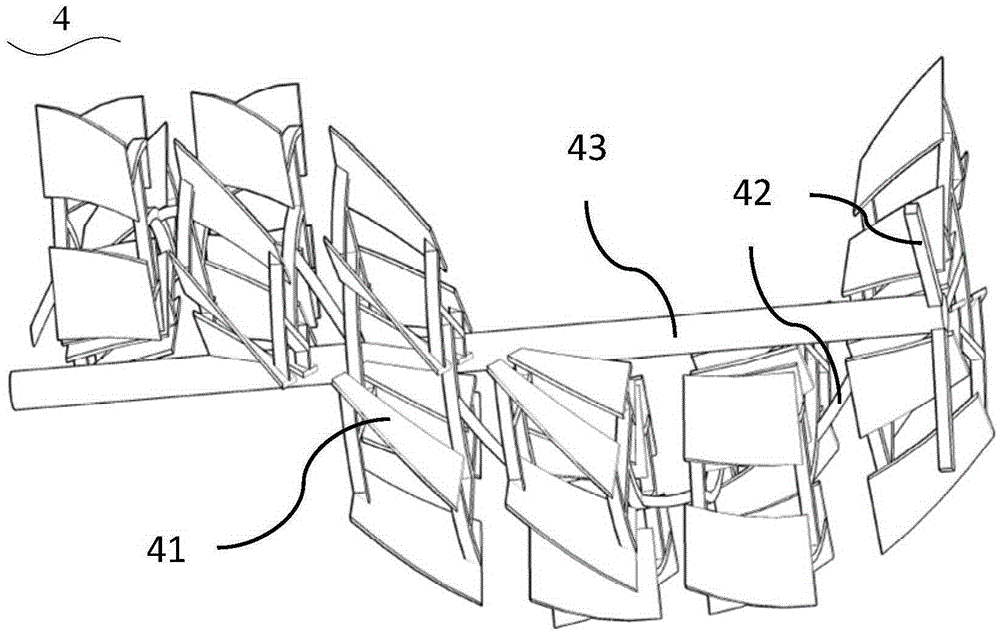

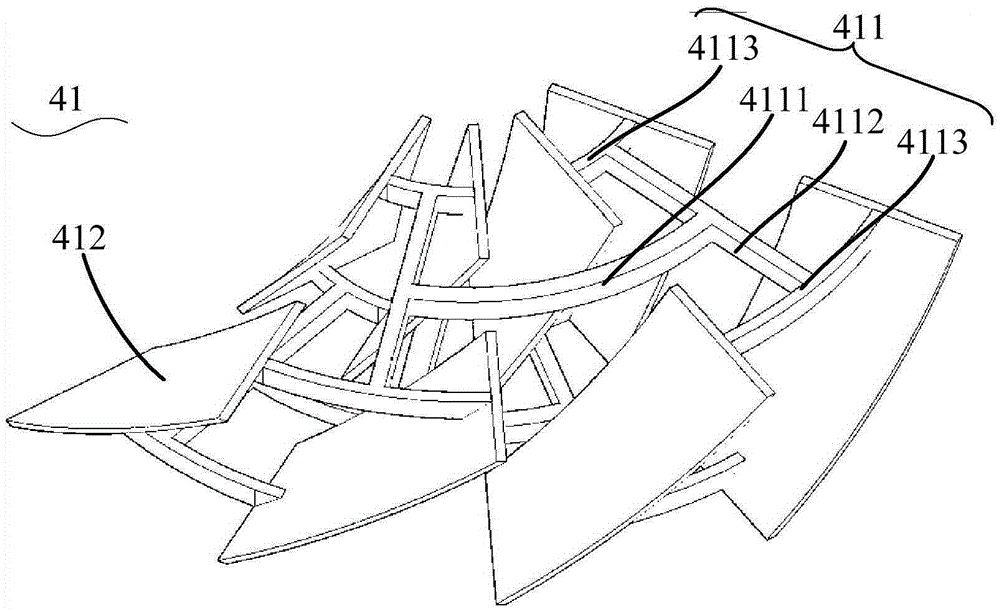

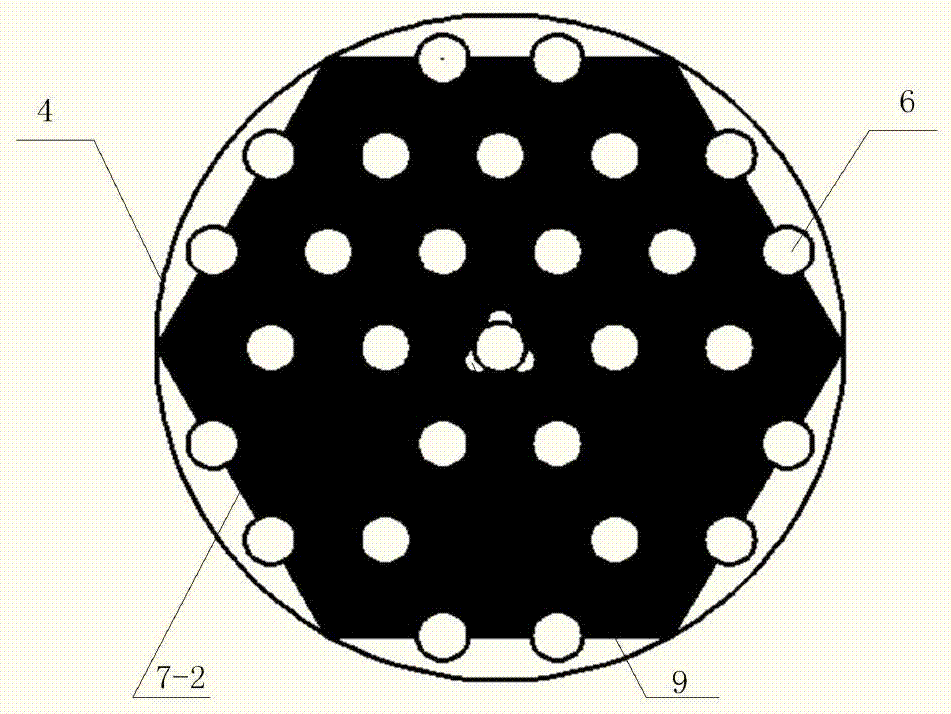

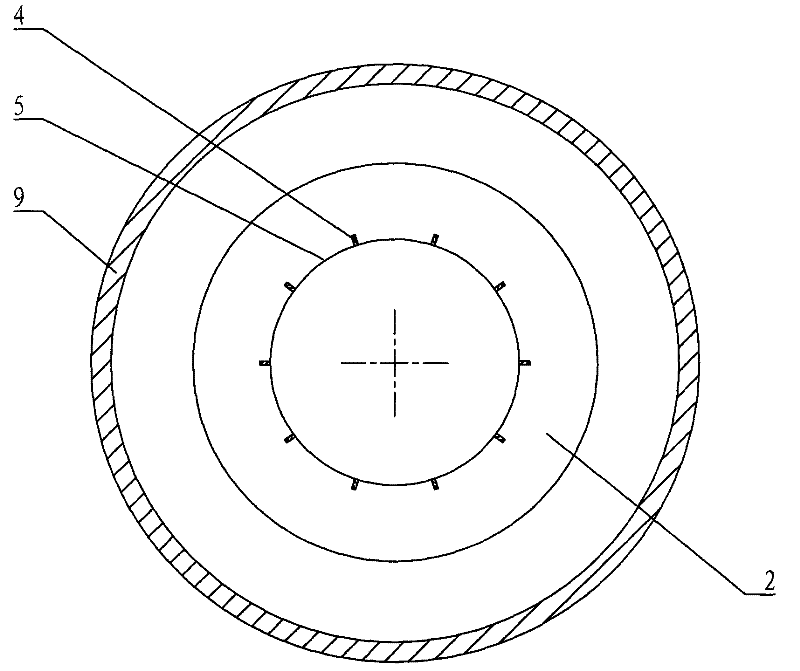

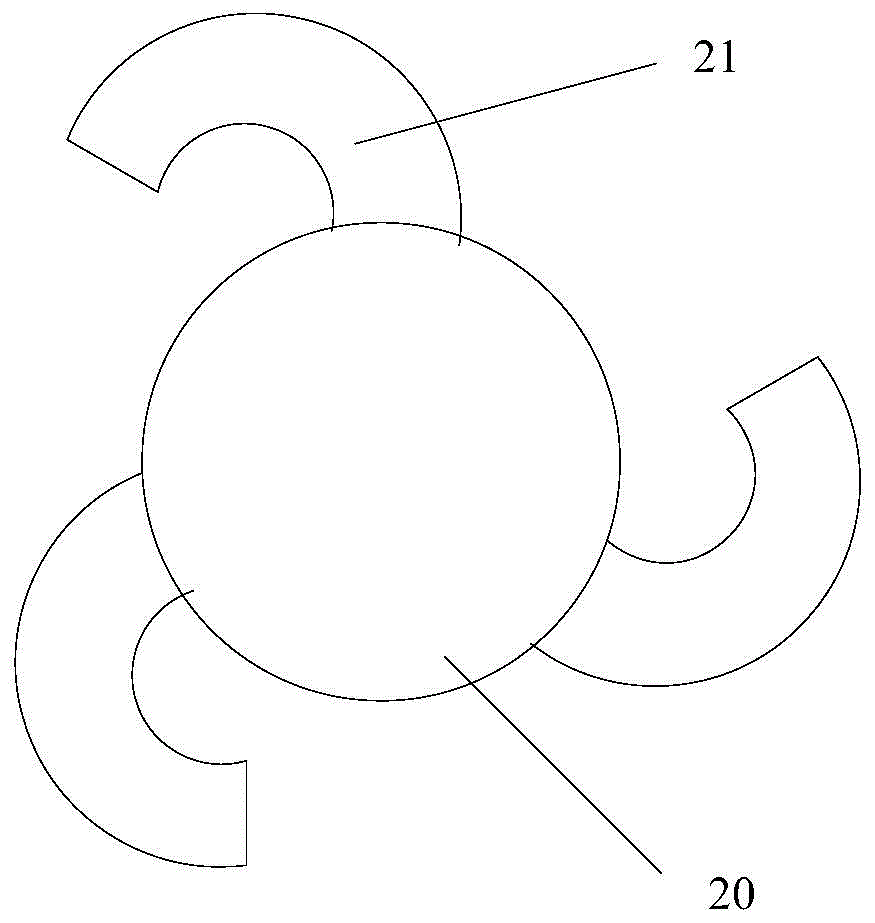

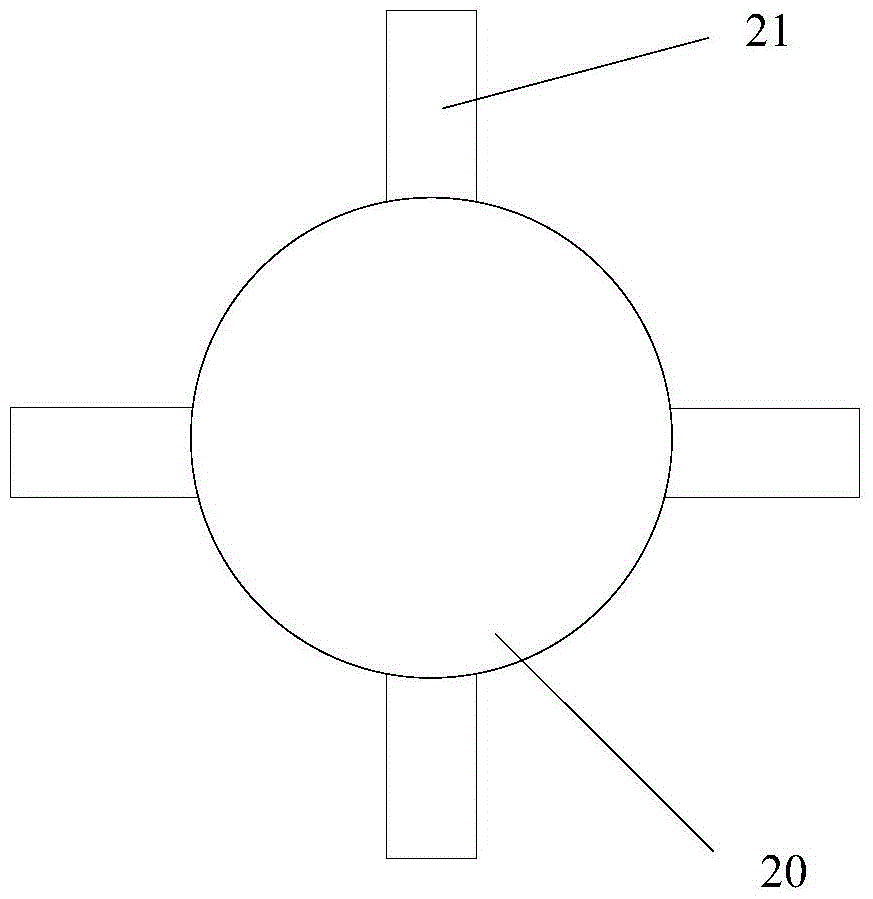

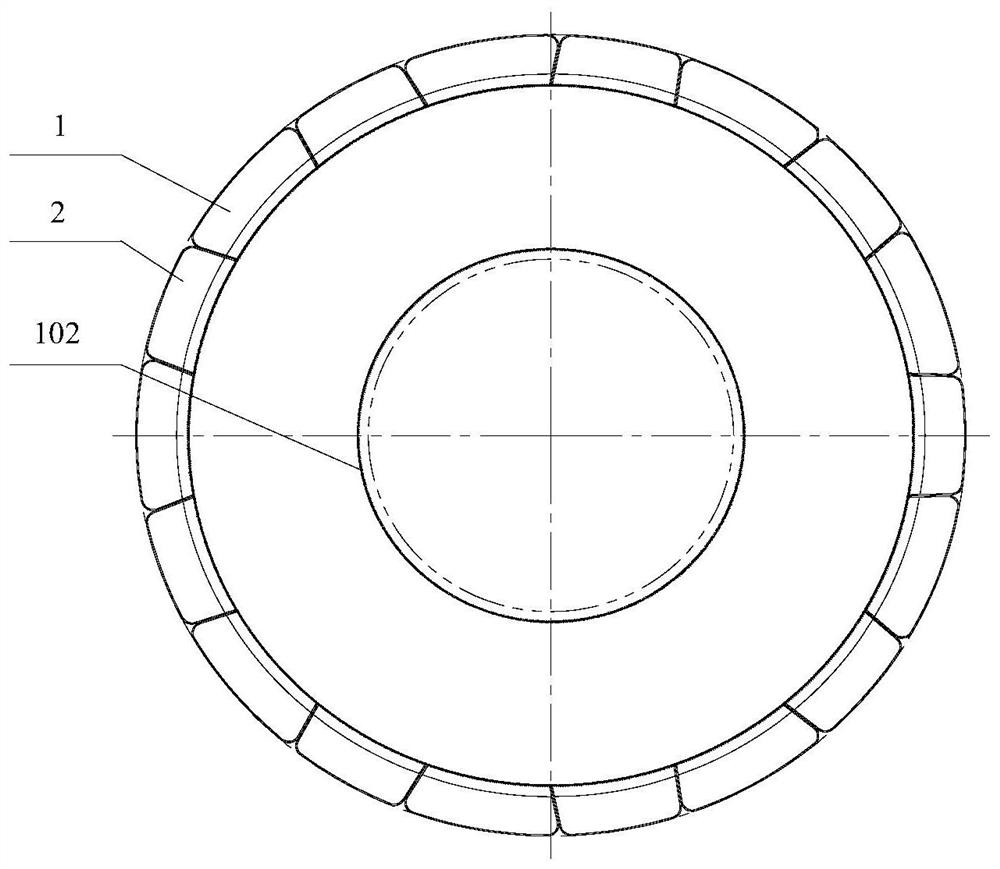

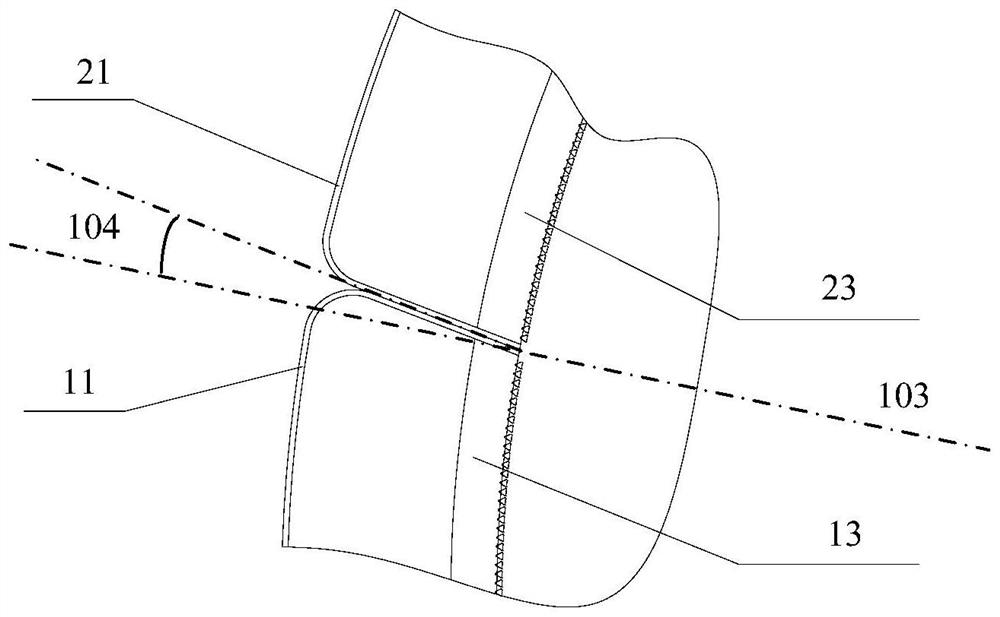

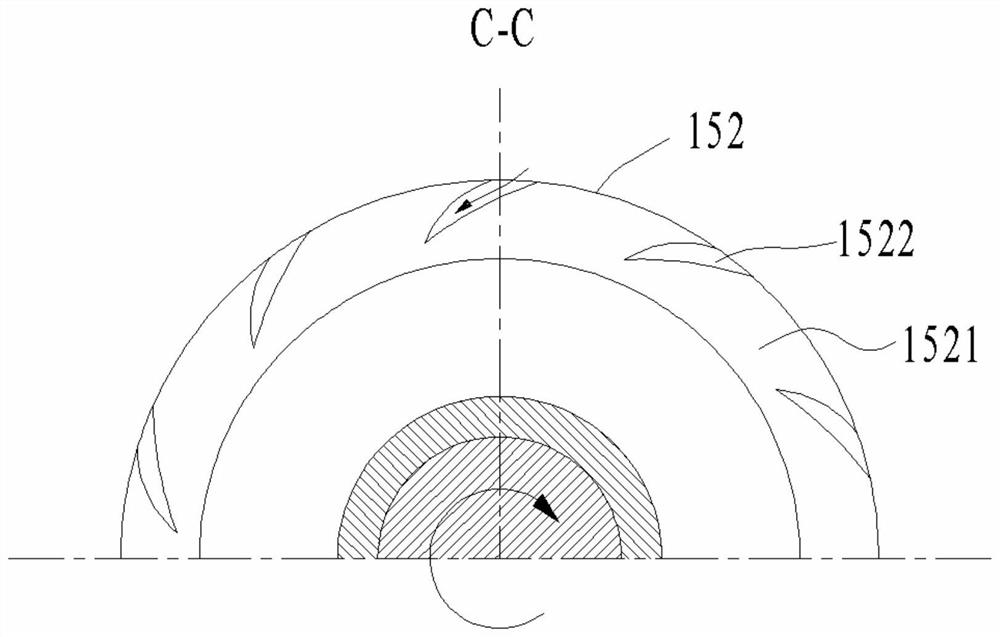

Fan-shaped cylinder assembly of reforming reactor

PendingCN113769667AEliminate flow dead zonesImprove liquidityChemical/physical processesPhysicsMechanical engineering

The invention relates to a fan-shaped cylinder assembly of a reforming reactor, and belongs to the technical field of reforming reaction equipment. According to the fan-shaped cylinder assembly provided by the invention, at least two concave fan-shaped cylinders and at least two convex fan-shaped cylinders are arranged, the concave fan-shaped cylinders and the convex fan-shaped cylinders are arranged at intervals, and the contact surfaces of the adjacent concave fan-shaped cylinders and convex fan-shaped cylinders are tightly attached, so that no gap exists between the adjacent fan-shaped cylinders. The included angle between each contact surface and the radial line of the fan-shaped cylinder assembly is 8-20 degrees, so that the extension direction of the contact surfaces is inconsistent with the flowing direction of a catalyst, and the possibility that the catalyst flows into the contact surfaces is reduced, the flowing dead zone of the catalyst is eliminated, the flowability of raw materials and the catalyst is enhanced, the filling amount of the catalyst is reduced, and the operation investment cost is further reduced. Meanwhile, the internal structures of the concave fan-shaped cylinders and the convex fan-shaped cylinders are welded, so that the structural strength of the fan-shaped cylinder assembly is high, and the service life of the fan-shaped cylinder assembly is long.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

