Liquid flow frame suitable for flow battery stack

A liquid flow battery and liquid flow frame technology, which is applied in fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve problems such as uneven flow velocity distribution and weaken local thermal effects, so as to reduce local heat release and polarization , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

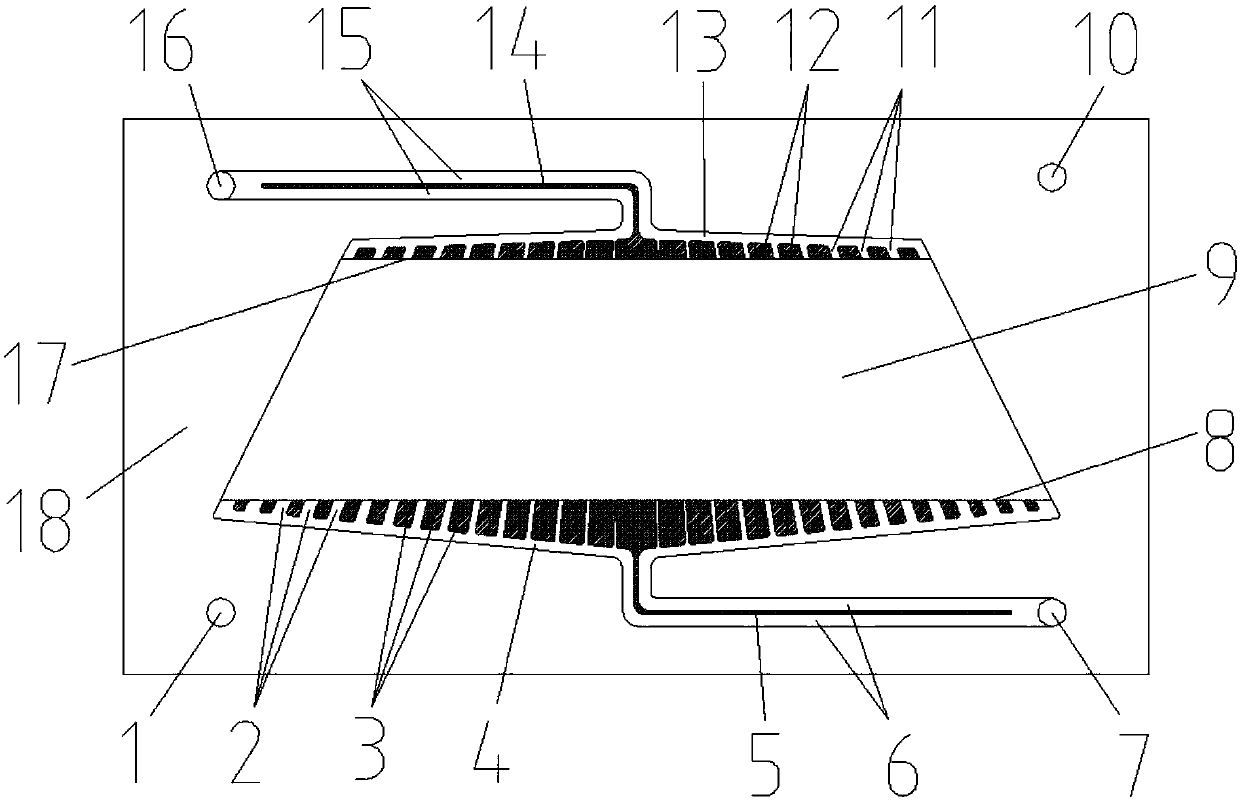

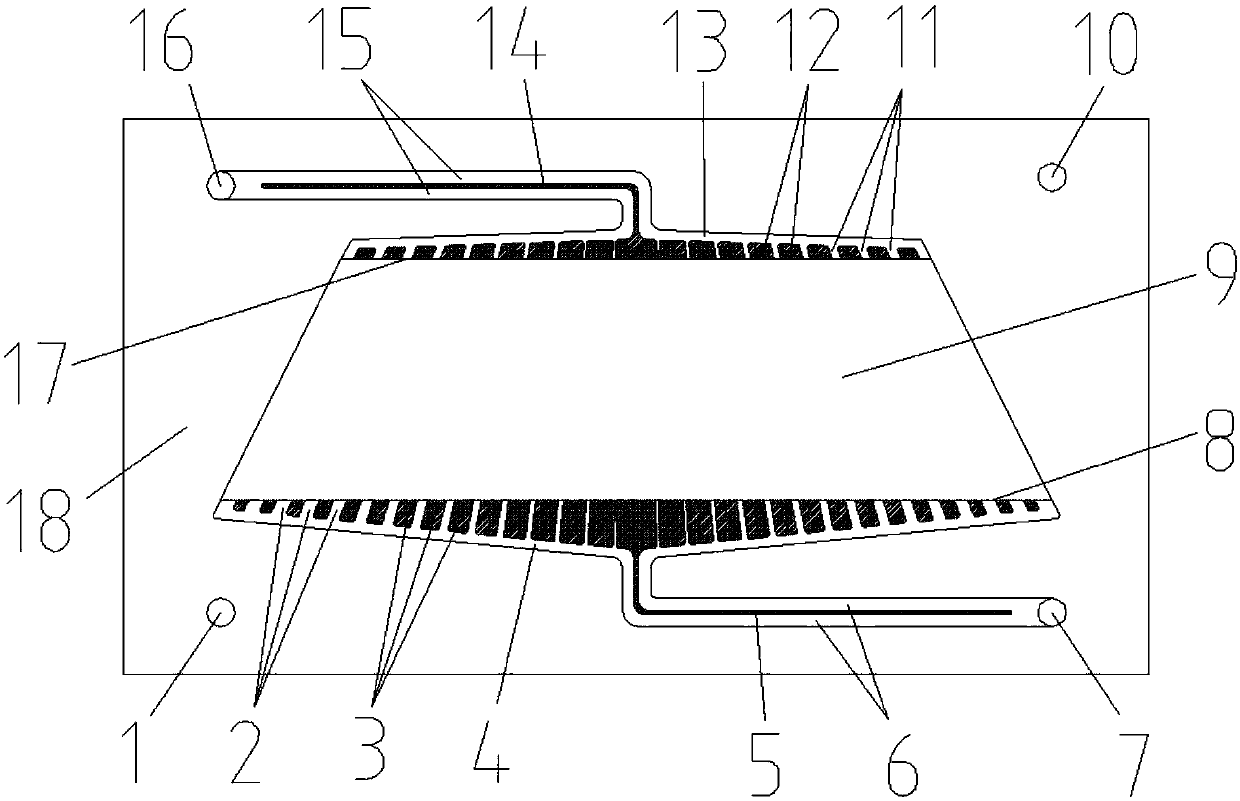

[0027] Such as figure 1As shown, a flow frame for a flow battery. It is made of polyethylene material and includes a liquid flow frame body 20. The frame body 20 is provided with a main flow inlet 7 of the positive electrolyte, a main flow inlet 1 of the negative electrolyte, a main flow outlet 16 of the positive electrolyte, and a main flow outlet 10 of the negative electrolyte. Wherein, the positive electrode electrolyte main flow inlet 7 and the negative electrode electrolyte main flow inlet 1 are located on the same side of the frame, the positive electrode electrolyte main flow outlet 16 and the negative electrode electrolyte main flow outlet 10 are located on the same side of the frame; the positive electrode electrolyte main flow inlet 7 and the positive electrode electrolyte The main flow outlet 16 is located on opposite sides of the frame body, and the main flow inlet 1 of the negative electrode electrolyte and the main flow outlet 10 of the negative electrode electro...