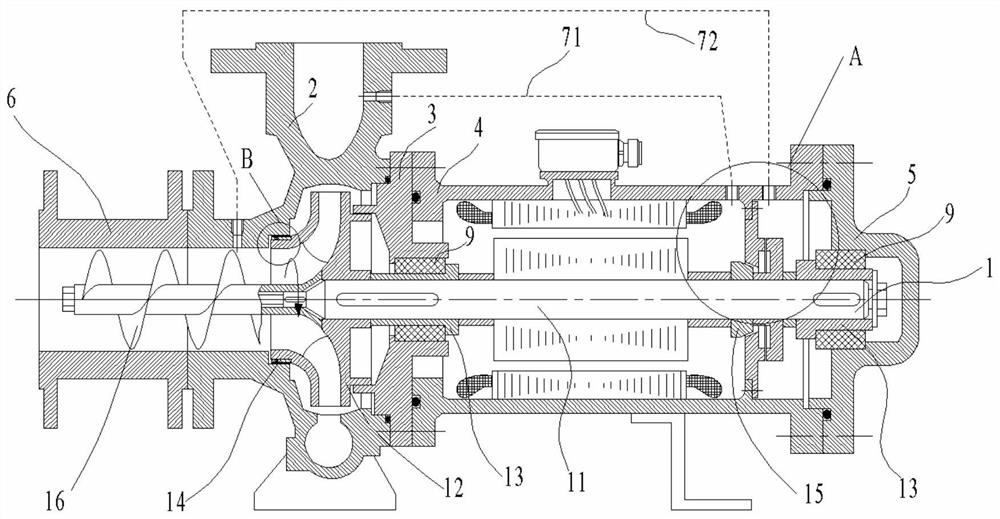

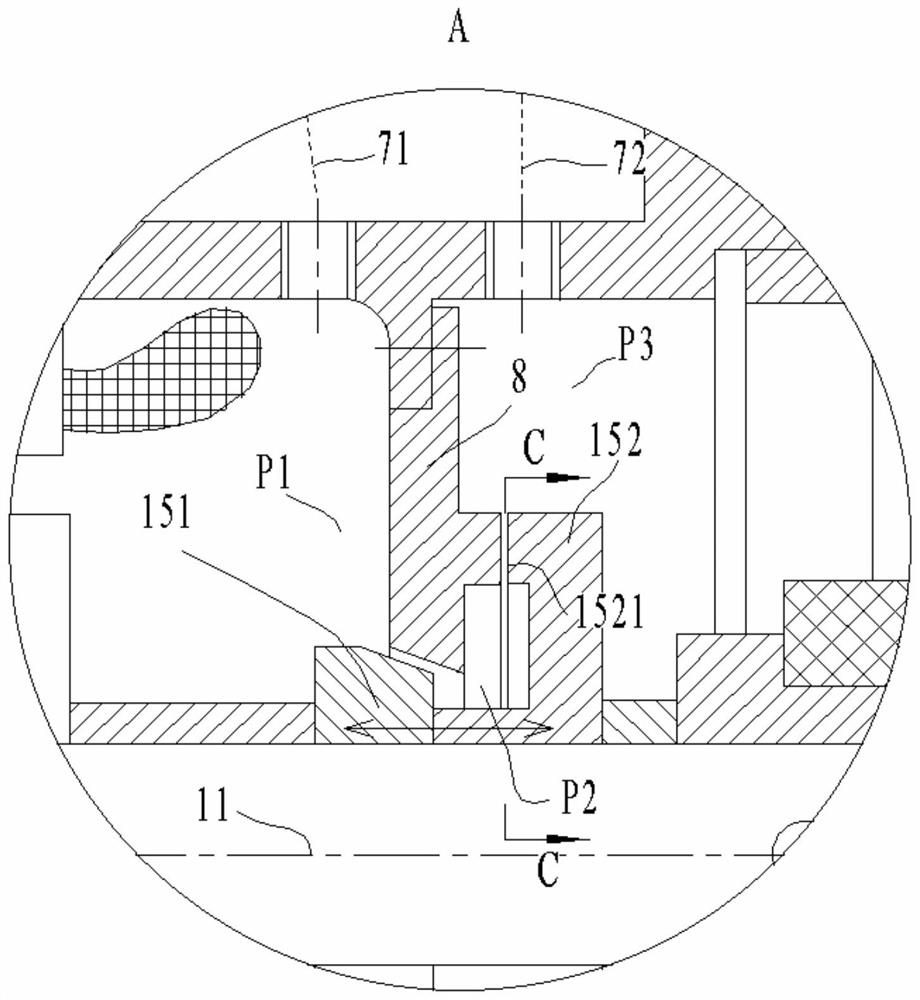

A low-noise canned pump with an axial force balance tube structure

ActiveCN110925244BAvoid accumulationAvoid collisionSpecific fluid pumpsPump componentsImpellerLow noise

The invention discloses a low-noise shielded pump with an axial force balance pipe structure, which includes a rotor part, a circulation pipe, a balance pipe, and a partition plate. The rotor part passes through the pump body, the pump cover, the motor casing and passes Bearings are used for rotatable support, and the pump body, pump cover, and motor casing are fixed by fasteners. Through holes are opened on the rear wall of the motor casing and the side wall of the outlet end of the pump body, and are connected by circulation pipes. The rotor components include the main shaft, impeller and balance assembly. The main shaft is installed on the central axis of the pump body, pump cover and motor casing through bearing support. The impeller is installed on the main shaft and located in the pump body. The balance assembly is installed on the main shaft and located in the motor. In the casing, a stationary partition plate is installed in the motor casing. The partition disk and the balance assembly overlap in the axial direction of the main shaft and divide the motor casing into two areas, one of which is connected to the outlet of the pump body through a circulation pipe. The other area is connected to the inlet port of the pump body through the balance pipe.

Owner:胡小青

A high-temperature fire-tube waste heat boiler tube plate cooling chamber

ActiveCN104791747BEvenly distributedFully distributedFire-tube steam boilersHeat transmissionCooling chamber

Owner:EAST CHINA UNIV OF SCI & TECH +1

Shell-and-tube heat exchanger with fractal structure

ActiveCN105258533BEfficient flowEffectively guide the flowStationary tubular conduit assembliesTubular elementsShell and tube heat exchangerPlate heat exchanger

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Vertical storage tank leakage monitoring system with dual-layer tank bottom plate structure

ActiveCN102785874BAvoid double-sided corrosionExtend the life cycleLarge containersProgrammable logic controllerMonitoring system

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST

Volute for centrifugal fan and centrifugal fan using volute

ActiveCN110259724AReduce flow dead zoneEliminate flow dead zonesPump componentsPumpsLine segmentImpeller

The invention discloses a volute for a centrifugal fan. The volute comprises a front cover and a rear cover which are parallel to each other, and a ring wall connected between the front cover and the rear cover, wherein an air outlet is formed among the front cover, the rear cover and an annular wall, a plane which is perpendicular to the front cover and the rear cover, penetrates through the annular wall, and is parallel to the air outlet is used as a section, on the section, a molded line of the annular wall comprises two line segments connecting the corresponding end portions of a front cover type line and a rear cover type line, and the middles of the line segments are more protruded out of the volute relative to the two ends. The invention further discloses a centrifugal fan using the volute. Compared with the prior art, the volute has the advantages that the annular wall can meet the characteristics that the flow speed of an outlet of an impeller is large in the middle, and small on the two sides, the non-uniform impact of the outlet air flow to the annular wall is weakened, airflow turbulence caused by mutual interference among air flow is reduced, circulation flowing caused by mutual interference among the air flow is eliminated, vortexes are eliminated, the performance of the fan can be effectively improved, and pneumatic noise is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A slurry bed loop reactor and its application and method for producing hydrogen peroxide

ActiveCN104549060BExtended operating cycleEasy to separatePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention relates to a slurry bed loop reactor, application and a method for producing hydrogen peroxide. The slurry bed loop reactor comprises a riser, a separation tank and a downcomer which are communicated sequentially, wherein an expansion section with expanded pipe diameter is arranged at the upper part of the riser, the upper part of the expansion section is communicated with the separation tank, a liquid phase outlet in the upper part of the separation tank is communicated with the upper part of the downcomer, the bottom of the downcomer is communicated with the bottom of the riser, and the bottom of the separation tank is communicated with the lower part of the downcomer; and a raw material inlet is formed in the bottom of the riser, gas outlets are formed in the top of the expansion section of the riser and in the top of the separation tank, a filtration component is arranged in the downcomer and a clear liquid outlet is formed in the upper part of the downcomer via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