Embodiment 2

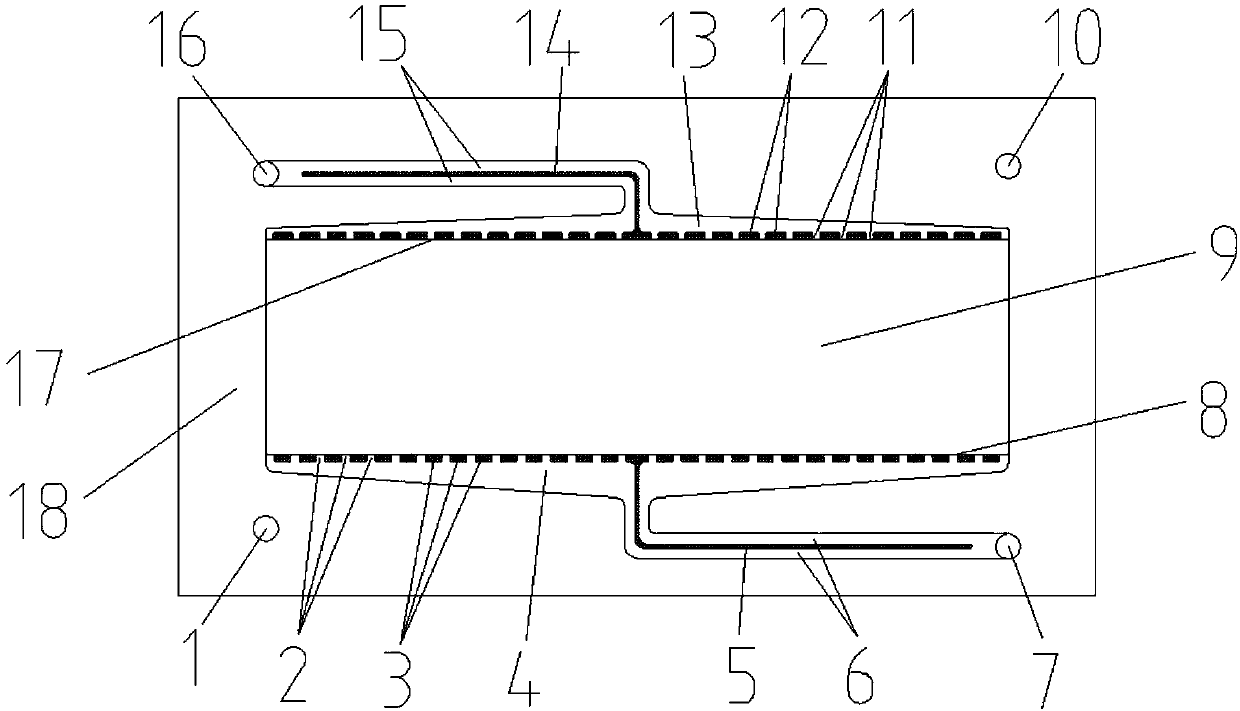

[0030] Such as figure 2 As shown, a flow frame for a flow battery. It is made of polyethylene material and includes a liquid flow frame body 20. The frame body 20 is provided with a main flow inlet 7 of the positive electrolyte, a main flow inlet 1 of the negative electrolyte, a main flow outlet 16 of the positive electrolyte, and a main flow outlet 10 of the negative electrolyte. Wherein, the positive electrode electrolyte main flow inlet 7 and the negative electrode electrolyte main flow inlet 1 are located on the same side of the frame, the positive electrode electrolyte main flow outlet 16 and the negative electrode electrolyte main flow outlet 10 are located on the same side of the frame; the positive electrode electrolyte main flow inlet 7 and the positive electrode electrolyte The main flow outlet 16 is located on opposite sides of the frame body, and the main flow inlet 1 of the negative electrode electrolyte and the main flow outlet 10 of the negative electrode elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com