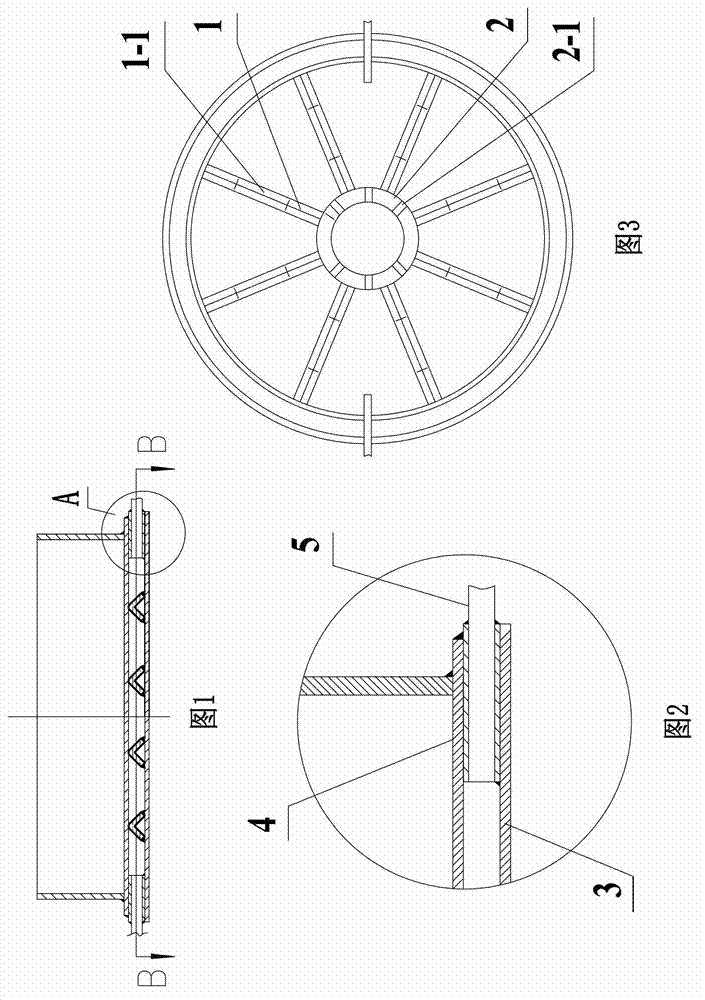

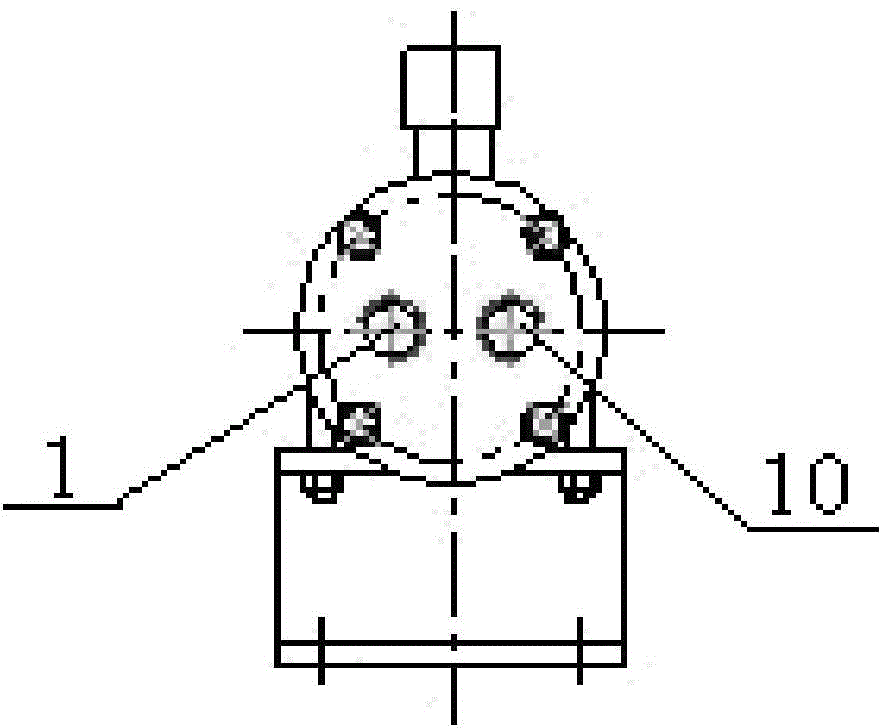

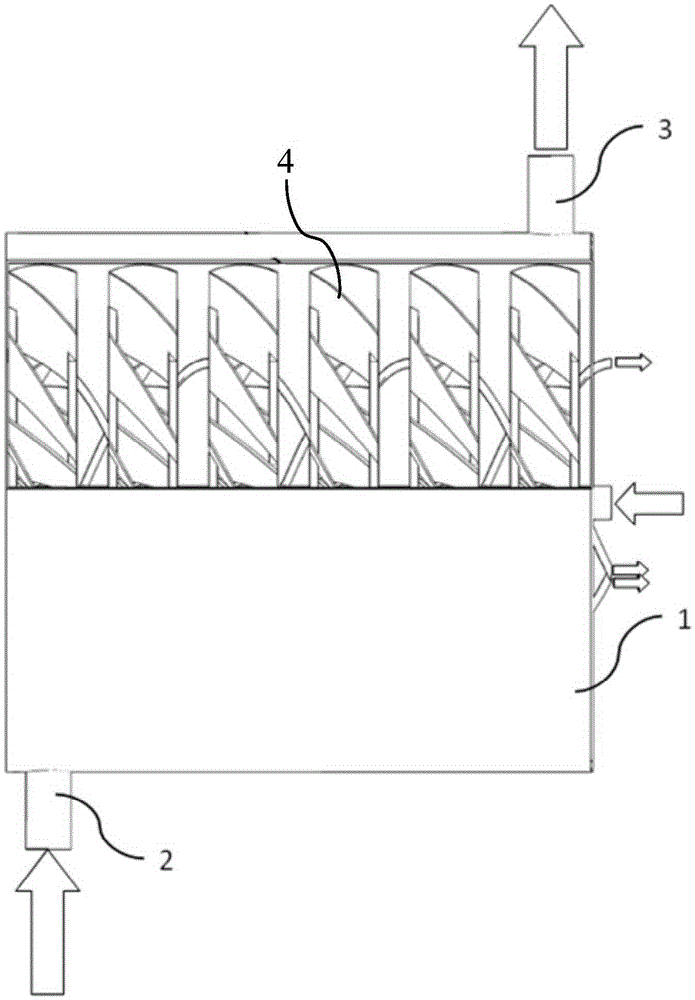

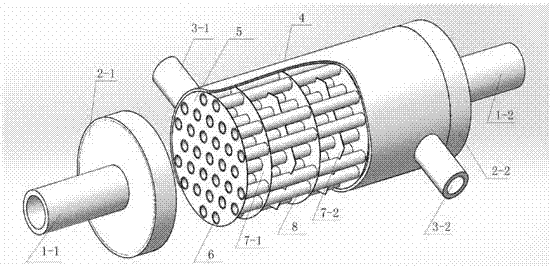

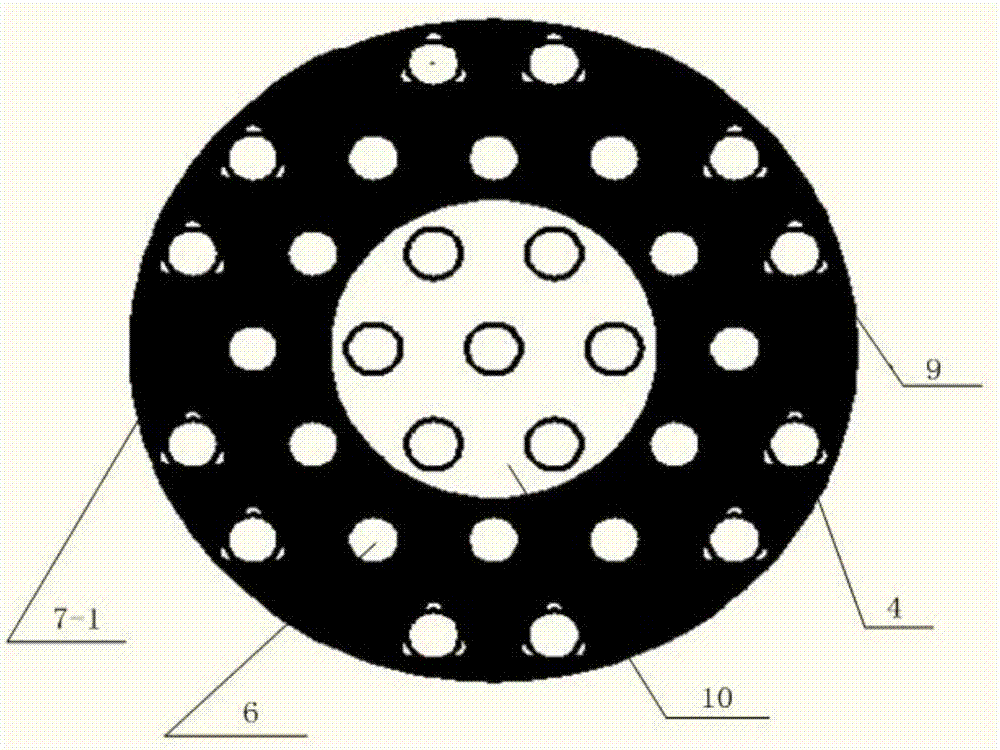

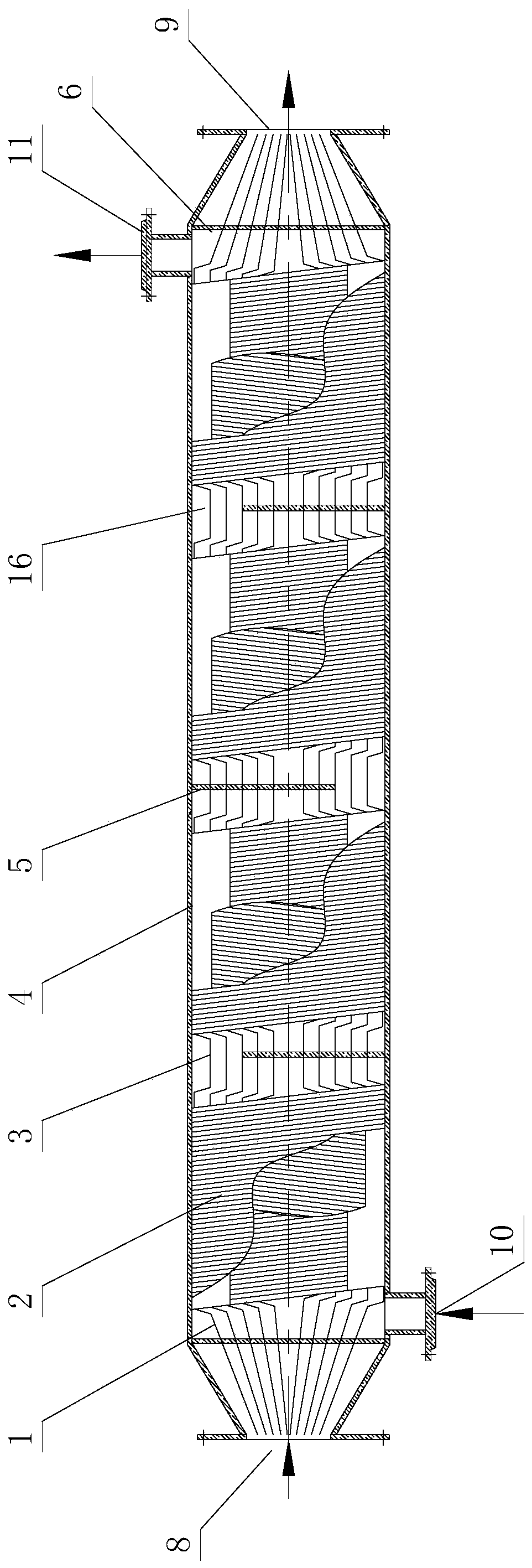

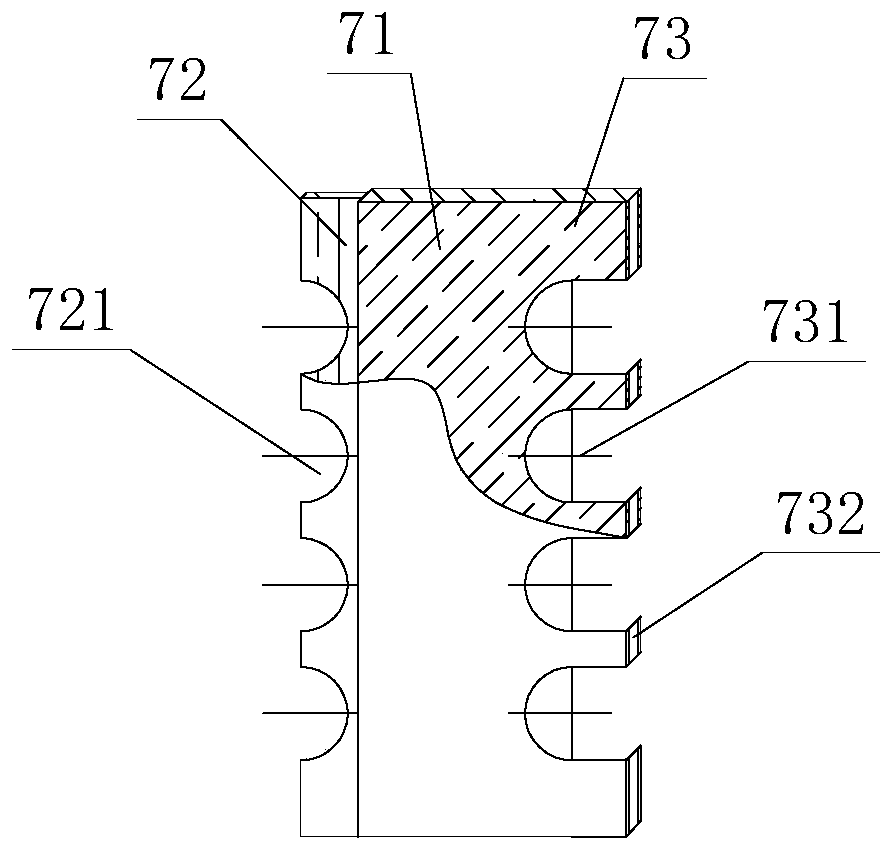

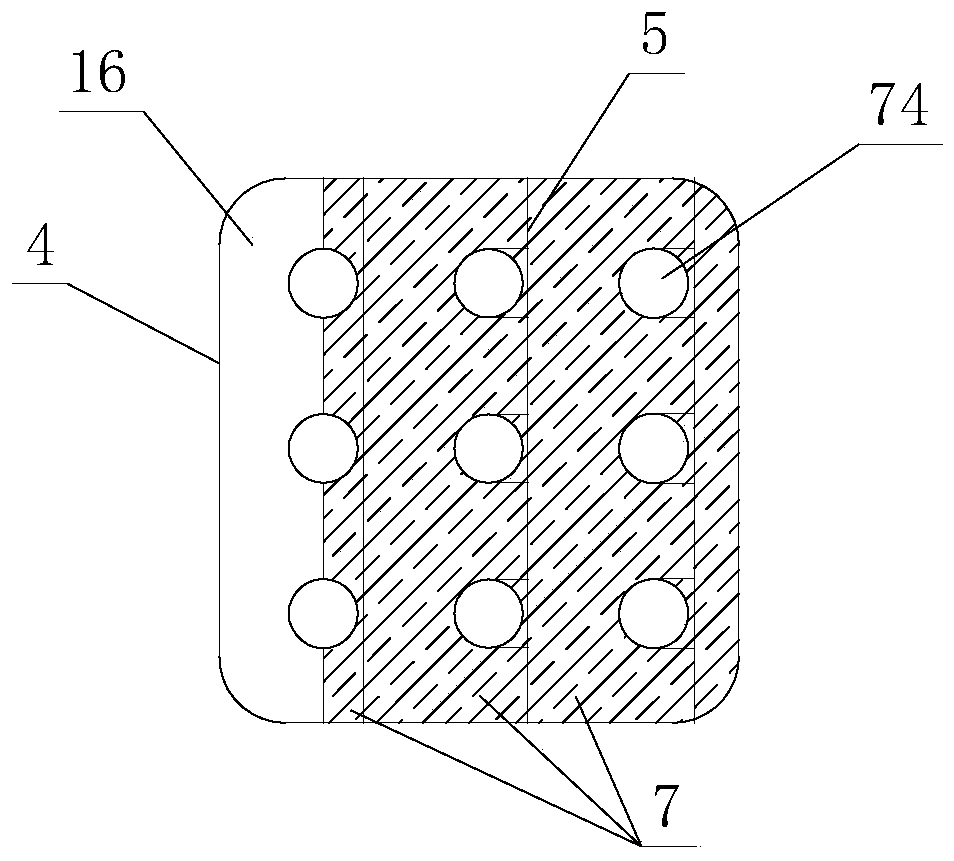

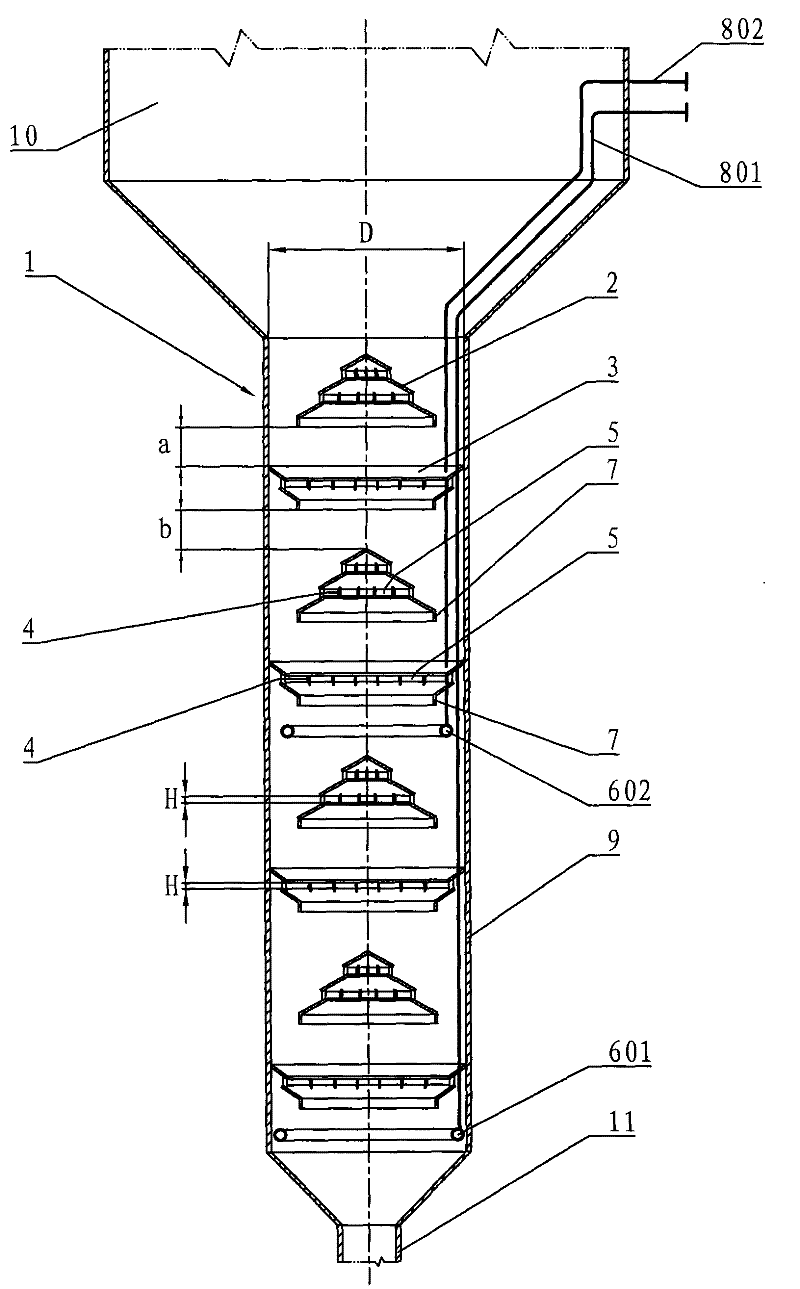

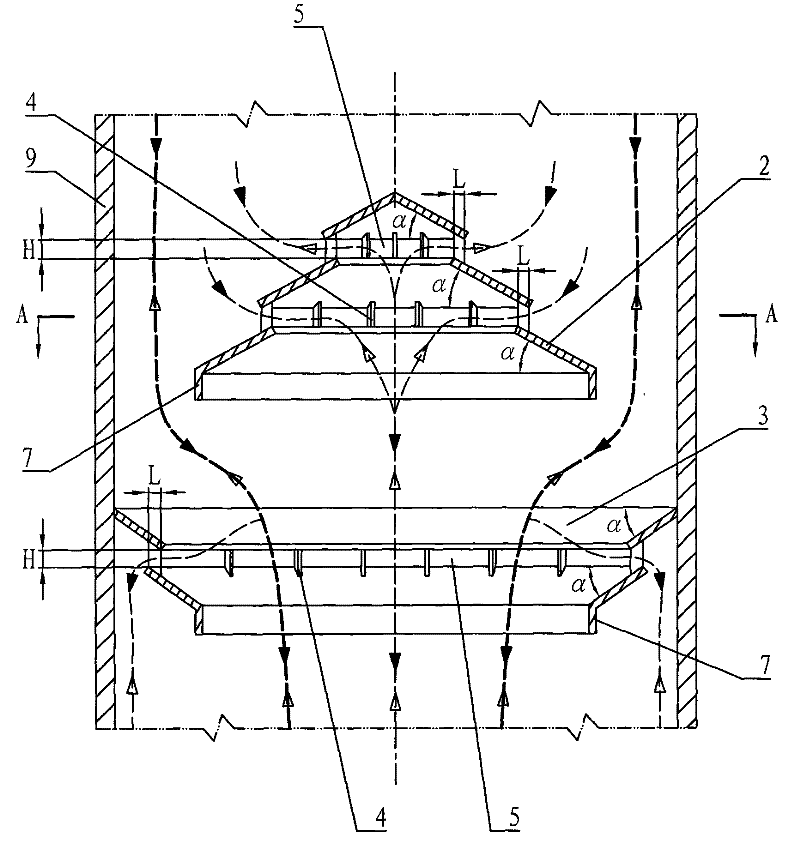

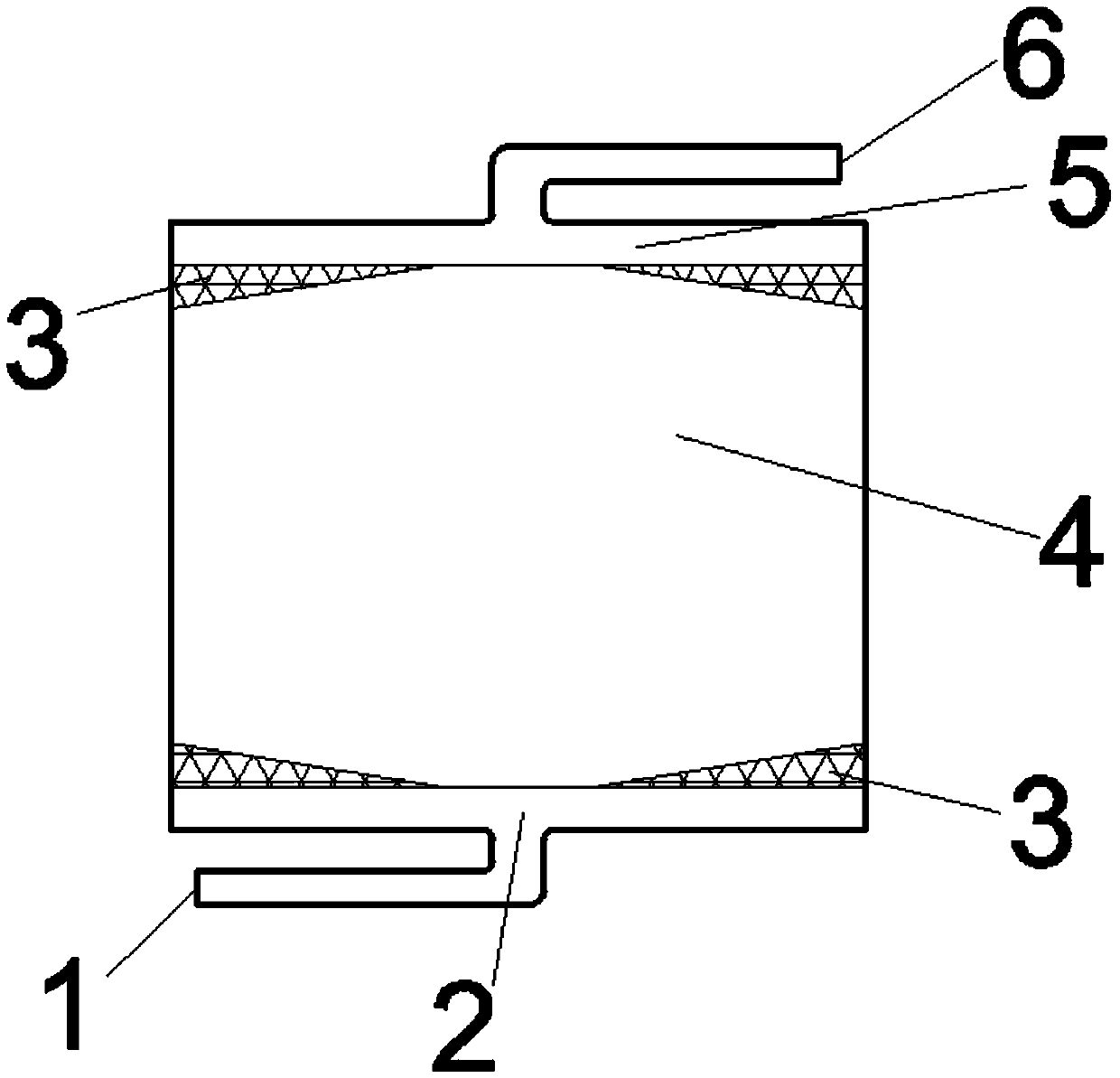

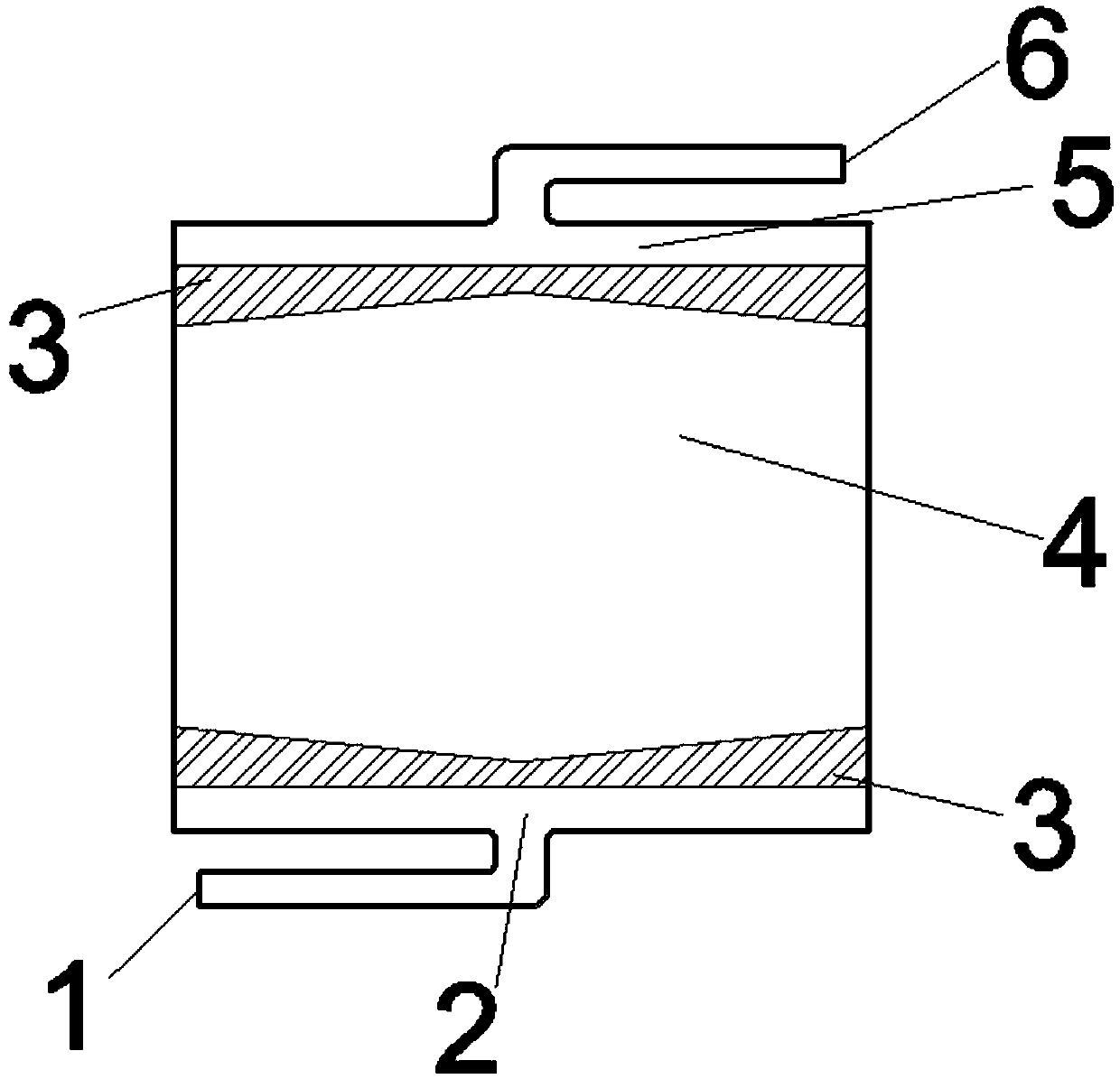

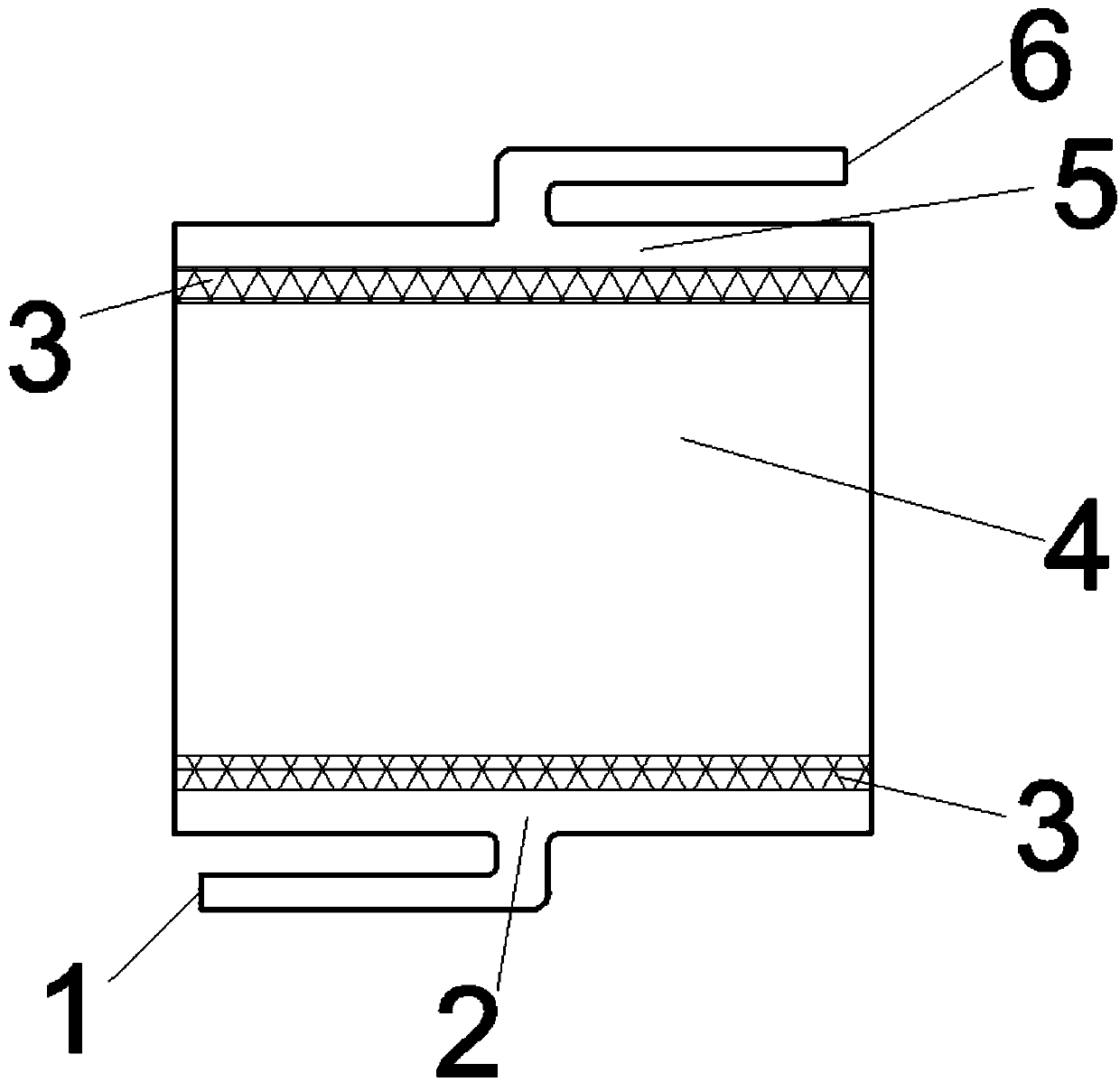

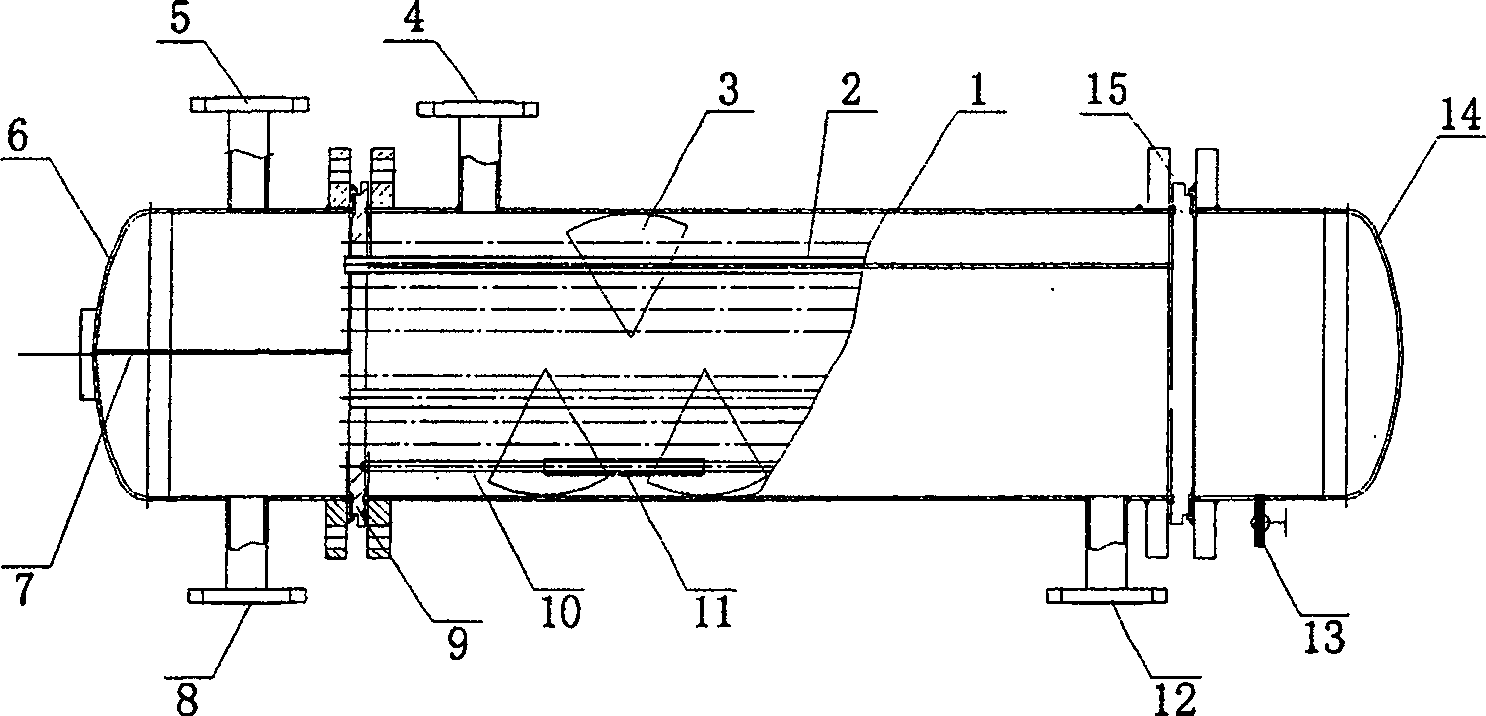

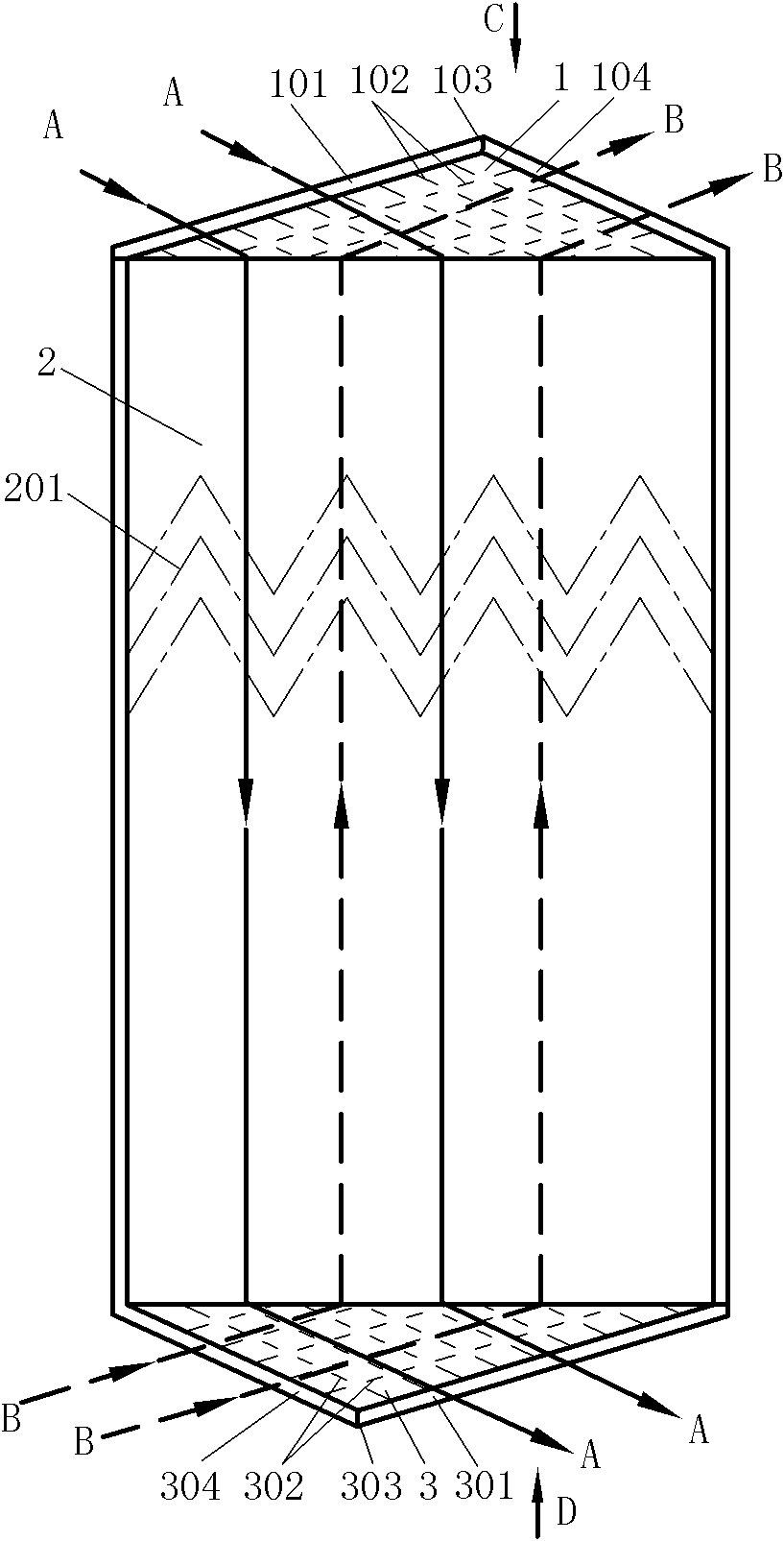

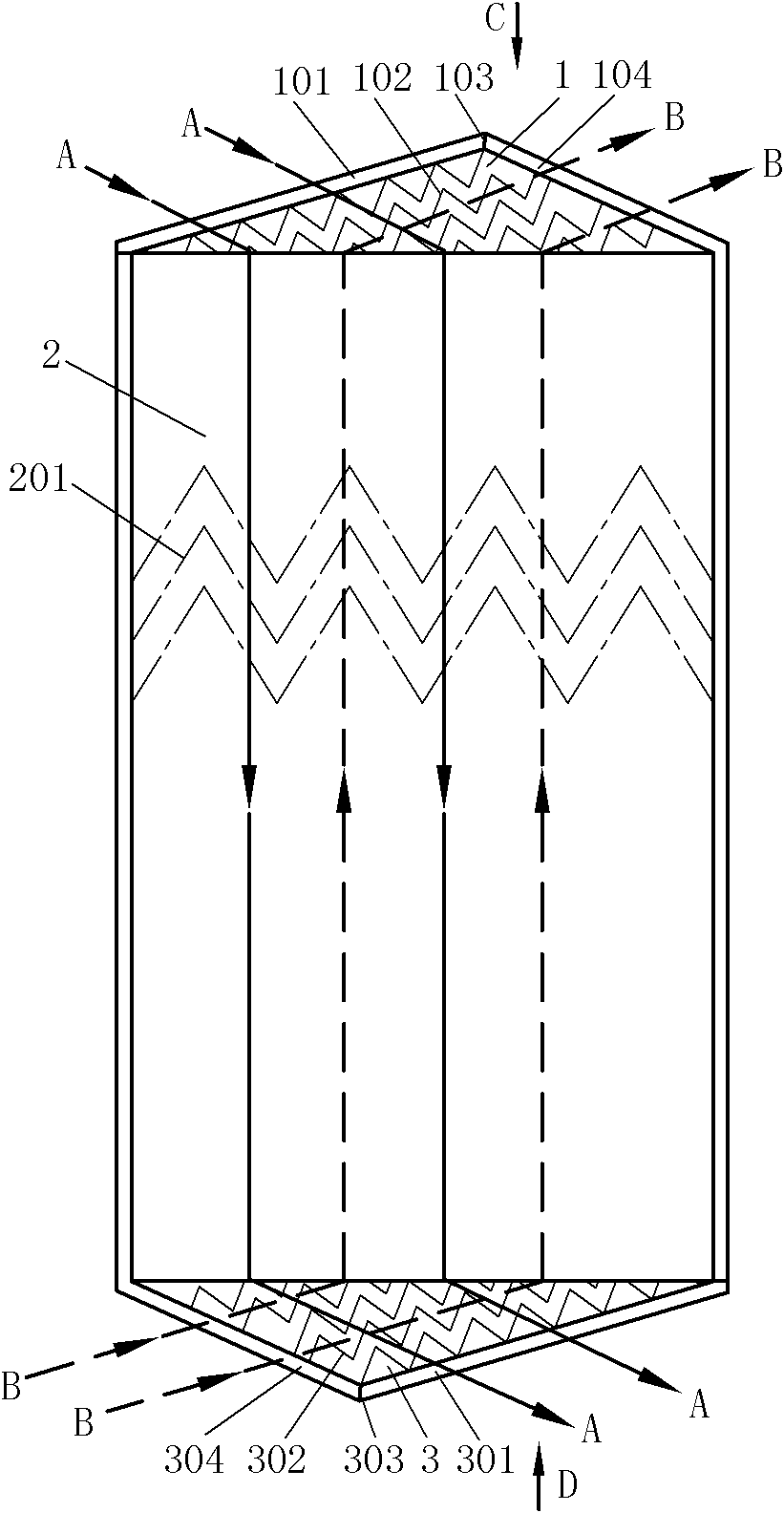

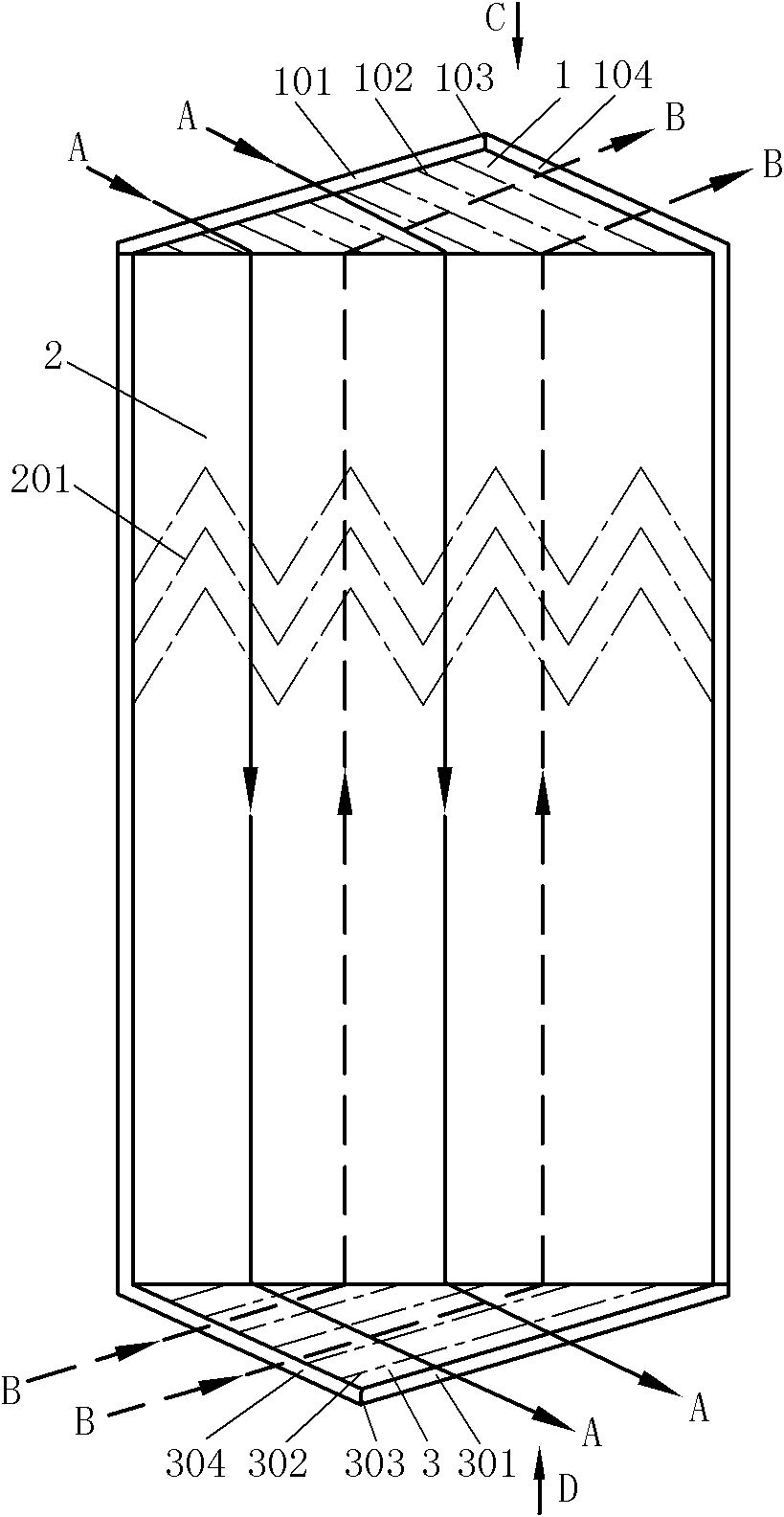

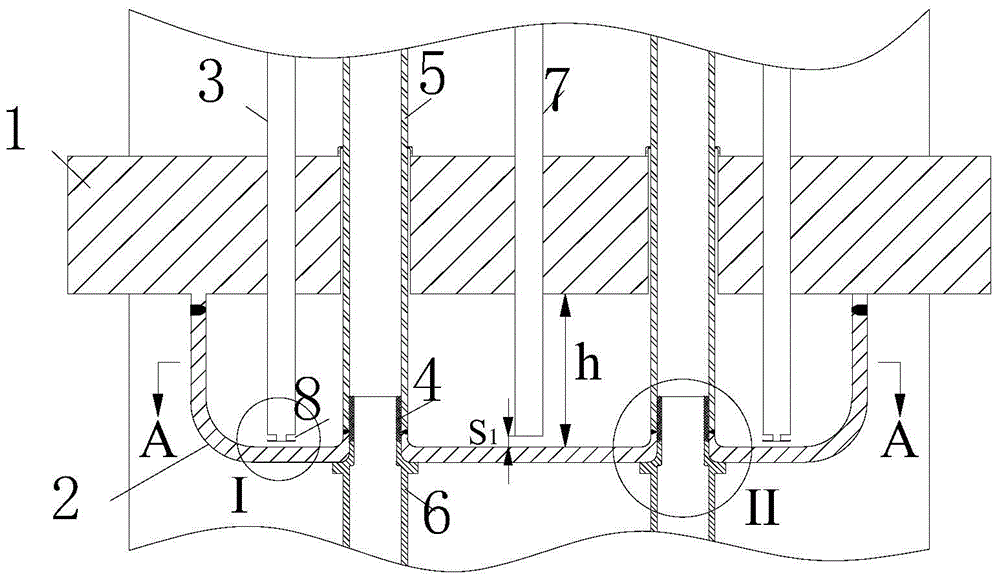

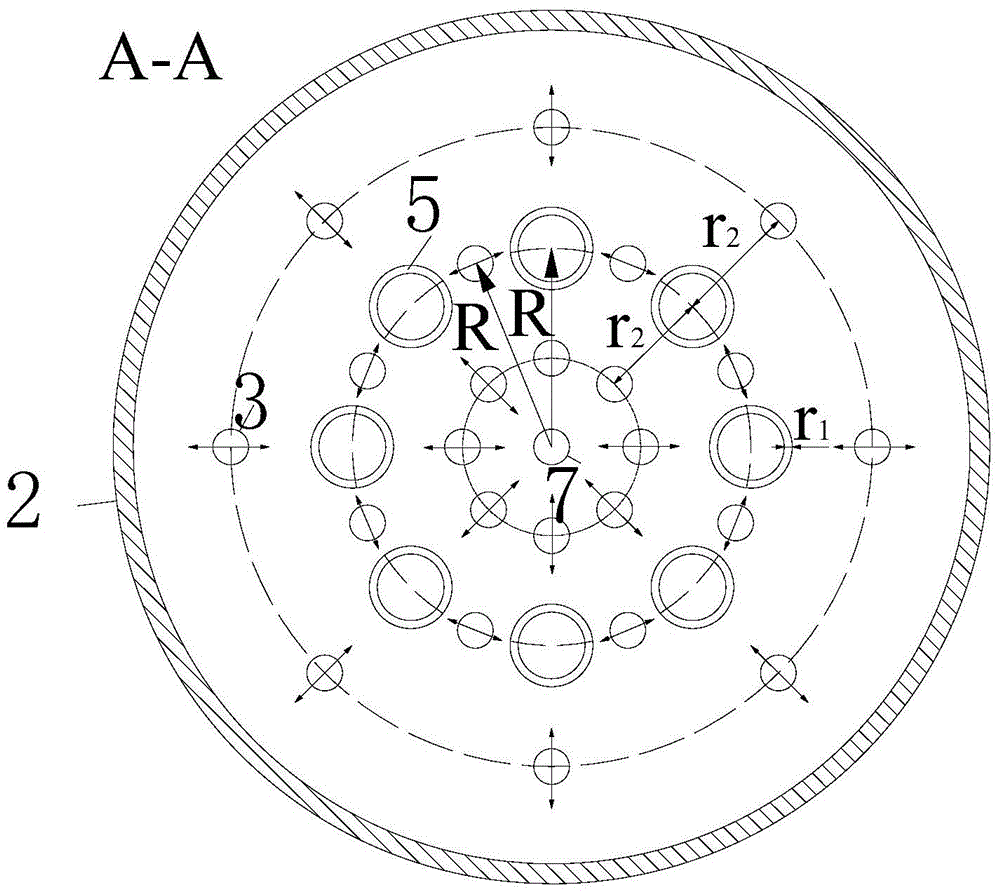

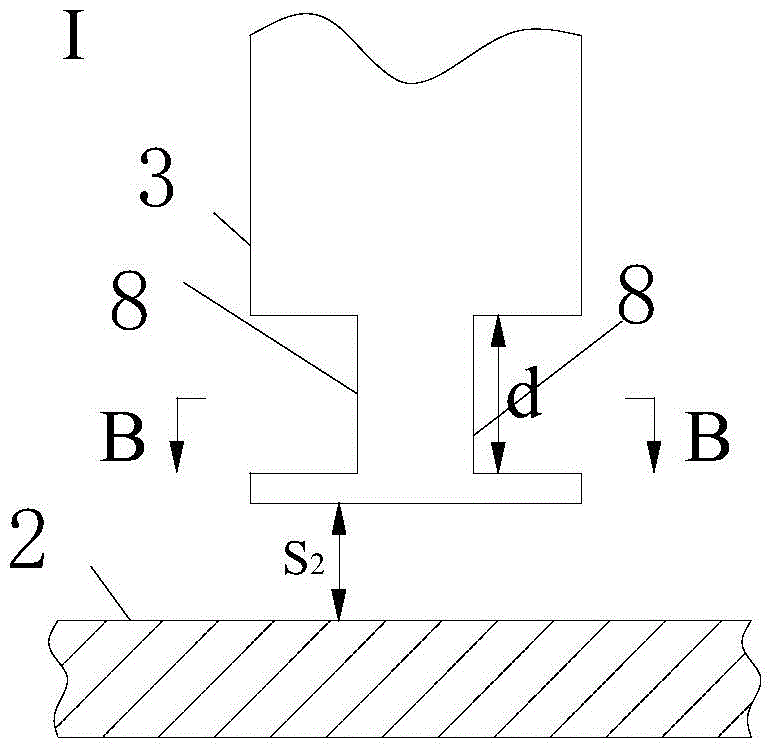

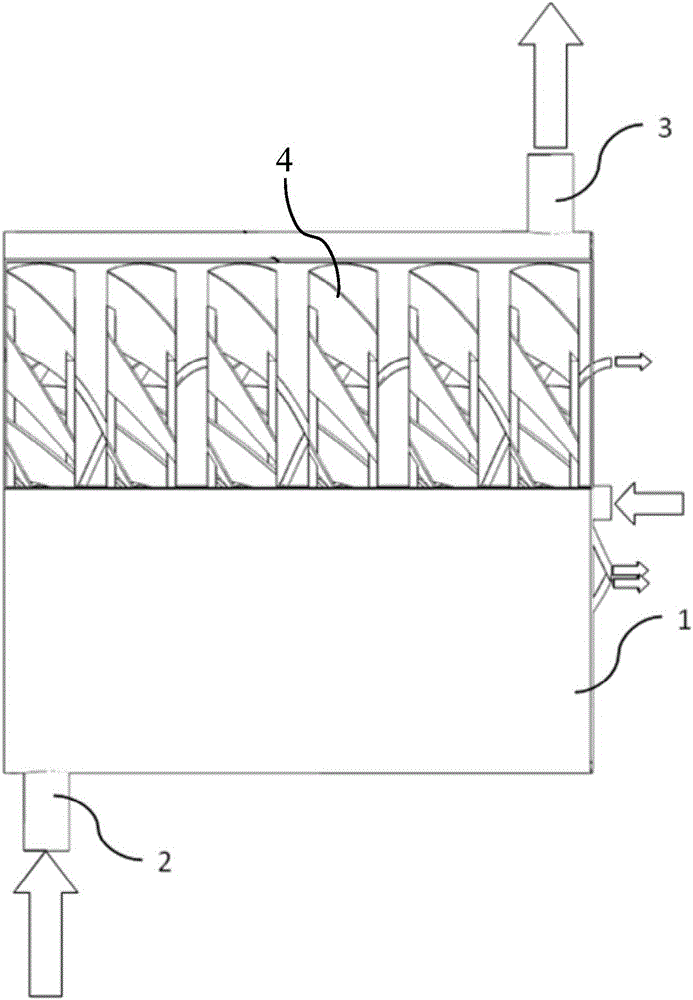

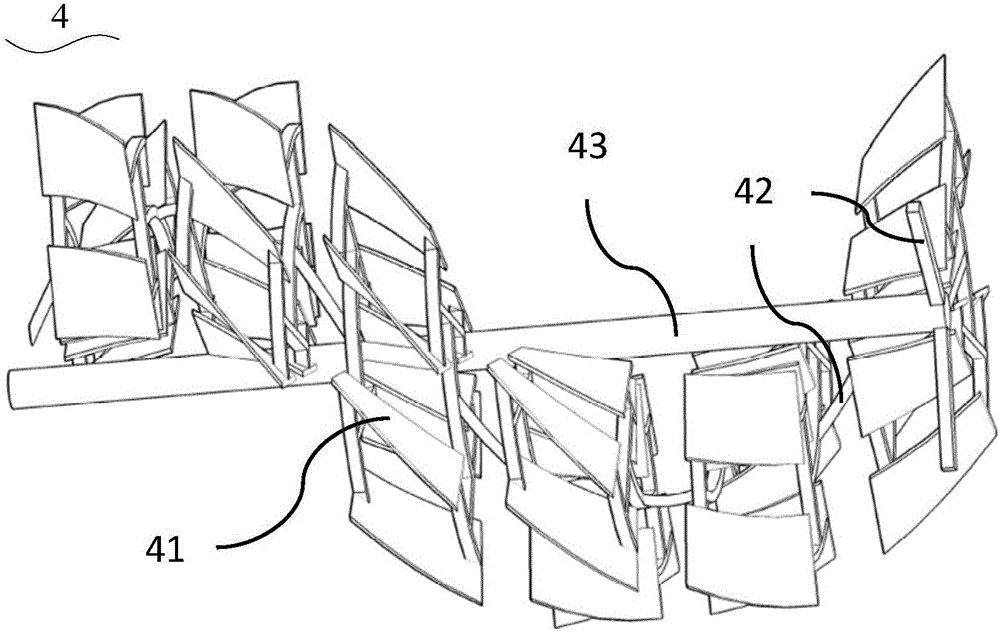

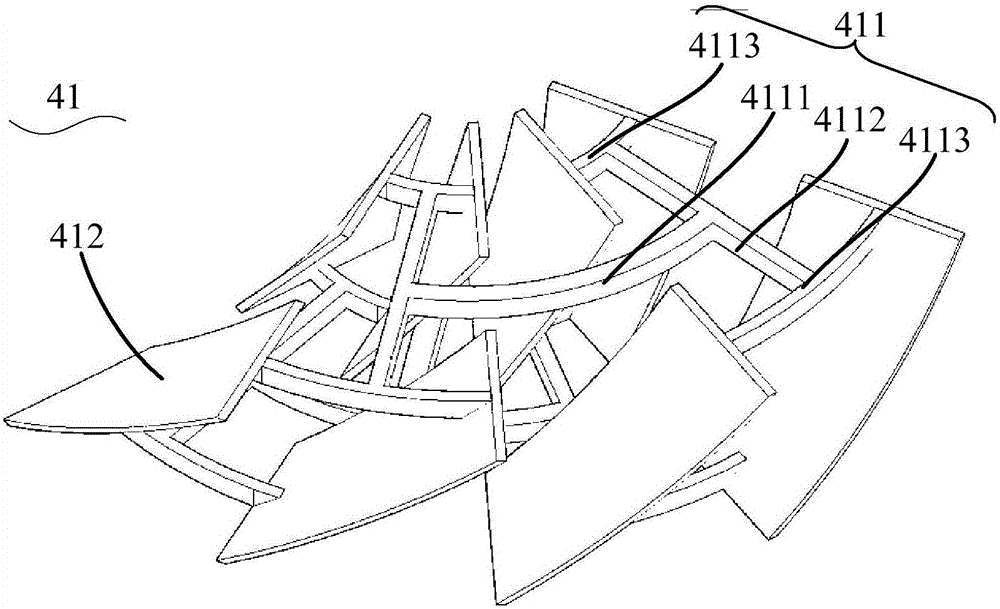

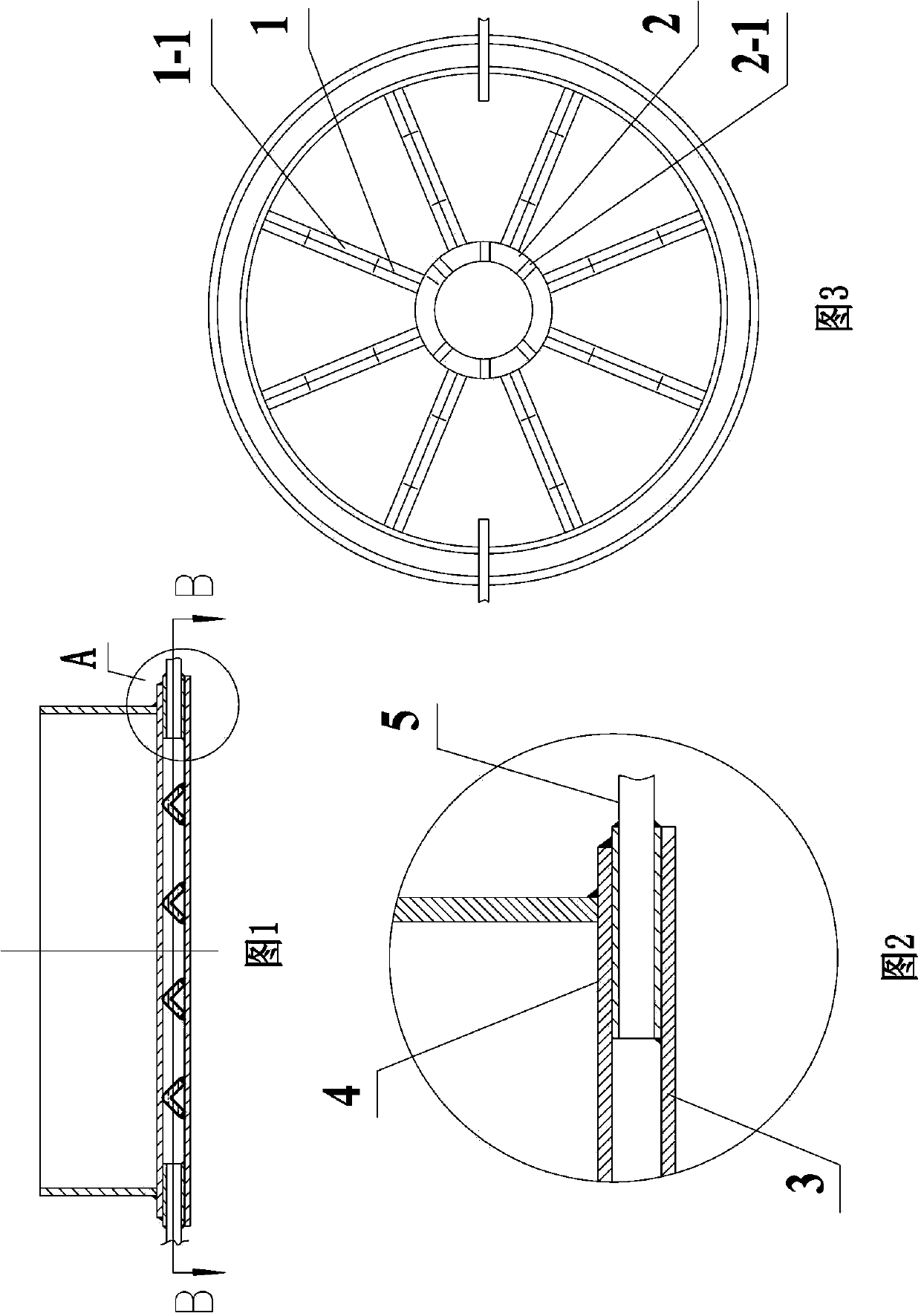

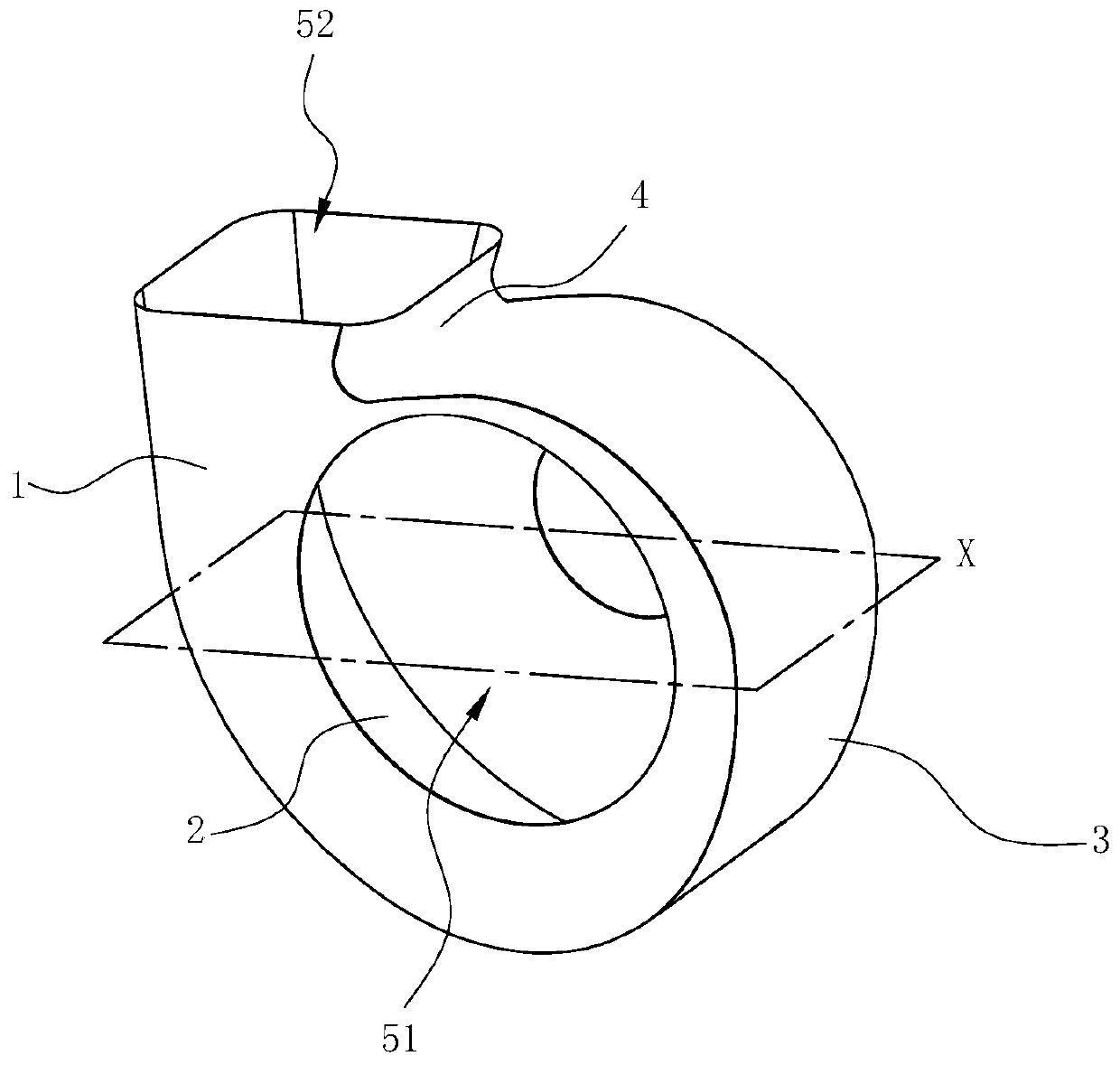

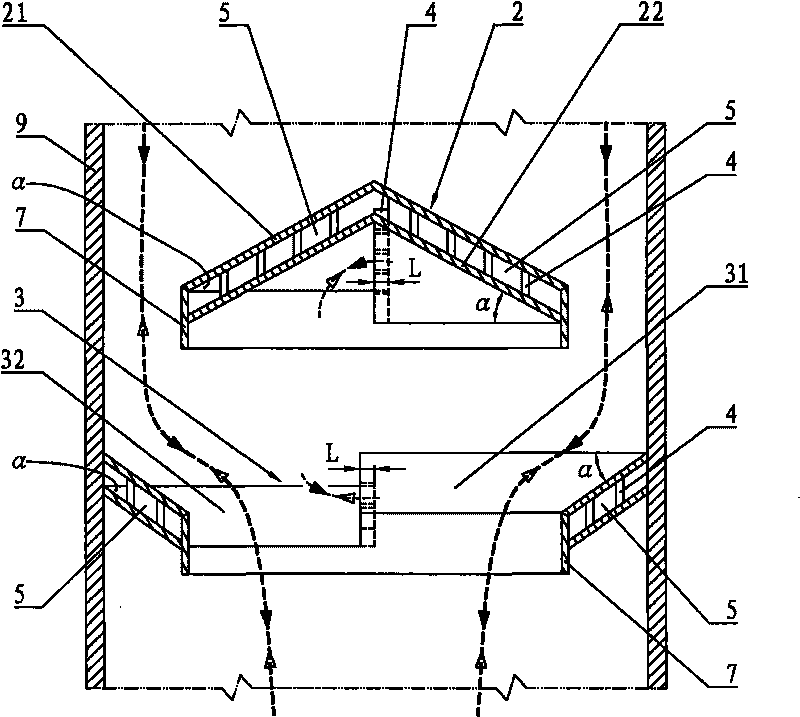

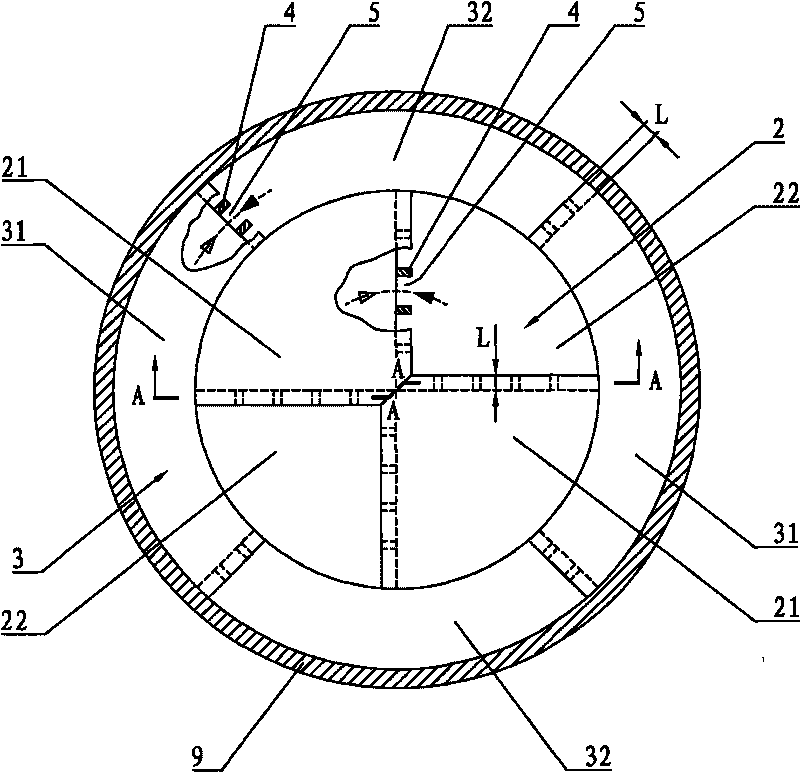

Catalytic conversion steam stripping device

ActiveCN101733044AImprove stripping efficiencyEasy to handleCatalytic crackingChemical/physical processesChemical industryEngineering

The invention discloses a catalytic conversion steam stripping device used by a catalytic conversion device in the field of oil refining and petro-chemical industry, solving the problem of low stripping efficiency of the conventional steam stripping device. The steam stripping device adopts a vane-type inner ring steam stripping baffle plate (2) and a vane-type outer ring steam stripping baffle plate (3), and both of which are composed of four, six or eight single vane-type inner ring steam stripping baffle plates and four, six or eight single vane-type outer ring steam stripping baffle plates which are arranged alternately up and down. The projections of the adjacent lateral peripheral area of an upper single vane-type inner ring steam stripping baffle plate and a lower single vane-type inner ring steam stripping baffle plate which are adjacent to each other and the projections of an upper single vane-type outer ring steam stripping baffle plate and a lower single vane-type outer ring steam stripping baffle plate which are adjacent to each other on the horizontal plane are overlapped respectively, and a connecting rib plate (4) is arranged between the lateral peripheral areas and the horizontal planes respectively to form a radial passage (5). The steam stripping device is suitable for the steam stripping of the reclaimable catalyst of entrained oil gas and the regenerated catalyst of the impurity of entrained gas in various processes of catalytic conversion processes.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com